Optimization of Hub-Based Milkrun Supply

Abstract

:1. Introduction

- More than 50% of the articles regarding milkrun-based supply were published in the last five years. This result indicates the scientific potential of the design and optimization of milkrun-based materials supply solutions.

- The articles that addressed the optimization of milkrun supply of assembly and production plants are focusing on conventional solutions and only a few of them describe the indirect milkrun-based supply, where an intermittent hub is responsible for the sequencing of collected components required by the assembly or production cells.

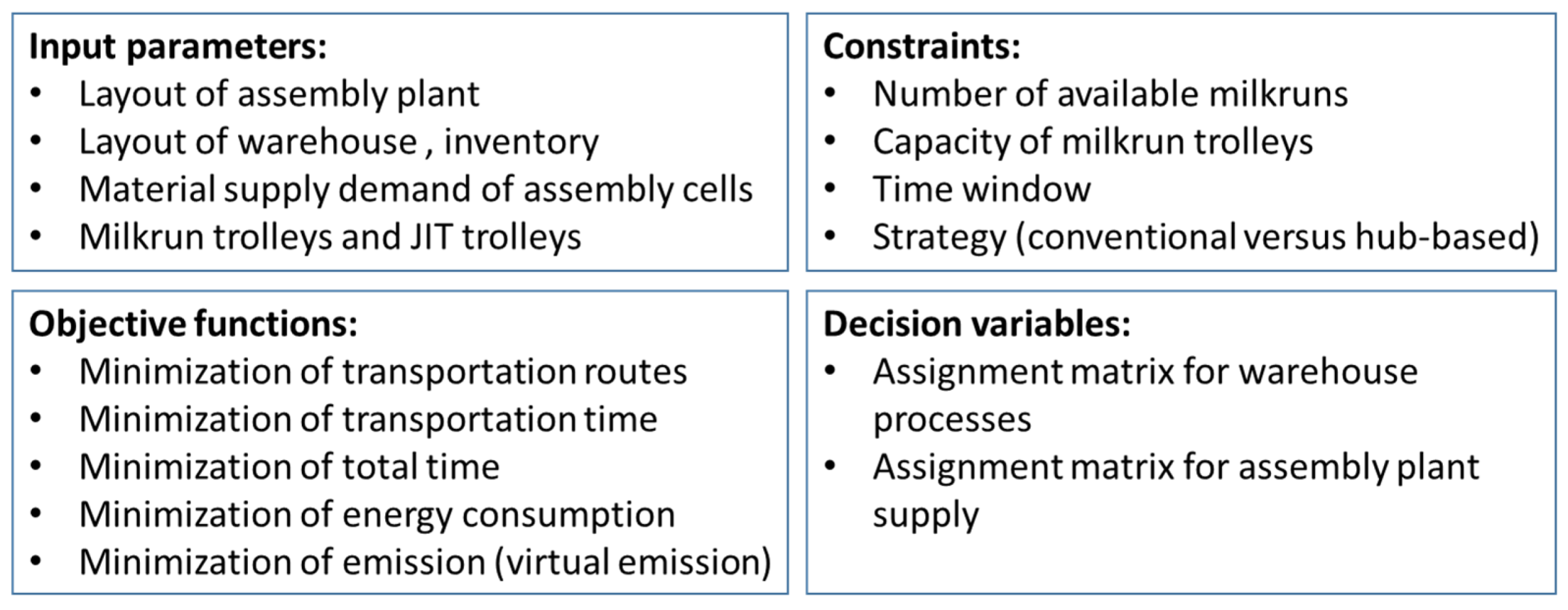

- A wide range of research articles discuss the logistics-related aspects of milkrun-based in-plant supply operations, but energy efficiency and environmental impacts are research gaps. These research topics still need more attention and research; therefore, the proposed mathematical model integrates sustainability aspects (minimization of energy consumption and GHG emission).

- The design and optimization of milkrun supply solutions is generally based on heuristics, metaheuristics, or simulation, commercial solvers are rarely used.

- The approach can be compared with recent methodologies. While Karouani and Elgarej [5] concentrate on the milkrun collection system, the approach described here addresses the integrated design and operation of both collection and distribution systems, considering milkruns for both processes. Arvidsson [1] explores the load factor paradox with economic and environmental implications, Novaes et al. [2] focus on the environmental impacts of milkrun design, DeSouza et al. [12] examine the logistics costs of milkrun operations, Mohd et al. [13] emphasize minimizing transportation distances, and Eroglu et al [14]. discuss the capacity-related aspects of milkrun design. This approach integrates these various aspects into a comprehensive design model, enabling consideration of multiple facets of milkrun design and operation.

2. Materials and Methods

2.1. Conceptional Model of Conventional and Hub-Based Milkrun Supply

2.2. Mathematical Model of Conventional and Hub-Based Milkrun Supply

- : coordinates of the available assembly cells, ;

- : coordinates of the available warehouse racks, ;

- : quantity of supply demand of assembly cell i in [LU];

- : capacity of milkrun trolleys in [LU];

- : average speed of milkrun trolleys in the assembly plant;

- : average speed of milkrun trolleys in the component’s warehouse;

- : specific materials handling time in the assembly plant (unloading time) in [s];

- : specific materials handling time in the component’s warehouse (unloading time) in [s];

- : total number of available milkrun trolleys in [pcs];

- : specific energy consumption of milkrun trolleys in [kWh/km];

- : specific GHG emission of milkrun trolleys in [CO2 g/km].

- is the length of milkrun routes in the component’s warehouse and in the assembly plant;

- is the index of milkrun routes in the assembly plant, , where is the total number of milkrun routes;

- is the index of stations of milkrun routes in the assembly plant, , where is the maximum number of stations within a milkrun route;

- is the index of milkrun routes in the component’s warehouse, , where is the total number of milkrun routes;

- is the index of stations of milkrun routes in the component’s warehouse, , where is the maximum number of stations within a milkrun route;

- is the first decision variable of the optimization problem defining the assignment of assembly cells to milkrun routes, where is the ID of the assembly cell assigned as station of milkrun route ;

- is the second decision variable of the optimization problem defining the assignment of racks in the component’s warehouse to milkrun routes, where is the ID of the rack in the component’s warehouse assigned as station of milkrun route .

3. Results

- Material supply demands of each assembly cells in [LU] (Table 3);

- Capacity of milkrun trolleys in [LU]: ;

- Average speed of milkrun in the assembly plant in [m/s]: ;

- Average material handling time at the assembly cells in [s]: ;

- Position of required components in the warehouse (see Table 4);

- Average speed of milkrun in the component’s warehouse in [m/s]: ;

- Average material handling time (unloading time) in the component’s warehouse in [s]: .

