Enhancing Logistical Performance in a Colombian Citrus Supply Chain Through Joint Decision Making: A Simulation Study

Abstract

:1. Introduction

2. Literature Review

2.1. Supply Chain Coordination

2.2. Coordination in Logistics and at Interfaces of the Supply Chain

2.3. Joint Decision-Making Mechanisms

| Authors | Function/ Interface | Structure of Supply Chain | Coordination Problem | Methodology | Performance Measures |

|---|---|---|---|---|---|

| [21] | Logistics and transportation | Hub-and-spoke supply chain structure with a single distributor and multiple retailers | Inefficient vehicle utilization caused by isolated decision making by individual retailers, leading to suboptimal vehicle usage and higher CO2 emissions | A simulation-based case study to analyze collaborative distribution scenarios in the logistics network | Transport distances, CO2 emissions, truck utilization, and cost savings |

| [27] | Network design | Multi-echelon, involving suppliers, production sites, and distribution centers | Integrate multiple companies and supply chain levels to achieve the triple-bottom-line (3BL) sustainability goals | Mixed-integer linear programming (MILP) model to optimize supply chain decisions | Total costs, profitability, carbon emissions |

| [29] | Coordination and collaboration | Two-echelon supply chains in high-tech industries: B2B supplier-customer | Limited understanding in the literature regarding why and when companies prefer joint over individual supply chain decision making, despite its benefits. | Case studies, semi-structured interviews conducted with supply chain managers of high-tech industries, conceptual framework of drivers and facilitators | Identification of key drivers and facilitators to enable joint decisions |

| [30] | Resource planning, forecasting, inventory management, distribution | Multiple echelon of the emergency care supply chain | Lack of centralized decision making between the healthcare services of the emergency care pathway to rationalize investments decisions | Discrete Event Simulation (DES) combined with mathematical modeling and multi-objective optimization techniques | Total number of incoming and served patients, response time, length of stay, door-to-doctor time, boarding time, total wait time |

| [31] | Logistics and transportation | Retail food supply chains (vendors, carriers, and retailers) | Achieve cooperation among vendors to optimize delivery planning and reduce transport costs while balancing competitive and cooperative delivery regimes | Integer linear programming (ILP) model to solve the vehicle routing (VR) problem, enabling multi-scenario sensitivity analysis for assessing the impact of cooperative delivery planning | Total cost, service level, vehicle utilization, delivery time-window constraints |

| [37] | Inventory management, demand forecasting, quality control | Two-echelon supply chain: buyer (retailer) and a vendor (manufacturer) system | Aligning the objectives of the buyer and the vendor to minimize total costs while complying with emission regulations (cap-and-trade or tax) | Mathematical modeling for minimizing total costs under environmental constraints, comparing decentralized and centralized decision making | Total cost, carbon emissions, cost efficiency of coordination, environmental impact |

| [46] | Order fulfillment | Two-level structure: single supplier and a single e-commerce enterprise | Address the supplier’s misreporting decision and its impact on fresh supply chain performance under conditions of information asymmetry | Stackelberg game models to analyze decision-making dynamics under various information transparency and power structures | Fresh-keeping level, after-sales rate, supply chain profit, sensitivity to fresh-keeping technology |

| [50] | Cybersecurity investment and coordination | Two-echelon supply chain (a retailer and multiple suppliers) | Externalities, such as free-riding and the prisoner’s dilemma, lead to poor security investments, causing inefficiencies and higher vulnerabilities in the network. | A game theory model is used to analyze optimal cybersecurity investment strategies, considering third-party risk propagation and externalities | Expected cost, investment efficiency, security level |

| [51] | Procurement-distribution | Three-tier supply chain structure | Align the objectives of diverse participants (suppliers, manufacturers, retailers) under supply disruption risks and capacity constraints | Mathematical modeling and arithmetic simulation to address a dual-source procurement optimization problem, incorporating capacity constraints | Expected profit, revenue sharing coefficient, repurchase coefficient |

| [52] | Logistics, transportation management | Small and medium enterprises (SMEs) in the wine industry in Western Australia: wine producers | SMEs face high transportation costs and a lack of resources, limiting their ability to engage in effective collaborative transportation without proper coordination | Qualitative and exploratory approach using case studies and the Theory of Planned Behavior (TPB) to model SMEs’ intentions to engage in collaborative transportation | Intentions to collaborate, cost reduction, and market expansion potential |

| [53] | Logistics | A single online store and a third-party logistics (TPL) provider | Achieve an optimal preservation effort level and address low preservation capacity in the online shopping supply chain, considering the allocation of cargo damage costs between stakeholders. | Game-theoretic modeling and numerical simulation to analyze different centralized and decentralized decision-making models | Preservation effort level, system profit, cost of damaged goods |

| Our study | Logistics | Multi-echelon food supply chain (small farmers, food hub, customers) | Address the logistical challenges faced by a smallholder-dominated supply chain while supporting broader sustainability goals | A simulation-based case study combining agent-based modeling to describe the system and simulate coordination mechanisms, with a case study approach to estimate model parameters | Total distance traveled, average travel times, loading/unloading times, and Load Capacity Utilization, total distribution cost, revenue, and gross profit margin. |

