Stories Told by Publications about the Relationship between Industry 4.0 and Lean: Systematic Literature Review and Future Research Agenda

Abstract

:1. Introduction

2. Theoretical Background

2.1. Industry 4.0

2.2. Lean Manufacturing and Its Key Concepts

3. Methods

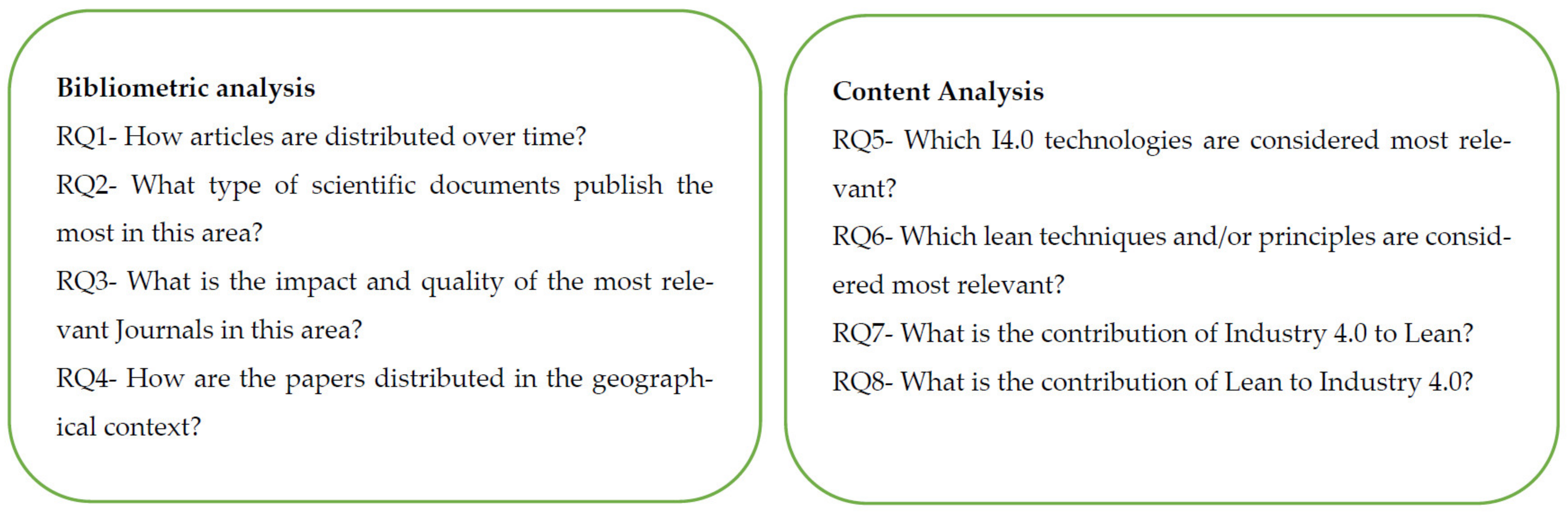

3.1. Motivation and Research Question

3.2. Research Formalities—Articles’ Selection

