In this section, we analyse how parameters such as the number and position of LEDs affect the horizontal illumination and uniformity in the lighting system. We then outline some rules of thumb according to which LED arrays can be optimally installed to meet the requirements of adequate illumination. We consider that both the lit area that is evaluated and the ceiling area have dimensions with the latter located parallel and at a distance above the first. Without loss of generality, we set m, luminous flux and Lambertian order , , unless otherwise specified.

3.1. Average Horizontal Illuminance

Let us first consider the dependency of the average illuminance on the placement of the LEDs. To this end, we consider a square area where

LEDs with

lm are attached to the ceiling in a square grid with spacing

between the LEDs. In

Figure 2, we show the average illuminance

, assuming

m,

and

where

is the maximum spacing for which all LEDs are within the area of interest. We only consider contributions from light radiated towards positions inside the considered area, and neglect reflection against walls and other objects. As can be observed, the average illuminance is relatively independent of the placement of the LEDs. For larger spacings

, the average illuminance slowly decays, because LEDs will be placed closer to the edges of the considered area, implying more light is lost as it is radiated towards a position outside the area of interest. The reduction will be larger when more LEDs are close to the edges of the area of interest, i.e., when the number of LEDs is large and the area of interest is relatively small. While the effect of the placement of the LEDs on the average illuminance in most cases is limited, the figure reveals that the impact of the number of LEDs is much more important. Hence, in the following, we analyse the dependency of the average illuminance on the number of LEDs.

Assume we measure the illuminance at a distance

below the ceiling, where the LEDs are attached. The horizontal illuminance

corresponding to a single LED, at a point at vertical distance

below the LED and seeing the LED from an incident angle

and azimuth angle

is given by (

3):

with

being the luminous flux output of the LED. Using this expression, we now will formulate an upper and lower bound on the average illuminance in a rectangular area with size

. We assume the LED is placed in the centre of this area. To find the upper bound, we compute the total illuminance in a circular area with radius

. A straightforward choice for

is

, corresponding to the smallest circle that encloses the rectangular area with size

. The resulting total illuminance within the circular area equals

, where

and

is the total illuminance in a circular area with radius

R corresponding to a maximum radiation angle

. As the circular area is larger than the rectangular area, this total illuminance is the upper bound to the total illuminance in the rectangular area. Dividing the total illuminance

by the area

of the rectangle therefore results in an upper bound on the average illuminance:

However, when the rectangular area is not close to a square area, this upper bound is far from tight. Therefore, we propose a tighter bound when the area is not close to a square. Assume

. Let us consider the circle with radius

. Although not all parts of the rectangular area are enclosed in this circle, the parts of the rectangle not contained in the circle lie at distance

from the LED. At the same time, some parts of the circle will not be enclosed in the rectangle. In this latter case, the distance between a position in those parts and the LED is in the interval

, with

. Taking into account that the illuminance (

4) reduces with the distance to the LED, it follows that the total illuminance in the circular area with radius

is larger than that of the rectangular area, provided that the circular area is larger than the rectangular area, i.e., when

. In this case, using

to compute (

6) yields a tighter upper bound as

. In conclusion, the upper bound is given by (

6), with

where

In the derivation of (

5), we assumed that the LED was positioned above the centre of the receiver area. This LED position maximises the amount of light inside the rectangular area

. However, in practice, LEDs will be distributed over the area to achieve good uniformity of lighting. When an LED is not positioned in the centre of the rectangular area, the amount of light that falls outside the area will increase, implying (

6) with

computed using (

7) can also serve as an upper bound for the total illumination within the rectangular area for other LED positions.

