A Framework for Leveraging Digital Technologies in Reverse Logistics Actions: A Systematic Literature Review

Abstract

:1. Introduction

2. Theoretical Background

2.1. Solid Waste, By-Products, and Reverse Logistics

- Collection—This refers to the gathering of used products, packaging, and materials. This process involves separating and disposing of recyclable materials, such as plastics, glass, paper, and metals, from various sources like homes, industries, or businesses [26].

- Transportation—Transportation is an important stage in Reverse Logistics, encompassing planning to optimize the collection, storage, and delivery of waste, and ensuring that it is handled safely and in an environmentally appropriate manner [27].

- Sorting—This refers to the separation and classification of the collected products. Sorting is performed at specialized centers, where materials are separated, contributing to the reduction in waste sent to landfills, lowering transportation costs, and enabling the commercialization of recyclable materials [28].

- Storage—Storage is accomplished at centers designed for the temporary deposit of materials, facilitating processes such as sorting, recycling, reuse, and proper disposal [28].

- Reuse—This involves extending the useful lives of goods or materials by means of their reuse in industrial or residential contexts without the need for significant modifications [29].

- Remanufacturing—This is a process that revitalizes products at the end of their lifecycle through stages like recovery, inspection, disassembly, polishing, renewal, and reassembly, resulting in an item that has a condition equivalent to that of a new product [29].

- Recycling—Recycling is the process of transforming solid waste by altering its properties so it can be reused, either as raw material or in the creation of new products [30].

- Disposal—Disposal is the final stage in Reverse Logistics, occurring when a product can no longer be reused or recycled. In this process, waste must be properly disposed of without harming the environment. According to current regulations, waste must be sent to landfills or other appropriate locations in compliance with local laws [30].

2.2. Industry 4.0 and Digital Technologies in Reverse Logistics

- Internet of Things (IoT): Connects physical and virtual objects to the internet, enabling communication between products, services, and environments via smart sensors that monitor and control remotely;

- Cyber–Physical Systems (CPS): Integration of physical and digital components, such as software-controlled sensors, that monitor and manage industrial processes in real time, improving automation and logistics efficiency;

- Industrial Internet of Things (IIoT): The application of the IoT in the industrial sector, using industrial devices and sensors to collect, analyze, and share real-time data;

- Machine-to-Machine Communication (M2M) Allows machines to communicate directly, automating processes and eliminating the need for human intervention, aiming to attain greater efficiency [41];

- Artificial Intelligence (AI): Technology that replicates the human ability to control processes and solve problems autonomously, optimizing production and improving efficiency;

- Big Data Analytics (BDA): Techniques used to process large volumes of data generated by industries, turning the data into valuable information for real-time decision-making;

- Cloud Computing (CC): Storing and processing data on remote servers, facilitating access and accruing cost savings for industries;

- System Integration (SI): Connecting machines, processes, and people to ensure efficient communication, increasing productivity and organizing industrial operations;

- Cybersecurity: Protecting data and interconnected systems from breaches and unauthorized access, crucial for ensuring the security and integrity of information in the industrial environment [42];

- Autonomous Robots: Robots that work alongside humans in production, performing high-complexity tasks quickly and precisely [43];

- Smart Sensors: Devices that monitor physical conditions and transmit data, enabling quick and automatic decisions within the industry;

- Mobile Systems and Devices: Tools, like smartphones and tablets, allowing efficient monitoring and control of industrial processes, ensuring access to real-time information [44];

- Digitization and Virtualization: Processes that convert physical elements into digital data and create virtual representations of that data, facilitating production integration and optimization [45];

- Simulation: Using digital models to replicate and analyze industrial systems and processes, aiding in optimization efforts and the anticipation of failures;

- Augmented Reality (AR) and Virtual Reality (VR): Technologies that integrate the physical and digital worlds, supporting activities such as maintenance, training, and real-time process visualization;

- Additive Manufacturing (AM): A manufacturing process in which materials are added layer by layer to create parts, using fewer resources and generating less waste, with applications in prototypes and the production of complex parts;

