Cost-Effective Synthesis of Bacterial Cellulose and Its Applications in the Food and Environmental Sectors

Abstract

1. Introduction

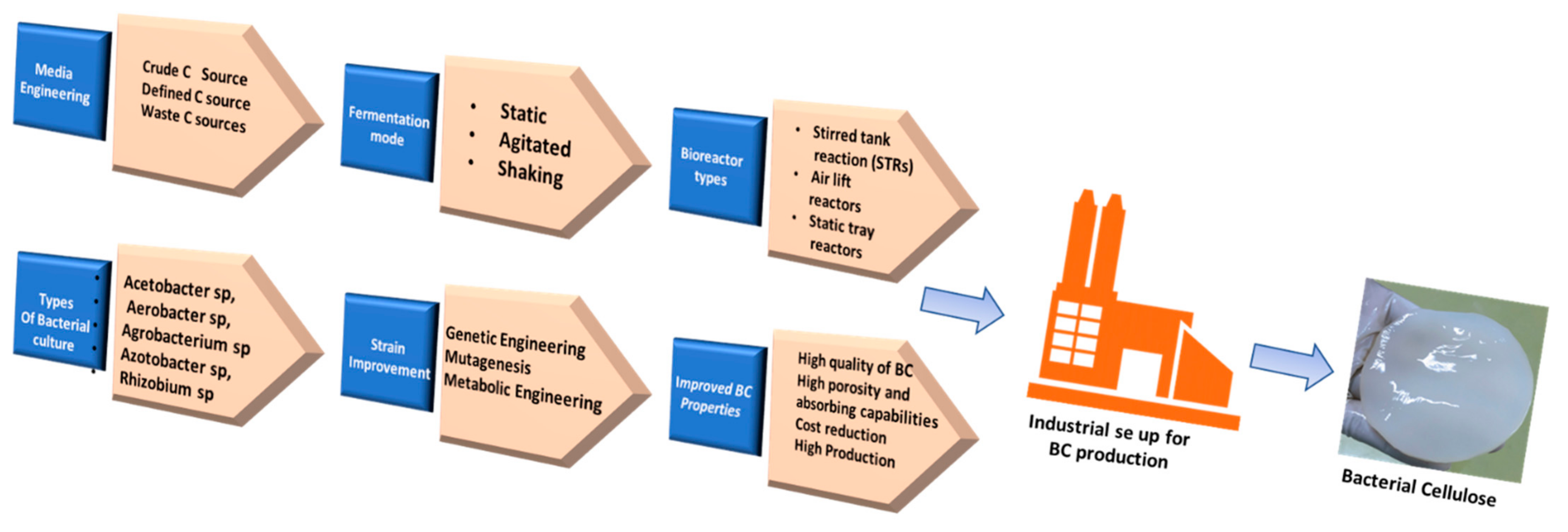

2. Bacterial Cellulose History, Synthesis, and Structural Features

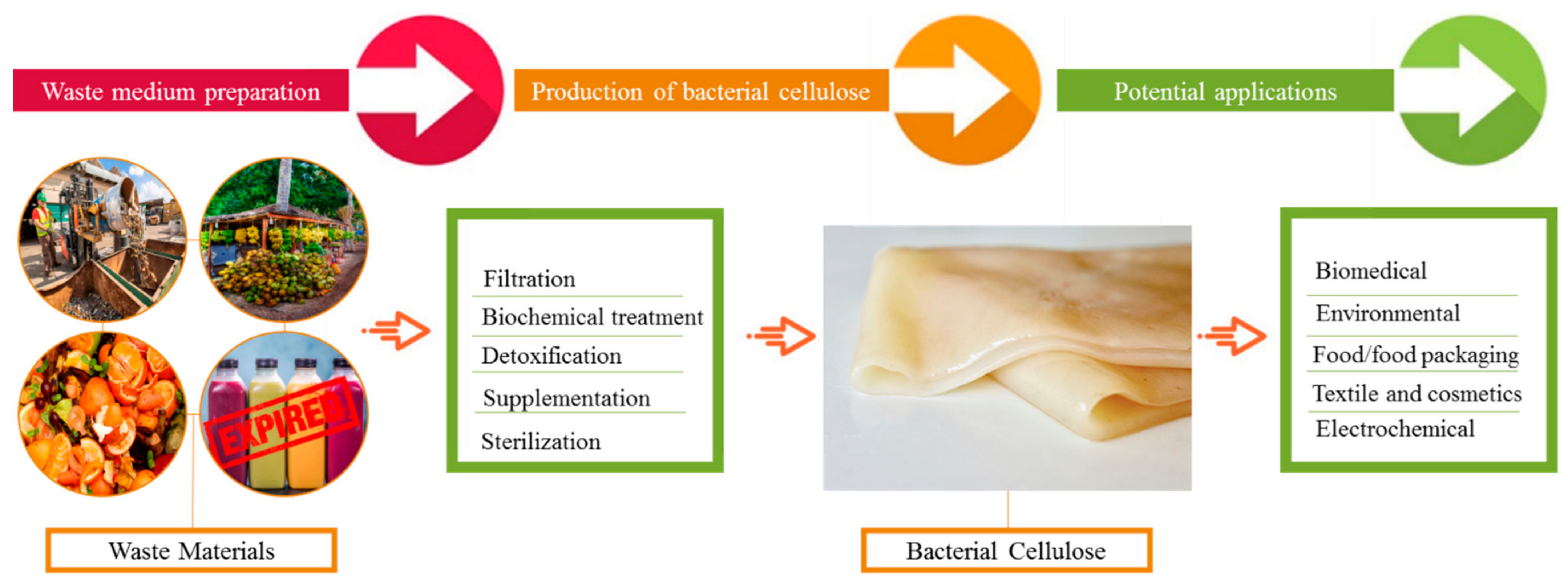

3. BC Production from Waste Resources

4. Techno-Economic Aspects of BC Production and Developing BC-Based Products

4.1. Commercialization of BC

4.2. BC Market and Selling Price

4.3. Techno-Economic Analysis for Large-Scale BC Production

5. BC Applications

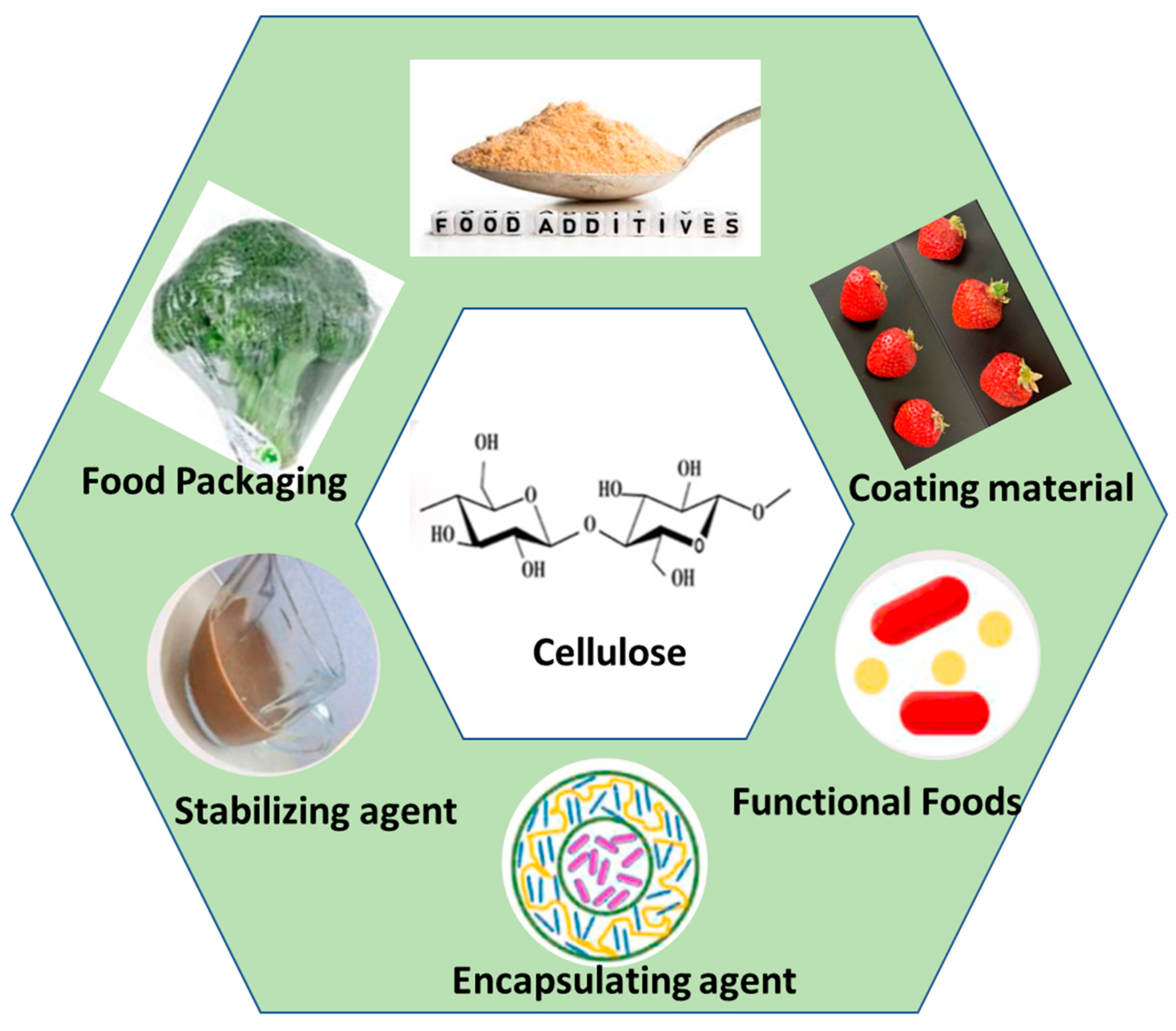

5.1. BC Applications in the Food Industry

5.1.1. Raw Food Material

5.1.2. Food Ingredient

5.1.3. Food Stabilizer

5.1.4. Fat Replacer

5.1.5. Meat Analog

5.1.6. Food Packaging

5.2. BC Applications in Environmental Sectors

5.2.1. Pollutant Absorption/Absorption of Organic Solvents

5.2.2. Filter Membrane for Water and Air Purification

5.3. Bio-Adsorbent for Heavy Metals

5.4. Protein Adsorption

5.5. Catalytic Support for Pollutant Degradation

6. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ul-Islam, M.; Ullah, M.W.; Khan, S.; Manan, S.; Khattak, W.A.; Ahmad, W.; Shah, N.; Park, J.K. Current Advancements of Magnetic Nanoparticles in Adsorption and Degradation of Organic Pollutants. Environ. Sci. Pollut. Res. 2017, 24, 12713–12722. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Li, Y.; Xiong, Z.; Pan, L.; Luo, Q.; Xu, X.; Lu, S. Water-Induced Shape Memory Effect of Nanocellulose Papers from Sisal Cellulose Nanofibers with Graphene Oxide. Carbohydr. Polym. 2018, 179, 110–117. [Google Scholar] [CrossRef] [PubMed]

- Muthu, S.S.; Rathinamoorthy, R. Bacterial Cellulose. In Bacterial Cellulose: Sustainable Material for Textiles; Muthu, S.S., Rathinamoorthy, R., Eds.; Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Singapore, 2021; pp. 19–60. ISBN 9789811595813. [Google Scholar]

- Liu, J.; Willför, S.; Mihranyan, A. On Importance of Impurities, Potential Leachables and Extractables in Algal Nanocellulose for Biomedical Use. Carbohydr. Polym. 2017, 172, 11–19. [Google Scholar] [CrossRef]

- Bacakova, L.; Filova, E.; Parizek, M.; Ruml, T.; Svorcik, V. Modulation of Cell Adhesion, Proliferation and Differentiation on Materials Designed for Body Implants. Biotechnol. Adv. 2011, 29, 739–767. [Google Scholar] [CrossRef]

- Wu, T.; Zhou, W.; Quan, Y.; Chen, M.; Tian, Q.; Han, X.; Xu, J.; Chen, J. Facile and Green Synthesis of Nanocellulose with the Assistance of Ultraviolet Light Irradiation for High-Performance Quasi-Solid-State Zinc-Ion Batteries. J. Colloid Interface Sci. 2022, 628, 1–9. [Google Scholar] [CrossRef]

- Ullah, M.W.; Ul-Islam, M.; Khan, S.; Kim, Y.; Park, J.K. Innovative Production of Bio-Cellulose Using a Cell-Free System Derived from a Single Cell Line. Carbohydr. Polym. 2015, 132, 286–294. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Ullah, M.W.; Ul-Islam, M.; Khan, S.; Jang, J.H.; Park, J.K. Self-Assembly of Bio-Cellulose Nanofibrils through Intermediate Phase in a Cell-Free Enzyme System. Biochem. Eng. J. 2019, 142, 135–144. [Google Scholar] [CrossRef]