To find a lower bound on the average illumination, we consider the circular area with radius

. Assuming the LED is placed in the centre of the rectangular area, this radius corresponds to the largest circle that is enclosed in the rectangular area. Hence, assuming the LED is placed in the centre, the resulting total illuminance within the circular area, i.e.,

(

5) with

, will be smaller than the total illuminance in the rectangular area as the parts of the rectangle that fall outside this circular area are neglected in the computation of the total illuminance. Further, to take into account that the total illuminance reduces when the LED is placed closer to the boundaries, we consider the worst case position for the LED. This worst case position is a corner of the rectangular area, resulting in a total illuminance

, as 75% of the light is radiated to directions outside the rectangular area. While this illuminance is a strict lower bound on the total illuminance, it also strongly underestimates the true average illuminance in practical scenarios where LEDs are distributed over the area. To obtain a tighter bound, we therefore consider the situation where the LED is positioned at the boundary of the area, more specifically in the middle of the smallest side of the rectangle. In that case, only 50% of the radiated light is lost. Dividing the resulting total illuminance by the area

, we obtain the following (approximate) lower bound on the average illuminance:

When

L LEDs are placed in the area, the average illuminance will be bounded by:

Let us assume we want an average illuminance equal to

lx, then we obtain the following bounds on the required number

L of LEDs:

and

To illustrate, we consider a rectangular area with m, m and m, and LEDs with and lm. For an average illuminance lx, we obtain and for lx, .

Let us compare the resulting bounds on

L with simulation results for the average illuminance. In this simulation, we placed

LEDs in the rectangular area mentioned above. The

L LEDs are attached separately to the ceiling in a rectangular grid of size

, with

,

m and

m, where the centre of the grid is the centre of the ceiling. The spacing between the LEDs equals

and

. The spatial average

of the horizontal illuminance is shown in

Figure 3 for different values of

and

, assuming

lm. We observe that the required number of LEDs to achieve an average horizontal illuminance between 300 and 500 lx varies with

, i.e., with the distribution of the LEDs over the ceiling. This is explained as LEDs near the boundaries will leak more light outside the receiver area than LEDs in the centre of the receiver area. Therefore, less LEDs will be needed to reach a given average illuminance when the LEDs are co-located in the centre, although it is clear that this will result in a worse uniformity than distributed LEDs. An average horizontal illuminance between 300 and 500 lx is obtained for

, or

. This falls within the interval predicted by the bounds on

L, i.e.,

. Hence, the bounds (

10) and (

11) are suitable for obtaining an approximation for the number of required LEDs, where the lower bound is appropriate when the LEDs are all centered in the room, while the upper bound is more suitable when the LEDs are distributed over the whole receiver area.

In our example, the number L of LEDs required to achieve an average illuminance in the interval lx was of the order 100–300. It is obvious that in practice, to reduce installation costs, these LEDs will not be attached individually to the ceiling. Instead, they will be grouped in luminaries containing several LEDs. In the following, we therefore assume that each luminary consists of an array of LEDs, resulting in arrays that need to be distributed over the ceiling, with . We assume that the arrays are placed in a rectangular grid with spacing and between the centers of the arrays. Within each array, we further assume that the spacing between the LEDs is small, so each luminary can be considered as a virtual LED with luminous flux .

3.2. Minimum Horizontal Illuminance

In the above analysis, we showed that the average illuminance imposes conditions on the required number of LEDs. In the following, we show that the optimal placement of the luminaries is determined by the uniformity of illumination, and more specifically by the minimum horizontal illuminance

. Taking into account that the required uniformity differs for the task area and surrounding area, we first define the task area

as the central area delimited by

and

, while the surrounding area

is the strip at the edges of the receiver area, as illustrated in

Figure 4.

First, we want to demonstrate that

is essentially independent of the size of the area, and that it is mainly determined by the four parameters defined in

Figure 5a, i.e., the distance

and

between the luminaries, and the distance

and

between the luminaries and the border of the area. To illustrate that, for given

, the minimum is highly independent of the size of the area, we determine

for different values of

and

with

The resulting

is shown in

Figure 5b. As can be observed, the minimum of the horizontal illuminance is indeed essentially independent of

and

and thus of the size of the considered area, whereas it strongly depends on

and, hence, the placement of the luminaries. Therefore, we will take a closer look at the impact of these four parameters on

.

