Sensitivity Enhanced Refractive Index Fiber Sensor Based on Long-Range Surface Plasmon Resonance in SiO2-Au-TiO2 Heterostructure

Abstract

:1. Introduction

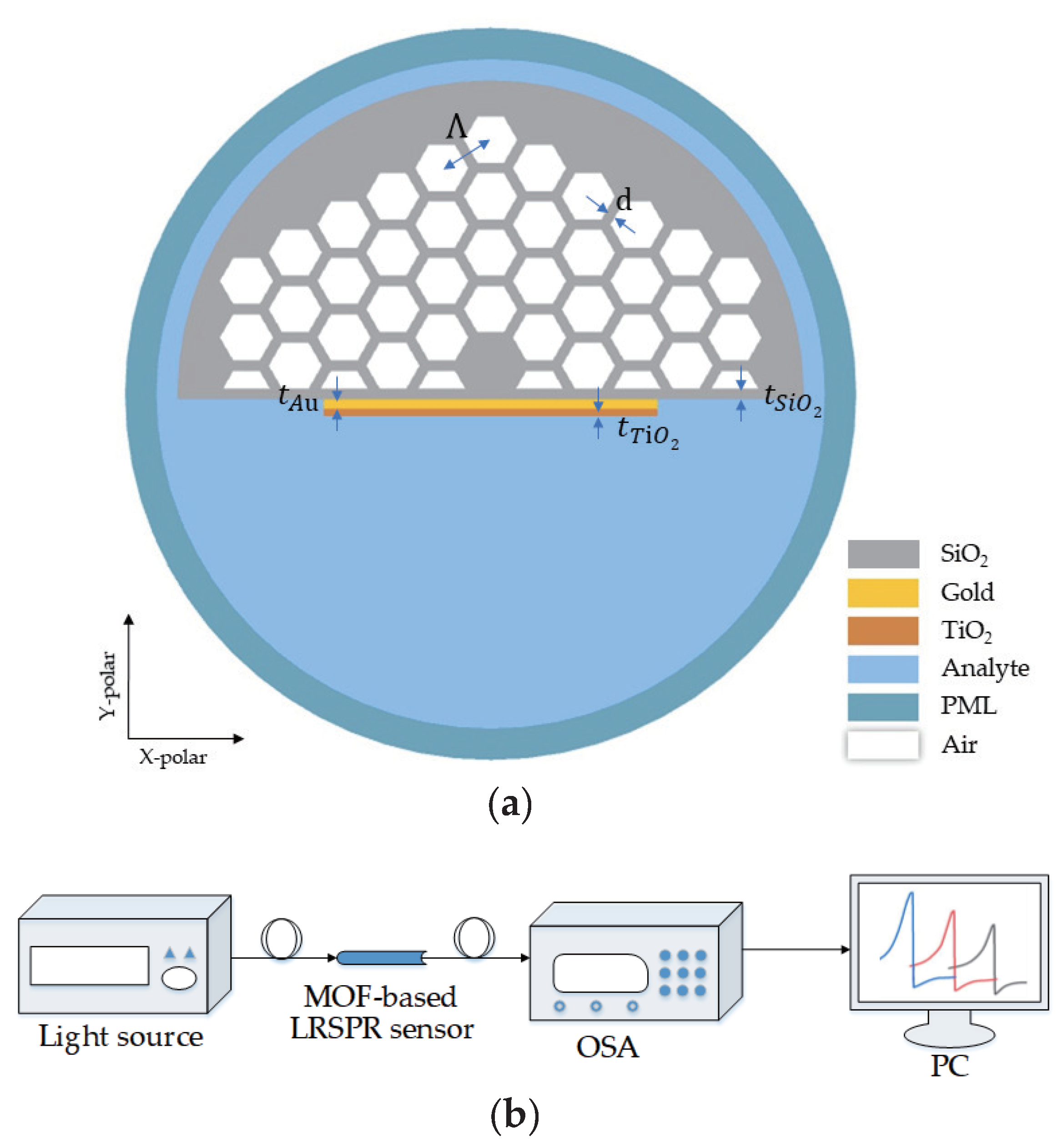

2. Structural and Theoretical Modeling

3. Discussion

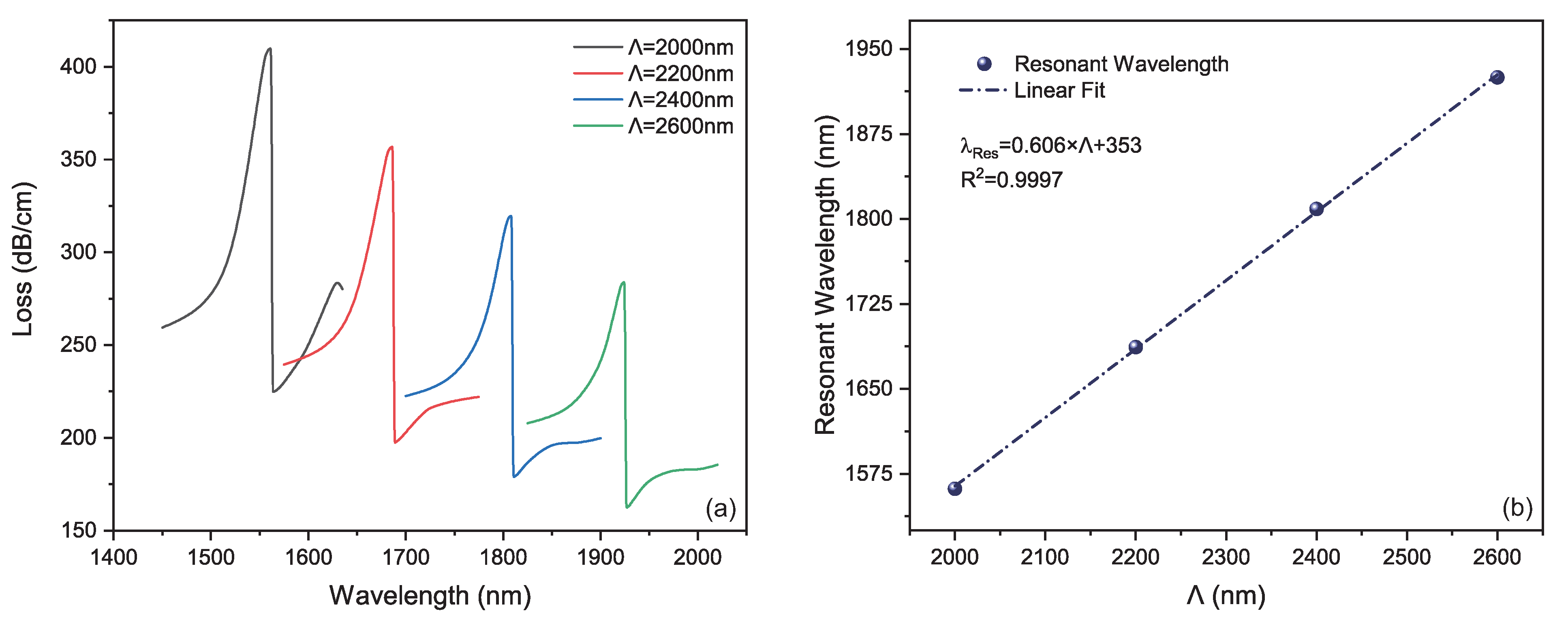

3.1. Influence of MOF’s Pitch on LRSPR

3.2. Influence of Silica-Web Thickness on LRSPR

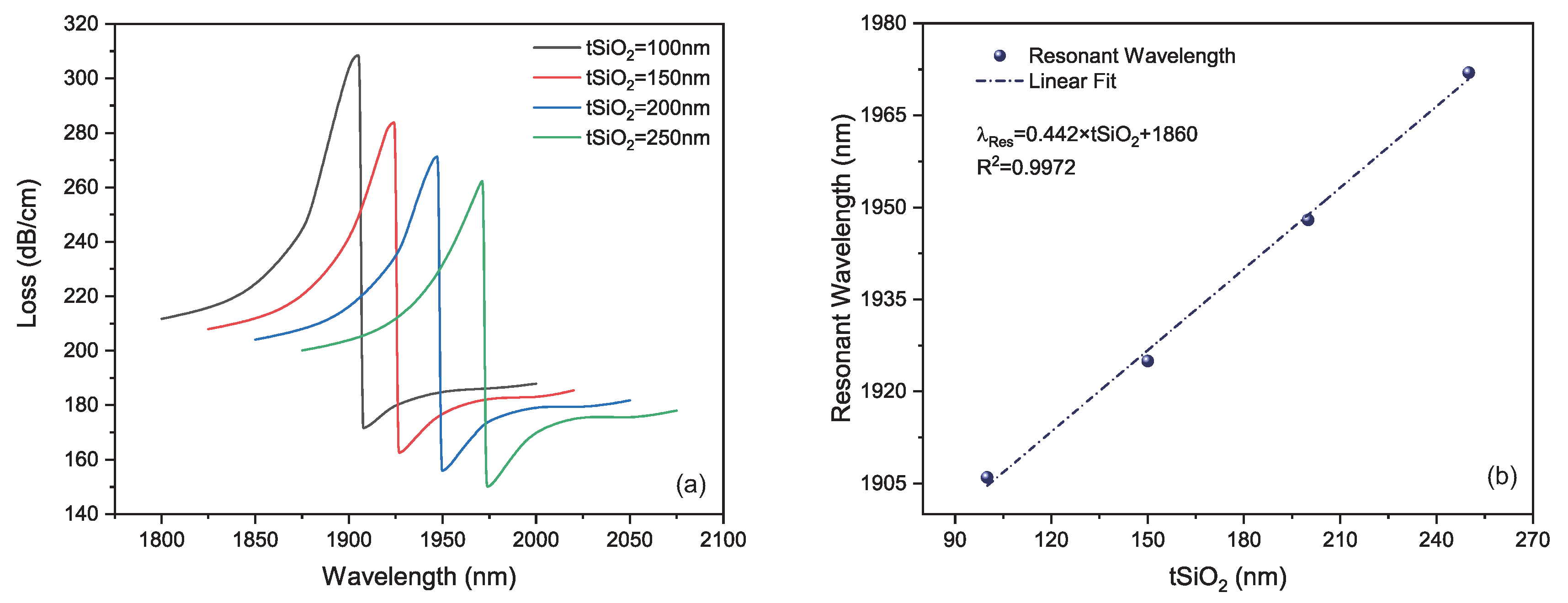

3.3. Influence of Planar-Silica Thickness on LRSPR

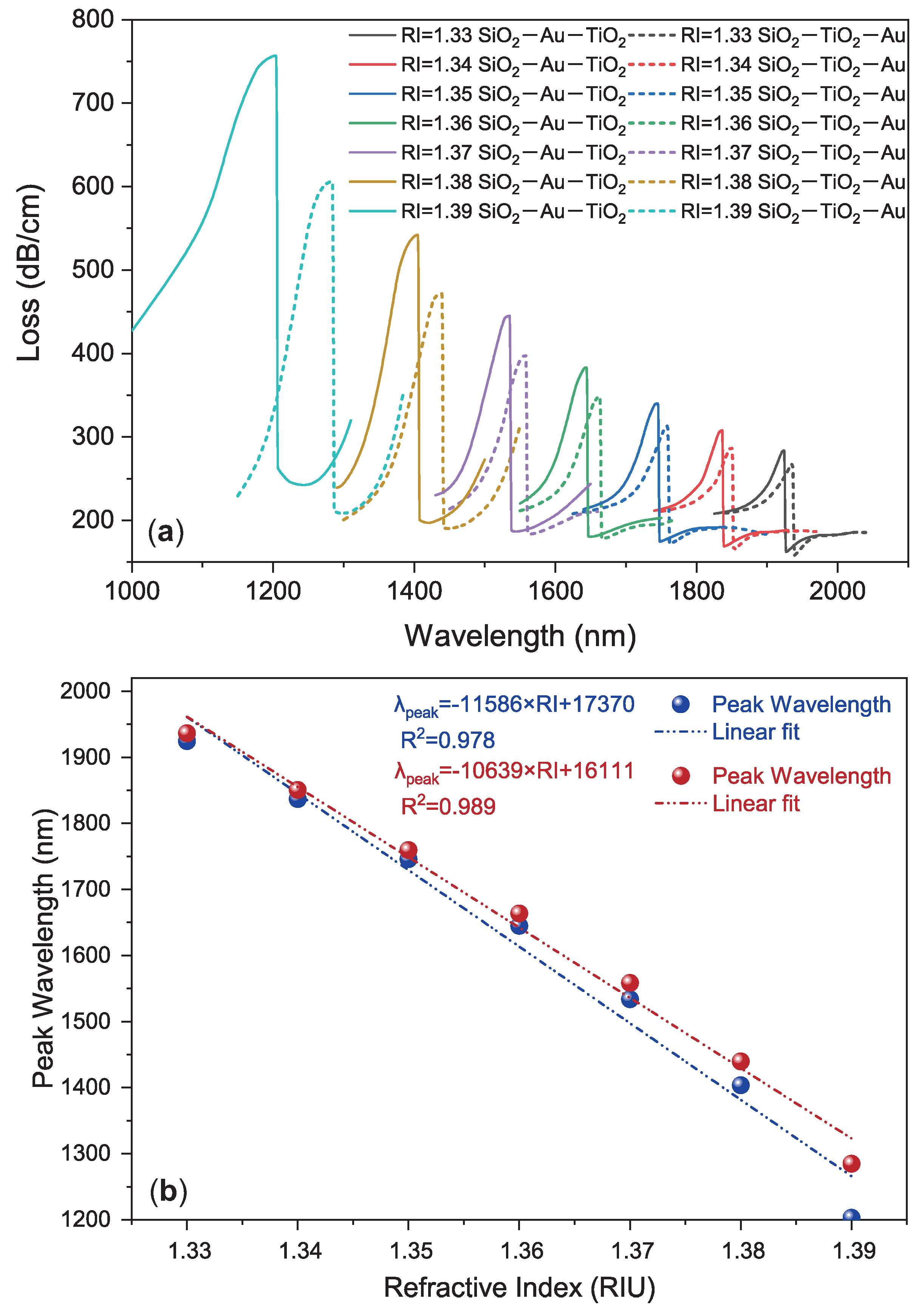

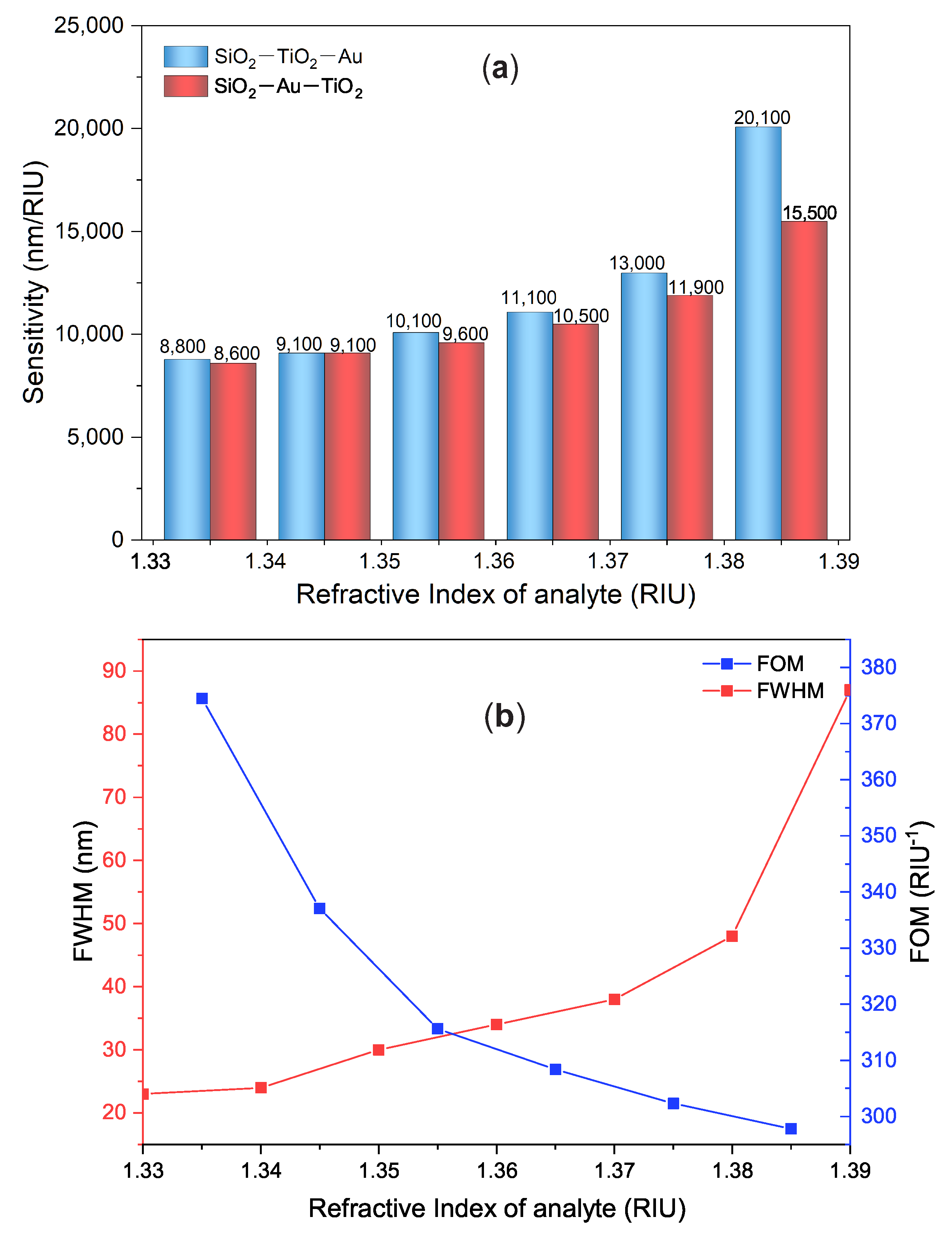

