Using Integrated MMD-TOPSIS to Solve the Supplier Selection and Fair Order Allocation Problem: A Tunisian Case Study

Abstract

:1. Introduction

2. Literature Review

2.1. Supplier Selection Problem

2.2. The Fair Order Allocation Problem

2.3. Optimization Techniques in the SSFOAP

3. Problem Description and Mathematical Model

3.1. Parameters

| Index of the supplier (I = 1,…, n) | |

| Item demand | |

| Item Unit Price | |

| The capacity of supplier | |

| Holding cost | |

| Shortage cost | |

| Storage upper bound | |

| Shortage lower bound | |

| Meaningful suitability index | |

| BT | Total budget |

3.2. Decision Variables

| Number of products ordered proportionally | |

| Product inventory | |

| Product shortage | |

| The positive threshold for equitable distribution of orders | |

| The negative threshold for equitable distribution of orders |

3.3. Mathematical Model

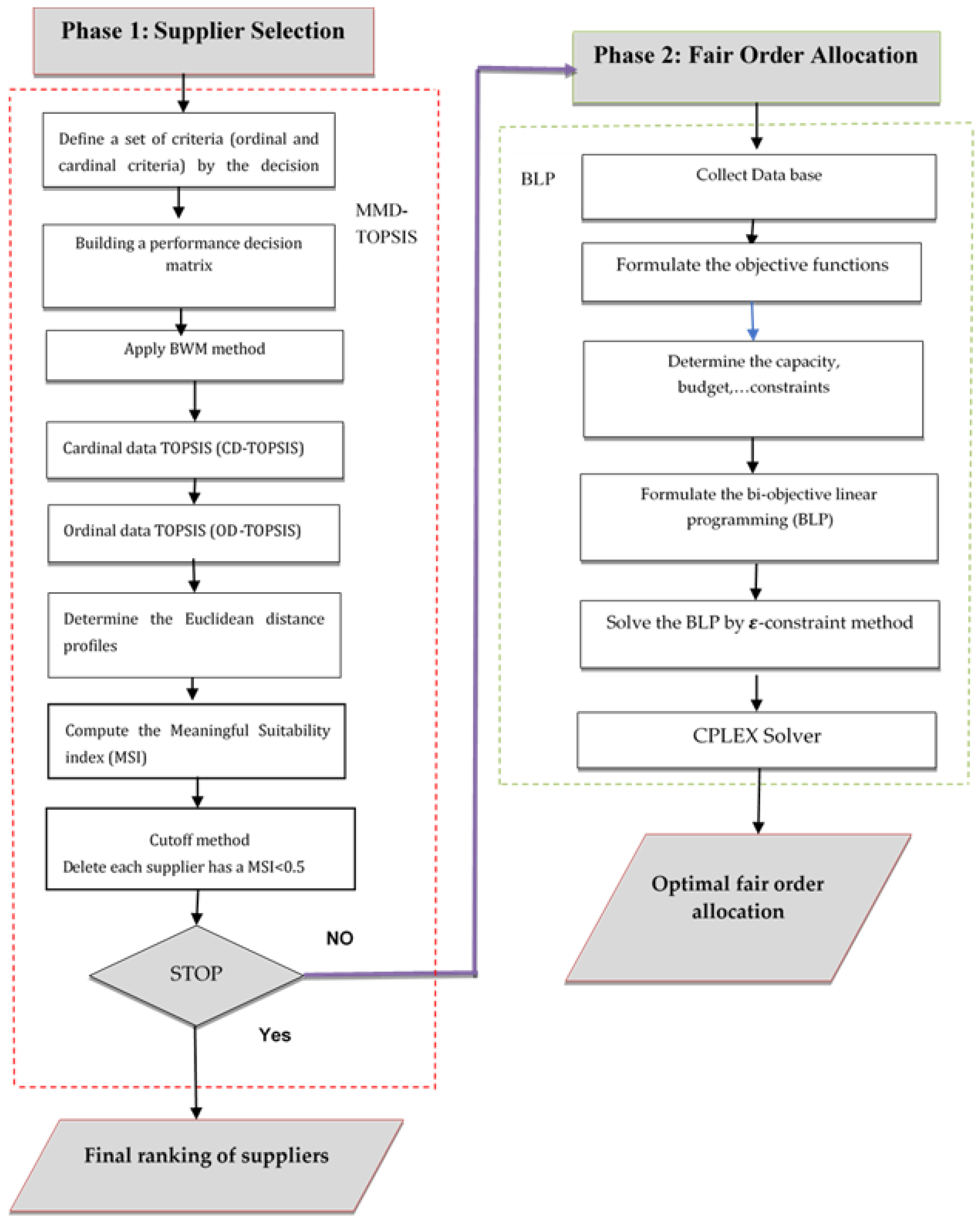

4. Integrated BWM-MMD-TOPSIS in SSFOAP

- (1)

- Phase 1: Apply the BWM-MMD-TOPSIS Method to Compute the MSI of Suppliers’ Selection for Cardinal and Ordinal Data.

- (1)

- Step 1. Establish the performance decision-making matrix.

- (2)

- Step 2. The Best–Worst Method (BWM) to evaluate criteria supplier selection.

- (3)

- Step 3. The Cardinal Data–TOPSIS step (CD-TOPSIS method).

- (4)

- Step 4. The Ordinal Data–TOPSIS step (CD-TOPSIS method).

- (5)

- Step 5. Compute the weighted Euclidean distance.

- (6)

- Step 6. Compute the relative closeness coefficients’s.

- (7)

- Step 7. Rank the suppliers based on the decreasing values of the relative closeness coefficients ci’s.

- (8)

- Step 8. Use the cutoff method to delete suppliers with MSI < ci min.

- (2)

- Phase 2: The Fair Order Allocation

4.1. Problem Statement: A Real Case Study in TSE Company in Tunisia

4.2. The Suggested Integrated Model

