Research on the Electrical Tree Deterioration Characteristics of Silicone Gel and Silicone Rubber Under Pulsed Electric Field

Abstract

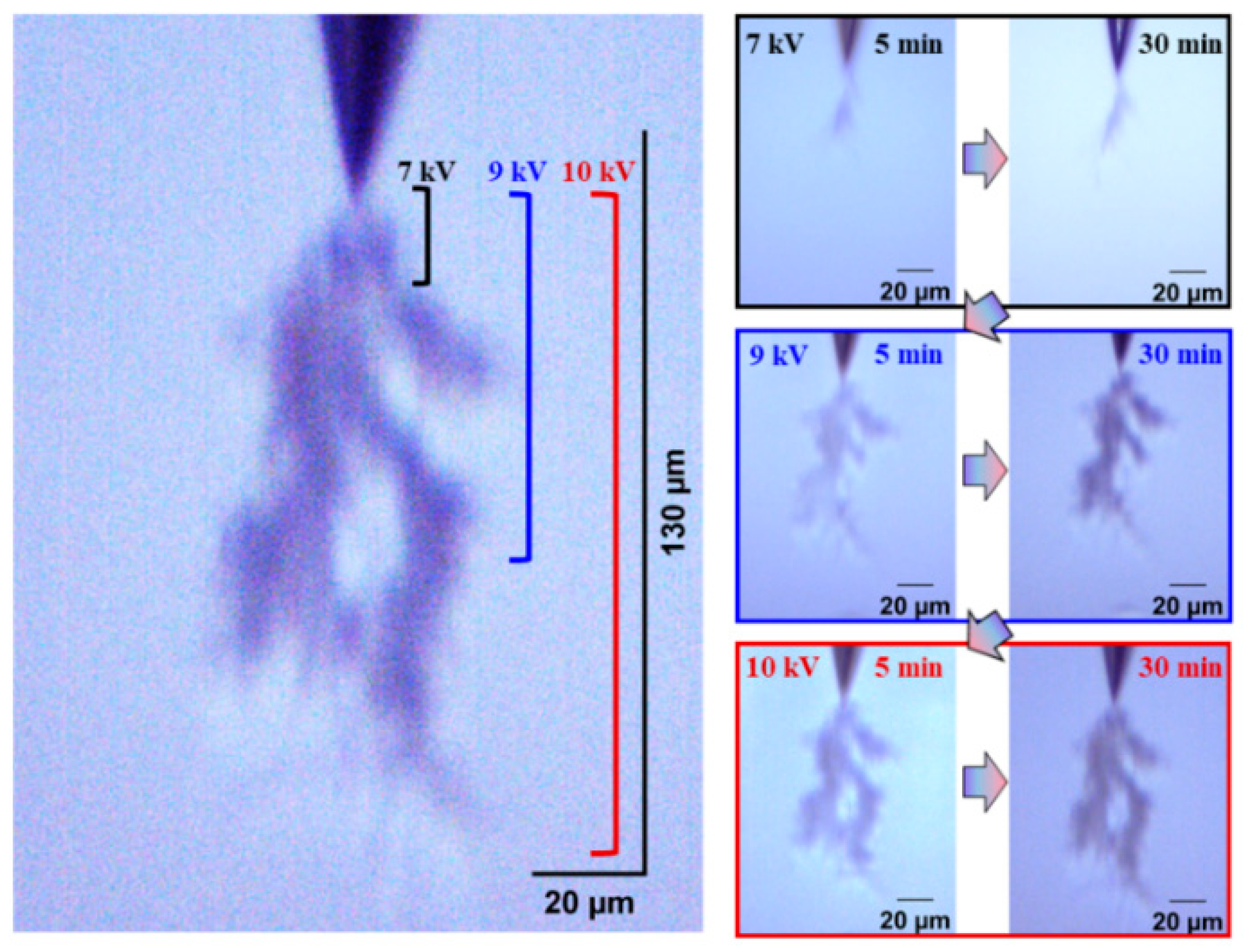

:1. Introduction

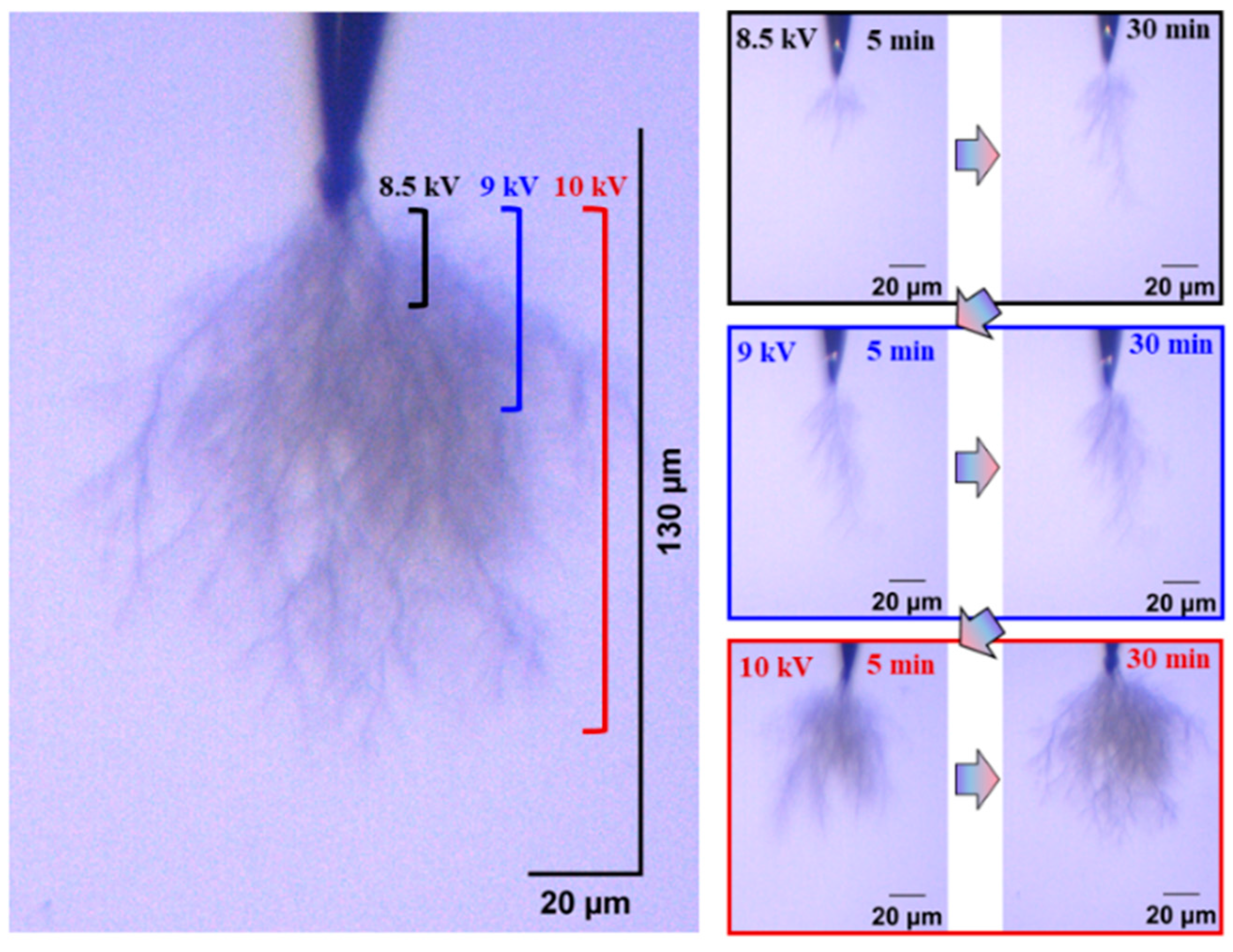

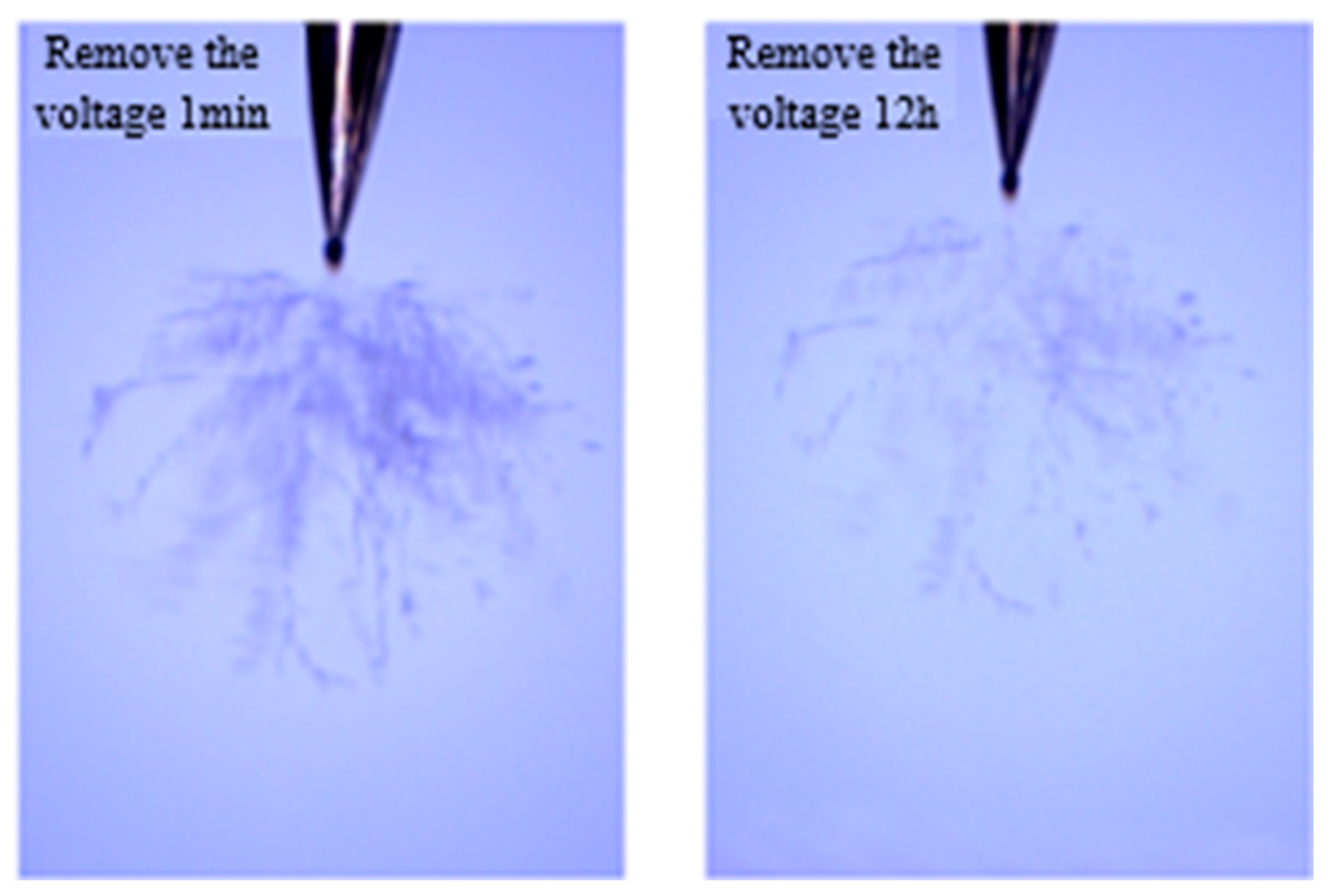

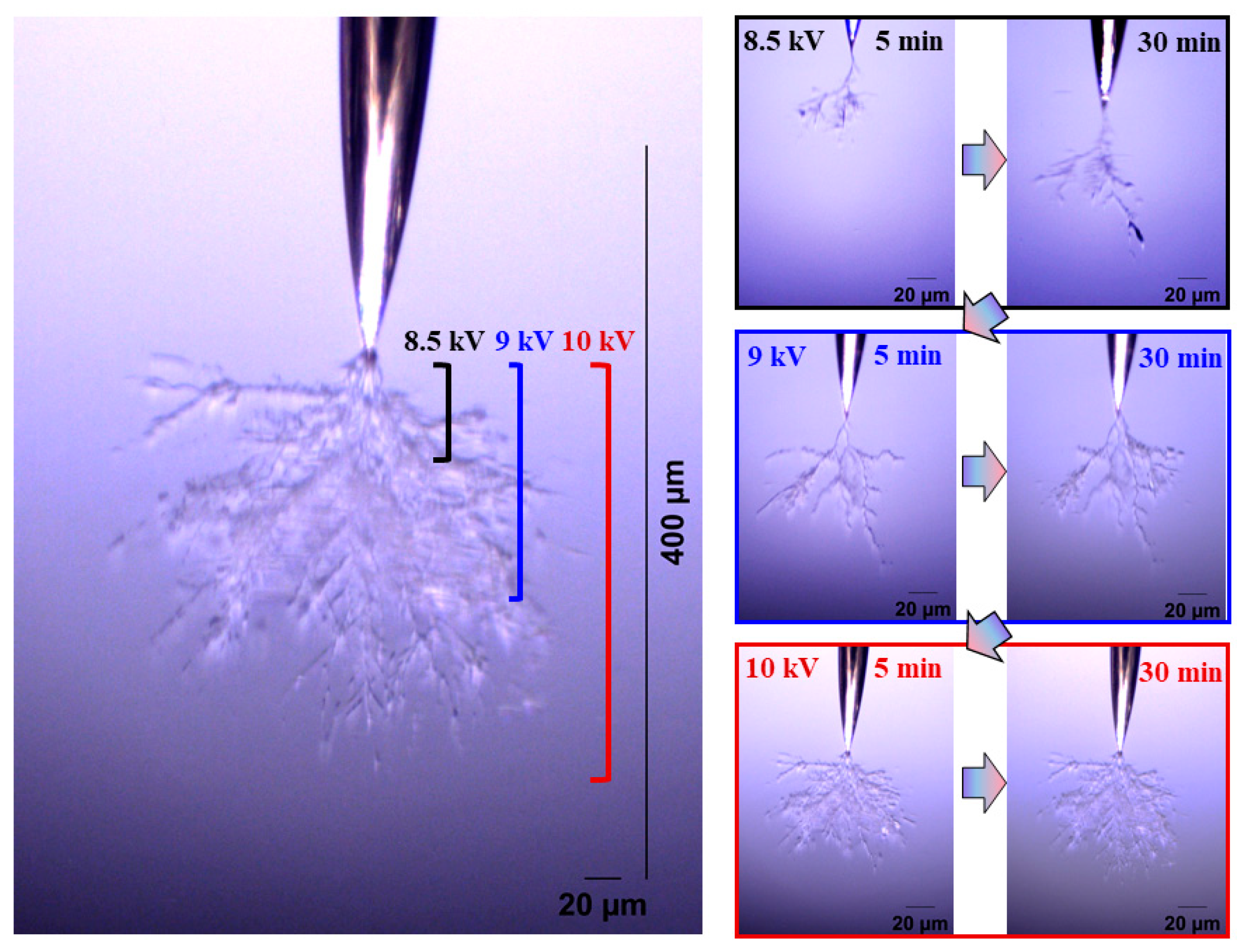

2. Results and Discussion

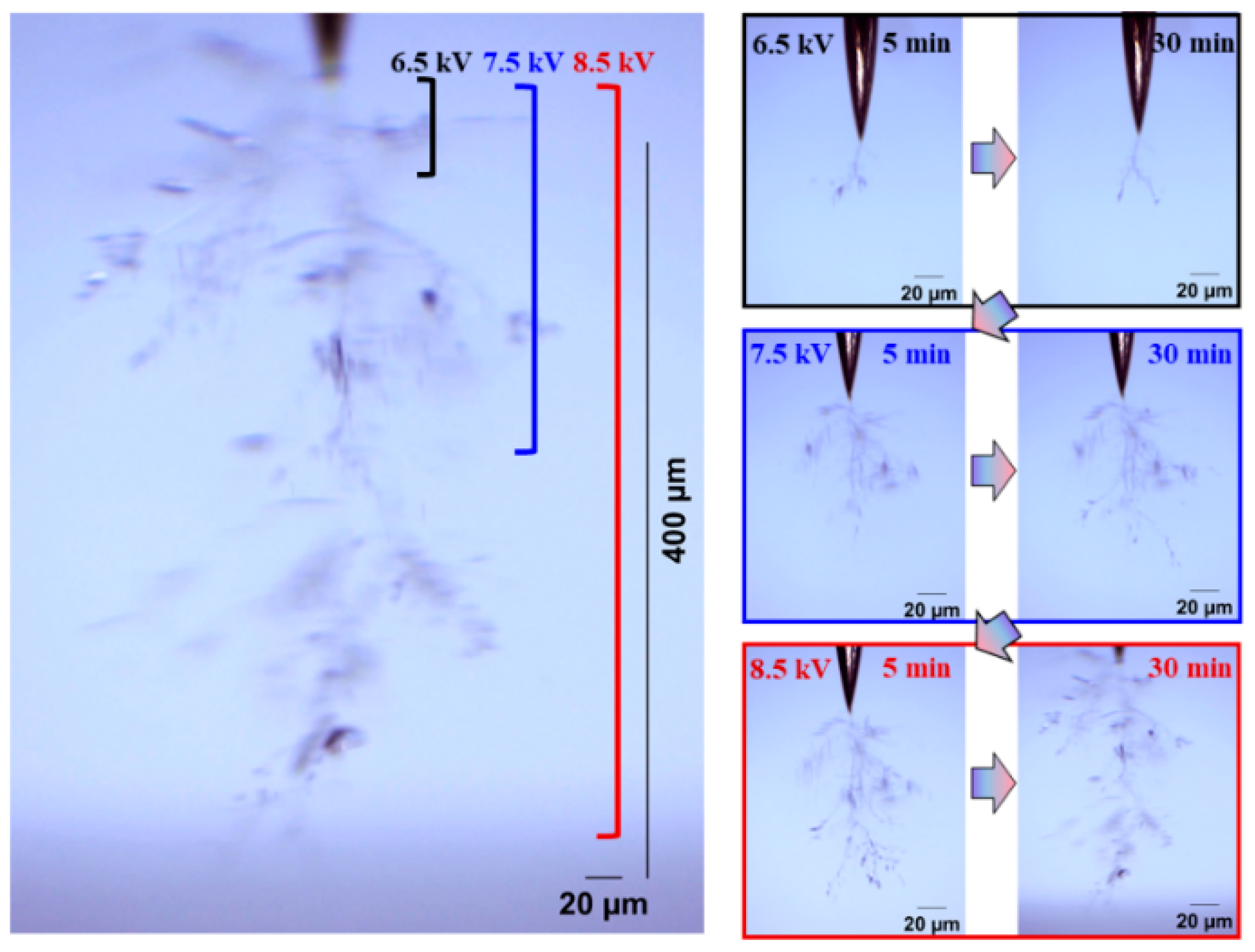

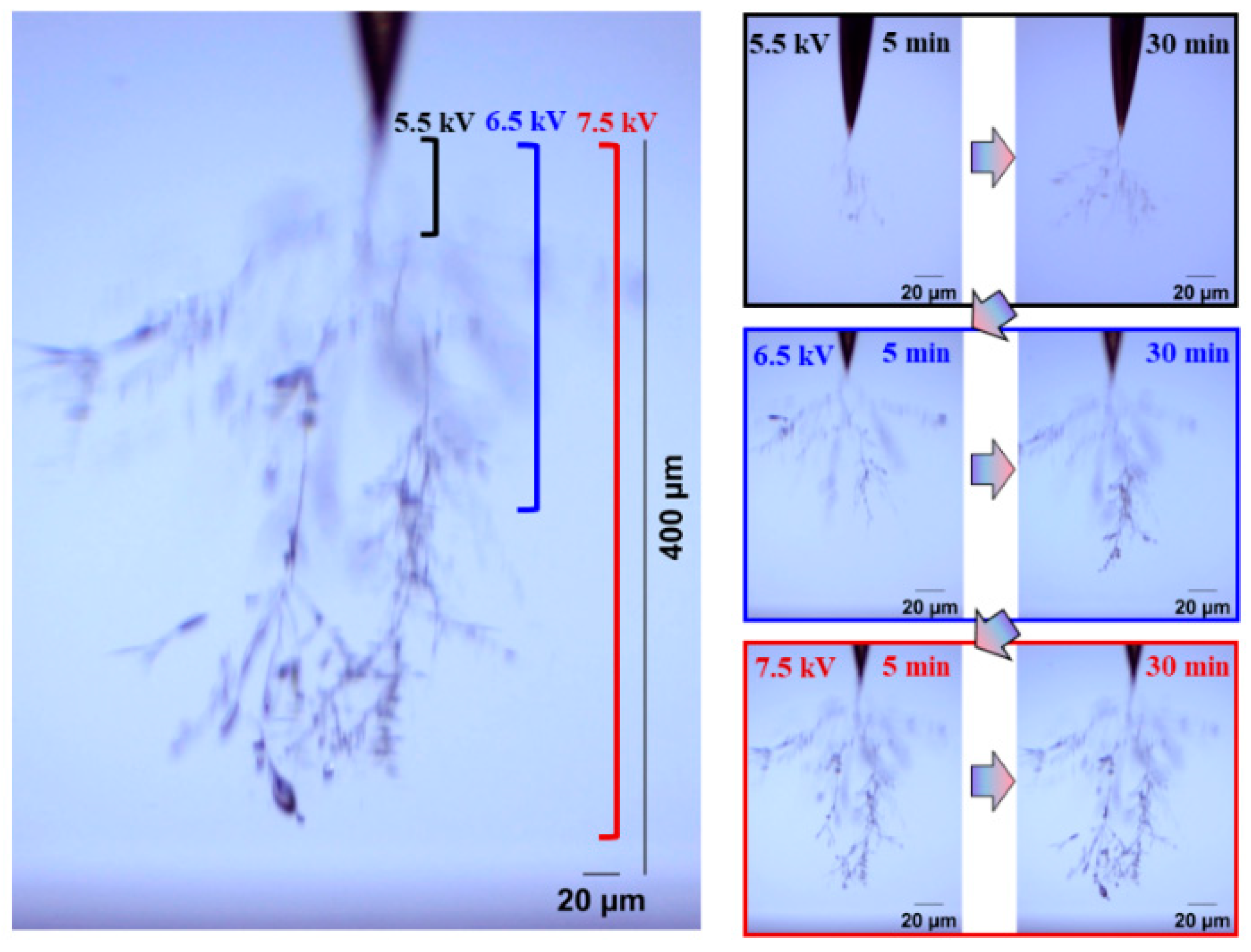