3.4. Comparison between SiO-Au-TiO and SiO-TiO-Au Heterostructures

3.5. Sensing Performance Comparison with Previous LRSPR-Based Fiber Sensors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Rahman, M.S.; Anower, M.S.; Hasan, M.R.; Hossain, M.B.; Haque, M.I. Design and numerical analysis of highly sensitive Au-MoS2-graphene based hybrid surface plasmon resonance biosensor. Opt. Commun. 2017, 396, 36–43. [Google Scholar] [CrossRef]

- Noman, A.A.; Haque, E.; Hossain, M.A.; Hai, N.H.; Namihira, Y.; Ahmed, F. Sensitivity enhancement of modified D-shaped microchannel PCF-based surface plasmon resonance sensor. Sensors 2020, 20, 6049. [Google Scholar] [CrossRef] [PubMed]

- Rifat, A.A.; Ahmed, R.; Mahdiraji, G.A.; Adikan, F.R.M. Highly sensitive D-shaped photonic crystal fiber-based plasmonic, biosensor in visible to Near-IR. IEEE Sens. J. 2017, 17, 2776–2783. [Google Scholar] [CrossRef]

- Shui, X.; Gu, Q.; Jiang, X.; Si, G. Surface plasmon resonance sensor based on polymer liquid-core fiber for refractive index detection. Photonics 2020, 7, 123. [Google Scholar] [CrossRef]

