Performances of PMMA-Based Optical Fiber Bragg Grating Sensor in Extended Temperature Range

Abstract

:1. Introduction

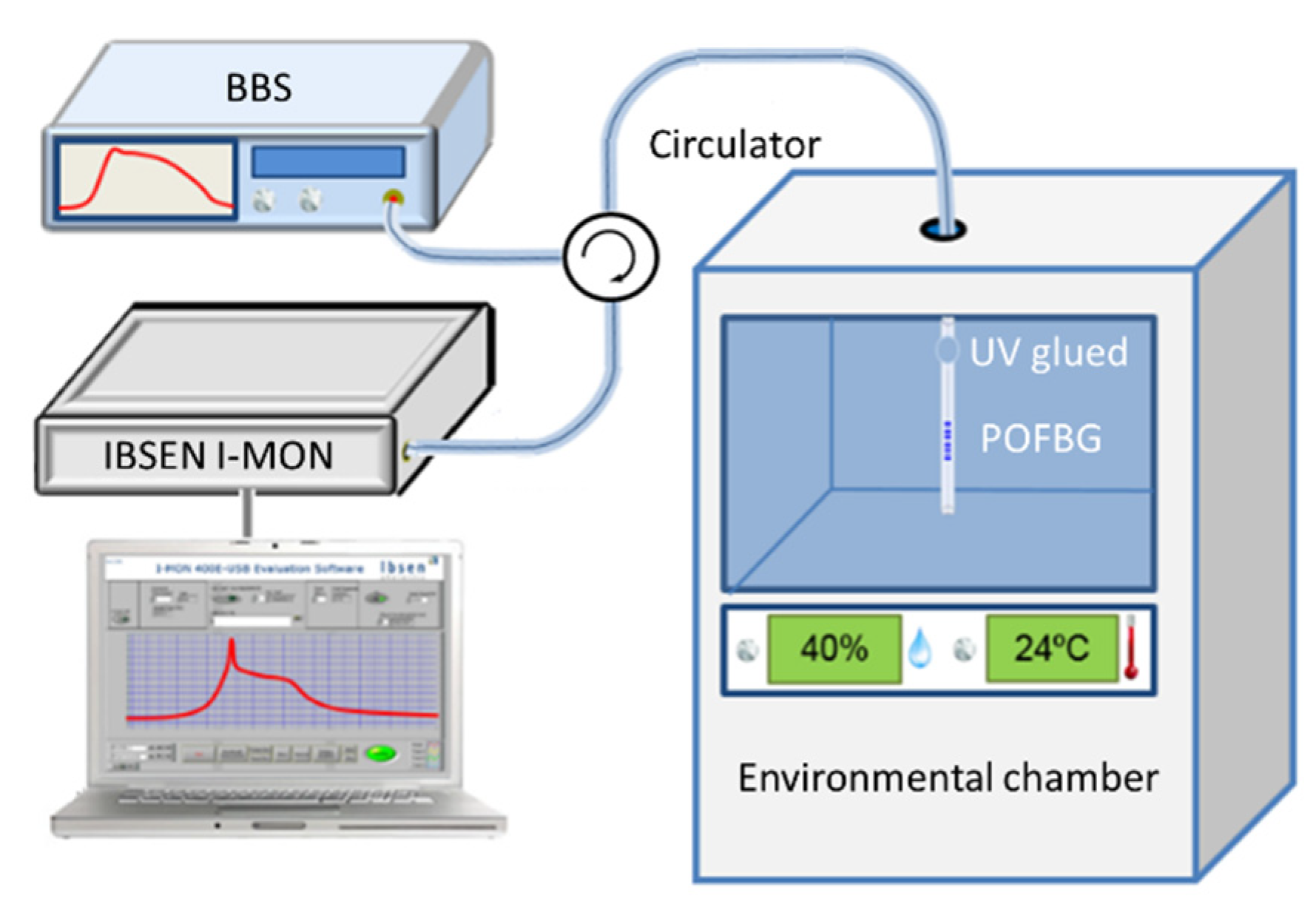

2. Experiments

3. Results

3.1. POFBG Humidity Sensitivity

3.2. POFBG Temperature Sensitivity

3.3. Analysis of POFBG Sensing Performance

- ρp, the polymer density, is a linear function of moisture;

- f (0 ≤ f ≤ 1) increases with temperature, and f = fc at the critical temperature of 50 °C;

- ki, is a weak function of temperature and humidity, approximately constant; and

- S slowly decreases with temperature.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Polishuk, P. Plastic optical fibers branch out. IEEE Commun. Mag. 2006, 44, 140–148. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, W.; Webb, D.J.; Peng, G.-D. Optical fiber temperature and humidity sensor. Electron. Lett. 2010, 46, 643. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Webb, D.J.; Lao, L.; Hammond, D.; Carpenter, M.; Williams, C. Water content detection in aviation fuel by using PMMA based optical fiber grating. Sens. Actuators B Chem. 2019, 282, 774–779. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Webb, D.J. Humidity responsivity of poly(methyl methacrylate)-based optical fiber Bragg grating sensors. Opt. Lett. 2014, 39, 3026–3029. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Webb, D.J.; Kalli, K. Polymer fiber Bragg gratings. In Fiber Bragg Grating Sensors: Thirty Years from Research to Market; Cusano, A., Cutolo, A., Albert, J., Eds.; Bentham Science Publishers Ltd.: New York, NY, USA, 2010. [Google Scholar]