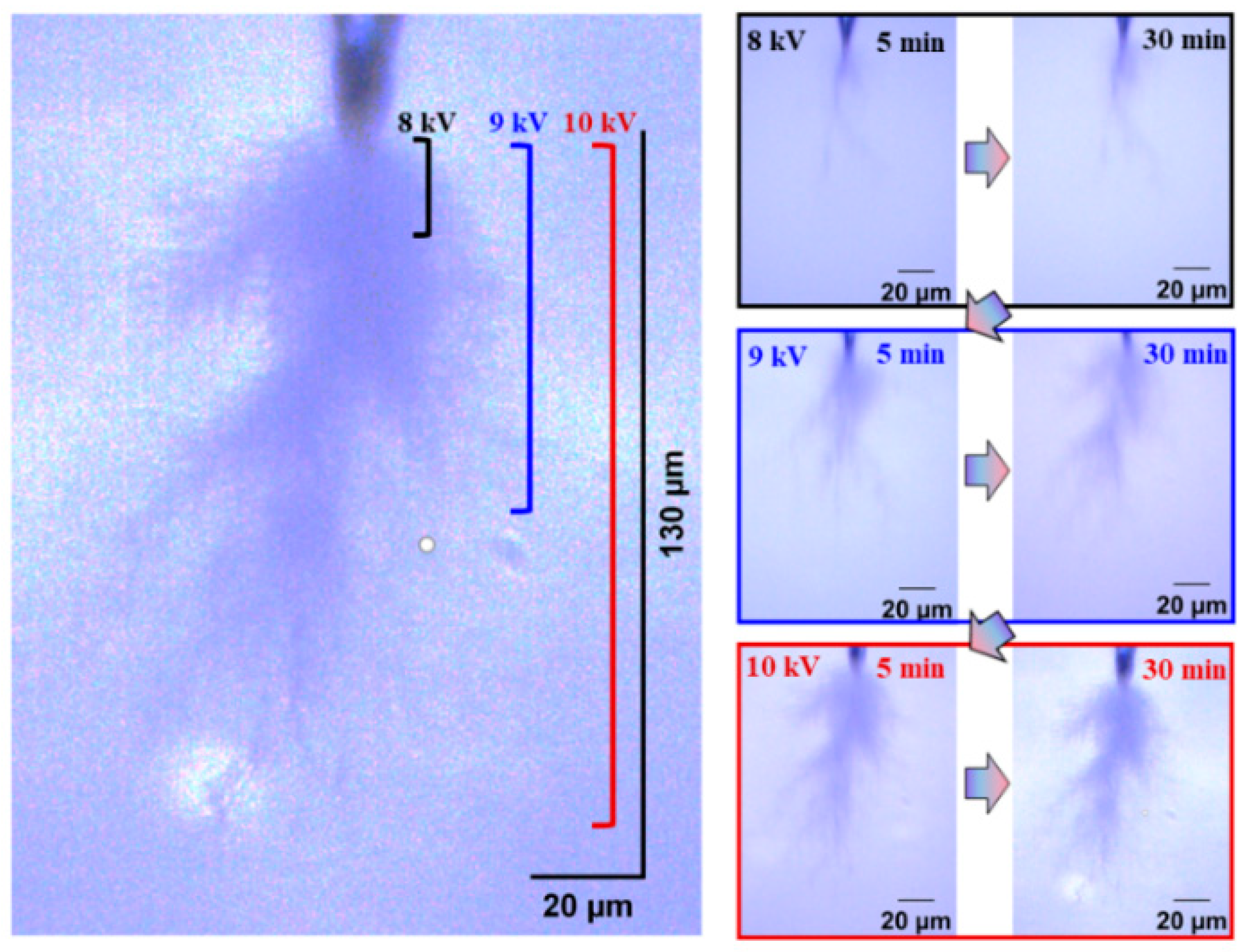

2.1. The Effect of Frequency

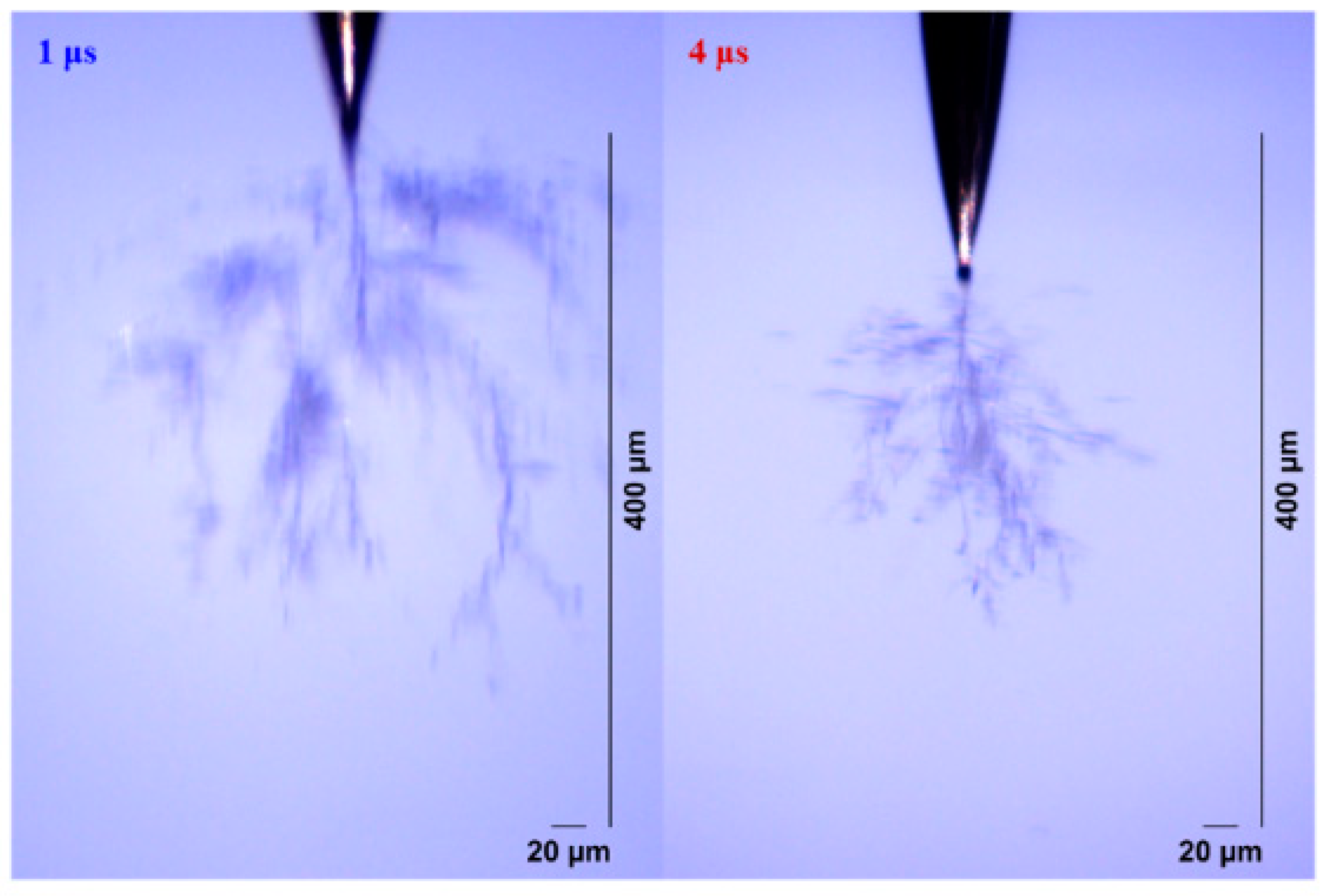

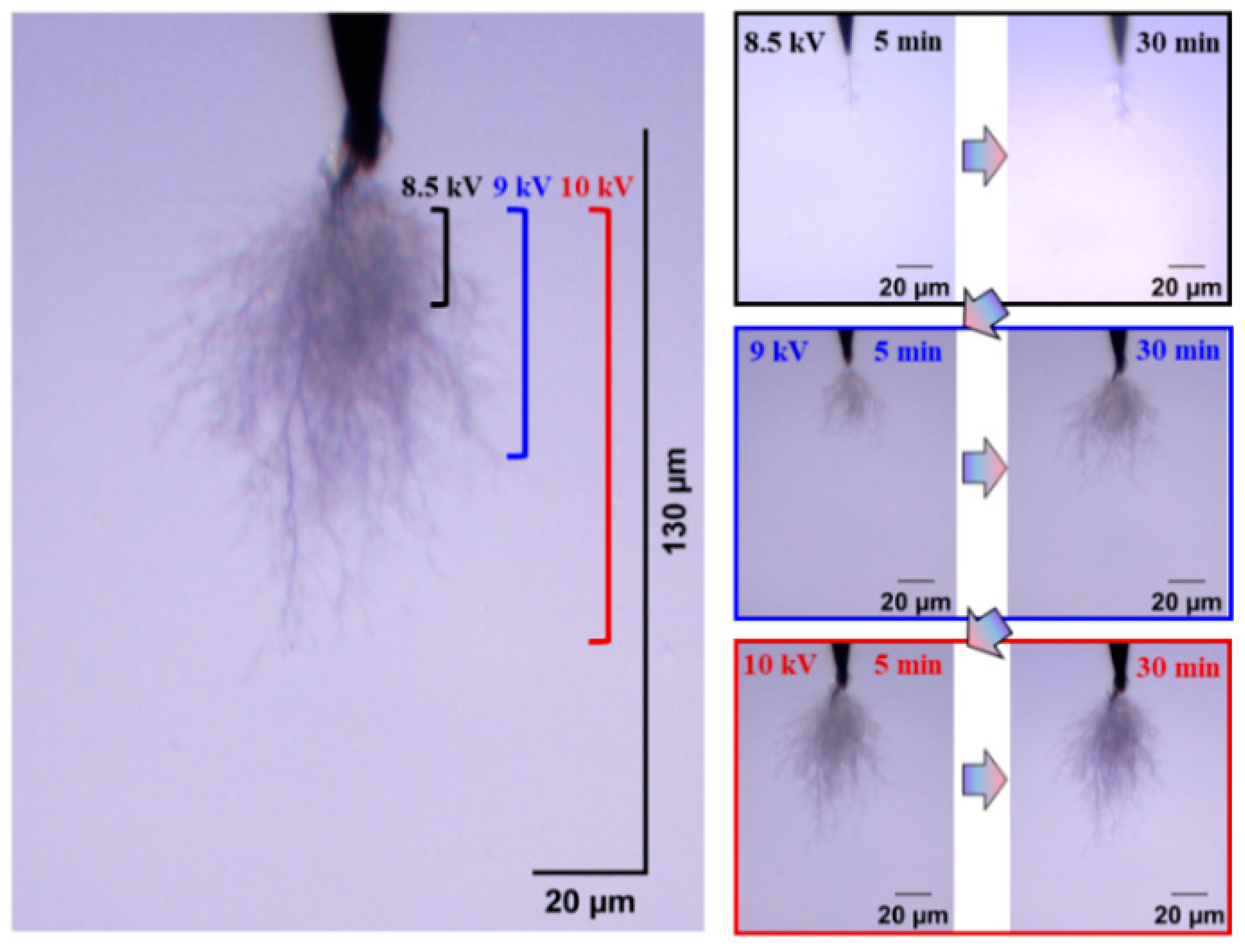

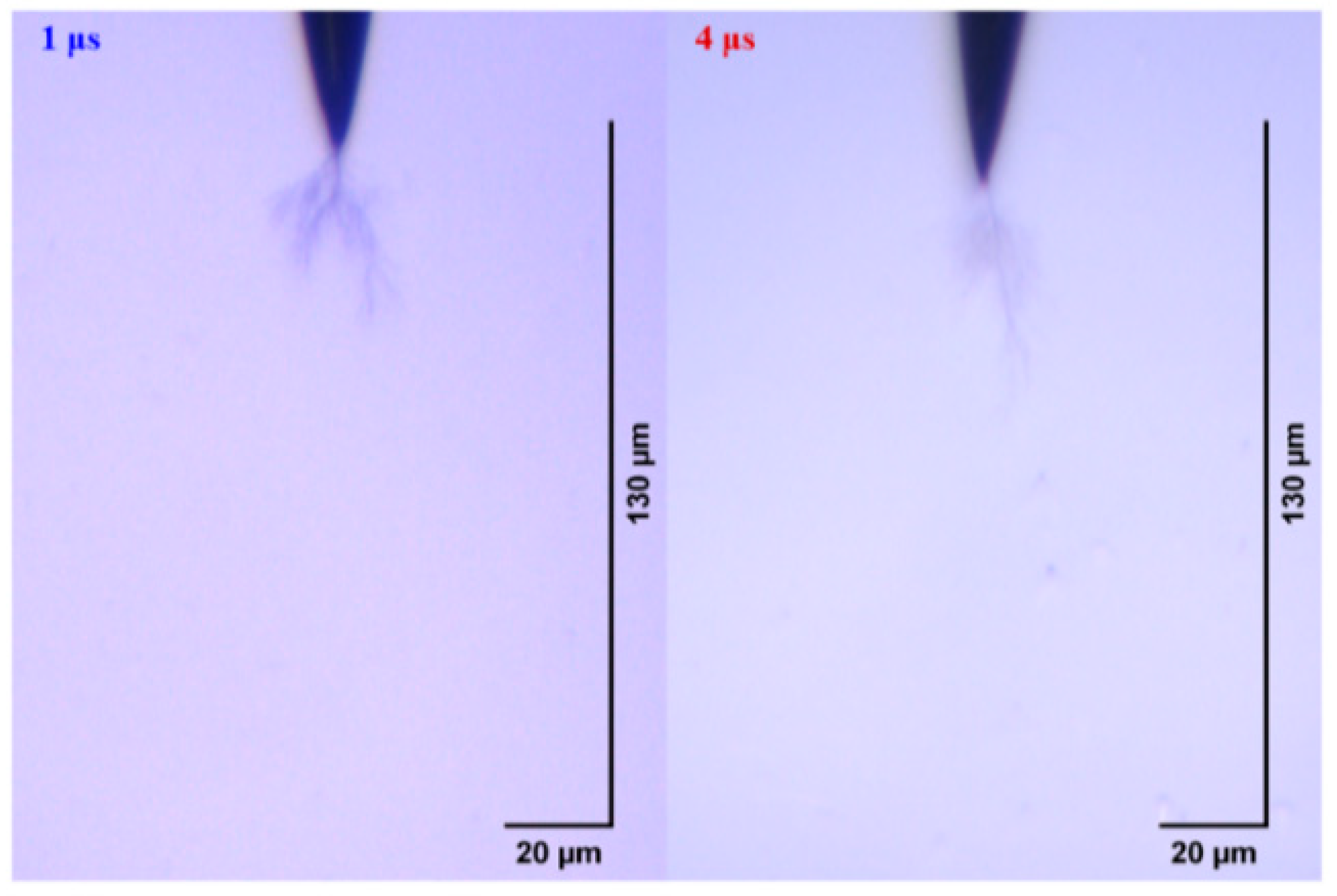

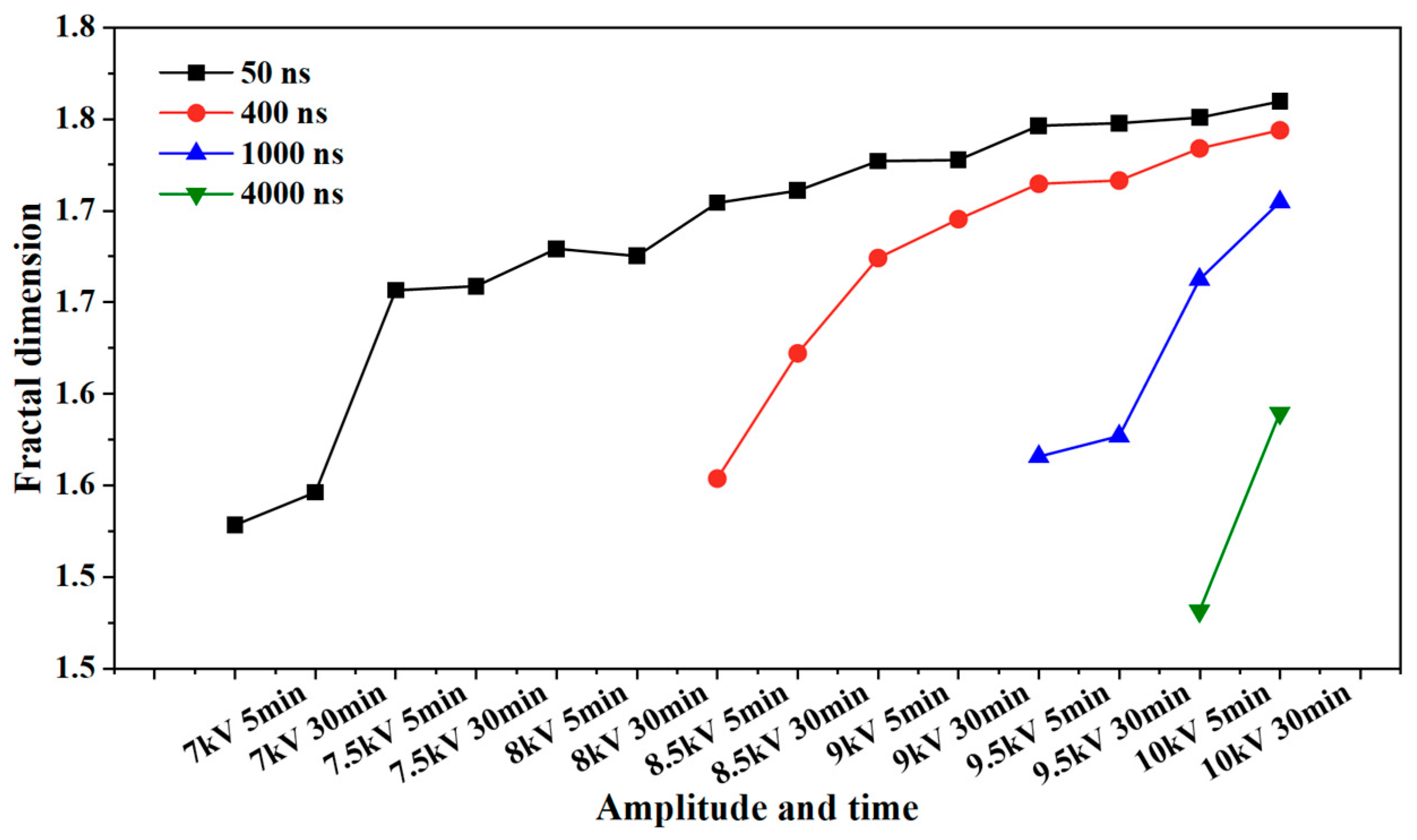

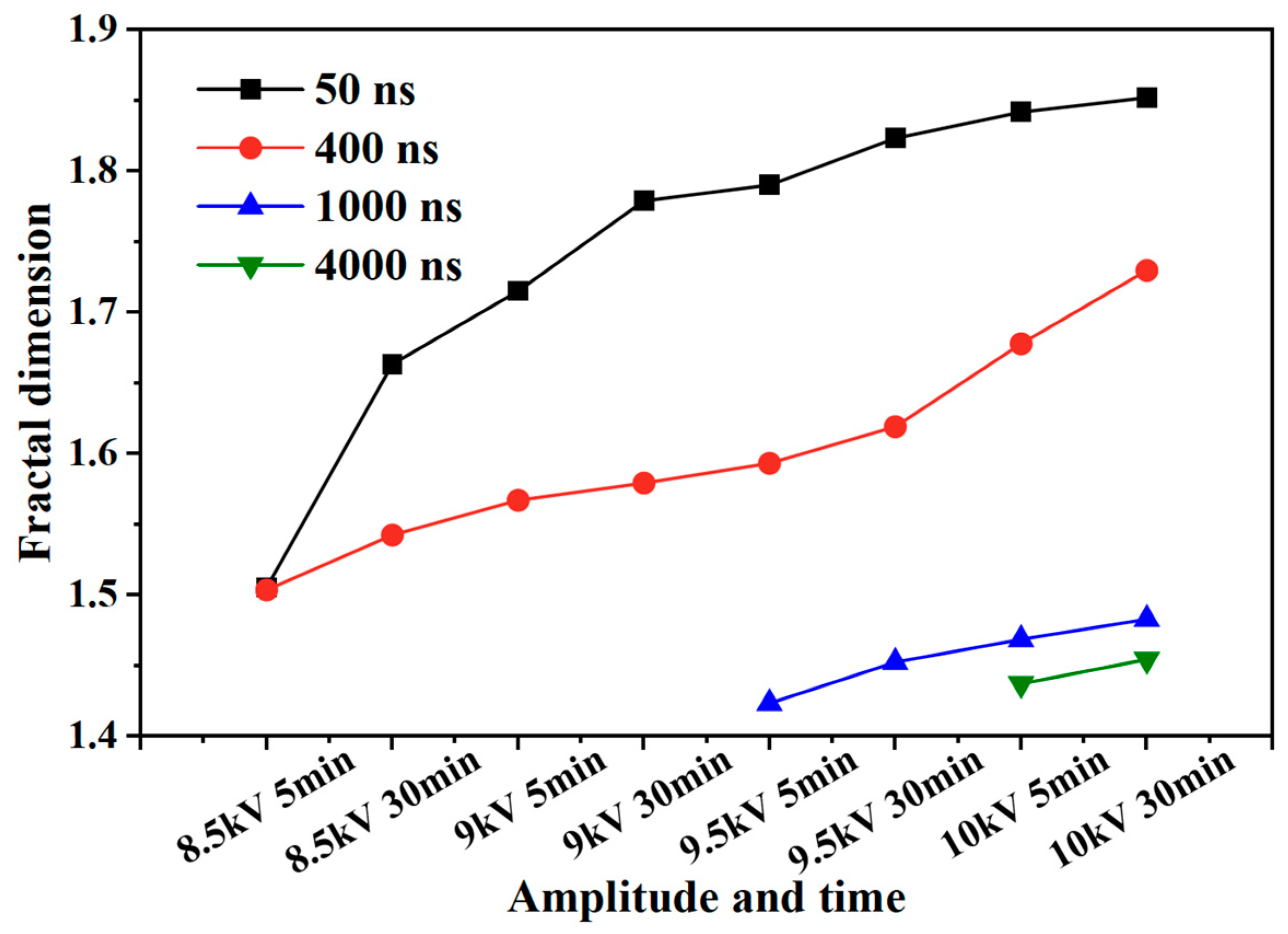

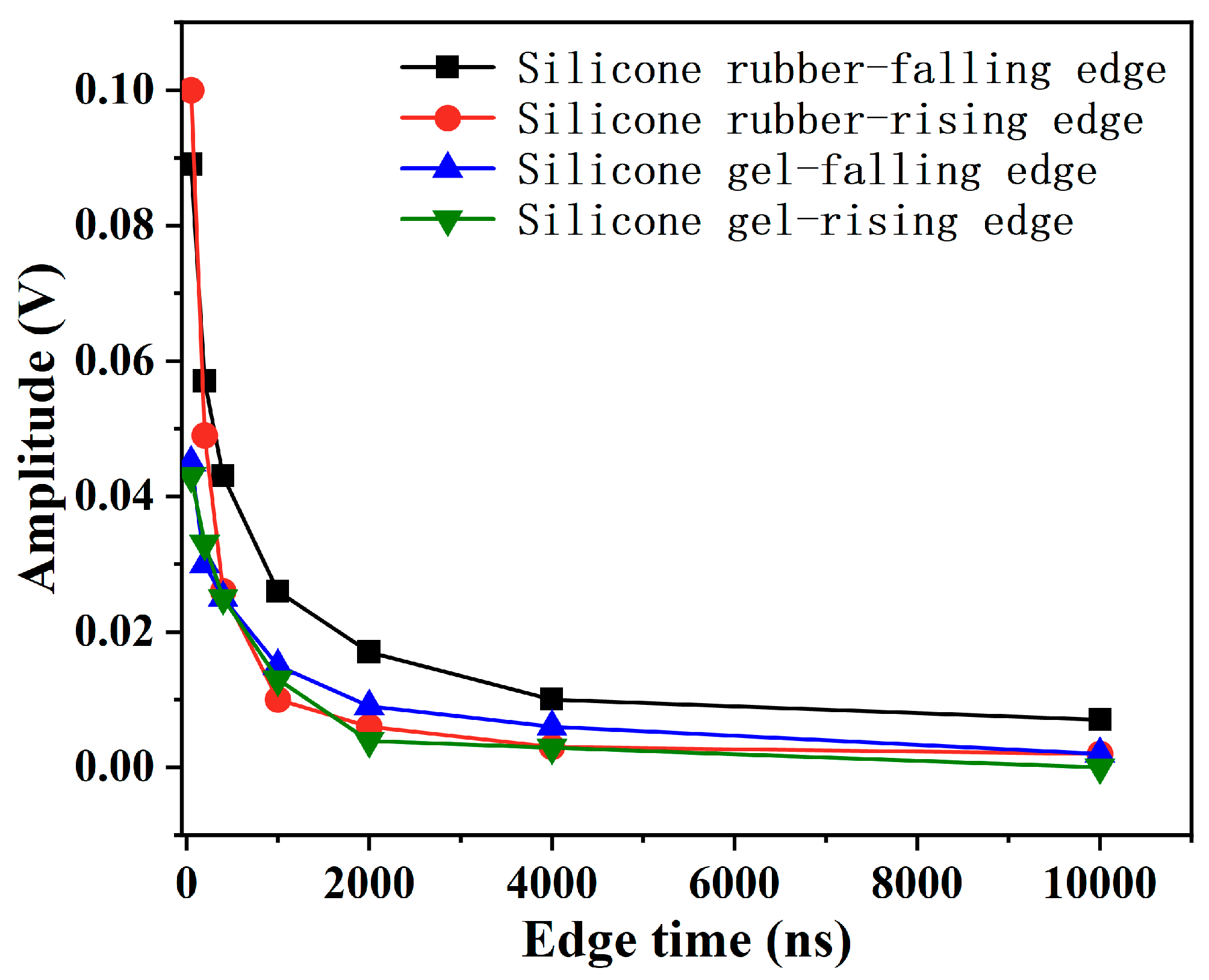

2.2. Effect of Edge Time

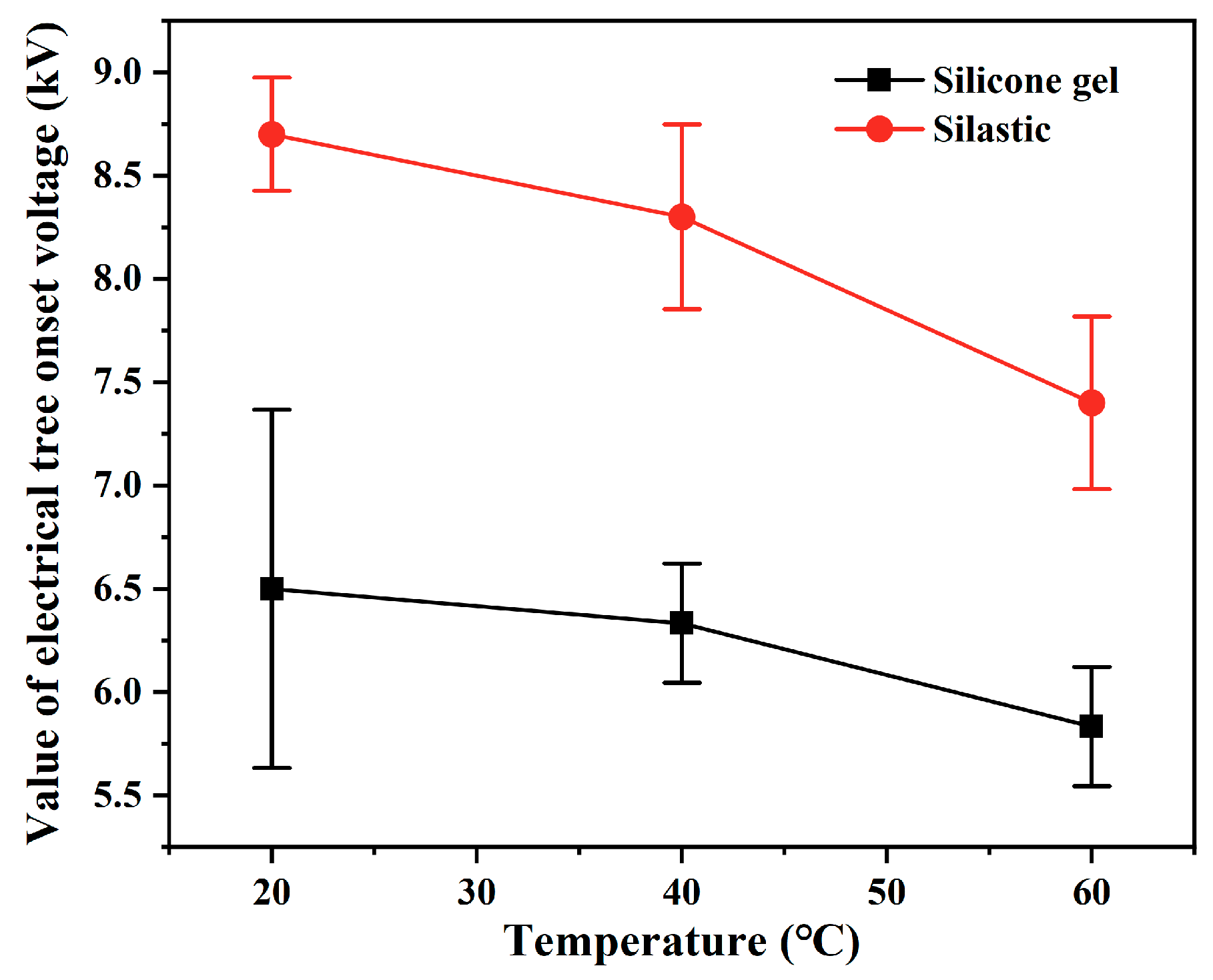

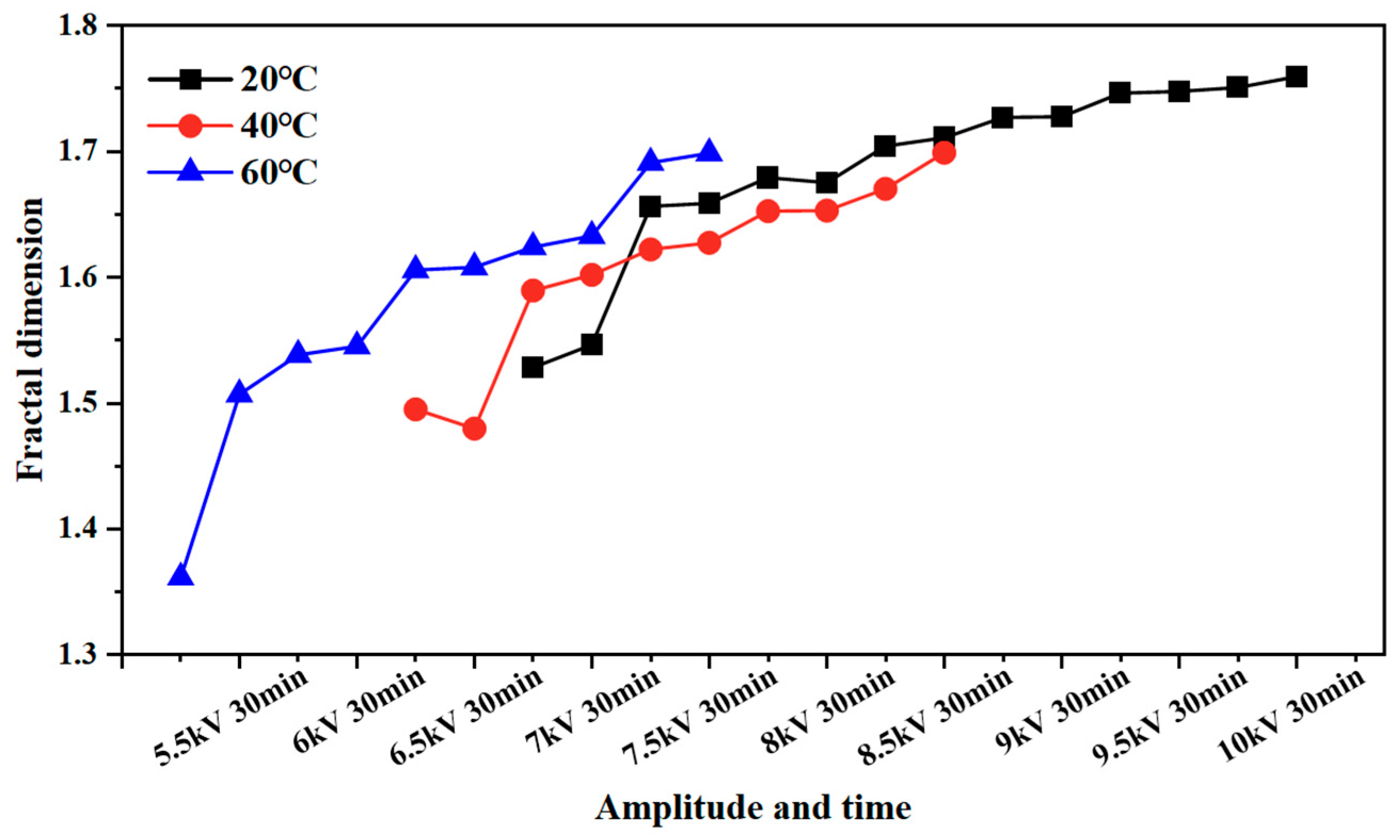

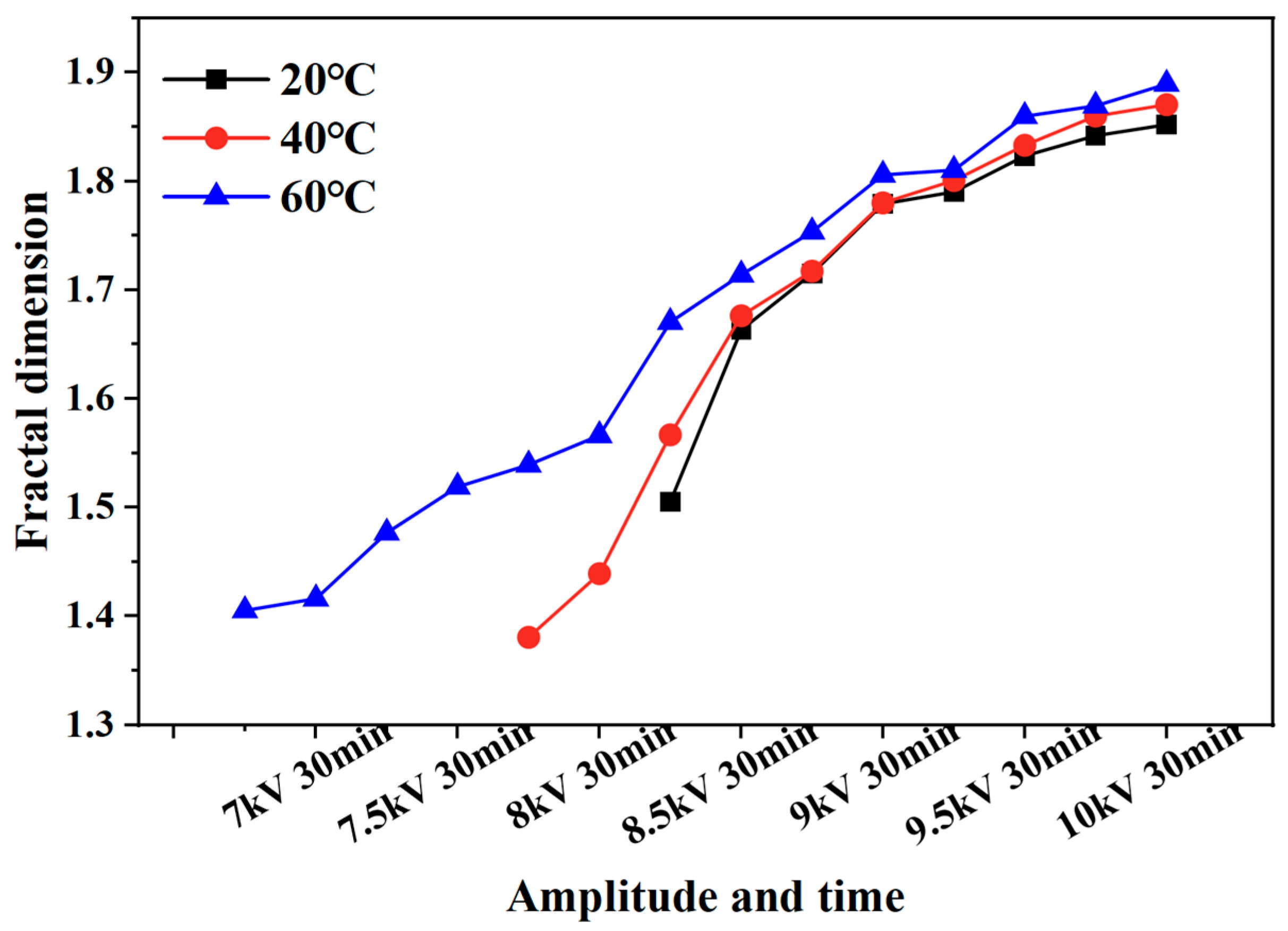

