High-Power, High-Efficiency Red Laser Diode Structures Grown on GaAs and GaAsP Metamorphic Superlattices

Abstract

:1. Introduction

2. Materials and Methods

2.1. Growth Parameters

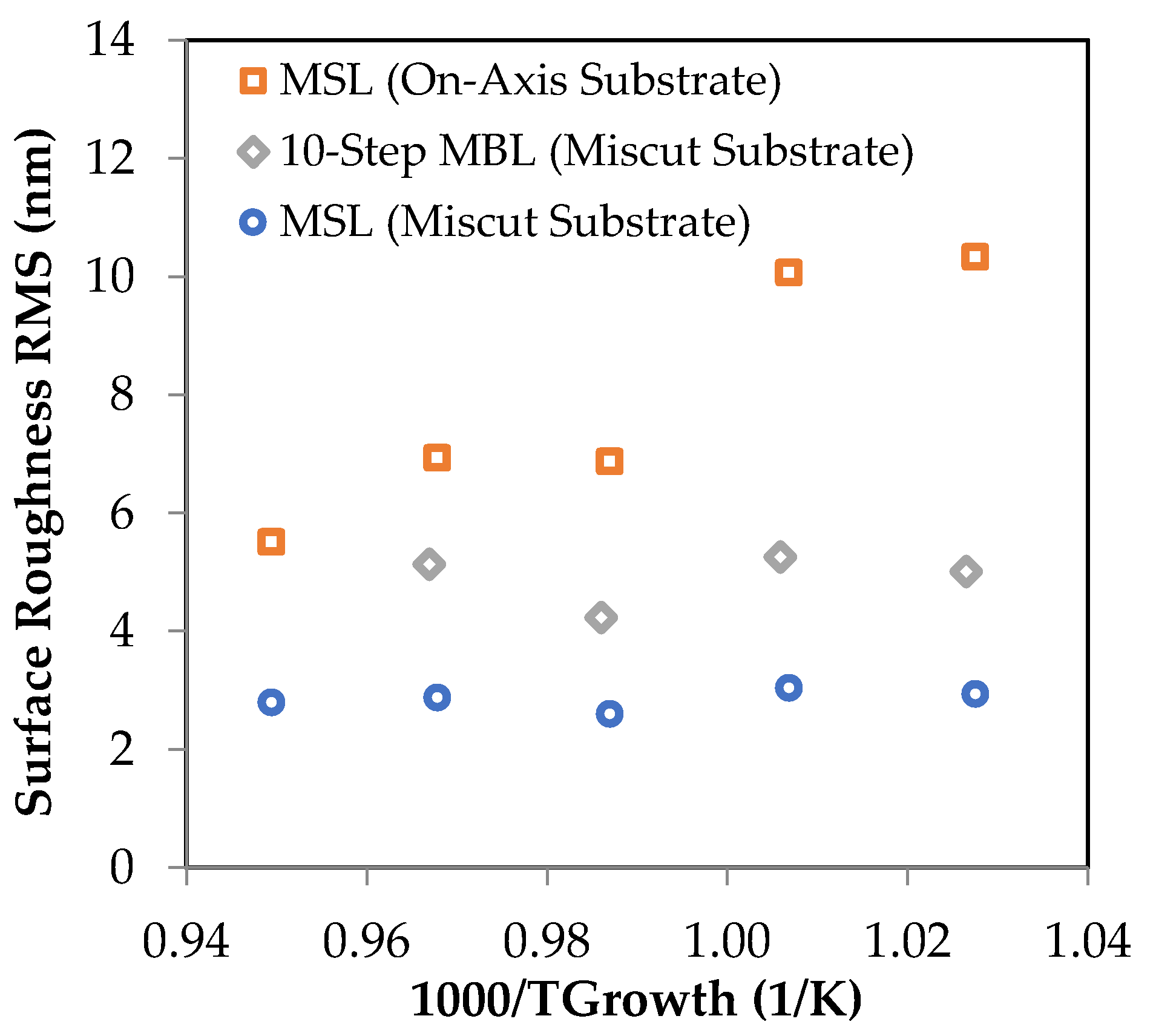

2.2. Metamorphic GaAsP

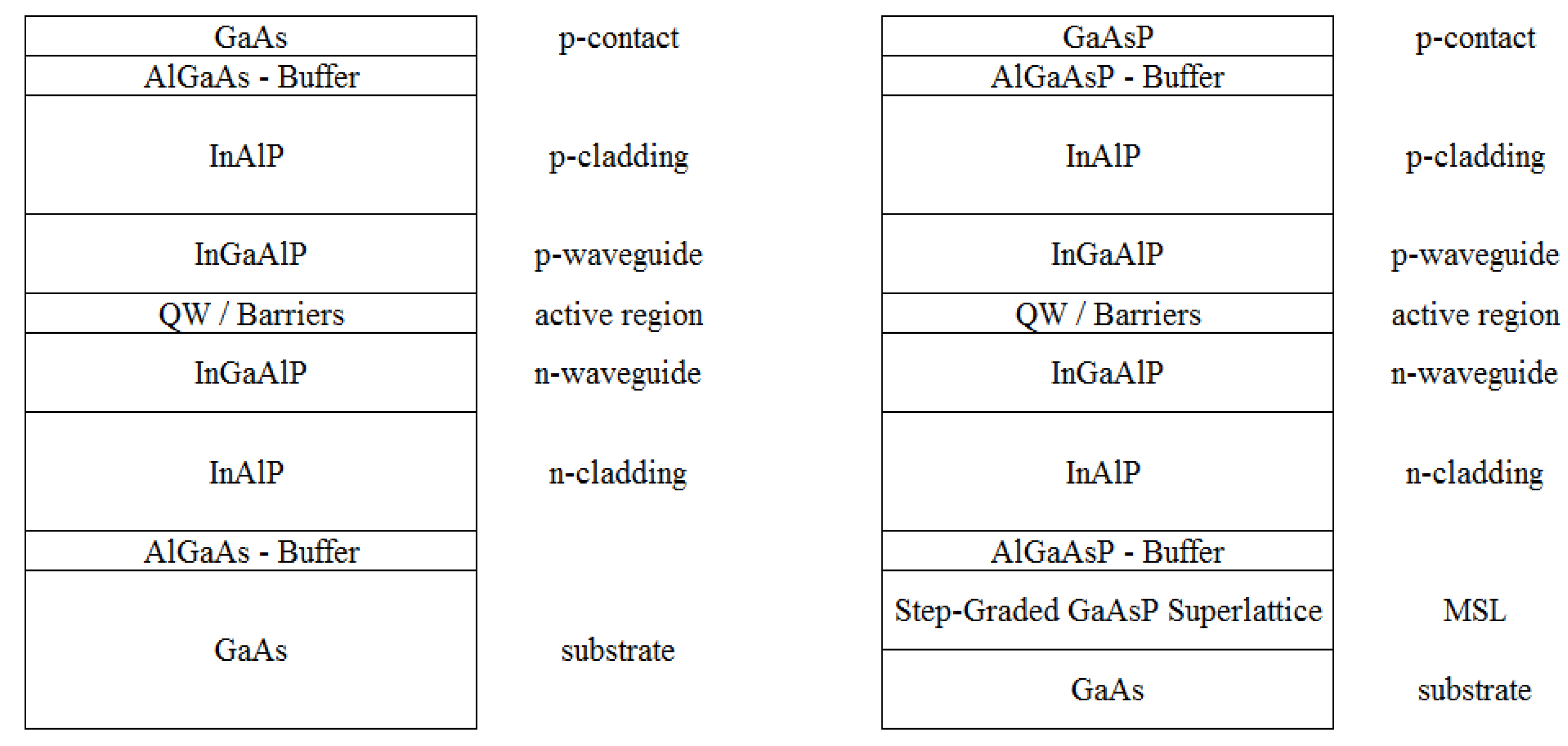

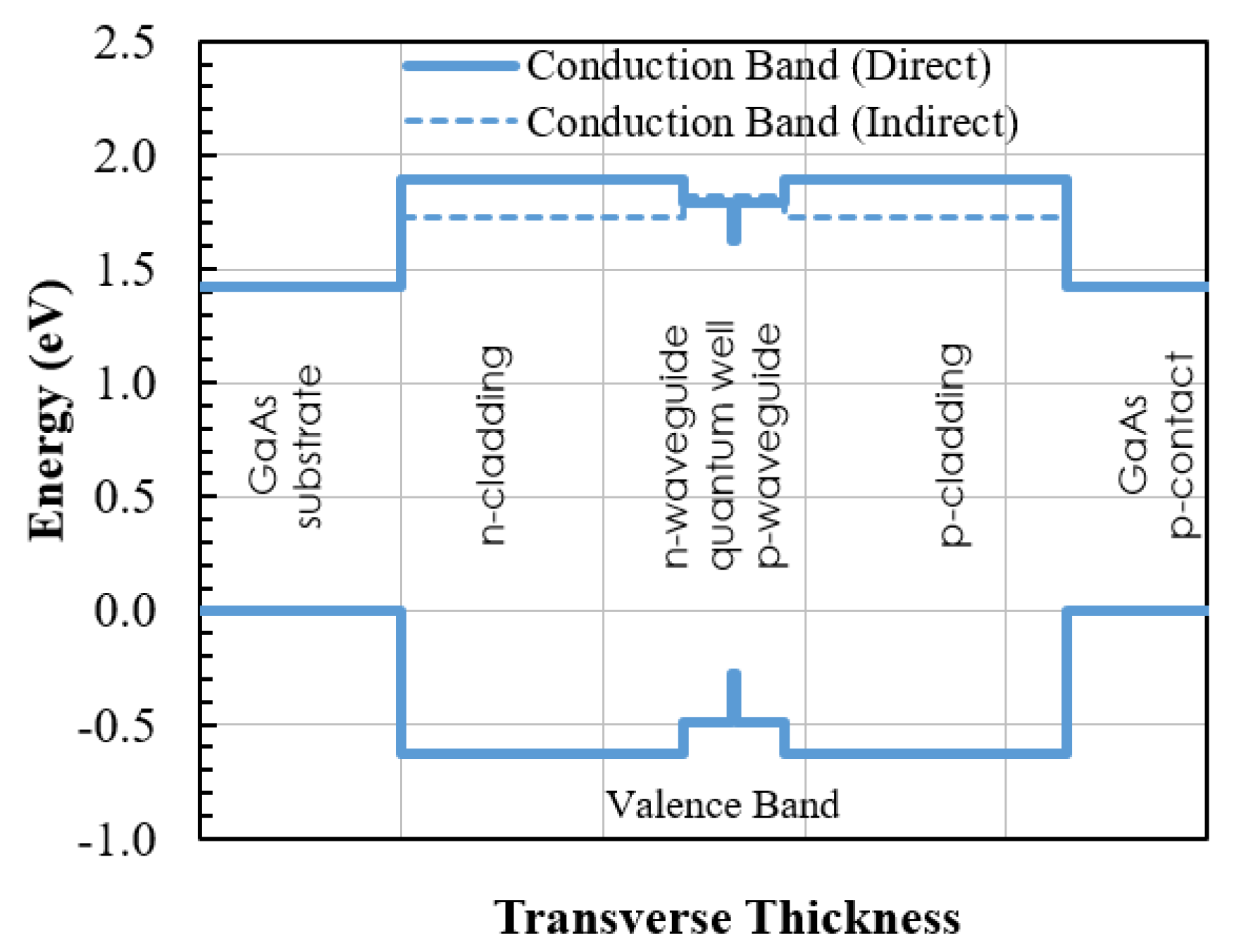

2.3. Laser Diode Structures

3. Results and Discussion

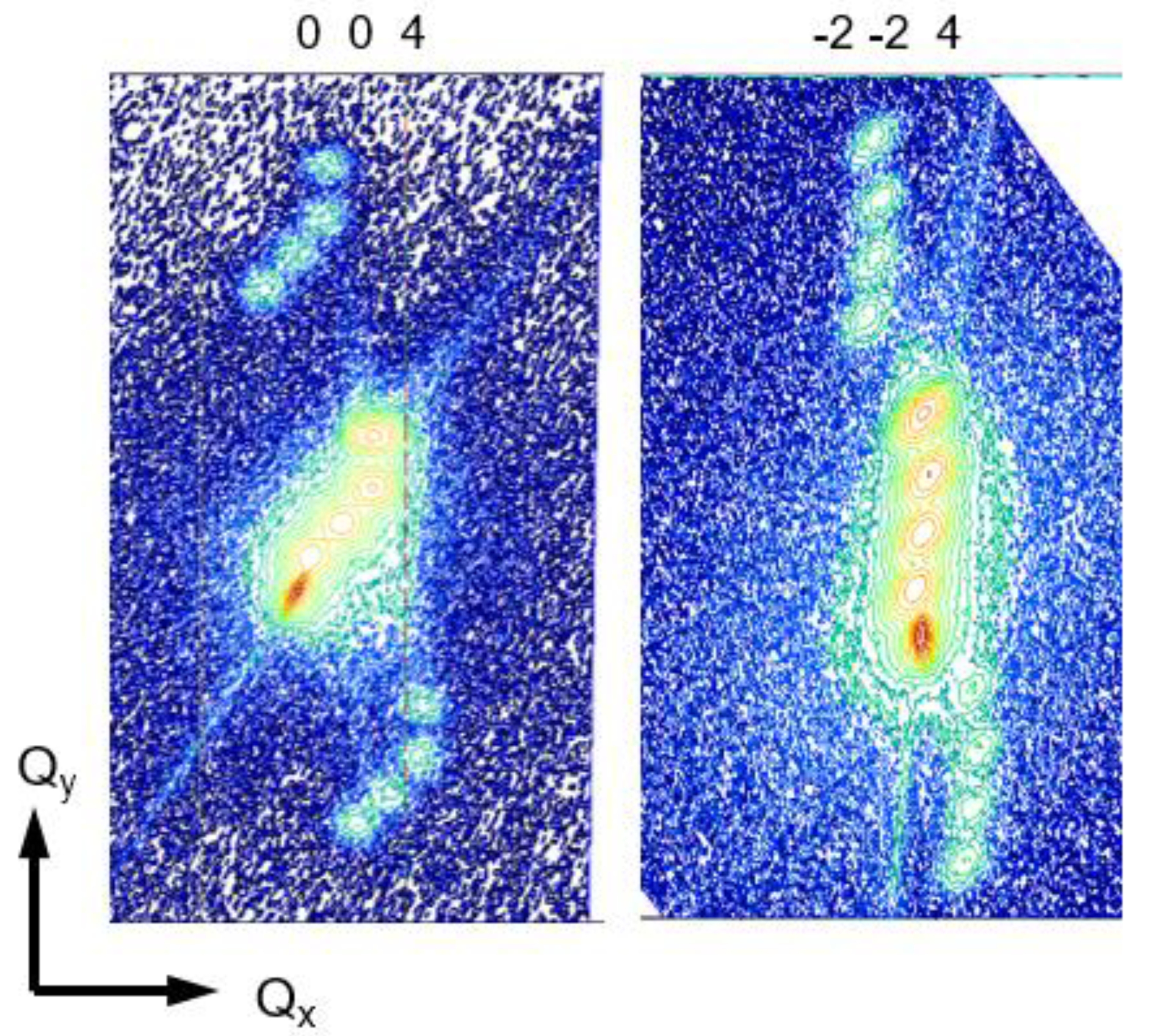

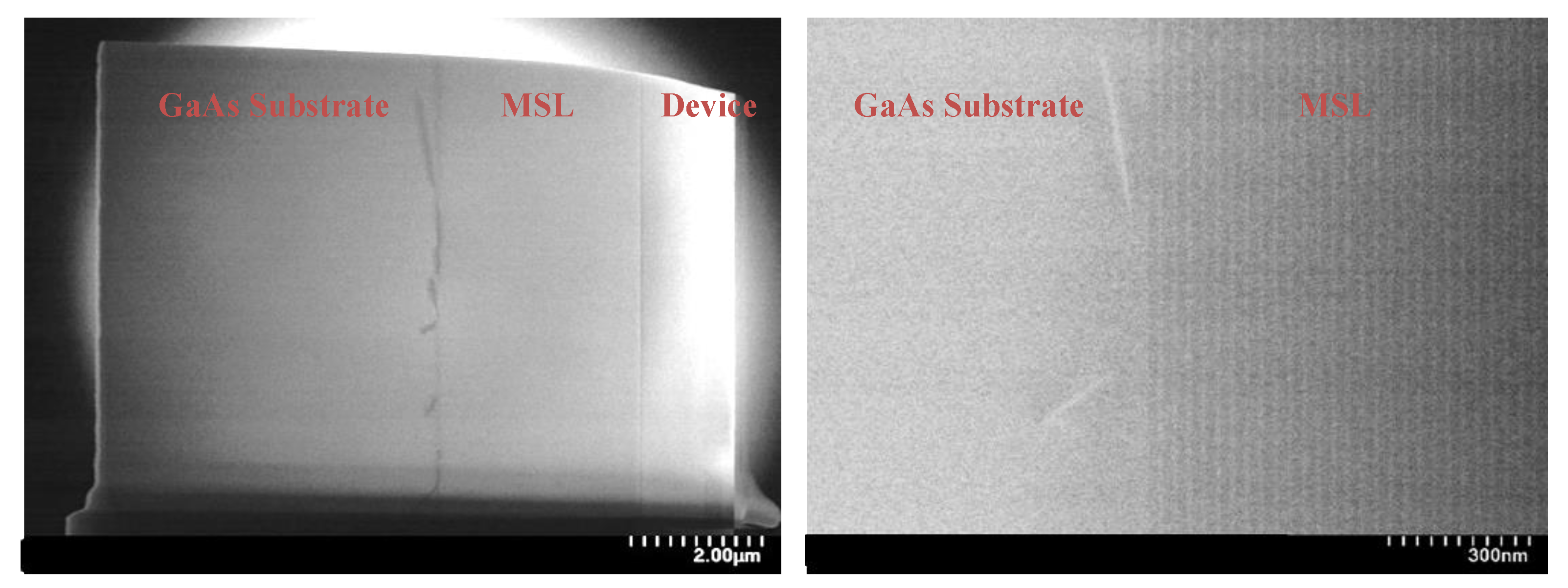

3.1. Metamorphic GaAsP

3.2. Laser Diode Structures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Overton, G. Mobile projection technologies proliferate. Laser Focus World 2007, 43, 67–70. [Google Scholar]