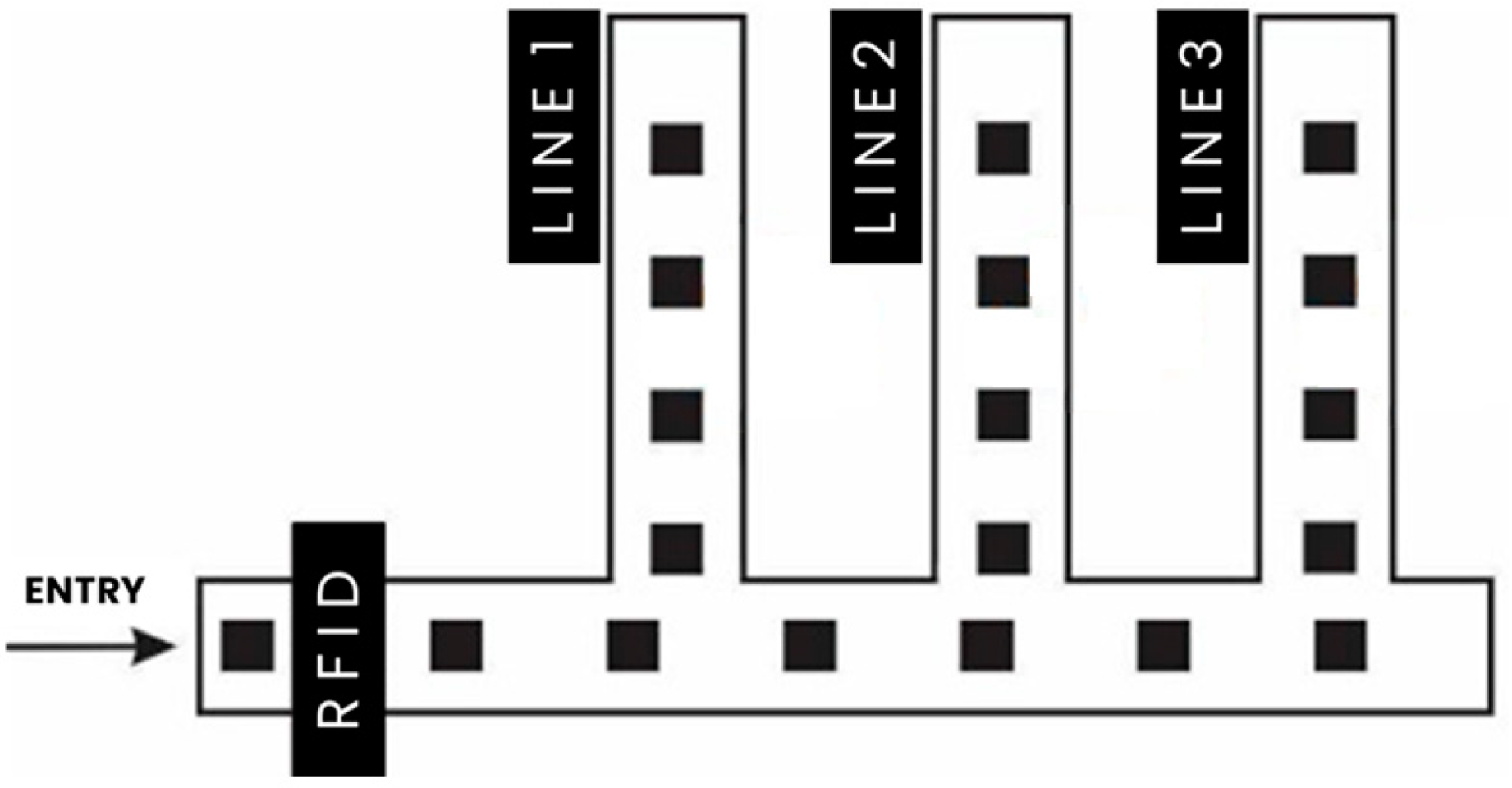

- Radio-Frequency Identification (RFID): a technology that uses radio waves to identify and track objects, animals, or people by transmitting data from a tag to a reader without physical contact;

- Blockchain (BC): a decentralized digital ledger that records transactions across a network of computers, ensuring immutability and transparency.

