Piston Error Extraction from Dual-Wavelength Interference Patterns Using Phase Retrieval Technique

Abstract

:1. Introduction

2. Theory

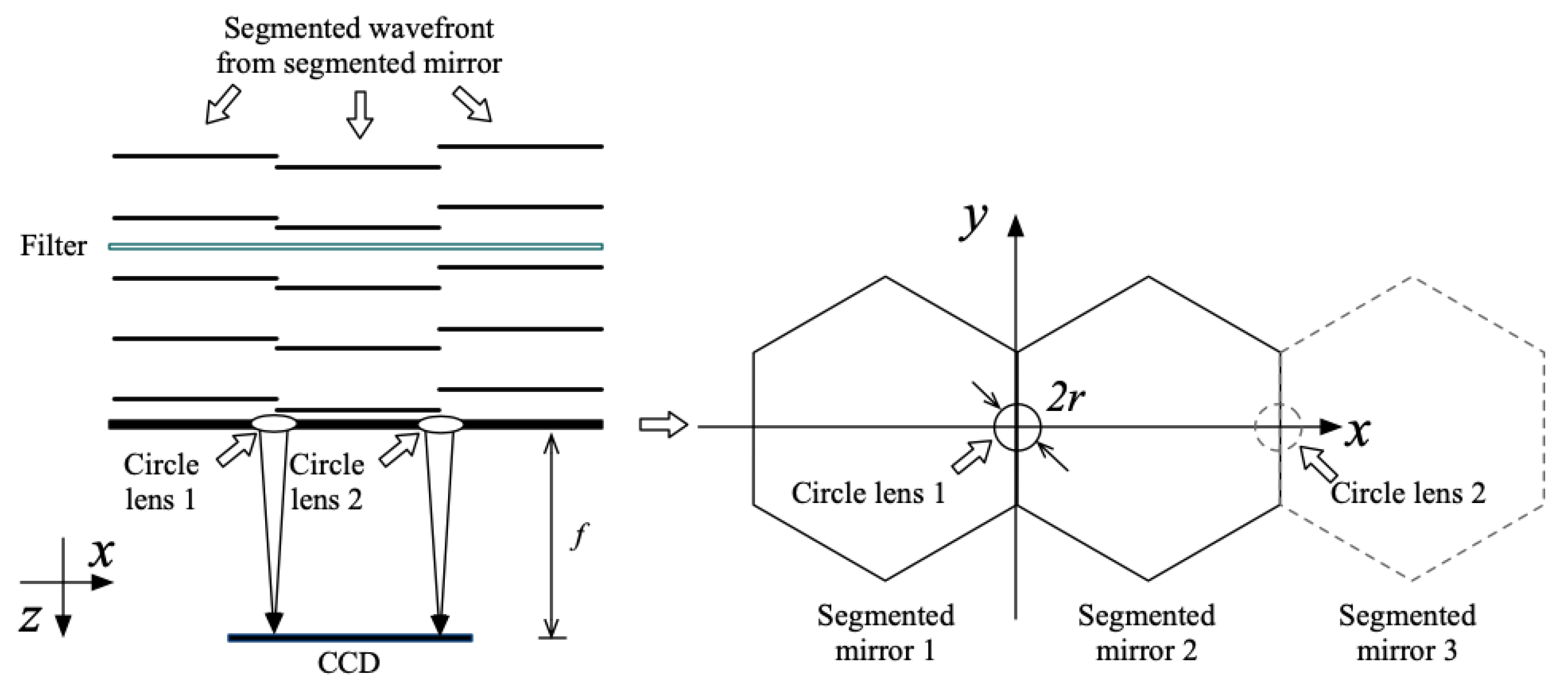

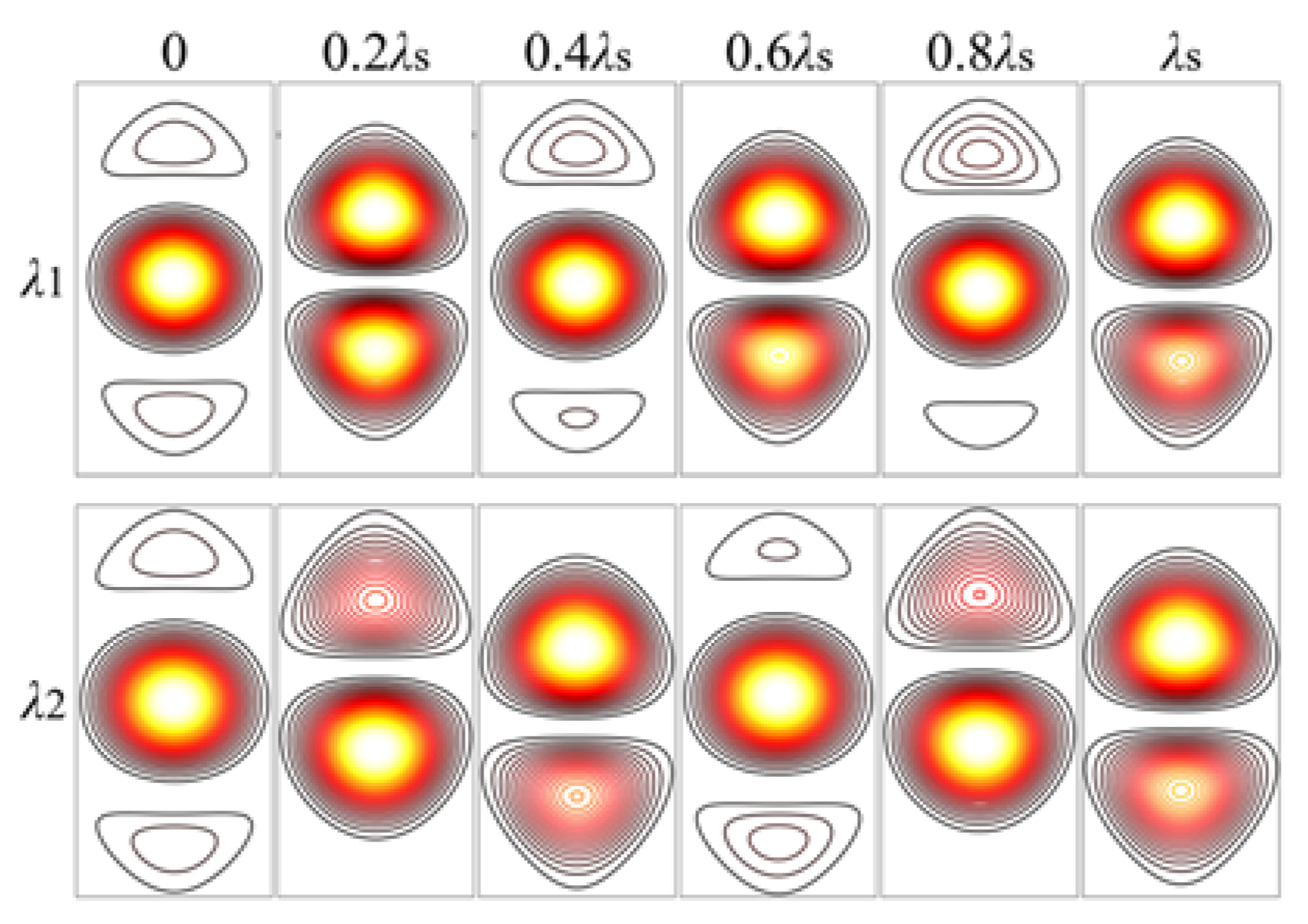

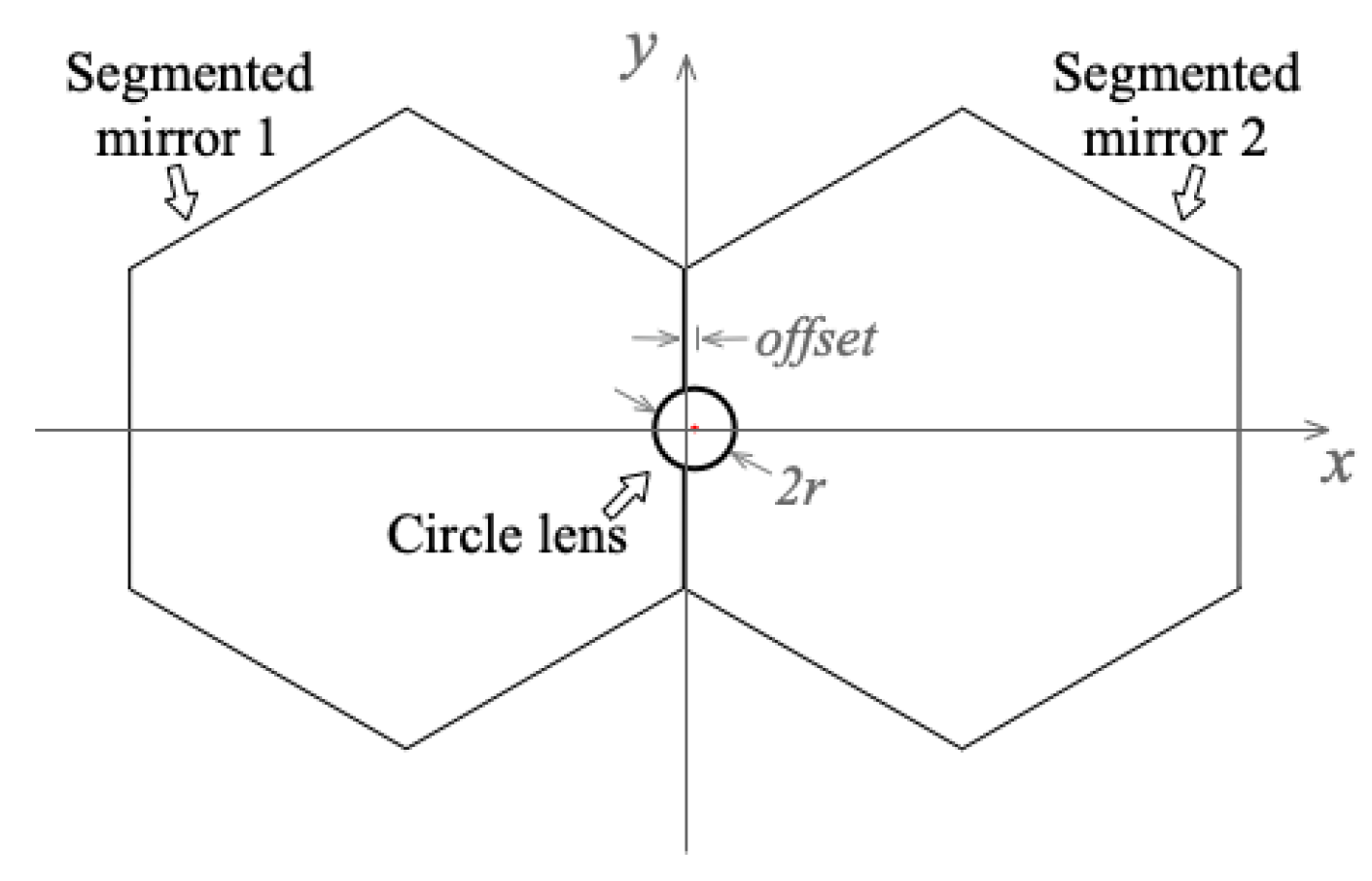

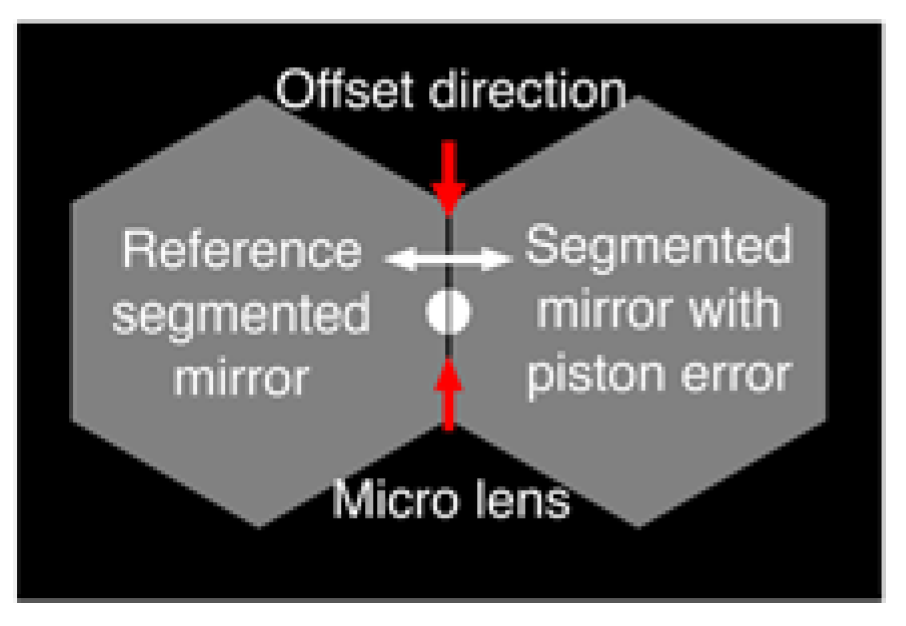

2.1. Interference Patterns Created by the Lens