3.2.1. Research Formula

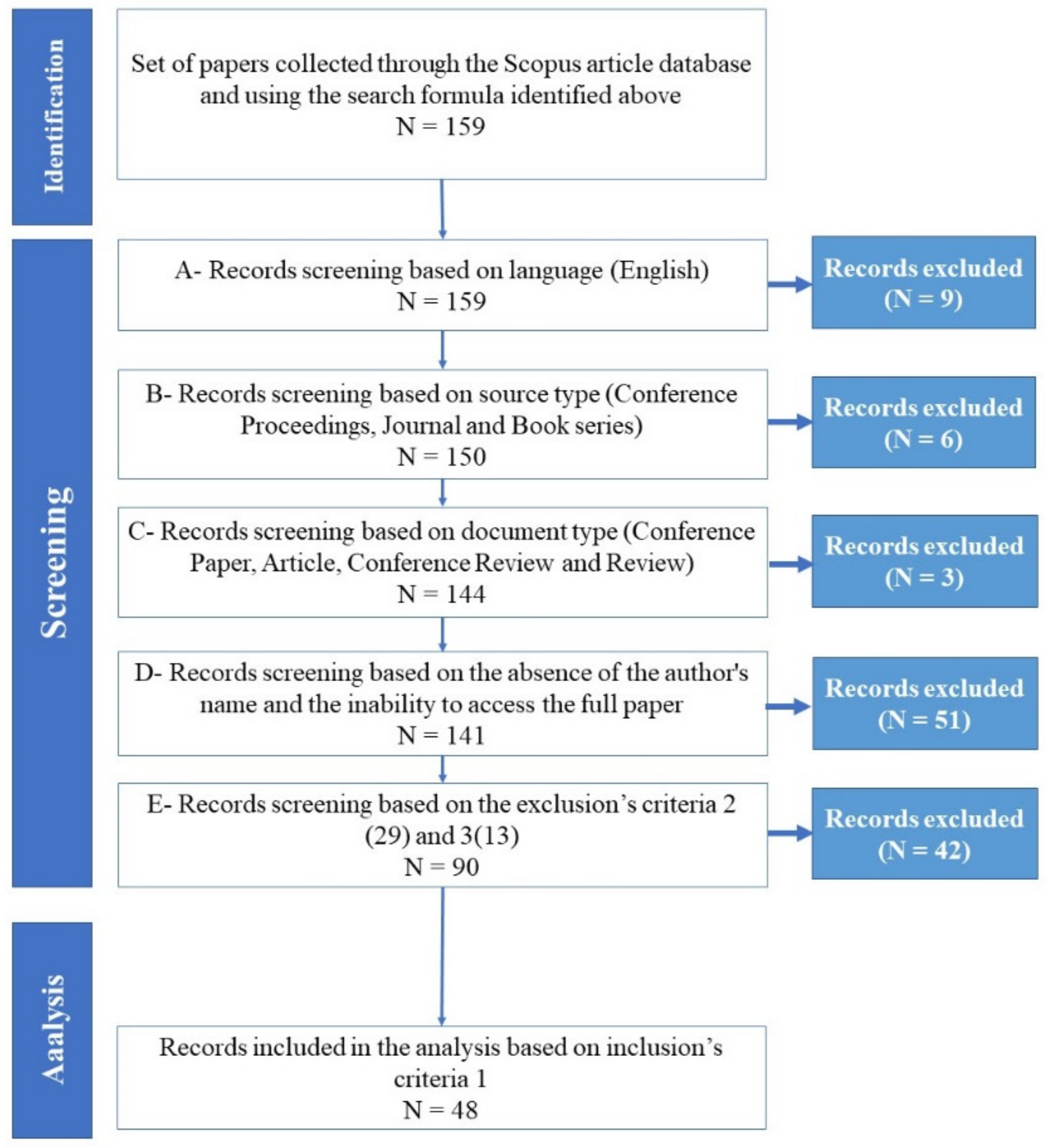

3.2.2. Exclusion and Inclusion Criteria—PRISMA Method

4. Results of Systematic Literature Review Study

4.1. Bibliometric Analysis

- RQ1: How Articles Are Distributed over Time?

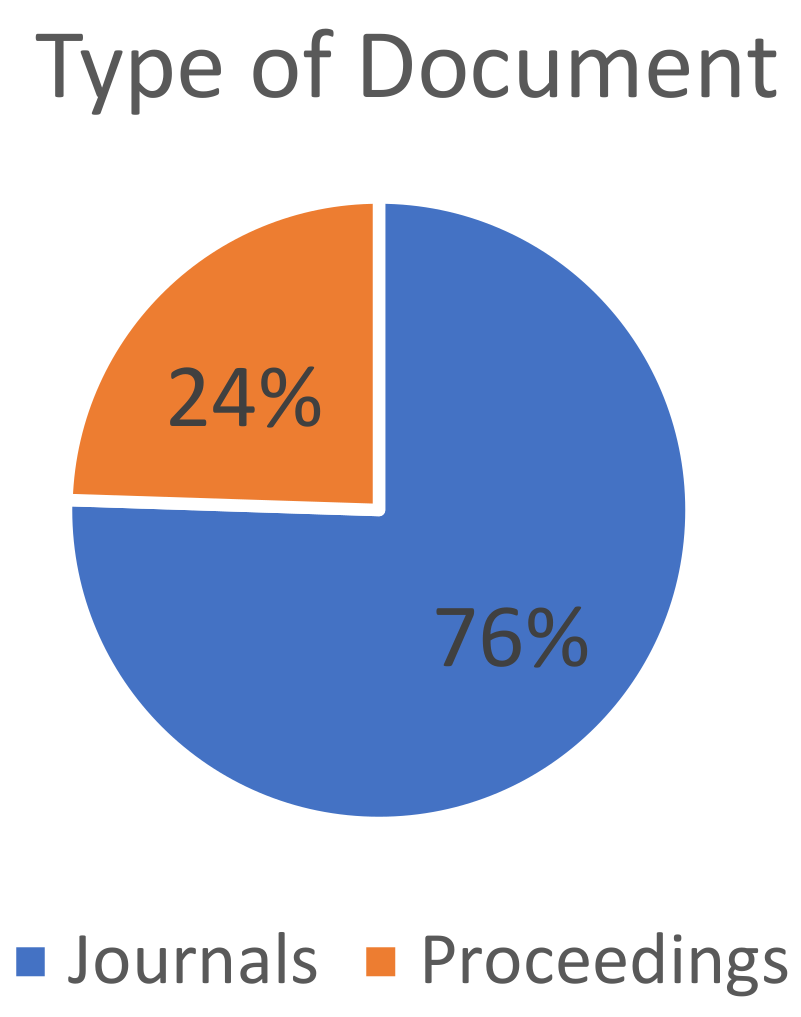

- RQ2: What Type of Scientific Documents Publish the Most in This Area?

