Exploring the Multi-Function Nature of Packaging in the Food Industry

Abstract

1. Introduction

- What are the elements of packaging that business executives recognize as being critical in the food supply chain?

- How (and if) are the views of executives differentiated concerning marketing, logistics, food technology and environmentally-friendly initiatives, with regard to the importance of the elements involved in food packaging? and

- Which manager is considered by the various executives of the food industry as the person who will make the final decision on what elements should be included in the packaging of the products offered?

2. Packaging Dimensions in the Food Sector

- Physical protection of products against damage, shock, vibration, temperature, heat, moisture, etc. during their handling and storage processes,

- Consumer health protection against microbial and bacterial contamination/spoilage, as well as climatic hazards of the products, keeping them healthy, clean, fresh, sterile and safe for their intended shelf life,

- Unitization of foods, sorted from one type of packaging to a bigger unit load, in order to facilitate their movement within the food supply chain. Primary packages (items) are grouped into secondary packaging units (e.g., cartons) and these in turn are grouped into tertiary packages transport packs, for example pallets.

- Provision of information to consumers on topics concerning the use, consumption, storage, and recycling of packaged foods.

- Attracting consumers to buy the product.

- Marketing: Silayoi and Speece [26] support the view that well-designed packaging attracts the attention of the consumer and is therefore an important tool in product differentiation. Furthermore, Wells et al. [27] and Keller [28] conclude that packaging can also serve as an effective communication tool. Many researchers have attempted to identify the elements of packaging that influence the buying behavior of consumers. Wells, Farley and Armstrong [27], as well as Butkeviciene, Stravinskiene and Rutelione [29] identify the factors that influence consumers’ purchase decisions. Vila and Ampuero [30] who examined the associations between different positioning strategies and the different graphic design variables and based on these associations, Simms and Trott [31] propose new product opportunities.

- Logistics Management: This is related to guidelines on how to optimize material flow and handling, warehousing functions, facilitation of transportation and distribution, the protection of both the products and the environment as well as the provision of information regarding the conditions and the placement of the product. Bowersox and Closs [21] identify the operational areas where the packaging positively influences the cost, monitoring or reducing the following: management (control) of inventory, product identification (of the packaging), handling of materials, picking and lead-time. Moreover, it contributes to increasing supply chain efficiency by facilitating procedural actions and reducing the respective errors. Lambert, Stock and Ellram [22] studied the positive influence of packaging on basic logistics operations, such as having more information available on the packaging, increased protection from the packaging, increased standardization and optimization in the use of available space.

- Food technology: This relates to information on the food/product, such as, for example, its nutrients, the existence of allergens, preparation/cooking instructions, information relating to production and best-by dates and whether the product is organic or certified. Packaging aims to preserve the quality and freshness of the food by maintaining its sensory characteristics, such as texture, color and flavor, as well as the nutritional value of high mineral and vitamin levels, and low chemical preservatives content. It informs the customer by describing the product and perhaps describing how to handle the package and use the product [32,33].

- Environmental information: This is principally aimed at reducing the environmental impact, reducing energy consumption, informing consumers about the option to reuse or recycle the packaging, etc. [34]. Of course, efforts to record the food product’s environmental footprint are not new, as from time to time various initiatives and programs have been designed and implemented, such as eco-friendly product labels, organic products and energy efficiency labels [35,36,37]. Recyclability of packaging in the food industry is a crucial step towards a circular economy. According to the Circular Economy Package proposed by European Commission, the target for recycling of packaging waste is 60% by 2020, 70% by 2025 and 80% by 2030 [38]. Other stated targets include 90% recycling for paper and 60% for packaging made of plastic by 2025, as well as 80% for packaging made of wood by 2030 [39]. Also for 2030: 90% recycling of all packaging consisting of iron, aluminum or glass.

3. Elements of Packaging in the Food Sector

4. Research Method

- Which are the elements of packaging that business executives recognize as critical in the food supply chain?

- How (and if) are the views of executives differentiated concerning marketing, logistics, food technology and environmentally-friendly initiatives, with regard to the importance of elements involved in food packaging?

- Which manager is considered by the various executives of the food industry as the person who will make the final decision on what elements should be included in the packaging of the products?

- The first section asked for information about the company,

- The second section tried to sketch the profile of the manager’s main role (marketing, logistics, food technology, or environmental) and

- The third section aimed to assess the significance of the packaging elements using a five-point Likert scale (from “1: Not significant” to “5: Very significant”). The 43 packaging elements that were provided at the Table 1 (Categorization of packaging elements for food products) are used.

- The fourth part included only two questions. The first question asked executives in the food industry to suggest the specific executive who would decide on which elements should be included/taken into account in the design of the packaging. The second question gave the opportunity to managers to suggest which other executive they would want to work with (each respondent had to nominate only one).