4.2.1. Phase 1: Supplier Selection Problem Using BWM and MMD-TOPSIS Method

- Step1: Building a Performance Decision Matrix

- Step 2: Determine the Criteria Weights by BWM

- Step 3: Determine the CD-TOPSIS Step

4.2.2. Phase 2: Fair Order Allocation

Database Collect for Bi-Objective LP

The -Constraint Method

5. Numerical Experiments

6. Discussions

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Euchi, J.; Frifita, S. Hybrid metaheuristic to solve the “one-to-many-to-one” problem: Case of distribution of soft drink in Tunisia. Manag. Decis. 2017, 55, 136–155. [Google Scholar] [CrossRef]

- Euchi, J. (Ed.) Transportation, Logistics, and Supply Chain Management in Home Healthcare: Emerging Research and Opportunities: Emerging Research and Opportunities; IGI Global: Hershey, PA, USA, 2019. [Google Scholar]

- Hu, Z.; Parwani, V.; Hu, G. Closed-Loop Supply Chain Network Design under Uncertainties Using Fuzzy Decision Making. Logistics 2021, 5, 15. [Google Scholar] [CrossRef]

- Elleuch, M.A.; Anane, M.; Euchi, J.; Frikha, A. Hybrid fuzzy multi-criteria decision making to solve the irrigation water allocation problem in the Tunisian case. Agric. Syst. 2019, 176, 102644. [Google Scholar] [CrossRef]

- Euchi, J.; Bouzidi, D.; Bouzid, Z. Interpretive structural modeling technique to analyze the interactions between the factors influencing the performance of the reverse logistics chain. Glob. J. Flex. Syst. Manag. 2019, 20, 43–55. [Google Scholar] [CrossRef]

- Bahramimianrood, B.; Bathae, M. The Impact of Information Technology on Knowledge Management in the Supply Chain. J. Sci. Manag. Tour. Lett. 2021, 2021, 1–6. [Google Scholar]

- Euchi, J. Hybrid adaptive memory programming to optimise the multi-commodity many to many vehicle routing problem. Int. J. Math. Oper. Res. 2020, 17, 492–513. [Google Scholar] [CrossRef]