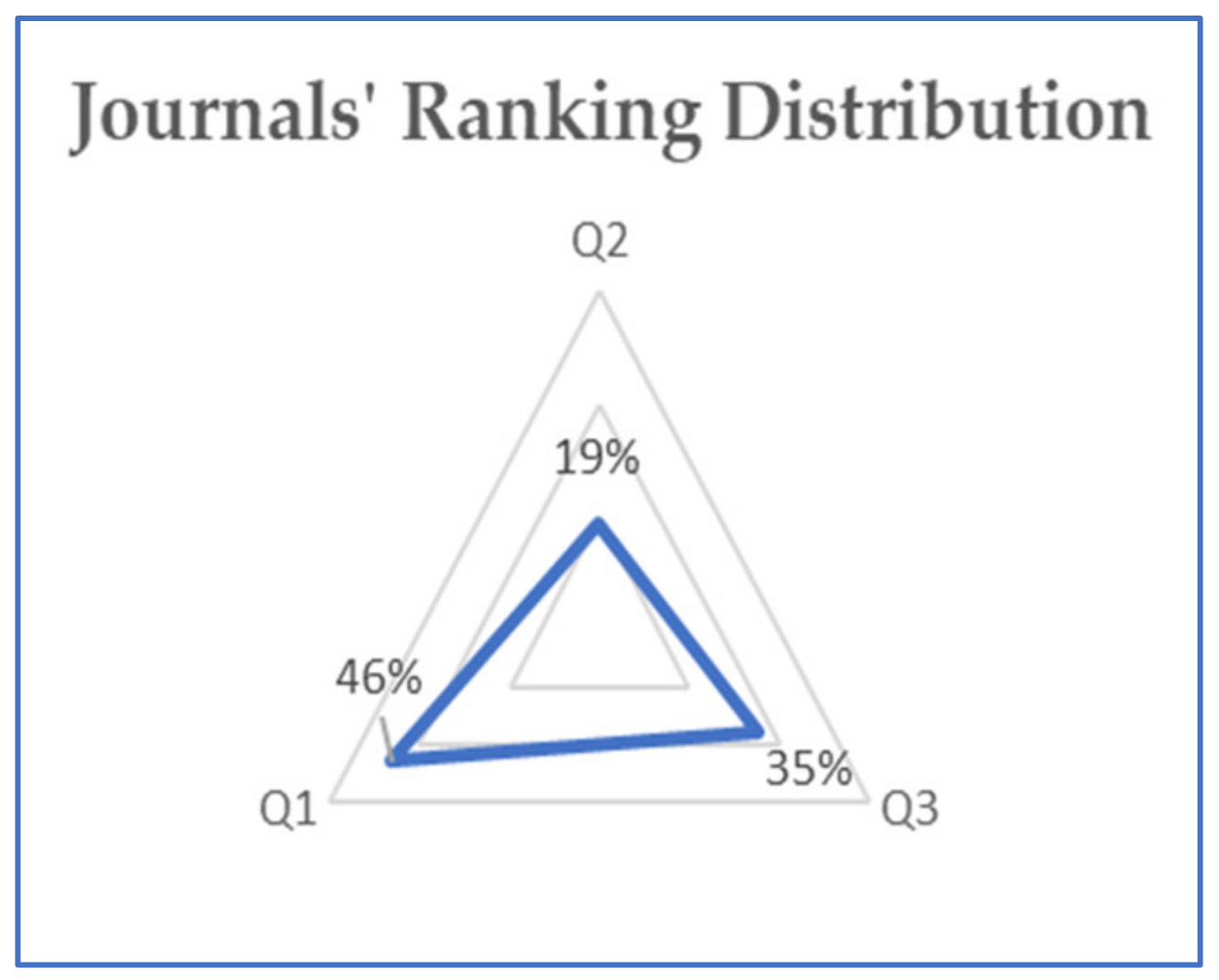

- RQ3: What is the Impact and Quality of the Most Relevant Journals in this Area?