2.4. Concluding Remarks

3. Materials and Methods

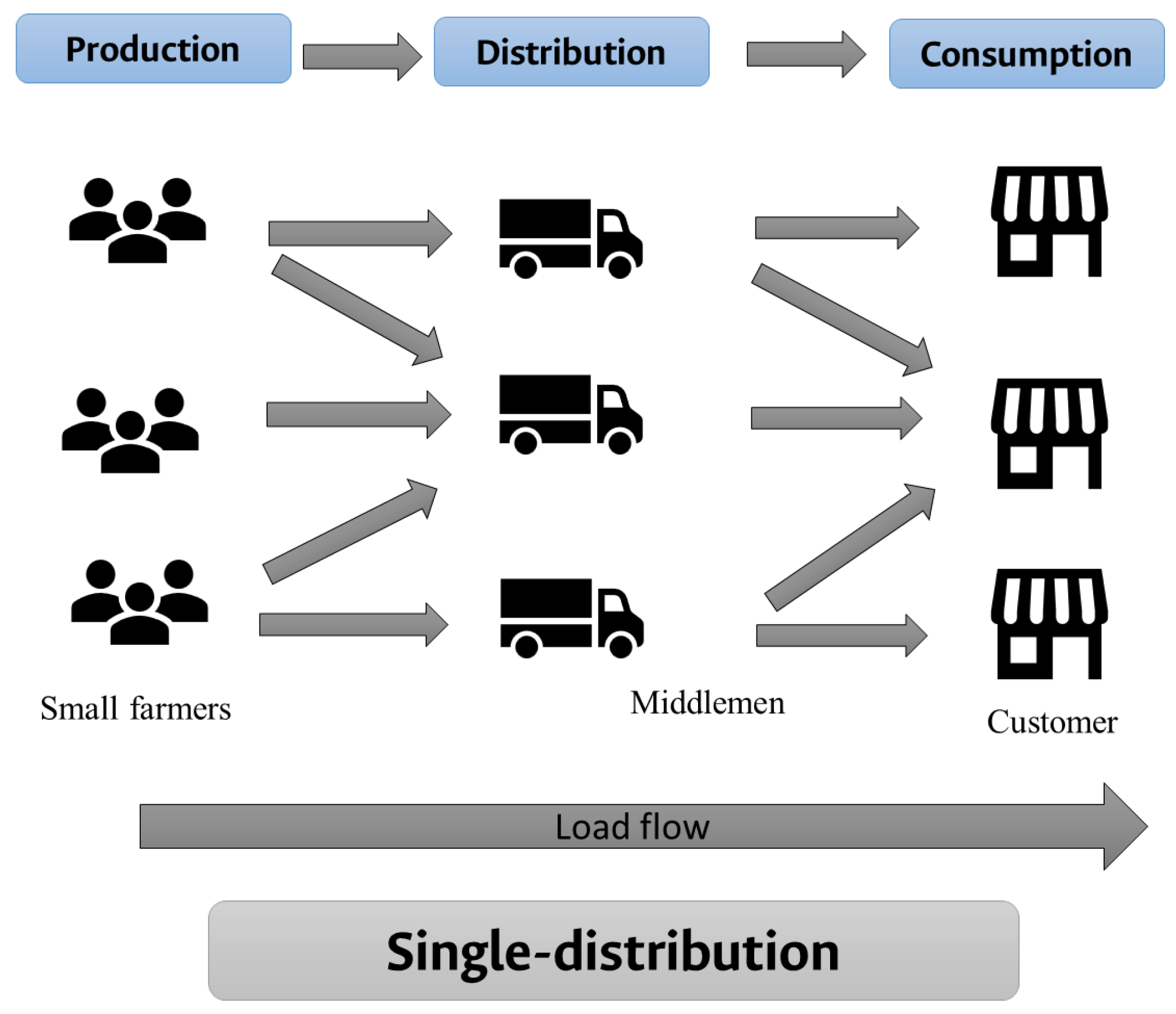

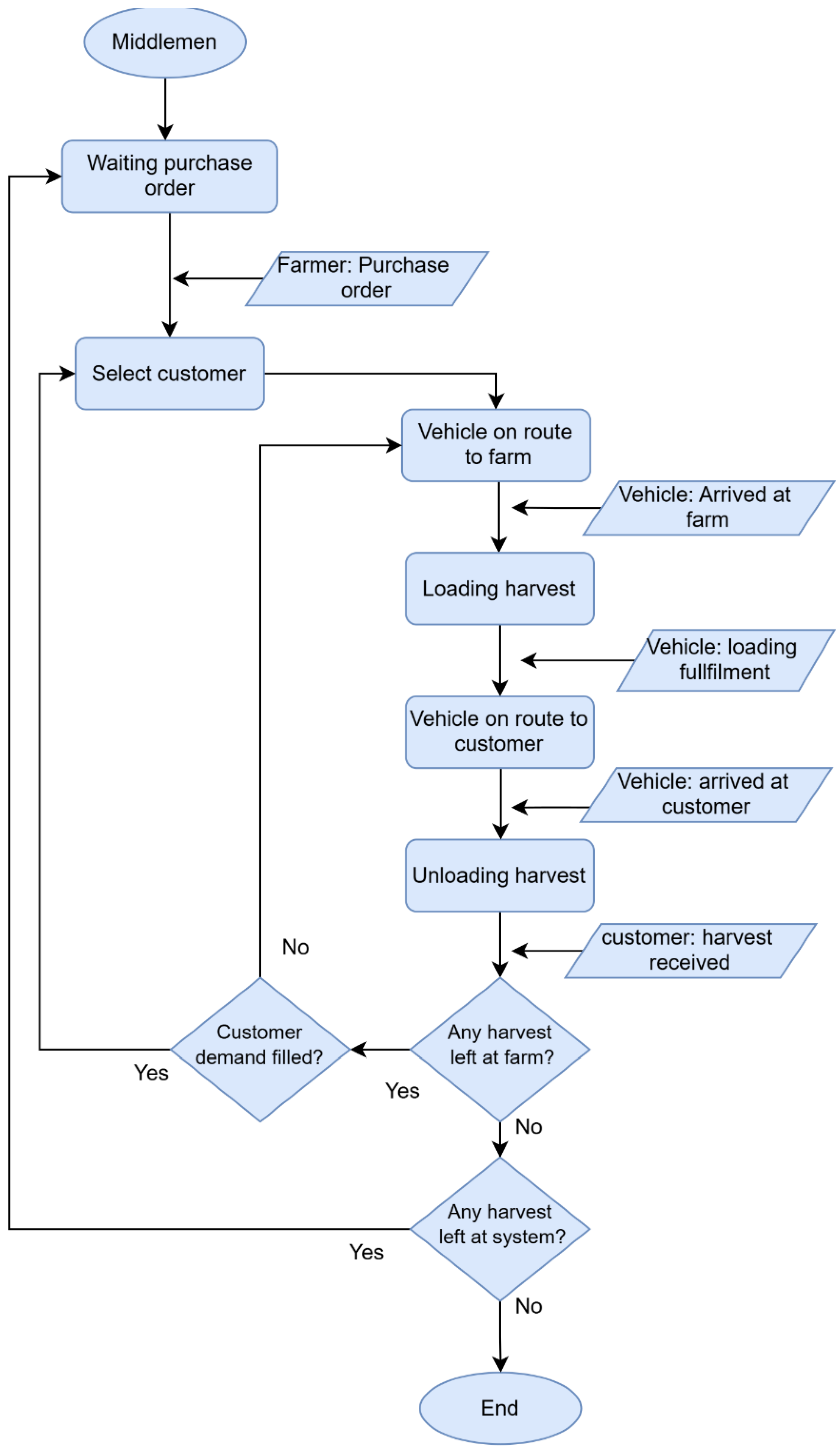

3.1. System Description and Base Scenario

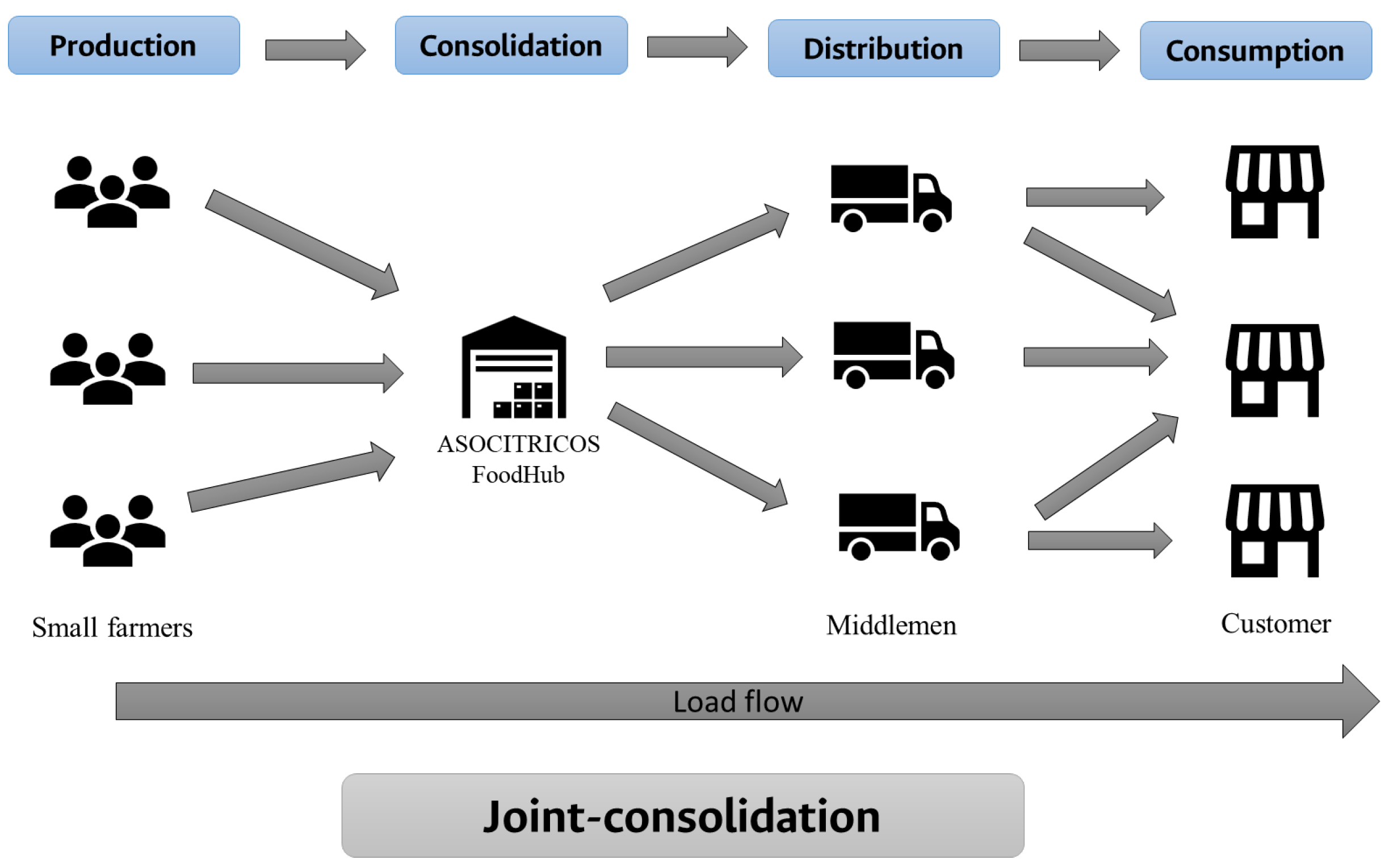

3.2. Joint-Consolidation Scenario

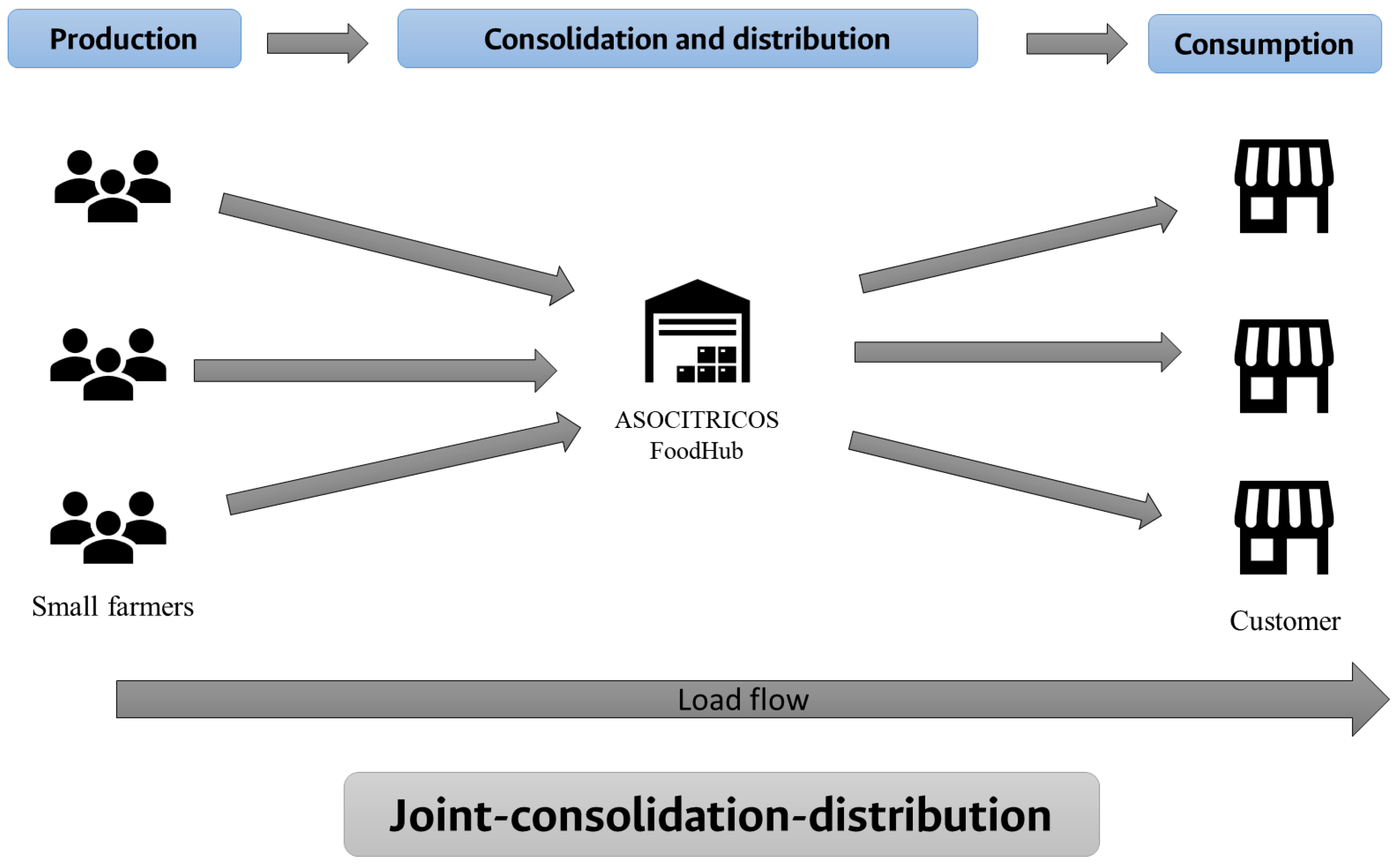

3.3. Joint-Consolidation-Distribution Scenario

3.4. Modeling

- The demand was known and matched supply, assuming that the farmers’ entire harvest was sold to consumers.

- Vehicles could exist in one of the following states: Idle/Available (0), when a vehicle was idle and ready to travel; Empty-Travel (1), when a vehicle was traveling without a load; Loading (2), when a vehicle was being loaded with a harvest; Load-Travel (3), when a vehicle was traveling with a load (operating at either full or partial capacity); and Unloading (4), when a vehicle was unloading a harvest.

- Collection and distribution were treated as separate systems to enable a clear comparison of coordination scenarios.

- Two-axle and three-axle trucks were used for collection and distribution, respectively.

- Maintenance of trucks was performed every 20,000 km or every year [61].

- Trucks were dedicated to delivering goods exclusively to their assigned customer, without making additional stops.

- An optimal route was determined for each scenario, considering the distances between farms, clients, and the food hub.

- Each farmer and customer were georeferenced to identify the optimal path.

- Fixed storage costs and revenues from sales were assumed to remain constant across all study scenarios.

- The simulation began at the time of harvest and ended upon delivery of the product to the customer.

- Our study focused on a citrus supply chain with seasonal production, characterized by predictable demand and supply.