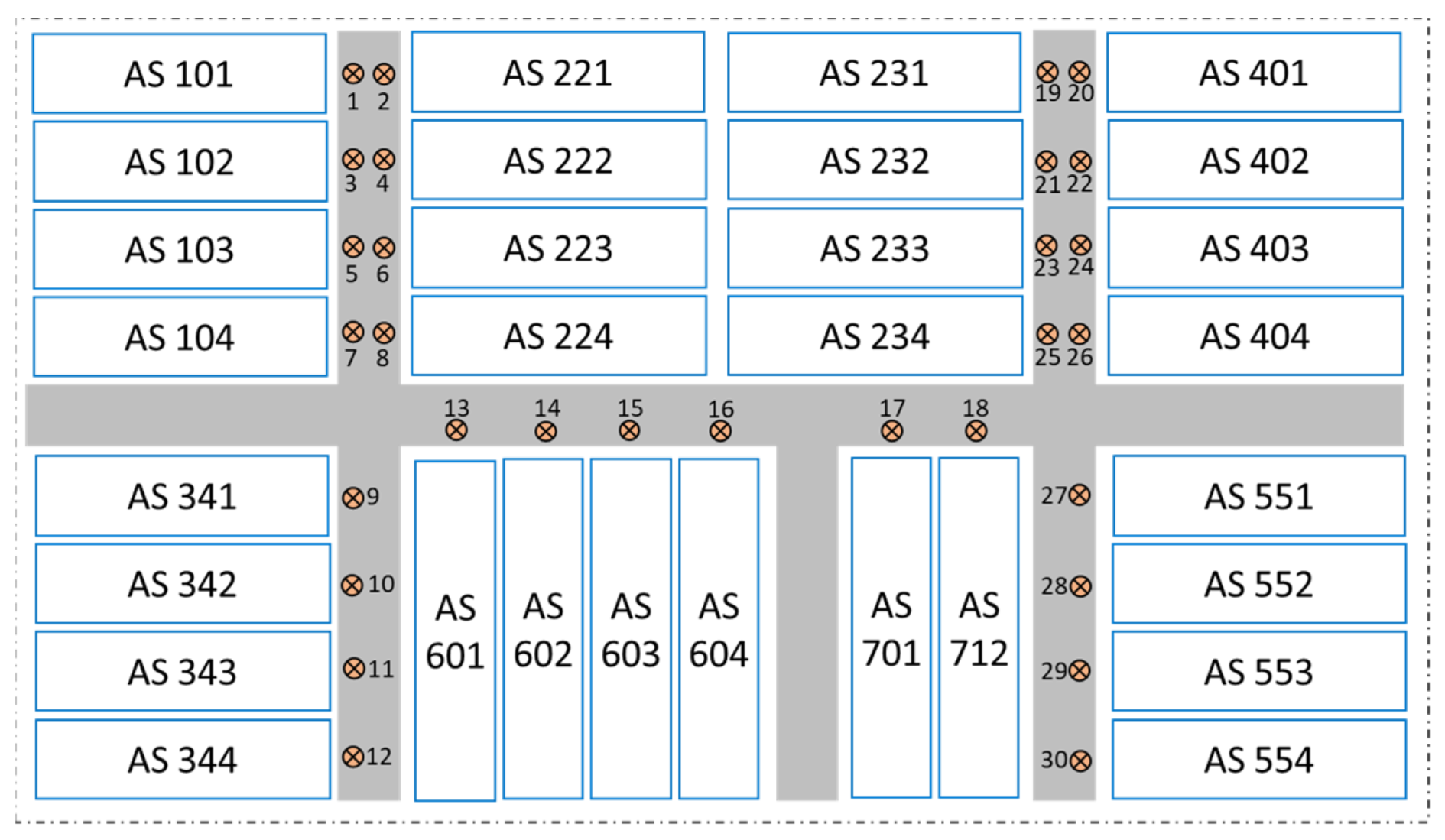

| Assembly Cell’s ID | Picking Point ID | Location (x, y) in [m] | Component Demand in [Type, LU] | Assembly Cell’s ID | Picking Point ID | Location (x, y) in [m] | Component Demand in [Type, LU] |