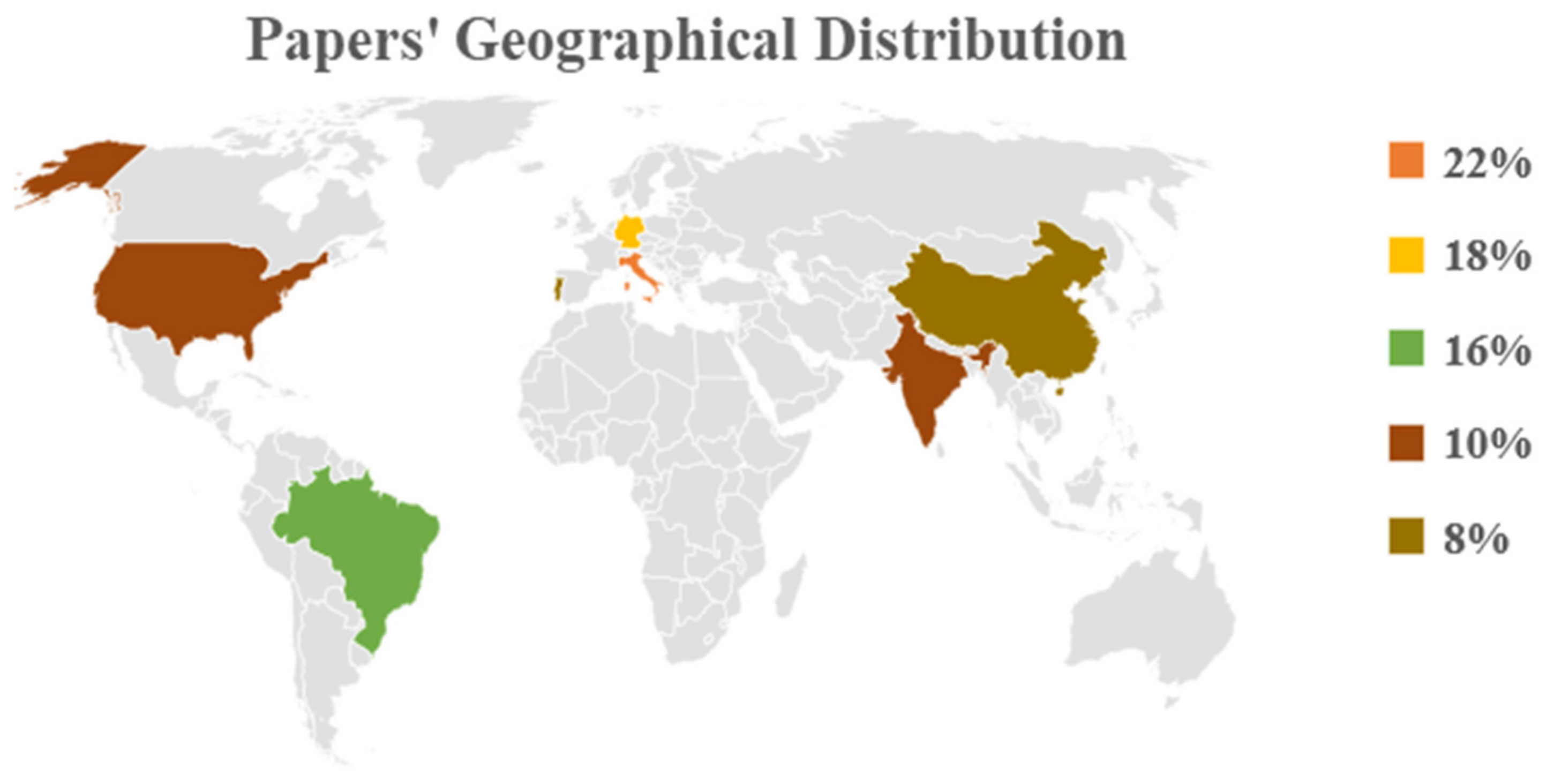

- RQ4: How Are the Papers Distributed in the Geographical Context?

4.2. Content Analysis

- RQ5: Which I4.0 Technologies Are Considered Most Relevant?

- RQ6: Which Lean Techniques and/or Principles Are Considered Most Relevant?

