1. Introduction

In the initial stage of development of the automobile industry, headlamps were primarily used to illuminate roads, and no requirement existed pertaining to long-range illumination or light beam shape. However, with the rapid development of light sources, automotive lighting technology and high-efficiency light sources have become highly integrated. Currently, the major objective of vehicle lighting is to improve the driver’s visual performance at night or in dark places. In the last two decades, incandescent and tungsten halogen bulbs have been used in vehicle lighting, and presently, high-intensity discharge (HID) bulbs are implanted into some products. Light-emitting diode (LED) lighting exhibits some favorable characteristics, such as long life, high reliability, resistance to vibrations and shocks, high environment friendliness, low power consumption, small size, and high feasibility for the optical design of light beam shape. Their continued improvement makes it realistic to project LEDs as a promising technology for vehicle lighting [

1,

2,

3]. For vehicle lighting, a well-designed headlamp can enable drivers to guide the vehicle safely at night along roads of varying geometries and to identify pedestrians and obstacles. For designing the light beam shape, various beam-shaping strategies for LED lighting [

4] and LED-based automotive headlamps [

3] have been proposed.

Automobiles are generally equipped with separate headlamps for generating high- and low-beam light. High-beam light offers superior visibility when driving at night on a deserted stretch of road. However, this light is too bright and can cause night blindness in oncoming drivers. In this case, a low-beam light directed toward the road without blinding the drivers in the front should be used. The Economic Commission for Europe (ECE) R112 regulation has declared clear low- and high-beam lighting requirements as well as measurement methods for lighting areas and spill zone intensity [

5]. According to the regulation, high-beam light should only be used to illuminate far-off distances where visibility is mostly low in the absence of streetlights, thereby enabling long-range illumination of the road surface. The shape requirements for low-beam light can prevent the glare impact caused on a driver by a car moving in the opposite direction; thus, accidents can be prevented. According to brightness of the illuminating area affecting the traffic information when driving, it must meet the regulations of spill zone intensity to illuminate the billboard road information. Therefore, the optical design of low-beam light is the most difficult aspect in automotive lighting. To achieve regulation requirements, three basic structures have been proposed for traditional low-beam headlamps that use tungsten halogen or HID sources: reflector optics, projector module, and lens optics. To meet the ECE R112 regulation, all headlamps should provide a low-beam cutoff line. However, the optical characteristics of white LEDs are highly different from those of tungsten halogen or HID sources. Moreover, the output power generated from a single LED is less than that generated by exiting light sources. Thus, multiple LEDs are required for designing an LED headlamp. The expected optical design of an LED headlamp that can obtain a regulated light pattern with high efficiency depends on the optical characteristics of the LEDs forming the headlamp. Several complicated LED headlamp lenses have been developed [

6], such as a lens that can transform the emergent ray into a rectangular beam region [

7]; a low-beam LED headlamp based on microlenses [

8]; an automotive headlight system incorporating digital micromirror devices [

9]; an optical system with an ellipsoidal reflector, a baffle, and a faceted reflector [

10]; an LED design with four main components: a focal LED, asymmetric metallic plate, freeform surface, and condenser lens [

11]; a low-beam headlamp designed with Oliker’s ellipses technology [

12]. Projector-type headlamps are substantially brighter in a focal spot than reflector headlamps are and, thus, can provide maximum vision when driving at night. Moreover, projector-type headlamps are less likely to cause night blindness in oncoming drivers because they are directed toward the road rather than the eyes of the drivers. Depending on their design and commercial use, projector-type LED headlamps can offer considerable benefits in vehicle lighting.