3.5. Simulation

3.6. Sensitivity Analysis

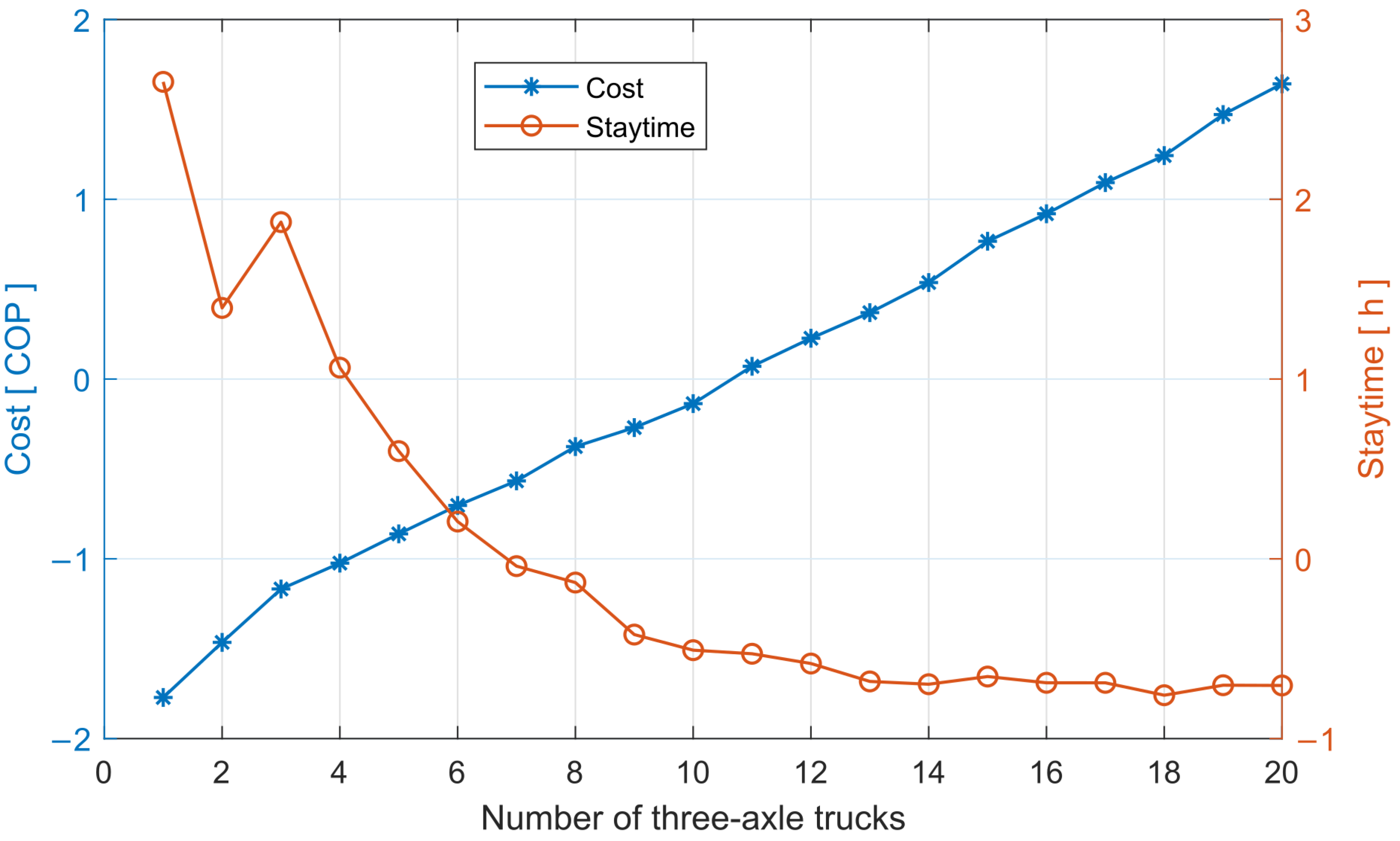

- Number of three-axle trucks (m): variations of ±2 vehicles were analyzed, corresponding to a change of ±33.34%.

- Maximum load capacity of three-axle trucks (wmax,3): Changes of ±2 tons were evaluated, equivalent to ±28.57%.

- Fuel price per gallon (F): This parameter was evaluated considering a variation in its value of ±20%.

4. Results

4.1. Modeling Parameters

4.2. Efficiency Key Performance Indicators

4.3. Financial Key Performance Indicators

4.4. Sensitivity Analysis

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arathoon, L.; Ruiz, A. Digital Agriculture Ecosystem Assessment: Colombia; Feed the future, the U.S. Government’s global hunger & food security initiative; The United States Agency for International Development (USAID), The AgTech Network: Washington, DC, USA, 2023.

- OECD. OECD Review of Agricultural Policies: Colombia 2015; OECD Review of Agricultural Policies; OECD Publishing: Paris, France, 2015; ISBN 978-92-64-22763-7. [Google Scholar]

- DANE. Producto Interno Bruto (PIB) IV Trimestre 2023 Preliminar; Technical Report; DANE: Bogotá, Colombia, 2024. Available online: https://www.dane.gov.co/files/operaciones/PIB/bol-PIB-IVtrim2023.pdf (accessed on 30 October 2024).

- ADR; FAO. Plan Integral de Desarrollo Agropecuario y Rural Con Enfoque Territorial: Departamento Del Cesar, TOMO I; Technical Report; ADR: Bogotá, Colombia, 2019. [Google Scholar]

- Hoz, J.R.V.D.L. Economía extractiva y pobreza en la ciénaga de Zapatosa. Rev. Banco República 2008, 81, 23–64. [Google Scholar]

- Ovalle Angarita, F.; Vigna, E.M. Plan de Desarrollo Departamento Del Cesar 2016–2019: El Camino Del Desarrollo y La Paz 2016. Available online: https://cesar.gov.co/d/filesmain/plan_desarrollo/plan_de_desarrollo_departamental_2016-2019_el_camino_del_desarrollo_y_la_paz.pdf (accessed on 30 October 2024).

- Hanson, C.; Davey, E.; Martínez, C.; Falla, P.; Katz, D.; Pinilla, S.; Thiercelin, L.; Velásquez, P.; Florido, A. Hoja de Ruta Para Una Nueva Economía de La Alimentación y Uso Del Suelo; Technical Report; The Food and Land Use Coalition: Bogotá, Colombia, 2019. [Google Scholar]

- Padilla Cabarcas, A.; Castillo Varela, Z.; Tovar, J.; Zahgui, N.; Martínez Zuleta, C.; Pinilla Pérez, S.; Katz Asprilla, D.; Rodriguez Díaz, A.; Veálasquez Espinosa, P. Hoja de Ruta Para Un Desarollo Sostenible y En Paz: Corredor Perija-Zapatosa 2018. Available online: https://e3asesorias.com/wp-content/uploads/documentos/Version%20m%C3%B3vil%20-%20Perija%20Zapatosa-compressed.pdf (accessed on 30 October 2024).

- Bedoya Mejía, L.M.; Barrera Gonzales, A.L.; Cabrera Bravo, J.A. El Cesar Productivo Ayer y Hoy; Universidad Nacional De Colombia: La Paz, Colombia, 2022; ISBN 978-958-50-5031-0. [Google Scholar]

- Mejía Montoya, J.W.; González, S.A.; Vargas, J.J.; Rios, R. Environmental Expectations, Socioeconomic Demands and Sustainability of the Zapatosa Marsh, Colombia: Perspectives from Local Stakeholders. Sustainability 2024, 16, 10806. [Google Scholar] [CrossRef]

- Soosay, C. Coordination in Supply Chains. In The Palgrave Handbook of Supply Chain Management; Sarkis, J., Ed.; Springer International Publishing: Cham, Switzerland, 2024; pp. 983–1008. ISBN 978-3-031-19884-7. [Google Scholar]

- Handayati, Y.; Simatupang, T.M.; Perdana, T. Agri-Food Supply Chain Coordination: The State-of-the-Art and Recent Developments. Logist. Res. 2015, 8, 5. [Google Scholar] [CrossRef]