5. Findings

5.1. Elements of Packaging that Managers Recognize as Critical in the Food Supply Chain

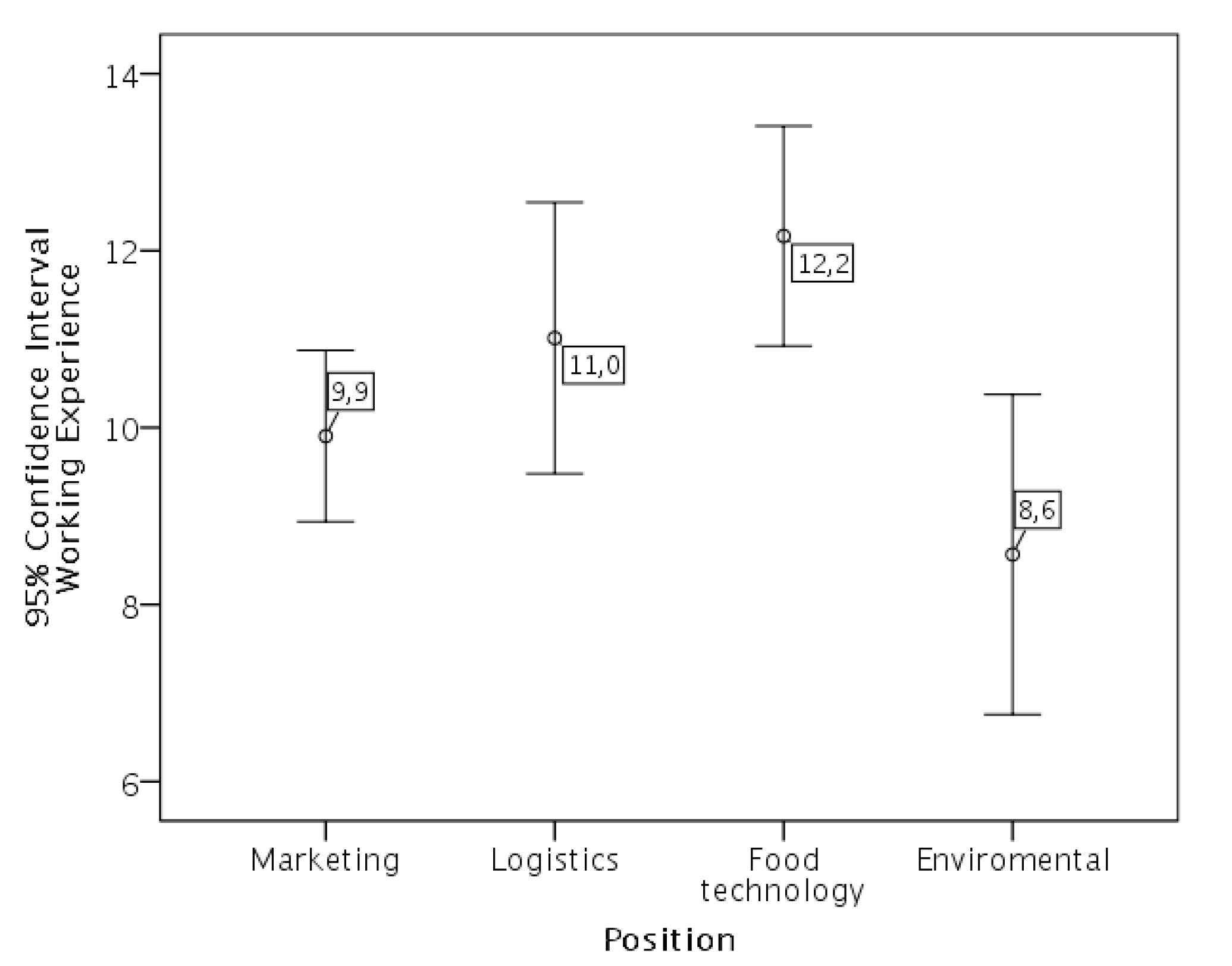

5.2. Differences and Similarities between Managers, with Regard to the Elements Involved in Food Packaging

- q6 Provides nutritional information.

- q9 Includes marks that show compliance to environmental practices.

- q30 Can easily be transported and handled.

- q20 Withstands corrosion and wear.

- q2 Has only one color (monochrome).

- q3 Has only a white color.

- q4 Has many blank parts (or has only white color as a background).

- q5 Has a picture.

- q14 Has a size marginally bigger than the product’s size.

- q15 Has a volume marginally bigger than the product’s volume.

- q26 Is light/has a low weight.

- q33 Suggests recipes for this product.

- q34 Is ready to cook.

- q35 Indicates the country of origin and secondary materials.

- q36 Shows the product temperature at any time.