- Mao, Y.; Liu, K.; Zhan, C.; Geng, L.; Chu, B.; Hsiao, B.S. Characterization of Nanocellulose Using Small-Angle Neutron, X-Ray, and Dynamic Light Scattering Techniques. J. Phys. Chem. B 2017, 121, 1340–1351. [Google Scholar] [CrossRef]

- Lin, N.; Huang, J.; Dufresne, A. Preparation, Properties and Applications of Polysaccharide Nanocrystals in Advanced Functional Nanomaterials: A Review. Nanoscale 2012, 4, 3274. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Azizi Samir, M.A.S.; Alloin, F.; Dufresne, A. Review of Recent Research into Cellulosic Whiskers, Their Properties and Their Application in Nanocomposite Field. Biomacromolecules 2005, 6, 612–626. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.S.; Chen, L.; Sisler, J.; Tam, K.C. Cellulose Nanocrystal (CNC)–Inorganic Hybrid Systems: Synthesis, Properties and Applications. J. Mater. Chem. B 2018, 6, 864–883. [Google Scholar] [CrossRef] [PubMed]

- Ullah, M.W.; Manan, S.; Ul-Islam, M.; Revin, V.V.; Thomas, S.; Yang, G. Introduction to Nanocellulose. In Nanocellulose: Synthesis, Structure, Properties and Applications; World Scientific: London, UK, 2021; pp. 1–50. [Google Scholar]

- Wang, L.; Mao, L.; Qi, F.; Li, X.; Ullah, M.W.; Zhao, M.; Shi, Z.; Yang, G. Synergistic Effect of Highly Aligned Bacterial Cellulose/Gelatin Membranes and Electrical Stimulation on Directional Cell Migration for Accelerated Wound Healing. Chem. Eng. J. 2021, 424, 130563. [Google Scholar] [CrossRef]

- Mao, L.; Wang, L.; Zhang, M.; Ullah, M.W.; Liu, L.; Zhao, W.; Li, Y.; Ahmed, A.A.Q.; Cheng, H.; Shi, Z. In Situ Synthesized Selenium Nanoparticles-Decorated Bacterial Cellulose/Gelatin Hydrogel with Enhanced Antibacterial, Antioxidant, and Anti-Inflammatory Capabilities for Facilitating Skin Wound Healing. Adv. Healthc. Mater. 2021, 10, 2100402. [Google Scholar] [CrossRef]

- Atta, O.M.; Manan, S.; Shahzad, A.; Ul-Islam, M.; Ullah, M.W.; Yang, G. Biobased Materials for Active Food Packaging: A Review. Food Hydrocoll. 2022, 125, 107419. [Google Scholar] [CrossRef]

- Atta, O.M.; Manan, S.; Ul-Islam, M.; Ahmed, A.A.Q.; Ullah, M.W.; Yang, G. Development and Characterization of Plant Oil-Incorporated Carboxymethyl Cellulose/Bacterial Cellulose/Glycerol-Based Antimicrobial Edible Films for Food Packaging Applications. Adv. Compos. Hybrid Mater. 2022, 5, 973–990. [Google Scholar] [CrossRef]

- Atta, O.M.; Manan, S.; Ul-Islam, M.; Ahmed, A.A.Q.; Ullah, M.W.; Yang, G. Silver Decorated Bacterial Cellulose Nanocomposites as Antimicrobial Food Packaging Materials. ES Food Agrofor. 2021, 6, 12–26. [Google Scholar] [CrossRef]

- Atta, O.M.; Manan, S.; Ahmed, A.A.Q.; Awad, M.F.; Ul-Islam, M.; Subhan, F.; Ullah, M.W.; Yang, G. Development and Characterization of Yeast-Incorporated Antimicrobial Cellulose Biofilms for Edible Food Packaging Application. Polymers 2021, 13, 2310. [Google Scholar] [CrossRef]

- Shoukat, A.; Wahid, F.; Khan, T.; Siddique, M.; Nasreen, S.; Yang, G.; Ullah, M.W.; Khan, R. Titanium Oxide-Bacterial Cellulose Bioadsorbent for the Removal of Lead Ions from Aqueous Solution. Int. J. Biol. Macromol. 2019, 129, 965–971. [Google Scholar] [CrossRef]

- Felgueiras, C.; Azoia, N.G.; Gonçalves, C.; Gama, M.; Dourado, F. Trends on the Cellulose-Based Textiles: Raw Materials and Technologies. Front. Bioeng. Biotechnol. 2021, 9, 608826. [Google Scholar] [CrossRef] [PubMed]