- Zynio, S.; Samoylov, A.; Surovtseva, E.; Mirsky, V.; Shirshov, Y. Bimetallic layers increase sensitivity of affinity sensors based on surface plasmon resonance. Sensors 2002, 2, 62–70. [Google Scholar] [CrossRef] [Green Version]

- Kashyap, R.; Chakraborty, S.; Zeng, S.; Swarnakar, S.; Kaur, S.; Doley, R.; Mondal, B. Enhanced Biosensing activity of bimetallic surface plasmon resonance sensor. Photonics 2019, 6, 108. [Google Scholar] [CrossRef] [Green Version]

- Ong, B.H.; Yuan, X.; Tjin, S.C.; Zhang, J.; Ng, H.M. Optimised film thickness for maximum evanescent field enhancement of a bimetallic film surface plasmon resonance biosensor. Sens. Actuators B Chem. 2006, 114, 1028–1034. [Google Scholar] [CrossRef]

- Liu, C.; Wang, J.; Wang, F.; Su, W.; Yang, L.; Lv, J.; Fu, G.; Li, X.; Liu, Q.; Sun, T.; et al. Surface plasmon resonance (SPR) infrared sensor based on D-shape photonic crystal fibers with ITO coatings. Opt. Commun. 2020, 464, 125496. [Google Scholar] [CrossRef]

- Gonzalez-Valencia, E.; Villar, I.D.; Torres, P. Novel Bloch wave excitation platform based on few-layer photonic crystal deposited on D-shaped optical fiber. Sci. Rep. 2021, 11, 11266. [Google Scholar] [CrossRef]