|---|---|---|---|---|---|---|---|

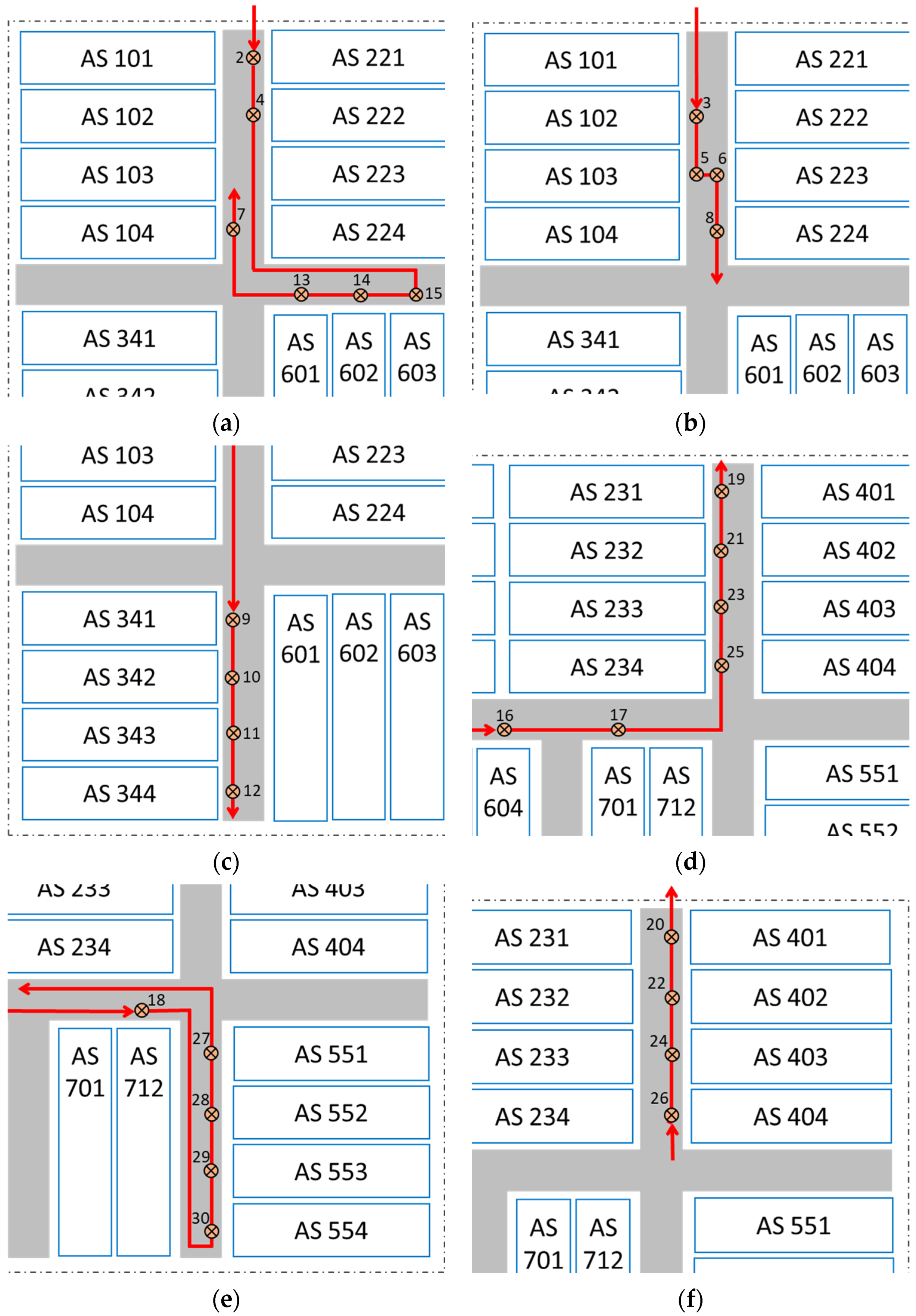

| AS 101 | 1 | (0, 0) | 0,0 | AS 344 | 12 | (0, 65) | X05, 44 |

| AS 102 | 3 | (0, 10) | X12, 23 | AS 401 | 20 | (65, 0) | X06, 27 |

| AS 103 | 5 | (0, 15) | X14, 38 | AS 402 | 22 | (65, 10) | X07, 33 |

| AS 104 | 7 | (0, 25) | Y07, 27 | AS 403 | 24 | (65, 15) | A12, 33 |

| AS 221 | 2 | (5, 0) | X08, 11 | AS 404 | 26 | (65, 25) | A44, 30 |

| AS 222 | 4 | (5, 10) | A02, 12 | AS 551 | 27 | (65, 40) | A51, 30 |

| AS 223 | 6 | (5, 15) | G72, 32 | AS 552 | 28 | (65, 50) | D30, 21 |

| AS 224 | 8 | (5, 25) | C33, 28 | AS 553 | 29 | (65, 55) | D40, 35 |

| AS 231 | 19 | (60, 0) | X11, 16 | AS 554 | 30 | (65, 65) | F03, 20 |

| AS 232 | 21 | (60, 10) | Y05, 11 | AS 601 | 13 | (10, 35) | F02, 11 |

| AS 233 | 23 | (60, 15) | C09, 32 | AS 602 | 14 | (20, 35) | X91, 18 |

| AS 234 | 25 | (60, 25) | B34, 10 | AS 603 | 15 | (25, 35) | Z01, 41 |

| AS 341 | 9 | (0, 40) | B35, 26 | AS 604 | 16 | (35, 35) | Z02, 35 |

| AS 342 | 10 | (0, 50) | X33, 15 | AS 701 | 17 | (45, 35) | Z03, 20 |

| AS 343 | 11 | (0, 55) | C41, 33 | AS 712 | 18 | (55, 35) | Z07, 17 |

| Rack ID | Picking Point ID | Location (x, y) in [m] | Component ID | Rack ID | Picking Point ID | Location (x, y) in [m] | Component ID |

