Graphene Oxide Sensitized No-Core Fiber Step-Index Distribution Sucrose Sensor

Abstract

1. Introduction

2. Sensor Principle

2.1. Working Principle

2.2. Simulation Analysis

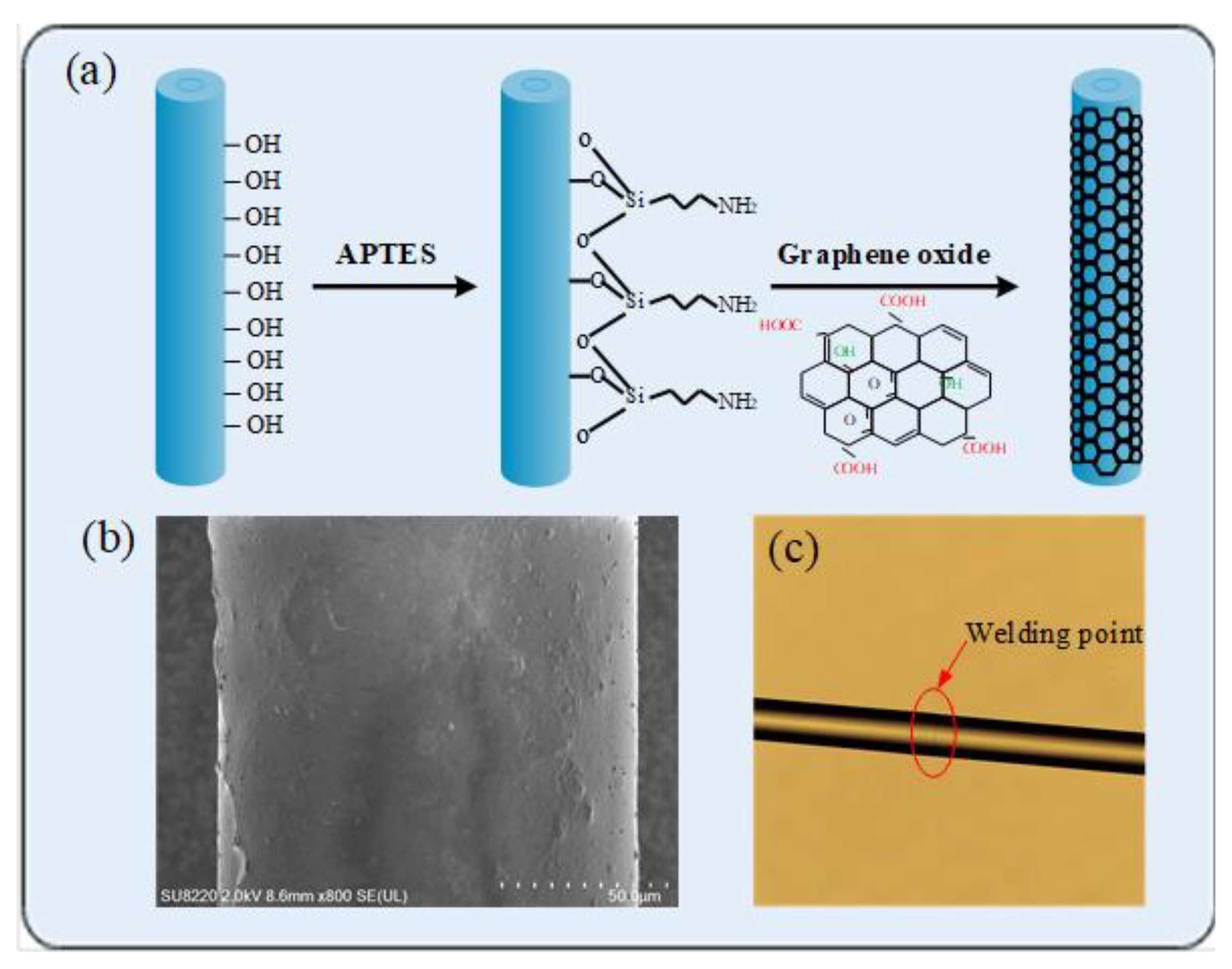

3. Device Fabrication

- (1)

- Use the GO powder to prepare an 80 μg/mL GO aqueous solution and dissolve it with ultrasonic waves for 30 min;

- (2)

- Fix the optical fiber on the glass slide, soak the optical fiber with 1.0 M NaOH solution for 1 h at room temperature (27 °C) to generate an OH bond on the NCF surface, and then wash with ethanol and distilled water three times each;

- (3)

- Soak the treated fiber with freshly prepared 5% APTES ethanol solution for 1 h. The APTES reacts with -OH to from an Si-O-Si bond, and then the ethanol solution is used to wash out the unbound APTES and placed in an oven. Dry for 30 min at 70 °C;

- (4)

- Immerse the treated optical fiber in an aqueous GO solution of 80 μg/mL and place it on a heated plate at 42 °C for 3 h. The epoxy group of GO reacts with the -NH2 of APTES. As the aqueous solution evaporates, the GO gradually adsorbs onto the NCF surface. Finally, wash with distilled water to remove the unbound GO on the fiber’s surface, and dry the fiber at 70 °C for 1 h;

- (5)

- Weld the optical fiber. The welding uses the FUJIKURA Corporation’s 61S welding machine, made in Japan. Put the NCF and SMF in the welding machine’s fixture and use the automatic mode for non-eccentric welding. After the welding is completed, use the same method to weld another SMF section to obtain the SNS fiber structure we need.