2.3. Effect of Temperature

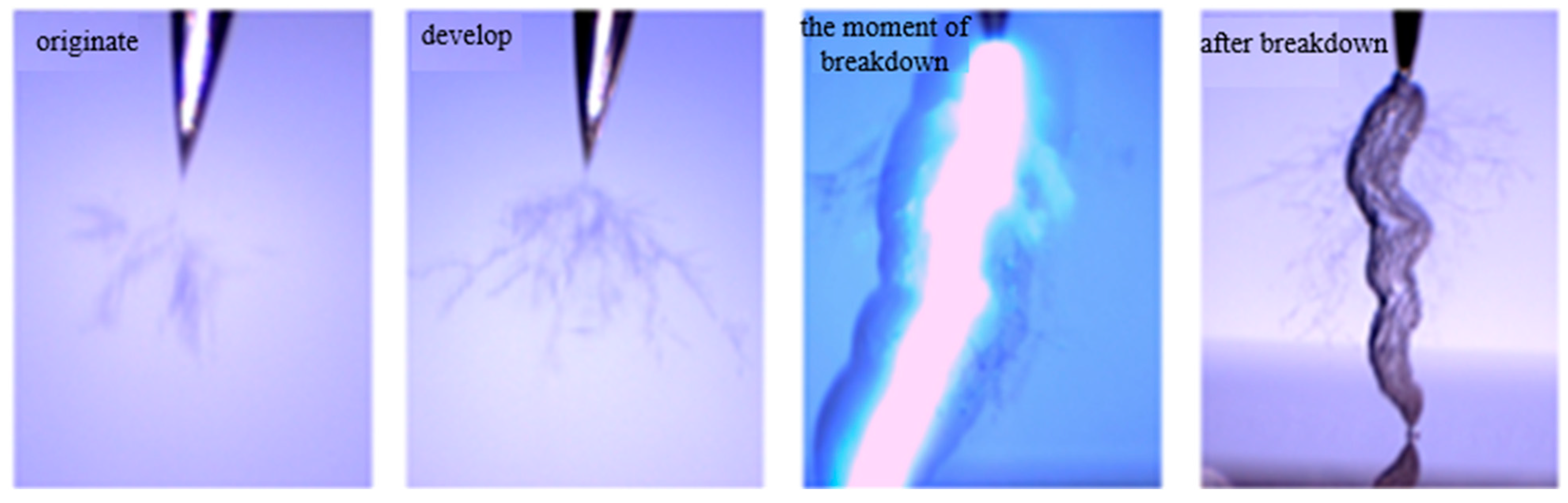

2.4. Mechanism of Deterioration Characteristics of Electric Branches

2.4.1. The Mechanism of Frequency

2.4.2. The Mechanism of Edge Time

2.4.3. The Mechanism of Temperature

3. Conclusions

4. Materials and Methods

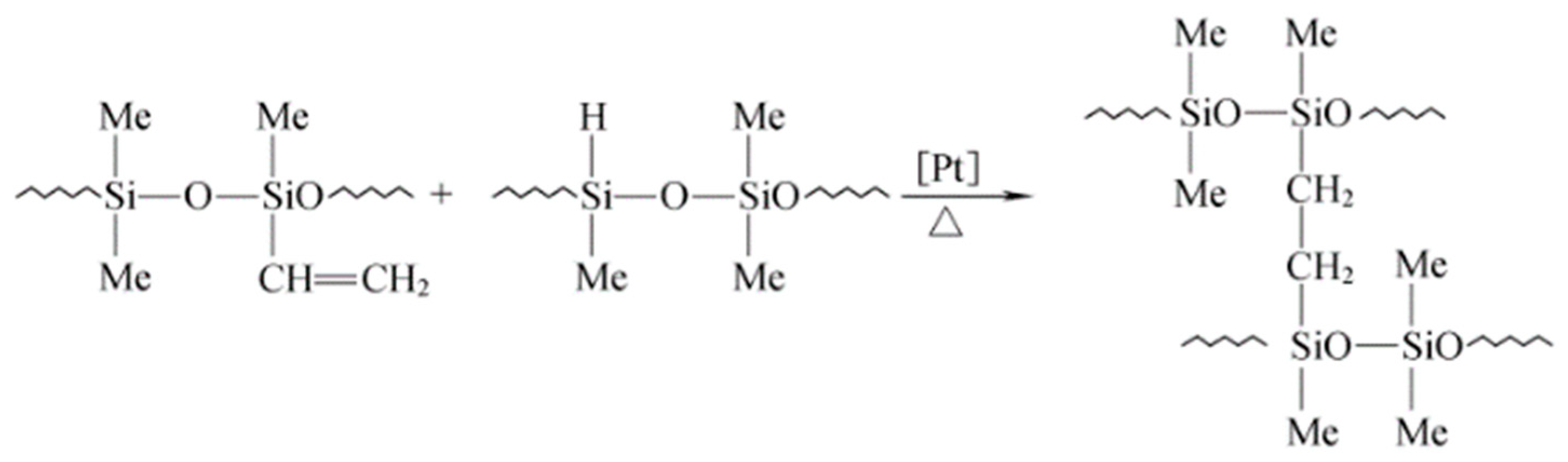

4.1. Preparation of Silicone Rubber and Silicone Gel

4.2. Preparation of the Electrical Tree