- Arshinder; Kanda, A.; Deshmukh, S.G. Supply Chain Coordination: Perspectives, Empirical Studies and Research Directions. Int. J. Prod. Econ. 2008, 115, 316–335. [Google Scholar] [CrossRef]

- Sabbaghnia, A.; Heydari, J.; Ülkü, M.A.; Zolfaghari, S. Sustainable Supply Chain Coordination: Extant Literature, Trends, and Future Research Directions. Ann. Oper. Res. 2024. [Google Scholar] [CrossRef]

- Bygballe, L.E.; Dubois, A.; Jahre, M. The Importance of Resource Interaction in Strategies for Managing Supply Chain Disruptions. J. Bus. Res. 2023, 154, 113333. [Google Scholar] [CrossRef]

- Palacios-Argüello, L.; Sanchez-Diaz, I.; Gonzalez-Feliu, J.; Gondran, N. The Role of Food Hubs in Enabling Local Sourcing for School Canteens. In Food Supply Chains in Cities: Modern Tools for Circularity and Sustainability; Aktas, E., Bourlakis, M., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 233–263. ISBN 978-3-030-34065-0. [Google Scholar]

- Barham, J.; Tropp, D.; Enterline, K.; Farbman, J.; Fisk, J.; Kiraly, S. Regional Food Hub Resource Guide; U.S. Department of Agriculture, Agricultural Marketing Service: Washington, DC, USA, 2012.

- Cleveland, D.A.; Müller, N.M.; Tranovich, A.C.; Mazaroli, D.N.; Hinson, K. Local Food Hubs for Alternative Food Systems: A Case Study from Santa Barbara County, California. J. Rural Stud. 2014, 35, 26–36. [Google Scholar] [CrossRef]

- Binsfeld, T.; Gerlach, B. Quantifying the Benefits of Digital Supply Chain Twins—A Simulation Study in Organic Food Supply Chains. Logistics 2022, 6, 46. [Google Scholar] [CrossRef]

- Michel-Villarreal, R. Towards Sustainable and Resilient Short Food Supply Chains: A Focus on Sustainability Practices and Resilience Capabilities Using Case Study. Br. Food J. 2022, 125, 1914–1935. [Google Scholar] [CrossRef]

- Danloup, N.; Mirzabeiki, V.; Allaoui, H.; Goncalves, G.; Julien, D.; Mena, C. Reducing Transportation Greenhouse Gas Emissions with Collaborative Distribution: A Case Study. Manag. Res. Rev. 2015, 38, 1049–1067. [Google Scholar] [CrossRef]

- McKinnon, A.C.; Browne, M.; Whiteing, A. Green Logistics: Improving the Environmental Sustainability of Logistics, 3rd ed.; Kogan Page: Londo, UK, 2009; ISBN 978 0 7494 5678 8. [Google Scholar]

- Chauhan, C.; Kaur, P.; Arrawatia, R.; Ractham, P.; Dhir, A. Supply Chain Collaboration and Sustainable Development Goals (SDGs). Teamwork Makes Achieving SDGs Dream Work. J. Bus. Res. 2022, 147, 290–307. [Google Scholar] [CrossRef]

- FAO. SAFA (Sustainability Assessment of Food and Agriculture Systems) Guidelines, 1st ed.; Food and Agriculture Organization of the United Nations (FAO): Rome, France, 2014; ISBN 978-92-5-108485-4. [Google Scholar]

- United Nations Sustainable Development Goals: Resolution Adopted by the General. 2015. Available online: www.un.org/sustainabledevelopment (accessed on 25 September 2015).

- Xu, L.; Beamon, B.M. Supply Chain Coordination and Cooperation Mechanisms: An Attribute-Based Approach. J. Supply Chain Manag. 2006, 42, 4–12. [Google Scholar] [CrossRef]

- Guo, Y.; Yu, J.; Allaoui, H.; Choudhary, A. Lateral Collaboration with Cost-Sharing in Sustainable Supply Chain Optimisation: A Combinatorial Framework. Transp. Res. Part E Logist. Transp. Rev. 2022, 157, 102593. [Google Scholar] [CrossRef]

- Malone, T.W.; Crowston, K. The Interdisciplinary Study of Coordination. ACM Comput. Surv. 1994, 26, 87–119. [Google Scholar] [CrossRef]

- Nurhayati, K.; Tavasszy, L.; Rezaei, J. Joint B2B Supply Chain Decision-Making: Drivers, Facilitators and Barriers. Int. J. Prod. Econ. 2023, 256, 108721. [Google Scholar] [CrossRef]

- Aboueljinane, L.; Frichi, Y. A Simulation Optimization Approach to Investigate Resource Planning and Coordination Mechanisms in Emergency Systems. Simul. Model. Pract. Theory 2022, 119, 102586. [Google Scholar] [CrossRef]

- Accorsi, R.; Baruffaldi, G.; Manzini, R.; Tufano, A. On the Design of Cooperative Vendors’ Networks in Retail Food Supply Chains: A Logistics-Driven Approach. Int. J. Logist. Res. Appl. 2018, 21, 35–52. [Google Scholar] [CrossRef]

- Stock, G.N.; Greis, N.P.; Kasarda, J.D. Enterprise Logistics and Supply Chain Structure: The Role of Fit. J. Oper. Manag. 2000, 18, 531–547. [Google Scholar] [CrossRef]

- Huiskonen, J.; Pirttilä, T. Lateral Coordination in a Logistics Outsourcing Relationship. Int. J. Prod. Econ. 2002, 78, 177–185. [Google Scholar] [CrossRef]

- Mason, R.; Lalwani, C.; Boughton, R. Combining Vertical and Horizontal Collaboration for Transport Optimisation. Supply Chain Manag. Int. J. 2007, 12, 187–199. [Google Scholar] [CrossRef]

- Yuan, Y.; Viet, N.; Behdani, B. The Impact of Information Sharing on the Performance of Horizontal Logistics Collaboration: A Simulation Study in an Agri-Food Supply Chain. IFAC-Pap. 2019, 52, 2722–2727. [Google Scholar] [CrossRef]

- Kirono, I.; Armanu, A.; Hadiwidjojo, D.; Solimun, S. Logistics Performance Collaboration Strategy and Information Sharing with Logistics Capability as Mediator Variable (Study in Gafeksi East Java Indonesia). Int. J. Qual. Reliab. Manag. 2019, 36, 1301–1317. [Google Scholar] [CrossRef]

- Toptal, A.; Çetinkaya, B. How Supply Chain Coordination Affects the Environment: A Carbon Footprint Perspective. Ann. Oper. Res. 2017, 250, 487–519. [Google Scholar] [CrossRef]

- Brinkmann, D.; Lang, J.; Petersen, B.; Wognum, N.; Trienekens, J. Towards a Chain Coordination Model for Quality Management Strategies to Strengthen the Competitiveness of European Pork Producers. J. Chain Netw. Sci. 2011, 11, 137–153. [Google Scholar] [CrossRef]

- Chikán, A. Integration of Production and Logistics—In Principle, in Practice and in Education. Int. J. Prod. Econ. 2001, 69, 129–140. [Google Scholar] [CrossRef]

- Pyke, D.F.; Cohen, M.A. Performance Characteristics of Stochastic Integrated Production-Distribution Systems. Eur. J. Oper. Res. 1993, 68, 23–48. [Google Scholar] [CrossRef]

- Fugate, B.; Sahin, F.; Mentzer, J.T. Supply Chain Management Coordination Mechanisms. J. Bus. Logist. 2006, 27, 129–161. [Google Scholar] [CrossRef]