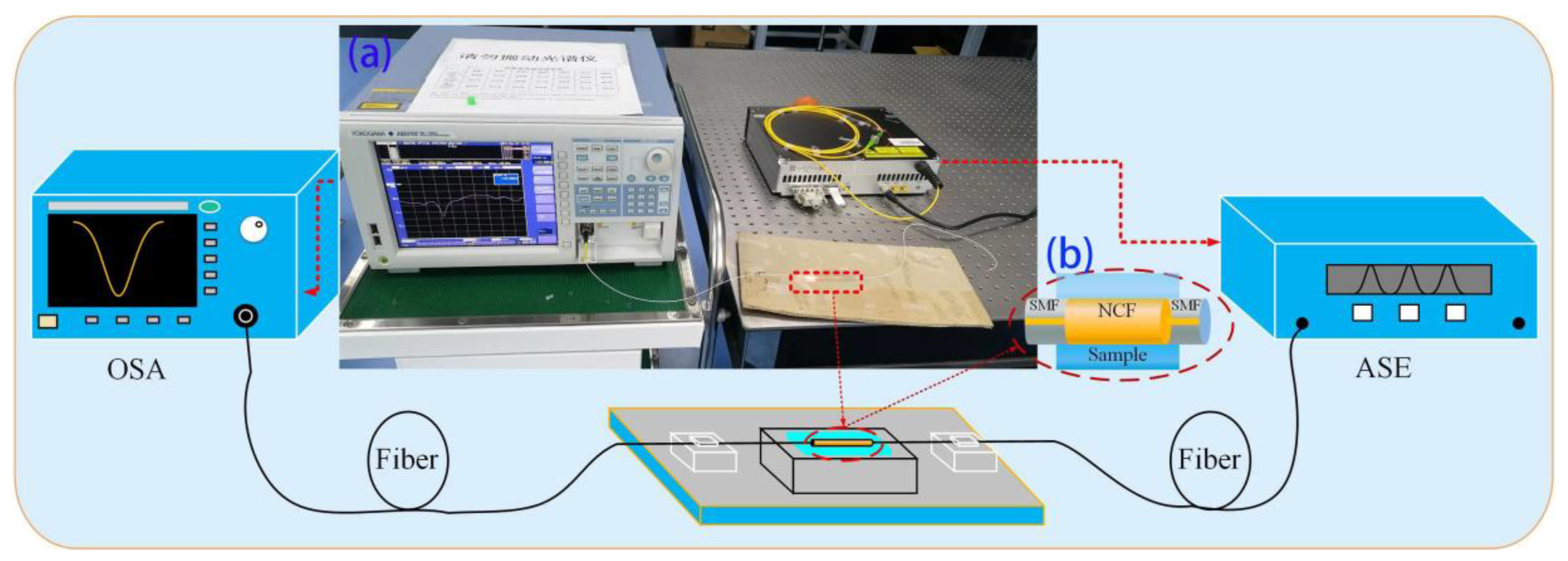

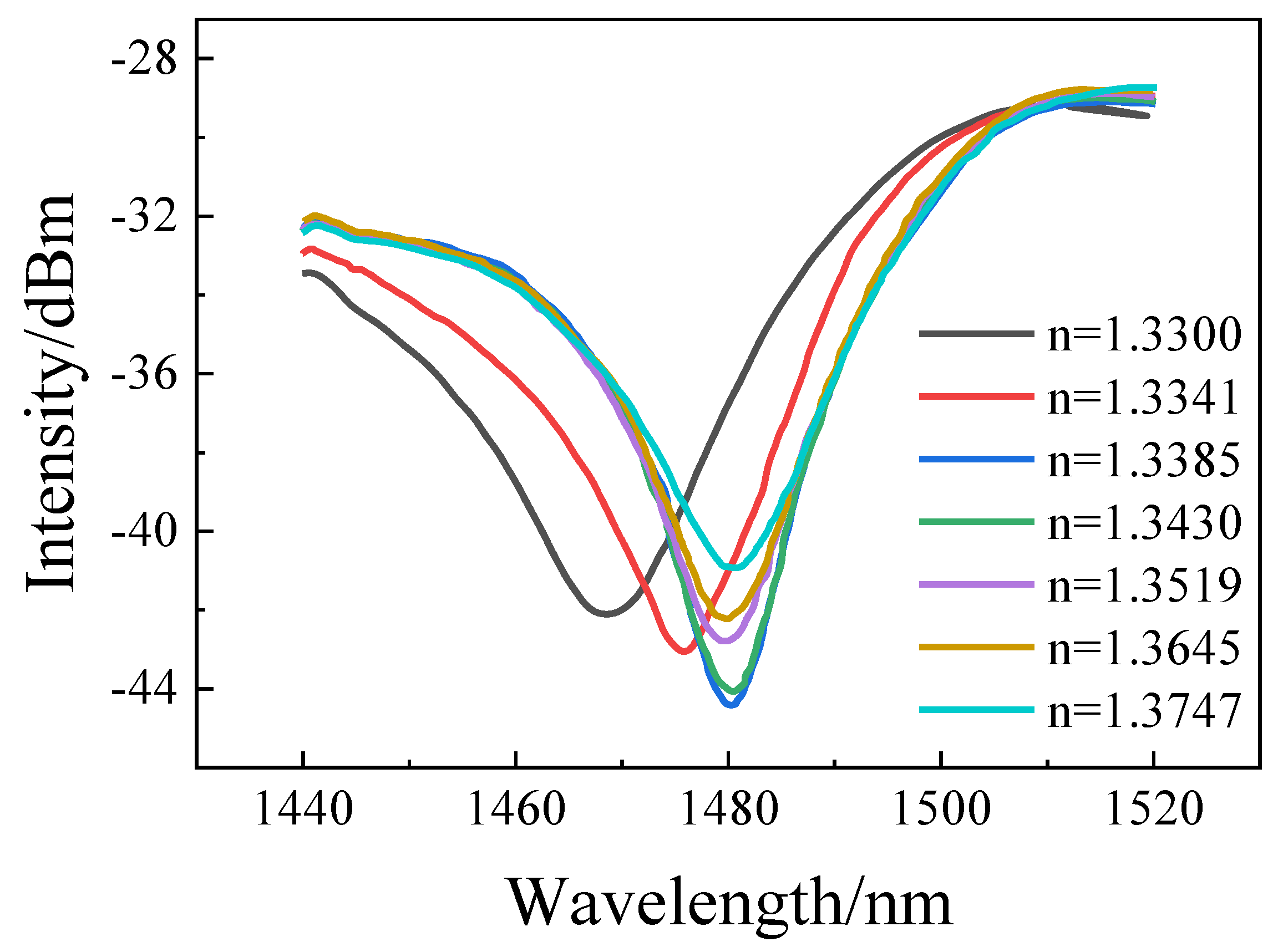

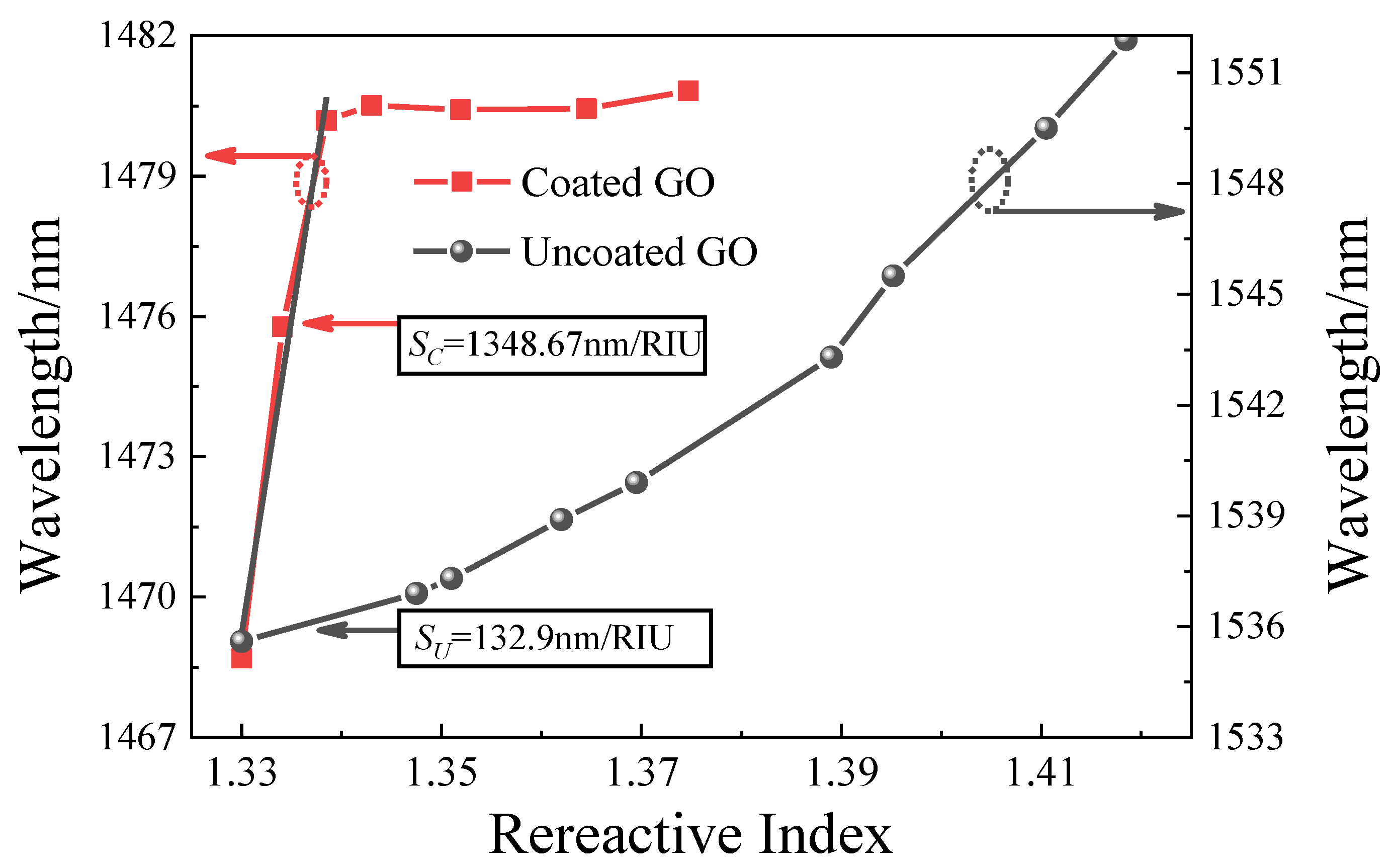

4. Experimental Results