Because of the complexity of the expressions for the horizontal illuminance, i.e., the horizontal illuminance depends on a large number of parameters, a simple analytical expression for this minimum is not available, implying the minimum must be obtained through a two-dimensional search over the considered area. As such, a two-dimensional search comes with high complexity and gives no insight into the optimisation problem, in the following, we derive approximate expressions for the position of the minimum, with which we are able to obtain (an approximation of) the value of the minimum in an analytical way. Taking into account the dependency of the horizontal illuminance on the distance, it is clear that the minimum illuminance in an area is found in the part of the area surrounded by the least number of LEDs, so close to the corners of the considered (task or surrounding) area. Therefore, we restrict our attention to the evaluation area

shown in

Figure 6, which includes the four arrays closest to the boundary (indicated by the red dots). In the case of the surrounding area, the minimum is determined by the parameters

. As all arrays are assumed to be inside the boundaries of the considered area,

and

are non-negative, and the relationship between

and

is given by (

12), i.e.,

and

. On the other hand, in the case of the task area,

is determined by the parameters

, where

and

can be negative if some of the arrays closest to the corner of the task area are located in the surrounding area. Assuming the task area has size

with

and

, with

, and

and

arrays are located inside the task area, it follows that

where the first lines in (

13) correspond to the case that all LEDs in the

x (

) and

y directions (

), respectively, are located in the task area, while in the second case, some of the LEDs are in the surrounding area. When

(

), the resulting

(

) will be negative. Depending on the values of

, the minimum illuminance will be in the corner

of the considered area (see

Figure 7a), close to the centre

of the four arrays (see

Figure 7b) or on the boundary of the considered area, close to the middle

of the two nearest arrays (see

Figure 7c), where the minimum can be on the boundary in the

x direction (

) or in the

y direction (

), as defined in

Figure 6. In our analysis, we will restrict our attention to these four positions, i.e.,

,

,

and

. In the remainder of this section, we drop the superscript

in

and

for notational simplicity.