- Yang, P.C.; Wee, H.M. A Single-Vendor and Multiple-Buyers Production–Inventory Policy for a Deteriorating Item. Eur. J. Oper. Res. 2002, 143, 570–581. [Google Scholar] [CrossRef]

- Noorul Haq, A.; Kannan, G. Design of an Integrated Supplier Selection and Multi-Echelon Distribution Inventory Model in a Built-to-Order Supply Chain Environment. Int. J. Prod. Res. 2006, 44, 1963–1985. [Google Scholar] [CrossRef]

- Hwarng, H.B.; Chong, C.S.P.; Xie, N.; Burgess, T.F. Modelling a Complex Supply Chain: Understanding the Effect of Simplified Assumptions. Int. J. Prod. Res. 2005, 43, 2829–2872. [Google Scholar] [CrossRef]

- Huq, F.; Cutright, K.; Jones, V.; Hensler, D.A. Simulation Study of a Two-level Warehouse Inventory Replenishment System. Int. J. Phys. Distrib. Logist. Manag. 2006, 36, 51–65. [Google Scholar] [CrossRef]

- Lin, Z.; Chen, R.; Luo, L.; Ren, H. Research on Coordination of Fresh Supply Chain Considering Supplier Misreporting and Consumer Return. Sustainability 2024, 16, 6225. [Google Scholar] [CrossRef]

- Ramanathan, U. Performance of Supply Chain Collaboration—A Simulation Study. Expert Syst. Appl. 2014, 41, 210–220. [Google Scholar] [CrossRef]

- Boyacı, T.; Gallego, G. Coordinating Pricing and Inventory Replenishment Policies for One Wholesaler and One or More Geographically Dispersed Retailers. Int. J. Prod. Econ. 2002, 77, 95–111. [Google Scholar] [CrossRef]

- Cai, X.; Chen, J.; Xiao, Y.; Xu, X. Optimization and Coordination of Fresh Product Supply Chains with Freshness-Keeping Effort. Prod. Oper. Manag. 2010, 19, 261–278. [Google Scholar] [CrossRef]

- Rosca, E.; Rusca, F.; Rosca, M.A.; Rusca, A. Performance Analysis of Automated Parcel Lockers in Urban Delivery: Combined Agent-Based–Monte Carlo Simulation Approach. Logistics 2024, 8, 61. [Google Scholar] [CrossRef]

- Kaboudvand, S.; Montreuil, B. Simulation-Based Assessment of Hyperconnected Megacity Parcel Logistics. Logistics 2024, 8, 66. [Google Scholar] [CrossRef]

- Aslam, T.; Ng, A. Agent-Based Simulation and Simulation-Based Optimisation for Supply Chain Management. In Enterprise Networks and Logistics for Agile Manufacturing; Wang, L., Koh, S.C.L., Eds.; Springer: London, UK, 2010; pp. 227–247. ISBN 978-1-84996-244-5. [Google Scholar]

- Van der Vorst, J.G.; da Silva, C.; Trienekens, J.H. Agro-Industrial Supply Chain Management: Concepts and Applications; Agricultural Management Marketing and Finance Occasional Paper; FAO: Rome, Italy, 2007; Volume 17, ISBN 978-92-5-105831-2. [Google Scholar]

- Luna Acosta, A.; Ortiz, C.; Corrales, E.; Sarmiento López, A.; Nieto, O.; Restrepo, S. Caracterización Socioecológica de Las Tres Ventanas Piloto de Humedales Ciénaga de Zapatosa, Ciénaga de La Virgen, Paz de Ariporo-Hato Corozal; Pontificia Universidad Javeriana: Bogotá, Colombia; Instituto de Investigación de Recursos Biológicos Alexander von Humboldt: Bogotá, Colombia, 2015. [Google Scholar]

- Nieto Moreno, O. Propuesta de Limite Del Humedal En La Ventana Piloto Ciénaga de Zapatosa. In Convenio Interadministrativo 13-014 (FA 005 de 2013), Equipo Humedales Fondo Adaptación; Instituto de Investigación de Recursos Biológicos Alexander von Humboldt—Fondo de Adaptación: Bogotá, Colombia, 2016. [Google Scholar]

- Castaño-Barreto, A.C.; Jaramillo-Cruz, C.A.; Molina Benavides, R.A.; Atzori, A.S. Scenarios of Sustainable Fishing in the Zapatosa Marsh (Colombia) Simulated with a System Dynamics Model. Sustainability 2020, 12, 3458. [Google Scholar] [CrossRef]

- Ministerio de Transporte Resolución 4100 de 2004 Ministerio de Transporte. Por La Cual Se Adoptan Los Límites de Pesos y Dimensiones En Los Vehículos de Transporte Terrestre Automotor de Carga Por Carretera, Para Su Operación Normal En La Red Vial a Nivel Nacional. Available online: https://www.alcaldiabogota.gov.co/sisjur/normas/Norma1.jsp?i=15600 (accessed on 23 January 2025).

- Li, Y.; Xu, L. Cybersecurity Investments in a Two-Echelon Supply Chain with Third-Party Risk Propagation. Int. J. Prod. Res. 2021, 59, 1216–1238. [Google Scholar] [CrossRef]

- Liu, L.; Huang, N.; Qian, Q.; Zhao, Y.; Yang, T.; Han, C. Coordination and Optimization Decision of Assembly Building Supply Chain under Supply Disruption Risk. Int. J. Ind. Eng. Comput. 2024, 15, 909–930. [Google Scholar] [CrossRef]

- Galbreath, J.; Georgiou, K.; Oloruntoba, R. Intention to Use Collaborative Transportation Among SMEs: An Exploratory Investigation of the Wine Industry. J. Small Bus. Strategy 2022, 32, 128–141. [Google Scholar] [CrossRef]

- Ren, H.; Hu, Y. Coordination of Online Shopping Supply Chain Considering Fresh Product Preservation Efforts and Cargo Damage Costs. J. Theor. Appl. Electron. Commer. Res. 2024, 19, 1337–1357. [Google Scholar] [CrossRef]

- Borshchev, A. The Big Book of Simulation Modeling: Multimethod Modeling with AnyLogic 6: Amazon.Com: Books, 1st ed.; Lightning Source Inc.: La Vergne, TN, USA, 2013; ISBN 978-0-9895731-7-7. [Google Scholar]

- Ghezavati, V.; Nia, N.S. Development of an Optimization Model for Product Returns Using Genetic Algorithms and Simulated Annealing. Soft Comput. 2015, 19, 3055–3069. [Google Scholar] [CrossRef]

- Roghanian, E.; Pazhoheshfar, P. An Optimization Model for Reverse Logistics Network under Stochastic Environment by Using Genetic Algorithm. J. Manuf. Syst. 2014, 33, 348–356. [Google Scholar] [CrossRef]

- Morganti, E. Urban Food Planning and City Logistics for Food Products: New Solutions for the Last Food Mile; CIHEAM Briefing Notes; International Centre for Advanced Mediterranean Agronomic Studies: Paris, France, 2013. [Google Scholar]

- Aguado-Gragera, C.; Sama-Berrocal, C.; Mesías, F.J.; Crespo-Cebada, E.; Diaz-Caro, C. Challenges and Opportunities of Short Food Supply Chains in Spain: A Stakeholder Participatory Study. J. Agric. Food Res. 2024, 18, 101276. [Google Scholar] [CrossRef]