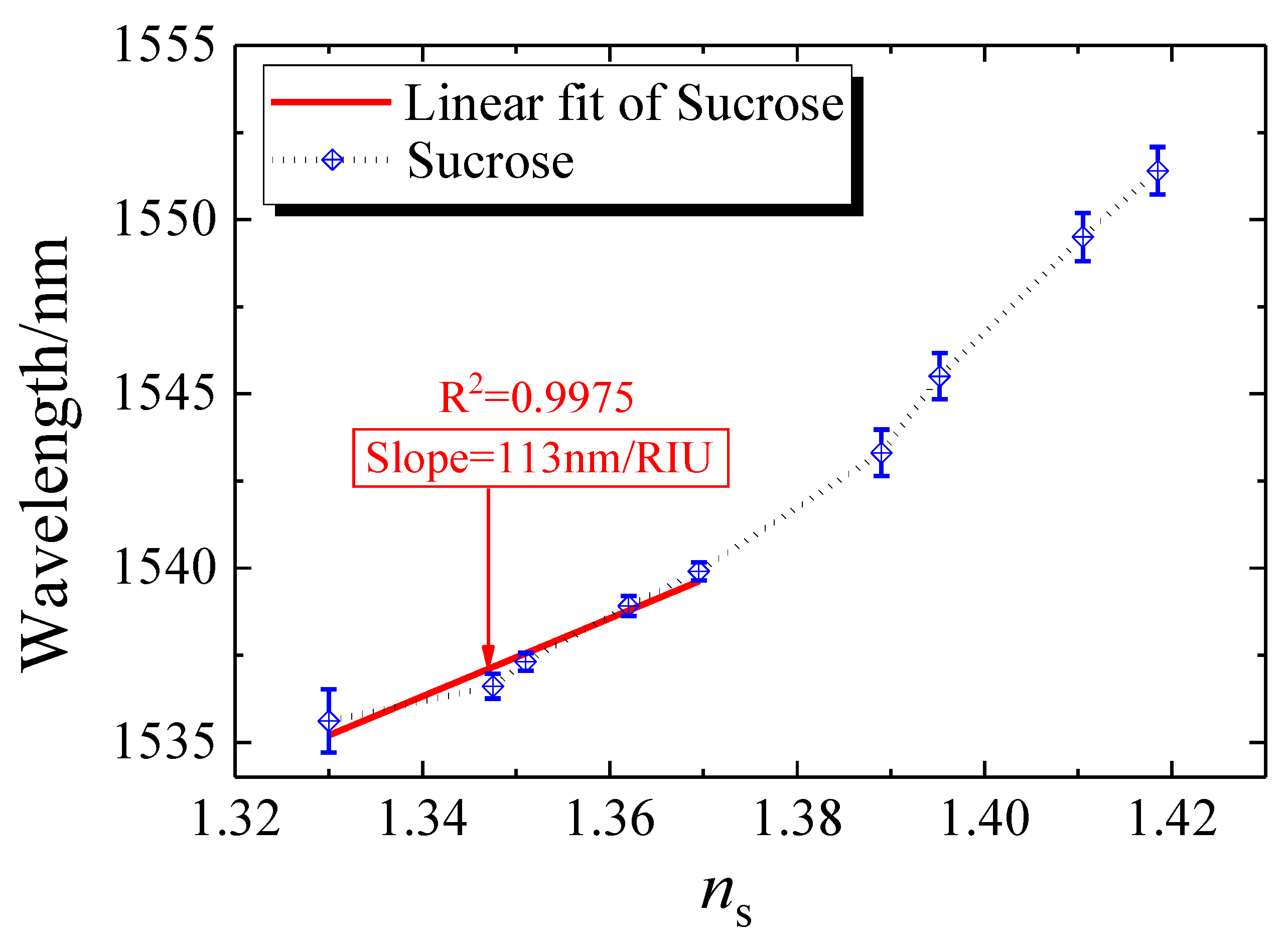

4.1. Sensor Calibration

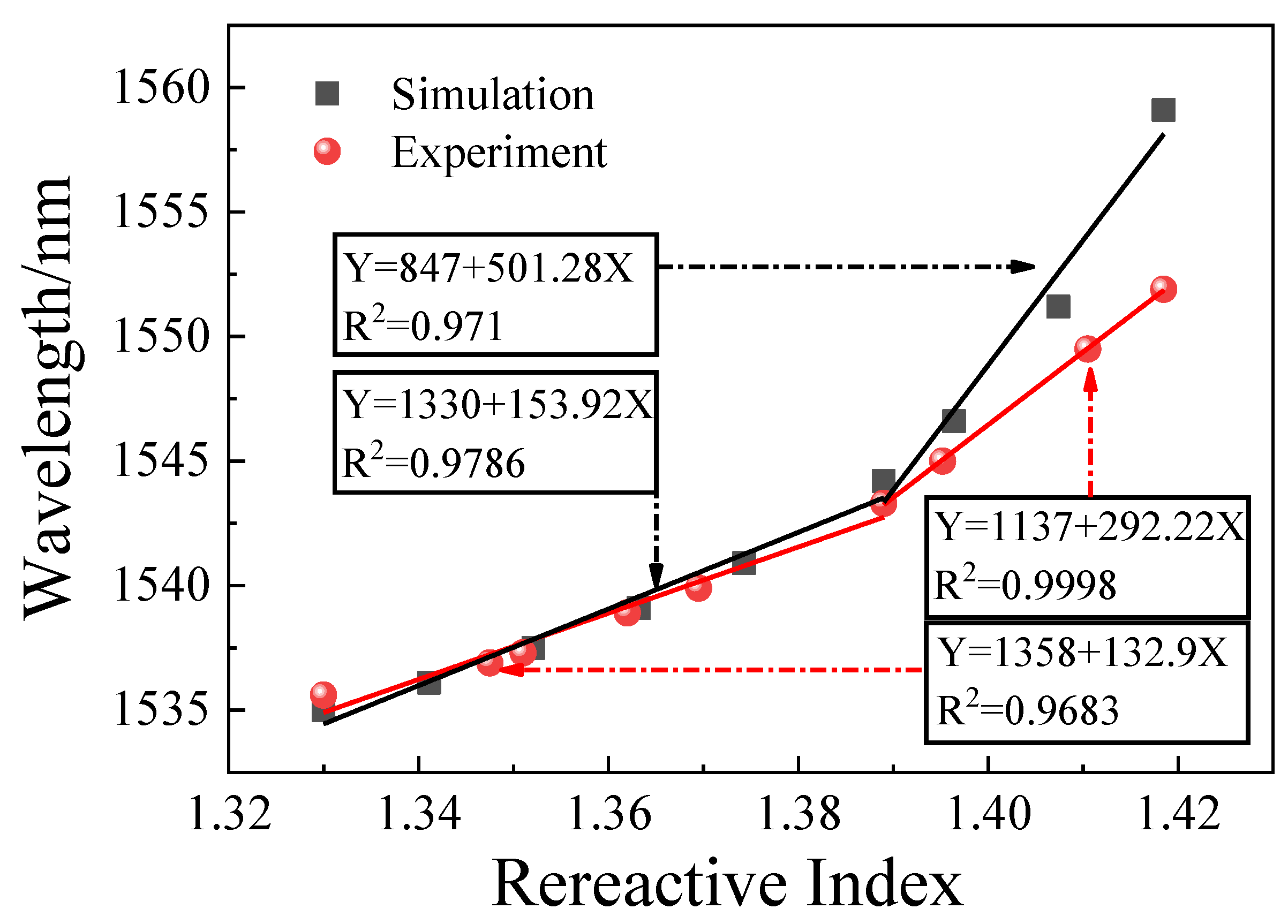

4.2. Results Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Donlagic, D.; Culshaw, B. Microbend sensor structure for use in distributed and quasi-distributed sensor systems based on selective launching and filtering of the modes in graded index multimode fiber. J. Lightwave Technol. 1999, 17, 1856–1868. [Google Scholar] [CrossRef]