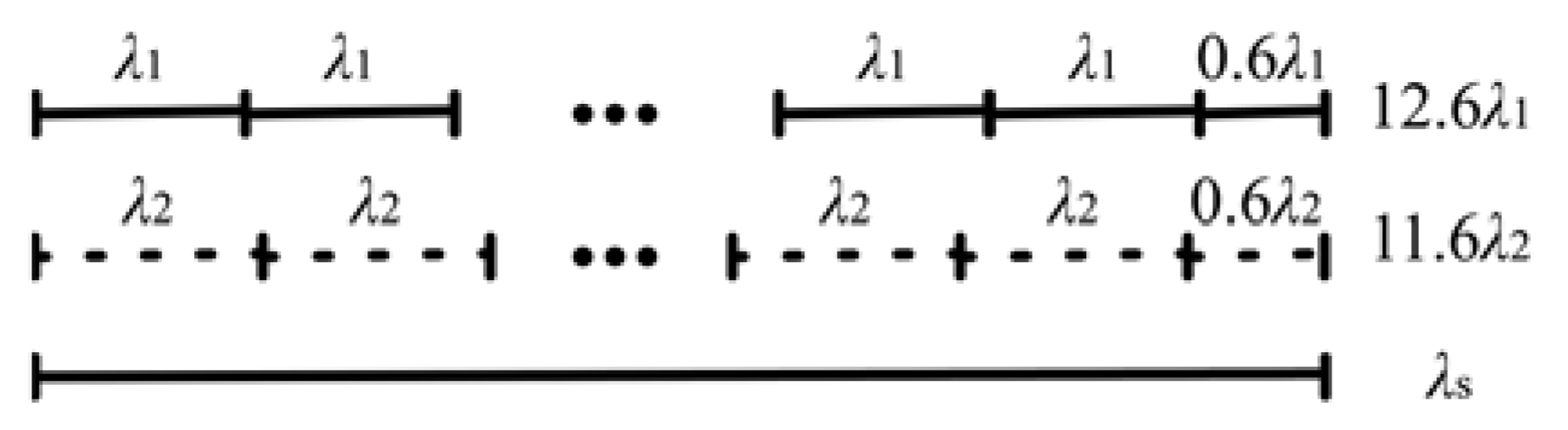

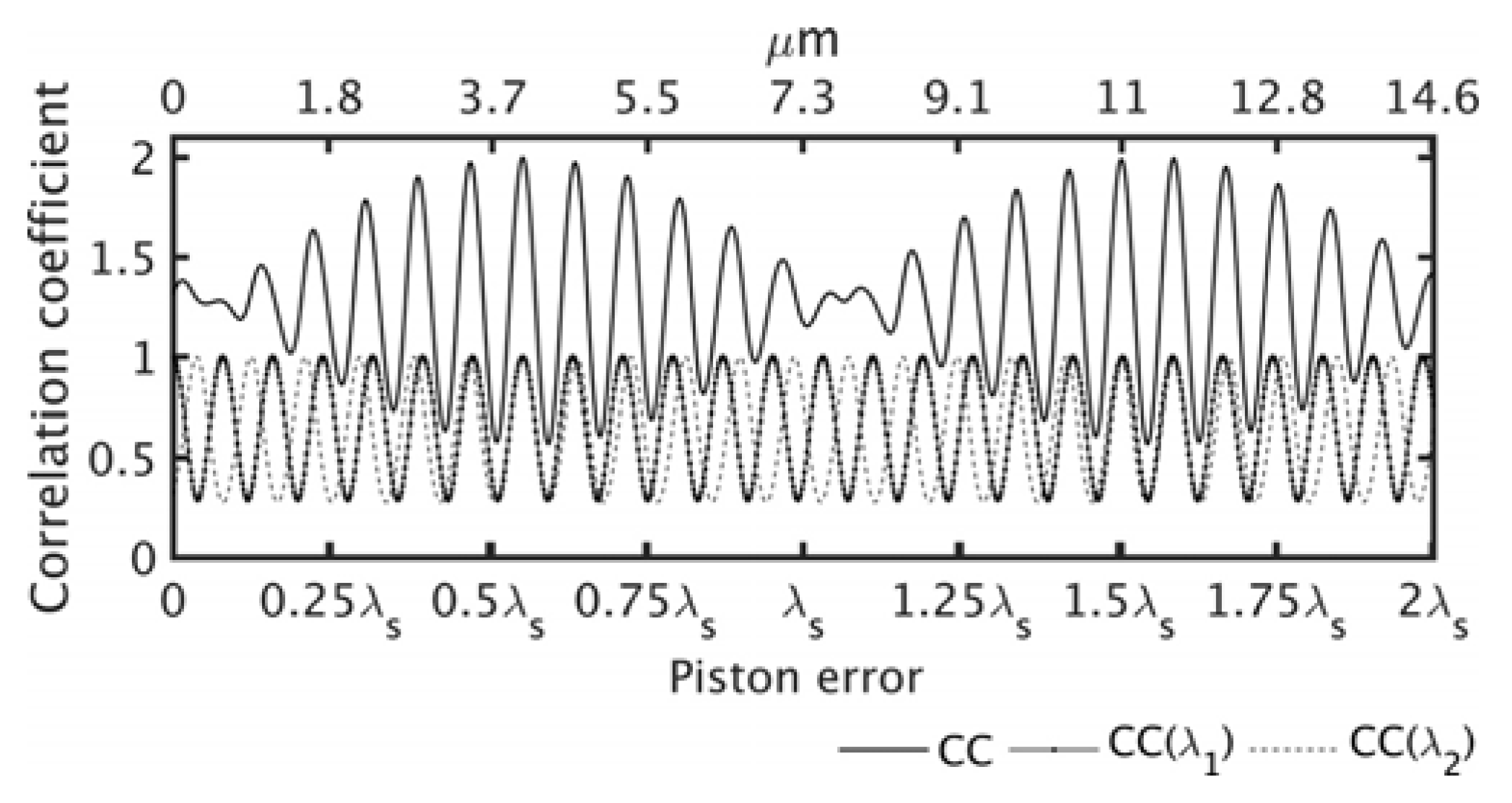

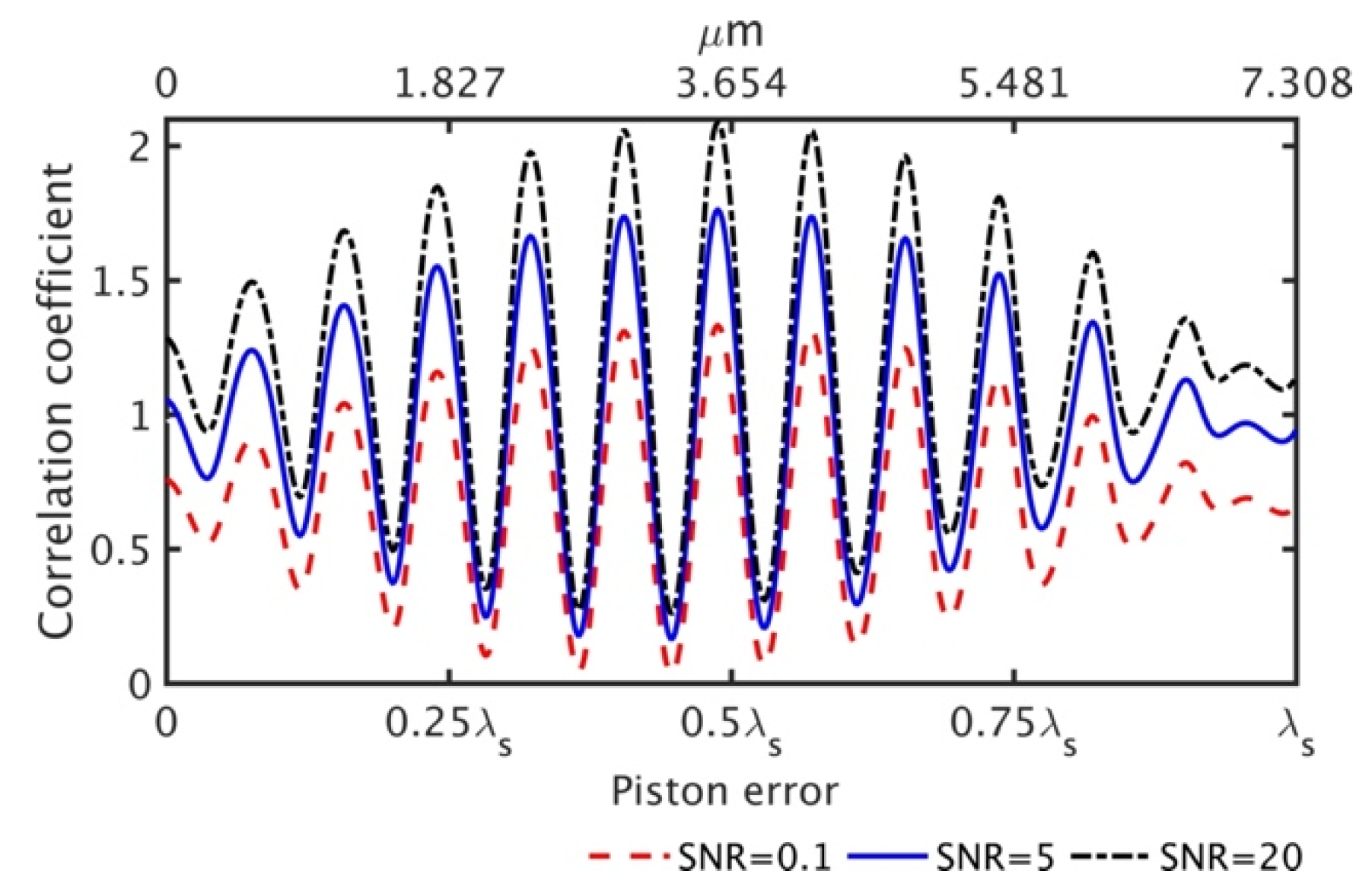

2.2. Extend the Detection Range Using Two Wavelengths

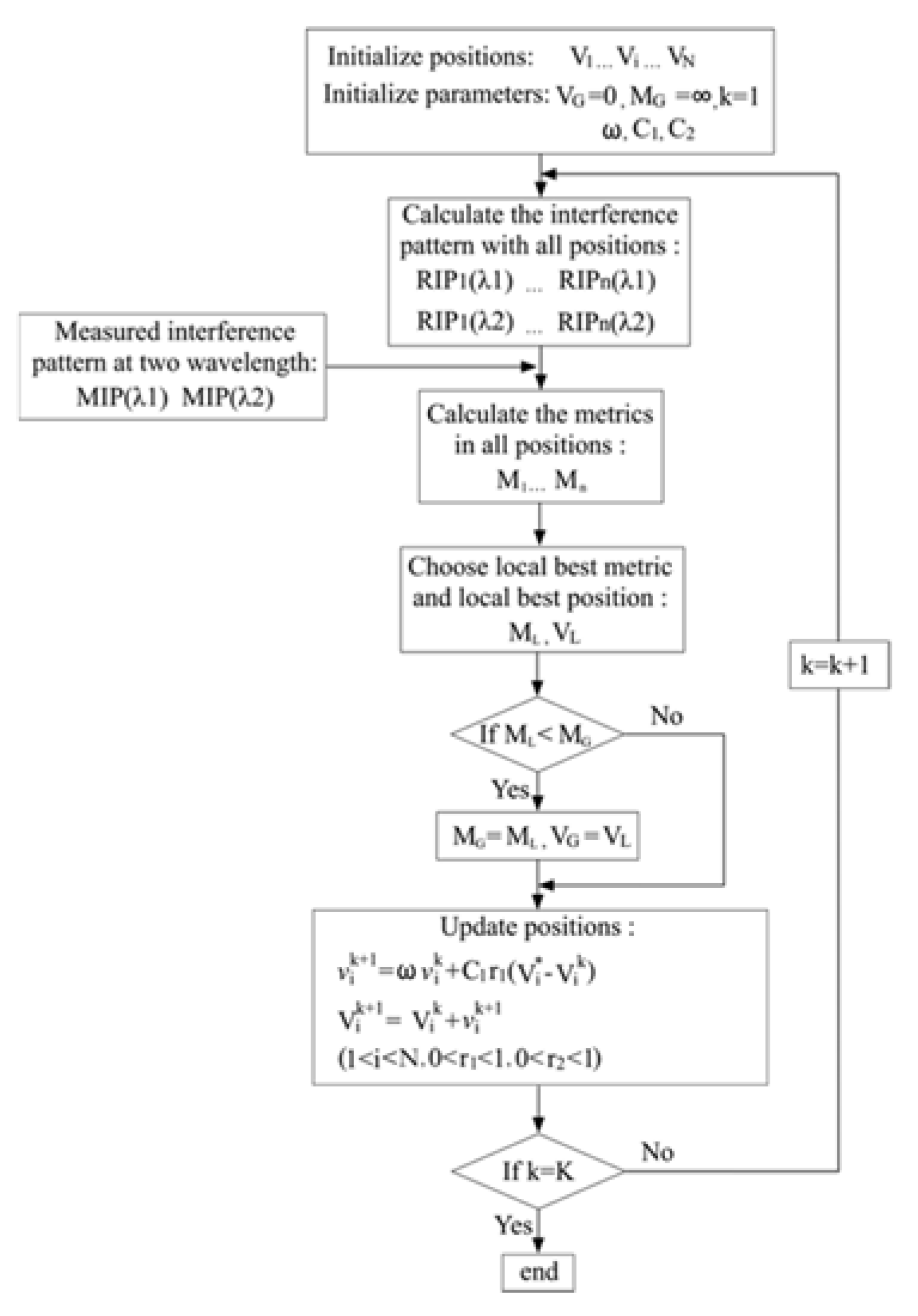

2.3. Piston Error Extraction Method

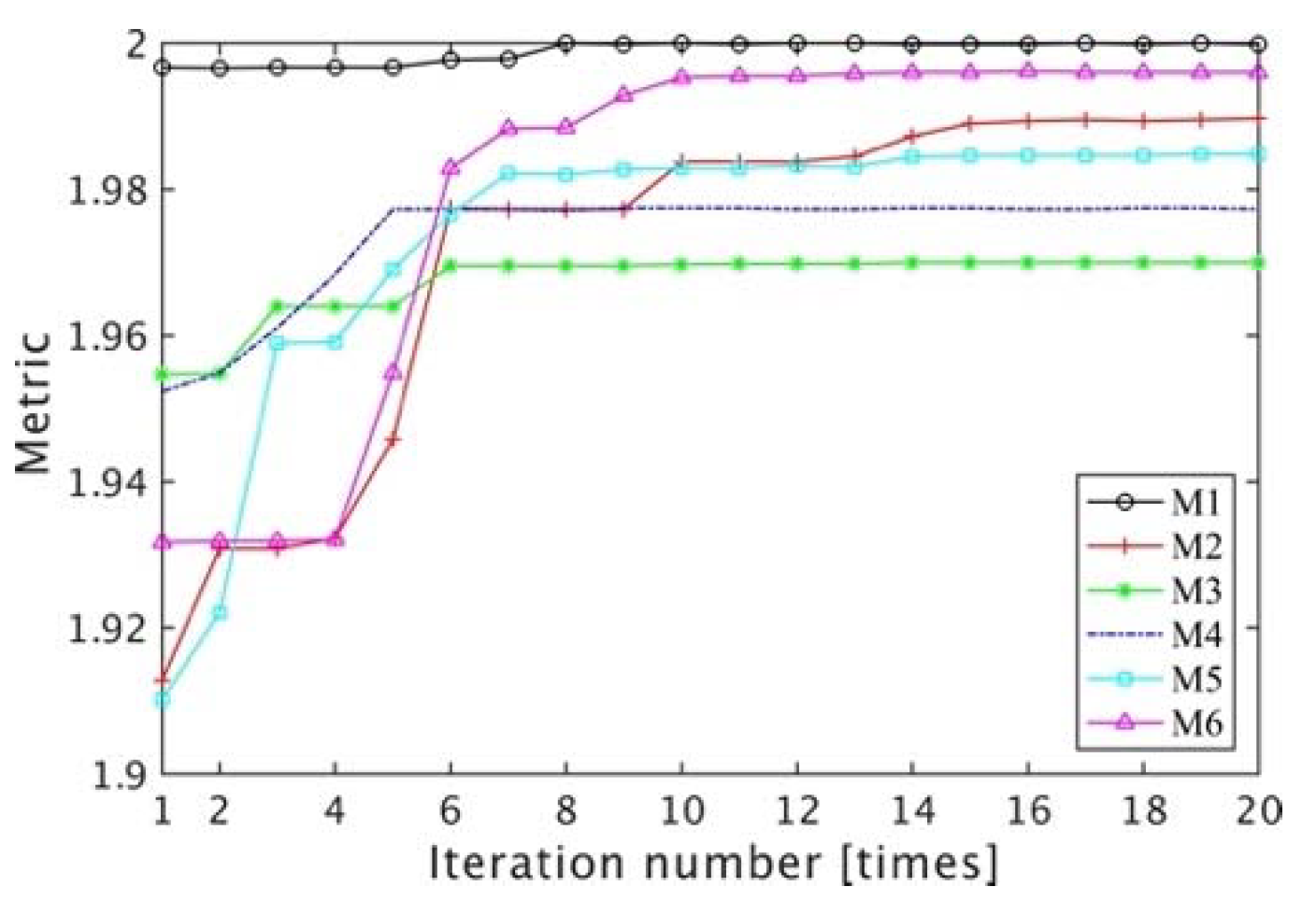

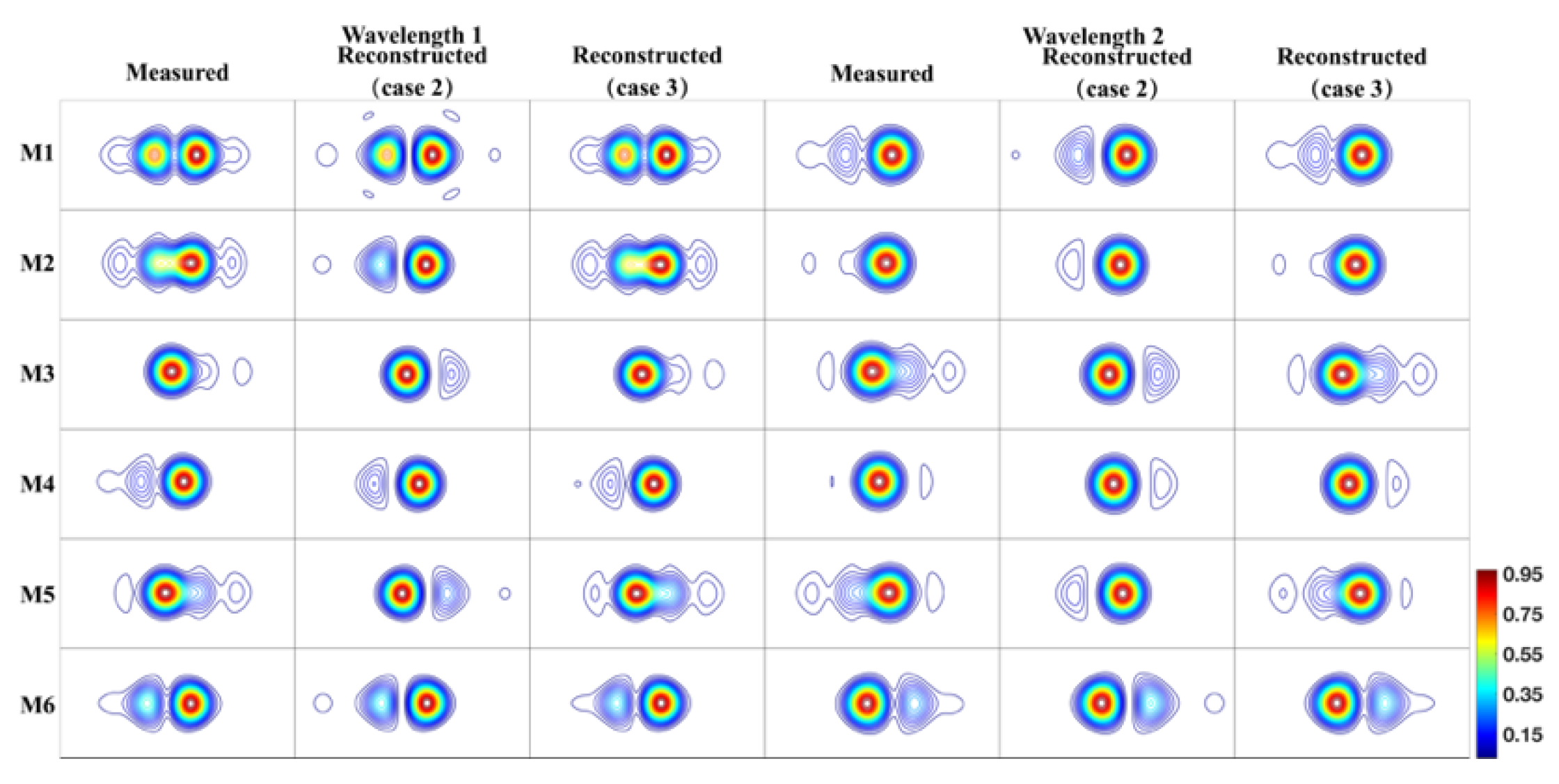

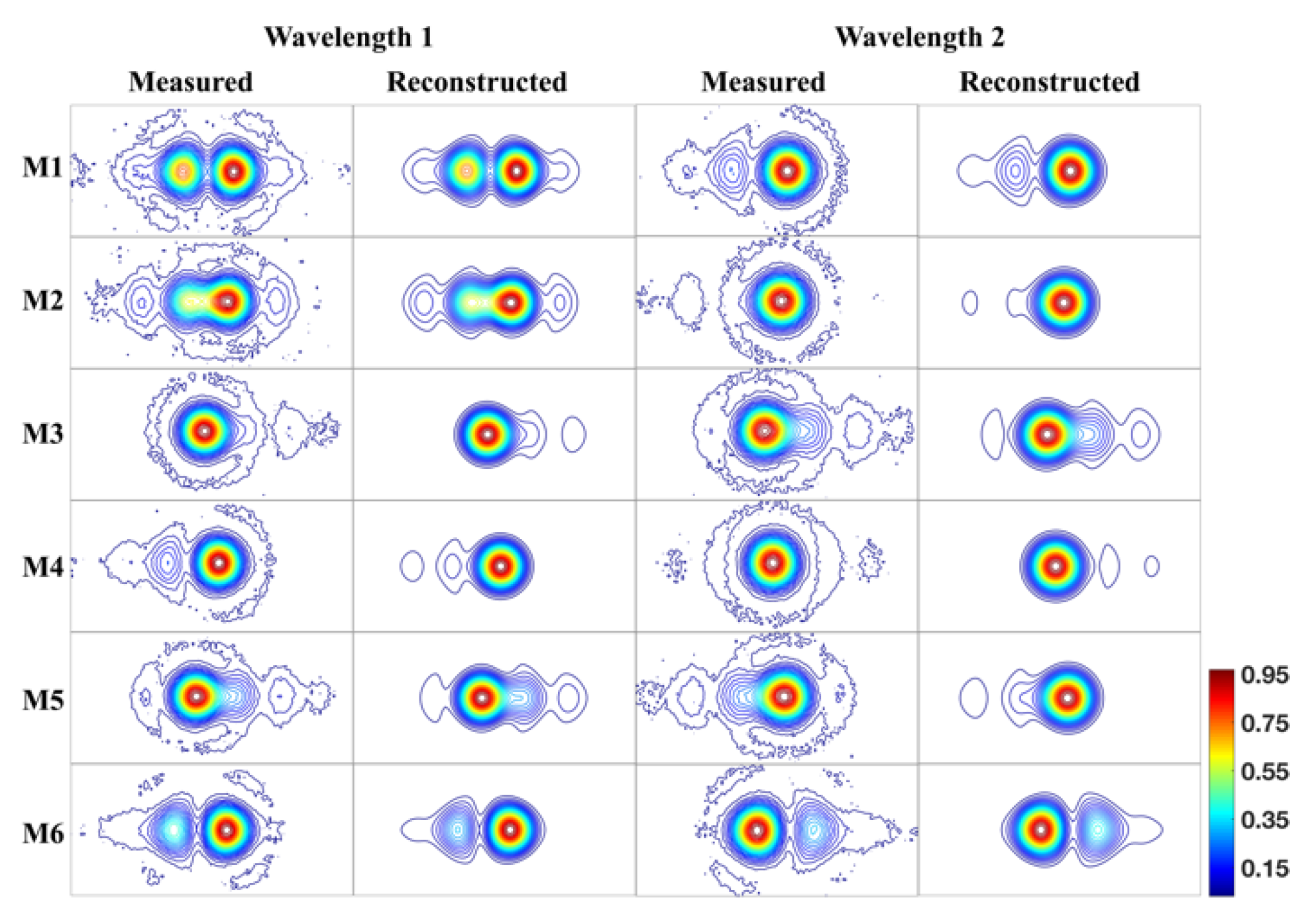

