Synthesis, Crystallography, Microstructure, Crystal Defects, Optical and Optoelectronic Properties of ZnO:CeO2 Mixed Oxide Thin Films

Abstract

1. Introduction

2. Experimental Details

2.1. Preparation Pure ZnO and Pure CeO2 Solution

2.2. Preparation of ZnO:CeO2 Mixed Oxides Solution

2.3. Deposition of ZnO:CeO2 Mixed Oxides Thin Films

2.4. Characterizations of ZnO:CeO2 Mixed Oxides Thin Films

3. Result and Discussion

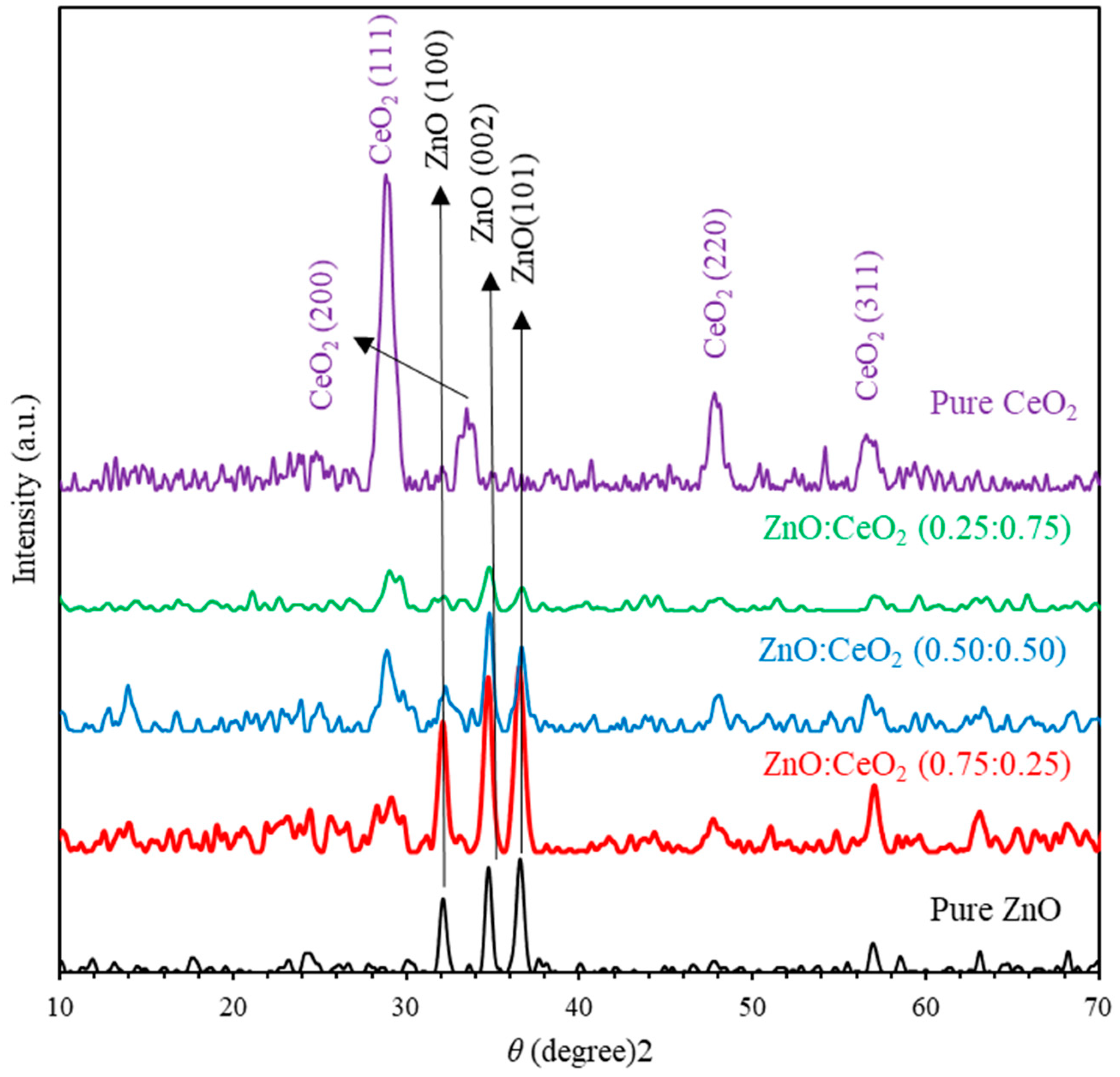

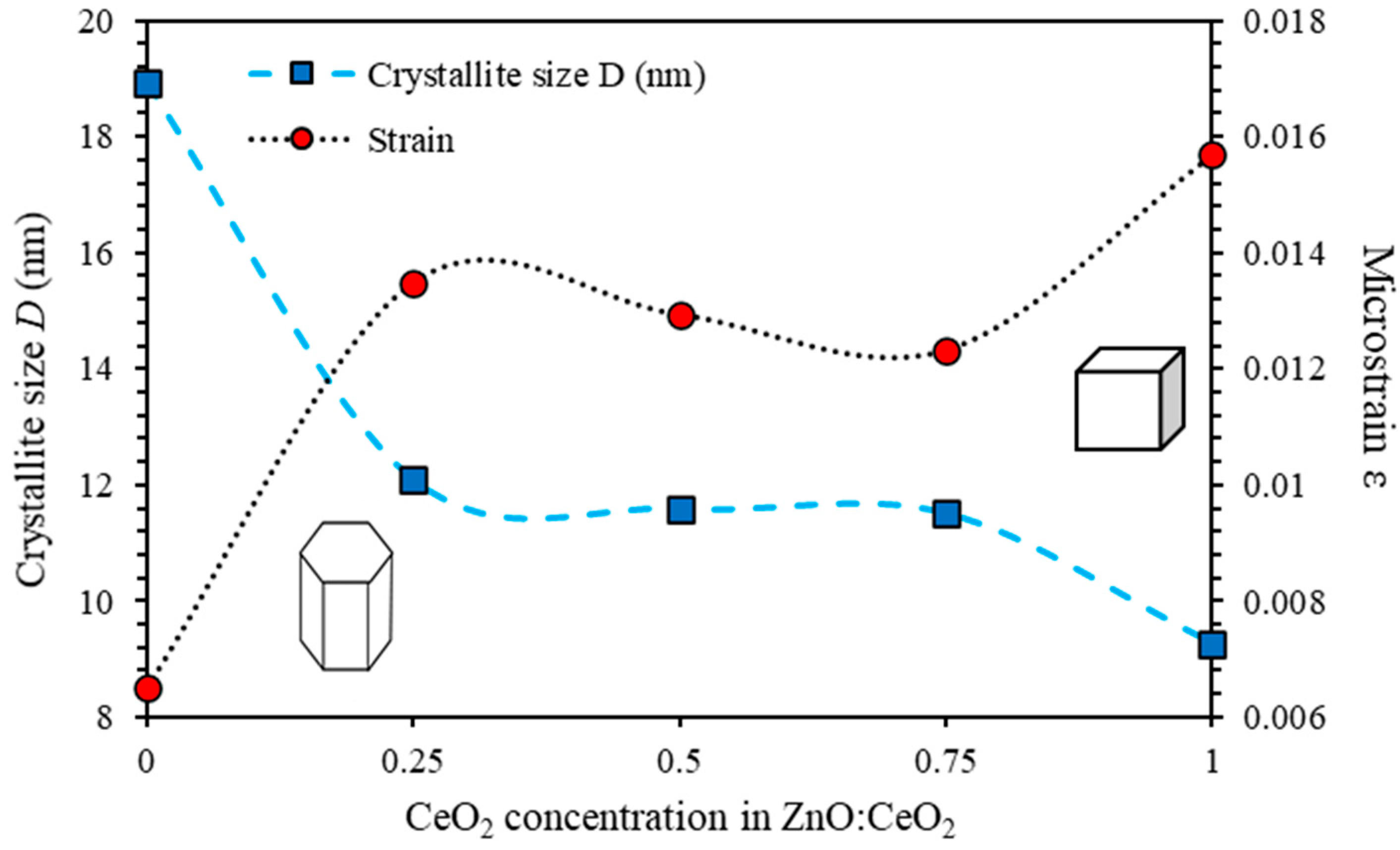