- Kang, J.; Yang, J.R.; Zhang, X.D.; Liu, C.Y.; Wang, L. Intensity Demodulated Refractive Index Sensor Based on Front-Tapered Single-Mode-Multimode-Single-Mode Fiber Structure. Sensors 2018, 18, 2396. [Google Scholar] [CrossRef] [PubMed]

- Ascorbe, J.; Corres, J.M.; Matias, I.R. Magnetic field sensor based on a single mode-multimode-single mode optical fiber structure. In Proceedings of the 2015 IEEE SENSORS, Busan, Korea, 1–4 November 2015. [Google Scholar]

- Peng, Z.; Wang, L.; Yan, H. Research on high-temperature sensing characteristics based on modular interference of single-mode multimode single-mode fiber. In Proceedings of the SPIE/COS Photonics Asia, Beijing, China, 12–14 October 2016. [Google Scholar]

- An, J.L.; Zhao, Y.; Jin, Y.X.; Shen, C.Y. Relative humidity sensor based on SMS fiber structure with polyvinyl alcohol coating. Opt. Int. J. Light Electron Opt. 2013, 124, 6178–6181. [Google Scholar] [CrossRef]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of Fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Semenova, Y.; Wang, P.F.; Farrell, G. High sensitivity SMS fiber structure based refractometer analysis and experiment. Opt. Express 2011, 19, 7937–7944. [Google Scholar] [CrossRef] [PubMed]

- Hu, T.; Zhao, Y.; Cai, L. Temperature and Refractive Index Sensor using a High-Birefringence Fiber Loop Mirror and Single Mode-Coreless-Single Mode Fiber Structure. Instrum. Sci. Technol. 2016, 44, 366–376. [Google Scholar] [CrossRef]

- Zhang, M.Z.; Zhu, G.X.; Lu, L.D.; Lou, X.P.; Zhu, L.Q. Refractive index sensor based on ultrafine tapered single-mode nocladding single-mode fiber structure. Opt. Fiber Technol. 2019, 48, 297–302. [Google Scholar] [CrossRef]

- Aguilar-Soto, J.G.; Antonio-Lopez, J.E.; Sanchez-Mondragon, J.J.; May-Arrioja, D.A. Fiber Optic Temperature Sensor Based on Multimode Interference Effects. J. Phys. Conf. Ser. 2011, 274. [Google Scholar] [CrossRef]

- Zhou, X.L.; Chen, K.; Mao, X.F.; Peng, W.; Yu, Q.X. A reflective fiber-optic refractive index sensor based on multimode interference in a coreless silica fiber. Opt. Commun. 2015, 340, 50–55. [Google Scholar] [CrossRef]

- Zhou, G.R.; Wu, Q.; Kumar, R.; Ng, W.P. High Sensitivity Refractometer Based on Reflective Smf-Small Diameter No Core Fiber Structure. Sensors 2017, 17, 1415. [Google Scholar] [CrossRef] [PubMed]

- Baharin, N.F.; Azmi, A.I.; Abdullah, A.S.; Noor, M.Y.M. Refractive index sensor based on lateral-offset of coreless silica interferometer. Opt. Laser Technol. 2018, 99, 396–401. [Google Scholar] [CrossRef]

- Liu, X.X.; Zhang, X.P.; Liu, Y.; Liu, Z.G.; Peng, W. Multi-point fiber-optic refractive index sensor by using coreless fibers. Opt. Commun. 2016, 365, 168–172. [Google Scholar] [CrossRef]

- Zhang, H.; Xing, C.Y.; Jing, G.H.; Liang, X. Graphene oxide/black phosphorus nanoflake aerogels with robust thermo-stability and significantly enhanced photothermal properties in air. Nanoscale 2017, 9, 8096. [Google Scholar]

- Xing, C.Y.; Chen, S.Y.; Qiu, M.; Liang, X.; Liu, Q.; Zou, Q.S.; Li, Z.J.; Xie, Z.J.; Wang, D.; Dong, B.Q.; et al. Conceptually Novel Black Phosphorus/Cellulose Hydrogels as Promising Photothermal Agents for Effective Cancer Therapy. Adv. Healthc. Mater. 2018, 7, 1701510. [Google Scholar] [CrossRef]

- Xie, Z.J.; Xing, C.Y.; Huang, W.C.; Fan, T.J. Ultrathin 2D Nonlayered Tellurium Nanosheets: Facile Liquid-Phase Exfoliation, Characterization, and Photoresponse with High Performance and Enhanced Stability. Adv. Funct. Mater. 2018, 28, 1705833.1–1705833.11. [Google Scholar] [CrossRef]