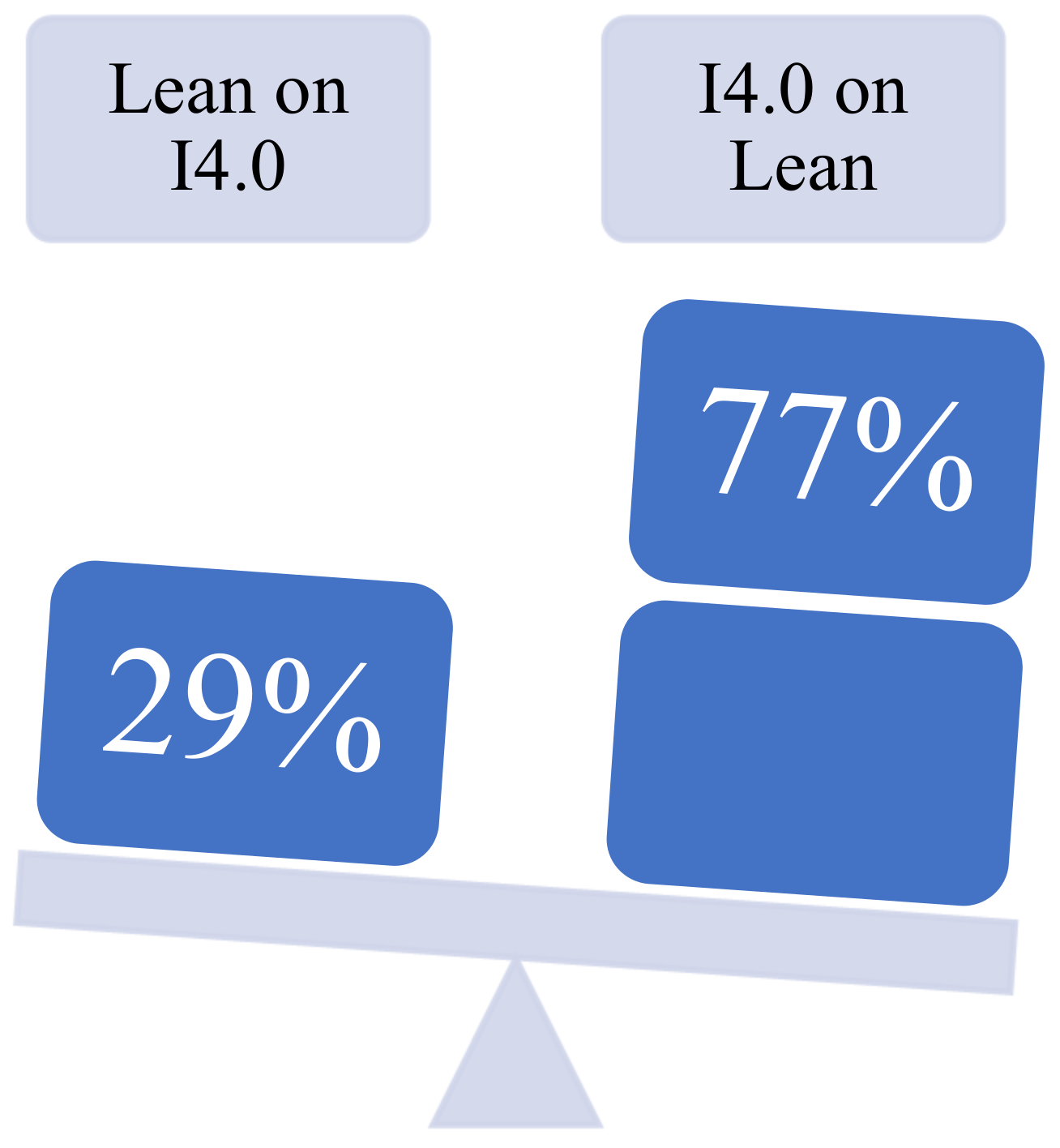

- RQ7: What is the Contribution of Industry 4.0 to Lean?

- RQ8: What is the Contribution of Lean to Industry 4.0?

5. Discussion

6. Conclusions

- Empirical validation of the synergies evidenced is necessary, either between I4.0 and lean or between lean and I4.0;

- A research more oriented to the impact of Lean in I4.0 is essential, with a view to the consolidation of results;

- For each implementation of technology belonging to the digital paradigm in support of a particular Lean principle, performance indicators should be measured to validate the impact.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pereira, A.C.; Dinis-Carvalho, J.; Alves, A.C.; Arezes, P. How Industry 4.0 can enhance lean practices. FME Trans. 2019, 47, 810–822. [Google Scholar] [CrossRef] [Green Version]

- Pagliosa, M.; Tortorella, G.; Ferreira, J.C.E. Industry 4.0 and Lean Manufacturing: A systematic literature review and future research directions. J. Manuf. Technol. Manag. 2019. [Google Scholar] [CrossRef]

- Rossini, M.; Costa, F.; Tortorella, G.L.; Portioli-Staudacher, A. The interrelation between Industry 4.0 and lean production: An empirical study on European manufacturers. Int. J. Adv. Manuf. Technol. 2019, 102, 3963–3976. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Rossini, M.; Costa, F.; Portioli Staudacher, A.; Sawhney, R. A comparison on Industry 4.0 and Lean Production between manufacturers from emerging and developed economies. Total Qual. Manag. Bus. Excell. 2019, 1–22. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D. Implementation of industry 4.0 and lean production in brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Rafique, M.Z.; Ab Rahman, M.N.; Saibani, N.; Arsad, N.; Saadat, W. RFID impacts on barriers affecting lean manufacturing. Ind. Manag. Data Syst. 2016, 116, 1585–1616. [Google Scholar] [CrossRef]

- Lugert, A.; Batz, A.; Winkler, H. Empirical assessment of the future adequacy of value stream mapping in manufacturing industries. J. Manuf. Technol. Manag. 2018, 29, 886–906. [Google Scholar] [CrossRef]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 technologies on Lean principles. Int. J. Prod. Res. 2020, 58, 1644–1661. [Google Scholar] [CrossRef]

- Pereira, A.G.; Lima, T.M.; Charrua-Santos, F. Society 5.0 as a result of the technological evolution: Historical approach. Adv. Intell. Syst. Comput. 2020, 1018, 700–705. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Dombrowski, U.; Richter, T. The Lean Production System 4.00 Framework—Enhancing Lean Methods by Industrie 4.0. In IFIP International Federation for Information Processing 2018; Springer International Publishing: Basel, Switzerland, 2018; Volume 536, pp. 473–481. ISBN 978-3-319-99706-3. [Google Scholar]

- Sader, S.; Husti, I.; Daróczi, M. Industry 4.0 as a key enabler toward successful implementation of total quality management practices. Period. Polytech. Soc. Manag. Sci. 2019, 27, 131–140. [Google Scholar] [CrossRef] [Green Version]

- Ayabakan, M.; Yilmaz, E. Digitalization of the Kanban System. In Proceedings of the 2019 Portland International Conference on Management of Engineering and Technology, Portland, OR, USA, 25–27 August 2019. [Google Scholar]

- Cattaneo, L.; Rossi, M.; Negri, E.; Powell, D.; Terzi, S. Lean thinking in the digital Era. In Product Lifecycle Management and the Industry of the Future; Íos, J., Bernard, A., Bouras, A., Foufou, S., Eds.; PLM: Seville, Spain, 2017; Volume 517, pp. 371–381. ISBN 9783319729046. [Google Scholar]