- Fawcett, S.E.; McCarter, M.W.; Fawcett, A.M.; Webb, G.S.; Magnan, G.M. Why Supply Chain Collaboration Fails: The Socio-Structural View of Resistance to Relational Strategies. Supply Chain Manag. Int. J. 2015, 20, 648–663. [Google Scholar] [CrossRef]

| Symbol | Description | Value |

|---|---|---|

| The number of two-axle trucks | 2 | |

| The number of three-axle trucks | 6 | |

| The location of the j-th farmer | Twenty-one coordinates | |

| The location of the c-th customer | Seven coordinates | |

| The total annual harvest produced by the supply chain | 634 | |

| The maximum load capacity of the 2-axle truck | 6 | |

| The maximum load capacity of the 3-axle truck | 7 | |

| The total annual harvest demanded by the c-th customer | 634 | |

| [COP] | The average price of citrus fruits per unit (ton) in the supply chain | COP 536,405 |

| The maintenance cost per year of the two-axle trucks | COP 11,221,775 | |

| [COP] | The maintenance cost per year of the three-axle trucks | COP 11,221,775 |

| Unpredictable and varied costs associated with the consolidation and distribution of the harvest | 10% Cost | |

| [COP] | The fuel price per gallon | COP 9000 |

| [km] | The estimated distance traveled per gallon by the three-axle truck | 16 km |

| [km] | The estimated distance traveled per gallon by the two-axle truck | 16 km |

| The annual utility expenses related with the consolidation and distribution of the harvest (e.g., electricity, water, and gas) | COP 6,316,000 | |

| The total wages paid to employees working at the food hub | COP 3,500,000 | |

| The maximum storage capacity (in tons) of the food hub for the harvest | 40 | |

| The average loading time (in hours) of a two-axle truck for the harvest | 1 | |

| The average loading time (in hours) of a three-axle truck for the harvest | 1.2 | |

| The average unloading time (in hours) of a two-axle truck for the harvest | 0.5 | |

| The average unloading time (in hours) of a three-axle truck for the harvest | 0.8 | |

| The maximum speed (in kilometers per hour) of a two-axle truck | 60 | |

| The maximum speed (in kilometers per hour) of a three-axle truck | 60 |

| Symbol | Description |

|---|---|

| The total simulation time to collect and distribute the entire production within the system | |

| The distance traveled by the q-th three-axle truck | |

| The distance traveled by the p-th two-axle truck | |

| The time spent by the q-th three-axle truck at the i-th state | |

| The time spent by the p-th two-axle truck at the i-th state | |

| The harvest load transported by the p-th two-axle truck during the travel state | |

| The harvest load transported by the q-th three-axle truck during the travel state | |

| The time at which the k-th unit of harvest reaches the customer location | |

| The time at which the k-th unit of harvest departs from the farm | |

| The total distance traveled by the two-axle trucks | |

| The total distance traveled by the three-axle trucks | |

| The time spent by the p-th two-axle truck at the i-th state | |

| The time spent by the p-th three-axle truck at the i-th state | |

| The time percentage spent by the p-th two-axle truck at the i-th state | |

| The time percentage spent by the p-th three-axle truck at the i-th state | |

| The StayTime of the harvest demanded by the c-th customer | |

| The proportion of the total load capacity used by the q-th three-axle truck at the load state | |

| REV | The total revenue |

| The total distribution costs | |

| The total storage costs | |

| The total truck maintenance costs | |

| Total logistics costs | |

| Gross profit margin |

| Agent | Attribute | Type | Description |

|---|---|---|---|

| Farmer | Location | Numerical | Geographic location of the farmer |

| Load | Numerical | The load of harvest produced by farmers (in tons) | |

| Food Hub | Capacity | Numerical | Total harvest capacity (in tons) that the food hub can handle |

| State | Categorical (full/empty) | State in which the food hub is at a specific time | |

| Customer | Location | Numerical | Geographic location of the customer |

| Load | Numerical | The load of harvest required by customer farmer (in tons) | |

| Vehicle | Owner | String | Owner of the vehicle (i.e., ASOCITRICOS or Middlemen) |

| Type | Categorical | Type of the truck (i.e., two-axle or three-axle) | |

| State | Categorical | State in which the vehicle was at a specific time (i.e., idle, travel loaded, travel unloaded, waiting, among others). | |

| Loading time | Numerical | Time spent loading a ton of citrus in the vehicle | |

| Unloading time | Numerical | Time spent unloading a ton of citrus out of the vehicle | |

| Destination | Numerical | Vehicle’s destination (customers’ geographical locations) for delivering the load | |

| Capacity | Numerical | Total harvest capacity (in tons) that the vehicle can carry per travel |

| Indicator Description | Single-Distribution | Joint-Consolidation | Joint-Consolidation-Distribution |

|---|---|---|---|

| N/A | 56.38 | 57.21 | |

| 107,660.00 | 104,205.00 | 105,392.00 | |

| 56.78% | 41.83% | 57.22% | |

| 21.71% | 40.71% | 25.34% | |

| 10.46% | 7.12% | 7.16% | |

| 5.6% | 3.24% | 3.25% | |

| 10.46% | 7.09% | 7.02% | |

| 50.24% | 29.55% | 42.40% | |

| 123.06 | 135.34 | 125.06 |

| Indicator Description | Single-Distribution | Joint-Consolidation | Joint-Consolidation-Distribution |

|---|---|---|---|

| Not assumed by association | Not assumed by association | COP 59,283,073.00 | |

| 1 | Individual cost borne by farmer | COP 9,816,000 | COP 9,816,000.00 |

| 2 | Not assumed by association | Not assumed by association | COP 67,330,650.00 |

| COP 0 | COP 981,600.00 | COP 13,642,972.00 | |

| COP 0 | COP 10,797,600.00 | COP 150,072,695.00 | |

| COP 340,081,000.00 | COP 408,097,200.00 | COP 680,162,000.00 | |

| COP 340,081,000.00 | COP 397,299,600.00 | COP 530,089,305.00 |

| Indicator Description | Single-Distribution 4 Trucks (−33%) | Single-Distribution 6 Trucks | Single-Distribution 8 Trucks (+33%) | Joint- Consolidation 4 Trucks (−33%) | Joint- Consolidation 6 Trucks | Joint-Consolidation 8 Trucks (+33%) | Joint-Consolidation-Distribution 4 Trucks (−33%) | Joint-Consolidation-Distribution 6 Trucks | Joint-Consolidation-Distribution 8 Trucks (+33%) |

|---|---|---|---|---|---|---|---|---|---|

| Efficiency | |||||||||

| N/A | N/A | N/A | 75.59 | 56.38 | 58.05 | 73.92 | 57.21 | 52.62 | |

| 85,848.44 | 107,659.8 | 113,683.04 | 100,096.26 | 104,205.38 | 128,139.14 | 91,072.28 | 105.392.13 | 118,920.84 | |

| 50.05% | 56.78% | 55.73% | 41.99% | 41.83% | 42.17% | 55.02% | 57.22% | 52.87% | |

| 23.37% | 21.71% | 18.48% | 41.30% | 40.71% | 41.88% | 26.60% | 25.34% | 30.29% | |

| 12.25% | 10.46% | 9.35% | 7.46% | 7.12% | 5.96% | 8.20% | 7.16% | 6.43% | |

| 2.08% | 5.6% | 7.10% | 2.00% | 3.24% | 4.10% | 2.17% | 3.25% | 4.22% | |

| 12.25% | 10.46% | 9.35% | 7.25% | 7.09% | 5.89% | 8.02% | 7.02% | 6.18% | |

| 51.93% | 50.24% | 51.07% | 31.04% | 29.55% | 23.96% | 48.32% | 42.40% | 34.38% | |

| 161.06 | 123.06 | 102.68 | 174.57 | 135.34 | 122.86 | 168.02 | 125.06 | 110.28 | |