- Moussi, R.; Euchi, J.; Yassine, A.; Ndiaye, N.F. A hybrid ant colony and simulated annealing algorithm to solve the container stacking problem at seaport terminal. Int. J. Oper. Res. 2015, 24, 399–422. [Google Scholar] [CrossRef]

- Aouadni, S.; Aouadni, I.; Rebaï, A. A systematic review on supplier selection and order allocation problems. J. Ind. Eng. Int. 2019, 15, 267–289. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.H.; Uppal, M.; Shi, J. A product driven approach to manufacturing supply chain selection. Supply Chain Manag. Int. J. 2002, 7, 189–199. [Google Scholar] [CrossRef]

- Dutta, P.; Jaikumar, B.; Arora, M. Applications of data envelopment analysis in supplier selection between 2000 and 2020: A literature review. Bus. Anal. Oper. Res. 2021, 2021, 1–56. [Google Scholar] [CrossRef]

- Euchi, J. Genetic scatter search algorithm to solve the one-commodity pickup and delivery vehicle routing problem. J. Model. Manag. 2017, 12, 2–18. [Google Scholar] [CrossRef]

- Lee, A.H.; Kang, H.Y.; Lai, C.M.; Hong, W.Y. An integrated model for lot sizing with supplier selection and quantity discounts. Appl. Math. Model. 2013, 37, 4733–4746. [Google Scholar] [CrossRef]

- Orji, I.J.; Ojadi, F. Investigating the COVID-19 pandemic’s impact on sustainable supplier selection in the Nigerian manufacturing sector. Comput. Ind. Eng. 2021, 160, 107588. [Google Scholar] [CrossRef]

- Dickson, G.W. An analysis of vendor selection systems and decisions. J. Purch. 1966, 2, 5–17. [Google Scholar] [CrossRef]

- Weber, C.A.; Current, J.R.; Benton, W.C. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P.K. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Thiruchelvam, S.; Tookey, J.E. Evolving trends of supplier selection criteria and methods. Int. J. Automot. Mech. Eng. 2011, 4, 437–454. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Aouadni, S.; Rebai, A.; Turskis, Z. The meaningful mixed data TOPSIS (TOPSIS-MMD) method and its application in supplier selection. Stud. Inform. Control 2017, 26, 353–363. [Google Scholar] [CrossRef] [Green Version]

- Lopes, A.P.; Rodriguez-Lopez, N. A Decision Support Tool for Supplier Evaluation and Selection. Sustainability 2021, 13, 12387. [Google Scholar] [CrossRef]

- Chen, C.H. A Hybrid Multi-Criteria Decision-Making Approach Based on ANP-Entropy TOPSIS for Building Materials Supplier Selection. Entropy 2021, 23, 1597. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.X.; Wong, W.K.; Leung, S.Y.S.; Fan, J.T.; Chan, S.F. A genetic-algorithm-based optimization model for scheduling flexible assembly lines. Int. J. Adv. Manuf. Technol. 2008, 36, 156–168. [Google Scholar] [CrossRef]

- Guo, C.; Li, X. A multi-echelon inventory system with supplier selection and order allocation under stochastic demand. Int. J. Prod. Econ. 2014, 151, 37–47. [Google Scholar] [CrossRef]

- Esfandiari, N.; Seifbarghy, M. Modeling a stochastic multi-objective supplier quota allocation problem with price-dependent ordering. Appl. Math. Model. 2013, 37, 5790–5800. [Google Scholar] [CrossRef]

- Gnanasekaran, S.; Velappan, S. Application of Analytical Hierarchy Process in Supplier Selection: An Automobile Industry Case Study. South Asian J. Manag. 2006, 13, 89–100. [Google Scholar]

- Magdalena, R. Supplier selection for food industry: A combination of Taguchi loss function and fuzzy analytical hierarchy process. Asian J. Technol. Manag. 2012, 5, 13–22. [Google Scholar]

- Al-Tit, A.; Omri, A.; Euchi, J. Critical success factors of small and medium-sized enterprises in Saudi Arabia: Insights from sustainability perspective. Adm. Sci. 2019, 9, 32. [Google Scholar] [CrossRef] [Green Version]