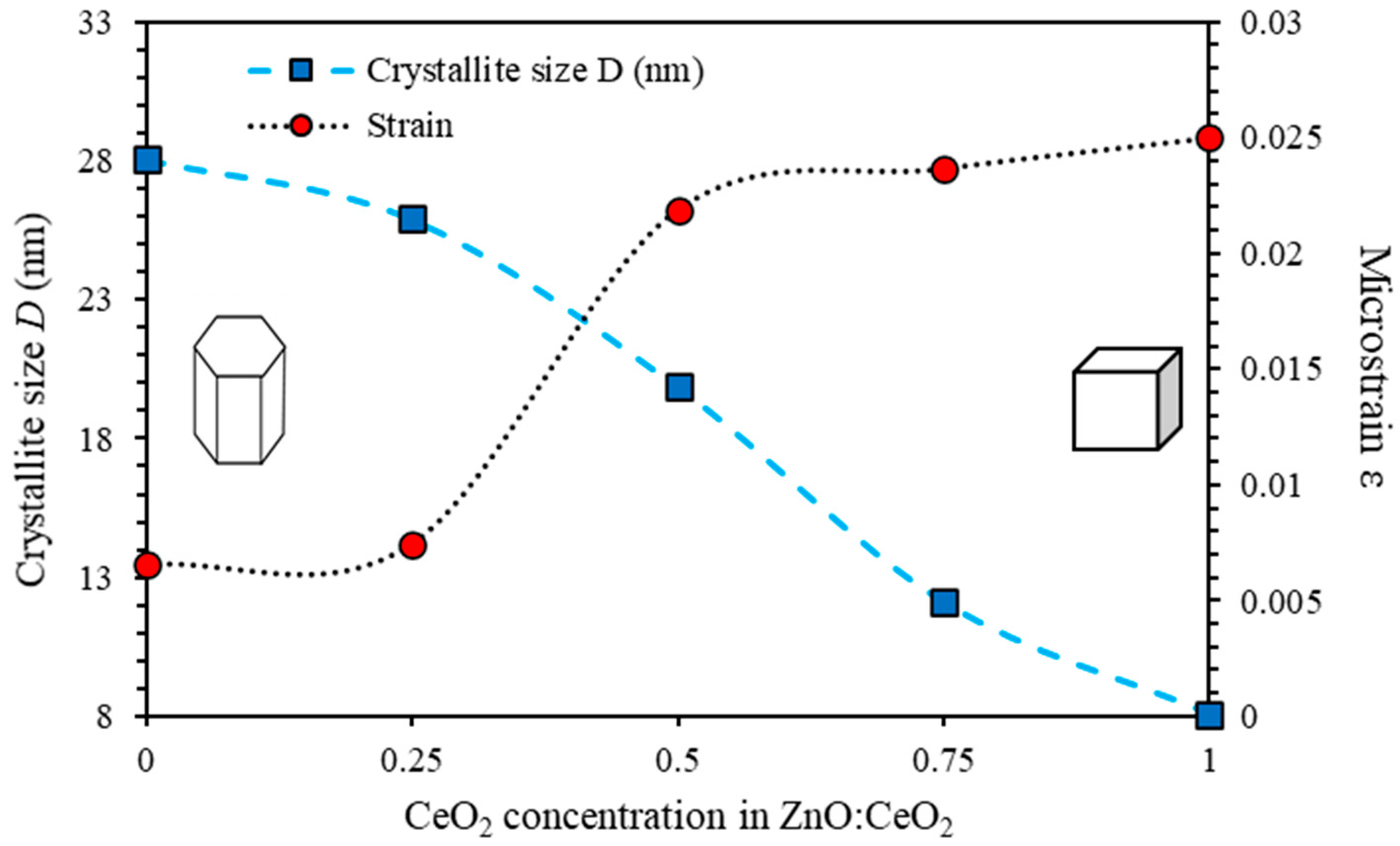

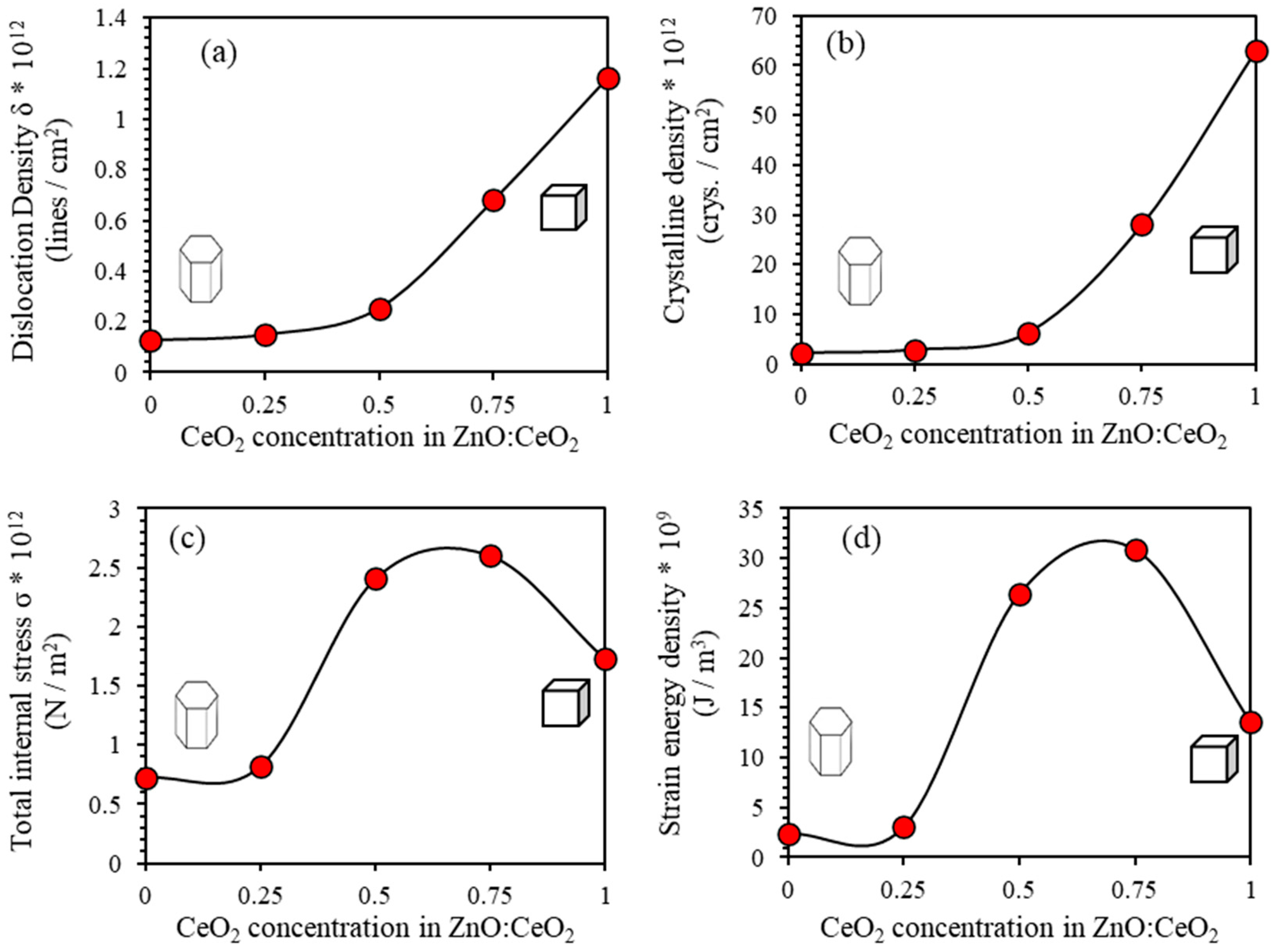

3.1. X-Ray Diffraction (XRD) Analysis

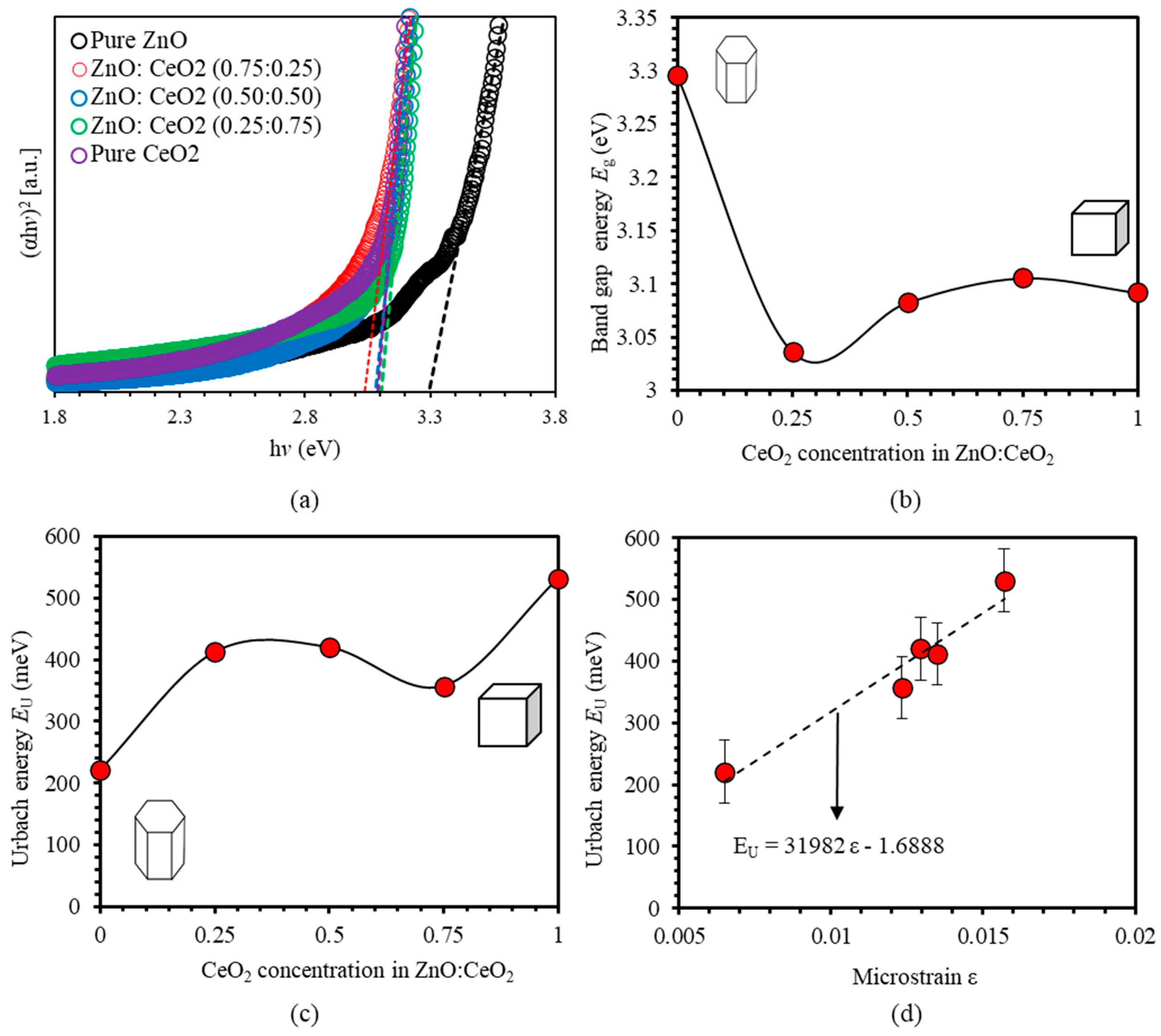

3.2. UV-Vis Spectroscopy Measurements of Optical Properties

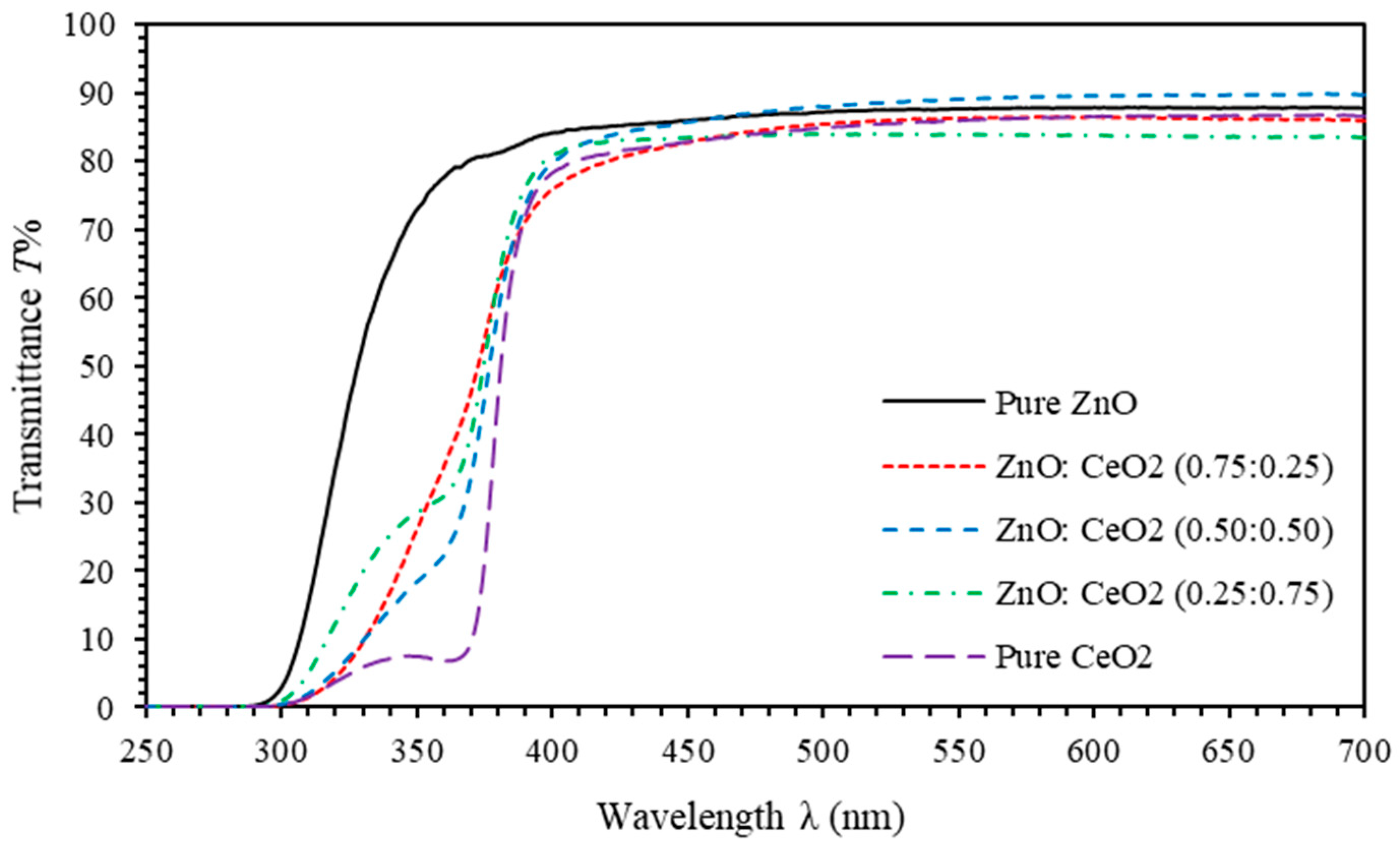

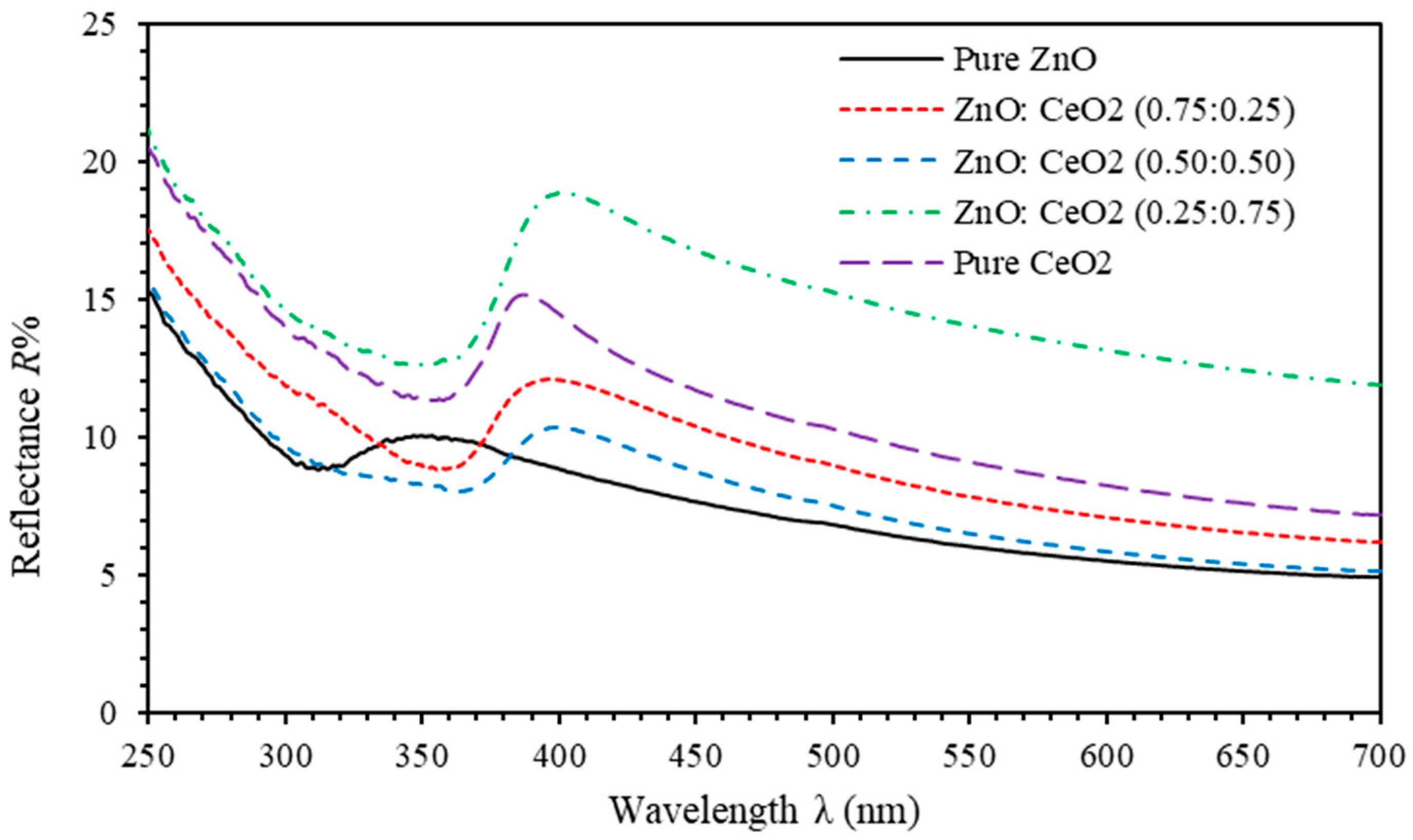

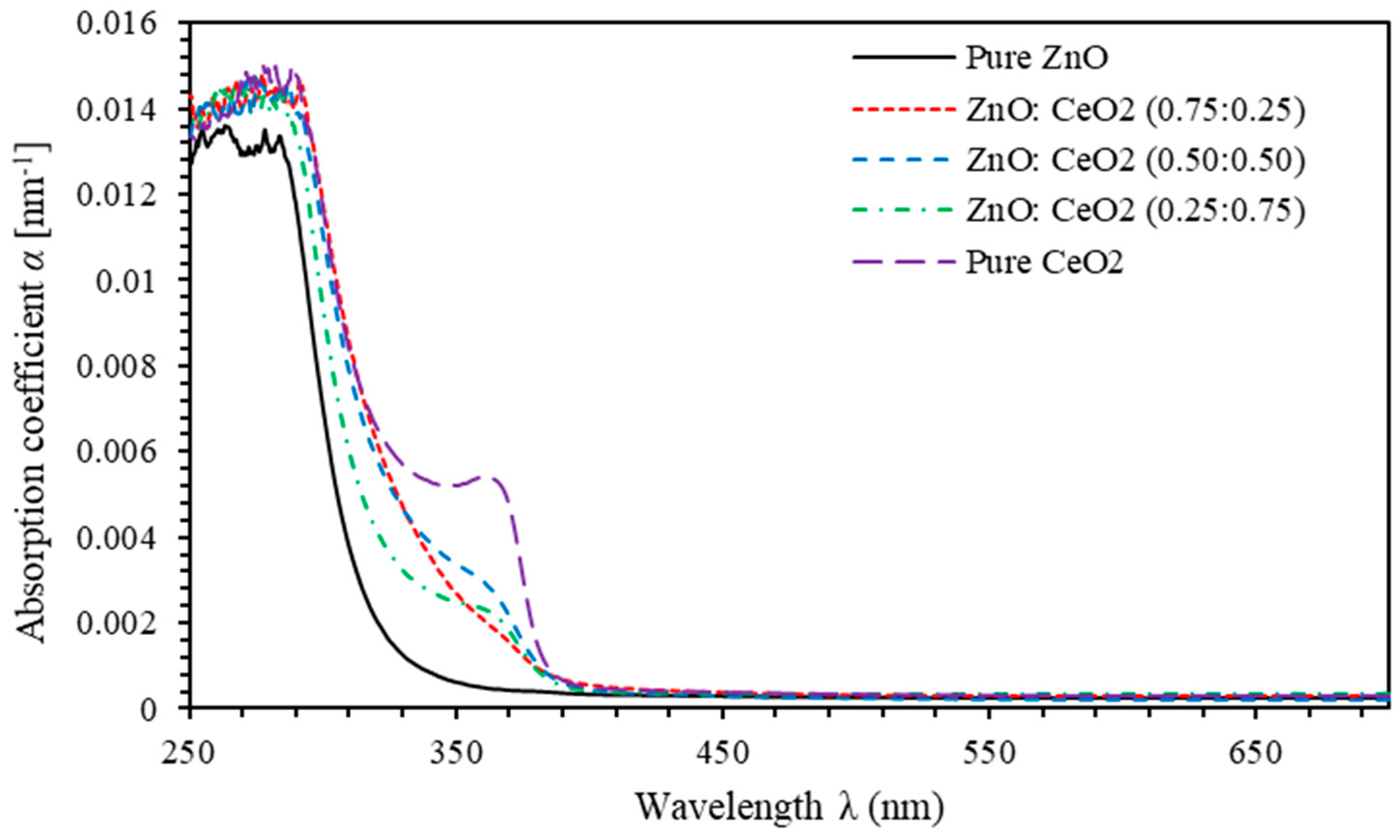

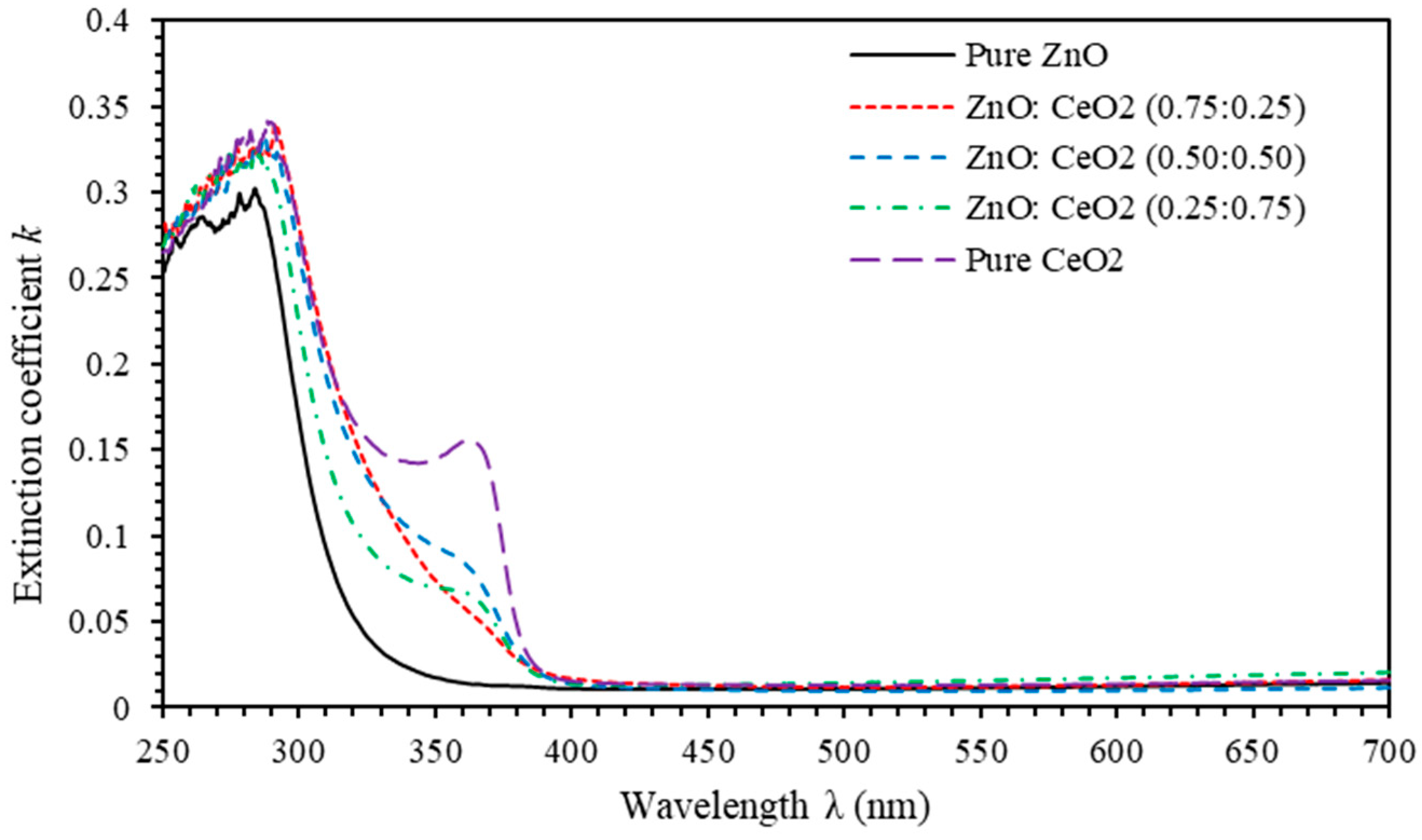

3.3. Analysis of Transmittance Spectra

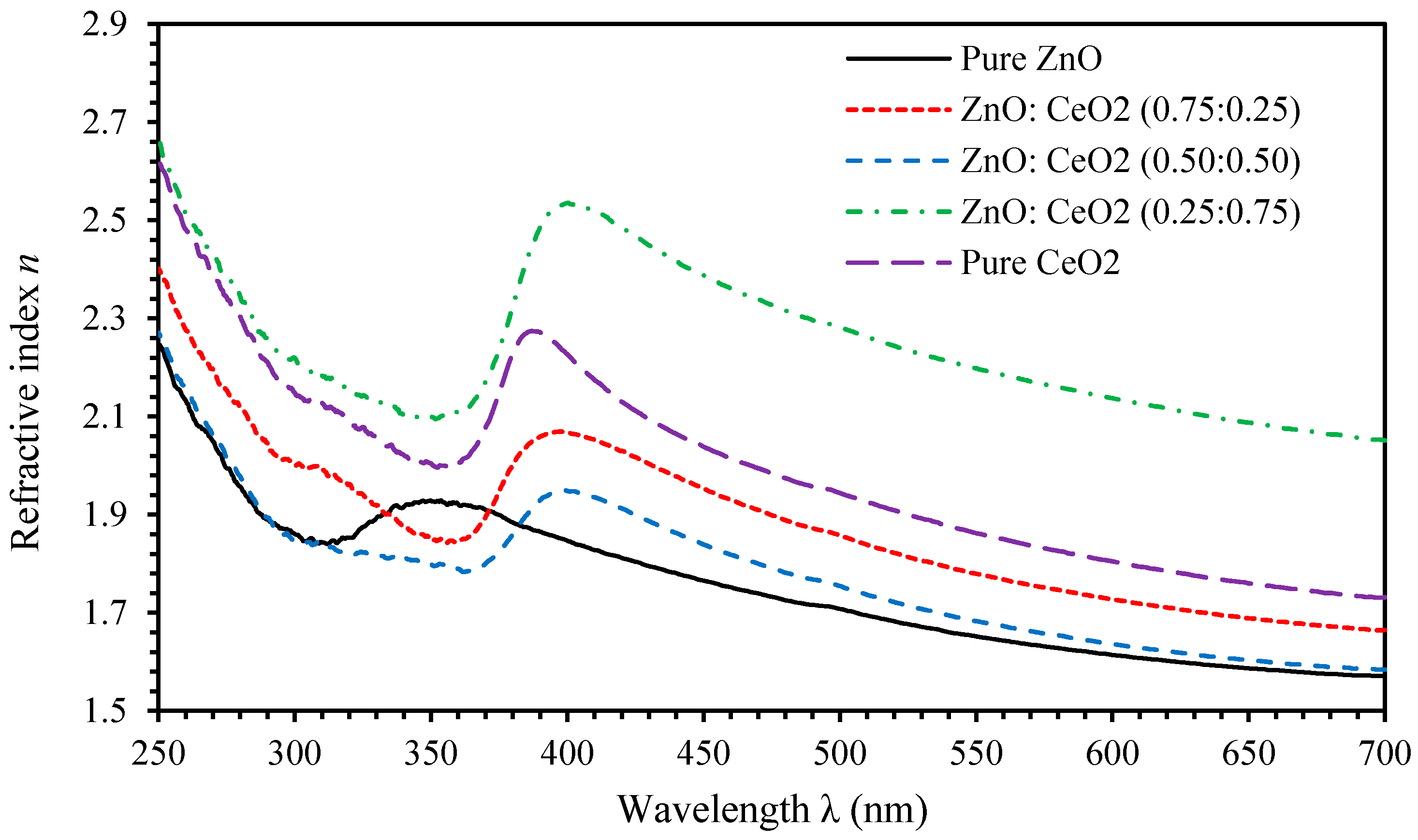

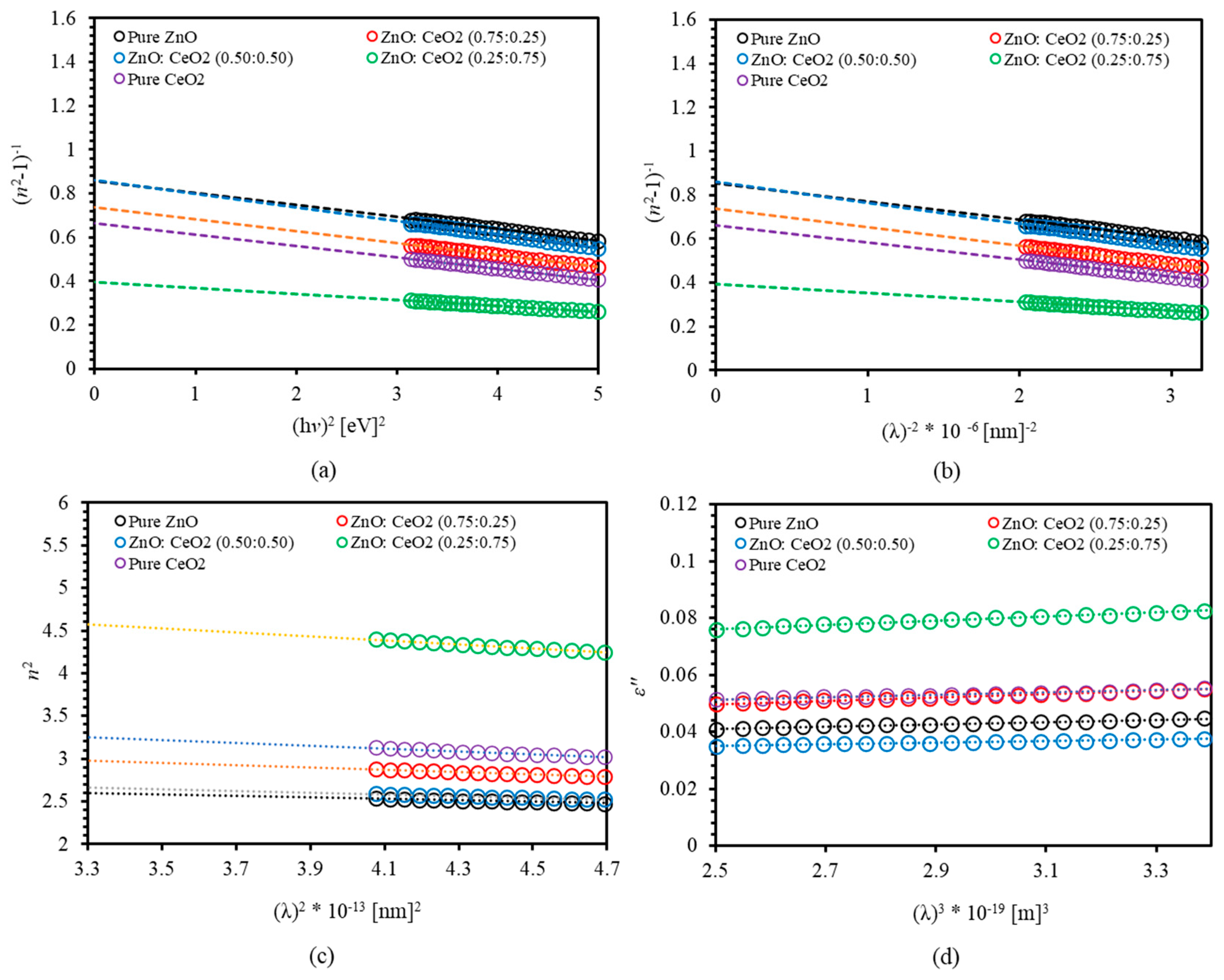