- q37 Increases the product life.

- q38 Has a smart label.

- q40 The shape of the package describes the product content.

- q1 Has vivid/strong colors.

- q11 Includes product identification coding schemes.

- q12 Includes marks for flammable/hazardous materials, etc.

- q13 Provides proposed ways of consumption.

- q21 Protects the product from theft.

- q24 Does not expose the product to light.

- q27 Is produced by materials/components.

- q16 Follows the common/typical shapes.

- q34 Is ready to cook.

- q35 Indicates the country of origin and secondary materials.

- q40 The shape of the package describes the product content.

- q41 Does not expose light to solar radiation.

5.3. Decision Making on Packaging Elements

6. Conclusions

6.1. Elements of Packaging that Managers Recognize as Critical in the Food Supply Chain

- Informational elements, that provide information about the company, product, production process, etc. and data that support traceability, logistics processes, etc.

- Operational elements that contribute to the protection of the product from theft, moisture, light, etc. allow visual contact with part of the product, ease of transportation and handling, while also permitting packaging in larger packages/logistics unit loads.

- Physical elements that refer to physical characteristics such as size, volume, shape, materials, price, weight, etc.

- Visual elements, referring to colors, blank parts and product photography/image/graphics.

6.2. Differences and Similarities between Managers, with Regard to the Elements Involved in Food Packaging

- Marketing executives place importance on the following element that logistics executives and food technologists consider as inferior: q16 (Follows the common/typical shapes); whereas for q13 (Provides proposed ways of consumption), these share a common view with food technologists and executives involved in environmentally-friendly initiatives.

- Logistics executives and food technologists have a common appreciation of q41 (Does not expose light to solar radiation).

- Logistics executives share perspectives for: q11 (Includes product identification coding schemes), q12 (Includes marks for flammable/hazardous materials, etc.), and q35 (Indicates country of origin and secondary materials) with food technologists and executives involved in environmentally-friendly practices.

- The following items: q27 (Is produced by materials/components, e.g., is made of durable materials that add prestige to the product), q24 (Does not expose the product to light), q34 (Is ready to cook), q1 (Has vivid/strong colors) and q21 (Protects the product from theft) are considered to be important by marketing executives, logistics executives and food technologists, but not by executives involved in environmentally-friendly practices, while the opposite is true for q40 (The shape of the package describes the product content).

6.3. Decision Making on Packaging Elements

Author Contributions

Funding

Conflicts of Interest

References

- NPCS; Board of Food Technologists. 55 Most Profitable Micro, Small, and Medium Scale Food Processing (Processed Food) Projects and Agriculture Based Business Ideas for Startup 2018; NIIR Project Consultancy Services: Delhi, India, 2018; p. 273. [Google Scholar]

- Saghir, M. The concept of packaging logistics. In Proceedings of the Second World Conference on POM and 15th Annual POM Conference, Cancun, Mexico, 30 April–3 May 2004. [Google Scholar]

- Jönson, G. Packaging Technology for the Logistician, 2nd ed.; Lund University: Lund, Sweden, 2000. [Google Scholar]

- Rundh, B. The multi-faceted dimension of packaging: Marketing logistics or marketing tool? Br. Food J. 2005, 107, 670–684. [Google Scholar] [CrossRef]

- Cahyorini, A.; Rusfian, E.Z. The effect of packaging design on impulse buying. J. Adm. Sci. Organ. 2011, 18, 11–21. [Google Scholar]

- Underwood, R.L.; Klein, N.M.; Burke, R.R. Packaging communication: Attentional effects of product imagery. J. Prod. Brand Manag. 2001, 10, 403–422. [Google Scholar] [CrossRef]

- Underwood, R.L.; Klein, N. Packaging as brand communication: Effects of product pictures on attitude towards the package and brand. J. Mark. Theory Pract. 2002, 10, 58–68. [Google Scholar] [CrossRef]

- Limon, Y.; Kahle, L.R.; Orth, U.R. Package design as a communications vehicle in cross cultural value shopping. J. Int. Mark. 2009, 17, 30–57. [Google Scholar] [CrossRef]

- Chung, J.E.; Yu, J.P.; Pysarchik, D.T. Cue Utilization to assess food product quality: A comparison of consumers and retailers in India. Int. Rev. Retail Distrib. Consum. Res. 2006, 16, 199–214. [Google Scholar] [CrossRef]

- Lofgren, M.; Witell, L. Lano’s theory of attractive quality and packaging. Qual. Manag. J. 2005, 12, 7–30. [Google Scholar] [CrossRef]

- IPSOS. Most Americans Say That the Design of a Product’s Packaging Often Influences Their Purchase Decisions. 2018. Available online: https://www.ipsos.com/en-us/news-polls/Most-Americans-Say-That-the-Design-of-a-Products-Packaging-Often-Influences-Their-Purchase-Decisions (accessed on 3 June 2020).