Automobiles are typically equipped with separate headlamp lanterns for generating low- and high-beam light. These lanterns are mounted adjacent to each other in the front of the car. Compared with conventional separate headlamp lanterns, a single headlamp producing both low- and high-beam light can be more compact and have less mechanical complexity. Moreover, the reduction in the number of parts and degrees of freedom during a single headlamp’s assembly simplifies the alignment of different light functions relative to each other. To produce both low- and high-beam light by using a single headlamp with halogen or HID bulbs, a movable shield or light baffle has been integrated into a projector-type headlamp [

13,

14]. For low-beam light, the shield blocks a portion of the lamp output to achieve the desired cutoff line. For high-beam light, the shield is moved out of the way and the light is allowed to pass through to enable long-range illumination of the road surface. However, because the moving parts in the structure are controlled by an electromagnetic actuator or a piezotranslator, which gradually deteriorates with time and changes in the environment and temperature, they can cause device failure. The aforementioned problem is a serious issue in vehicle lighting. To address this issue, white LEDs can be used to develop a single headlamp generating both low- and high-beam light. Zhu used an LED array to develop a single headlamp generating both low- and high-beam light [

7], where a second optical lens was used to concentrate the light generated from the LED array to form a beam region on the screen. Then, different blocks were illuminated by lighting up different LEDs in the LED array to realize low- and high-beam lighting simultaneously. However, the uniformity of multiple LEDs in a single lifespan and the complicated circuit configuration were the challenges faced in this design. A compact LED composed of two rows of LED chips was also used as an automotive headlamp light source combining low- and high-beam light [

2]. The primary optics in the structure collected the emission of the two closely spaced chip rows and simultaneously separated the respective contributions. Then, the secondary optics, which were based on a faceted reflector, were used to shape and realize the low- and high-beam patterns. The structure of a projector-type LED headlamp can be used to obtain both low- and high-beam light from a single headlamp. The light emitted from the low-beam LED array is reflected by the ellipsoidal reflector and cut off by the vertically oriented light baffle. Then, a low-beam output with a bright or dark edge is transmitted through the lens to form the desired cutoff line. Moreover, the lower surface of the vertically oriented light baffle is designed to redirect the light emitted from the high-beam LED array through the lens. The additive light reflected from the lower surface of the vertically oriented light baffle is transmitted through the lens and forms a bright or dark edge lacking high-beam light [

15]. In a previous study, a single headlamp producing both low- and high-beam light was achieved with the reflected light baffle in a projector-type headlamp by adopting a condenser lens with a specific second surface to spread the light and obtain a predetermined beam pattern [

16]. However, the structure of this condenser lens is complex, and difficulties exist in its manufacturing process.