- Buckley, E. Holographic Laser Projection. J. Disp. Technol. 2011, 7, 135–140. [Google Scholar] [CrossRef]

- Angelov, I.P. Light enhancement of in vitro antitumor activity of galactosylated phthalocyanines. Photonics Lasers Med. 2016, 5, 123–140. [Google Scholar] [CrossRef]

- Nishida, T.; Shimada, N.; Ogawa, T.; Miyashita, M.; Yagi, T. Short Wavelength Limitation in High Power AlGaInP Laser Diodes. Proc. SPIE 2011, 2011, 791811. [Google Scholar]

- Saha, S.K. Different Approaches to Improve Metamorphic Buffer Layers Grown on a GaAs Substrate. Master’s Thesis, McMaster University, Hamilton, ON, Canada, 2009. [Google Scholar]

- Galiev, G.B.; Vasil’Evskii, I.S.; Pushkarev, S.S.; Klimov, E.A.; Imamov, R.M.; Buffat, P.A.; Dwir, B.; Suvorova, E.I. Metamorphic InAlAs/InGaAs/InAlAs/GaAs HEMT heterostructures containing strained superlattices and inverse steps in the metamorphic buffer. J. Cryst. Growth 2013, 366, 55–60. [Google Scholar] [CrossRef]

- Fischer, R.; Morkoc, H.; Neumann, D.A.; Zabel, H.; Choi, C.; Otsuka, N.; Longerbone, M.; Erickson, L.P. Material properties of high-quality GaAs epitaxial layers grown on Si substrates. J. Appl. Phys. 1986, 60, 1640–1647. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Nishioka, T.; Sugo, M. Analysis of strained-layer superlattice effects on dislocation density reduction in GaAs on Si substrates. Appl. Phys. Lett. 1989, 54, 1. [Google Scholar] [CrossRef]