- Skočaj, M. Bacterial Nanocellulose in Papermaking. Cellulose 2019, 26, 6477–6488. [Google Scholar] [CrossRef]

- McCarthy, R.R.; Ullah, M.W.; Booth, P.; Pei, E.; Yang, G. The Use of Bacterial Polysaccharides in Bioprinting. Biotechnol. Adv. 2019, 37, 107448. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, R.R.; Ullah, M.W.; Pei, E.; Yang, G. Antimicrobial Inks: The Anti-Infective Applications of Bioprinted Bacterial Polysaccharides. Trends Biotechnol. 2019, 37, 1155–1159. [Google Scholar] [CrossRef]

- Aljohani, W.; Ullah, M.W.; Zhang, X.; Yang, G. Bioprinting and Its Applications in Tissue Engineering and Regenerative Medicine. Int. J. Biol. Macromol. 2018, 107, 261–275. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Jasim, A.; Zhao, W.; Fu, L.; Ullah, M.W.; Shi, Z.; Yang, G. Fabrication of PH-Electroactive Bacterial Cellulose/Polyaniline Hydrogel for the Development of a Controlled Drug Release System. ES Mater. Manuf. 2018, 1, 41–49. [Google Scholar] [CrossRef]

- Ul-Islam, M.; Subhan, F.; Islam, S.U.; Khan, S.; Shah, N.; Manan, S.; Ullah, M.W.; Yang, G. Development of Three-Dimensional Bacterial Cellulose/Chitosan Scaffolds: Analysis of Cell-Scaffold Interaction for Potential Application in the Diagnosis of Ovarian Cancer. Int. J. Biol. Macromol. 2019, 137, 1050–1059. [Google Scholar] [CrossRef] [PubMed]

- Farooq, U.; Ullah, M.W.; Yang, Q.; Aziz, A.; Xu, J.; Zhou, L.; Wang, S. High-Density Phage Particles Immobilization in Surface-Modified Bacterial Cellulose for Ultra-Sensitive and Selective Electrochemical Detection of Staphylococcus Aureus. Biosens. Bioelectron. 2020, 157, 112163. [Google Scholar] [CrossRef] [PubMed]

- Jasim, A.; Ullah, M.W.; Shi, Z.; Lin, X.; Yang, G. Fabrication of Bacterial Cellulose/Polyaniline/Single-Walled Carbon Nanotubes Membrane for Potential Application as Biosensor. Carbohydr. Polym. 2017, 163, 62–69. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Mariano, M.; Huang, J.; Lin, N.; Ahmad, I.; Dufresne, A.; Thomas, S. Recent Developments on Nanocellulose Reinforced Polymer Nanocomposites: A Review. Polymer 2017, 132, 368–393. [Google Scholar] [CrossRef]

- Seo, C.; Lee, H.W.; Suresh, A.; Yang, J.W.; Jung, J.K.; Kim, Y.C. Improvement of Fermentative Production of Exopolysaccharides from Aureobasidium Pullulans under Various Conditions. Korean J. Chem. Eng. 2014, 31, 1433–1437. [Google Scholar] [CrossRef]

- Shoda, M.; Sugano, Y. Recent Advances in Bacterial Cellulose Production. Biotechnol. Bioprocess Eng. 2005, 10, 1–8. [Google Scholar] [CrossRef]

- Shah, N.; Ul-Islam, M.; Khattak, W.A.; Park, J.K. Overview of Bacterial Cellulose Composites: A Multipurpose Advanced Material. Carbohydr. Polym. 2013, 98, 1585–1598. [Google Scholar] [CrossRef] [PubMed]

- Ullah, M.W.; Ul-Islam, M.; Khan, S.; Kim, Y.; Park, J.K. Structural and Physico-Mechanical Characterization of Bio-Cellulose Produced by a Cell-Free System. Carbohydr. Polym. 2016, 136, 908–916. [Google Scholar] [CrossRef] [PubMed]

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Shi, Z.; Gauthier, M.; Yang, G. Bacterial Cellulose: Molecular Regulation of Biosynthesis, Supramolecular Assembly, and Tailored Structural and Functional Properties. Prog. Mater. Sci. 2022, 129, 100972. [Google Scholar] [CrossRef]

- Manan, S.; Shahzad, A.; Ul-Islam, M.; Ullah, M.W.; Yang, G. Synthesis Routes and Applications of Cellulose in Food Industry. In Bacterial Cellulose; CRC Press: Boca Raton, FL, USA, 2021; pp. 115–143. [Google Scholar]