|---|---|---|---|---|---|---|---|

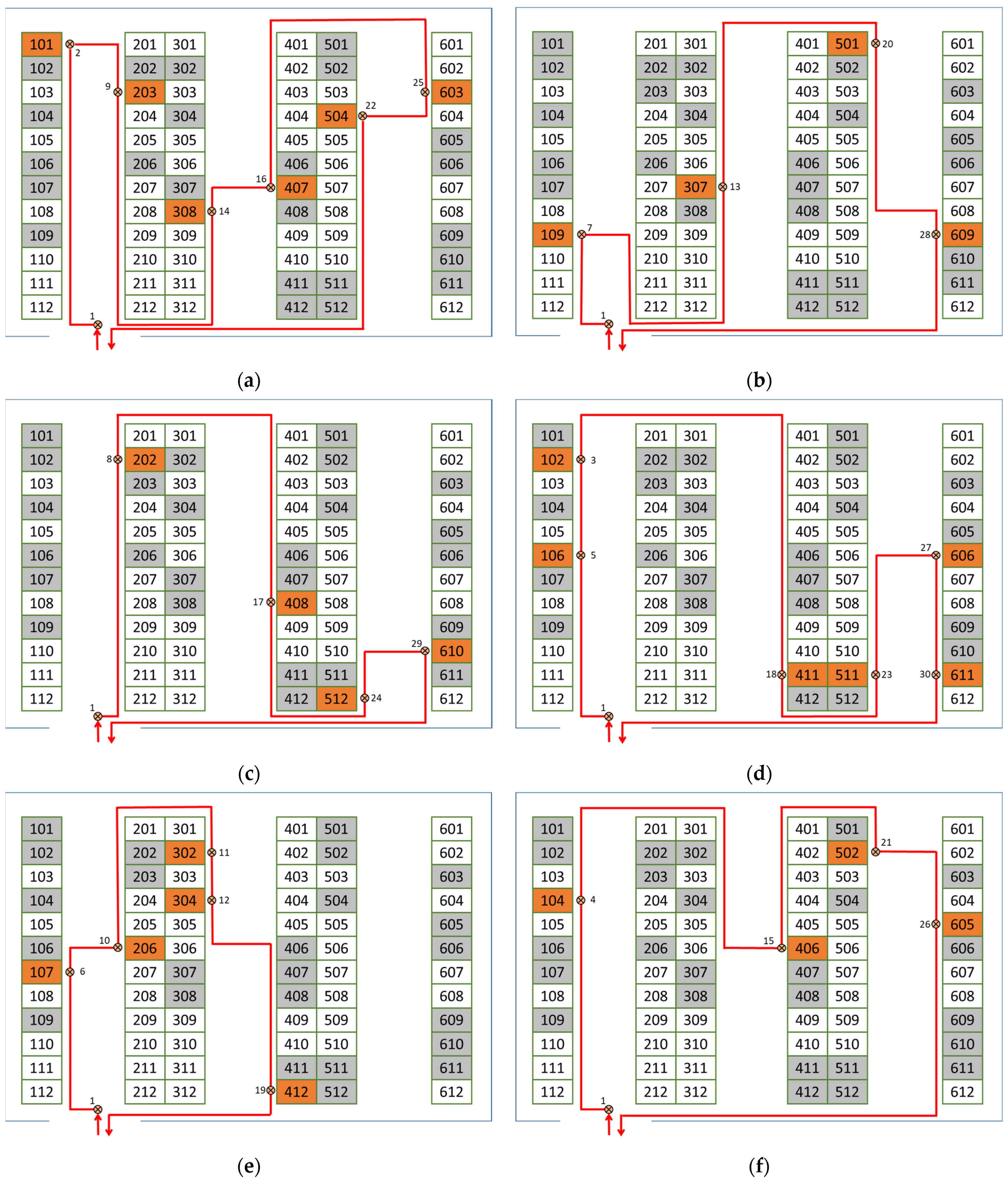

| Entry | 1 | (2, 0) | - | 407 | 16 | (12, 28) | F02 |

| 101 | 2 | (2, 52) | Y07 | 408 | 17 | (12, 24) | X33 |

| 102 | 3 | (2, 48) | X11 | 411 | 18 | (12, 12) | C09 |

| 104 | 4 | (2, 40) | X06 | 412 | 19 | (12, 8) | D40 |

| 106 | 5 | (2, 32) | Y05 | 501 | 20 | (16, 52) | X14 |

| 107 | 6 | (2, 28) | A51 | 502 | 21 | (16, 48) | A12 |

| 109 | 7 | (2, 20) | X12 | 504 | 22 | (16, 40) | X91 |

| 202 | 8 | (4, 48) | B35 | 511 | 23 | (16, 12) | B34 |

| 203 | 9 | (4, 44) | Z01 | 512 | 24 | (16, 8) | C41 |

| 206 | 10 | (4, 32) | D30 | 603 | 25 | (20, 44) | A02 |

| 302 | 11 | (8, 48) | Z07 | 605 | 26 | (20, 36) | A44 |

| 304 | 12 | (8, 40) | F03 | 606 | 27 | (20, 32) | Z02 |

| 307 | 13 | (8, 28) | G72 | 609 | 28 | (20, 20) | C33 |

| 308 | 14 | (8, 24) | X08 | 610 | 29 | (20, 16) | X05 |

| 406 | 15 | (12, 32) | X07 | 611 | 30 | (20, 12) | Z03 |

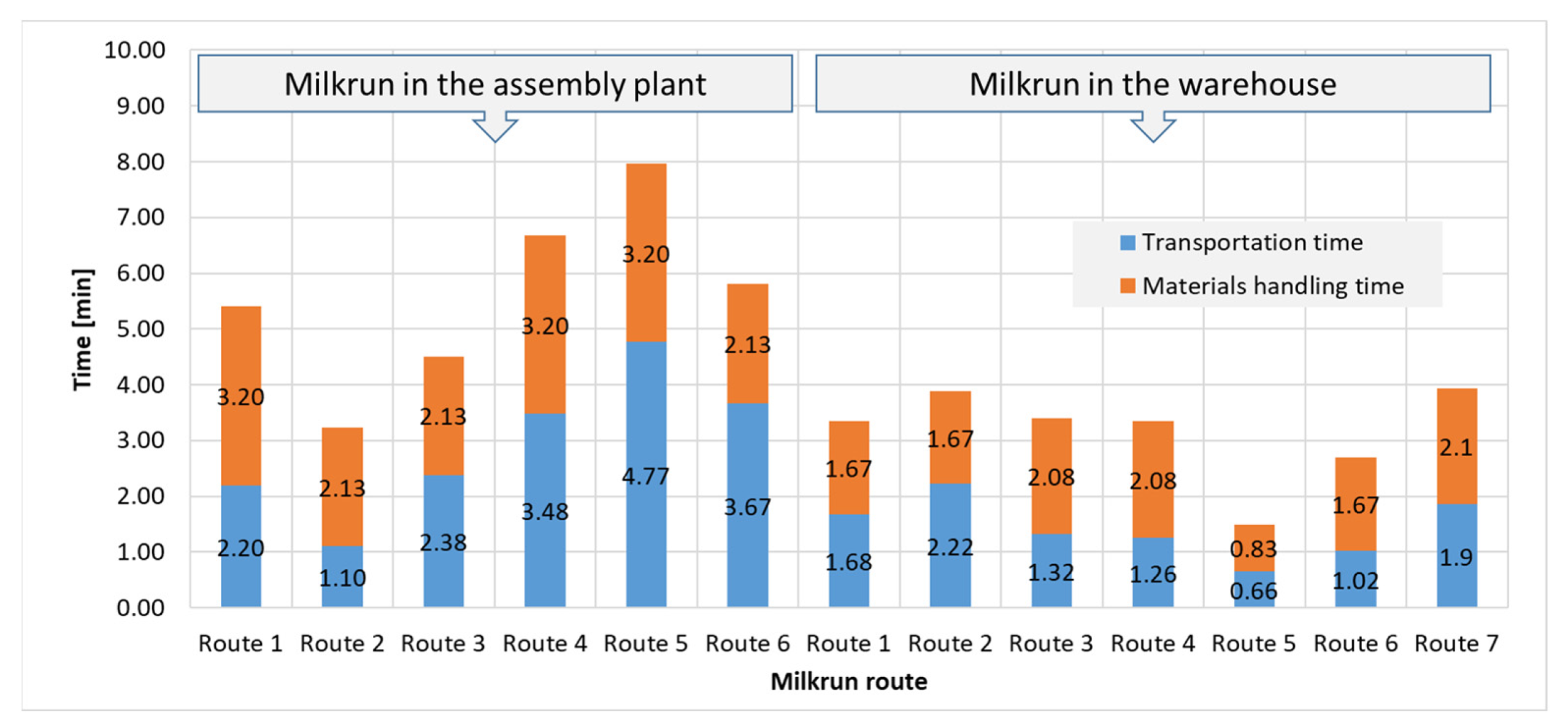

3.1. Computational Results of Conventional Milkrun Supply Optimization

3.2. Computational Results of Hub-Based Milkrun Supply Optimization

3.3. Comparison of the Computational Results

- The material handling time is the same both in the component’s warehouse and in the assembly plant, but there are additional sequencing operations in the hub, which led to increased materials handling time (sequencing);

- The collection routes are not based on the demands of the assembly stations, but they are optimized to minimize the collection routes in the component’s warehouse;

- The optimization of collection routes in the component’s warehouse and in the assembly plant is integrated, which means that the collection and distribution routes are optimized parallel, which can lead to decreased transportation time both in the component’s warehouse and in the assembly plant.

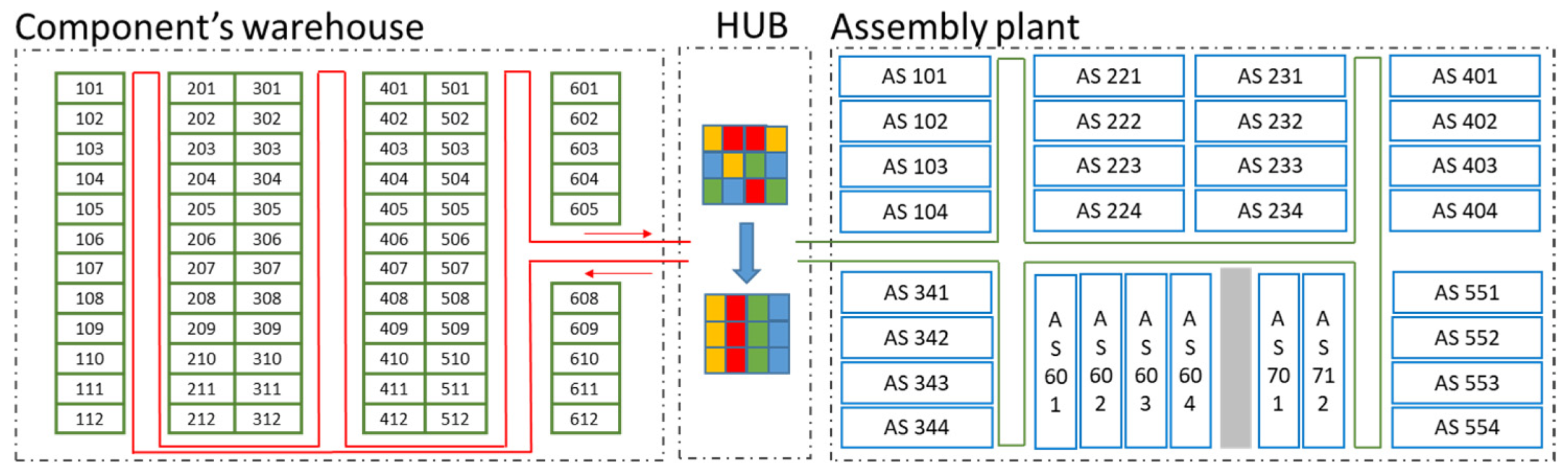

- A free area is needed between the component’s warehouse and the assembly plant where the hub for the sequencing operations can be established. This hub will serve as a critical intermediate storage, performing the efficient transfer of components from component’s warehouse to the assembly cells. The hub’s primary task is to create optimized milkruns in the assembly plant, to ensure that the assembly plant receives the necessary components in a timely and organized manner. These milkruns must be tailored to meet the specific demands of the assembly cells, taking into consideration the assembly schedule, component usage rates, and any potential fluctuations in demand. By establishing a hub, the overall material flow can be streamlined, reducing bottlenecks and minimizing downtime in the assembly process.