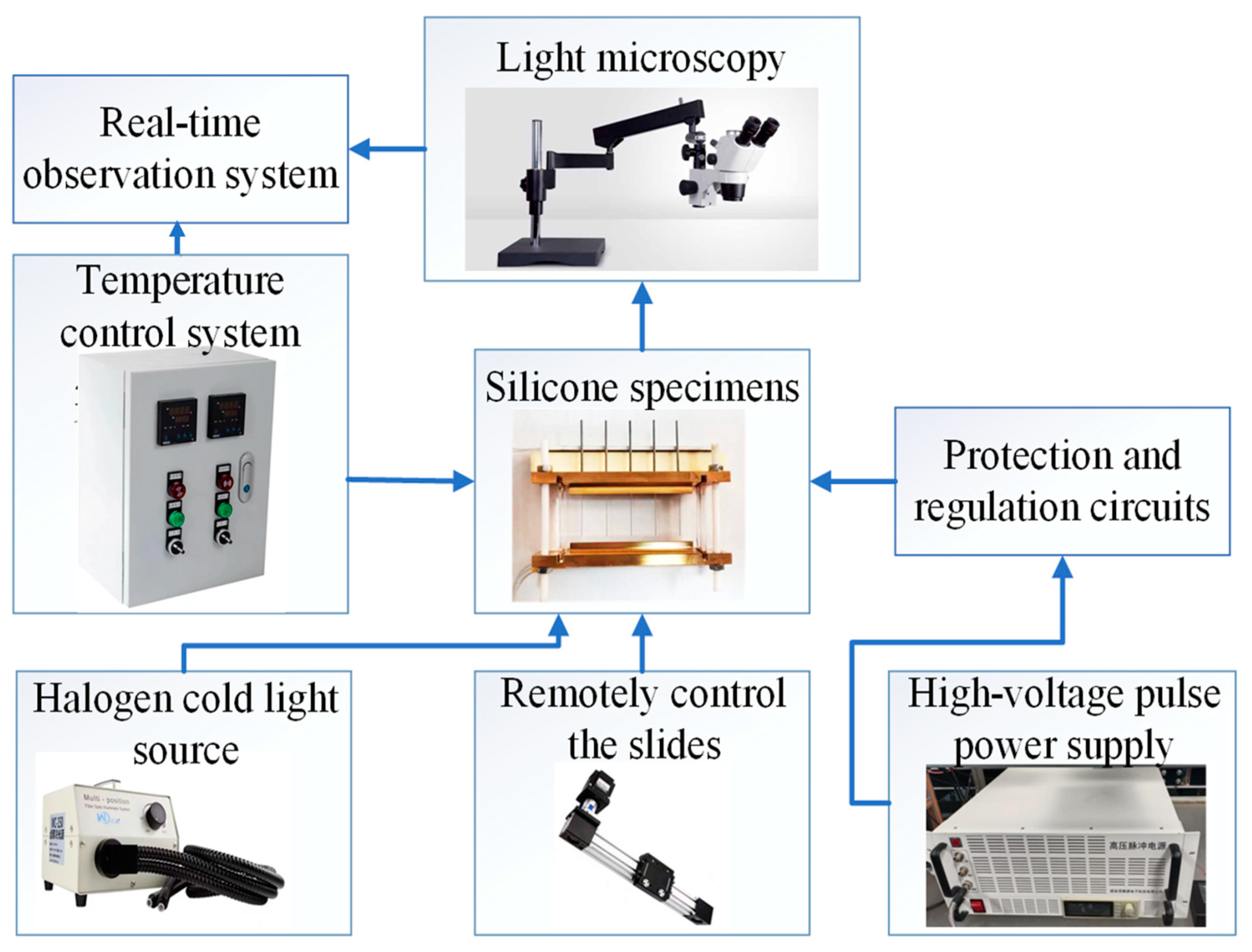

4.3. Experimental Platform

4.4. Experiment and Data Processing Methods

5. Patents

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, H.; Liu, P. High-Temperature encapsulation materials for power modules: Technology and guture development trends. Trans. Compon. Packag. Manuf. Technol. 2022, 12, 1867–1881. [Google Scholar]

- Locatelli, M.