- Molenda, P.; Jugenheimer, A.; Haefner, C.; Oechsle, O.; Karat, R. Methodology for the visualization, analysis and assessment of information processes in manufacturing companies. Procedia CIRP 2019, 84, 5–10. [Google Scholar] [CrossRef]

- Rossit, D.A.; Tohmé, F.; Frutos, M. Production planning and scheduling in Cyber-Physical Production Systems: A review. Int. J. Comput. Integr. Manuf. 2019, 32, 385–395. [Google Scholar] [CrossRef]

- Cimini, C.; Boffelli, A.; Lagorio, A.; Kalchschmidt, M.; Pinto, R. How do industry 4.0 technologies influence organisational change? An empirical analysis of Italian SMEs. J. Manuf. Technol. Manag. 2020. [Google Scholar] [CrossRef]

- Peters, E.; Klieštik, T.; Musa, H.; Durana, P. Product Decision-Making Information Systems, Real-Time Big Data Analytics, and Deep Learning-enabled Smart Process Planning in Sustainable Industry 4.0. J. Self-Gov. Manag. Econ. 2020, 8, 16–22. [Google Scholar]

- Rosienkiewicz, M.; Kowalski, A.; Helman, J.; Zbieć, M. Development of lean hybrid furniture production control system based on glenday sieve, artificial neural networks and simulation modeling. Drv. Ind. 2018, 69, 163–173. [Google Scholar] [CrossRef]

- Bittencourt, V.L.; Alves, A.C.; Leão, C.P. Lean Thinking contributions for Industry 4.0: A systematic literature review. IFAC-PapersOnLine 2019, 52, 904–909. [Google Scholar] [CrossRef]

- Lucato, W.C.; Pacchini, A.P.T.; Facchini, F.; Mummolo, G. Model to evaluate the Industry 4.0 readiness degree in Industrial Companies. IFAC-PapersOnLine 2019, 52, 1808–1813. [Google Scholar] [CrossRef]

- Li, C.H.; Lau, H.K. Embedding CSPC database with CPS to enhance toy product safety. In Proceedings of the 2019 IEEE International Conference on Industrial Technology (ICIT), Melbourne, VIC, Australia, 13–15 February 2019; pp. 1580–1584. [Google Scholar] [CrossRef]

- Balaji, V.; Venkumar, P.; Sabitha, M.S.; Amuthaguka, D. DVSMS: Dynamic value stream mapping solution by applying IIoT. Sadhana Acad. Proc. Eng. Sci. 2020, 45, 38. [Google Scholar] [CrossRef]

- Gambhire, G.; Gujar, T.; Pathak, S. Business Potential and Impact of Industry 4.0 in Manufacturing Organizations. In Proceedings of the 2018 Fourth International Conference on Computing Communication Control and Automation (ICCUBEA), Pune, India, 16–18 August 2018. [Google Scholar] [CrossRef]

- Malik, A.A.; Bilberg, A. Complexity-based task allocation in human-robot collaborative assembly. Ind. Rob. 2019, 46, 471–480. [Google Scholar] [CrossRef]

- Kliestik, T.; Nica, E.; Musa, H.; Poliak, M.; Mihai, E.A. Networked, smart, and responsive devices in industry 4.0 manufacturing systems. Econ. Manag. Financ. Mark. 2020, 15, 23–29. [Google Scholar] [CrossRef]

- Rossini, M.; Costa, F.; Staudacher, A.P.; Tortorella, G. Industry 4.0 and lean production: An empirical study. IFAC-PapersOnLine 2019, 52, 42–47. [Google Scholar] [CrossRef]

- Dutta, G.; Kumar, R.; Sindhwani, R.; Singh, R.K. Digital transformation priorities of India’s discrete manufacturing SMEs—A conceptual study in perspective of Industry 4.0. Compet. Rev. 2020, 30, 289–314. [Google Scholar] [CrossRef]

- Ma, J.; Wang, Q.; Zhao, Z. SLAE–CPS: Smart lean automation engine enabled by cyber-physical systems technologies. Sensors 2017, 17, 1500. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wagner, T.; Herrmann, C.; Thiede, S. Industry 4.0 Impacts on Lean Production Systems. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Erro-Garcés, A. Industry 4.0: Defining the research agenda. Benchmarking 2019. [Google Scholar] [CrossRef]

- Ramadan, M.; Salah, B.; Othman, M.; Ayubali, A.A. Industry 4.0-based real-time scheduling and dispatching in lean manufacturing systems. Sustainability 2020, 12, 2272. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Kim, J.; Sadri, A.; Dowey, S.; Dargusch, M.S. Industry 4.0: Development of a multi-agent system for dynamic value stream mapping in SMEs. J. Manuf. Syst. 2019, 52, 1–12. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Pradhan, N.; Macias de Anda, E.; Trevino Martinez, S.; Sawhney, R.; Kumar, M. Designing lean value streams in the fourth industrial revolution era: Proposition of technology-integrated guidelines. Int. J. Prod. Res. 2020, 58, 5020–5033. [Google Scholar] [CrossRef]