- Kim, H.; Shi, B.; Lingley, Z.; Li, Q.; Rajeev, A.; Brodie, M.; Lau, K.M.; Kuech, T.F.; Sin, Y.; Mawst, L.J. Electrically injected 1.64 µm emitting In0.65Ga0.35As 3-QW laser diodes grown on mismatched substrates by MOVPE. Opt. Express 2019, 27, 33205–33216. [Google Scholar] [CrossRef] [PubMed]

- Matthews, J.W. Defects associated with the accommodation of misfit between crystals. J. Vac. Sci. Technol. 1975, 12, 126–133. [Google Scholar] [CrossRef]

- Matthews, J.W.; Blakeslee, A.E. Defects in epitaxial multilayers. J. Cryst. Growth 1974, 27, 118–125. [Google Scholar] [CrossRef]

- Bour, D.P. AlGaInP Quantum Well Lasers. In Quantum Well Lasers; Zory, P.S., Ed.; Academic Press: London, UK, 1993; pp. 415–453. [Google Scholar]

- Petroff, P.M.; Weisbuch, C.; Dingle, R.; Gossard, A.C.; Wiegmann, W. Luminescence properties of GaAs-Ga(1-x)Al(x)As double heterostructures and multiquantum-well superlattices grown by molecular beam epitaxy. Appl. Phys. Lett. 1981, 38, 965–967. [Google Scholar] [CrossRef]

- Lee, D.; Park, M.S.; Tang, Z.; Luo, H.; Beresford, R.; Wie, C.R. Characterization of metamorphic InxAl1−xAs/GaAs buffer layers using reciprocal space mapping. J. Appl. Phys. 2007, 101, 063523-1-8. [Google Scholar] [CrossRef] [Green Version]