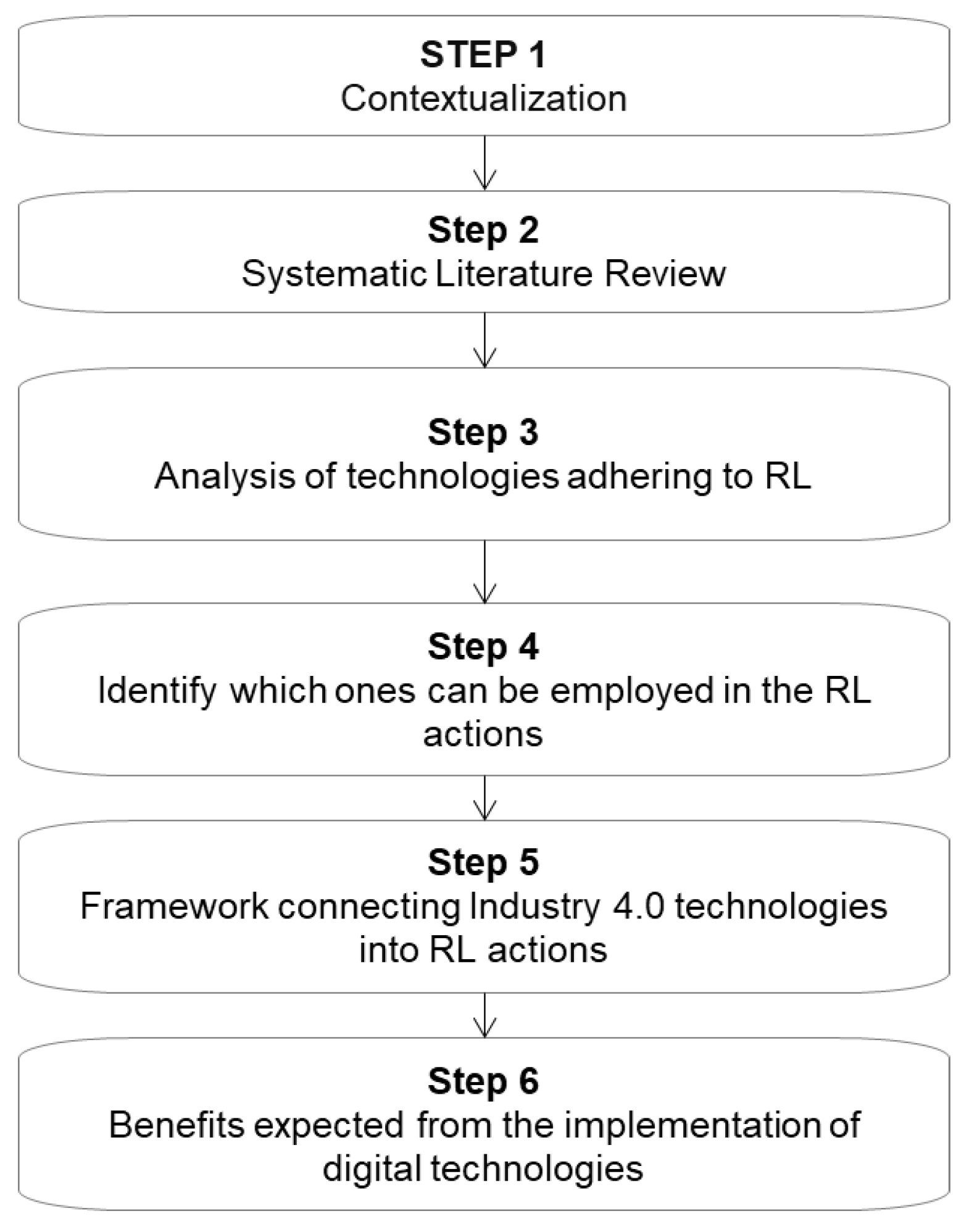

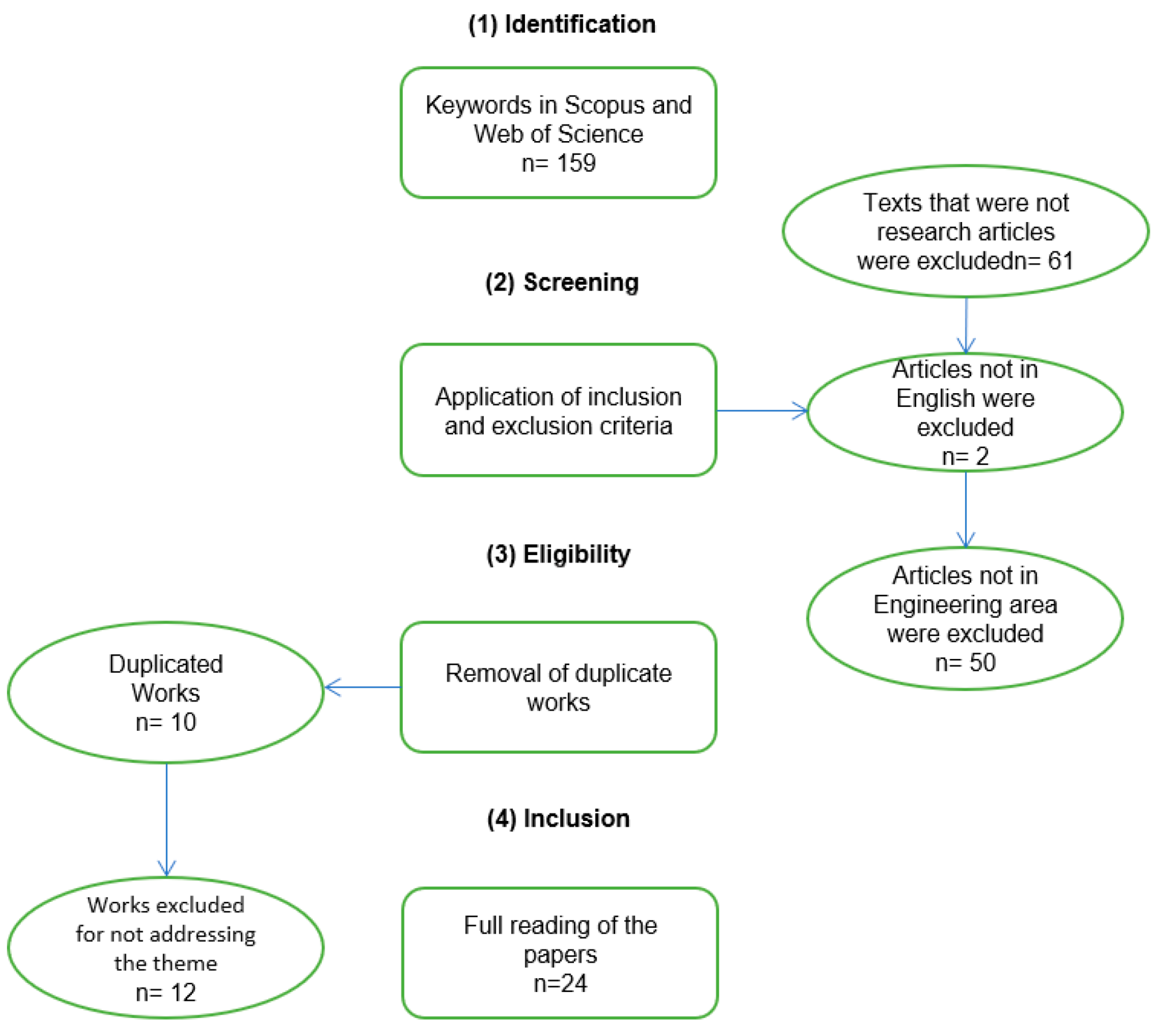

3. Materials and Methods

4. Results

4.1. Digital Technologies That Contribute to RL Actions

- Operational Level: Technologies such as RFID and the IoT enable real-time tracking and monitoring of returned products, thereby enhancing efficiency in collection and sorting processes.

- Tactical Level: Machine learning and data analytics help in decision-making regarding refurbishment, redistribution, and waste management practices.

- Strategic Level: Blockchain offers transparency and traceability in Reverse Logistics networks, enhancing compliance with environmental regulations and fostering stakeholder trust.

4.2. Digital Technologies That Can Be Employed in RL Actions

Impact on Sustainability

- Reduction of Waste: AI-driven analytics and IoT-based tracking prevent unnecessary disposal of returned goods by optimizing repair and redistribution processes.

- Enhanced Resource Recovery: Blockchain and RFID facilitate better traceability, ensuring materials are effectively recovered and reintegrated into production cycles.

- Carbon Footprint Reduction: Digital tools help optimize transportation routes for returned goods, minimizing emissions and improving energy efficiency.

4.3. Operational Level

4.4. Tactical Level

4.5. Strategic Level

5. Discussion and Implications

5.1. Enhancing Reverse Logistics Through Digital Technologies

5.2. Addressing the Role of Solid Waste in Reverse Logistics

5.3. Implications for Industry and Sustainability

6. Conclusions and Future Research Directions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mommert, M.; Sigel, M.; Neuhausler, M.; Scheibenreif, L.; Borth, D. Characterization of Industrial Smoke Plumes from Remote Sensing Data. arXiv 2020, arXiv:2011.11344. [Google Scholar]

- Dixit, A.; Madhav, S.; Mishra, R.; Srivastav, A.L.; Garg, P. Impact of Climate Change on Water Resources, Challenges and Mitigation Strategies to Achieve Sustainable Development Goals. Arab. J. Geosci. 2022, 15, 1296. [Google Scholar] [CrossRef]