- You, S.Y.; Zhang, L.J.; Xu, X.G.; Liu, H.C. A new integrated multi-criteria decision making and multi-objective programming model for sustainable supplier selection and order allocation. Symmetry 2020, 12, 302. [Google Scholar] [CrossRef] [Green Version]

- Euchi, J.; Chabchoub, H. A hybrid tabu search to solve the heterogeneous fixed fleet vehicle routing problem. Logist. Res. 2010, 2, 3–11. [Google Scholar] [CrossRef]

- Chen, P.S.; Wu, M.T. A modified failure mode and effects analysis method for supplier selection problems in the supply chain risk environment: A case study. Comput. Ind. Eng. 2013, 66, 634–642. [Google Scholar] [CrossRef]

- Deng, S.; Aydin, R.; Kwong, C.K.; Huang, Y. Integrated product line design and supplier selection: A multi-objective optimization paradigm. Comput. Ind. Eng. 2014, 70, 150–158. [Google Scholar] [CrossRef]

- Dweiri, F.; Kumar, S.; Khan, S.A.; Jain, V. Designing an integrated AHP based decision support system for supplier selection in automotive industry. Expert Syst. Appl. 2016, 62, 273–283. [Google Scholar] [CrossRef]

- Lin, C.T.; Chen, C.B.; Ting, Y.C. An ERP model for supplier selection in electronics industry. Expert Syst. Appl. 2011, 38, 1760–1765. [Google Scholar] [CrossRef]

- Dou, Y.; Zhu, Q.; Sarkis, J. Evaluating green supplier development programs with a grey-analytical network process-based methodology. Eur. J. Oper. Res. 2013, 233, 420–431. [Google Scholar] [CrossRef]

- Memari, A.; Dargi, A.; Jokar, M.R.A.; Ahmad, R.; Rahim, A.R.A. Sustainable supplier selection: A multi-criteria intuitionistic fuzzy TOPSIS method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Javad, M.O.M.; Darvishi, M.; Javad, A.O.M. Green supplier selection for the steel industry using BWM and fuzzy TOPSIS: A case study of Khouzestan steel company. Sustain. Futures 2020, 2, 100012. [Google Scholar] [CrossRef]

- Fei, L.; Deng, Y.; Hu, Y. DS-VIKOR: A new multi-criteria decision-making method for supplier selection. Int. J. Fuzzy Syst. 2019, 21, 157–175. [Google Scholar] [CrossRef]

- Gao, H.; Ju, Y.; Gonzalez, E.D.S.; Zhang, W. Green supplier selection in electronics manufacturing: An approach based on consensus decision making. J. Clean. Prod. 2020, 245, 118781. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, K.; Zeng, B.; Xu, H.; Yang, Y. Supplier selection in nuclear power industry with extended VIKOR method under linguistic information. Appl. Soft Comput. 2016, 48, 444–457. [Google Scholar] [CrossRef]

- You, X.Y.; You, J.X.; Liu, H.C.; Zhen, L. Group multi-criteria supplier selection using an extended VIKOR method with interval 2-tuple linguistic information. Expert Syst. Appl. 2015, 42, 1906–1916. [Google Scholar] [CrossRef]

- Tian, Z.P.; Wang, J.Q.; Zhang, H.Y. An integrated approach for failure mode and effects analysis based on fuzzy best-worst, relative entropy, and VIKOR methods. Appl. Soft Comput. 2018, 72, 636–646. [Google Scholar] [CrossRef]

- Bai, C.; Kusi-Sarpong, S.; Badri Ahmadi, H.; Sarkis, J. Social sustainable supplier evaluation and selection: A group decision-support approach. Int. J. Prod. Res. 2019, 57, 7046–7067. [Google Scholar] [CrossRef]

- Gan, J.; Zhong, S.; Liu, S.; Yang, D. Resilient supplier selection based on fuzzy BWM and GMo-RTOPSIS under supply chain environment. Discret. Dyn. Nat. Soc. 2019, 2019, 2456260. [Google Scholar] [CrossRef] [Green Version]