-L.; Khazaka, R.; Diaham, S.; Cong-Duc, P.; Bechara, M.; Dinculescu, S.; Bidan, P. Evaluation of encapsulation materials for High-Temperature power device packaging. IEEE Trans. Power Electron. 2014, 29, 2281–2288. [Google Scholar]

- Ghassemi, M. Accelerated insulation aging due to fast, repetitive voltages: A review identifying challenges and future research needs. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1558–1568. [Google Scholar] [CrossRef]

- Li, K.; Zhang, B.; Li, X.; Ke, H. The influence of degassing time and curing time on insulation behaviours of silicone gel in IGBT modules. IET Conf. Proc. 2021, 2021, 1537–1541. [Google Scholar]

- Wang, W.; Gong, Y.; Ren, H.; Wang, J.; Li, Q. High-Temperature failure mechanism and lifetime assessment of silicone gel package insulation for High-Power electronic devices based on pyrolysis kinetics. IEEE Trans. Ind. Appl. 2024, 60, 1298–1309. [Google Scholar]

- Kabanov, V.Y.; Feldman, V.I.; Ershov, B.G.; Polikarpov, A.I.; Kiryukhin, D.P.; Apel, P.Y. Radiation chemistry of polymers. High Energy Chem. 2009, 43, 1–18. [Google Scholar]

- Shit, S.C.; Shah, P. A review on silicone rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar]

- Khazaka, R.; Mendizabal, L.; Henry, D.; Hanna, R. Survey of High-Temperature reliability of power electronics packaging components. IEEE Trans. Power Electron. 2015, 30, 2456–2464. [Google Scholar]