- Ghassemi, N.; Poulhazan, A.; Deligey, F.; Mentink-Vigier, F.; Marcotte, I.; Wang, T. Solid-State NMR Investigations of Extracellular Matrixes and Cell Walls of Algae, Bacteria, Fungi, and Plants. Chem. Rev. 2022, 122, 10036–10086. [Google Scholar] [CrossRef]

- Ul-Islam, M.; Khan, S.; Ullah, M.W.; Park, J.K. Comparative Study of Plant and Bacterial Cellulose Pellicles Regenerated from Dissolved States. Int. J. Biol. Macromol. 2019, 137, 247–252. [Google Scholar] [CrossRef]

- Khan, S.; Ul-Islam, M.; Ullah, M.W.; Zhu, Y.; Narayanan, K.B.; Han, S.S.; Park, J.K. Fabrication Strategies and Biomedical Applications of Three-Dimensional Bacterial Cellulose-Based Scaffolds: A Review. Int. J. Biol. Macromol. 2022, 209, 9–30. [Google Scholar] [CrossRef]

- Fatima, A.; Yasir, S.; Ul-Islam, M.; Kamal, T.; Ahmad, M.; Abbas, Y.; Manan, S.; Ullah, M.W.; Yang, G. Ex Situ Development and Characterization of Green Antibacterial Bacterial Cellulose-Based Composites for Potential Biomedical Applications. Adv. Compos. Hybrid Mater. 2022, 5, 307–321. [Google Scholar] [CrossRef]

- Islam, M.U.; Ullah, M.W.; Khan, S.; Shah, N.; Park, J.K. Strategies for Cost-Effective and Enhanced Production of Bacterial Cellulose. Int. J. Biol. Macromol. 2017, 102, 1166–1173. [Google Scholar] [CrossRef]

- Ha, J.H.; Shah, N.; Ul-Islam, M.; Khan, T.; Park, J.K. Bacterial Cellulose Production from a Single Sugar Alpha-Linked Glucuronic Acid-Based Oligosaccharide. Process Biochem. 2011, 46, 1717–1723. [Google Scholar] [CrossRef]

- Ullah, M.W.; Khattak, W.A.; Ul-Islam, M.; Khan, S.; Park, J.K. Metabolic Engineering of Synthetic Cell-Free Systems: Strategies and Applications. Biochem. Eng. J. 2016, 105, 391–405. [Google Scholar] [CrossRef]

- Ha, J.H.; Shehzad, O.; Khan, S.; Lee, S.Y.; Park, J.W.; Khan, T.; Park, J.K. Production of Bacterial Cellulose by a Static Cultivation Using the Waste from Beer Culture Broth. Korean J. Chem. Eng. 2008, 25, 812–815. [Google Scholar] [CrossRef]

- Bae, S.; Shoda, M. Statistical Optimization of Culture Conditions for Bacterial Cellulose Production Using Box-Behnken Design. Biotechnol. Bioeng. 2005, 90, 20–28. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.T.; Flanagan, B.; Gidley, M.J.; Dykes, G.A. Characterization of Cellulose Production by a Gluconacetobacter xylinus Strain from Kombucha. Curr. Microbiol. 2008, 57, 449. [Google Scholar] [CrossRef] [PubMed]

- Zhong, C. Industrial-Scale Production and Applications of Bacterial Cellulose. Front. Bioeng. Biotechnol. 2020, 8, 605374. [Google Scholar] [CrossRef]

- Ullah, M.W.; Manan, S.; Kiprono, S.J.; Ul-Islam, M.; Yang, G. Synthesis, Structure, and Properties of Bacterial Cellulose. Nanocellulose Fundam. Adv. Mater. 2019, 81–113. [Google Scholar] [CrossRef]

- Moniri, M.; Boroumand Moghaddam, A.; Azizi, S.; Abdul Rahim, R.; Bin Ariff, A.; Zuhainis Saad, W.; Navaderi, M.; Mohamad, R. Production and Status of Bacterial Cellulose in Biomedical Engineering. Nanomaterials 2017, 7, 257. [Google Scholar] [CrossRef]

- Rongpipi, S.; Ye, D.; Gomez, E.D.; Gomez, E.W. Progress and Opportunities in the Characterization of Cellulose–an Important Regulator of Cell Wall Growth and Mechanics. Front. Plant Sci. 2019, 9, 1894. [Google Scholar] [CrossRef]