- US EPA. Waste, Chemical, and Cleanup Enforcement. Available online: https://www.epa.gov/enforcement/waste-chemical-and-cleanup-enforcement (accessed on 19 February 2025).

- L12305. Available online: https://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm (accessed on 19 February 2025).

- UNEP-UN Environment Programme. Panorama Global Do Manejo de Resíduos Em 2024. Available online: https://www.unep.org/pt-br/resources/panorama-global-do-manejo-de-residuos-em-2024 (accessed on 19 February 2025).

- Gomes, L.d.C. Mitigation of Supply Chain Vulnerability Through Collaborative Planning, Forecasting, and Replenishment (CPFR). Int. Ser. Oper. Res. Manag. Sci. 2022, 332, 95–119. [Google Scholar] [CrossRef]

- Miranda, B.V.; Monteiro, G.F.A.; Rodrigues, V.P. Circular Agri-Food Systems: A Governance Perspective for the Analysis of Sustainable Agri-Food Value Chains. Technol. Forecast. Soc. Chang. 2021, 170, 120878. [Google Scholar] [CrossRef]

- Da Silva, G.A.F.R.; Baierle, I.C.; Gomes, L.d.C.; Correa, R.G.d.F.; Peres, F.A.P. A Comprehensive Roadmap for Connecting Industry 4.0 Technologies to the Basic Model of Collaborative Planning, Forecasting, and Replenishment (CPFR). Adm. Sci. 2024, 14, 108. [Google Scholar] [CrossRef]

- Dos Santos, L.M.A.L.; da Costa, M.B.; Kothe, J.V.; Benitez, G.B.; Schaefer, J.L.; Baierle, I.C.; Nara, E.O.B. Industry 4.0 Collaborative Networks for Industrial Performance. J. Manuf. Technol. Manag. 2021, 32, 245–265. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 Framework: A Systematic Literature Review Identifying the Current Trends and Future Perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Baierle, I.C.; Schaefer, J.L.; Sellitto, M.A.; Fava, L.P.; Furtado, J.C.; Nara, E.O.B. Moona Software for Survey Classification and Evaluation of Criteria to Support Decision-Making for Properties Portfolio. Int. J. Strateg. Prop. Manag. 2020, 24, 226–236. [Google Scholar] [CrossRef]

