Mechanical Properties of Polyvinyl Alcohol Fiber-Reinforced Cementitious Composites after High-Temperature Exposure

Abstract

1. Introduction

2. Experimental Results and Discussions

2.1. Experimental Phenomena

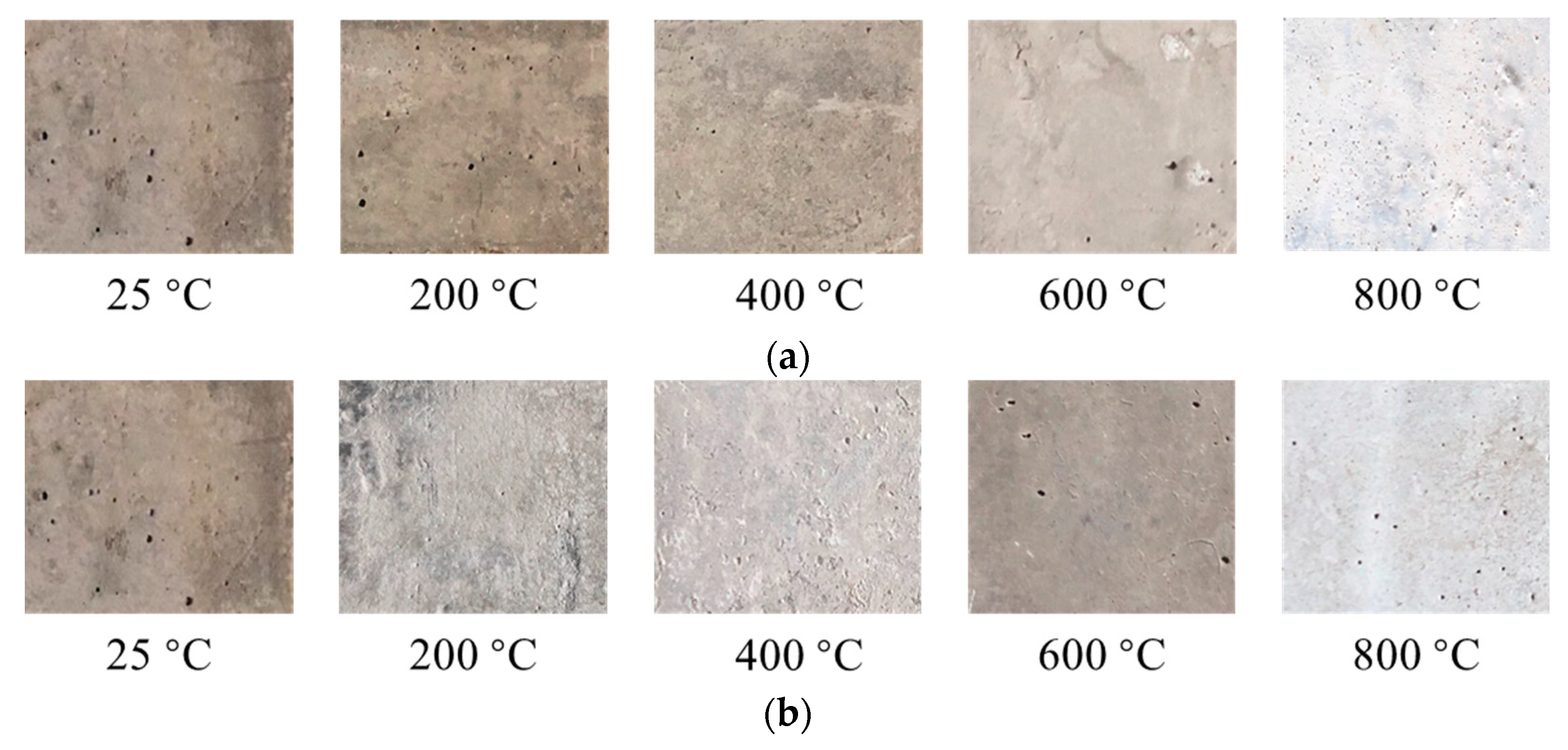

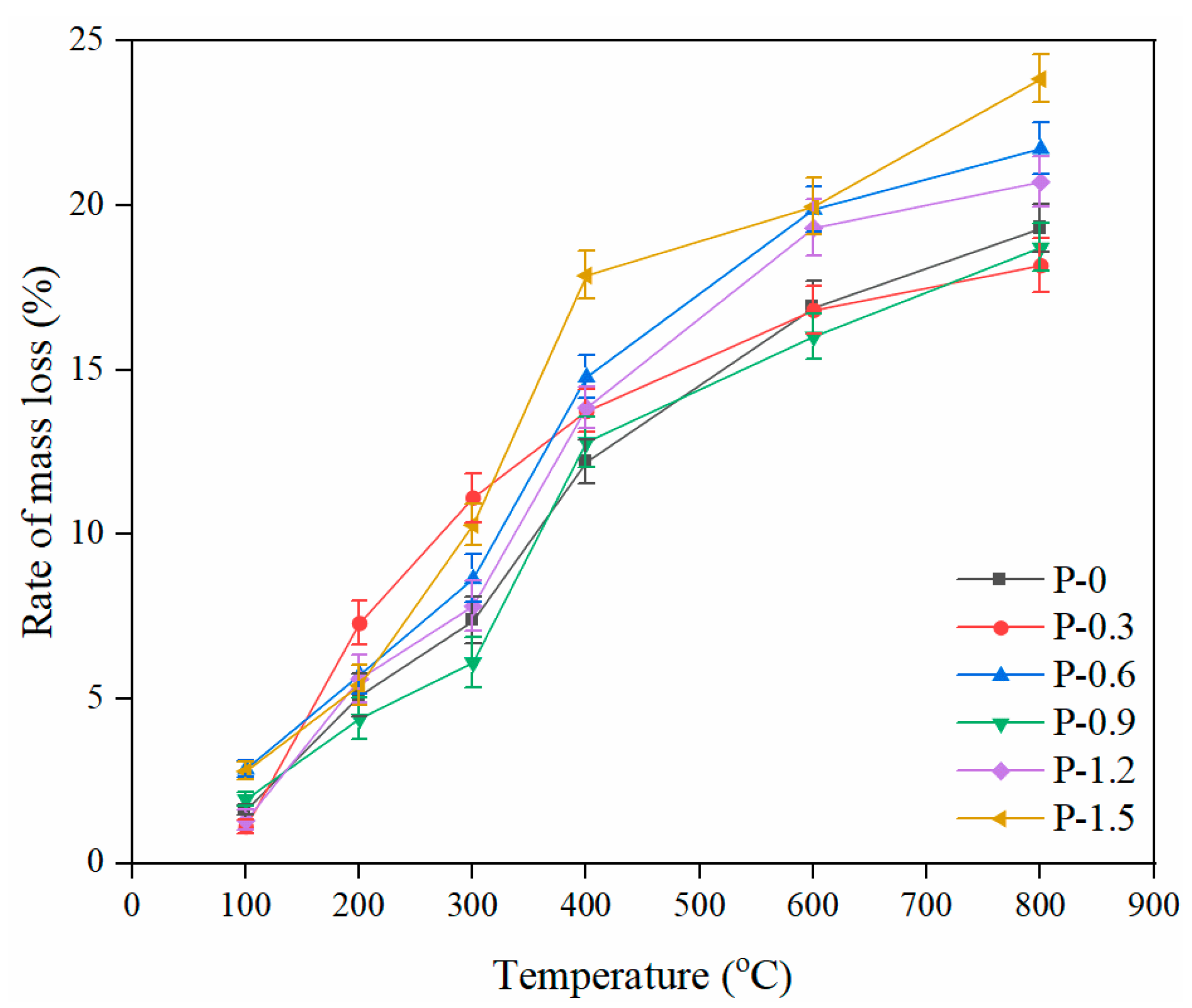

2.2. Appearance Changes and Mass Loss after High-Temperature Exposure

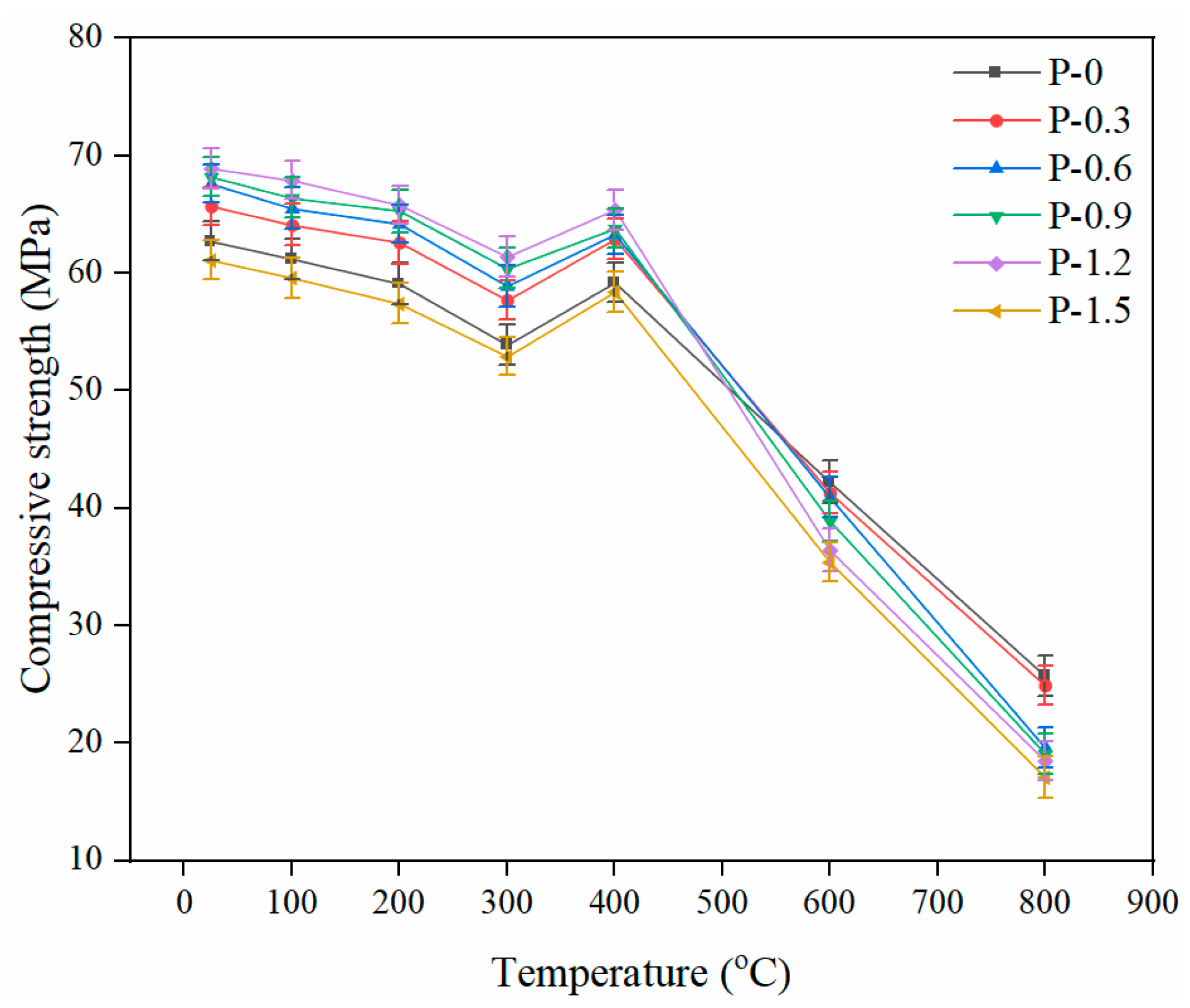