- Schulte, K.L.; Strand, M.T.; Kuech, T.F. Evolution of epilayer tilt in thick In(x)Ga(1-x)As metamorphic buffer layers grown by hydride vapor phase epitaxy. J. Cryst. Growth 2015, 426, 283–286. [Google Scholar] [CrossRef] [Green Version]

- Bour, D.P.; Geels, R.S.; Treat, D.W.; Paoli, T.L.; Ponce, F.; Thornton, R.L.; Krusor, B.S.; Bringans, R.D.; Welch, D.F. Strained GaxIn1-xP/(AlGa)0.5In0.5P Heterostructures and Quantum-Well Laser Diodes. J. Quantum Electron. 1994, 30, 593–607. [Google Scholar] [CrossRef]

- Yagi, T.; Kuramoto, K.; Kadoiwa, K.; Wakamatsu, R.; Miyashita, M. Reliability study on high power 638-nm triple emitter broad area laser diode. Proc. SPIE 2016, 9733, 973305. [Google Scholar]

- Nishida, T.; Kuramoto, K.; Iwai, Y.; Fujita, T.; Yagi, T. Multiemitter 638-nm high-power broad area laser diodes for display application. Opt. Eng. 2019, 58, 086113. [Google Scholar] [CrossRef]

| Linearly-Graded | Step-Graded MBL | MSL | |

|---|---|---|---|

| MBL | (10 Steps) | (4 Stages) | |

| RMS Roughness (nm) | 6.52 | 5.14 | 1.73 |

| TDD (cm−2) | 1.1 × 106 | 3.0 × 105 | 7.1 × 104 |

| Barrier | Well | ||||

|---|---|---|---|---|---|

| Estimated Net P Fraction | In-Plane Lattice Const. (Å) | Out-of-Plane Lattice Const. (Å) | Out-of-Plane Lattice Const. (Å) | Relative Tilt to <111>A (Degrees) | |

| Substrate | 0.000 | 5.653 | |||

| MSL Stage 1 | 0.046 | 5.644 | 5.571 | 5.720 | 0.048 |

| MSL Stage 2 | 0.085 | 5.637 | 5.560 | 5.711 | 0.129 |

| MSL Stage 3 | 0.136 | 5.626 | 5.550 | 5.701 | 0.219 |

| MSL Stage 4 | 0.176 | 5.620 | 5.538 | 5.687 | 0.231 |

| Laser Diode Design | Baseline | Optimization | Baseline on MSL | |

|---|---|---|---|---|

| Parameter | ||||

| Internal Quantum Efficiency, ηi | 0.900 | 0.918 | 0.977 | |

| Internal Loss, αi (cm⁻¹) | 2.38 | 1.97 | 3.96 | |

| Transparency Current Density, Jtr (A/cm2) | 203.1 | 186.0 | 173.5 | |

| Characteristic Temperature, T0 (K) | 61 | 77 | 90 | |

| Characteristic Temperature, T1 (K) | 221 | 266 | 299 | |

| Polarization | TM | TM | TE | |

| CW Center Wavelength (nm) | 633.6 | 637.8 | 639.4 | |

| CW Peak PCE (%) | 39.0 | 45.0 | 35.5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruder, S.; Earles, T.; Galstad, C.; Klaus, M.; Olson, D.; Mawst, L.J. High-Power, High-Efficiency Red Laser Diode Structures Grown on GaAs and GaAsP Metamorphic Superlattices. Photonics 2022, 9, 436. https://doi.org/10.3390/photonics9070436

Ruder S, Earles T, Galstad C, Klaus M, Olson D, Mawst LJ. High-Power, High-Efficiency Red Laser Diode Structures Grown on GaAs and GaAsP Metamorphic Superlattices. Photonics. 2022; 9(7):436. https://doi.org/10.3390/photonics9070436

Chicago/Turabian StyleRuder, Steven, Tom Earles, Christian Galstad, Michael Klaus, Don Olson, and Luke J. Mawst. 2022. "High-Power, High-Efficiency Red Laser Diode Structures Grown on GaAs and GaAsP Metamorphic Superlattices" Photonics 9, no. 7: 436. https://doi.org/10.3390/photonics9070436

APA StyleRuder, S., Earles, T., Galstad, C., Klaus, M., Olson, D., & Mawst, L. J. (2022). High-Power, High-Efficiency Red Laser Diode Structures Grown on GaAs and GaAsP Metamorphic Superlattices. Photonics, 9(7), 436. https://doi.org/10.3390/photonics9070436