- Loureiro, M.L.; Gracia, A.; Nayga, R.M. Do consumers value nutritional labels? Eur. Rev. Agric. Econ. 2006, 33, 249–268. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food Packaging and Its Environmental Impact, Food Technology. 2007, pp. 46–50. Available online: http://www.ift.org/~/media/Knowledge%20Center/Science%20Reports/Scientific%20Status%20Summaries/Editorial/editorial_0407_foodpackaging.pdf (accessed on 3 June 2020).

- Marsh, K.; Bugusu, B. Food Packaging-Roles, Materials, and Environmental Issues. J. Food Sci. 2007, 72, 40–55. [Google Scholar] [CrossRef]

- EPA. Containers and Packaging: Product-Specific Data. 2019. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/containers-and-packaging-product-specific-data (accessed on 3 June 2020).

- Eurostat. Packaging Waste Statistics. 2020. Available online: https://ec.europa.eu/Eurostat/statistics-explained/index.php/Packaging_waste_statistics#Waste_generation_by_packaging_material (accessed on 3 June 2020).

- Rundh, B. Linking Packaging to Marketing: How packaging is influencing the marketing strategy. Br. Food J. 2013, 115, 1547–1563. [Google Scholar] [CrossRef]

- Linda, H.; Williams, H.; Olsson, A.; Wikstrom, F. Elucidating the indirect contributions of packaging to sustainable development: A terminology of packaging functions and features. Packag. Technol. Sci. 2016, 29, 225–246. [Google Scholar] [CrossRef]

- Singh, P.; Wani, A.; Langowski, H.-W. Packaging Materials, Testing & Quality Assurance; CRC Press Taylor & Francis Group: Cleveland, OH, USA, 2017; ISBN 9781466559950. [Google Scholar]

- Silayoi, P.; Speece, M. The importance of packaging attributes: A conjoint analysis approach. Eur. J. Mark. 2007, 41, 1495–1517. [Google Scholar] [CrossRef]

- Bowersox, D.; Closs, D. Logistical Management: The Integrated Supply Chain Process; McGraw-Hil: New York, NY, USA, 1996. [Google Scholar]

- Lambert, D.M.; Stock, J.R.; Ellram, L.M. Fundamentals of Logistics Management; Irwin/McGraw-Hill: Boston, MA, USA, 1998. [Google Scholar]

- Louw, A.; Kimber, M. The Power of Packaging, The Customer Equity Company is A Wholly Owned Subsidiary of TNS (UK). 2007. Available online: www.tnsglobal.com/_assets/files/The_power_of_packaging.pdf (accessed on 3 June 2020).

- Prendergast, G.; Pitt, L. Packaging marketing logistics and the environment are there trade-offs? Int. J. Phys. Distrib. Logist. Manag. 1996, 26, 66–72. [Google Scholar] [CrossRef]

- Petljak, K.; Naletina, D.; Bilogrevic, K. Considering ecologically sustainable packaging during decision-making while buying food product. Econ. Agric. 2019, 66, 107–126. [Google Scholar] [CrossRef]

- Silayoi, P.; Speece, M. Packaging and purchase decisions: An exploratory study on the impact of involvement level and time pressure. Br. Food J. 2004, 106, 607–628. [Google Scholar] [CrossRef]

- Wells, L.E.; Farley, H.; Armstrong, G. A The Importance of Packaging Design for Own-label Food Brands. Int. J. Retail Distrib. Manag. 2007, 35, 677–690. [Google Scholar] [CrossRef]

- Keller, K. Building strong brands in a modern marketing communications environment. J. Mark. Commun. 2009, 15, 139–155. [Google Scholar] [CrossRef]

- Butkeviciene, V.J.; Stravinskiene, A. Rutelione Impact of consumer package communication on consumer decision making process. Eng. Econ. 2008, 56, 57–65. [Google Scholar]

- Vila, N.; Ampuero, O. The role of packaging in positioning an orange juice. J. Food Prod. Mark. 2007, 13, 21–48. [Google Scholar] [CrossRef]

- Simms, C.; Trott, P. Packaging development: A conceptual framework for identifying new product opportunities. Mark. Theory 2010, 10, 397–415. [Google Scholar] [CrossRef]

- Appendini, P.; Hotchkiss, J.H. Review of Antimicrobial Food Packaging. Innov. Food Sci. Emerg. Technol. 2002, 3, 113–126. [Google Scholar] [CrossRef]

- Sorrentino, A.; Gorrasi, G.; Vittoria, V. Potential Perspectives of Bio-Nanocomposites for Food Packaging Applications. Trends Food Sci. Technol. 2007, 18, 84–95. [Google Scholar] [CrossRef]