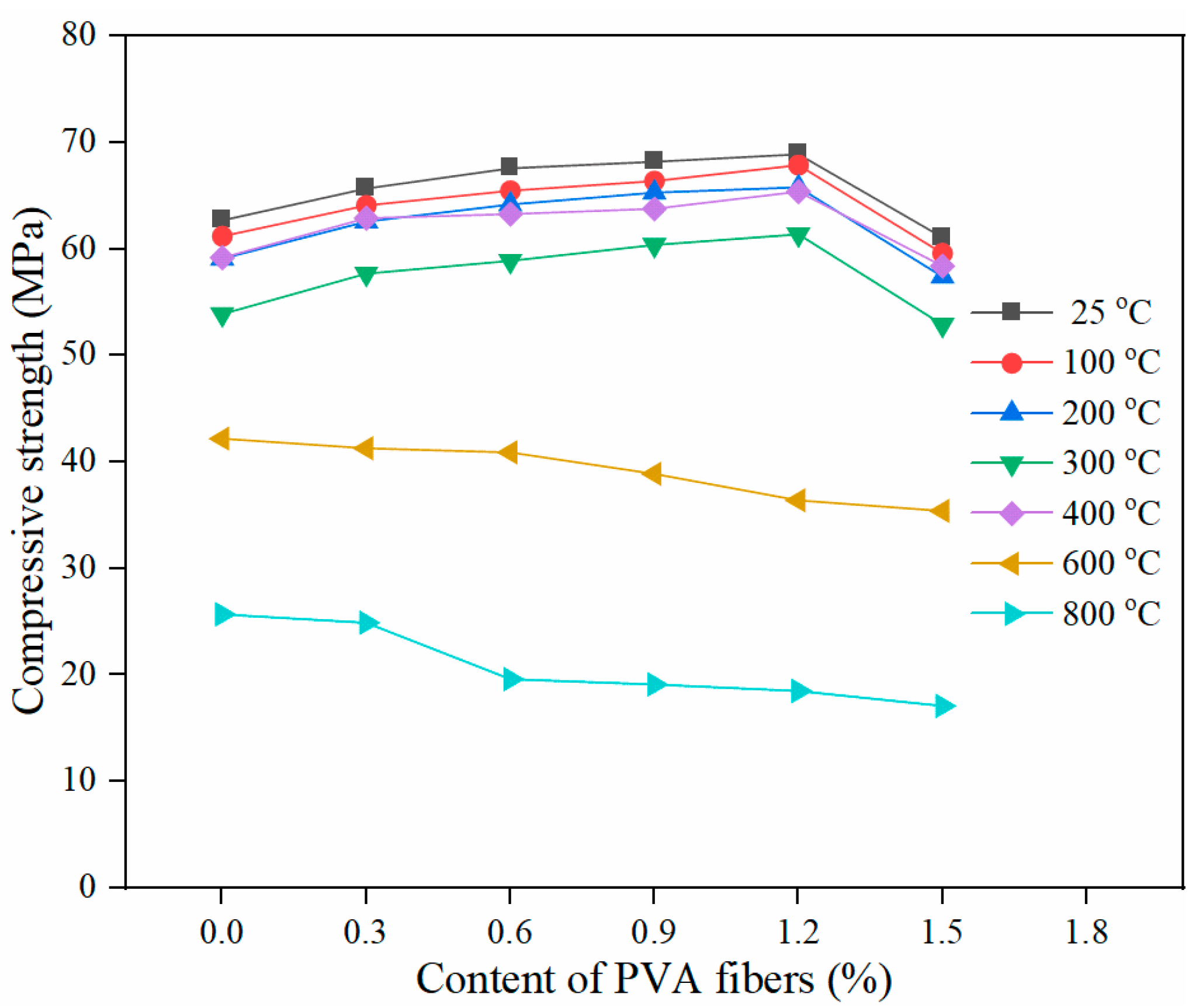

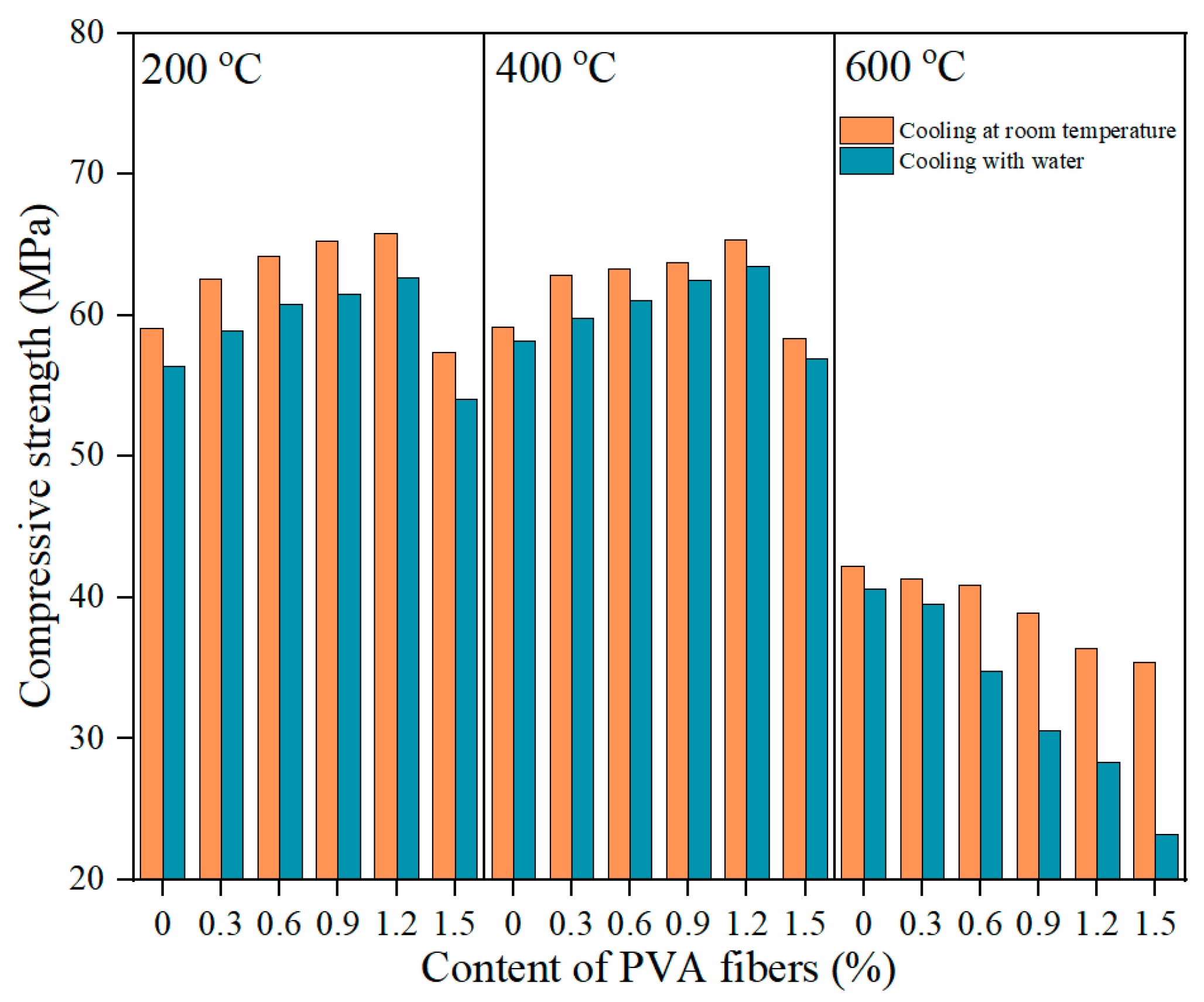

2.3. Compressive Strength after High-Temperature Exposure

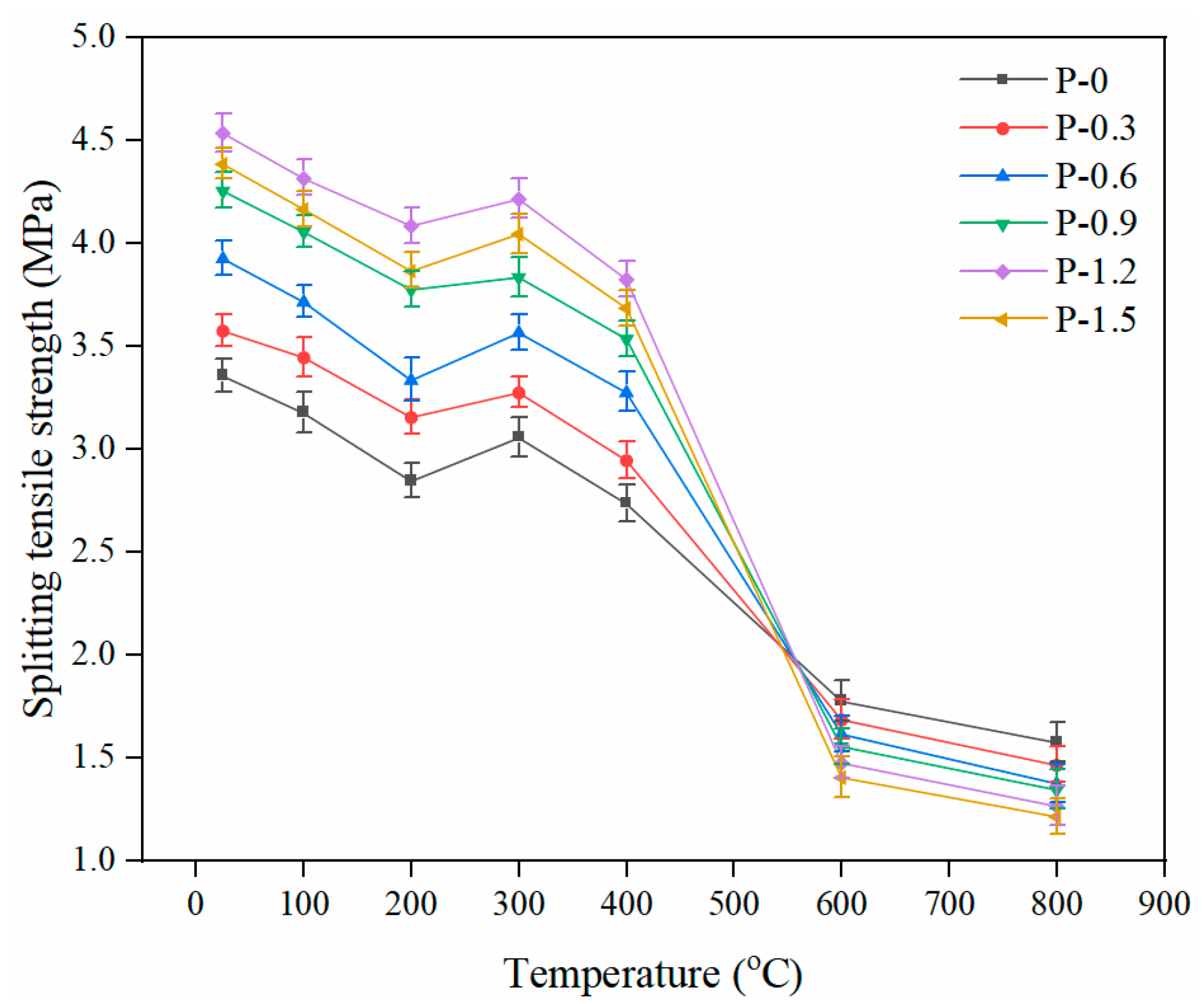

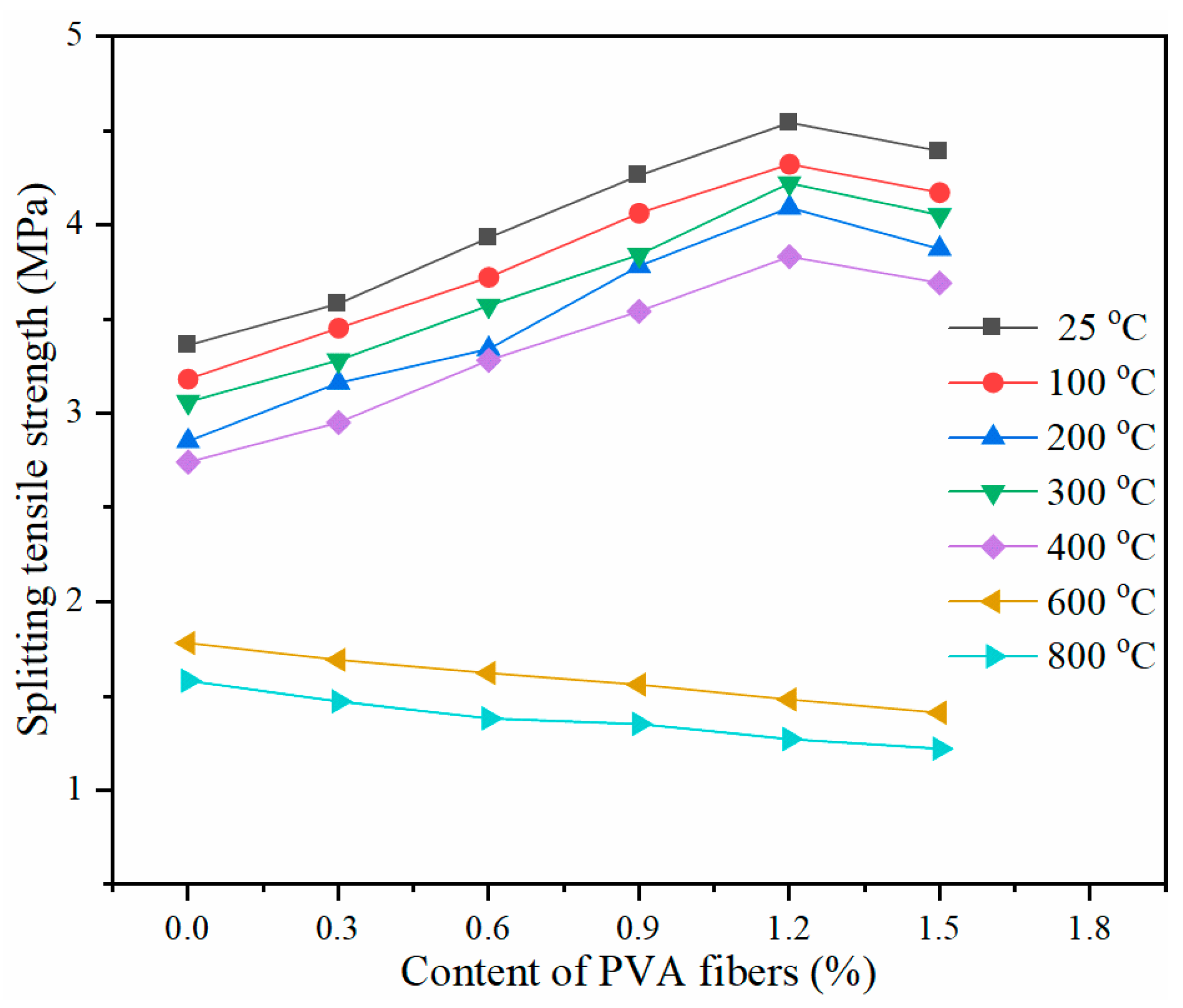

2.4. Splitting Tensile Strength after High-Temperature Exposure

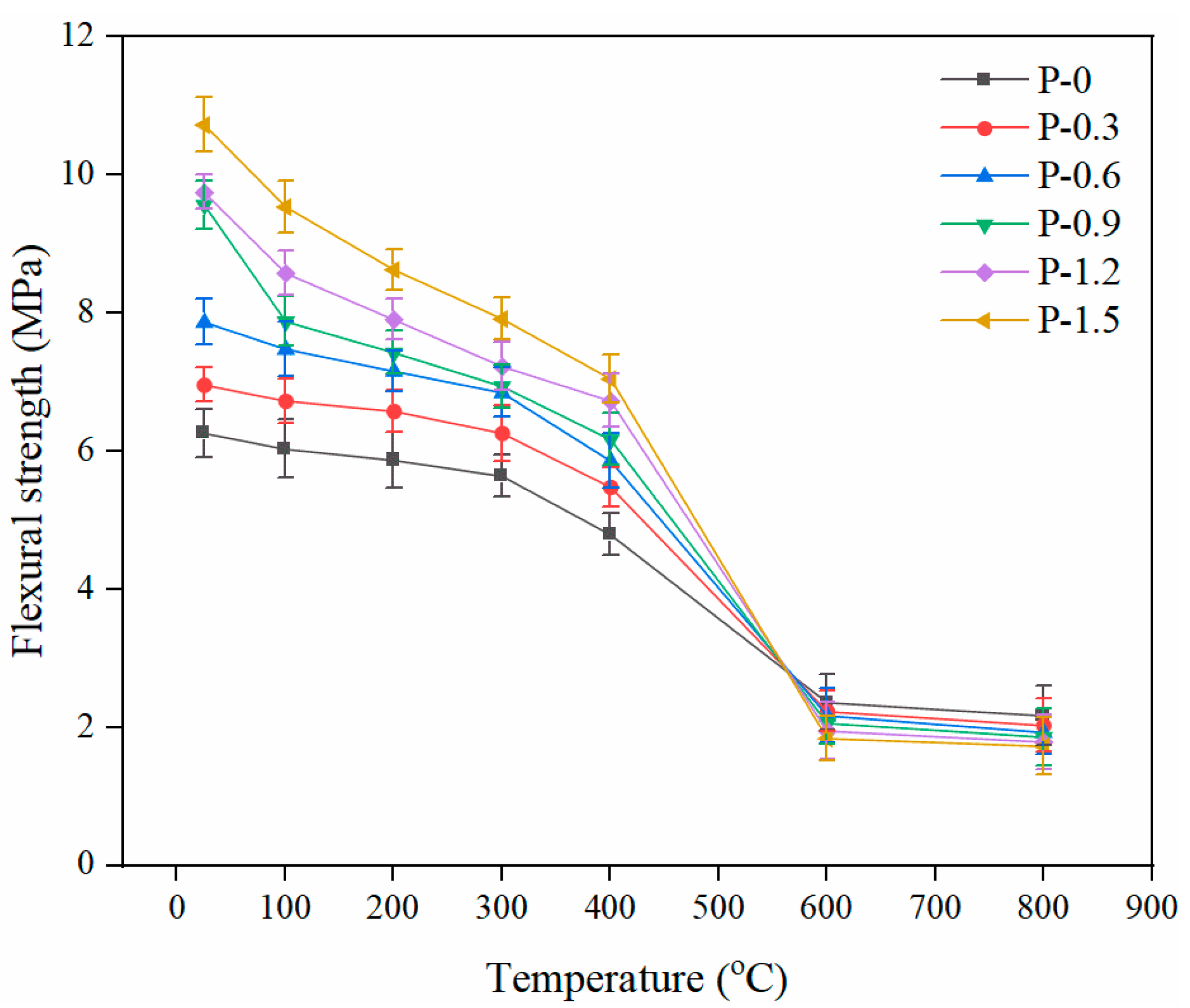

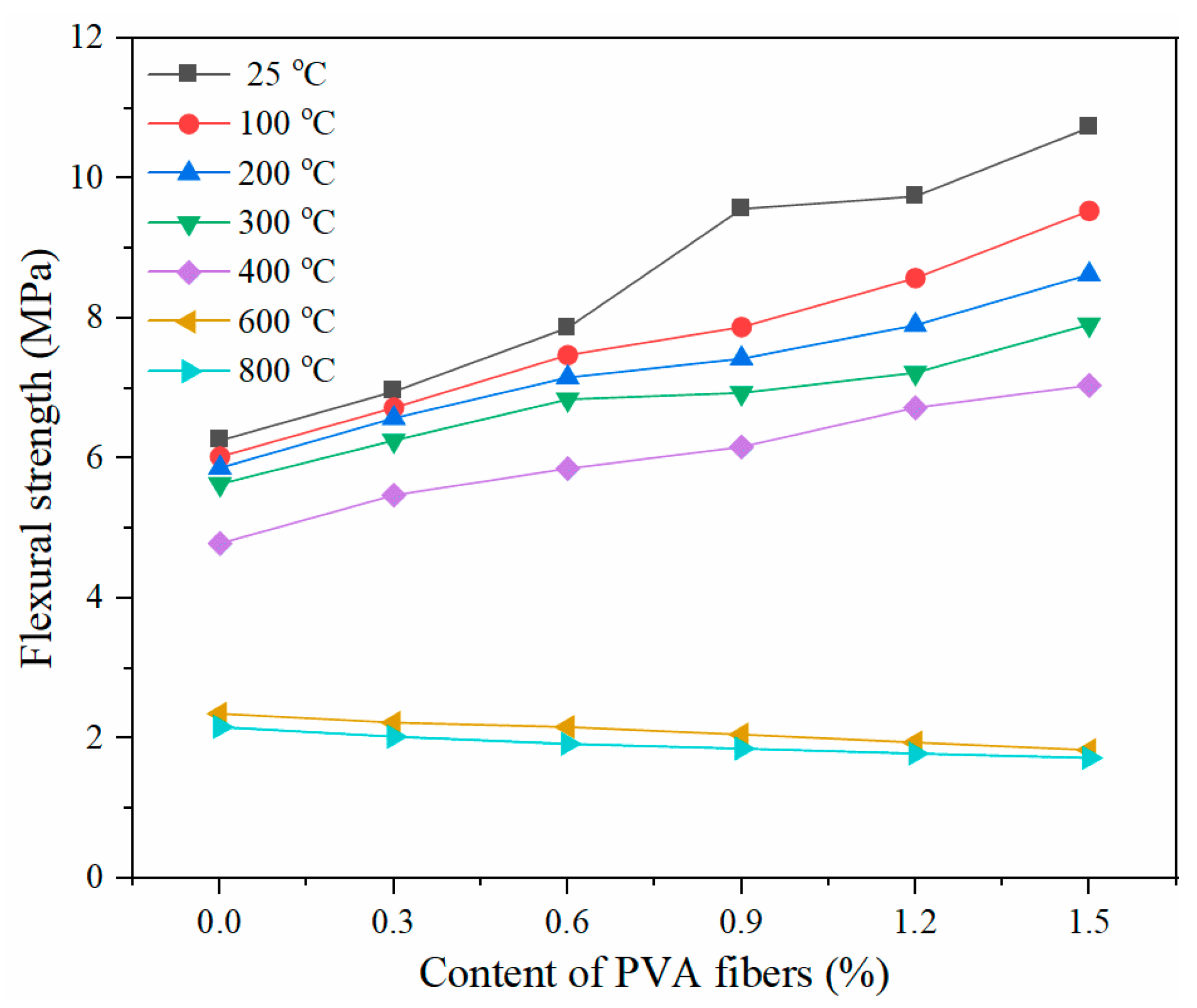

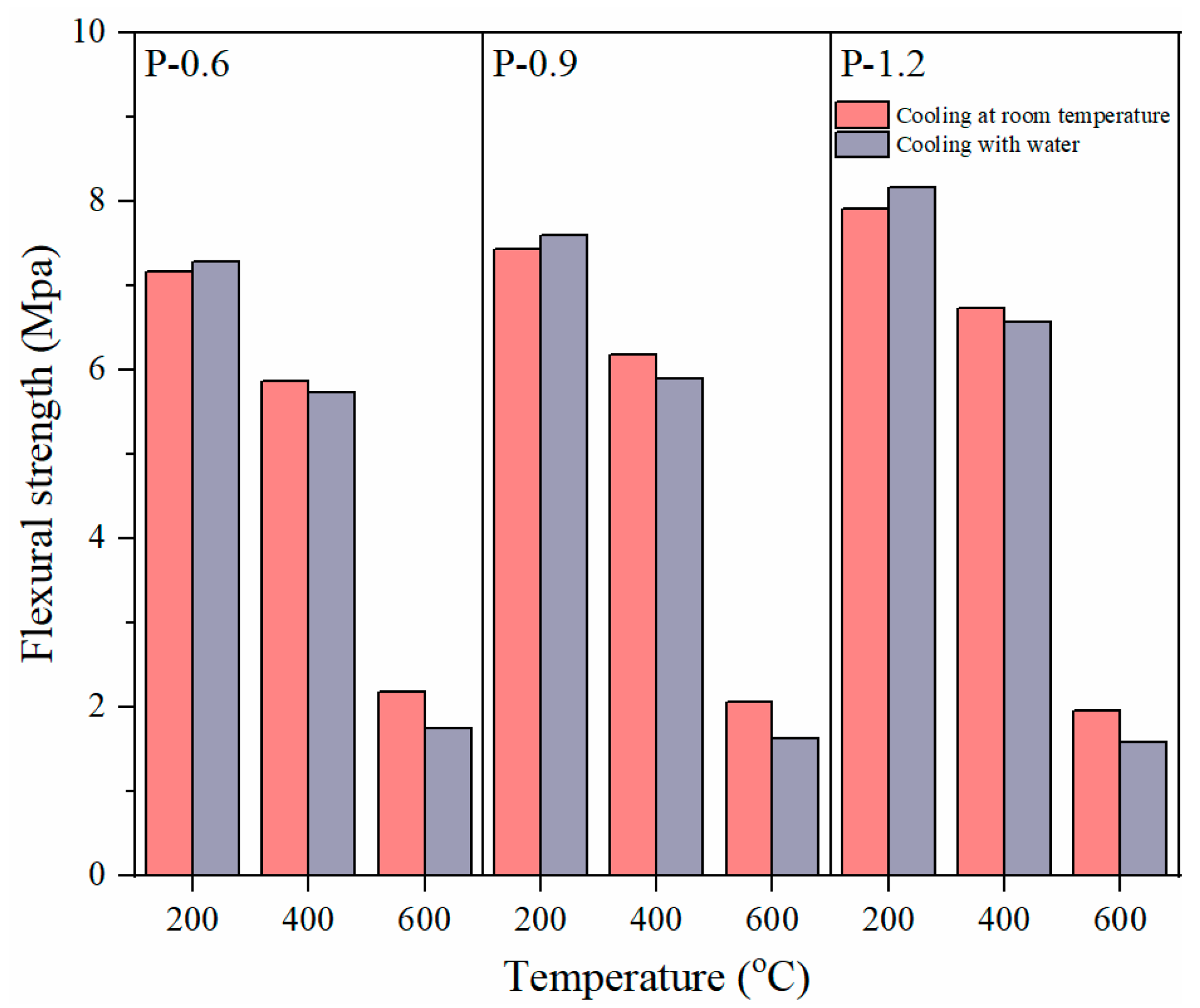

2.5. Flexural Strength after High-Temperature Exposure