- Peng, G.-D. Handbook of Optical Fibers; Springer Nature Singapore Pte Ltd.: Singapore, 2019. [Google Scholar]

- Abang, A.; Webb, D.J. Demountable connection for polymer optical fiber grating sensors. Opt. Eng. 2012, 51, 080503. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Webb, D.J.; Peng, G.-D. Investigation into time response of polymer fibre Bragg grating based humidity sensors. IEEE J. Lightwave Technol. 2012, 30, 1090–1096. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Webb, D.J. General Expression of Poly(Methyl Methacrylate) Optical Fiber Bragg Grating Sensing Response. IEEE Photonics Technol. Lett. 2019, 31, 234–237. [Google Scholar] [CrossRef]

- Salem; David, R. Structure Formation in Polymeric Fibers; Hanser-Gardner Publications: Cincinnati, OH, USA, 2001. [Google Scholar]

- Carroll, K.E.; Zhang, C.; Webb, D.J.; Kalli, K.; Argyros, A.; Large, M.C.J. Thermal response of Bragg gratings in PMMA mi-crostructured optical fibers. Opt. Express 2007, 15, 8844–8850. [Google Scholar] [CrossRef] [PubMed]

- Stajanca, P.; Cetinkaya, O.; Schukar, M.; Mergo, P.; Webb, D.J.; Krebber, K. Molecular alignment relaxation in polymer optical fibers for sensing applications. Opt. Fiber Technol. 2016, 28, 11–17. [Google Scholar] [CrossRef] [Green Version]

- Ishigure, T.; Hirai, M.; Sato, M.; Koike, Y. Graded-Index Plastic Optical Fiber with High Mechanical Properties Enabling Easy Network Installations. I. J. Appl. Polym. Sci. 2004, 91, 404–409. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Webb, D.J.; Peng, G.-D. Enhancing the sensitivity of poly(methyl methacrylate) based optical fiber Bragg grating temperature sensors. Opt. Lett. 2015, 40, 4046–4049. [Google Scholar] [CrossRef] [PubMed]

- Woyessaa, G.; Pedersen, J.K.M.; Nielsenc, K.; Bang, O. Enhanced pressure and thermal sensitivity of polymer optical fiber Bragg grating sensors. Opt. Laser Technol. 2020, 130, 106357. [Google Scholar] [CrossRef]

- Prod’Homme, L. A new approach to the thermal change in the refractive index of glasses. Phys. Chem. Glasses 1960, 1, 119–122. [Google Scholar]

- Waxler, R.M.; Horowitz, D.; Feldman, A. Optical and physical parameters of Plexiglas 55 and Lexan. Appl. Opt. 1979, 18, 101–104. [Google Scholar] [CrossRef] [PubMed]

- Startsev, O.V.; Rudnev, V.P. Reversible moisture effects in the climatic ageing of organic glass. Polym. Degrad. Stab. 1993, 39, 373–379. [Google Scholar] [CrossRef]

- Thomas, A.M. Moisture permeability, diffusion and sorption in organic film-forming materials. J. Appl. Chem. 1951, 1, 141–158. [Google Scholar] [CrossRef]

- Liu, Y.; Daum, P.H. Relationship of refractive index to mass density and self-consistency of mixing rules for multicomponent mixtures like ambient aerosols. Aerosol Sci. 2008, 39, 974–986. [Google Scholar] [CrossRef]

- Watanabe, T.; Ooba, N.; Hida, Y.; Hikita, M. Influence of humidity on refractive index of polymers for optical waveguide and its temperature dependence. Appl. Phys. Lett. 1998, 72, 1533. [Google Scholar] [CrossRef]

- Turner, D.T. Polymethyl methacrylate plus water: Sorption kinetics and volumetric changes. Polymer 1982, 23, 197–202. [Google Scholar] [CrossRef]

- Patel, M.P.; Davy, K.W.M.; Braden, M. Refractive index and molar refraction of methacrylate monomers and polymers. Biomaterials 1992, 13, 643–645. [Google Scholar] [CrossRef]

- Fan, X. Mechanics of Moisture for Polymers: Fundamental Concepts and Model Study. In Proceedings of the 9th International Conference on Thermal, Mechanical and Multiphysics Simulation and Experiments in Micro-Electronics and Micro-Systems, EuroSimE 2008, Freiburg im Breisgau, Germany, 20–23 April 2008. [Google Scholar]

- Zhang, W.; Webb, D.J. Factors Influencing the Temperature Sensitivity of PMMA Based Optical Fiber Bragg Gratings; Photonics Europe: Brussels, Belgium, 2014. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Webb, D.J. Performances of PMMA-Based Optical Fiber Bragg Grating Sensor in Extended Temperature Range. Photonics 2021, 8, 180. https://doi.org/10.3390/photonics8060180

Zhang W, Webb DJ. Performances of PMMA-Based Optical Fiber Bragg Grating Sensor in Extended Temperature Range. Photonics. 2021; 8(6):180. https://doi.org/10.3390/photonics8060180

Chicago/Turabian StyleZhang, Wei, and David J. Webb. 2021. "Performances of PMMA-Based Optical Fiber Bragg Grating Sensor in Extended Temperature Range" Photonics 8, no. 6: 180. https://doi.org/10.3390/photonics8060180

APA StyleZhang, W., & Webb, D. J. (2021). Performances of PMMA-Based Optical Fiber Bragg Grating Sensor in Extended Temperature Range. Photonics, 8(6), 180. https://doi.org/10.3390/photonics8060180