Super-Resolution Imaging with Patchy Microspheres

Abstract

:1. Introduction

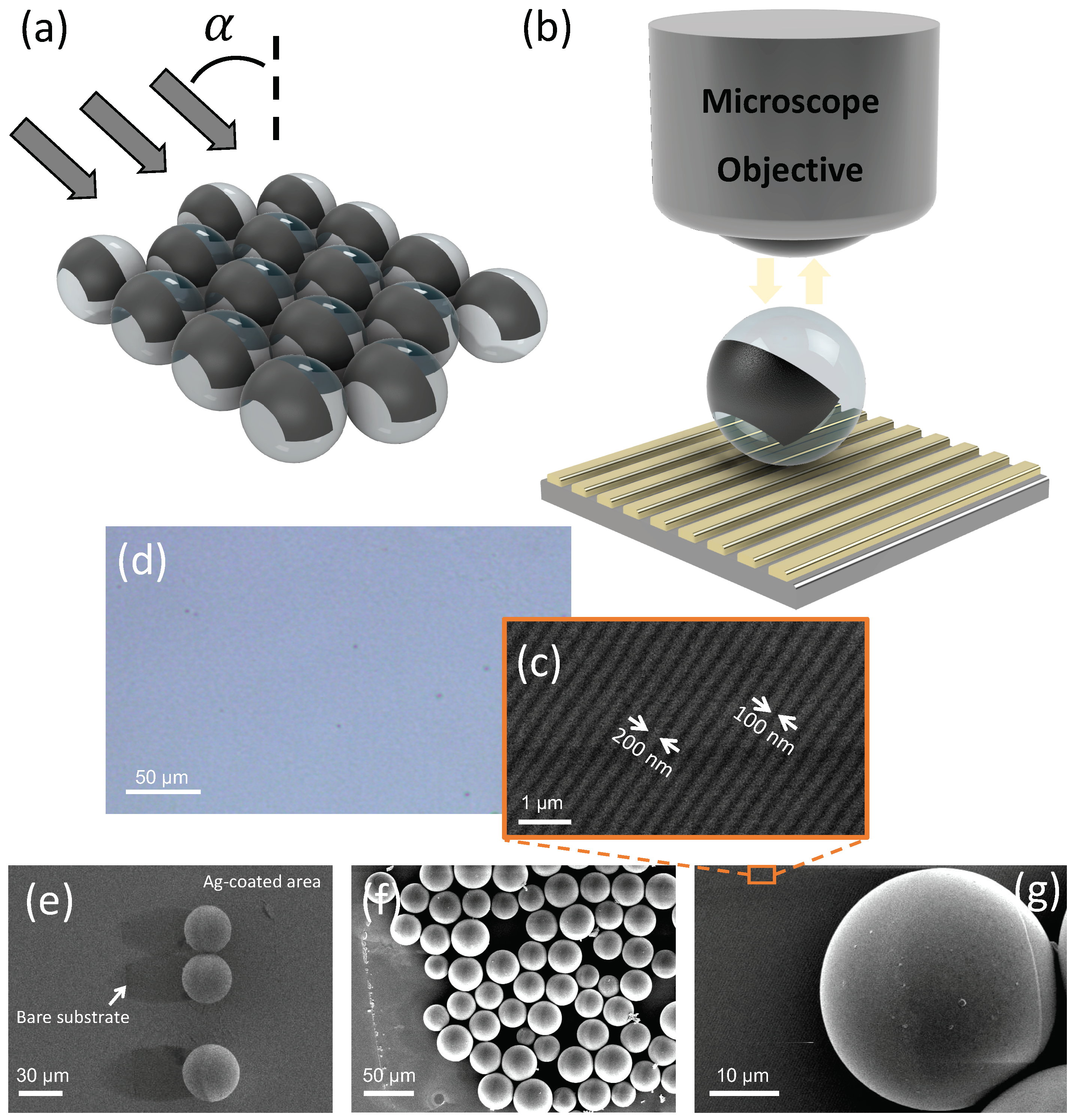

2. Materials and Methods

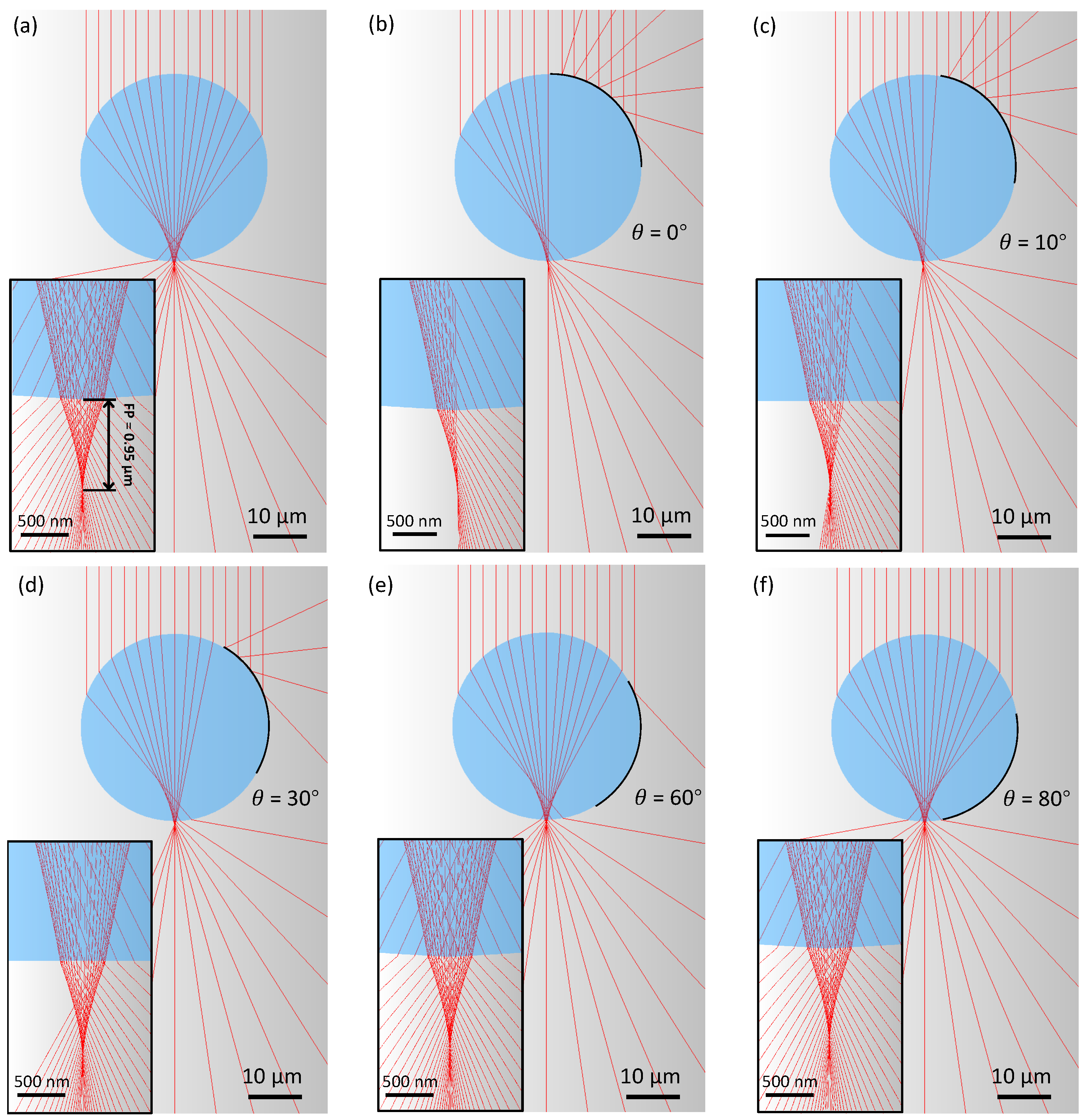

3. Results and Discussion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, J.Y.; Hong, B.H.; Kim, W.Y.; Min, S.K.; Kim, Y.; Jouravlev, M.V.; Bose, R.; Kim, K.S.; Hwang, I.C.; Kaufman, L.J.; et al. Near-field focusing and magnification through self-assembled nanoscale spherical lenses. Nature 2009, 460, 498–501. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, W.; Li, L.; Luk’Yanchuk, B.; Khan, A.; Liu, Z.; Chen, Z.; Hong, M. Optical virtual imaging at 50 nm lateral resolution with a white-light nanoscope. Nat. Commun. 2011, 2, 218. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Li, L.; Feng, C.; Guo, W.; Lee, S.; Hong, M.H. Microsphere-coupled scanning laser confocal nanoscope for sub-diffraction-limited imaging at 25 nm lateral resolution in the visible spectrum. ACS Nano 2014, 8, 1809–1816. [Google Scholar] [CrossRef] [PubMed]

- Allen, K.W.; Farahi, N.; Li, Y.; Limberopoulos, N.I.; Walker, D.E.; Urbas, A.M.; Liberman, V.; Astratov, V.N. Super-resolution microscopy by movable thin-films with embedded microspheres: Resolution analysis. Ann. Phys. 2015, 527, 513–522. [Google Scholar] [CrossRef]

- Perrin, S.; Li, H.; Leong-Hoi, A.; Lecler, S.; Montgomery, P. Illumination conditions in microsphere-assisted microscopy. J. Microsc. 2019, 274, 69–75. [Google Scholar] [CrossRef]