- Mohad, F.T.; Gomes, L.d.C.; Tortorella, G.d.L.; Lermen, F.H. Operational Excellence in Total Productive Maintenance: Statistical Reliability as Support for Planned Maintenance Pillar. Int. J. Qual. Reliab. Manag. 2024, 42, 1274–1296. [Google Scholar] [CrossRef]

- Bouzon, M.; Govindan, K.; Rodriguez, C.M.T. Reducing the Extraction of Minerals: Reverse Logistics in the Machinery Manufacturing Industry Sector in Brazil Using ISM Approach. Resour. Policy 2015, 46, 27–36. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P.; Kennedy, C. Environment: Waste Production Must Peak This Century. Nature 2013, 502, 615–617. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Hu, N.; Teng, J.; Liu, X.; Li, Y.; Ling, J. A Study on the Resource Utilization Strategy for Industrial Solid Waste in China. Strateg. Study Chin. Acad. Eng. 2017, 19, 109–114. [Google Scholar] [CrossRef]

- Azam, M.; Jahromy, S.S.; Raza, W.; Raza, N.; Lee, S.S.; Kim, K.H.; Winter, F. Status, Characterization, and Potential Utilization of Municipal Solid Waste as Renewable Energy Source: Lahore Case Study in Pakistan. Environ. Int. 2020, 134, 105291. [Google Scholar] [CrossRef] [PubMed]

- Lino, F.A.M.; Bizzo, W.A.; Da Silva, E.P.; Ismail, K.A.R. Energy Impact of Waste Recyclable in a Brazilian Metropolitan. Resour. Conserv. Recycl. 2010, 54, 916–922. [Google Scholar] [CrossRef]

- Meade, L.M.; Sarkis, J.; Presley, A. The Theory and Practice to Reverse Logistics. Int. J. Logist. Syst. Manag. 2007, 3, 56–84. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H. A Review of Reverse Logistics and Closed-Loop Supply Chains: A Journal of Cleaner Production Focus. J. Clean. Prod. 2017, 142, 371–384. [Google Scholar] [CrossRef]

- Fani, V.; Bucci, I.; Bandinelli, R.; da Silva, E.R. Sustainable Reverse Logistics Network Design Using Simulation: Insights from the Fashion Industry. Clean. Logist. Supply Chain 2025, 14, 100201. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse Logistics and Closed-Loop Supply Chain: A Comprehensive Review to Explore the Future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Khoei, M.A.; Aria, S.S.; Gholizadeh, H.; Goh, M.; Cheikhrouhou, N. Big Data-Driven Optimization for Sustainable Reverse Logistics Network Design. J. Ambient Intell. Humaniz. Comput. 2023, 14, 10867–10882. [Google Scholar] [CrossRef]

- Moheb-Alizadeh, H.; Sadeghi, A.H.; Sahebi Fakhrabad, A.; Jaunich, M.K.; Kemahlioglu-Ziya, E.; Handfield, R.B. Reverse Logistics Network Design to Estimate the Economic and Environmental Impacts of Take-Back Legislation: A Case Study for E-Waste Management System in Washington State. arXiv 2023, arXiv:2301.09792. [Google Scholar]

- Vanderlei de Almeida, I.T.G.; Ribeiro, A.R.B.; Ramalho, L.L.; de Sousa Floriano, L.; de Araújo, R.S.C. Circular Economy and Reverse Logistics: A Systematic Review. Rev. Gestão Soc. E Ambient. 2023, 18, e04146. [Google Scholar] [CrossRef]

- Alkahtani, M.; Ziout, A.; Salah, B.; Alatefi, M.; Elgawad, A.E.E.A.; Badwelan, A.; Syarif, U. An Insight into Reverse Logistics with a Focus on Collection Systems. Sustainability 2021, 13, 548. [Google Scholar] [CrossRef]

- Romero, J.A.V.; Gutiérrez, J.G. Reverse Logistics in Transportation. Available online: https://www.academia.edu/392533/Reverse_Logistics_in_Transportation (accessed on 18 February 2025).

- Melo, A.C.S.; de Lucena Nunes, D.R.; Júnior, A.E.B.; Brandão, R.; Nagata, V.d.M.N.; Martins, V.W.B. Analysis of Activities That Make up Reverse Logistics Processes: Proposition of a Conceptual Framework. Braz. J. Oper. Prod. Manag. 2022, 19, 1–16. [Google Scholar] [CrossRef]

- Rubio, S.; Jiménez-Parra, B. Reverse Logistics: Overview and Challenges for Supply Chain Management. Int. J. Eng. Bus. Manag. 2014, 6, 12. [Google Scholar] [CrossRef]

- Daaboul, J.; Le Duigou, J.; Penciuc, D.; Eynard, B. Reverse Logistics Network Design: A Holistic Life Cycle Approach. J. Remanuf. 2014, 4, 7. [Google Scholar] [CrossRef]

- Sun, X.; Yu, H.; Solvang, W.D.; Govindan, K. A Two-Level Decision-Support Framework for Reverse Logistics Network Design Considering Technology Transformation in Industry 4.0: A Case Study in Norway. Int. J. Adv. Manuf. Technol. 2024, 134, 389–413. [Google Scholar] [CrossRef]