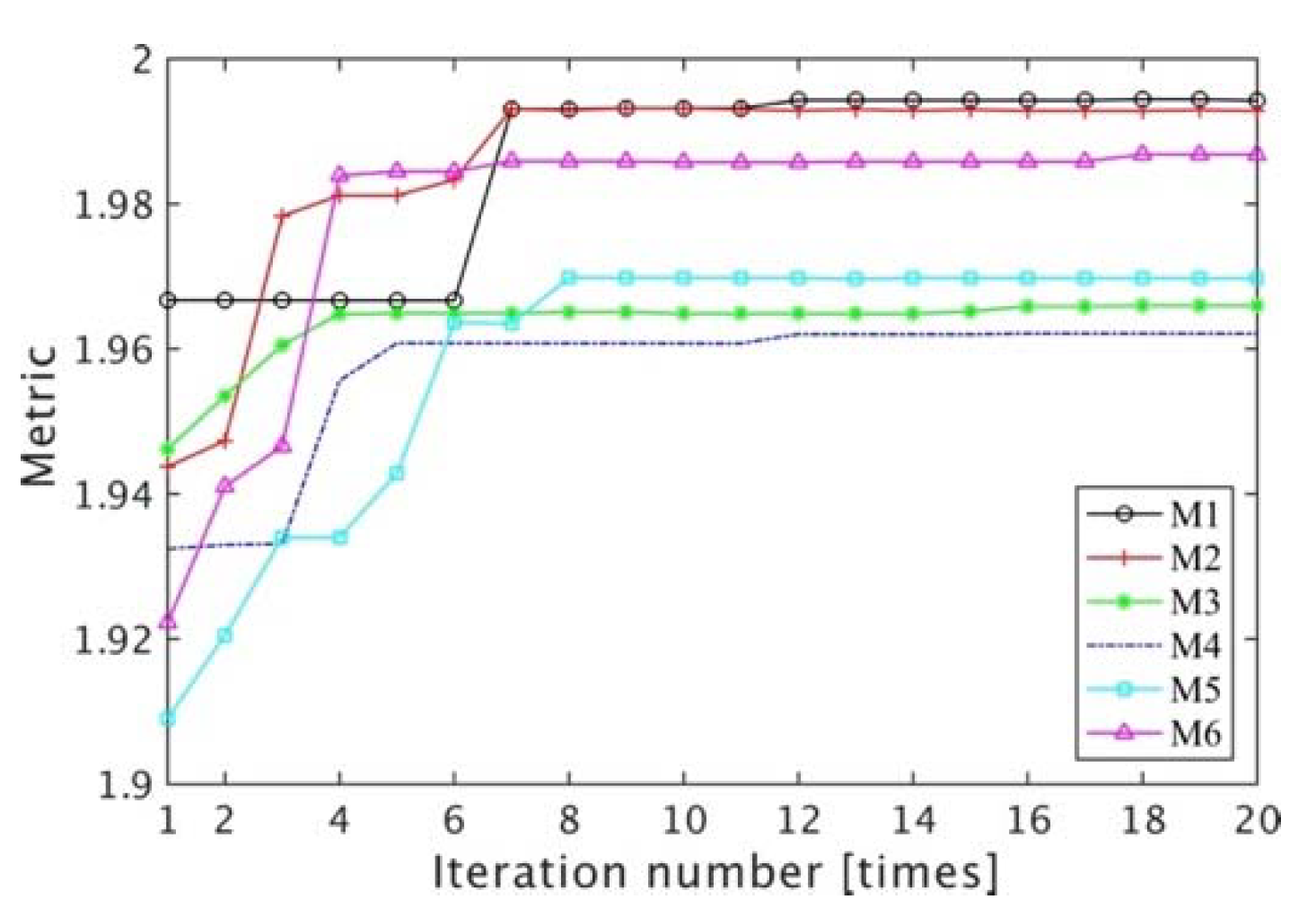

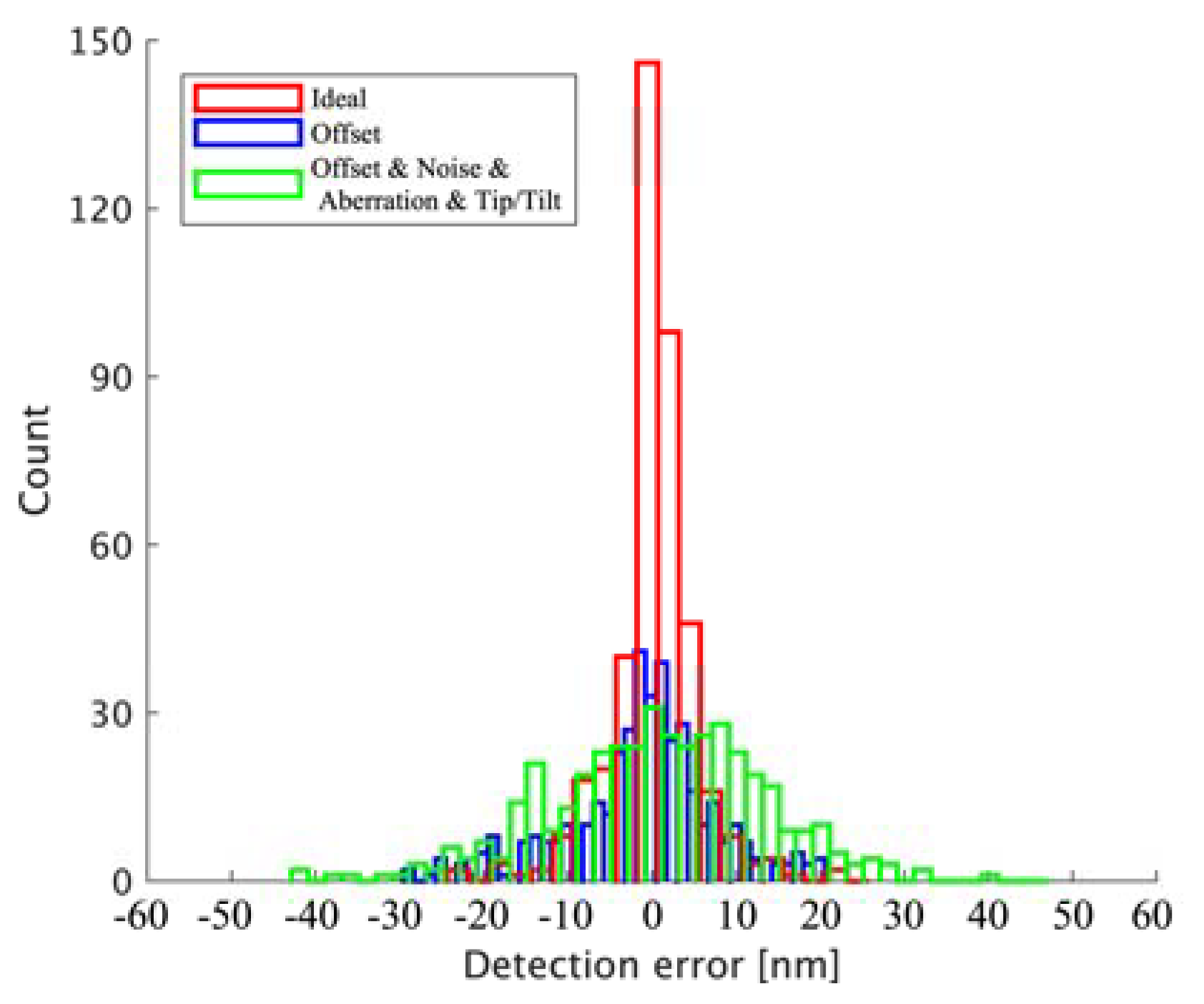

3. Simulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Fender, S. Synthetic apertures: An overview. In Proceedings of the 27th Annual Technical Symposium, San Diego, CA, USA, 23–25 August 1983; Volume 440, pp. 2–7. [Google Scholar]