- Jiang, X.T.; Zhang, L.J.; Liu, S.X.; Zhang, Y.Y.; He, Z.L. Ultrathin Metal–Organic Framework: An Emerging Broadband Nonlinear Optical Material for Ultrafast Photonics. Adv. Opt. Mater. 2018, 6, 1800561.1–1800561.11. [Google Scholar] [CrossRef]

- Qi, X.; Zhang, Y.P.; Ou, Q.D.; Ha, S.T.; Qiu, C.W.; Zhang, H.; Cheng, Y.B.; Xiong, Q.H.; Bao, Q.L. Photonics and Optoelectronics of 2D Metal-Halide Perovskites. Small 2018, 14, 1800682. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Lim, C.K.; Dai, Z.G.; Yu, G.N.; Haus, J.W.; Zhang, H.; Prasad, P.N. Photonics and optoelectronics using nano-structured hybrid perovskite media and their optical cavities. Phys. Rep. 2019, 795, 1–51. [Google Scholar] [CrossRef]

- Jiang, Y.Q.; Miao, L.L.; Jiang, G.B.; Chen, Y.; Qi, X.; Jiang, X.F.; Zhang, H.; Wen, S.C. Broadband and enhanced nonlinear optical response of MoS2/graphene nanocomposites for ultrafast photonics applications. Sci. Rep. 2015, 5, 16372. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, M.X.; Guo, Z.N.; Miao, L.L. Recent advances in black phosphorus-based photonics, electronics, sensors and energy devices. Mater. Horiz. 2017, 4, 997–1019. [Google Scholar] [CrossRef]

- Li, Z.J.; Qiao, H.; Guo, Z.N.; Ren, X.H. High-Performance Photo-Electrochemical Photodetector Based on Liquid-Exfoliated Few-Layered InSe Nanosheets with Enhanced Stability. Adv. Funct. Mater. 2018, 28, 1705237. [Google Scholar] [CrossRef]

- Tao, W.; Kong, N.; Ji, X.Y.; Zhang, Y.P. Emerging two-dimensional monoelemental materials (Xenes) for biomedical applications. Chem. Soc. Rev. 2019, 48, 2891. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Jiang, X.T.; Zhang, R.Y.; Zhang, Y.; Wu, L.M.; Lu, W.; Li, J.Q. MXene-Enabled Electrochemical Microfluidic Biosensor: Applications toward Multicomponent Continuous Monitoring in Whole Blood. Adv. Funct. Mater. 2018, 29, 1807326. [Google Scholar] [CrossRef]

- Qiu, M.; Ren, X.R.; Jeong, T.; Won, M. Omnipotent phosphorene: A next-generation, two-dimensional nanoplatform for multidisciplinary biomedical applications. Chem. Soc. Rev. 2018, 47, 5588–5601. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Hurch, S.; Nolan, H.; Hallam, T.; Berner, N.C.; McEvoy, N.; Duesberg, G.S. Inkjet-defined field-effect transistors from chemical vapour deposited graphene. Carbon 2014, 71, 332–337. [Google Scholar] [CrossRef]

- Vakil, A.; Engheta, N. Transformation optics using graphene. Science 2011, 332, 1291–1294. [Google Scholar] [CrossRef] [PubMed]

- Obraztsov, P.A.; Rybin, M.G.; Tyurnina, A.V.; Garnov, S.V.; Obraztsova, E.D.; Obraztsov, A.N.; Svirko, Y.P. Broadband light-induced absorbance change in multilayer graphene. Nano Lett. 2011, 11, 1540–1545. [Google Scholar] [CrossRef]

- Jablan, M.; Buljan, H.; Soljačić, M. Plasmonics in graphene at infra-red frequencies. Phys. Rev. B 2009, 80, 245435. [Google Scholar] [CrossRef]

- Stankovich, S.; Piner, R.D.; Nguyen, S.B.T.; Ruoff, R.S. Synthesis and exfoliation of isocyanate-treated graphene oxide nanoplatelets. Carbon 2006, 44, 3342–3347. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.Y.; Wu, Y.; Nguyen, S.B.T.; Ruoff, R.S. Synthesis of graphene-based Nano sheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Arasu, P.T.; Noor, A.S.M.; Shabaneh, A.A.; Yaacob, M.H.; Lim, H.N.; Mahdi, M.A. Fiber bragg grating assisted surface plasmon resonance sensor with graphene oxide sensing layer. Opt. Commun. 2016, 380, 260–266. [Google Scholar] [CrossRef]

- Shang, J.Z.; Ma, L.; Li, J.W.; Ai, W.; Yu, T.; Gurzadyan, T.T. The origin of fluorescence from graphene oxide. Sci. Rep. 2012, 2, 792. [Google Scholar] [CrossRef]

- Dash, J.N.; Jha, R. Temperature insensitive PCF interferometer coated with graphene oxide tip sensor. IEEE Photonics Technol. Lett. 2016, 28, 1006–1009. [Google Scholar]