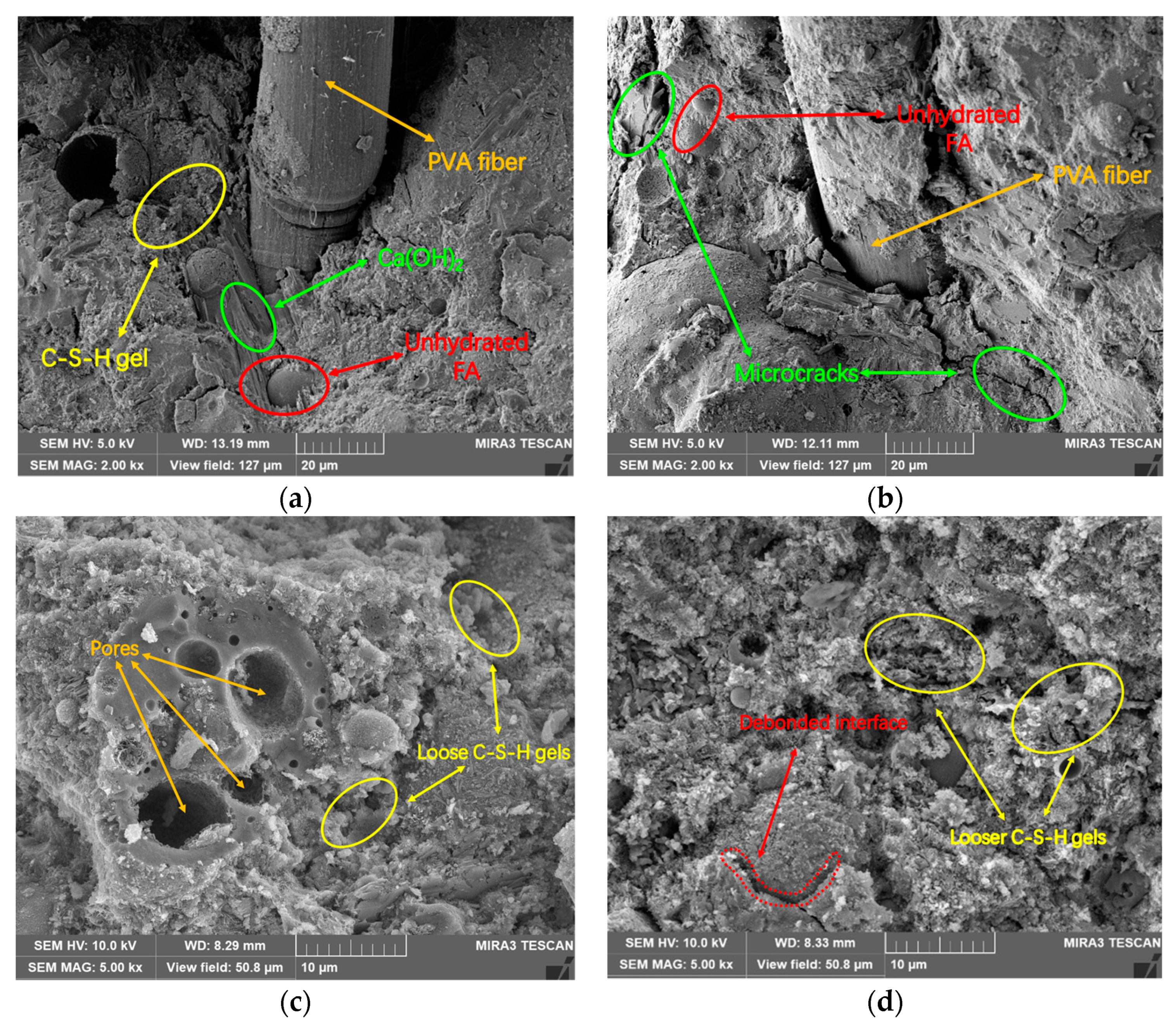

2.6. Microstructure Characterization

3. Conclusions

- (1)

- During the heating process, some samples of cementitious composites without PVA fibers burst. With the exposure temperature increasing, the appearance of color in the cementitious composite specimens gradually move from deep to shallow, and the number of cracks, spalling, and mass loss gradually increased. The final mass loss of the PVA-FRCC samples after exposure to 800 °C ranged from 18.19% to 23.86%.

- (2)

- The high temperature reduced the compressive, splitting tensile strength and flexural strengths of the PVA-FRCC specimens. The mechanical properties of the PVA-FRCC samples decreased with increasing temperature. Before the PVA fibers were melted, the fibers were conducive to the tensile and flexural properties of the specimens. On the contrary, the pores and channels caused by melted fibers could significantly reduce the mechanical properties of specimens. In addition, the compressive strength of specimens cooled at room temperature exceeded that of the specimens cooled with water. The method of cooling with water could aggravate the damage caused by an elevated temperature.

- (3)

- The dense microstructure of specimens resulted in excellent mechanical performance at room temperature. After exposure to 200 °C, the microstructure of the specimens did not change significantly. After exposure to 400 °C, the melted fibers caused the formation of many pores and channels, which primarily caused the strength decline. After being subjected to high temperatures of 600 °C and 800 °C, the microstructure became loose and the residual strength was reduced.