3.4. Refractive Index Analysis

4. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Al-Bataineh, Q.M.; Alsaad, A.; Ahmad, A.A.; Al-Sawalmih, A. Structural, Electronic and Optical Characterization of ZnO Thin Film-Seeded Platforms for ZnO Nanostructures: Sol–Gel Method Versus Ab Initio Calculations. J. Electron. Mater. 2019, 48, 5028–5038. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Alsaad, A.M.; Al-Bataineh, Q.M.; Al-Naafa, M.A. Optical and structural investigations of dip-synthesized boron-doped ZnO-seeded platforms for ZnO nanostructures. Appl. Phys. A 2018, 124, 458. [Google Scholar] [CrossRef]

- Alsaad, A.; Ahmad, A.A.; Qattan, I.A.; AlBataineh, Z.; AlBataineh, Z. Structural, Optoelectrical, Linear, and Nonlinear Optical Characterizations of Dip-Synthesized Undoped ZnO and Group III Elements (B, Al, Ga, and In)-Doped ZnO Thin Films. Crystals 2020, 10, 252. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Alsaad, Q.A.-B. Optical and structural characterization of dip synthesized Al-B Co-doped ZnO seeded platforms for ZnO nanostructures. Jordan J. Phys. 2017, 10, 33–48. [Google Scholar]

- Muchuweni, E.; Sathiaraj, T.; Nyakotyo, H. Synthesis and characterization of zinc oxide thin films for optoelectronic applications. Heliyon 2017, 3, e00285. [Google Scholar] [CrossRef]

- Malik, G.; Mourya, S.; Jaiswal, J.; Chandra, R. Effect of annealing parameters on optoelectronic properties of highly ordered ZnO thin films. Mater. Sci. Semicond. Process. 2019, 100, 200–213. [Google Scholar] [CrossRef]