- Pekarčíková, M.; Trebuňa, P.; Kliment, M. Digitalization effects on the usability of lean tools. Acta Logist. 2019, 6, 9–13. [Google Scholar] [CrossRef]

- Haddud, A.; Khare, A. Digitalizing supply chains potential benefits and impact on lean operations. Int. J. Lean Six Sigma 2020. [Google Scholar] [CrossRef]

- Varela, L.; Araújo, A.; Ávila, P.; Castro, H.; Putnik, G. Evaluation of the relation between lean manufacturing, industry 4.0, and sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.S.A.; Mohamad, E.; Abdul Rahman, A.A. Enhancement of overall equipment effectiveness (OEE) data by using simulation as decision making tools for line balancing. Indones. J. Electr. Eng. Comput. Sci. 2020, 18, 1040–1047. [Google Scholar] [CrossRef]

- Santos, J.; Muñoz-Villamizar, A.; Ormazábal, M.; Viles, E. Using problem-oriented monitoring to simultaneously improve productivity and environmental performance in manufacturing companies. Int. J. Comput. Integr. Manuf. 2019, 32, 183–193. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Giglio, R.; van Dun, D.H. Industry 4.0 adoption as a moderator of the impact of lean production practices on operational performance improvement. Int. J. Oper. Prod. Manag. 2019, 39, 860–886. [Google Scholar] [CrossRef]

- Yeen Gavin Lai, N.; Hoong Wong, K.; Halim, D.; Lu, J.; Siang Kang, H. Industry 4.0 Enhanced Lean Manufacturing. In Proceedings of the 2019 8th international conference on Industrial technology and management (ICITM), Cambridge, UK, 2–4 March 2019; pp. 206–211. [Google Scholar] [CrossRef]

- Kolberg, D.; Knobloch, J.; Zühlke, D. Towards a lean automation interface for workstations. Int. J. Prod. Res. 2017, 55, 2845–2856. [Google Scholar] [CrossRef]

- Kolberg, D.; Zühlke, D. Lean Automation enabled by Industry 4.0 Technologies. IFAC-PapersOnLine 2015, 28, 1870–1875. [Google Scholar] [CrossRef]

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 2018, 56, 848–861. [Google Scholar] [CrossRef] [Green Version]

- Meissner, A.; Müller, M.; Hermann, A.; Metternich, J. Digitalization as a catalyst for lean production: A learning factory approach for digital shop floor management. Procedia Manuf. 2018, 23, 81–86. [Google Scholar] [CrossRef]

- Anegón, F.D.M.-; Chinchilla-Rodríguez, Z.; Vargas-Quesada, B.; Corera-Álvarez, E.; Muñoz-Fernández, F.J.; González-Molina, A.; Herrero-Solana, V. Coverage analysis of Scopus: A journal metric approach. Scientrometrics 2007, 73, 53–78. [Google Scholar] [CrossRef] [Green Version]

- Mrugalska, B.; Wyrwicka, M.K. Towards Lean Production in Industry 4.0. Procedia Eng. 2017, 182, 466–473. [Google Scholar] [CrossRef]

- Bortolotti, T.; Boscari, S.; Danese, P. Successful lean implementation: Organizational culture and soft lean practices. Int. J. Prod. Econ. 2015, 160, 182–201. [Google Scholar] [CrossRef] [Green Version]

- Ante, G.; Facchini, F.; Mossa, G.; Digiesi, S. Developing a key performance indicators tree for lean and smart production systems. IFAC-PapersOnLine 2018, 51, 13–18. [Google Scholar] [CrossRef]

- Phuong, N.A.; Guidat, D.-I.T. Sustainable value stream mapping and technologies of Industry 4.0 in manufacturing process reconfiguration: A case study in an apparel company. In Proceedings of the 2018 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Singapore, 31 July–2 August 2018; pp. 85–90. [Google Scholar]

- Marcello, B.; Davide, C.; Marco, F.; Roberto, G.; Leonardo, M.; Luca, P. An ensemble-learning model for failure rate prediction. Procedia Manuf. 2020, 42, 41–48. [Google Scholar] [CrossRef]

- Passath, T.; Mertens, K. Decision Making in Lean Smart Maintenance: Criticality Analysis as a Support Tool. IFAC-PapersOnLine 2019, 52, 364–369. [Google Scholar] [CrossRef]

- Nicoletti, B. Lean and digitized innovation. In Proceedings of the 2014 International Conference on Engineering, Technology and Innovation (ICE), Bergamo, Italy, 23–25 June 2014. [Google Scholar] [CrossRef]

- Rauch, E.; Dallasega, P.; Matt, D.T. Critical Factors for Introducing Lean Product Development to Small and Medium sized Enterprises in Italy. Procedia CIRP 2017, 60, 362–367. [Google Scholar] [CrossRef]

- Qu, Y.; Ming, X.; Ni, Y.; Li, X.; Liu, Z.; Zhang, X.; Xie, L. An integrated framework of enterprise information systems in smart manufacturing system via business process reengineering. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018. [Google Scholar] [CrossRef]