- Shafkat, A.; Rashed, A.N.Z.; El-Hageen, H.M.; Alatwi, A.M. The effects of adding different adhesive layers with a micro-structure fiber sensor based on surface plasmon resonance: A Numerical Study. Plasmonics 2021, 16, 819–832. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Song, Z.; Qi, K. Simulation of a microstructure fiber pressure sensor based on lossy mode resonance. AIP Adv. 2019, 9, 095005. [Google Scholar]

- Takagi, K.; Watanabe, K. Near infrared characterization of hetero-core optical fiber SPR sensors coated with Ta2O5 film and their applications. Sensors 2012, 12, 2208–2218. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, A.K.; Dominic, A.; Kaur, B.; Popescu, V.A. Fluoride fiber sensor with huge performance enhancement via optimum radiative damping at Ag–Al2O3–Graphene heterojunction on silicon. J. Light. Technol. 2019, 37, 5641–5646. [Google Scholar] [CrossRef]

- Azad, S.; Sadeghi, E.; Parvizi, R.; Mazaheri, A.; Yousefi, M. Sensitivity optimization of ZnO clad-modified optical fiber humidity sensor by means of tuning the optical fiber waist diameter. Opt. Laser Technol. 2017, 90, 96–101. [Google Scholar] [CrossRef]

- Hosoki, A.; Nishiyama, M.; Igawa, H.; Seki, A.; Choi, Y.; Watanabe, K. A surface plasmon resonance hydrogen sensor using Au/Ta2O5/Pd multi-layers on hetero-core optical fiber structures. Sens. Actuators B Chem. 2013, 185, 53–58. [Google Scholar] [CrossRef]

- Del Villar, I.; Zamarreno, C.R.; Hernaez, M.; Arregui, F.J.; Matias, I.R. Lossy mode resonance generation with indium-tin-oxide-coated optical fibers for densing applications. J. Light. Technol. 2010, 28, 111–117. [Google Scholar] [CrossRef] [Green Version]

- Kaur, D.; Sharma, V.K.; Kapoor, A. High sensitivity lossy mode resonance sensors. Sens. Actuators B Chem. 2014, 198, 366–376. [Google Scholar] [CrossRef]

- Paul, A.K.; Mollah, M.A.; Hassan, M.Z.; Gomez-Cardona, N.; Reyes-Vera, E. Graphene-coated highly sensitive photonic crystal fiber surface plasmon resonance sensor for aqueous solution: Design and numerical analysis. Photonics 2021, 8, 155. [Google Scholar] [CrossRef]

- Zeng, S.; Hu, S.; Xia, J.; Anderson, T.; Dinh, X.; Meng, X.; Coquet, P.; Yong, K. Graphene–MoS2 hybrid nanostructures enhanced surface plasmon resonance biosensors. Sens. Actuators B Chem. 2015, 207, 801–810. [Google Scholar] [CrossRef]

- Sharma, A.K.; Kaur, B.; Popescu, V.A. On the role of different 2D materials/heterostructures in fiber-optic SPR humidity sensor in visible spectral region. Opt. Mater. 2020, 102, 109824. [Google Scholar] [CrossRef]

- Berini, P. Long-range surface plasmon polaritons. Adv. Opt. Photonics 2009, 1, 484–588. [Google Scholar] [CrossRef]

- Jing, J.; Wang, Q.; Zhao, W.; Wang, B. Long-range surface plasmon resonance and its sensing applications: A review. Opt. Laser Eng. 2019, 112, 103–118. [Google Scholar] [CrossRef]

- Liu, F.; Li, Y.; Wan, R.; Huang, Y.; Feng, X.; Zhang, W. Hybrid coupling between long-range surface plasmon polariton mode and dielectric waveguide mode. J. Light. Technol. 2011, 29, 1265–1273. [Google Scholar] [CrossRef]

- Berini, P. Plasmon-polariton modes guided by a metal film of finite width bounded by different dielectrics. Opt. Express 2000, 7, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Vala, M.; Robelek, R.; Bocková, M.; Wegener, J.; Homola, J. Real-time label-free monitoring of the cellular response to osmotic stress using conventional and long-range surface plasmons. Biosens. Bioelectron. 2013, 40, 417–421. [Google Scholar] [CrossRef]

- Vala, M.; Etheridge, S.; Roach, J.A.; Homola, J. Long-range surface plasmons for sensitive detection of bacterial analytes. Sens. Actuators B Chem. 2009, 139, 59–63. [Google Scholar] [CrossRef]