- Sandeep, K.; Bhat, S.; Dharmaprakash, S. Structural, optical, and LED characteristics of ZnO and Al doped ZnO thin films. J. Phys. Chem. Solids 2017, 104, 36–44. [Google Scholar] [CrossRef]

- Kim, J.; Ji, J.-H.; Min, S.-W.; Jo, G.-H.; Jung, M.-W.; Park, M.-J.; Lee, S.-K.; Koh, J.-H. Enhanced conductance properties of UV laser/RTA annealed Al-doped ZnO thin films. Ceram. Int. 2017, 43, 3900–3904. [Google Scholar] [CrossRef]

- Kokate, S.K.; Jagtap, C.V.; Baviskar, P.K.; Jadkar, S.; Pathan, H.M.; Mohite, K.C. CdS sensitized cadmium doped ZnO solar cell: Fabrication and characterizations. Optik 2018, 157, 628–634. [Google Scholar] [CrossRef]

- Qiao, S.; Liu, J.; Fu, G.; Ren, K.; Li, Z.; Wang, S.; Pan, C. ZnO nanowire based CIGS solar cell and its efficiency enhancement by the piezo-phototronic effect. Nano Energy 2018, 49, 508–514. [Google Scholar] [CrossRef]

- Zhu, L.; Zeng, W. Room-temperature gas sensing of ZnO-based gas sensor: A review. Sens. Actuators A Phys. 2017, 267, 242–261. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Al-Bataineh, Q.M.; Alsaad, A.M.; Samara, T.O.; Al-izzy, K.A. Optical properties of hydrophobic ZnO nano-structure based on antireflective coatings of ZnO/TiO2/SiO2 thin films. Phys. B Condens. Matter 2020, 593, 412263. [Google Scholar] [CrossRef]

- Khan, I.A.; Belkhedkar, M.R.; Salodkar, R.V.; Ubale, A.U. Physical properties of nanostructured CeO2 thin films grown by SILAR method. In Proceedings of the 2nd International Conference on Condensed Matter and Applied Physics (Icc 2017), Bikaner, India, 24–25 November 2017; AIP Publishing: Melville, NY, USA AIP Conference Proceedings 2018. ; Volume 1953, p. 030102. [Google Scholar]

- Kumar, P.; Kumar, P.; Kumar, A.; Sulania, I.; Chand, F.; Kandasami, A. Structural, optical and magnetic properties of N ion implanted CeO2 thin films. RSC Adv. 2017, 7, 9160–9168. [Google Scholar] [CrossRef]

- Jewariya, M.; Singh, P.; Moona, G.; Shanker, G.; Srivatsa, K.; Baek, I.H.; Jeong, Y.U. Investigation of dynamic optical behavior of CeO2 thin film using terahertz spectroscopy. Opt. Mater. 2018, 85, 295–297. [Google Scholar] [CrossRef]

- Zinzuvadiya, S.; Pandya, N.C.; Joshi, U.S. Optoelectronic response of (111) oriented CeO2 films for UV photodetector. Thin Solid Films 2019, 669, 525–530. [Google Scholar] [CrossRef]

- Tiwari, S.; Sen, S.; Shirage, P.M. Effect of Transition Elements Substitution on Structural, Optoelectronic, Magnetic and Mechanical Properties of CeO2. Ph.D. Thesis, IIT Indore, Indore, India, 2019. [Google Scholar]

- Miller, H.A.; Lavacchi, A.; Vizza, F.; Marelli, M.; Di Benedetto, F.; D’Acapito, F.; Paska, Y.; Page, M.; Dekel, D.R. A Pd/C-CeO2 Anode Catalyst for High-Performance Platinum-Free Anion Exchange Membrane Fuel Cells. Angew. Chem. Int. Ed. 2016, 55, 6004–6007. [Google Scholar] [CrossRef]

- Li, L.; Zhu, B.; Zhang, J.; Yan, C.; Wu, Y. Electrical properties of nanocube CeO2 in advanced solid oxide fuel cells. Int. J. Hydrog. Energy 2018, 43, 12909–12916. [Google Scholar] [CrossRef]

- Hadi, A.; Rashid, F.L.; Hussein, H.Q.; Hashim, A. Novel of water with (CeO2-WC) and (SiC-WC) nanoparticles systems for energy storage and release applications. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Baghdad, Iraq, 6–7 March 2019; IOP Publishing; Volume 518, p. 032059. [Google Scholar]

- Sun, H.; Li, Y.; Yan, X.; Zhao, J.; Wang, Z. Thermochemical energy storage performance of Al2O3/CeO2 co-doped CaO-based material under high carbonation pressure. Appl. Energy 2020, 263, 114650. [Google Scholar] [CrossRef]

- Peng, R.; Li, S.; Sun, X.; Ren, Q.; Chen, L.; Fu, M.; Wu, J.; Ye, D. Size effect of Pt nanoparticles on the catalytic oxidation of toluene over Pt/CeO2 catalysts. Appl. Catal. B Environ. 2018, 220, 462–470. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, F.; Yang, Y.; Wang, Y.; Liu, N.; Chen, D.; Yang, Y. A facile synthesis for cauliflower like CeO2 catalysts from Ce-BTC precursor and their catalytic performance for CO oxidation. Appl. Surf. Sci. 2017, 423, 771–779. [Google Scholar] [CrossRef]

- Gao, G.; Shi, J.W.; Liu, C.; Gao, C.; Fan, Z.; Niu, C. Mn/CeO2 catalysts for SCR of NOx with NH3: Comparative study on the effect of supports on low-temperature catalytic activity. Appl. Surf. Sci. 2017, 411, 338–346. [Google Scholar] [CrossRef]

- Lin, B.; Liu, Y.; Heng, L.; Wang, X.; Ni, J.; Lin, J.; Wang, X. Morphology Effect of Ceria on the Catalytic Performances of Ru/CeO2 Catalysts for Ammonia Synthesis. Ind. Eng. Chem. Res. 2018, 57, 9127–9135. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Bahlakeh, G.; Ramezanzadeh, M. Polyaniline-cerium oxide (PAni-CeO2) coated graphene oxide for enhancement of epoxy coating corrosion protection performance on mild steel. Corros. Sci. 2018, 137, 111–126. [Google Scholar] [CrossRef]

- Li, B.; Zhang, W.; Li, D.; Wang, J. Electrodeposition of Ni W/ZrO2 nanocrystalline film reinforced by CeO2 nanoparticles: Structure, surface properties and corrosion resistance. Mater. Chem. Phys. 2019, 229, 495–507. [Google Scholar] [CrossRef]

- Torres-Huerta, A.; Domínguez-Crespo, M.; Brachetti-Sibaja, S.B.; Rosales, H.D.; Hernández-Pérez, M.; Lois-Correa, J.A. Preparation of ZnO:CeO2–x thin films by AP-MOCVD: Structural and optical properties. J. Solid State Chem. 2010, 183, 2205–2217. [Google Scholar] [CrossRef]

- Al-Kuhaili, M.; Durrani, S.; Bakhtiari, I.; Al-Kuhaili, M.F. Carbon monoxide gas-sensing properties of CeO2–ZnO thin films. Appl. Surf. Sci. 2008, 255, 3033–3039. [Google Scholar] [CrossRef]

- Qian, J.; Wang, Y.; Pan, J.; Chen, Z.; Wang, C.; Chen, J.; Wu, Z. Yangyue Non-enzymatic glucose sensor based on ZnO–CeO2 whiskers. Mater. Chem. Phys. 2020, 239, 122051. [Google Scholar] [CrossRef]

- Xiong, Z.; Lei, Z.; Xu, Z.; Chen, X.; Gong, B.; Zhao, Y.; Zhao, H.; Zhang, J.; Zheng, C. Flame spray pyrolysis synthesized ZnO/CeO2 nanocomposites for enhanced CO2 photocatalytic reduction under UV–Vis light irradiation. J. CO2 Util. 2017, 18, 53–61. [Google Scholar] [CrossRef]

- Liang, X.; Wang, P.; Gao, Y.; Huang, H.; Tong, F.; Zhang, Q.; Wang, Z.; Liu, Y.; Zheng, Z.; Dai, Y.; et al. Design and synthesis of porous M-ZnO/CeO2 microspheres as efficient plasmonic photocatalysts for nonpolar gaseous molecules oxidation: Insight into the role of oxygen vacancy defects and M=Ag, Au nanoparticles. Appl. Catal. B Environ. 2020, 260, 118151. [Google Scholar] [CrossRef]

- Ghouri, Z.K.; Barakat, N.A.; Kim, H.-Y.; Park, M.; Khalil, K.A.; El-Newehy, M.H.; Al-Deyab, S.S. Nano-engineered ZnO/CeO2 dots@CNFs for fuel cell application. Arab. J. Chem. 2016, 9, 219–228. [Google Scholar] [CrossRef]