- The synchronization of milkrun routes between the component’s warehouse and the assembly plant is crucial for maximizing efficiency. Proper synchronization can significantly reduce the floor space required for the hub, as it allows for a more continuous and predictable material flow. Without synchronization, there could be periods of congestion or underutilization, both of which could lead to inefficiencies. By aligning the milkrun schedules with the assembly master plan, the hub can operate more smoothly, ensuring that components are delivered just-in-time, thus minimizing inventory levels and reducing storage space requirements.

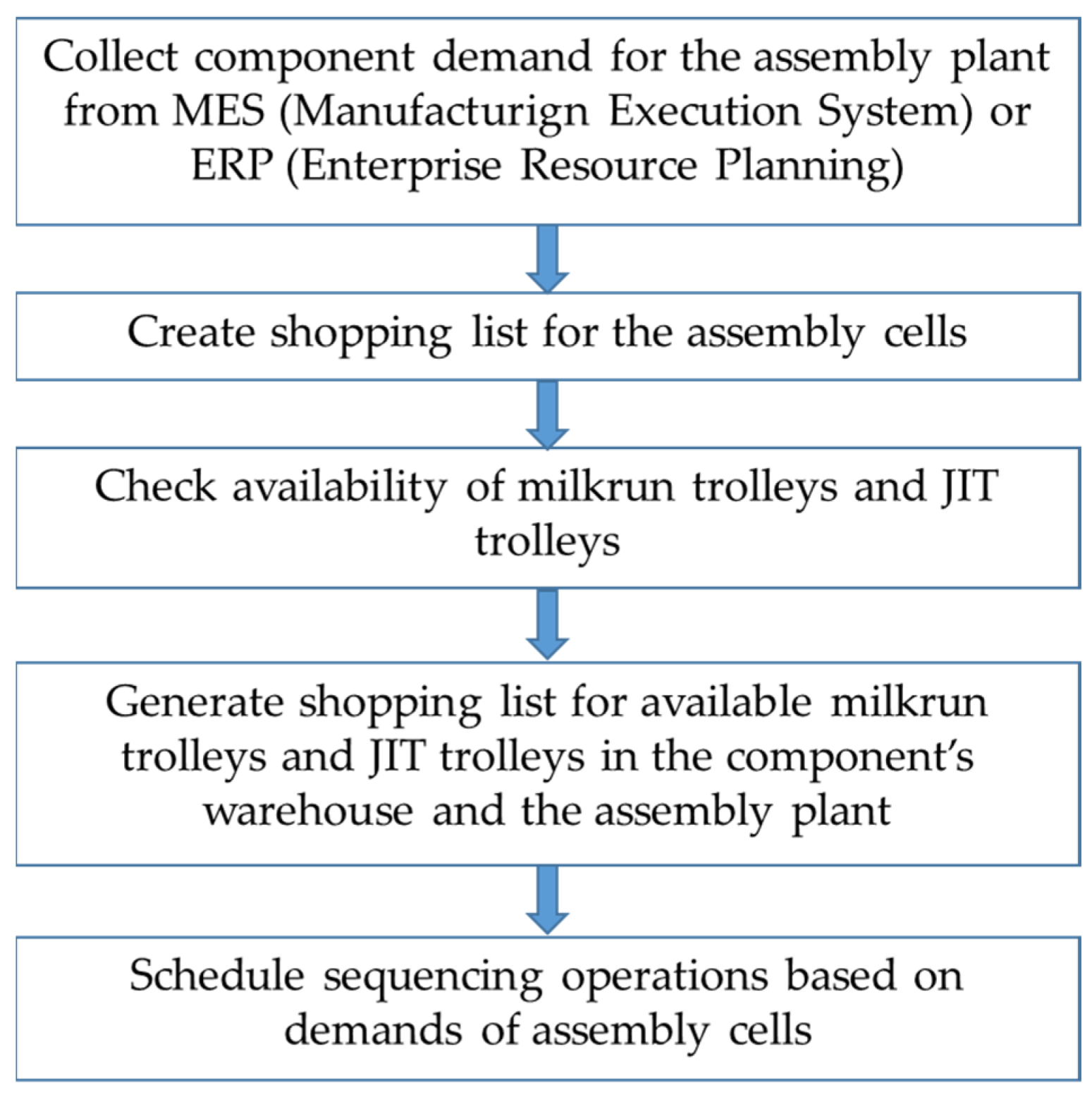

- Reliable demand data is essential for the effective operation of this proposed approach. Accurate and up-to-date information from ERP (Enterprise Resource Planning) or MES (Manufacturing Execution Systems) is critical in forecasting the component needs of the assembly plant. Without reliable data, the milkrun routes cannot be properly planned, leading to either shortages or surpluses of components. Such discrepancies could disrupt the assembly process, causing delays or assembly stoppages, and ultimately leading to increased costs and reduced product quality. Therefore, maintaining accurate demand forecasts is key to ensuring the reliability and efficiency of the entire supply chain. By integrating robust data systems with the hub’s operations, the assembly plant can achieve a more responsive and adaptive production process, capable of handling fluctuations in demand while maintaining high levels of operational efficiency.

4. Discussion

Funding

Data Availability Statement

Conflicts of Interest

References

- Arvidsson, N. The milk run revisited: A load factor paradox with economic and environmental implications for urban freight transport. Transp. Res. Part A Policy Pract. 2013, 51, 56–62. [Google Scholar] [CrossRef]

- Novaes, A.G.N.; Bez, E.T.; Burin, P.J.; Aragão, D.P. Dynamic milk-run OEM operations in over-congested traffic conditions. Comput. Ind. Eng. 2015, 88, 326–340. [Google Scholar] [CrossRef]

- Emde, S.; Abedinnia, H.; Glock, C.H. Scheduling electric vehicles making milk-runs for just-in-time delivery. IISE Trans. 2018, 50, 1013–1025. [Google Scholar] [CrossRef]

- Luo, X.; Jiang, Y.; Wu, Q.; Zhao, B.; Yao, Z. Design of hub stops and milk-run routes in transit network between urban area and suburb. Harbin Gongye Daxue Xuebao J. Harbin Inst. Technol. 2019, 51, 135–140. [Google Scholar] [CrossRef]

- Karouani, Y.; Elgarej, M. Milk-run collection monitoring system using the internet of things based on swarm intelligence. Int. J. Inf. Syst. Supply Chain Manag. 2022, 15, 3. [Google Scholar] [CrossRef]

- Dewitz, M.; Günthner, W.A.; Arlt, T. Timetable optimization for in-plant milk-run systems. Logist. J. 2014, 1, 1–14. [Google Scholar] [CrossRef]

- Kilic, H.S.; Durmusoglu, M.B.; Baskak, M. Classification and modeling for in-plant milk-run distribution systems. Int. J. Adv. Manuf. Technol. 2012, 62, 1135–1146. [Google Scholar] [CrossRef]

- Bocewicz, G.; Banaszak, Z.; Rudnik, K.; Smutnicki, C.; Witczak, M. An ordered-fuzzy-numbers-driven approach to the milk-run routing and scheduling problem. J. Comput. Sci. 2021, 49, 101288. [Google Scholar] [CrossRef]