- Guo, M.; Ye, Y.H.; Hou, J.; Du, B. Size-dependent optical imaging properties of high-index immersed microsphere lens. Appl. Phys. B-Lasers Opt. 2016, 122, 15. [Google Scholar] [CrossRef]

- Darafsheh, A.; Walsh, G.F.; Negro, L.D.; Astratov, V.N. Optical super-resolution by high-index liquid-immersed microspheres. Appl. Phys. Lett. 2012, 101, 141128. [Google Scholar] [CrossRef]

- Wang, F.; Yang, S.; Ma, H.; Shen, P.; Wei, N.; Wang, M.; Xia, Y.; Deng, Y.; Ye, Y.H. Microsphere-assisted super-resolution imaging with enlarged numerical aperture by semi-immersion. Appl. Phys. Lett. 2018, 112, 023101. [Google Scholar] [CrossRef]

- Zhou, Y.; Tang, Y.; He, Y.; Liu, X.; Hu, S. Effects of immersion depth on super-resolution properties of index-different microsphere-assisted nanoimaging. Appl. Phys. Express 2018, 11, 032501. [Google Scholar] [CrossRef]

- Lee, S.; Li, L.; Wang, Z.; Guo, W.; Yan, Y.; Wang, T. Immersed transparent microsphere magnifying sub-diffraction-limited objects. Appl. Opt. 2013, 52, 7265–7270. [Google Scholar] [CrossRef]

- Hao, X.; Kuang, C.; Liu, X.; Zhang, H.; Li, Y. Microsphere based microscope with optical super-resolution capability. Appl. Phys. Lett. 2011, 99, 10–13. [Google Scholar] [CrossRef]

- Ye, R.; Ye, Y.-H.; Ma, H.F.; Cao, L.; Ma, J.; Wyrowski, F.; Shi, R.; Zhang, J.-Y. Experimental imaging properties of immersion microscale spherical lenses. Sci. Rep. 2014, 4, 3769. [Google Scholar] [CrossRef]

- Ye, R.; Ye, Y.H.; Ma, H.F.; Ma, J.; Wang, B.; Yao, J.; Liu, S.; Cao, L.; Xu, H.; Zhang, J.Y. Experimental far-field imaging properties of a ∼5-μm diameter spherical lens. Opt. Lett. 2013, 38, 1829–1831. [Google Scholar] [CrossRef]

- Hou, B.; Xie, M.; He, R.; Ji, M.; Trummer, S.; Fink, R.H.; Zhang, L. Microsphere assisted super-resolution optical imaging of plasmonic interaction between gold nanoparticles. Sci. Rep. 2017, 7, 13789. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Moullan, N.; Auwerx, J.; Gijs, M.A. Super-resolution biological microscopy using virtual imaging by a microsphere nanoscope. Small 2014, 10, 1712–1718. [Google Scholar] [CrossRef] [PubMed]

- Huszka, G.; Yang, H.; Gijs, M.A. Microsphere-based super-resolution scanning optical microscope. Opt. Express 2017, 25, 86–90. [Google Scholar] [CrossRef]

- Li, L.; Guo, W.; Yan, Y.; Lee, S.; Wang, T. Label-free super-resolution imaging of adenoviruses by submerged microsphere optical nanoscopy. Light. Sci. Appl. 2013, 2, e104. [Google Scholar] [CrossRef]

- Lee, S.; Li, L.; Ben-Aryeh, Y.; Wang, Z.; Guo, W. Overcoming the diffraction limit induced by microsphere optical nanoscopy. J. Opt. 2013, 15, 125710. [Google Scholar] [CrossRef]

- Yan, B.; Yue, L.; Monks, J.N.; Yang, X.; Xiong, D.; Jiang, C.; Wang, Z. Superlensing plano-convex-microsphere (PCM) lens for direct laser nano-marking and beyond. Opt. Lett. 2020, 45, 1168–1171. [Google Scholar] [CrossRef]

- Yan, B.; Song, Y.; Yang, X.; Xiong, D.; Wang, Z. Unibody microscope objective tipped with a microsphere: Design, fabrication, and application in subwavelength imaging. Appl. Opt. 2020, 59, 2641–2648. [Google Scholar] [CrossRef]

- Luo, H.; Yu, H.; Wen, Y.; Zhang, T.; Li, P.; Wang, F.; Liu, L. Enhanced high-quality super-resolution imaging in air using microsphere lens groups. Opt. Lett. 2020, 45, 2981–2984. [Google Scholar] [CrossRef]

- Su, H.; Price, C.-A.H.; Jing, L.; Tian, Q.; Liu, J.; Qian, K. Janus particles: Design, preparation, and biomedical applications. Mater. Today Bio 2019, 4, 100033. [Google Scholar] [CrossRef]