- Suchard, H.T.; Polonski, M.J. A theory of environment buyer behavior and its validity: The environmental action-behaviour model. AMA Summer Educ. Conf. Proc. Am. Mark. Assoc. 1991, 2, 187–201. [Google Scholar]

- Teisl, M.F.; Roe, B.; Hicks, R.L. Can Eco-Labels Tune a Market? Evidence from Dolphin-Safe Labeling. J. Environ. Econ. Manag. 2002, 43, 339–359. [Google Scholar] [CrossRef]

- Leire, C.; Thidell, A. Product-related environmental information to guide consumer purchases—A review and analysis of research on perceptions, understanding and use among Nordic consumers. J. Clean. Prod. 2005, 13, 1061–1070. [Google Scholar] [CrossRef]

- Lee, S.; Rajagopalan, P. Building energy efficiency labeling programme in Singapore. Energy Policy 2008, 36, 3982–3992. [Google Scholar] [CrossRef]

- European Parliament. Circular Economy Package, four Legislative Proposals on Waste. 2016. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20170120STO59356/the-circular-economy-package-new-eu-targets-for-recycling (accessed on 3 June 2020).

- European Commission. Environment: Higher Recycling Targets to Drive Transition to a Circular Economy with New Jobs and Sustainable Growth. 2014. Available online: https://www.rsupply.com/en/home-en/9-news/29-eu-defines-70-recycling-target-for-2030-to-promote-circular-economy (accessed on 3 June 2020).

- European Commission. Food Information to Consumers—Legislation. 2014. Available online: https://ec.europa.eu/food/safety/labelling_nutrition/labelling_legislation_en (accessed on 3 June 2020).

- Prendergast, G.; Marr, N. Perceptions of generic products: A macro and micro view. J. Prod. Brand Manag. 1997, 6, 93–108. [Google Scholar] [CrossRef]

- Rettie, R.; Brewer, C. The verbal and visual components of package design. J. Prod. Brand Manag. 2000, 9. [Google Scholar] [CrossRef]

- Estiri, M.; Hasangholipour, T.; Yazdani, H.; Nejad, H.; Rayej, H. Food Products Consumer Behaviors: The Role of Packaging Elements. J. Appl. Sci. 2010, 10, 535–543. [Google Scholar] [CrossRef]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef]

- Cabot, I.; Luque, A.; de las Heras, A.; Aguayo, F. Correction: Aspects of sustainability and design engineering for the production of interconnected smart food packaging. PLoS ONE 2019, 14, e0218337. [Google Scholar] [CrossRef] [PubMed]

- Molina-Besch, K.; Wikström, F.; Williams, H. The environmental impact of packaging in food supply chains-does life cycle assessment of food provide the full picture? Int. J. Life Cycle Assess. 2019, 24, 37–50. [Google Scholar] [CrossRef]

- Wikström, F.; Williams, H. Potential environmental gains from reducing food losses through development of new packaging-A life cycle model. Packag. Technol. Sci. 2010, 23, 403–411. [Google Scholar] [CrossRef]

- Paine, F. Packing and the Environment; Wiley Online Library: Hoboken, NJ, USA, 1992. [Google Scholar]

- Regattieri, A.; Santarelli, G. The Important Role of Packaging in Operations Management; Intechopen: London, UK, 2012. [Google Scholar] [CrossRef]

- Rundh, B. Packaging design: Creating competitive advantage with product packaging. Br. Food J. 2009, 111, 988–1002. [Google Scholar] [CrossRef]

- Konstantoglou, A.; Kokmotos, E.; Folinas, D.; Fotiadis, T. Significance of packaging elements from a marketing and logistics points of view. In Proceedings of the 4th International Conference on Contemporary Marketing Issues, Heraklion, Greece, 22–24 June 2016. [Google Scholar]

- Konstantoglou, A.; Folinas, D.; Fotiadis, T.; Damalis, V.; Voulgarakis, N. The influence of consumer habits and behaviors in the appreciation of labeling and packaging elements: A study in the food supply chain. In Proceedings of the 5th International Conference on Contemporary Marketing Issues, Thessaloniki, Greece, 21–23 June 2017. [Google Scholar]

- Konstantoglou, A.; Folinas, D.; Fotiadis, T.; Rallis, S.L.; Chatzithomas, L.; Gasteratos, A. Development of a holistic framework for the key packaging elements of agri-food products. J. Eng. Sci. Technol. Rev. 2020, 13, 23–31. [Google Scholar] [CrossRef]

- PWC. Food and Beverage Industry/Annual Sectorial Report. 2018. Available online: https://www.pwc.com/gr/en/publications/greek-thought-leadership/the-food%20&%20beverage-sector-in-greece(en).pdf (accessed on 3 June 2020).