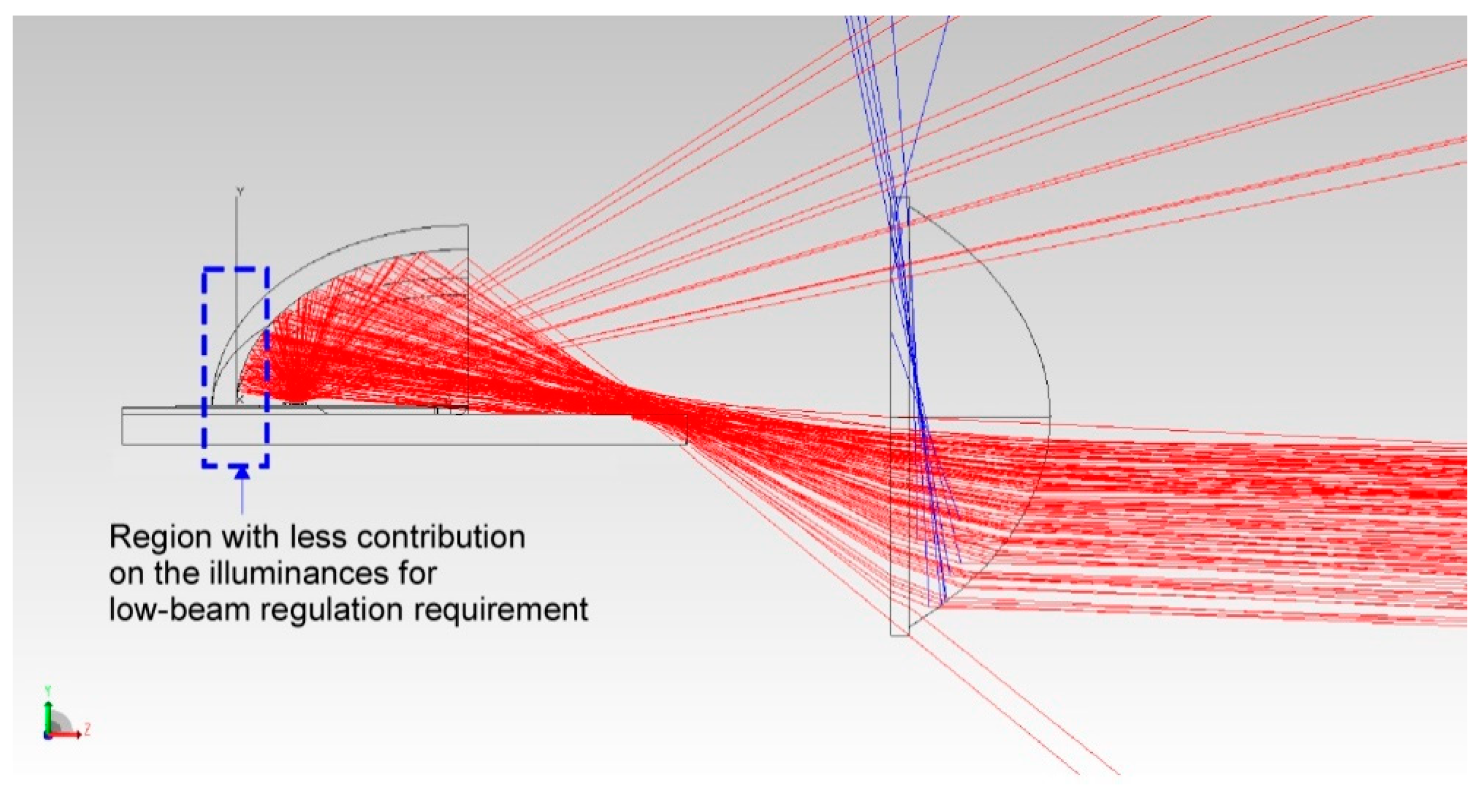

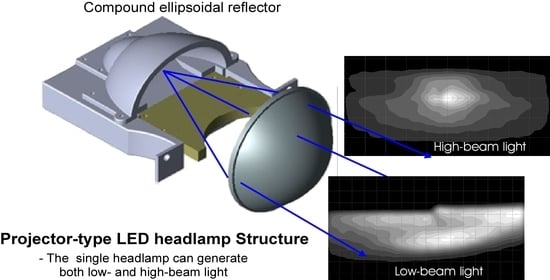

To address the aforementioned issues, the present paper proposes a novel LED headlamp design with a projector-type structure, in which both low- and high-beam light are generated using a single headlamp. As shown in

Figure 1, the compound ellipsoidal reflector comprises a primary ellipsoidal reflector with a low-beam LED array device for generating low-beam light and a secondary ellipsoidal reflector with a high-beam LED array for generating high-beam light. The light emitted from the low-beam LED array device (ray 1) is reflected by the primary ellipsoidal reflector and cut off by the baffle. The low-beam output with a bright or dark edge is then transmitted through the lens to form a cutoff line for the low-beam light. Some of the light emitted from the high-beam LED array device (ray 2) is reflected by the secondary ellipsoidal reflector and the top surface of the baffle. This reflected light is then transmitted through the lens to illuminate the upper half region for generating high-beam light. In addition, some of the light emitted from the high-beam LED array device (ray 3) is reflected by the primary ellipsoidal reflector and then transmitted through the lens to illuminate the lower-half region for generating high-beam light. Thus, the illumination requirements of high-beam light can be achieved with the high-beam LED array device alone. The proposed compound ellipsoidal reflector design can be achieved using two simple ellipsoidal reflectors and a conventional condenser lens instead of a condenser lens with a complex surface. By using a projector-type structure with a specific condenser lens and baffle plate, the design of a single headlamp producing low- and high-beam light can meet the ECE R112 requirements.