- He, D.; Zhang, Z.; Wang, G.; Liu, K.; Wang, H.; Xu, Z.; Teyssedre, G.; Zhang, Y. Mechanism analysis of bubble discharge within silicone gels under pulsed electric field. Gels 2024, 10, 799. [Google Scholar] [CrossRef]

- Racles, C.; Bele, A.; Vasiliu, A.-L.; Sacarescu, L. Emulsion gels as precursors for porous silicones and all-Polymer composites—A proof of concept based on siloxane stabilizers. Gels 2022, 8, 377. [Google Scholar] [CrossRef]

- Liu, H.; Chen, X.; Xiao, Y.; Xing, Z.-J.; Ju, M.-j.; Xu, L.-g. Preparation and properties of two-component silicone gel cured at room temperature. J. East China Univ. Sci. Technol. (Nat. Sci. Ed.) 2017, 43, 66–69+148. [Google Scholar]

- Wang, J.; Chen, C.; Yan, H.; Li, Z.; Wang, W.; Zou, L.; Zhang, L.; Li, Q. Electrical trees growth and self-healing properties in silicone gel encapsulation materials for power module at high frequencies. Proc. Chin. Soc. Electr. Eng. 2024, 44, 4134–4144. [Google Scholar]

- Wang, Z.; Luo, M.; Wang, R.; Li, M.; Zhou, Y.; Cheng, Y. Research on heat resistance and dielectric properties of phenyl modified silicone gels for IGBT packaging. Proc. Chin. Soc. Electr. Eng. 2024, 44, 5833–5844. [Google Scholar]

- Wen, F.; Wang, L.; Li, S.; Guo, H.; Liu, B. Preparation and properties of rGO@Al2O3 filled thermal conductive silicon gel. J. Mater. Eng. 2024, 52, 139–145. [Google Scholar]

- Xu, J.; Cui, X.; Li, X.; Li, C.; Zhao, Z. Propagation of electrical tree and characteristic of partial discharge in silicone gel used for the encapsulation in power module. High Volt. Eng. 2021, 47, 1796–1804. [Google Scholar]

- Munoz, O.; Schurch, R.; Ardila-Rey, J.A. Electrical tree growth identification by means of discrete wavelet transform (DWT) and principal component analysis (PCA). IEEE Trans. Instrum. Meas. 2023, 72, 6006109. [Google Scholar] [CrossRef]

- Su, J.; Du, B.; Li, J.; Li, Z. Electrical tree degradation in high-voltage cable insulation: Progress and challenges. High Volt. 2020, 5, 353–364. [Google Scholar]

- Mancinelli, P.; Cavallini, A.; Chalashkanov, N.; Dodd, S.J.; Dissado, L.A. Electrical treeing in silicone gel under square voltage: Frequency, rise time and crosslinking influence. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 979–982. [Google Scholar]

- Gao, T.; He, D.; Xu, Z.; Wei, J.; Xie, S.; Teyssede, G.; Liu, Z.; Cui, B. Degradation induced by charge relaxation in silicone gels under the ultra-fast pulsed electric field. High Volt. 2024, 9, 1383–1392. [Google Scholar]

- Tang, X.; Sima, W.; Chen, Y.; Sun, P.; Xu, J.; Huang, Y. Research on insulation failure characteristics of encapsulated insulating resin under impulse electric. IET Conf. Proc. 2021, 2021, 2127–2131. [Google Scholar] [CrossRef]

- Bao, M.; Yin, X.; He, J. Analysis of electrical tree propagation in XLPE power cable insulation. Phys. B Condens. Matter 2011, 406, 1556–1560. [Google Scholar] [CrossRef]

- Chen, G.; Tham, C.H. Electrical treeing characteristics in XLPE power cable insulation in frequency range between 20 and 500 Hz. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 179–188. [Google Scholar] [CrossRef]

- Maruyama, S. Fundamental studies on fractals of electrical tree in polymeric insulating materials. Res. Rep. Sch. Sci. Technol. Meiji Univ. 1995, 12, 17–69. [Google Scholar]

- Liu, Y.; Cao, X. Electrical tree initiation in XLPE cable insulation by application of DC and impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1691–1698. [Google Scholar]

- Wang, P.; Chen, Y.; Akram, S.; Meng, P.; Castellon, J.; Ul Haq, I.; Javed, M.S. Effects of bipolar repetitive square wave voltage parameters on electrical tree characteristics of epoxy resin. Polym. Test. 2021, 103, 107371. [Google Scholar] [CrossRef]

- Fujii, M.; Ihori, H.; Hyeon-Gu, J. Dependence of pearl-chain type tree in silicone gel on the waveform and the frequency of applied voltage. 2017 Int. Symp. Electr. Insul. Mater. Proc. 2017, 2, 727–730. [Google Scholar]

- Mancinelli, P.; Cavallini, A.; Dodd, S.J.; Chalashkanov, N.M.; Dissado, L.A. Analysis of electrical tree inception in silicone gels. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3974–3984. [Google Scholar] [CrossRef]

- Nakamura, S.; Kumada, A.; Hidaka, K.; Sato, M.; Hayase, Y.; Takano, S.; Yamashiro, K.; Takano, T. Electrical treeing in silicone gel under repetitive voltage impulses. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1919–1925. [Google Scholar] [CrossRef]

- Du, B.X.; Han, T.; Su, J.G. Effect of low temperature on tree characteristics in silicone rubber with different power frequency. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1680–1686. [Google Scholar] [CrossRef]

- Du, B.X.; Zhang, Y.; Han, T.; Li, Z.L. Temperature gradient affecting electrical tree in silicone rubber under impulse superimposed on DC voltage. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1480–1487. [Google Scholar] [CrossRef]

- Fuyu, W.; Tao, H.; Jingang, S.; Yaguang, G. Temperature-dependent electrical tree in silicone rubber under repetitive pulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2291–2298. [Google Scholar]

- Han, T.; Du, B.; Su, J. Electrical tree initiation and growth in silicone rubber under combined DC-Pulse voltage. Energies 2018, 11, 764. [Google Scholar] [CrossRef]

- Wang, H.; He, D.; Zhou, X.; Wang, W.; Guo, H.; Li, Q. Effect of the Rise Edge of the Pulse Voltage on Initiation and Growth Characteristics of the Electrical Tree of the Silicone Rubber. In Proceedings of the 2023 IEEE 4th International Conference on Electrical Materials and Power Equipment (ICEMPE), Shanghai, China, 7–10 May 2023; pp. 1–4. [Google Scholar]

- Chen, X.; Xu, Y.; Cao, X.; Dodd, S.J.; Dissado, L.A. Effect of Tree Channel Conductivity on Electrical Tree Shape and Breakdown in XLPE Cable Insulation Samples. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 847–860. [Google Scholar]

- Du, B.X.; Gao, Z.L.M.Y.; Han, T. Effect of temperature on electrical tree in silicone rubber. In Proceedings of the 2010 10th IEEE International Conference on Solid Dielectrics, Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Fan, Y.; Zhang, D.; Li, J. Study on the fractal dimension and growth time of the electrical treeing degradation at different temperature and moisture. Adv. Mater. Sci. Eng. 2018, 2018, 6019269. [Google Scholar]

- Zhou, Y.; Chen, M.; Zhang, Y.; Dai, C.; Chen, Z. Influence of temperature on DC electrical tree initiation in silicone rubber. High Volt. Eng. 2018, 44, 3784–3790. [Google Scholar]

- Zhou, Y.; Hou, F.; Nie, Q.; Liu, R.; Yang, L.; Zhao, J.; Chen, Z.; Xue, W.; Zhang, X. Temperature Effects on Electrical Tree Aging Characteristics of Silicone Rubber. High Volt. Eng. 2012, 38, 2640–2646. [Google Scholar]

- Zhang, T.; He, D.; Wei, J.; Liu, H.; Li, Q.; Teyssedre, G. Charge vibration behaviour in polyimide under the pulse voltage with different rise and fall times. High Volt. 2022, 7, 64–74. [Google Scholar] [CrossRef]

- He, D.; Zhang, C. One-Step Solvent-Free Preparation of vinyl-terminated methylphenyl polysiloxane and Silicone Gel. CN202411758089.8, 31 December 2024. [Google Scholar]

- He, D.; Li, Y.; Li, Q.; Liu, H.; Wang, H.; Li, Q. Phenyl Silicone Elastomer for High-Power Semiconductor Device Encapsulation and Preparation Method. CN202410442814.4, 14 June 2024. [Google Scholar]

- Du, B.; Ma, T.; Su, J.; Tian, M.; Han, T.; Kong, X. Effects of temperature gradient on electrical tree growth and partial discharge in silicone rubber under AC voltage. IEEE Access 2020, 8, 54009–54018. [Google Scholar]

| Resistance Value | Pulse Edge Time |

| 250 Ω | 50 ns |

| 1 kΩ | 200 ns |

| 2 kΩ | 400 ns |

| 5 kΩ | 1 μs |

| 10 kΩ | 2 μs |

| 20 kΩ | 4 μs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; An, X.; Li, Q.; Wu, J.; Xu, Z.; Khaled, U.; He, D.; Zhu, L. Research on the Electrical Tree Deterioration Characteristics of Silicone Gel and Silicone Rubber Under Pulsed Electric Field. Gels 2025, 11, 253. https://doi.org/10.3390/gels11040253

Zhang C, An X, Li Q, Wu J, Xu Z, Khaled U, He D, Zhu L. Research on the Electrical Tree Deterioration Characteristics of Silicone Gel and Silicone Rubber Under Pulsed Electric Field. Gels. 2025; 11(4):253. https://doi.org/10.3390/gels11040253

Chicago/Turabian StyleZhang, Cong, Xiangze An, Qingfa Li, Jian Wu, Zhe Xu, Usama Khaled, Dongxin He, and Lin Zhu. 2025. "Research on the Electrical Tree Deterioration Characteristics of Silicone Gel and Silicone Rubber Under Pulsed Electric Field" Gels 11, no. 4: 253. https://doi.org/10.3390/gels11040253

APA StyleZhang, C., An, X., Li, Q., Wu, J., Xu, Z., Khaled, U., He, D., & Zhu, L. (2025). Research on the Electrical Tree Deterioration Characteristics of Silicone Gel and Silicone Rubber Under Pulsed Electric Field. Gels, 11(4), 253. https://doi.org/10.3390/gels11040253