- Nath, B.; Chaliha, C.; Kalita, E.; Kalita, M. Synthesis and characterization of ZnO:CeO2:nanocellulose:PANI bionanocomposite. A bimodal agent for arsenic adsorption and antibacterial action. Carbohydr. Polym. 2016, 148, 397–405. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.Y.; Lin, Z.F.; Li, X.B.; Cheng, W.H.; Fu, Y.; Xu, L. Preparation and corrosion resistance of ZnO/CeO2 composite films. Surf. Eng. 2014, 32, 32–37. [Google Scholar] [CrossRef]

- Mueen, R.; Morlando, A.; Qutaish, H.; Lerch, M.; Cheng, Z.; Konstantinov, K. ZnO/CeO2 nanocomposite with low photocatalytic activity as efficient UV filters. J. Mater. Sci. 2020, 55, 6834–6847. [Google Scholar] [CrossRef]

- Kickelbick, G. The search of a homogeneously dispersed material—The art of handling the organic polymer/metal oxide interface. J. Sol-Gel Sci. Technol. 2008, 46, 281–290. [Google Scholar] [CrossRef]

- Mosley, D.W.; Auld, K.; Conner, D.; Gregory, J.; Liu, X.-Q.; Pedicini, A.; Thorsen, D.; Wills, M.; Khanarian, G.; Simon, E.S. High performance encapsulants for ultra high-brightness LEDs. SPIE Int. Soc. Opt. Eng. 2008, 6910, 691017. [Google Scholar]

- Allen, R.D.; Wallraff, G.M.; Hofer, D.C.; Kunz, R.R. Photoresists for 193-nm lithography. IBM J. Res. Dev. 1997, 41, 95–104. [Google Scholar] [CrossRef]

- Nakamura, T.; Fujii, H.; Juni, N.; Tsutsumi, N. Enhanced Coupling of Light from Organic Electroluminescent Device Using Diffusive Particle Dispersed High Refractive Index Resin Substrate. Opt. Rev. 2006, 13, 104–110. [Google Scholar] [CrossRef]

- Regolini, J.; Benoit, D.; Morin, P. Passivation issues in active pixel CMOS image sensors. Microelectron. Reliab. 2007, 47, 739–742. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y. Structural and magnetic studies of Mn-doped CeO2 thin films prepared by sol-gel method. Integr. Ferroelectr. 2017, 185, 176–182. [Google Scholar] [CrossRef]

- Alsaad, A.; Ahmad, A.A.; Al-Bataineh, Q.M.; Bani-Salameh, A.A.; Abdullah, H.S.; Qattan, I.A.; AlBataineh, Z.; Telfah, A. Optical, Structural, and Crystal Defects Characterizations of Dip Synthesized (Fe-Ni) Co-Doped ZnO Thin Films. Materials 2020, 13, 1737. [Google Scholar] [CrossRef]

- Mishra, B.G.; Rao, G.R. Promoting effect of ceria on the physicochemical and catalytic properties of CeO2–ZnO composite oxide catalysts. J. Mol. Catal. A Chem. 2006, 243, 204–213. [Google Scholar] [CrossRef]

- Shechtman, D.; Blech, I.; Gratias, D.; Cahn, J.W. Metallic Phase with Long-Range Orientational Order and No Translational Symmetry. Phys. Rev. Lett. 1984, 53, 1951–1953. [Google Scholar] [CrossRef]

- Sarma, H.; Sarma, K. X-ray Peak Broadening Analysis of ZnO Nanoparticles Derived by Precipitation method. Int. J. Sci. Res. Publ. 2014, 4, 1–7. [Google Scholar]

- Kamakanth, K. Basics of X-ray Diffraction and Its Application; IK: New Delhi, India, 2007. [Google Scholar]

- Fu, D.-W.; Zhang, W.; Cai, H.-L.; Ge, J.-Z.; Zhang, Y.; Xiong, R.-G. Diisopropylammonium Chloride: A Ferroelectric Organic Salt with a High Phase Transition Temperature and Practical Utilization Level of Spontaneous Polarization. Adv. Mater. 2011, 23, 5658–5662. [Google Scholar] [CrossRef]

- Zak, A.K.; Majid, W.A.; Abrishami, M.E.; Yousefi, R. X-ray analysis of ZnO nanoparticles by Williamson–Hall and size–strain plot methods. Solid State Sci. 2011, 13, 251–256. [Google Scholar] [CrossRef]

- Shull, C.G. The Determination of X-ray Diffraction Line Widths. Phys. Rev. 1946, 70, 679–684. [Google Scholar] [CrossRef]

- Pielaszek, R. Diffraction Studies of Microstructure of Nanocrystals Exposed to High Pressure. Ph.D. Thesis, Warsaw University, Warsaw, Poland, 2003. [Google Scholar]

- Jona, F.; Shirane, G. Ferroelectric Crystals, International Series of Monographs on Solid State Physics; Pergamon Press: Oxford, UK, 1962. [Google Scholar]

- Horiuchi, S.; Tokunaga, Y.; Giovannetti, G.; Picozzi, S.; Itoh, H.; Shimano, R.; Kumai, R.; Tokura, Y. Above-room-temperature ferroelectricity in a single-component molecular crystal. Nat. Cell Biol. 2010, 463, 789–792. [Google Scholar] [CrossRef]

- Das, R.; Sarkar, S. Determination of intrinsic strain in poly (vinylpyrrolidone)-capped silver nano-hexapod using X-ray diffraction technique. Curr. Sci. 2015, 109, 775–778. [Google Scholar]

- Balzar, D.; Ledbetter, H. Voigt-function modeling in Fourier analysis of size- and strain-broadened X-ray diffraction peaks. J. Appl. Crystallogr. 1993, 26, 97–103. [Google Scholar] [CrossRef]

- Warren, B.E.; Averbach, B.L. The Separation of Cold-Work Distortion and Particle Size Broadening in X-ray Patterns. J. Appl. Phys. 1952, 23, 497. [Google Scholar] [CrossRef]

- Hall, W.H. X-ray Line Broadening in Metals. Proc. Phys. Soc. Sect. A 1949, 62, 741–743. [Google Scholar] [CrossRef]

- Akl, A.A.; Hassanien, A. Microstructure and crystal imperfections of nanosized CdSxSe1−x thermally evaporated thin films. Superlattices Microstruct. 2015, 85, 67–81. [Google Scholar] [CrossRef]

- Akl, A.; Mahmoud, S.A.; Al-Shomar, S.; Hassanien, A.S. Improving microstructural properties and minimizing crystal imperfections of nanocrystalline Cu2O thin films of different solution molarities for solar cell applications. Mater. Sci. Semicond. Process. 2018, 74, 183–192. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E., III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Fu, D.-W.; Cai, H.-L.; Liu, Y.; Ye, Q.; Zhang, W.; Zhang, Y.; Chen, X.-Y.; Giovannetti, G.; Capone, M.; Li, J.; et al. Diisopropylammonium Bromide Is a High-Temperature Molecular Ferroelectric Crystal. Scienve 2013, 339, 425–428. [Google Scholar] [CrossRef] [PubMed]

- Dawber, M.; Rabe, K.M.; Scott, J.F. Physics of thin-film ferroelectric oxides. Rev. Mod. Phys. 2005, 77, 1083–1130. [Google Scholar] [CrossRef]

- Scott, J.F. Applications of Modern Ferroelectrics. Science 2007, 315, 954–959. [Google Scholar] [CrossRef]

- Aly, K.; Khalil, N.; Algamal, Y.; Saleem, Q.M. Estimation of lattice strain for zirconia nano-particles based on Williamson- Hall analysis. Mater. Chem. Phys. 2017, 193, 182–188. [Google Scholar] [CrossRef]

- Goktas, A. High-quality solution-based Co and Cu co-doped ZnO nanocrystalline thin films: Comparison of the effects of air and argon annealing environments. J. Alloy. Compd. 2018, 735, 2038–2045. [Google Scholar] [CrossRef]

- Gungor, E.; Güngör, T.; Caliskan, D.; Ceylan, A.; Ozbay, E. Co doping induced structural and optical properties of sol–gel prepared ZnO thin films. Appl. Surf. Sci. 2014, 318, 309–313. [Google Scholar] [CrossRef]

- Samanta, K. Synthesis and Characterization of 3d-transation Metal Ions Doped ZnO Based Dilute Magnetic Semiconductor Thin Films. Ph.D. Thesis, Universidad de Puerto Rico, San Juan, Puerto Rico, 2009. [Google Scholar]

- Alsaad, A.; AlBataineh, Z.; Ahmad, A.; AlBataineh, Z.; Telfah, A. Optical band gap and refractive index dispersion parameters of boron-doped ZnO thin films: A novel derived mathematical model from the experimental transmission spectra. Optik 2020, 211, 164641. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Liu, Y.; Shen, D.; Lu, Y.; Zhang, J.; Fan, X. Structural and optical properties of nanocrystalline ZnO films grown by cathodic electrodeposition on Si substrates. Phys. B Condens. Matter 2002, 322, 31–36. [Google Scholar] [CrossRef]