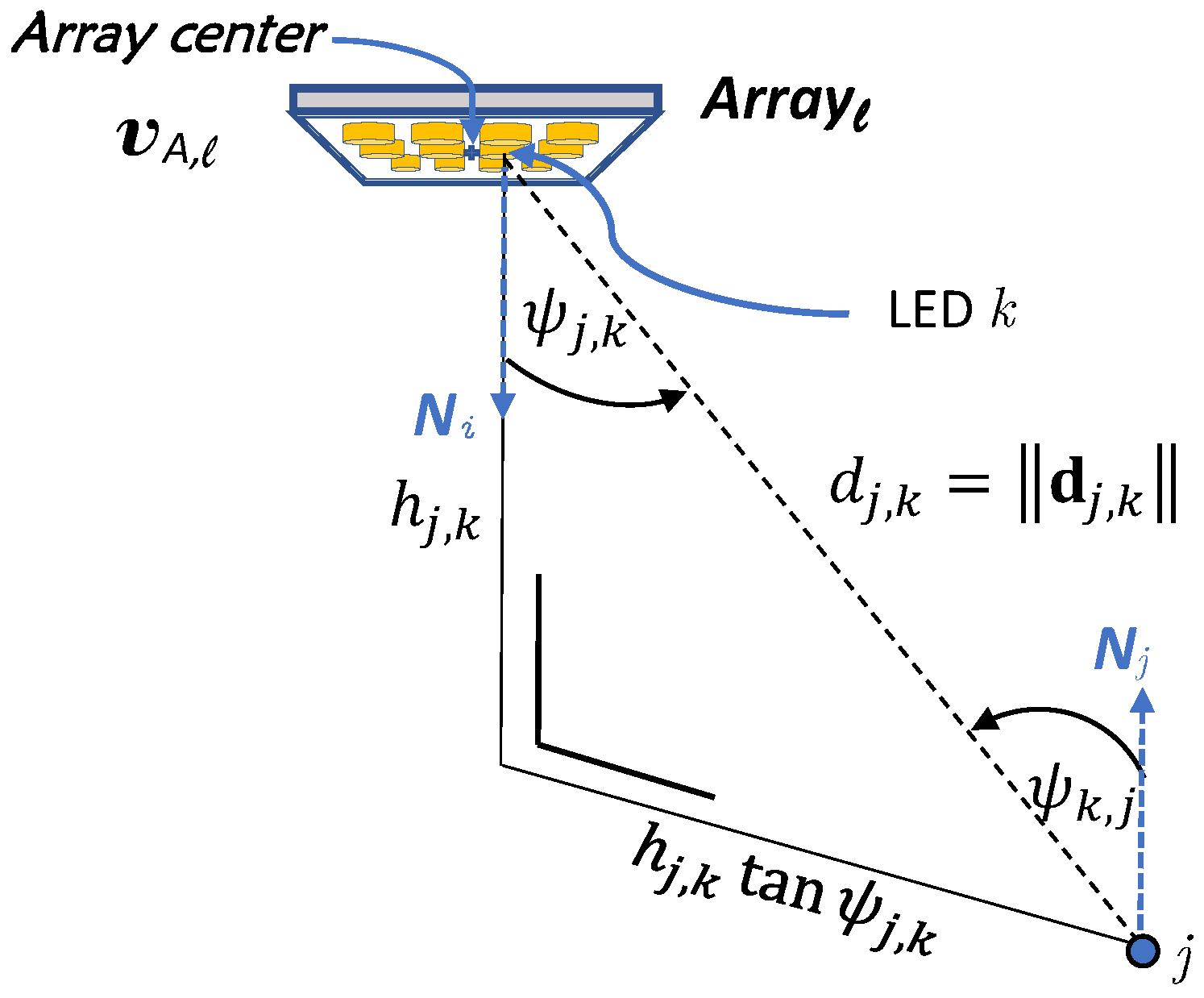

To determine which of the four reference positions corresponds to the minimum for a given 4-tuple

, we evaluate the horizontal illuminance at these points. The horizontal illuminance at a distance

below an array and at a horizontal distance

d from the array is equal to

where

C is a factor that is independent of the distance

d. As we want to compare illuminance levels at different positions in a horizontal plane at vertical distance

from the array, we ignore in the following analysis the common factor

C and use the function

in the comparison. Combining the contributions from the four nearest arrays, we obtain the illuminance

where

,

are the distances between the reference point and the four considered arrays. These distances are given in

Table 2 for the different reference points. To further simplify (

15), we only consider the contributions from the nearest arrays, i.e., with the smallest

:

where

and

is the number of terms in (

15) corresponding to arrays at distance

to the reference point. Using the resulting approximations (

16), we will determine the reference point at which the horizontal illuminance is the smallest:

where

. In the following, the subscript ’

o’ is used to indicate the parameters corresponding to this optimal reference point. Note that when

or

,

,

and/or

will fall outside the considered area, in which case we will omit the corresponding reference positions in our comparison. Taking into account (

14), this comparison will result in inequalities of the form

with

, and

. From

Table 2 and Equations (

12) and (

13), it follows that these inequalities give constraints on the spacing

and

between the arrays. More specifically, we can identify regions for each reference point in the

plane, bounded by the conic sections following from the inequalities (

18). This is illustrated in

Figure 8a, in which we show the reference position that results in the minimum horizontal illuminance as a function of

and

, as well as the ellipses

,

,

and

, that form the decision regions between

and

with

and

, and the hyperbola

that bounds the decision region between

and

. In

Figure 8b,c, we show the true

for the surrounding area and task area, respectively, and for

m,

m,

m,

,

and

, along with their delimiting conic sections. To find the true

in the simulation, we used the true illuminance (

14) and the contributions of all

luminaries, where the minimum

is found through an exhaustive search. As can be expected, the dependency of the minimum illuminance to the spacing between the luminaries is different for the two areas. For small

, i.e., when the luminaries are tightly clustered in the centre of the ceiling, the corners of the area are poorly illuminated, resulting in a low

in the surrounding area. At the same time, the centre of the area is better lit, implying

in the task area is much higher. We observe in the figures that

reaches a maximum value at some

, but the position of the maximum is different for the task and the surrounding area. However, for both the task area and the surrounding area, the maximum

is located on their respective hyperbolas,

and

, in the segment determined by the intersections between the ellipses

and

, and the ellipses

and

.