- Fernando, Y.; Shaharudin, M.S.; Abideen, A.Z. Circular Economy-Based Reverse Logistics: Dynamic Interplay between Sustainable Resource Commitment and Financial Performance. Eur. J. Manag. Bus. Econ. 2023, 32, 91–112. [Google Scholar] [CrossRef]

- Krikke, H.R.; Van Harten, A.; Schuur, P.C. On a Medium Term Product Recovery and Disposal Strategy for Durable Assembly Products. Int. J. Prod. Res. 1998, 36, 111–140. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Borchardt, M.; Pereira, G.M.; Gomes, L.P. Environmental Performance Assessment of a Provider of Logistical Services in an Industrial Supply Chain. Theor. Found. Chem. Eng. 2012, 46, 691–703. [Google Scholar] [CrossRef]

- Singh, S.; Bala, N. Industry 4.0: Its Evolution and Future Prospects. In Industry 4.0; CRC Press: Boca Raton, FL, USA, 2023; pp. 1–24. [Google Scholar] [CrossRef]

- Zawadzki, P.; Zywicki, K. Smart Product Design and Production Control for Effective Mass Customization in the Industry 4.0 Concept. Manag. Prod. Eng. Rev. 2016, 7, 105–112. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A Survey on Technologies, Applications and Open Research Issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Nara, E.O.B.; da Costa, M.B.; Baierle, I.C.; Schaefer, J.L.; Benitez, G.B.; do Santos, L.M.A.L.; Benitez, L.B. Expected Impact of Industry 4.0 Technologies on Sustainable Development: A Study in the Context of Brazil’s Plastic Industry. Sustain. Prod. Consum. 2021, 25, 102–122. [Google Scholar] [CrossRef]

- Saydulu Kolasani. Revolutionizing Manufacturing, Making It More Efficient, Flexible, and Intelligent with Industry 4.0 Innovations. Int. J. Sustain. Dev. Through AI ML IoT 2024, 3, 1–17. Available online: https://ijsdai.com/index.php/IJSDAI/article/view/46 (accessed on 20 February 2025).

- Hafidy, I.; Benghabrit, A.; Zekhnini, K.; Benabdellah, A.C. Driving Supply Chain Resilience: Exploring the Potential of Operations Management and Industry 4.0. Procedia Comput. Sci. 2024, 232, 2458–2467. [Google Scholar] [CrossRef]

- Verma, P.K.; Verma, R.; Prakash, A.; Agrawal, A.; Naik, K.; Tripathi, R.; Alsabaan, M.; Khalifa, T.; Abdelkader, T.; Abogharaf, A. Machine-to-Machine (M2M) Communications: A Survey. J. Netw. Comput. Appl. 2016, 66, 83–105. [Google Scholar] [CrossRef]

- Lezzi, M.; Lazoi, M.; Corallo, A. Cybersecurity for Industry 4.0 in the Current Literature: A Reference Framework. Comput. Ind. 2018, 103, 97–110. [Google Scholar] [CrossRef]

- Heyer, C. Human-Robot Interaction and Future Industrial Robotics Applications. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 4749–4754. [Google Scholar] [CrossRef]

- Almada-Lobo, F. The Industry 4.0 Revolution and the Future of Manufacturing Execution Systems (MES). J. Innov. Manag. 2015, 3, 16–21. [Google Scholar] [CrossRef]

- Borangiu, T.; Trentesaux, D.; Thomas, A.; Leitão, P.; Barata, J. Digital Transformation of Manufacturing through Cloud Services and Resource Virtualization. Comput. Ind. 2019, 108, 150–162. [Google Scholar] [CrossRef]

- Rüdiger, D.; Hohaus, C.; Uriarte, A.; Ibañez, N.; Guarde, D.; Marquinez, I.; Manjon, D.; Kovács, P. Towards Efficient End-of-Life Processes of Electrical and Electronic Waste with Passive RF Communication. In Proceedings of the 2012 Electronics Goes Green 2012+, Berlin, Germany, 9–12 September 2012; Available online: https://ieeexplore.ieee.org/abstract/document/6360488 (accessed on 18 February 2025).

- Snyder, H. Literature Review as a Research Methodology: An Overview and Guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Brereton, P.; Kitchenham, B.A.; Budgen, D.; Turner, M.; Khalil, M. Lessons from Applying the Systematic Literature Review Process within the Software Engineering Domain. J. Syst. Softw. 2007, 80, 571–583. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef] [PubMed]

- Ghadge, A.; Mogale, D.G.; Bourlakis, M.; Maiyar, L.M.; Moradlou, H. Link between Industry 4.0 and Green Supply Chain Management: Evidence from the Automotive Industry. Comput. Ind. Eng. 2022, 169, 108303. [Google Scholar] [CrossRef]

- Yu, H.; Sun, X. Uncertain Remanufacturing Reverse Logistics Network Design in Industry 5.0: Opportunities and Challenges of Digitalization. Eng. Appl. Artif. Intell. 2024, 133, 108578. [Google Scholar] [CrossRef]