- Çakir, E.; Ulukan, Z.; Kahraman, C.; Saǧlam, C.Ö.; Kuleli Pak, B. Intuitionistic fuzzy multi-objective milk-run modelling under time window constraints. J. Intell. Fuzzy Syst. 2022, 42, 47–62. [Google Scholar] [CrossRef]

- Facchini, F.; Mossa, G.; Sassanelli, C.; Digiesi, S. IoT-based milk-run routing for manufacturing system: An application case in an automotive company. Int. J. Prod. Res. 2024, 62, 536–555. [Google Scholar] [CrossRef]

- Akkad, M.Z.; Bányai, T. Energy Consumption Optimization of Milk-Run-Based In-Plant Supply Solutions: An Industry 4.0 Approach. Processes 2023, 11, 799. [Google Scholar] [CrossRef]

- De Souza, R.; William, L.; Lee, C.K. Marginalizing last mile logistics cost through 4th party milk run. Adv. Sci. Technol. Eng. Syst. 2019, 4, 462–467. [Google Scholar] [CrossRef]

- Mohd, S.; Noor, A.; Ahmad, S.F.; Shaharudin, M.R.; Rahim, S.A. Evaluation of transportation distance optimization route for milk run logistics system. Int. J. Supply Oper. Manag. 2023, 10, 295–318. [Google Scholar] [CrossRef]

- Eroglu, D.Y.; Cagliano, A.C.; Rafele, C. A multi-capacity integrated vehicle routing and loading model for pickup milk run. Int. J. Mech. Control 2017, 18, 107–122. [Google Scholar]

- Adriano, D.D.; Montez, C.; Novaes, A.G.; Wangham, M. DMRVR: Dynamic milk-run vehicle routing solution using fog-based vehicular ad hoc networks. Electronics 2020, 9, 2010. [Google Scholar] [CrossRef]

- Gil Vilda, F.; Yagüe-Fabra, J.A.; Sunyer Torrents, A. An in-plant milk-run design method for improving surface occupation and optimizing mizusumashi work time. CIRP Ann. 2020, 69, 405–408. [Google Scholar] [CrossRef]

- Dat Minh, N.; Trung Kien, D.; Khac Hau, P. Applying milk-run method to optimize cost of transport: An empirical evidence. Int. J. Supply Oper. Manag. 2020, 7, 178–188. [Google Scholar] [CrossRef]

- Mai, J.-J.; Chen, F. Uncertain milk run-based cross docking scheduling: Model and algorithms. Shanghai Jiaotong Daxue Xuebao J. Shanghai Jiaotong Univ. 2011, 45, 159–163. [Google Scholar]

- Bocewicz, G.; Bozejko, W.; Wójcik, R.; Banaszak, Z. Milk-run routing and scheduling subject to a trade-off between vehicle fleet size and storage capacity. Manag. Prod. Eng. Rev. 2019, 10, 41–53. [Google Scholar] [CrossRef]

- Bocewicz, G.; Nielsen, I.; Gola, A.; Banaszak, Z. Reference model of milk-run traffic systems prototyping. Int. J. Prod. Res. 2021, 59, 4495–4512. [Google Scholar] [CrossRef]

- Chee, S.L.; Mong, M.Y.; Chin, J.F. Milk-run kanban system for raw printed circuit board withdrawal to surface-mounted equipment. J. Ind. Eng. Manag. 2012, 5, 382–405. [Google Scholar] [CrossRef]

- Du, T.; Wang, B.; Lu, P.-Y. A real-time vehicle-dispatching system for consolidating milk runs. Transp. Res. Part E Logist. Transp. Rev. 2007, 43, 565–577. [Google Scholar] [CrossRef]

- Emde, S.; Zehtabian, S.; Disser, Y. Point-to-point and milk run delivery scheduling: Models, complexity results, and algorithms based on Benders decomposition. Ann. Oper. Res. 2023, 322, 467–496. [Google Scholar] [CrossRef]

- Goto, M.; Masui, T.; Tawara, N. A mixed distribution system of direct and relay delivery methods based on an analogy of milk-run logistics. J. Jpn. Ind. Manag. Assoc. 2007, 58, 79–86. [Google Scholar]

- Klenk, E.; Galka, S.; Günthner, W.A. Potentials of a in-plant milk run control. ZWF Z. Fuer Wirtsch. Fabr. 2015, 110, 805–809. [Google Scholar] [CrossRef]

- Aragão, D.P.; Novaes, A.G.N.; Luna, M.M.M. An agent-based approach to evaluate collaborative strategies in milk-run OEM operations. Comput. Ind. Eng. 2019, 129, 545–555. [Google Scholar] [CrossRef]

- Marialuisa, M.; Matteo, M.; Muhammad, S. Optimizing milk-run system and IT-based Kanban with artificial intelligence: An empirical study on multi-lines assembly shop floor. Prod. Manuf. Res. 2023, 11, 2179123. [Google Scholar] [CrossRef]

- Korytkowski, P.; Karkoszka, R. Simulation-based efficiency analysis of an in-plant milk-run operator under disturbances. Int. J. Adv. Manuf. Technol. 2016, 82, 827–837. [Google Scholar] [CrossRef]

- Chen, J.; Wang, K.; Huang, Y. An integrated inbound logistics mode with intelligent scheduling of milk-run collection, drop and pull delivery and LNG vehicles. J. Intell. Manuf. 2021, 32, 2257–2265. [Google Scholar] [CrossRef]

- Meyer, A.; Amberg, B. Transport concept selection considering supplier milk runs—An integrated model and a case study from the automotive industry. Transp. Res. Part E Logist. Transp. Rev. 2018, 113, 147–169. [Google Scholar] [CrossRef]

- Baals, J. Environmental aspects in supplier networks-a bi-objective just-in-time truck routing problem. Int. J. Prod. Res. 2024, 62, 4290–4313. [Google Scholar] [CrossRef]

- Katon, Y.C.; Artana, K.B.; Pujawan, I.N.; Putra, B.W. Performance Assessment of Fertilizer Industry Supply Chain Using a System Dynamics Approach. Int. Rev. Mech. Eng. 2023, 17, 557–565. [Google Scholar] [CrossRef]

- Nalbur, B.E.; Yavas, O. System dynamics model and discrete-event simulation of green logistics cases for the electric bus industries. Int. J. Glob. Warm. 2024, 32, 148–159. [Google Scholar] [CrossRef]

- Zhou, B.; Zhu, Z. Optimally scheduling and loading tow trains of in-plant milk-run delivery for mixed-model assembly lines. Assem. Autom. 2020, 40, 511–530. [Google Scholar] [CrossRef]

- Sarkar, B.D.; Joshi, P.V.; Shah, N. Reverse milk run—The logistics retrenchment strategy. Emerald Emerg. Mark. Case Stud. 2023, 13, 1–23. [Google Scholar] [CrossRef]

- Kochanska, J.; Burduk, A.; Łapczynska, D.; Musiał, K. The solution of MRSLP with the use of heuristic algorithms. Bull. Pol. Acad. Sci. Tech. Sci. 2024, 72, 146407. [Google Scholar] [CrossRef]