3. Experimental Implementation and Discussion

In this study, Monte Carlo ray tracing simulations were performed to confirm the optical characteristics of the proposed novel design of a single headlamp generating both low- and high-beam light. A low-beam LED array device with a total output power of 700 lm was positioned at F

1 of the primary ellipsoidal reflector, and a high-beam LED array device with a total output power of 1050 lm was positioned at F

1 of the secondary ellipsoidal reflector. The target plane was placed 25 m from the lens. The simulated illuminance distribution of the low-beam light in the target plane is shown in

Figure 11, and the simulated and measured illuminances are listed in

Table 2. The illuminance distribution of the low-beam light generated by the proposed headlamp with only the low-beam LED array device has a cutoff line meeting the ECE requirement. In addition, all illuminances of each point and line meet the ECE R112 regulation for low-beam light.

For the generation of high-beam light by using the proposed headlamp, a high-beam LED array device with a total output power of 1050 lm is positioned at F

1 of the secondary ellipsoidal reflector. The simulated illuminance distribution of the low-beam light in the target plane is depicted in

Figure 12, and the simulated and measured illuminances are listed in

Table 3. The illuminance distribution of the high-beam light generated by the proposed headlamp with only the high-beam LED array device forms a light pattern with a large area, and all illuminances at each point and line meet the ECE R112 regulation for high-beam light.

To verify the effectiveness of the proposed design, a prototype of the proposed headlamp was developed, as depicted in

Figure 13. For the generation of low-beam light by using the proposed headlamp, the OSLON Black Flat S device (KW HJL531.TE, OSRAM Opto Semiconductors) was positioned at the first focal point of the primary ellipsoidal reflector and operated at 8.795 V and 0.5 A with an output of 700 lm. For generating high-beam light by using the proposed headlamp, the OSLON Black Flat S device was positioned at the first focal point of the secondary ellipsoidal reflector and operated at 9.339 V and 1.083 A with an output of 1050 lm. The luminous intensity distribution of the headlamp with only low- or high-beam light was measured using a goniophotometer (GMS-1800C; SENSING). The measurement results are listed in

Table 2 and

Table 3. All the illuminances of each point and line met the ECE R112 requirements for low- and high-beam light. However, the measured illuminances of each point and line in

Table 2 and

Table 3 are lower than the simulated ones. The reduction of the output powers of the low- and high-beam LED arrays owing to the heat is believed to be responsible for the lower measured illuminances of each point and line than the simulated ones.

4. Conclusions

This paper proposes a novel design of a single headlamp generating both low- and high-beam light to meet the ECE R112 regulation. The proposed headlamp adopts the structure of the projector-type headlamp and comprises a compound ellipsoidal reflector, a baffle plate, a condenser lens, and LED array devices generating low- and high-beam light. The compound ellipsoidal reflector comprises a primary ellipsoidal reflector for generating low-beam light and a secondary ellipsoidal reflector for generating high-beam light. The light emitted from the low- and high-beam LED array devices is reflected by the primary and secondary ellipsoidal reflectors, respectively, and transmitted through the condenser lens to illuminate the detection plane. Monte Carlo ray tracing simulations were performed to confirm the optical characteristics of the proposed design. The simulation results of the low-beam light with only the low-beam LED array device show that the proposed headlamp created a correct light pattern and performed an obvious cutoff line. All the simulated illuminances of each point met the ECE R112 regulation for low-beam light. Moreover, the simulation results of the high-beam light with only the high-beam LED array device formed a light pattern with a large area. In addition, all the simulated illuminances of each point and line met the ECE R112 regulation for high-beam light. A prototype of the proposed headlamp was also developed to verify the design’s effectiveness. By using the low-beam LED array device of merely 4.397 W, the measured illuminance distributions of the low-beam light can reach the illuminances of each point met the ECE R112 regulation for low-beam light. Additionally, the measured illuminance distributions of the high-beam light can reach the illuminances of each point and line met the ECE R112 regulation for high-beam light when the high-beam LED array device of merely 10.11 W was used. As a result, the proposed headlamp in this study is feasible for the application of single headlamp generating both low- and high-beam light.