- Pourmehdi, M.; Paydar, M.M.; Ghadimi, P.; Azadnia, A.H. Analysis and Evaluation of Challenges in the Integration of Industry 4.0 and Sustainable Steel Reverse Logistics Network. Comput. Ind. Eng. 2022, 163, 107808. [Google Scholar] [CrossRef]

- Mejía-Moncayo, C.; Kenné, J.P.; Hof, L.A. On the Development of a Smart Architecture for a Sustainable Manufacturing-Remanufacturing System: A Literature Review Approach. Comput. Ind. Eng. 2023, 180, 109282. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and Circular Economy: Operational Excellence for Sustainable Reverse Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Tsai, F.M.; Bui, T.D.; Tseng, M.L.; Ali, M.H.; Lim, M.K.; Chiu, A.S. Sustainable Supply Chain Management Trends in World Regions: A Data-Driven Analysis. Resour. Conserv. Recycl. 2021, 167, 105421. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Swami, S. Diffusion of Green Products in Industry 4.0: Reverse Logistics Issues during Design of Inventory and Production Planning System. Int. J. Prod. Econ. 2020, 223, 107519. [Google Scholar] [CrossRef]

- Shahidzadeh, M.H.; Shokouhyar, S.; Javadi, F.; Shokoohyar, S. Unscramble Social Media Power for Waste Management: A Multilayer Deep Learning Approach. J. Clean. Prod. 2022, 377, 134350. [Google Scholar] [CrossRef]

- Saldanha-da-Gama, F. Facility Location in Logistics and Transportation: An Enduring Relationship. Transp. Res. Part E Logist. Transp. Rev. 2022, 166, 102903. [Google Scholar] [CrossRef]

- Krstić, M.; Agnusdei, G.P.; Miglietta, P.P.; Tadić, S.; Roso, V. Applicability of Industry 4.0 Technologies in the Reverse Logistics: A Circular Economy Approach Based on COmprehensive Distance Based RAnking (COBRA) Method. Sustainability 2022, 14, 5632. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 Technologies to Enable Circular Economy Practices in a Manufacturing Context: A Business Model Proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Khan, S.A.; Laalaoui, W.; Hokal, F.; Tareq, M.; Ahmad, L. Connecting Reverse Logistics with Circular Economy in the Context of Industry 4.0. Kybernetes 2023, 52, 6279–6320. [Google Scholar] [CrossRef]

- Bajar, K.; Kamat, A.; Shanker, S.; Barve, A. Blockchain Technology: A Catalyst for Reverse Logistics of the Automobile Industry. Smart Sustain. Built Environ. 2024, 13, 133–178. [Google Scholar] [CrossRef]

- Bayramov, K. The Role of Software in Reverse Logistics and Effect on Oily Waste Management. J. Transp. Supply Chain Manag. 2023, 17, 941. [Google Scholar] [CrossRef]

- Tombido, L.L.; Louw, L.; van Eeden, J. A Systematic Review of 3pls’ Entry into Reverse Logistics. South Afr. J. Ind. Eng. 2018, 29, 235–260. [Google Scholar] [CrossRef]

- Sung, S.I.; Kim, Y.S.; Kim, H.S. Study on Reverse Logistics Focused on Developing the Collection Signal Algorithm Based on the Sensor Data and the Concept of Industry 4.0. Appl. Sci. 2020, 10, 5016. [Google Scholar] [CrossRef]

- Ulgiati, S.; Casazza, M.; Lomas, P.L.; Richnák, P.; Fidlerová, H. Impact and Potential of Sustainable Development Goals in Dimension of the Technological Revolution Industry 4.0 within the Analysis of Industrial Enterprises. Energies 2022, 15, 3697. [Google Scholar] [CrossRef]

- Bensassi, N.; Rezzai, M.; Wafaa, D.; Medromi, H. Sustainable Manufacturing in Industry 4.0 Context: Theoretical Background and Multi-Agent Architecture. Int. J. Eng. Trends Technol. 2022, 70, 179–193. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Industry 4.0 Model for Integrated Circular Economy-Reverse Logistics Network. Int. J. Logist. Res. Appl. 2022, 25, 837–877. [Google Scholar] [CrossRef]

- Yu, H. Modeling a Remanufacturing Reverse Logistics Planning Problem: Some Insights into Disruptive Technology Adoption. Int. J. Adv. Manuf. Technol. 2022, 123, 4231–4249. [Google Scholar] [CrossRef]

- Neto, O.; De Araujo, G.C.D.; Gomes, S.A.; Alliprandini, R.A.; Flausino, D.H.; Cardoso De Oliveira Neto, G.; Alves De Araujo, S.; Gomes, R.A.; Alliprandini, D.H.; Flausino, F.R.; et al. Simulation of Electronic Waste Reverse Chains for the Sao Paulo Circular Economy: An Artificial Intelligence-Based Approach for Economic and Environmental Optimizations. Sensors 2023, 23, 9046. [Google Scholar] [CrossRef]