- Wang, Y.Q.; Shen, C.Y.; Lou, W.M.; Shentu, F.Y.; Zhong, C.; Dong, X.Y.; Tong, L.M. Fiber optic relative humidity sensor based on the tilted fiber Bragg grating coated with graphene oxide. Appl. Phys. Lett. 2016, 109, 031107. [Google Scholar] [CrossRef]

- Gao, S.S.; Qiu, H.W.; Zhang, C.; Jiang, S.Z.; Li, Z.; Liu, X.Y.; Yue, W.W.; Yang, C.; Huo, Y.Y.; Feng, D.J.; et al. Absorbance response of a graphene oxide coated U-bent optical fiber sensor for aqueous ethanol detection. RSC Adv. 2016, 6, 15808–15815. [Google Scholar] [CrossRef]

- Yu, C.B.; Wu, Y.; Liu, X.L.; Fu, F.; Gong, Y.; Rao, Y.J.; Chen, Y.F. Miniature fiber-optic NH3 gas sensor based on Pt nanoparticle-incorporated graphene oxide. Sens. Actuators B Chem. 2016, 244, 107–113. [Google Scholar] [CrossRef]

- Divagar, M.; Gowri, A.; John, S.; Sai, V.V.R. Graphene oxide coated U-Bent plastic optical fiber based chemical sensor for organic solvents. Sens. Actuators B Chem. 2018, 262, 1006–1012. [Google Scholar] [CrossRef]

- Li, J.X.; Tong, Z.R.; Jing, L.; Zhang, W.H.; Qin, J.; Liu, J.W. Fiber temperature and humidity sensor based on photonic crystal fiber coated with graphene oxide. Opt. Commun. 2020, 467, 125707. [Google Scholar] [CrossRef]

- Koshiba, M.; Saitoh, K.; Kokubun, Y. Heterogeneous multi-core fibers: Proposal and design principle. IEICE Electron. Express 2009, 6, 98–103. [Google Scholar] [CrossRef]

- Rifat, A.A.; Mahdiraji, G.A.; Sua, Y.M.; Ahmed, R.; Shee, Y.G.; Adikan, F.R.M. Highly sensitive multi-core flat fiber surface plasmon resonance refractive index sensor. Opt. Express 2016, 24, 2485–2495. [Google Scholar] [CrossRef]

| Type | Core Refractive Index | Cladding Refractive Index | Core Radius/μm |

|---|---|---|---|

| SMF | 1.4682 | 1.4628 | 8.2 |

| NCF | 1.4440 | 1.3300~1.4185 | 62.5 |

| Sucrose Concentration | 0% | 10% | 20% | 25% | 30% | 35% | 40% | 45% | 50% |

| The Refractive Index | 1.330 | 1.348 | 1.351 | 1.362 | 1.370 | 1.389 | 1.395 | 1.411 | 1.419 |

| Structure | Detection RI Range | RI Sensitivity | Age | Refs. |

|---|---|---|---|---|

| SMS fiber structure-based refractometer | 1.342~1.437 | 1815 nm/RIU | 2011 | [7] |

| High-birefringence fiber loop mirror and SNS fiber structure | aqueous of NaCl solution | 96.42 nm/RIU | 2016 | [8] |

| Ultrafine tapered SNS fiber structure | 1.333~1.350 | 686 nm/RIU | 2019 | [9] |

| GO sensitized SNS Fiber | 1.330~1.3385 | 1348.67 nm/RIU | 2020 | Our work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, G.; Zhang, K.; Yang, Y.; Yang, H.; Guo, L.; Li, J.; Yuan, L. Graphene Oxide Sensitized No-Core Fiber Step-Index Distribution Sucrose Sensor. Photonics 2020, 7, 101. https://doi.org/10.3390/photonics7040101

Xiao G, Zhang K, Yang Y, Yang H, Guo L, Li J, Yuan L. Graphene Oxide Sensitized No-Core Fiber Step-Index Distribution Sucrose Sensor. Photonics. 2020; 7(4):101. https://doi.org/10.3390/photonics7040101

Chicago/Turabian StyleXiao, Gongli, Kaifu Zhang, Yuting Yang, Hongyan Yang, Ling Guo, Jianqing Li, and Libo Yuan. 2020. "Graphene Oxide Sensitized No-Core Fiber Step-Index Distribution Sucrose Sensor" Photonics 7, no. 4: 101. https://doi.org/10.3390/photonics7040101

APA StyleXiao, G., Zhang, K., Yang, Y., Yang, H., Guo, L., Li, J., & Yuan, L. (2020). Graphene Oxide Sensitized No-Core Fiber Step-Index Distribution Sucrose Sensor. Photonics, 7(4), 101. https://doi.org/10.3390/photonics7040101