- Hellström, T. Dimensions of environmentally sustainable innovation: The structure of eco-innovation concepts. Sustain. Dev. 2006, 15, 148–159. [Google Scholar] [CrossRef]

| Category | Elements |

|---|---|

| Informational elements Provides information about the company, information about the product (ingredients), nutritional information, production or remaking techniques, quality standard marks, compliance with environmental practices, data that support traceability, lot number, product identification coding schemes such as barcode, QR-code, etc., marks for flammable/hazardous materials, proposed ways of consumption, storage conditions and brand elements (logos, slogans, symbols, etc.). |

|

| Operational elements Supports (physical) operational elements, such as: protection of the product from theft, protection of the product from moisture, ease of placing/mounting the product on the shelf, does not expose the product to light, allows visual contact with part of the product, ease of transportation and handling, while also permitting packaging in larger packages/logistics units (cartons, pallets, etc.). |

|

| Physical elements |

|

| Refers to physical characteristics such as: size (marginally bigger than the product size), volume (marginally bigger than the product volume), shape (following common/typical shapes e.g., square, rectangle, triangle, circle), material/components (e.g., made of durable materials, materials that add prestige to the product, materials that are environmentally friendly, materials that can be reused and materials that allow for elongation), being waterproof, withstanding mechanical stress, corrosion and wear, cheap (a low price of production or recycling) and having a light/low weight. | |

| Visual elements |

|

| Refers to: vivid (strong) colors, only one color (monochrome), only a white color (background), many blank parts and/or product photography/image/graphics. |

| N. | Element | Mean | Std. Deviation | |

|---|---|---|---|---|

| Informational | ||||

| q8 | Includes quality standard marks | 4.25 | 0.944 | |

| q6 | Provides nutritional information | 4.11 | 1.046 | |

| q12 | Includes marks for flammable/hazardous materials | 3.98 | 1.101 | |

| q9 | Includes marks for compliance to environmental practices | 3.98 | 1.055 | |

| q11 | Includes product identification coding schemes | 3.93 | 1.176 | |

| q10 | Includes data that support traceability | 3.91 | 1.114 | |

| q35 | Indicates country of origin and secondary materials | 3.86 | 1.202 | |

| q39 | Designates a protected origin name | 3.81 | 1.110 | |

| q7 | Reports production or reproduction techniques | 3.70 | 1.176 | |

| q13 | Provides proposed ways of consumption | 3.53 | 1.149 | |

| q33 | Suggests recipes for this product | 3.42 | 1.181 | |

| Operational | ||||

| q22 | Protects the product from moisture | 4.06 | 0.999 | |

| q24 | Does not expose the product to light | 3.98 | 1.023 | |

| q30 | Can easily be transported and handled | 3.97 | 0.973 | |

| q41 | Does not expose light to solar radiation | 3.89 | 1.065 | |

| q31 | Allows packaging in larger packages/logistics units | 3.81 | 1.087 | |

| q23 | Can easily be mounted on the shelf | 3.78 | 1.108 | |

| q38 | Smart label | 3.62 | 1.174 | |

| q25 | Allows visual contact with part of the product | 3.60 | 1.216 | |

| q40 | The shape of the package | 3.52 | 1.186 | |

| q36 | Shows the product temperature at any time | 3.48 | 1.171 | |

| q37 | Increases product life | 3.44 | 1.152 | |

| q34 | Is ready to cook | 3.34 | 1.160 | |

| q21 | Protects the product from theft | 3.24 | 1.287 | |

| Physical | ||||

| q42 | Does not allow odors to leak | 4.02 | 1.077 | |

| q20 | Withstands corrosion and wear | 4.01 | 1.102 | |

| q28 | Is produced by environmentally-friendly materials | 3.94 | 1.093 | |

| q19 | Withstands mechanical stress | 3.83 | 1.125 | |

| q18 | Is waterproof | 3.79 | 1.090 | |

| q17 | Is made of durable materials | 3.78 | 1.011 | |

| q43 | Is made of recycled materials | 3.75 | 1.147 | |

| q32 | Is cheap (low price of production or recycling) | 3.72 | 1.091 | |

| q29 | Is produced by materials that can be reused | 3.71 | 1.173 | |

| q27 | Is produced by materials/components | 3.64 | 1.102 | |

| q14 | Has a size marginally bigger than the product’s size | 3.32 | 1.162 | |

| q26 | Is light/has a low weight | 3.22 | 1.047 | |

| q15 | Has volume marginally bigger than the product’s volume | 3.19 | 1.169 | |