- Schneikart, G.; Mayrhofer, W.; Frysak, J.; Löffler, C. A Returnable Transport Item to Integrate Logistics 4.0 and Circular Economy in Pharma Supply Chains. Teh. Glas. 2023, 17, 375–382. [Google Scholar] [CrossRef]

- Misni, F.; Lee, L.S.; Misni, F.; Lee, L.S. A Review on Strategic, Tactical and Operational Decision Planning in Reverse Logistics of Green Supply Chain Network Design. J. Comput. Commun. 2017, 5, 83–104. [Google Scholar] [CrossRef]

- Schaefer, J.L.; Tardio, P.R.; Baierle, I.C.; Nara, E.O.B. GIANN—A Methodology for Optimizing Competitiveness Performance Assessment Models for Small and Medium-Sized Enterprises. Adm. Sci. 2023, 13, 56. [Google Scholar] [CrossRef]

- Krstić, M.; Agnusdei, G.P.; Miglietta, P.P.; Tadić, S. Evaluation of the Smart Reverse Logistics Development Scenarios Using a Novel MCDM Model. Clean. Environ. Syst. 2022, 7, 100099. [Google Scholar] [CrossRef]

- Govindan, K.; Bouzon, M. From a Literature Review to a Multi-Perspective Framework for Reverse Logistics Barriers and Drivers. J. Clean. Prod. 2018, 187, 318–337. [Google Scholar] [CrossRef]

| Filters | Scopus | Web of Science |

|---|---|---|

| Searched for | Title, abstract, and keywords | Title, abstract, and keywords |

| Publication year | 2011–2024 | 2011–2024 |

| Area | Engineering | Engineering |

| Document Type | Article | Article |

| Language | English | English |

| Search terms | (“Industry 4.0”) OR (“smart manufacturing”) OR (“Digital Technologies”) AND (“reverse logistics”) | (“Industry 4.0”) OR (“smart manufacturing”) OR (“Digital Technologies”) AND (“reverse logistics”) |

| DIGITAL TECHNOLOGIES | Internet of Things | Big Data | Cloud Computing | Artificial Intelligence | Blockchain | Additive Manufacturing | Autonomous Robots | Cyber–Physical Systems | RFID | Simulation | Digital Twin | Digitalization | Intelligent Sensors | Augmented and Virtual Reality |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Reference | ||||||||||||||

| [50] | x | x | x | x | x | x | ||||||||

| [51] | x | x | x | x | x | |||||||||

| [52] | x | x | ||||||||||||

| [53] | x | x | x | x | x | x | x | x | x | |||||

| [54] | x | x | x | x | x | |||||||||

| [55] | x | x | x | |||||||||||

| [56] | x | x | x | x | ||||||||||

| [57] | x | x | ||||||||||||

| [58] | x | x | x | x | x | x | ||||||||

| [59] | x | x | x | x | x | x | x | x | ||||||

| [60] | x | x | x | |||||||||||

| [61] | x | x | ||||||||||||

| [62] | x | |||||||||||||

| [63] | x | x | x | x | x | |||||||||

| [64] | x | x | ||||||||||||

| [65] | x | x | ||||||||||||

| [66] | x | x | x | x | ||||||||||

| [67] | x | x | x | x | x | x | x | |||||||

| [68] | x | x | ||||||||||||

| [69] | x | x | x | x | ||||||||||

| [31] | x | x | ||||||||||||

| [70] | x | x | ||||||||||||

| [59] | x | x | ||||||||||||

| [71] | x | |||||||||||||

| TOTAL | 16 | 10 | 9 | 8 | 6 | 6 | 6 | 6 | 5 | 5 | 4 | 3 | 3 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, S.P.; Gomes, L.d.C.; Peres, F.A.P.; Correa, R.G.d.F.; Baierle, I.C. A Framework for Leveraging Digital Technologies in Reverse Logistics Actions: A Systematic Literature Review. Logistics 2025, 9, 54. https://doi.org/10.3390/logistics9020054

Rodrigues SP, Gomes LdC, Peres FAP, Correa RGdF, Baierle IC. A Framework for Leveraging Digital Technologies in Reverse Logistics Actions: A Systematic Literature Review. Logistics. 2025; 9(2):54. https://doi.org/10.3390/logistics9020054

Chicago/Turabian StyleRodrigues, Sílvia Patrícia, Leonardo de Carvalho Gomes, Fernanda Araújo Pimentel Peres, Ricardo Gonçalves de Faria Correa, and Ismael Cristofer Baierle. 2025. "A Framework for Leveraging Digital Technologies in Reverse Logistics Actions: A Systematic Literature Review" Logistics 9, no. 2: 54. https://doi.org/10.3390/logistics9020054

APA StyleRodrigues, S. P., Gomes, L. d. C., Peres, F. A. P., Correa, R. G. d. F., & Baierle, I. C. (2025). A Framework for Leveraging Digital Technologies in Reverse Logistics Actions: A Systematic Literature Review. Logistics, 9(2), 54. https://doi.org/10.3390/logistics9020054