- French, A.D. Idealized Powder Diffraction Patterns for Cellulose Polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Gupta, P.K.; Uniyal, V.; Naithani, S. Polymorphic Transformation of Cellulose I to Cellulose II by Alkali Pretreatment and Urea as an Additive. Carbohydr. Polym. 2013, 94, 843–849. [Google Scholar] [CrossRef]

- Lehrhofer, A.F.; Goto, T.; Kawada, T.; Rosenau, T.; Hettegger, H. In Vitro Synthesis of Cellulose—A Mini-Review. Carbohydr. Polym. 2022, 285, 119222. [Google Scholar] [CrossRef] [PubMed]

- Ul-Islam, M.; Khattak, W.A.; Ullah, M.W.; Khan, S.; Park, J.K. Synthesis of Regenerated Bacterial Cellulose-Zinc Oxide Nanocomposite Films for Biomedical Applications. Cellulose 2014, 21, 433–447. [Google Scholar] [CrossRef]

- Khan, S.; Ul-Islam, M.; Khattak, W.A.; Ullah, M.W.; Park, J.K. Bacterial Cellulose-Titanium Dioxide Nanocomposites: Nanostructural Characteristics, Antibacterial Mechanism, and Biocompatibility. Cellulose 2015, 22, 565–579. [Google Scholar] [CrossRef]

- Orlando, I.; Basnett, P.; Nigmatullin, R.; Wang, W.; Knowles, J.C.; Roy, I. Chemical Modification of Bacterial Cellulose for the Development of an Antibacterial Wound Dressing. Front. Bioeng. Biotechnol. 2020, 8, 557885. [Google Scholar] [CrossRef]

- Schlufter, K.; Schmauder, H.-P.; Dorn, S.; Heinze, T. Efficient Homogeneous Chemical Modification of Bacterial Cellulose in the Ionic Liquid 1-N-Butyl-3-Methylimidazolium Chloride. Macromol. Rapid Commun. 2006, 27, 1670–1676. [Google Scholar] [CrossRef]

- Brown, A.J. XLIII.—On an Acetic Ferment Which Forms Cellulose. J. Chem. Soc. Trans. 1886, 49, 432–439. [Google Scholar] [CrossRef]

- Nishi, Y.; Uryu, M.; Yamanaka, S.; Watanabe, K.; Kitamura, N.; Iguchi, M.; Mitsuhashi, S. The Structure and Mechanical Properties of Sheets Prepared from Bacterial Cellulose. J. Mater. Sci. 1990, 25, 2997–3001. [Google Scholar] [CrossRef]

- Yamanaka, S.; Watanabe, K.; Kitamura, N.; Iguchi, M.; Mitsuhashi, S.; Nishi, Y.; Uryu, M. The Structure and Mechanical Properties of Sheets Prepared from Bacterial Cellulose. J. Mater. Sci. 1989, 24, 3141–3145. [Google Scholar] [CrossRef]

- Sajjad, W.; Khan, T.; Ul-Islam, M.; Khan, R.; Hussain, Z.; Khalid, A.; Wahid, F. Development of Modified Montmorillonite-Bacterial Cellulose Nanocomposites as a Novel Substitute for Burn Skin and Tissue Regeneration. Carbohydr. Polym. 2019, 206, 548–556. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, R.; Liu, X.; Liu, X.; Chen, H. Green Synthesis of Bacterial Cellulose via Acetic Acid Pre-Hydrolysis Liquor of Agricultural Corn Stalk Used as Carbon Source. Bioresour. Technol. 2017, 234, 8–14. [Google Scholar] [CrossRef]

- Goelzer, F.D.E.; Faria-Tischer, P.C.S.; Vitorino, J.C.; Sierakowski, M.-R.; Tischer, C.A. Production and Characterization of Nanospheres of Bacterial Cellulose from Acetobacter Xylinum from Processed Rice Bark. Mater. Sci. Eng. C 2009, 29, 546–551. [Google Scholar] [CrossRef]

- Hong, F.; Zhu, Y.X.; Yang, G.; Yang, X.X. Wheat Straw Acid Hydrolysate as a Potential Cost-Effective Feedstock for Production of Bacterial Cellulose. J. Chem. Technol. Biotechnol. 2011, 86, 675–680. [Google Scholar] [CrossRef]