- Marschelke, C.; Fery, A.; Synytska, A. Janus particles: From concepts to environmentally friendly materials ans sustainable applications. Colloid Polym. Sci. 2020, 298, 841–865. [Google Scholar] [CrossRef]

- Aizawa, S.; Seto, K.; Tokunaga, E. External field response and applications of metal coated hemispherical Janus particles. Appl. Sci. 2018, 8, 653. [Google Scholar] [CrossRef]

- Yue, L.; Minin, O.V.; Wang, Z.; Monks, J.N.; Shalin, A.S.; Minin, I.V. Photonic hook: A new curved light beam. Opt. Lett. 2018, 43, 771–774. [Google Scholar] [CrossRef]

- Minin, I.V.; Minin, O.V.; Katyba, G.M.; Chernomyrdin, N.V.; Kurlov, V.N.; Zaytsev, K.I.; Yue, L.; Wang, Z.; Christodoulides, D.N. Experimental observation of a photonic hook. Appl. Phys. Lett. 2019, 114, 031105. [Google Scholar] [CrossRef]

- Gu, G.; Shao, L.; Song, J.; Qu, J.; Zheng, K.; Shen, X.; Peng, Z.; Hu, J.; Chen, X.; Chen, M.; et al. Photonic hooks from Janus microcylinders. Opt. Express 2019, 27, 37771–37780. [Google Scholar] [CrossRef]

- Pawar, A.B.; Kretzschmar, I. Patchy particles by glancing angle deposition. Langmuir 2008, 24, 355–358. [Google Scholar] [CrossRef]

- Yang, S.; Cao, Y.; Shi, Q.; Wang, X.; Chen, T.; Wang, J.; Ye, Y.-H. Label-free super-resolution imaging of transparent dielectric objects assembled on a silver film by a microsphere-assisted microscope. J. Phys. Chem. C 2019, 123, 28353–28358. [Google Scholar] [CrossRef]

- Cao, Y.; Yang, S.; Wang, J.; Shi, Q.; Ye, Y.-H. Surface plasmon enhancement for microsphere-assisted super-resolution imaging of metallodielectric nanostructures. J. Appl. Phys. 2020, 127, 233103. [Google Scholar] [CrossRef]

- Ye, R.; Ye, Y.H.; Zhou, Z.; Xu, H. Gravity-assisted convective assembly of centimeter-sized uniform two-dimensional colloidal crystals. Langmuir 2013, 29, 1796–1801. [Google Scholar] [CrossRef] [PubMed]

- Fang, C.; Yang, S.; Wang, X.; He, P.; Ye, R.; Ye, Y.H. Fabrication of two-dimensional silica colloidal crystals via a gravity-assisted confined self-assembly method. Colloid Interface Sci. Commun. 2020, 37, 100286. [Google Scholar] [CrossRef]

- Sanchez, C.; Cristóbal, G.; Bueno, G.; Blanco, S.; Borrego-Ramos, M.; Olenici, A.; Pedraza, A.; Ruiz-Santaquiteria, J. Oblique illumination in microscopy: A quantitative evaluation. Micron 2018, 105, 47–54. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Li, J.; Lu, L.; Sun, J.; Hu, Y.; Zhang, J.; Li, Z.; Shen, Q.; Wang, B.; Zhang, R.; et al. Smart computational light microscopes (SCLMs) of smart computational imaging laboratory (SCILab). PhotoniX 2021, 2, 19. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, Q.; Tang, F.; Yu, L.; Oubaha, H.; Caina, D.; Yang, S.; Melinte, S.; Zuo, C.; Wang, Z.; Ye, R. Super-Resolution Imaging with Patchy Microspheres. Photonics 2021, 8, 513. https://doi.org/10.3390/photonics8110513

Shang Q, Tang F, Yu L, Oubaha H, Caina D, Yang S, Melinte S, Zuo C, Wang Z, Ye R. Super-Resolution Imaging with Patchy Microspheres. Photonics. 2021; 8(11):513. https://doi.org/10.3390/photonics8110513

Chicago/Turabian StyleShang, Qingqing, Fen Tang, Lingya Yu, Hamid Oubaha, Darwin Caina, Songlin Yang, Sorin Melinte, Chao Zuo, Zengbo Wang, and Ran Ye. 2021. "Super-Resolution Imaging with Patchy Microspheres" Photonics 8, no. 11: 513. https://doi.org/10.3390/photonics8110513

APA StyleShang, Q., Tang, F., Yu, L., Oubaha, H., Caina, D., Yang, S., Melinte, S., Zuo, C., Wang, Z., & Ye, R. (2021). Super-Resolution Imaging with Patchy Microspheres. Photonics, 8(11), 513. https://doi.org/10.3390/photonics8110513