- Constantinescu, C.L.; Francalanza, E.; Matarazzo, D. Towards knowledge capturing and innovative human-system interface in an open-source factory modelling and simulation environment. Procedia CIRP 2015, 33, 23–28. [Google Scholar] [CrossRef]

- Teixeira, L.; Ferreira, C.; Santos, B.S. An Information Management Framework to Industry 4.0: A Lean Thinking Approach. In International Conference on Human Systems Engineering and Design; Springer International Publishing: Basel, Switzerland, 2019; Volume 3, pp. 215–220. ISBN 9783030020538. [Google Scholar]

- Črešnar, R.; Potočan, V.; Nedelko, Z. Speeding Up the Implementation of Industry 4.0 with Management Tools: Empirical Investigations in Manufacturing Organizations. Sensors 2020, 20, 3469. [Google Scholar] [CrossRef]

| Scope | String |

|---|---|

| Industry 4.0 | (“Industry 4.0” OR “fourth industrial revolution” OR digitization* OR “Digital Twin”) |

| Lean | (lean OR Kaizen OR “Value Stream mapping” OR “Just-in-time” OR “Total productive maintenance” OR “Kanban” OR “Total Quality Management”) |

| Impact between the two concepts | (Effect* OR influence* OR impact* OR response* OR reaction*) |

| Criteria Number | Criteria Specification |

|---|---|

| 1 | The paper investigates I4.0 and Lean, showing contributions of both concepts to each other, carrying out systematic reviews, case studies, practical applications or surveys design and distribution. |

| 2 | The paper investigates in an exploratory way about I4.0 and Lean, evidencing contributions of both concepts to each other, creating frameworks that initiate ideas for more practical studies. |

| 3 | The paper refers to I4.0 and Lean concepts in a broad way just for contextualize, with no interconnection of the terms. |

| 4 | The paper uses the notions of lean and I4.0, however it applies them in another area than manufacturing sector. |

| Article | Journal/Proceedings | Citations | Year |

|---|---|---|---|

| Kolberg et al. | IFAC-PapersOnline | 164 | 2015 |

| Yin et al. | International Journal of Production Research | 83 | 2018 |

| Tortorella et al. | International Journal of Production Research | 79 | 2018 |

| Wagner et al. | Procedia CIRP | 74 | 2017 |

| Kolberg et al. | International Journal of Production Research | 60 | 2017 |

| I4.0 Technologies | Frequency |

| Internet of Things | 47% |

| Big Data Analytics | 43% |

| Cloud Computing | 35% |

| Cyber-Physical Systems | 31% |

| Virtual Reality and Augmented Reality | 25% |

| Robotics | 22% |

| 3D Printing | 22% |

| Lean Principles and Tools | Frequency |

|---|---|

| Just-In-Time | 18% |

| Value Stream Mapping | 18% |

| Heijunka | 16% |

| Jidoka | 14% |

| Kaizen/Continuous Improvement | 14% |

| Andon | 12% |

| Kanban | 12% |

| Key Performance Indicators | 10% |

| Total Productive Maintenance | 10% |

| Single Minute Exchange of Die | 8% |

| Poka yoke | 6% |

| Visual Management | 4% |

| 5S | 4% |

| Just-in-Time | Standardization | Heijunka | Kaizen | Pull Flow | VSM | 5S’s | SMED | Andon | Jidoka | Kanban | Poka Yoke | TPM | KPI’s | Visual Management | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Augmented Reality | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x |

| Big Data Analytics | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x |

| Cloud Computing | x | x | x | x | x | x | x | x | x | x | x | x | x | x | x |

| Cyber-Physical Systems | x | x | x | x | x | x | x | x | x | x | x | x | x | x | - |

| Internet of Things | x | x | x | x | x | x | x | x | x | x | x | x | x | - | x |

| Robotics | x | x | - | x | x | x | x | x | - | x | x | x | x | - | - |

| Virtual Reality | x | x | x | x | - | x | x | - | - | - | - | - | - | - | - |

| Artificial Intelligence | - | x | x | - | - | - | - | - | x | - | - | - | - | - | - |

| 3D Printing | x | - | - | - | x | - | - | x | - | - | - | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salvadorinho, J.; Teixeira, L. Stories Told by Publications about the Relationship between Industry 4.0 and Lean: Systematic Literature Review and Future Research Agenda. Publications 2021, 9, 29. https://doi.org/10.3390/publications9030029

Salvadorinho J, Teixeira L. Stories Told by Publications about the Relationship between Industry 4.0 and Lean: Systematic Literature Review and Future Research Agenda. Publications. 2021; 9(3):29. https://doi.org/10.3390/publications9030029

Chicago/Turabian StyleSalvadorinho, Juliana, and Leonor Teixeira. 2021. "Stories Told by Publications about the Relationship between Industry 4.0 and Lean: Systematic Literature Review and Future Research Agenda" Publications 9, no. 3: 29. https://doi.org/10.3390/publications9030029

APA StyleSalvadorinho, J., & Teixeira, L. (2021). Stories Told by Publications about the Relationship between Industry 4.0 and Lean: Systematic Literature Review and Future Research Agenda. Publications, 9(3), 29. https://doi.org/10.3390/publications9030029