- Chen, X.; Bu, W.; Wu, Z.; Zhang, H.; Shum, P.P.; Shao, X.; Pu, J. Near-infrared long-range surface plasmon resonance in a D-shaped honeycomb microstructured optical fiber coated with Au film. Opt. Express 2021, 29, 16455–16468. [Google Scholar] [CrossRef]

- Wang, H.; Rao, W.; Luo, J.; Fu, H. A dual-channel surface plasmon resonance sensor based on dual-polarized photonic crystal fiber for ultra-wide range and high sensitivity of refractive index detection. IEEE Photonics J. 2021, 13, 1–11. [Google Scholar]

- Hossain, M.A.; Namihira, Y.; Islam, M.A.; Razzak, S.M.A.; Hirako, Y.; Miyagi, K.; Kaijage, S.F.; Higa, H. Tailoring supercontinuum generation using highly nonlinear photonic crystal fiber. Opt. Laser Technol. 2012, 44, 1889–1896. [Google Scholar] [CrossRef]

- Sehmi, H.S.; Langbein, W.; Muljarov, E.A. Optimizing the Drude-Lorentz model for material permittivity: Method, program, and examples for gold, silver, and copper. Phys. Rev. B 2017, 95, 115444. [Google Scholar] [CrossRef] [Green Version]

- Vial, A.; Grimault, A.; Macias, D.; Barchiesi, D.; De la Chapelle, M.L. Improved analytical fit of gold dispersion: Application to the modeling of extinction spectra with a finite-difference time-domain method. Phys. Rev. B 2005, 71, 85411–85416. [Google Scholar] [CrossRef]

- Zhang, N.; Humbert, G.; Gong, T.; Shum, P.P.; Li, K.; Auguste, J.; Wu, Z.; Hu, D.J.J.; Luan, F.; Dinh, Q.X.; et al. Side-channel photonic crystal fiber for surface enhanced Raman scattering sensing. Sens. Actuators B Chem. 2016, 223, 195–201. [Google Scholar] [CrossRef]

- Zhang, N.M.Y.; Li, K.; Shum, P.P.; Yu, X.; Zeng, S.; Wu, Z.; Wang, Q.J.; Yong, K.T.; Wei, L. Hybrid graphene/gold plasmonic fiber-optic biosensor. Adv. Mater. Technol. 2017, 2, 1600185. [Google Scholar] [CrossRef]

- Wu, T.; Shao, Y.; Wang, Y.; Cao, S.; Cao, W.; Zhang, F.; Liao, C.; He, J.; Huang, Y.; Huang, M.; et al. Surface plasmon resonance biosensor based on gold-coated side-polished hexagonal structure photonic crystal fiber. Opt. Express 2017, 25, 20313–20322. [Google Scholar] [CrossRef] [Green Version]

- Xie, Q.; Chen, Y.; Li, X.; Yin, Z.; Wang, L.; Geng, Y.; Hong, X. Characteristics of D-shaped photonic crystal fiber surface plasmon resonance sensors with different side-polished lengths. Appl. Opt. 2017, 56, 1550–1555. [Google Scholar] [CrossRef]

- Zhang, N.M.Y.; Hu, D.J.J.; Shum, P.P.; Wu, Z.; Li, K.; Huang, T.; Wei, L. Design and analysis of surface plasmon resonance sensor based on high-birefringent microstructured optical fiber. J. Opt. 2016, 18, 65005. [Google Scholar] [CrossRef]

- Klantsataya, E.; François, A.; Ebendorff-Heidepriem, H.; Hoffmann, P.; Monro, T. Surface plasmon scattering in exposed core optical fiber for enhanced resolution refractive index sensing. Sensors 2015, 15, 25090–25102. [Google Scholar] [CrossRef] [Green Version]

- Morales-Luna, G.; Herrera-Domínguez, M.; Pisano, E.; Balderas-Elizalde, A.; Hernandez-Aranda, R.I.; Ornelas-Soto, N. Plasmonic biosensor based on an effective medium theory as a simple tool to predict and analyze refractive index changes. Opt. Laser Technol. 2020, 1314, 106332. [Google Scholar] [CrossRef]