4. Experimental Program

4.1. Raw Materials

4.2. Mix Proportions and Preparation of PVA-FRCC Specimens

4.3. Curing and Heating Regimens

4.4. Physical and Mechanical Property Tests

4.5. Microscopic Test

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Li, G.; Li, X.; Guo, F.; Tang, S.; Lu, X.; Hanif, A. Influence of reactivity and dosage of MgO expansive agent on shrinkage and crack resistance of face slab concrete. Cem. Concr. Compos. 2022, 126, 104333. [Google Scholar] [CrossRef]

- Golewski, G.L.; Szostak, B. Strengthening the very early-age structure of cementitious composites with coal fly ash via incorporating a novel nanoadmixture based on C-S-H phase activators. Constr. Build. Mater. 2021, 312, 125426. [Google Scholar] [CrossRef]

- Ramachandra Murthy, A.; Karihaloo, B.L.; Vindhya Rani, P.; Shanmuga Priya, D. Fatigue behaviour of damaged RC beams strengthened with ultra high performance fibre reinforced concrete. Int. J. Fatigue 2018, 116, 659–668. [Google Scholar] [CrossRef]

- Yu, J.; Weng, W.; Yu, K. Effect of different cooling regimes on the mechanical properties of cementitious composites subjected to high temperatures. Sci. World J. 2014, 2014, 289213. [Google Scholar] [CrossRef]

- Peng, Y.X.; Tang, S.W.; Huang, J.S.; Tang, C.; Wang, L.; Liu, Y.F. Fractal analysis on pore structure and modeling of hydration of magnesium phosphate cement paste. Fractal Fract. 2022, 6, 337. [Google Scholar] [CrossRef]

- Wang, L.; Yu, Z.Q.; Liu, B.; Zhao, F.; Tang, S.W.; Jin, M.M. Effects of fly ash dosage on shrinkage, crack resistance and fractal characteristics of face slab concrete. Fractal Fract. 2022, 6, 335. [Google Scholar] [CrossRef]

- Li, V.C. From micromechanics to structure engineering-the design of cementitious composites for civil engineering application. JSCE 1993, 10, 37–48. [Google Scholar]

- Caverzan, A.; Cadoni, E.; di Prisco, M. Dynamic tensile behaviour of high performance fibre reinforced cementitious composites after high temperature exposure. Mech. Mater. 2013, 59, 87–109. [Google Scholar] [CrossRef]

- Jogl, M.; Kotatkova, J.; Reiterman, P. Differences in the mechanical properties of lightweight refractory cementitious composites reinforced by various types of fibers. Key. Eng. Mater. 2016, 677, 29–32. [Google Scholar] [CrossRef]

- Alani, S.S.; Hassan, M.S.; Jaber, A.A. Iop, Residual Strength and Degradation of Cement Mortar Containing Polypropylene Fibers at Elevated Temperature; Istanbul Tech Univ: Istanbul, Turkey, 2019. [Google Scholar]

- Zhang, W.; Zhang, Y.; Wu, Z.; Liu, N.; Yuan, D. Optimization design and properties of glass fiber reinforced cementitious composites. Mater. Rev. 2019, 33, 2331–2336. [Google Scholar]

- Çavdar, A. A study on the effects of high temperature on mechanical properties of fiber reinforced cementitious composites. Compos. Part B Eng. 2012, 43, 2452–2463. [Google Scholar] [CrossRef]

- Qian, G.; Dao, X.; Qian, C. Effects of PVA fiber on mechanical property of concrete. China Concr. Cem. Prod. 2010, 37, 52–54. [Google Scholar]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.J.; Wang, T.Y. Influencing factors analysis and optimized prediction model for rheology and flowability of nano-SiO2 and PVA fiber reinforced alkali-activated composites. J. Clean Prod. 2022, 366, 132988. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.X.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- Tosun-Felekoglu, K.; Felekoglu, B. Effects of fiber-matrix interaction on multiple cracking performance of polymeric fiber reinforced cementitious composites. Compos. Part B Eng. 2013, 52, 62–71. [Google Scholar] [CrossRef]

- Meng, D.; Huang, T.; Zhang, Y.X.; Lee, C.K. Mechanical behaviour of a polyvinyl alcohol fibre reinforced engineered cementitious composite (PVA-ECC) using local ingredients. Constr. Build. Mater. 2017, 141, 259–270. [Google Scholar] [CrossRef]

- Gao, S.L.; Qi, L.; Wang, W.C.; Hu, G.H.; Shi, H.F.; Alhaj, A. Fatigue fracture investigation of engineered cementitious composites. J. Test. Eval. 2021, 49, 3412–3430. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.P.; Cundy, A.B.; Tsioulou, O.T.; Al-Rekabi, S. A novel corrosion resistant repair technique for existing reinforced concrete (RC) elements using polyvinyl alcohol fibre reinforced geopolymer concrete (PVAFRGC). Constr. Build. Mater. 2018, 164, 603–619. [Google Scholar] [CrossRef]

- Georgali, B.; Tsakiridis, P.E. Microstructure of fire-damaged concrete. A case study. Cem. Concr. Compos. 2005, 27, 255–259. [Google Scholar] [CrossRef]

- Durgun, M.Y.; Özen, S.; Karakuzu, K.; Kobya, V.; Bayqra, S.H.; Mardani-Aghabaglou, A. Effect of high temperature on polypropylene fiber-reinforced mortars containing colemanite wastes. Constr. Build. Mater. 2022, 316, 125827. [Google Scholar] [CrossRef]

- Varona, F.B.; Baeza, F.J.; Bru, D.; Ivorra, S. Evolution of the bond strength between reinforcing steel and fibre reinforced concrete after high temperature exposure. Constr. Build. Mater. 2018, 176, 359–370. [Google Scholar] [CrossRef]

- Erdem, T.K. Specimen size effect on the residual properties of engineered cementitious composites subjected to high temperatures. Cem. Concr. Compos. 2014, 45, 1–8. [Google Scholar] [CrossRef]

- Vejmelkova, E.; Konvalinka, P.; Padevet, P.; Kopecky, L.; Keppert, M.; Cerny, R. Mechanical, hygric, andthermal properties of cement-based composite with hybrid fiber reinforcement subjected to high temperatures. Int. J. Thermophys. 2009, 30, 1310–1322. [Google Scholar] [CrossRef]

- Tian, L.; Zhang, J.; Dong, S.; Yuan, G.; Zahng, Q. Study on mechanical properties of cementitious composites reinforced with PVA fibers after exposure to high temperatures. Concrete 2011, 33, 31–48. [Google Scholar]

- Du, Q.; Wei, J.; Lv, J. Effects of high temperature on mechanical properties of polyvinyl alcohol engineered cementitious composites (PVA-ECC). Int. J. Civ. Eng. 2018, 16, 965–972. [Google Scholar] [CrossRef]

- Pourfalah, S. Behaviour of engineered cementitious composites and hybrid engineered cementitious composites at high temperatures. Constr. Build. Mater. 2018, 158, 921–937. [Google Scholar] [CrossRef]

- Şahmaran, M.; Özbay, E.; Yücel, H.E.; Lachemi, M.; Li, V.C. Effect of fly ash and PVA fiber on microstructural damage and residual properties of engineered cementitious composites exposed to high temperatures. J. Mater. Civ. Eng. 2011, 23, 1735–1745. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, W.; Lv, Y.; Gao, Z.; Dai, S. Effect of polymer coatings on the permeability and chloride ion penetration pesistances of nano-particles and fibers-modified cementitious composites. Polymers 2022, 14, 3258. [Google Scholar] [CrossRef] [PubMed]

- Alakara, E.H.; Sevim, O.; Demir, I.; Simsek, O. Experimental study on firebrick powder-based cementitious composites under the effect of elevated temperature. J. Build. Eng. 2022, 61, 105277. [Google Scholar] [CrossRef]

- Slusarek, J.; Nowoswiat, A.; Olechowska, M. Logistic model of phase transformation of hardening concrete. Materials 2022, 15, 4403. [Google Scholar] [CrossRef] [PubMed]

- Ozawa, M.; Morimoto, H. Effects of various fibres on high-temperature spalling in high-performance concrete. Constr. Build. Mater. 2014, 71, 83–92. [Google Scholar] [CrossRef]