| q16 | Follows the common/typical shapes | 2.98 | 1.242 | |

| Visual | ||||

| q5 | Has a picture | 3.14 | 1.177 | |

| q1 | Has vivid/strong colors | 2.69 | 1.026 | |

| q4 | Has many blank parts | 2.35 | 1.069 | |

| q3 | Has only a white color | 2.17 | 0.902 | |

| q2 | Has only one color (monochrome) | 1.94 | 0.855 | |

| Informational | |||||||

|---|---|---|---|---|---|---|---|

| Group | Question | Mean (S.Dev.) | Marketing | Logistics | Food Tech. | Environment | P (1) |

| inf.q1 | q.6 | 4.1 (1) | 4.1 (1.1) | 4.2 (0.9) | 4.1 (1.1) | 4.1 (1) | 0.836 |

| inf.q2 | q.7 | 3.7 (1.2) | 3.7 (1.2) | 3.5 (1.2) | 3.9 (1.1) | 3.6 (1.2) | 0.036 |

| inf.q3 | q.9 | 4.2 (0.9) | 4.1 (1) | 4.4 (0.8) | 4.3 (1) | 4.3 (0.9) | 0.314 |

| inf.q4 | q.10 | 4 (1.1) | 3.8 (1.1) | 4.1 (1) | 4.1 (1.1) | 3.9 (0.9) | 0.138 |

| inf.q5 | q.11 | 3.9 (1.1) | 3.6 (1.2) | 4.2 (0.9) | 4 (1.1) | 4.1 (1) | 0.002 |

| inf.q6 | q.12 | 3.9 (1.2) | 3.5 (1.2) | 4.1 (1) | 4.1 (1.2) | 4.2 (1) | 0.000 |

| inf.q7 | q.13 | 4 (1.1) | 3.7 (1.2) | 4.2 (1.1) | 4.0 (1.0) | 4.2 (0.9) | 0.005 |

| inf.q8 | q.33 | 3.5 (1.1) | 3.5 (1.1) | 3.5 (1.0) | 3.8 (1.1) | 3.2 (1.4) | 0.012 |

| inf.q9 | q.35 | 3.4 (1.2) | 3.1 (1.2) | 3.5 (1.1) | 3.7 (1.2) | 3.6 (1) | 0.000 |

| inf.q10 | q.39 | 3.9 (1.2) | 3.7 (1.2) | 3.9 (1.3) | 3.9 (1.2) | 4 (1.1) | 0.214 |

| inf.q11 | q.36 | 3.8 (1.1) | 3.7 (1.2) | 3.8 (1.1) | 4 (1.1) | 3.7 (0.9) | 0.060 |

| Operational | |||||||

| Group | Question | Mean (S.Dev) | Marketing | Logistics | Food Tech. | Environment | P (1) |

| oper.q1 | q.21 | 3.2 (1.3) | 3.3 (1.3) | 3.3 (1.2) | 3.4 (1.3) | 2.7 (1.3) | 0.005 |

| oper.q2 | q.22 | 4.1 (1) | 4.1 (0.9) | 4.1 (0.9) | 4.1 (1) | 3.7 (1.2) | 0.037 |

| oper.q3 | q.23 | 3.8 (1.1) | 3.7 (1.1) | 4.0 (1.0) | 3.9 (1) | 3.6 (1.2) | 0.047 |

| oper.q4 | q.24 | 4 (1) | 3.9 (1) | 4.2 (1.0) | 4.1 (0.9) | 3.6 (1.1) | 0.002 |

| oper.q5 | q.25 | 3.6 (1.2) | 3.7 (1.1) | 3.6 (1.4) | 3.6 (1.2) | 3.4 (1.1) | 0.633 |

| oper.q6 | q.30 | 4 (1) | 3.8 (1.1) | 4.1 (0.8) | 4 (1) | 4.1 (0.9) | 0.045 |

| oper.q7 | q.31 | 3.8 (1.1) | 3.6 (1.1) | 4.0 (1.0) | 3.9 (1) | 3.9 (1.2) | 0.025 |

| oper.q8 | q.34 | 3.3 (1.2) | 3.4 (1.2) | 3.3 (1.1) | 3.5 (1.1) | 2.9 (1.2) | 0.004 |

| oper.q9 | q.36 | 3.5 (1.2) | 3.3 (1.2) | 3.6 (1.2) | 3.7 (1.1) | 3.3 (1) | 0.011 |

| oper.q10 | q.37 | 3.4 (1.2) | 3.3 (1.2) | 3.3 (1.1) | 3.8 (1.2) | 3.3 (1) | 0.010 |

| oper.q11 | q.38 | 3.6 (1.2) | 3.6 (1.2) | 3.8 (1.2) | 3.5 (1.2) | 3.5 (1) | 0.308 |

| oper.q12 | q.40 | 3.5 (1.2) | 3.3 (1.2) | 3.6 (1.1) | 3.5 (1.3) | 4 (0.9) | 0.000 |