3.3. Uniformity

Using the analysis of

Section 3.1, we are able to determine the range for the total number

L of LEDs required to satisfy the constraints on the average horizontal illuminance. The next step is to determine how these LEDs must be grouped in luminaries, i.e., arrays of LEDs, to satisfy the uniformity constraints. It is obvious that when the number of luminaries is large, the uniformity constraints will be satisfied, although this will come with a large installation cost. Hence, we are interested in finding (1) the minimum number of luminaries for which in both areas the uniformity is larger than the threshold

,

, and (2) the range over which the spacing

may vary for a given number of luminaries. In the following, we define

as the ratio between the dimensions of the area, and

as the ratio of the number of arrays in each dimension.

In

Figure 9, we show the uniformity as a function of the spacing

for both the task and surrounding area, for

m,

,

,

,

and

m. The uniformity is computed using (

14) and takes into account the contributions from all luminaries, where to obtain

, we use the estimated position (

17) of the minimum. We also show in both figures the region in which the uniformity exceeds the respective thresholds, i.e.,

(bounded by the red curve) for the task area, and

(bounded by the green curve) for the surrounding area, as well as the compliance region

(bounded by the dotted curve), which is the region for

where the uniformity constraints in both the task and surrounding area are satisfied:

. This compliance region changes when we alter one or more of the following parameters: the area size

, the number of arrays

, the Lambertian order

or the vertical distance

. In some cases, the compliance region will be empty, e.g., if the number of arrays is not sufficiently large to meet the uniformity constraints irrespective of the spacing between the arrays. In general, if the number of arrays is sufficiently large, the compliance region will result in a relatively large range of potential spacings

. Unfortunately, due to the complexity of the problem, no analytical expression for the boundaries of this compliance region can be derived.

We will therefore approach the problem from a slightly different viewpoint. Let us consider the maximum uniformity in the task and the surrounding area. Firstly, this maximum will give an indication if the compliance region is empty. Indeed, if the maximum value of the uniformity is below the threshold in the task or surrounding area, the compliance region will be empty. However, even if for both the task area and surrounding area the maximum is above the threshold, it is not guaranteed that the compliance region is non-empty, i.e., if the regions for the task area and surrounding area do not overlap. Secondly, for a given number of luminaries, the maximum uniformity will result in the highest comfort to the user. Therefore, we look for the values of where for given , the corresponding value for results in the largest uniformity, i.e., the ridge in the uniformity distribution. As we can observe in the figure, the ridge of maximum values of the uniformity for a given in the surrounding area approximately corresponds to the hyperbola . This is obvious, as in the previous section, the maximum value of for given was shown to be on this hyperbola, and the average horizontal illuminance is largely independent of the array spacing. For the task area, the ridge of maxima of will fall on the hyperbola provided that no luminaries are located outside the task area. However, when for this maximum some luminaries are outside the task area, the hyperbola no longer follows the ridge of maxima. Regardless of the placement of the luminaries, we observed in our simulations that the hyperbola of the surrounding area roughly follows the ridge of maxima in the task area. Therefore, we will consider for both areas the hyperbola to determine the value of corresponding to the maximum uniformity for a given .

To obtain the range of

and corresponding

for which the uniformity constraints are satisfied, we determine the intersections between the hyperbola and the regions where the uniformity is above the threshold in the task and surrounding area, respectively, i.e., for the task area,

when the point

on the hyperbola satisfies

and for the surrounding area

when the point

on the hyperbola satisfies

, as indicated in

Figure 9. The range for

where the uniformity constraints are satisfied for both regions, i.e., where the spacing

belongs to the compliance region, is then given by the intersection of the two intervals:

, where

and

. As can be observed in the figure, the upper bound

may coincide with the maximum possible spacing

, or in some situations with

. Let us therefore first compute the points

and

on the hyperbola

corresponding to the maximum spacing

and

. After some straightforward derivations, it follows that

if

, and that

if

. Hence, when

, the hyperbola will first cross the maximum

, implying this is the tightest maximum spacing, while when

, then the hyperbola first crosses the maximum

, which then is the tightest maximum spacing. Hence, the following upper bound on

can be formulated:

with

Taking into account that

, it follows that both bounds in (

19) are linear in

.