- Ezziane, M.; Molez, L.; Messaoudene, I. Non-destructive characteristion of mortars reinfored with various fibres exposed to high temperature. Min. Sci. 2018, 25, 179–194. [Google Scholar]

- Mueller, P.; Novak, J.; Holan, J. Destructive and non-destructive experimental investigation of polypropylene fibre reinforced concrete subjected to high temperature. J. Build. Eng. 2019, 26, 100906. [Google Scholar] [CrossRef]

- Ezziane, M.; Kadri, T.; Molez, L.; Jauberthie, R.; Belhacen, A. High temperature behaviour of polypropylene fibres reinforced mortars. Fire Saf. J. 2015, 71, 324–331. [Google Scholar] [CrossRef]

- Zhang, P.; Han, Q.; Wu, J.; Zhang, Y. Mechanical properties of nano-SiO2 reinforced engineered cementitious composites after exposure to high temperatures. Constr. Build. Mater. 2022, 356, 129123. [Google Scholar] [CrossRef]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Shie, J.L.; Chen, Y.H.; Chang, C.Y.; Lin, J.P.; Lee, D.J.; Wu, C.H. Thermal pyrolysis of poly(vinyl alcohol) and its major products. Energy Fuels 2002, 16, 109–118. [Google Scholar] [CrossRef]

- Khoury, G.A. Compressive strength of concrete at high-tempertures-a reassessment. Mag. Concr. Res. 1992, 44, 291–309. [Google Scholar] [CrossRef]

- Morsy, M.S.; Al-Salloum, Y.A.; Abbas, H.; Alsayed, S.H. Behavior of blended cement mortars containing nano-metakaolin at elevated temperatures. Constr. Build. Mater. 2012, 35, 900–905. [Google Scholar] [CrossRef]

- Yu, K.Q.; Dai, J.G.; Lu, Z.D.; Leung, C.K.Y. Mechanical properties of engineered cementitious composites subjected to elevated temperatures. J. Mater. Civ. Eng. 2015, 27, 04014268. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, J.; Wang, C.; Liu, J. Experimental study on axial compression performance of recycled concrete filled square steel tube short column after exposure to high temperature and water cooling. J. Nat. Disasters. 2020, 29, 25–37. [Google Scholar]

- Han, Q.Y.; Zhang, P.; Wu, J.J.; Jing, Y.T.; Zhang, D.; Zhang, T.H. Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2. Nanotechnol. Rev. 2022, 11, 1478–1498. [Google Scholar] [CrossRef]

- Yang, H.M.; Zhang, S.M.; Wang, L.; Chen, P.; Shao, D.K.; Tang, S.W.; Li, J.Z. High-ferrite Portland cement with slag: Hydration, microstructure, and resistance to sulfate attack at elevated temperature. Cem. Concr. Compos. 2022, 130, 104560. [Google Scholar] [CrossRef]

- Kalifa, P.; Chene, G.; Galle, C. High-temperature behaviour of HPC with polypropylene fibres—From spalling to microstructure. Cem. Concr. Res. 2001, 31, 1487–1499. [Google Scholar] [CrossRef]

- GB175-2007; Common Portland Cement. China Standards Press City: Beijing, China, 2007.

- Zhang, P.; Wei, S.; Wu, J.; Zhang, Y.; Zheng, Y. Investigation of mechanical properties of PVA fiber-reinforced cementitious composites under the coupling effect of wet-thermal and chloride salt environment. Case Stud. Constr. Mater. 2022, 17, e01325. [Google Scholar] [CrossRef]

- Danish, A.; Ozbakkaloglu, T. Greener cementitious composites incorporating sewage sludge ash as cement replacement: A review of progress, potentials, and future prospects. J. Clean Prod. 2022, 371, 133364. [Google Scholar] [CrossRef]

- Zhang, P.; Han, X.; Hu, S.; Wang, J.; Wang, T. High-temperature behavior of polyvinyl alcohol fiber-reinforced metakaolin/fly ash-based geopolymer mortar. Compos. Part B Eng. 2022, 244, 110171. [Google Scholar] [CrossRef]

- JGJ/T70-2009; Standard for Test Method of Performance on Building Mortar. China Building Industry Press City: Beijing, China, 2009.

- GB/T7897-2008; Test Methods of Mechanical Properties of Mortar for Ferrocement. China Standards Press City: Beijing, China, 2008.

| Temperature (°C) | Appearance Color | Crack State | Spalling | ||

|---|---|---|---|---|---|

| Cooling at Room Temperature | Cooling with Water | Cooling at Room Temperature | Cooling with Water | ||

| 25 | Dark gray | Dark gray | None | None | None |

| 200 | Dark gray | Gray | None | Few | None |

| 400 | Gray | Gray | Very few and thin | Many | None |

| 600 | Gray | Dark gray | Few and thin | All over | Few |

| 800 | Light gray | Light gray | Many | All over | Few |

| Composition (%) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | SO3 |

|---|---|---|---|---|---|---|---|---|

| OPC | 21.05 | 5.28 | 2.57 | 63.14 | 3.58 | 0.17 | 0.58 | 2.39 |

| FA | 52.12 | 17.86 | 6.57 | 9.12 | 3.26 | 2.38 | 2.05 | 0.23 |

| Length (mm) | Elongation (%) | Section Expansion Ratio (%) | Dry Elongation at Break (%) | Tensile Strength (MPa) | Alkali Resistance (%) | Melting Point (°C) |

|---|---|---|---|---|---|---|

| 12 | 6.5 | 320 | 17 | 1540 | 99 | 230 |

| Mixture ID | OPC | FA | Quartz Sand | PVA Fiber | Water | SP |

|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | % | kg/m3 | kg/m3 | |

| P-0 | 650 | 350 | 500 | 0 | 350 | 1.5 |

| P-0.3 | 650 | 350 | 500 | 0.3 | 350 | 2.0 |

| P-0.6 | 650 | 350 | 500 | 0.6 | 350 | 2.5 |

| P-0.9 | 650 | 350 | 500 | 0.9 | 350 | 3.0 |

| P-1.2 | 650 | 350 | 500 | 1.2 | 350 | 3.5 |

| P-1.5 | 650 | 350 | 500 | 1.5 | 350 | 4.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Zhang, P.; Wu, J.; Zhang, Y.; Guo, J. Mechanical Properties of Polyvinyl Alcohol Fiber-Reinforced Cementitious Composites after High-Temperature Exposure. Gels 2022, 8, 662. https://doi.org/10.3390/gels8100662

Zhang P, Zhang P, Wu J, Zhang Y, Guo J. Mechanical Properties of Polyvinyl Alcohol Fiber-Reinforced Cementitious Composites after High-Temperature Exposure. Gels. 2022; 8(10):662. https://doi.org/10.3390/gels8100662

Chicago/Turabian StyleZhang, Peng, Peishuo Zhang, Jingjiang Wu, Yong Zhang, and Jinjun Guo. 2022. "Mechanical Properties of Polyvinyl Alcohol Fiber-Reinforced Cementitious Composites after High-Temperature Exposure" Gels 8, no. 10: 662. https://doi.org/10.3390/gels8100662

APA StyleZhang, P., Zhang, P., Wu, J., Zhang, Y., & Guo, J. (2022). Mechanical Properties of Polyvinyl Alcohol Fiber-Reinforced Cementitious Composites after High-Temperature Exposure. Gels, 8(10), 662. https://doi.org/10.3390/gels8100662