- Zhou, B.; Zhao, Z. An adaptive artificial bee colony algorithm enhanced by Deep Q-Learning for milk-run vehicle scheduling problem based on supply hub. Knowl.-Based Syst. 2023, 264, 110367. [Google Scholar] [CrossRef]

- Ranjbaran, F.; Husseinzadeh Kashan, A.; Kazemi, A. Mathematical formulation and heuristic algorithms for optimisation of auto-part milk-run logistics network considering forward and reverse flow of pallets. Int. J. Prod. Res. 2020, 58, 1741–1775. [Google Scholar] [CrossRef]

- Amaral, V.P.; Ferreira, A.C.; Ramos, B. Internal Logistics Process Improvement using PDCA: A Case Study in the Automotive Sector. Bus. Syst. Res. 2022, 13, 100–115. [Google Scholar] [CrossRef]

- Humang, W.P.; Hadiwardoyo, S.P.; Nahry, A. Bi-level model on freight distribution network integration in archipelagic region with milk run time windows and uncertainty. Int. J. Eng. Res. Technol. 2020, 13, 831–841. [Google Scholar] [CrossRef]

- Kocaoglu, Y.; Cakmak, E.; Kocaoglu, B.; Taskin Gumus, A. A Novel Approach for Optimizing the Supply Chain: A Heuristic-Based Hybrid Algorithm. Math. Probl. Eng. 2020, 2020, 3943798. [Google Scholar] [CrossRef]

- Yan, B.; Chen, X.; Liu, Y.; Xia, C. Replenishment decision and coordination contract in cluster supply chain. Ind. Manag. Data Syst. 2019, 119, 1374–1399. [Google Scholar] [CrossRef]

- Ali, S.S.; Deka, S.; Ahmad, Z.; Ahmed, S.; Jaswal, M. Feasibility of drone integration as last mile delivery. Emerald Emerg. Mark. Case Stud. 2019, 9, 1–17. [Google Scholar] [CrossRef]

- The Power of Milkrun in Logistics. Available online: https://www.multitube.com/en/power-milk-run-in-logistics/l776c30 (accessed on 16 August 2024).

- Milkrun Optimization—Calculate Cost-Optimal Routes for Inbound and Outbound Shipments. Available online: https://log-hub.com/supply-chain-apps/milkrun-optimization/ (accessed on 16 August 2024).

- Milk Run Supply Chain Automation. Available online: https://www.nitorinfotech.com/wp-content/uploads/2021/05/Milk-Run-Supply-Chain-Automation.pdf (accessed on 16 August 2024).

- Chen, C. Supply-hub-based Collaborative Replenishment Decisions for Enterprise Supply Logistics Under Demand Uncertainty. Front. Bus. Econ. Manag. 2023, 8, 77–81. [Google Scholar] [CrossRef]

| Design Aspects | Application Fields | Technologies and Tools |

|---|---|---|

| Economic implications [1] | Traffic networks [2,4,20] | Electric vehicles [3] |

| Environmental implications [2] | Distribution systems [7] | LNG vehicles [29] |

| Timetable optimization [6] | Automotive industry [10] | Internet of Things [5,10] |

| Uncertain environment [8,9,18] | Kanban systems [21,27] | Industry 4.1 technologies [11] |

| Logistics cost [12,17] | Mixed distribution [24] | Fog-based networks [15] |

| Transportation distance [13] | Inbound logistics [29] | Agent-based approaches [26] |

| Capacity [14] | Supplier networks [31] | Artificial intelligence [27] |

| Surface occupation [16] | Fertilizer industry [32] | Simulation-based design [28,33,34] |

| Fleet size optimization [19] | Reverse milkrun [35] | Heuristic optimization [36] |

| Consolidating milkruns [22] | Mixed-model assembly lines [34] | Deep Q-learning [37] |

| Complexity analysis [23] | Pallet flow [38] | PDCA [39] |

| Milkrun control [25] | Archipelagic region [40] | Hybrid algorithms [41] |

| Transport concept selection [30] | Cluster supply chain [42] | Drones in milkrun [43] |

| Notations and Symbols | Description |

|---|---|

| . | |

| . | |

| Quantity of supply demand of assembly cell i in [LU]. | |

| Capacity of milkrun trolleys in [LU]. | |

| Average speed of milkrun trolleys in the assembly plant. | |

| Average speed of milkrun trolleys in the component’s warehouse. | |

| Specific materials handling time in the assembly plant (unloading time) in [s]. | |

| Specific materials handling time in the component’s warehouse (unloading time) in [s]. | |

| Total number of available milkrun trolleys in [pcs]. | |

| Specific energy consumption of milkrun trolleys in [kWh/km]. | |

| Specific GHG emission of milkrun trolleys in [CO2 g/km]. | |

| The length of milkrun routes in the component’s warehouse and in the assembly plant. | |

| The index of milkrun routes in the assembly plant. | |

| The index of stations of milkrun routes in the assembly plant. | |

| The index of milkrun routes in the component’s warehouse. | |

| The index of stations of milkrun routes in the component’s warehouse. | |

| Assignment of assembly cells to milkrun routes (first decision variable). | |

| The assignment of racks in the component’s warehouse to milkrun routes (second decision variable). | |

| The transportation time of milkrun routes in the component’s warehouse and in the assembly plant. | |

| The total time of milkrun routes in the component’s warehouse and in the assembly plant. | |

| The total energy consumption of milkrun trolleys. | |

| The current load of the milkrun at assembly cell. | |

| The total GHG emission of milkrun trolleys. | |

| . |

| Route ID | Parameter | Picking Points | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Warehouse | Assembly Plant | ||||||||||||

| 1st | 2nd | 3rd | 4th | 5th | 6th | 1st | 2nd | 3rd | 4th | 5th | 6th | ||

| 1 | PPID 1 | 2 | 9 | 14 | 16 | 25 | 22 | 2 | 4 | 15 | 14 | 13 | 7 |

| Utilization | 21.6% | 54.4% | 63.2% | 72.0% | 81.6% | 96.0% | 96.0% | 87.2% | 77.6% | 68.8% | 36.0% | 21.6% | |

| 2 | PPID | 7 | 13 | 20 | 28 | - | - | 3 | 5 | 6 | 8 | - | - |

| Utilization | 18.4% | 44.0% | 74.4% | 96.8% | - | - | 96.8% | 66.4% | 40.8% | 18.4% | - | - | |

| 3 | PPID | 8 | 17 | 24 | 29 | - | - | 9 | 10 | 11 | 12 | - | - |

| Utilization | 20.8% | 32.8% | 59.2% | 94.4% | - | - | 94.4% | 73.6% | 61.6% | 26.4% | - | - | |

| 4 | PPID | 5 | 3 | 18 | 23 | 27 | 30 | 16 | 17 | 25 | 23 | 21 | 19 |

| Utilization | 8.8% | 21.6% | 47.2% | 55.2% | 83.2% | 99.2% | 99.2% | 71.2% | 55.2% | 47.2% | 21.6% | 12.8% | |

| 5 | PPID | 6 | 10 | 11 | 12 | 19 | - | 18 | 30 | 29 | 28 | 27 | - |

| Utilization | 24.0% | 40.8% | 54.4% | 70.4% | 98.4% | - | 98.4% | 84.8% | 68.0% | 52.0% | 24.0% | - | |

| 6 | PPID | 4 | 15 | 21 | 26 | - | - | 26 | 24 | 22 | 20 | - | - |

| Utilization | 21.6% | 48.0% | 74.4% | 98.4% | - | - | 98.4% | 74.4% | 48.0% | 21.6% | - | - | |