- Cárdenas-Barrón, L.E.; González-Velarde, J.L.; Treviño-Garza, G. A new approach to solve the multi-product multi-period inventory lot sizing with supplier selection problem. Comput. Oper. Res. 2015, 64, 225–232. [Google Scholar] [CrossRef]

- Pazhani, S.; Ventura, J.A.; Mendoza, A. A serial inventory system with supplier selection and order quantity allocation considering transportation costs. Appl. Math. Model. 2016, 40, 612–634. [Google Scholar] [CrossRef]

- Aouadni, S.; Allouche, M.A.; Rebaï, A. Supplier selection: An analytic network process and imprecise goal programming model integrating the decision-maker’s preferences. Int. J. Oper. Res. 2013, 16, 137–154. [Google Scholar] [CrossRef]

- Sodenkamp, M.A.; Tavana, M.; Di Caprio, D. Modeling synergies in multi-criteria supplier selection and order allocation: An application to commodity trading. Eur. J. Oper. Res. 2016, 254, 859–874. [Google Scholar] [CrossRef]

- Junior, F.R.L.; Osiro, L.; Carpinetti, L.C.R. A comparison between Fuzzy AHP and Fuzzy TOPSIS methods to supplier selection. Appl. Soft Comput. 2014, 21, 194–209. [Google Scholar] [CrossRef]

- Rouyendegh, B.D.; Saputro, T.E. Supplier selection using integrated fuzzy TOPSIS and MCGP: A case study. Procedia Soc. Behav. Sci. 2014, 116, 3957–3970. [Google Scholar] [CrossRef] [Green Version]

- Fu, Y.K. An integrated approach to catering supplier selection using AHP-ARAS-MCGP methodology. J. Air Transp. Manag. 2019, 75, 164–169. [Google Scholar] [CrossRef]

- Kilic, H.S.; Yalcin, A.S. Modified two-phase fuzzy goal programming integrated with IF-TOPSIS for green supplier selection. Appl. Soft Comput. 2020, 93, 106371. [Google Scholar] [CrossRef]

- Amid, A.; Ghodsypour, S.H.; O’Brien, C. A weighted max–min model for fuzzy multi-objective supplier selection in a supply chain. Int. J. Prod. Econ. 2011, 131, 139–145. [Google Scholar] [CrossRef]

- Nazari-Shirkouhi, S.; Shakouri, H.; Javadi, B.; Keramati, A. Supplier selection and order allocation problem using a two-phase fuzzy multi-objective linear programming. Appl. Math. Model. 2013, 37, 9308–9323. [Google Scholar] [CrossRef]

- Haldar, A.; Banerjee, D.; Ray, A.; Ghosh, S. An integrated approach for supplier selection. Procedia Eng. 2012, 38, 2087–2102. [Google Scholar] [CrossRef] [Green Version]

- Euchi, J.; Sadok, A. Hybrid genetic-sweep algorithm to solve the vehicle routing problem with drones. Phys. Commun. 2021, 44, 101236. [Google Scholar] [CrossRef]