Next, we determine the other bounds for

for given parameter settings, i.e., for different

,

,

,

,

,

,

and

. To this end, let us compute the true uniformity

and

, i.e., without use of any approximations, and determine the bounds using an exhaustive search. In

Figure 10, we show the resulting range of

, i.e., the green areas, as a function of the size

of the area for different values of

,

and

, for

m and

. As can be observed in the figure, the bounds

and

depend in a piece-wise linear way on the size

of the area. This piece-wise linear behaviour could be expected, as to keep an as large as possible uniformity, scaling the area while keeping the number of luminaries equal will result in a scaling of the spacing between the luminaries, resulting in a linear behaviour. The piece-wise character of the bounds is because at some point the lower (upper) bound corresponding to the task area becomes tighter than that of the surrounding area, or vice versa. Therefore, we approximate the range for

as a function of

as a piece-wise linear upper and lower bound, as shown in

Figure 11. The first bound is (

19), due to the maximum allowed spacing to keep all luminaries within the considered area. The spacing

serves as an upper bound on the spacing for the task area as well as for the surrounding area in case the uniformity constraints still hold for this maximum possible spacing, which occurs when the considered area is sufficiently small. When the area size is larger, the uniformity constraints no longer will be met for the maximum possible spacing

. In that case, the upper bound on

will be determined by

. In our simulations, we always found that

, implying we can ignore the bound

. To find the expressions for the linear equations for

,

and

, we carried out a large number of simulations for various values for the parameters

,

,

,

and

, and matched the coefficients of the linear equations to the simulated bounds. This resulted in the empirical equations

where

, and

follows from the definition of the size of the task area. The resulting bounds are shown in

Figure 10. As can be observed, the bounds match well the true bounds on

for given area size. The bounds were tested for the parameter ranges given in

Table 3, and were found to be accurate. Hence, the empirical bounds (

21) can be used for at least these parameter settings. Taking into account that it is required that

, it follows that

. This yields the following lower bound on the number of luminaries:

and consequently

To verify the resulting bounds on

, let us consider the same example we used to determine the range for the number of LEDs to achieve an average illuminance in the range [300,500] lx, i.e., with

m,

m,

,

lm and

(i.e.,

). By using (

10) and (

11), we determined that the number

L of LEDs needed to have an average horizontal illumination between 300 and 500 lux ranges in

. In the following, we assume

. These LEDs must be grouped in luminaries, in a grid of

luminaries. In our example, we assume

, i.e.,

. Further, the dimensions of the task area are selected as

with

and

. For the task area, we assume the threshold for uniformity is

and for the surrounding area

. This yields

. Applying the bounds (

22) and (

23), it follows that the number of luminaries is lower bounded by

and

. This gives

LEDs per luminary. As

, it follows that the bound

(

19) is determined by the maximum spacing

. This yields

m. On the other hand,

m, implying

m. Similarly, we compute the lower bounds using Equation (

21) to obtain

m and

m, and thus

m. This results in the interval

m.

To check if this interval corresponds to the true compliance region for the given parameter values, we computed the true uniformity and average illuminance. The uniformity for the task and surrounding area are shown in

Figure 12a, and the average horizontal illuminance for the task area

, surrounding area

and the whole area of interest

in

Figure 12b. In the figure, we show the true compliance interval

in which the uniformity in both the task and surrounding area are above the threshold. As can be observed, the predicted compliance region

is contained in the true compliance region

,

, although the predicted interval slightly underestimates the true interval. We noticed in our simulations that when the difference

, the predicted interval tends to underestimate the interval, although the predicted interval still results in a system setup that satisfies the constraints on the illuminance level and uniformity. In

Figure 13, the compliance intervals are shown for different values for

, for

. As can be observed, the predicted and the true compliance interval match very well for

. As in practice, the number of luminaries is scaled with the dimensions of the area, i.e.,

, this implies the proposed approximations predict the range of potential spacings between the luminaries well.