- Gunturk, B.K.; Miller, N.J.; Watson, E.A. Camera phasing in multi-aperture coherent imaging. Opt. Express 2012, 20, 11796–11805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Janin-Potiron, P.; Martinez, P.; Baudoz, P.; Carbillet, M. The self-coherent camera as a focal plane phasing sensor. EAS Publ. Ser. 2016, 78–79, 287–305. [Google Scholar] [CrossRef]

- Galicher, R.; Baudoz, P.; Rousset, G. Wavefront error correction and Earth-like planet detection by a self-coherent camera in space. Astron. Astrophys. 2008, 488, L9–L12. [Google Scholar] [CrossRef] [Green Version]

- Chanan, G.; Troy, M.; Sirko, E. Phase discontinuity sensing: A method for phasing segmented mirrors in the infrared. Appl. Opt. 1999, 38, 704–713. [Google Scholar] [CrossRef] [PubMed]

- Surdej, I.; Yaitskova, N.; Gonte, F. On-sky performance of the Zernike phase contrast sensor for the phasing of segmented telescopes. Appl. Opt. 2010, 49, 4052–4062. [Google Scholar] [CrossRef] [PubMed]

- Esposito, S.; Pinna, E.; Puglisi, A.; Tozzi, A.; Stefanini, P. Pyramid sensor for segmented mirror alignment. Opt. Lett. 2005, 30, 2572–2574. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.M.; Wang, C.C.; Duan, W.R. Simulation of detecting piston error between segmented mirrors by Fizaeu interference technique on ZEMAX. Optik 2019, 183, 828–834. [Google Scholar] [CrossRef]

- Yue, D.; He, Y.H.; Li, Y.S. Piston Error Measurement for Segmented Telescopes with an Artificial Neural Network. Sensors 2021, 21, 3364. [Google Scholar] [CrossRef] [PubMed]