| Papers | Optimization Techniques | Order Allocation | Supplier Selection |

|---|---|---|---|

| [13] | Multi-objective decision analysis | × | |

| [53] | Fuzzy multi-objective linear programming | × | |

| [54] | Fuzzy multi-objective linear programming | × | |

| [20] | MMD-TOPSIS method | × | |

| [24] | A mixed-integer nonlinear programming model | × | |

| [25] | Genetic algorithm | × | |

| [26] | Fuzzy AHP | × | |

| [31] | AHP | × | |

| [32] | AHP | × | |

| [33] | AHP | × | |

| [34] | ANP+TOPSIS + linear programming | × | × |

| [35] | ANP | × | |

| [36] | TOPSIS | × | |

| [37] | TOPSIS | × | |

| [41] | VIKOR | × | |

| [40] | VIKOR | × | |

| [38] | VIKOR | × | |

| [39] | VIKOR | × | |

| [45] | Genetic algorithm | × | |

| [47] | ANP + MOLP | × | × |

| [48] | Multi-objective linear programming | × | |

| [55] | QFD + TOPSIS | × | |

| [50] | Fuzzy TOPSIS + Goal programming | × | × |

| [51] | AHP, ARAS, and MCGP | × | × |

| [52] | fuzzy goal programming + IF-TOPSIS | × | × |

| Ordinal Criteria | Cardinal Criteria | ||

|---|---|---|---|

| Suppliers/Criteria | Quality | Flexibility | Delivery |

| Scap | VG | VG | 4 |

| Camilec | VG | G | 5 |

| Siala | VG | G | 1 |

| Compto | G | G | 3 |

| Dcbel | G | I | 3 |

| Best Criterion | Quality | Flexibility | Delivery |

|---|---|---|---|

| Quality | 1 | 2 | 2 |

| Worst Criterion | Quality | Flexibility | Delivery |

|---|---|---|---|

| Delivery | 3 | 2 | 1 |

| Suppliers | S-Score | I-Score | ||

|---|---|---|---|---|

| Quality | Flexibility | Quality | Flexibility | |

| Scap | 2 | 4 | 0 | 0 |

| Camilec | 2 | 1 | 0 | 1 |

| Siala | 2 | 1 | 0 | 1 |

| Compto | 0 | 1 | 3 | 1 |

| Dcbel | 0 | 0 | 3 | 4 |

| Ordinal Data | Cardinal Data | ||

|---|---|---|---|

| Quality | Flexibility | Delivery | |

| Scap | 1 | 1 | 0.42 |

| Camilec | 1 | 0.5 | 0.28 |

| Siala | 1 | 0.5 | 0.85 |

| Compto | 0 | 0.5 | 0.57 |

| Dcbel | 0 | 0.25 | 0.57 |

| Suppliers | Separation Measures | |

|---|---|---|

| Scap | 0.317 | 0.8688 |

| Camilec | 0.4533 | 0.7573 |

| Siala | 0.2382 | 0.8756 |

| Compto | 0.7781 | 0.3840 |

| Dcbel | 0.7985 | 0.3316 |

| Suppliers | Ci | Pi |

|---|---|---|

| Scap | 18,000 | 2200 |

| Camilec | 13,000 | 2300 |

| Siala | 15,000 | 2400 |

| Compto | 16,000 | 2350 |

| Dcbel | 9000 | 2150 |

| Suppliers | Scap | Camelic | Siala | Compto | Dcbel |

|---|---|---|---|---|---|

| Meaningful suitability index | 0.73 | 0.62 | 0.79 | 0.33 | 0.29 |

| Optimal fair order allocation | 7961.232 | 6761.594 | 8615.580 | 3598.913 | 3162.681 |

| Suppliers | Scap | Camelic | Siala |

|---|---|---|---|

| Meaningful suitability index | 0.73 | 0.62 | 0.79 |

| Optimal fair order allocation | 10,267.76 | 8720.561 | 11,111.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aouadni, S.; Euchi, J. Using Integrated MMD-TOPSIS to Solve the Supplier Selection and Fair Order Allocation Problem: A Tunisian Case Study. Logistics 2022, 6, 8. https://doi.org/10.3390/logistics6010008

Aouadni S, Euchi J. Using Integrated MMD-TOPSIS to Solve the Supplier Selection and Fair Order Allocation Problem: A Tunisian Case Study. Logistics. 2022; 6(1):8. https://doi.org/10.3390/logistics6010008

Chicago/Turabian StyleAouadni, Sourour, and Jalel Euchi. 2022. "Using Integrated MMD-TOPSIS to Solve the Supplier Selection and Fair Order Allocation Problem: A Tunisian Case Study" Logistics 6, no. 1: 8. https://doi.org/10.3390/logistics6010008

APA StyleAouadni, S., & Euchi, J. (2022). Using Integrated MMD-TOPSIS to Solve the Supplier Selection and Fair Order Allocation Problem: A Tunisian Case Study. Logistics, 6(1), 8. https://doi.org/10.3390/logistics6010008