- Atkins, P.W.; Jones, L.; Straushein, B. Chemistry: Molecules, Matter, and Change; WH Freeman: New York, NY, USA, 1997; Volume 354. [Google Scholar]

- Desiraju, G.; Steiner, T. The Weak Hydrogen Bond; Oxford University Press (OUP): Oxford, UK, 2001; Volume 9. [Google Scholar]

- Motohiro, N.; Hirota, M.; Umezawa, Y. The CH/p Interaction. Evidence, Nature, and Consequences; Wiley-VCH, Inc.: New York, NY, USA, 1998. [Google Scholar]

- Hassanien, A.; Akl, A.A. Effect of Se addition on optical and electrical properties of chalcogenide CdSSe thin films. Superlattices Microstruct. 2016, 89, 153–169. [Google Scholar] [CrossRef]

- Hassanien, A.S.; Akl, A.A. Optical characteristics of iron oxide thin films prepared by spray pyrolysis technique at different substrate temperatures. Appl. Phys. A 2018, 124, 752. [Google Scholar] [CrossRef]

- Urbach, F. The Long-Wavelength Edge of Photographic Sensitivity and of the Electronic Absorption of Solids. Phys. Rev. 1953, 92, 1324. [Google Scholar] [CrossRef]

- Hassanien, A.S.; Akl, A.A. Influence of composition on optical and dispersion parameters of thermally evaporated non-crystalline Cd50S50−xSex thin films. J. Alloys Compd. 2015, 648, 280–290. [Google Scholar] [CrossRef]

- Parmar, R.; Kundu, R.; Punia, R.; Aghamkar, P.; Kishore, N. Iron modified structural and optical spectral properties of bismuth silicate glasses. Phys. B Condens. Matter 2014, 450, 39–44. [Google Scholar] [CrossRef]

- Liu, J.-G.; Ueda, M. High refractive index polymers: Fundamental research and practical applications. J. Mater. Chem. 2009, 19, 8907–8919. [Google Scholar] [CrossRef]

- Duerloo, K.-A.N.; Ong, M.T.; Reed, E.J. Intrinsic Piezoelectricity in Two-Dimensional Materials. J. Phys. Chem. Lett. 2012, 3, 2871–2876. [Google Scholar] [CrossRef]

- Alsaad, A.; Marin, C.M.; Alaqtash, N.; Chao, H.-W.; Chang, T.-H.; Cheung, C.L.; Ahmad, A.; Qattan, I.; Sabirianov, R.F. Crystallographic, vibrational modes and optical properties data of α-DIPAB crystal. Data Brief 2018, 16, 667–684. [Google Scholar] [CrossRef]

- Yen, H.-J.; Liou, G.-S. A facile approach towards optically isotropic, colorless, and thermoplastic polyimidothioethers with high refractive index. J. Mater. Chem. 2010, 20, 4080–4084. [Google Scholar] [CrossRef]

- Macdonald, E.K.; Shaver, M.P. Intrinsic high refractive index polymers. Polym. Int. 2014, 64, 6–14. [Google Scholar] [CrossRef]

- Oriaku, C.; Osuwa, J.; Njoku, C. Single Oscillator Parameters and Optical Energies of Laser Irradiated Cu Doped Cds Thin Films. J. Non Oxide Glasses 2011, 3, 25–30. [Google Scholar]

- Hassanien, A.S.; Sharma, I. Optical properties of quaternary a-Ge15-x Sbx Se50 Te35 thermally evaporated thin-films: Refractive index dispersion and single oscillator parameters. Optik 2020, 200, 163415. [Google Scholar] [CrossRef]

- Sutcliffe, B.T.; Wilson, S. Potential energy curves and surfaces. Handb. Mol. Phys. Quantum Chem. 2003, 1, 574–587. [Google Scholar]

- Wemple, S.H.; DiDomenico, M. Behavior of the Electronic Dielectric Constant in Covalent and Ionic Materials. Phys. Rev. B 1971, 3, 1338–1351. [Google Scholar] [CrossRef]

- Patil, V.; Jundale, D.; Pawar, S.; Chougule, M.; Godse, P.; Patil, S.; Raut, B.; Sen, S.; Vikas, P.; Datta, J.; et al. Nanocrystalline CuO Thin Films for H2S Monitoring: Microstructural and Optoelectronic Characterization. J. Sens. Technol. 2011, 1, 36–46. [Google Scholar] [CrossRef]

- Fasasi, A.Y.; Osagie, E.; Pelemo, D.; Obiajunwa, E.; Ajenifuja, E.; Ajao, J.; Osinkolu, G.; Makinde, W.O.; Adeoye, A.E. Effect of Precursor Solvents on the Optical Properties of Copper Oxide Thin Films Deposited Using Spray Pyrolysis for Optoelectronic Applications. Am. J. Mater. Synth. Process. 2018, 3, 12. [Google Scholar] [CrossRef]

- Spitzer, W.G.; Fan, H.Y. Determination of Optical Constants and Carrier Effective Mass of Semiconductors. Phys. Rev. 1957, 106, 882–890. [Google Scholar] [CrossRef]

- Hassanien, A.S. Studies on dielectric properties, opto-electrical parameters and electronic polarizability of thermally evaporated amorphous Cd50S50−xSex thin films. J. Alloys Compd. 2016, 671, 566–578. [Google Scholar] [CrossRef]

- Farag, A.; Ashery, A.; Shenashen, M. Optical absorption and spectrophotometric studies on the optical constants and dielectric of poly (o-toluidine) (POT) films grown by spin coating deposition. Phys. B Condens. Matter 2012, 407, 2404–2411. [Google Scholar] [CrossRef]

| Thin Film Sample | Structure | ||

|---|---|---|---|

| ZnO | Hexagonal | 3.216 | 5.161 |

| CeO2 | Cubic | 5.350 | - |

| Parameter | ZnO | ZnO:CeO2 (0.75:0.25) | ZnO:CeO2 (0.50:0.50) | ZnO:CeO2 (0.25:0.75) | CeO2 |

| Effective single oscillator energy,(eV) | 3.959 | 3.673 | 3.723 | 3.841 | 3.603 |

| Dispersion energy,(eV) | 4.625 | 4.977 | 4.325 | 9.716 | 5.443 |

| zero-frequency refractive index, | 1.472 | 1.535 | 1.470 | 1.879 | 1.585 |

| Zero-frequency dielectric constant, | 2.168 | 2.355 | 2.162 | 3.529 | 2.511 |

| Average oscillator wavelength, | 313.16 | 337.63 | 332.94 | 322.75 | 344.21 |

| Oscillator length strength, | 1.191 | 1.189 | 1.048 | 2.428 | 1.275 |

| Density of states,() | 1.018 | 1.645 | 1.236 | 2.880 | 2.041 |

| Charge carrier density,() | 4.081 | 6.594 | 4.955 | 11.512 | 8.182 |

| High-frequency dielectric constant, | 2.868 | 3.419 | 2.997 | 5.349 | 3.801 |

| Relaxation time,(s) | 2.282 | 2.410 | 3.929 | 3.428 | 4.143 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Bataineh, Q.M.; Telfah, M.; Ahmad, A.A.; Alsaad, A.M.; Qattan, I.A.; Baaziz, H.; Charifi, Z.; Telfah, A. Synthesis, Crystallography, Microstructure, Crystal Defects, Optical and Optoelectronic Properties of ZnO:CeO2 Mixed Oxide Thin Films. Photonics 2020, 7, 112. https://doi.org/10.3390/photonics7040112

Al-Bataineh QM, Telfah M, Ahmad AA, Alsaad AM, Qattan IA, Baaziz H, Charifi Z, Telfah A. Synthesis, Crystallography, Microstructure, Crystal Defects, Optical and Optoelectronic Properties of ZnO:CeO2 Mixed Oxide Thin Films. Photonics. 2020; 7(4):112. https://doi.org/10.3390/photonics7040112

Chicago/Turabian StyleAl-Bataineh, Qais M., Mahmoud Telfah, Ahmad A. Ahmad, Ahmad M. Alsaad, Issam A. Qattan, Hakim Baaziz, Zoulikha Charifi, and Ahmad Telfah. 2020. "Synthesis, Crystallography, Microstructure, Crystal Defects, Optical and Optoelectronic Properties of ZnO:CeO2 Mixed Oxide Thin Films" Photonics 7, no. 4: 112. https://doi.org/10.3390/photonics7040112

APA StyleAl-Bataineh, Q. M., Telfah, M., Ahmad, A. A., Alsaad, A. M., Qattan, I. A., Baaziz, H., Charifi, Z., & Telfah, A. (2020). Synthesis, Crystallography, Microstructure, Crystal Defects, Optical and Optoelectronic Properties of ZnO:CeO2 Mixed Oxide Thin Films. Photonics, 7(4), 112. https://doi.org/10.3390/photonics7040112