| Financial | |||||||||

| Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | COP 51,228,158 | COP 59,283,073 | COP 66,892,973 | |

| Cost borne by each farmer | Cost borne by each farmer | Cost borne by each farmer | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | |

| Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | COP 44,887,100 | COP 67,330,650 | COP 89,774,200 | |

| COP 0 | COP 0 | COP 0 | COP 981,600.00 | COP 981,600.00 | COP 981,600.00 | COP 10,593,126 | COP 13,642,972 | COP 16,648,317 | |

| COP 0 | COP 0 | COP 0 | COP 10,797,600.00 | COP 10,797,600.00 | COP 10,797,600.00 | COP 116,524,383 | COP 150,072,695 | COP 183,131,490 | |

| REV | COP 340,081,000 | COP 340,081,000 | COP 340,081,000 | COP 408,097,200 | COP 408,097,200 | COP 408,097,200 | COP 680,162,000 | COP 680,162,000 | COP 680,162,000 |

| COP 340,081,000 | COP 340,081,000 | COP 340,081,000 | COP 397,299,600 | COP 397,299,600 | COP 397,299,600 | COP 563,637,617 | COP 530,089,305 | COP 497,030,510 | |

| Indicator Description | Single-Distribution 5 Ton (−28%) | Single-Distribution 7 Ton | Single-Distribution 9 Ton (+28%) | Joint-Consolidation 5 Ton (−28%) | Joint-Consolidation 7 Ton | Joint-Consolidation 9 Ton (+28%) | Joint-Consolidation-Distribution —5 Ton (−28%) | Joint-Consolidation-Distribution 7 Ton | Joint-Consolidation-Distribution 9 Ton (+28%) |

|---|---|---|---|---|---|---|---|---|---|

| Efficiency | |||||||||

| N/A | N/A | N/A | 74.75 | 56.38 | 55.54 | 79.34 | 57.21 | 53.04 | |

| 123,974.99 | 107,659.8 | 114,178.26 | 128,871.52 | 104,205.38 | 88,382.86 | 117,169.77 | 105,392.13 | 91,597.55 | |

| 60.39% | 56.78% | 54.95% | 43.60% | 41.83% | 34.64% | 53.40% | 57.22% | 51.41% | |

| 25.97% | 21.71% | 14.31% | 42.94% | 40.71% | 33.86% | 31.76% | 25.34% | 17.50% | |

| 6.00% | 10.46% | 12.26% | 5.42% | 7.12% | 14.57% | 5.96% | 7.16% | 14.87% | |

| 1.63% | 5.6% | 6.22% | 2.81% | 3.24% | 3.27% | 3.05% | 3.25% | 3.64% | |

| 6.00% | 10.46% | 12.26% | 5.22% | 7.09% | 14.45% | 5.82% | 7.02% | 13.78% | |

| 53.30% | 50.24% | 49.76% | 32.67% | 29.55% | 29.09% | 45.60% | 42.40% | 47.15% | |

| 131.55 | 123.06 | 140.6 | 154.46 | 135.34 | 135.78 | 140.56 | 125.06 | 137.38 | |

| Financial | |||||||||

| Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | COP 65,907,996 | COP 59,283,073 | COP 51,274,395 | |

| Cost borne by each farmer | Cost borne by each farmer | Cost borne by each farmer | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | |

| Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | Not assumed by association | COP 67,330,650 | COP 67,330,650 | COP 67,330,650 | |

| COP 0 | COP 0 | COP 0 | COP 981,600 | COP 981,600 | COP 981,600 | COP 14,305,465 | COP 13,642,972 | COP 12,842,105 | |

| COP 0 | COP 0 | COP 0 | COP 10,797,600 | COP 10,797,600 | COP 10,797,600 | COP 157,360,110 | COP 150,072,695 | COP 141,263,150 | |

| REV | COP 340,081,000 | COP 340,081,000 | COP 340,081,000 | COP 408,097,200 | COP 408,097,200 | COP 408,097,200 | COP 680,162,000 | COP 680,162,000 | COP 680,162,000 |

| COP 340,081,000 | COP 340,081,000 | COP 340,081,000 | COP 397,299,600 | COP 397,299,600 | COP 397,299,600 | COP 522,801,890 | COP 530,089,305 | COP 538,898,851 | |

| Indicator Description | Single-Distribution | Joint-Consolidation | Joint-Consolidation-Distribution −20% Fuel Price/Gallon | Joint- Consolidation-Distribution | Joint-Consolidation-Distribution +20% Fuel Price/Gallon |

|---|---|---|---|---|---|

| Efficiency | |||||

| N/A | 56.00 km | 57.00 km | 57.21 km | 57.00 km | |

| 107,660.00 km | 104,205.00 km | 105,392.00 km | 105,392.00 km | 105,392.00 km | |

| 21.71% | 40.72% | 57.22% | 57.22% | 57.22% | |

| 51.78% | 41.83% | 25.34% | 25.34% | 25.34% | |

| 10.46% | 7.12% | 7.16% | 7.16% | 7.16% | |

| 10.46% | 7.09% | 7.03% | 7.03% | 7.03% | |

| 5.60% | 3.24% | 3.25% | 3.25% | 3.25% | |

| 50.24% | 29.55% | 42.40% | 42.40% | 42.40% | |

| 123.00 h | 135.00 h | 125.00 h | 125.00 h | 125.00 h | |

| Financial | |||||

| Not assumed by association | Not assumed by association | COP 47,426,459 | COP 59,283,073 | COP 71,139,688 | |

| Cost borne by each farmer | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | COP 9,816,000 | |

| Not assumed by association members | Not assumed by association members | COP 67,330,650 | COP 67,330,650 | COP 67,330,650 | |

| COP 0 | COP 981,600 | COP 12,457,311 | COP 13,642,972 | COP 14,828,634 | |

| COP 0 | COP 10,797,600 | COP 137,030,419 | COP 150,072,695 | COP 163,114,972 | |

| REV | COP 340,081,000 | COP 408,097,200 | COP 680,162,000 | COP 680,162,000 | COP 680,162,000 |

| COP 340,081,000 | COP 397,299,600 | COP 543,131,581 | COP 530,089,305 | COP 517,047,028 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vargas-Muñoz, J.C.; Sanchez-Nitola, F.A.; Adarme Jaimes, W.; Rios, R. Enhancing Logistical Performance in a Colombian Citrus Supply Chain Through Joint Decision Making: A Simulation Study. Logistics 2025, 9, 30. https://doi.org/10.3390/logistics9010030

Vargas-Muñoz JC, Sanchez-Nitola FA, Adarme Jaimes W, Rios R. Enhancing Logistical Performance in a Colombian Citrus Supply Chain Through Joint Decision Making: A Simulation Study. Logistics. 2025; 9(1):30. https://doi.org/10.3390/logistics9010030

Chicago/Turabian StyleVargas-Muñoz, Juan Camilo, Flor Angela Sanchez-Nitola, Wilson Adarme Jaimes, and Richard Rios. 2025. "Enhancing Logistical Performance in a Colombian Citrus Supply Chain Through Joint Decision Making: A Simulation Study" Logistics 9, no. 1: 30. https://doi.org/10.3390/logistics9010030

APA StyleVargas-Muñoz, J. C., Sanchez-Nitola, F. A., Adarme Jaimes, W., & Rios, R. (2025). Enhancing Logistical Performance in a Colombian Citrus Supply Chain Through Joint Decision Making: A Simulation Study. Logistics, 9(1), 30. https://doi.org/10.3390/logistics9010030