- Kanev, F.Y.; Lukin, V.P.; Makenova, N.A. Algorithm for phasing a segmented mirror. Atmos. Ocean Opt. 2003, 16, 991–995. [Google Scholar]

- Kanev, F.Y.; Lukin, V.P.; Makenova, N.A. Cophasing of a telescope segmented mirror. Proc. SPIE 2004, 5396, 157–162. [Google Scholar]

- Li, Y.; Wang, S.Q.; Rao, C.H. Dispersed-fringe-accumulation-based left-subtract-right method for fine co-phasing of a dispersed fringe sensor. Appl. Opt. 2017, 56, 4267–4273. [Google Scholar] [CrossRef] [PubMed]

- Shi, F.; Chanan, G.; Ohara, C.; Troy, M.; Redding, D.C. Experimental verification of dispersed fringe sensing as a segment phasing technique using the Keck telescope. Appl. Opt. 2004, 43, 4474–4481. [Google Scholar] [CrossRef] [PubMed]

- Chanan, G.; Ohara, C.; Troy, M. Phasing the mirror segments of the Keck telescopes II: The narrow-band phasing algorithm. Appl. Opt. 2000, 39, 4706–4714. [Google Scholar] [CrossRef] [PubMed]

- Chanan, G.; Troy, M.; Dekens, F.; Michaels, S.; Nelson, J.; Mast, T.; Kirkman, D. Phasing the mirror segments of the Keck telescopes: The broadband phasing algorithm. Appl. Opt. 1998, 37, 140–155. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schumacher, A.; Devaney, N.; Montoya, L. Phasing segmented mirrors: A modification of the Keck narrow-band technique and its application to extremely large telescopes. Appl. Opt. 2002, 41, 1297–1307. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.H.; Fu, Q.; Shen, F.; Rao, C.H. Piston and tilt cophasing of segmented laser array using Shack Hartmann sensor. Opt. Express 2012, 20, 4663–4674. [Google Scholar] [CrossRef] [PubMed]

- Gonsalves, R.A. Phase retrieval and diversity in adaptive optics. Opt. Eng. 1982, 21, 829–832. [Google Scholar] [CrossRef]

- Ying, G.R.; Wei, Q.W.; Han, S.S. A two-step phase-retrieval method in fourier-transform ghost imaging. Opt. Commun. 2008, 281, 5130–5132. [Google Scholar] [CrossRef]

- Troy, M.; Chanan, G.; Michaels, S.; Bartos, R.; Bothwell, G.; Give’on, A.; Hein, R.; Radin, M.; Roberts, J.; Rodgers, J.M.; et al. A conceptual design for the Thirty Meter Telescope alignment and phasing system. Proc. SPIE 2008, 7012, 70120Y. [Google Scholar]

- Goodman, J. Introduction to Fourier Optics, 3rd ed.; Roberts & Company Publishers: Englewood, NJ, USA, 2004. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95 International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Noll, R.J. Zernike polynomials and atmospheric turbulence. J. Opt. Soc. Am. 1976, 66, 207–211. [Google Scholar] [CrossRef]

- Shi, Y.; Eberhart, R.C. Parameter selection in particle swarm optimization. In Proceedings of the 7th International Conference, EP 98, San Diego, CA, USA, 25–27 March 1998; pp. 591–600. [Google Scholar]

- Mohamed, B. Nonlinear Optimization in Electrical Engineering with Applications in MATLAB; The Institution of Engineering and Technology: Stevenage, UK, 2013. [Google Scholar]

| Case-1 | Case-2 | Case-3 | Case-4 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Loaded | Extracted | Loaded | Extracted | Loaded | Extracted | Loaded | Extracted | ||

| Piston error(nm) | Sub-0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Sub-1 | 5534 nm | 5534 nm | 5534 nm | 5544 nm | 5534 nm | 5534 nm | 5534 nm | 5539 nm | |

| Sub-2 | 4974 nm | 4972 nm | 4974 nm | 5626 nm | 4974 nm | 4968 nm | 4974 nm | 4974 nm | |

| Sub-3 | 6472 nm | 6480 nm | 6472 nm | 7030 nm | 6472 nm | 6474 nm | 6472 nm | 6482 nm | |

| Sub-4 | 5680 nm | 5698 nm | 5680 nm | 5713 nm | 5680 nm | 5702 nm | 5680 nm | 5712 nm | |

| Sub-5 | 4232 nm | 4251 nm | 4232 nm | 2449 nm | 4232 nm | 4251 nm | 4232 nm | 4220 nm | |

| Sub-6 | 2700 nm | 2711 nm | 2700 nm | 2725 nm | 2700 nm | 2711 nm | 2700 nm | 2721 nm | |

| Offset of micro lens (μm) | M1 | / | / | 260 μm | / | 260 μm | 254 μm | 260 μm | 267 μm |

| M2 | / | / | 460 μm | / | 460 μm | 473 μm | 460 μm | 436 μm | |

| M3 | / | / | 470 μm | / | 470 μm | 446 μm | 470 μm | 457 μm | |

| M4 | / | / | 250 μm | / | 250 μm | 232 μm | 250 μm | 249 μm | |

| M5 | / | / | 470 μm | / | 470 μm | 460 μm | 470 μm | 439 μm | |

| M6 | / | / | 190 μm | / | 190 μm | 173 μm | 190 μm | 194 μm | |

| Gauss noise | / | / | / | SNR = 20 dB | |||||

| Zernike coefficients (radians) | / | / | / | Z = [0, 0, 0, 0.2418, 0.1737, 0.3891, −0.2801, −0.2822, −0.0677, −0.1963, 0.492]; ; ; | |||||

| Parameters of PSO | ; ω = 0.3; c1 = c2 = 0.8; Number of particles = 30; | ; ω = 0.3; c1 = c2 = 0.8; Number of particles = 30; | ; ω=0.8; c1 = c2 = 1; Number of particles = 30; | ; ω = 0.9; c1 = c2 = 0.9; Number of particles = 30; | |||||

| One iteration step time (s) | 1.5 (CPU: Intel core I7 @2.6 GHZ, Chengdu, China; RAM: 16 G.) | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Yang, X.; Wang, S.; Li, B.; Xian, H. Piston Error Extraction from Dual-Wavelength Interference Patterns Using Phase Retrieval Technique. Photonics 2022, 9, 111. https://doi.org/10.3390/photonics9020111

Li X, Yang X, Wang S, Li B, Xian H. Piston Error Extraction from Dual-Wavelength Interference Patterns Using Phase Retrieval Technique. Photonics. 2022; 9(2):111. https://doi.org/10.3390/photonics9020111

Chicago/Turabian StyleLi, Xiaoyang, Xu Yang, Shengqian Wang, Bincheng Li, and Hao Xian. 2022. "Piston Error Extraction from Dual-Wavelength Interference Patterns Using Phase Retrieval Technique" Photonics 9, no. 2: 111. https://doi.org/10.3390/photonics9020111