- Tuniz, A.; Wieduwilt, T.; Schmidt, M.A. Tuning the effective PT phase of plasmonic eigenmodes. Phys. Rev. Lett. 2019, 123, 213903. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haque, E.; Hossain, M.A.; Ahmed, F.; Namihira, Y. Surface plasmon resonance sensor based on modified D-shaped photonic crystal fiber for wider range of refractive index detection. IEEE Sens. J. 2018, 18, 8287–8293. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, Y.; Wang, Y.; Yang, F.; Hu, S.; Chen, Y.; Zhu, W.; Qiu, W.; Guan, H.; Lu, H.; et al. Side-polished few-mode fiber based surface plasmon resonance biosensor. Opt. Express 2019, 27, 11348–11360. [Google Scholar] [CrossRef] [PubMed]

- Momota, M.R.; Hasan, M.R. Hollow-core silver coated photonic crystal fiber plasmonic sensor. Opt. Mater. 2018, 76, 287–294. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, X.; Zhu, X.; Shi, Y. Long-range surface plasmon resonance sensor based on the GK570/Ag coated hollow fiber with an asymmetric layer structure. Opt. Express 2019, 27, 9550–9560. [Google Scholar] [CrossRef]

- Gomez-Cardona, N.; Reyes-Vera, E.; Torres, P. High sensitivity refractive index sensor based on the excitation of long-range surface plasmon polaritons in H-shaped optical fiber. Sensors 2020, 20, 2111. [Google Scholar] [CrossRef] [Green Version]

- Jing, J.; Li, S.; Wang, X.; Zhu, Q.; Meng, F.; Wang, Q. A D-type fiber based symmetrical long-range surface plasmon resonance sensor with high quality factor. Measurement 2019, 140, 395–406. [Google Scholar] [CrossRef]

- Ahmed, K.; AlZain, M.; Abdullah, H.; Luo, Y.; Vigneswaran, D.; Faragallah, O.; Eid, M.; Rashed, A. Highly sensitive twin resonance coupling refractive index sensor based on gold- and MgF2-coated nano metal films. Biosensors 2021, 11, 104. [Google Scholar] [CrossRef] [PubMed]

| Description | RI Range | (nm/RIU) | Resolution (RIU) | FOM (RIU) | Ref. |

|---|---|---|---|---|---|

| GK570/silver in hollow fiber | 1.4772–1.5116 | 12,500 | 150 | [43] (Experiment) | |

| Liquid-core PTFE-based POF 3 | 1.325–1.35 | 16,750 | 310.6 | [4] (Simulation) | |

| H-shaped MOF with DMDW | 1.33–1.39 | 7540 | 280 | [44] (Simulation) | |

| D-type LRSPR sensor with high Q | 1.33–1.38 | 3500.6 | 107.52 | [45] (Experiment) | |

| Dual-channel fiber with Au/TiO | 1.39–1.43 | 13,200 | 363 | [28] (Simulation) | |

| Gold-and MgF-Coated RI sensor | 1.32–1.38 | 27,959 | – | [46] (Simulation) | |

| This work | 1.33–1.39 | 20,100 | 374 | (Simulation) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, W.; Wu, Z.; Shum, P.P.; Shao, X.; Pu, J. Sensitivity Enhanced Refractive Index Fiber Sensor Based on Long-Range Surface Plasmon Resonance in SiO2-Au-TiO2 Heterostructure. Photonics 2021, 8, 379. https://doi.org/10.3390/photonics8090379

Bu W, Wu Z, Shum PP, Shao X, Pu J. Sensitivity Enhanced Refractive Index Fiber Sensor Based on Long-Range Surface Plasmon Resonance in SiO2-Au-TiO2 Heterostructure. Photonics. 2021; 8(9):379. https://doi.org/10.3390/photonics8090379

Chicago/Turabian StyleBu, Wenyi, Zhifang Wu, Perry Ping Shum, Xuguang Shao, and Jixiong Pu. 2021. "Sensitivity Enhanced Refractive Index Fiber Sensor Based on Long-Range Surface Plasmon Resonance in SiO2-Au-TiO2 Heterostructure" Photonics 8, no. 9: 379. https://doi.org/10.3390/photonics8090379

APA StyleBu, W., Wu, Z., Shum, P. P., Shao, X., & Pu, J. (2021). Sensitivity Enhanced Refractive Index Fiber Sensor Based on Long-Range Surface Plasmon Resonance in SiO2-Au-TiO2 Heterostructure. Photonics, 8(9), 379. https://doi.org/10.3390/photonics8090379