| oper.q13 | q.41 | 3.9 (1.1) | 3.6 (1.1) | 4.1 (1.1) | 4.2 (1) | 3.7 (0.9) | 0.000 |

| Physical | |||||||

| Group | Question | Mean (S.Dev) | Marketing | Logistics | Food Tech. | Environment | P (1) |

| phys.q1 | q.14 | 3.3 (1.2) | 3.1 (1.1) | 3.5 (1.2) | 3.5 (1.1) | 3.4 (1.3) | 0.027 |

| phys.q2 | q.15 | 3.2 (1.2) | 3 (1.2) | 3.3 (1.2) | 3.3 (1.1) | 3.1 (1.2) | 0.062 |

| phys.q3 | q.16 | 3 (1.2) | 2.7 (1.1) | 3.4 (1.2) | 3 (1.3) | 3 (1.3) | 0.005 |

| phys.q4 | q.17 | 3.8 (1) | 3.7 (1) | 3.8 (1) | 3.8 (1) | 3.9 (1) | 0.771 |

| phys.q5 | q.18 | 3.8 (1.1) | 3.7 (1.1) | 3.9 (1) | 4 (1) | 3.6 (1.1) | 0.060 |

| phys.q6 | q.19 | 3.8 (1.1) | 3.8 (1.1) | 3.9 (1.1) | 3.9 (1.1) | 3.7 (1.2) | 0.506 |

| phys.q7 | q.20 | 4 (1.1) | 3.9 (1.1) | 4.2 (1) | 3.9 (1.2) | 4.1 (1.1) | 0.202 |

| phys.q8 | q.26 | 3.2 (1) | 3.1 (1.1) | 3.4 (1) | 3.3 (1) | 3.1 (0.9) | 0.076 |

| phys.q9 | q.27 | 3.6 (1.1) | 3.7 (1.1) | 3.6 (1.1) | 3.9 (1.1) | 3.2 (1) | 0.000 |

| phys.q10 | q.28 | 3.9 (1.1) | 3.8 (1.2) | 4.1 (0.8) | 4.1 (1.2) | 3.7 (1.1) | 0.019 |

| phys.q11 | q.29 | 3.7 (1.2) | 3.7 (1.2) | 3.7 (1) | 3.9 (1.2) | 3.4 (1.3) | 0.099 |

| phys.q12 | q.32 | 3.7 (1.1) | 3.7 (1.1) | 3.9 (1) | 3.7 (1.1) | 3.5 (1.2) | 0.167 |

| phys.q13 | q.42 | 4 (1.1) | 3.8 (1.1) | 4.1 (0.9) | 4.2 (1.1) | 3.8 (1.1) | 0.013 |

| phys.q14 | q.43 | 3.7 (1.1) | 3.6 (1.2) | 4 (1) | 3.7 (1.2) | 3.7 (1) | 0.035 |

| Visual | |||||||

| Group | Question | Mean (S.Dev) | Marketing | Logistics | Food Tech. | Environment | P (1) |

| vis.q1 | q.1 | 2.7 (1) | 2.8 (1) | 2.7 (1) | 2.8 (1) | 2.2 (0.9) | 0.001 |

| vis.q2 | q.2 | 1.9 (0.9) | 1.9 (0.7) | 2 (1) | 1.9 (0.9) | 1.9 (0.9) | 0.664 |

| vis.q3 | q.3 | 2.2 (0.9) | 2.2 (0.9) | 2.1 (0.8) | 2.3 (0.9) | 2.1 (0.9) | 0.347 |

| vis.q4 | q.4 | 2.3 (1.1) | 2.4 (1) | 2.2 (1.1) | 2.4 (1.1) | 2.3 (1) | 0.282 |

| vis.q5 | q.5 | 3.1 (1.2) | 3.3 (1.1) | 2.8 (1.2) | 3.3 (1.3) | 3.1 (1) | 0.018 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konstantoglou, A.; Folinas, D.; Fotiadis, T. Exploring the Multi-Function Nature of Packaging in the Food Industry. Logistics 2020, 4, 21. https://doi.org/10.3390/logistics4030021

Konstantoglou A, Folinas D, Fotiadis T. Exploring the Multi-Function Nature of Packaging in the Food Industry. Logistics. 2020; 4(3):21. https://doi.org/10.3390/logistics4030021

Chicago/Turabian StyleKonstantoglou, Ageliki, Dimitris Folinas, and Thomas Fotiadis. 2020. "Exploring the Multi-Function Nature of Packaging in the Food Industry" Logistics 4, no. 3: 21. https://doi.org/10.3390/logistics4030021

APA StyleKonstantoglou, A., Folinas, D., & Fotiadis, T. (2020). Exploring the Multi-Function Nature of Packaging in the Food Industry. Logistics, 4(3), 21. https://doi.org/10.3390/logistics4030021