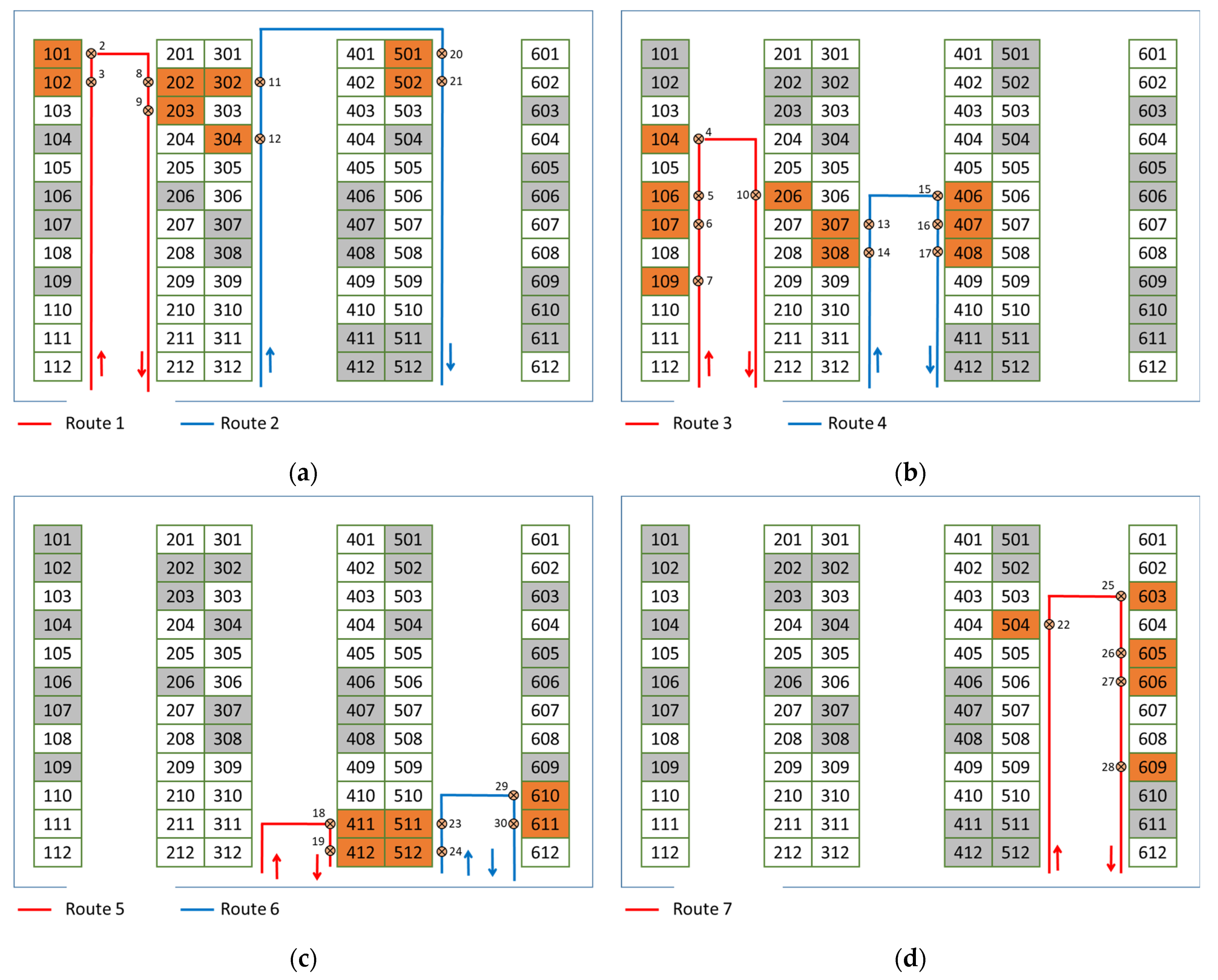

| Route | Parameter | Picking Point | |||||

|---|---|---|---|---|---|---|---|

| Route 1 Assembly Plant | PPID 1 | 2 | 9 | 14 | 16 | 25 | 22 |

| Utilization | 21.6% | 54.4% | 63.2% | 72.0% | 81.6% | 96.0% | |

| Route 2 Assembly Plant | PPID | 7 | 13 | 20 | 28 | - | - |

| Utilization | 18.4% | 44.0% | 74.4% | 96.8% | - | - | |

| Route 3 Assembly Plant | PPID | 8 | 17 | 24 | 29 | - | - |

| Utilization | 20.8% | 32.8% | 59.2% | 94.4% | - | - | |

| Route 4 Assembly Plant | PPID | 5 | 3 | 18 | 23 | 27 | 30 |

| Utilization | 8.8% | 21.6% | 47.2% | 55.2% | 83.2% | 99.2% | |

| Route 5 Assembly Plant | PPID | 6 | 10 | 11 | 12 | 19 | - |

| Utilization | 24.0% | 40.8% | 54.4% | 70.4% | 98.4% | - | |

| Route 6 Assembly Plant | PPID | 4 | 15 | 21 | 26 | - | - |

| Utilization | 21.6% | 48.0% | 74.4% | 98.4% | - | - | |

| Route 1 Warehouse | PPID | 3 | 2 | 8 | 9 | - | - |

| Utilization | 12.8% | 34.4% | 55.2% | 88.0% | - | - | |

| Route 2 Warehouse | PPID | 12 | 11 | 20 | 21 | - | - |

| Utilization | 1.0% | 29.6% | 60.0% | 86.4% | - | - | |

| Route 3 Warehouse | PPID | 7 | 6 | 5 | 4 | 10 | - |

| Utilization | 18.4% | 42.4% | 51.2% | 72.8% | 89.6% | - | |

| Route 4 Warehouse | PPID | 14 | 13 | 15 | 16 | 17 | - |

| Utilization | 8.8% | 34.4% | 60.8% | 69.6% | 81.6% | - | |

| Route 5 Warehouse | PPID | 18 | 19 | - | - | - | - |

| Utilization | 25.6% | 53.6% | - | - | - | - | |

| Route 6 Warehouse | PPID | 24 | 23 | 29 | 30 | - | - |

| Utilization | 26.4% | 34.4% | 69.6% | 85.6% | - | - | |

| Route 7 Warehouse | PPID | 22 | 25 | 26 | 27 | 28 | - |

| Utilization | 14.4% | 24.0% | 48.0% | 76.0% | 98.4% | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bányai, T. Optimization of Hub-Based Milkrun Supply. Logistics 2024, 8, 86. https://doi.org/10.3390/logistics8030086

Bányai T. Optimization of Hub-Based Milkrun Supply. Logistics. 2024; 8(3):86. https://doi.org/10.3390/logistics8030086

Chicago/Turabian StyleBányai, Tamás. 2024. "Optimization of Hub-Based Milkrun Supply" Logistics 8, no. 3: 86. https://doi.org/10.3390/logistics8030086

APA StyleBányai, T. (2024). Optimization of Hub-Based Milkrun Supply. Logistics, 8(3), 86. https://doi.org/10.3390/logistics8030086