- Kurosumi, A.; Sasaki, C.; Yamashita, Y.; Nakamura, Y. Utilization of Various Fruit Juices as Carbon Source for Production of Bacterial Cellulose by Acetobacter xylinum NBRC 13693. Carbohydr. Polym. 2009, 76, 333–335. [Google Scholar] [CrossRef]

- Fatima, A.; Yasir, S.; Khan, M.S.; Manan, S.; Ullah, M.W.; Ul-Islam, M. Plant Extract-Loaded Bacterial Cellulose Composite Membrane for Potential Biomedical Applications. J. Bioresour. Bioprod. 2021, 6, 26–32. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Y.; Zhang, Y.; Sun, S.; Ullah, M.W.; Xu, W. Biotransformation of Nylon-6,6 Hydrolysate to Bacterial Cellulose. Green Chem. 2021, 23, 7805–7815. [Google Scholar] [CrossRef]

- Khattak, W.A.; Khan, T.; Ul-Islam, M.; Ullah, M.W.; Khan, S.; Wahid, F.; Park, J.K. Production, Characterization and Biological Features of Bacterial Cellulose from Scum Obtained during Preparation of Sugarcane Jaggery (Gur). J. Food Sci. Technol. 2015, 52, 8343–8349. [Google Scholar] [CrossRef]

- Skiba, E.A.; Budaeva, V.V.; Ovchinnikova, E.V.; Gladysheva, E.K.; Kashcheyeva, E.I.; Pavlov, I.N.; Sakovich, G.V. A Technology for Pilot Production of Bacterial Cellulose from Oat Hulls. Chem. Eng. J. 2020, 383, 123128. [Google Scholar] [CrossRef]

- Huang, C.; Yang, X.-Y.; Xiong, L.; Guo, H.-J.; Luo, J.; Wang, B.; Zhang, H.-R.; Lin, X.-Q.; Chen, X.-D. Evaluating the Possibility of Using Acetone-Butanol-Ethanol (ABE) Fermentation Wastewater for Bacterial Cellulose Production by Gluconacetobacter xylinus. Lett. Appl. Microbiol. 2015, 60, 491–496. [Google Scholar] [CrossRef]

- Huang, C.; Guo, H.-J.; Xiong, L.; Wang, B.; Shi, S.-L.; Chen, X.-F.; Lin, X.-Q.; Wang, C.; Luo, J.; Chen, X.-D. Using Wastewater after Lipid Fermentation as Substrate for Bacterial Cellulose Production by Gluconacetobacter xylinus. Carbohydr. Polym. 2016, 136, 198–202. [Google Scholar] [CrossRef]

- Eslahi, N.; Mahmoodi, A.; Mahmoudi, N.; Zandi, N.; Simchi, A. Processing and Properties of Nanofibrous Bacterial Cellulose-Containing Polymer Composites: A Review of Recent Advances for Biomedical Applications. Polym. Rev. 2020, 60, 144–170. [Google Scholar] [CrossRef]

- Khan, S.; Siddique, R.; Huanfei, D.; Shereen, M.A.; Nabi, G.; Bai, Q.; Manan, S.; Xue, M.; Ullah, M.W.; Bowen, H. Perspective Applications and Associated Challenges of Using Nanocellulose in Treating Bone-Related Diseases. Front. Bioeng. Biotechnol. 2021, 9, 616555. [Google Scholar] [CrossRef] [PubMed]

- Bakadia, B.M.; Boni, B.O.O.; Ahmed, A.A.Q.; Zheng, R.; Shi, Z.; Ullah, M.W.; Lamboni, L.; Yang, G. In Situ Synthesized Porous Bacterial Cellulose/Poly (Vinyl Alcohol)-Based Silk Sericin and Azithromycin Release System for Treating Chronic Wound Biofilm. Macromol. Biosci. 2200201. [CrossRef] [PubMed]

- Di, Z.; Shi, Z.; Ullah, M.W.; Li, S.; Yang, G. A Transparent Wound Dressing Based on Bacterial Cellulose Whisker and Poly(2-Hydroxyethyl Methacrylate). Int. J. Biol. Macromol. 2017, 105, 638–644. [Google Scholar] [CrossRef] [PubMed]

- Sriplai, N.; Pinitsoontorn, S. Bacterial Cellulose-Based Magnetic Nanocomposites: A Review. Carbohydr. Polym. 2021, 254, 117228. [Google Scholar] [CrossRef] [PubMed]

- Hussain, Z.; Sajjad, W.; Khan, T.; Wahid, F. Production of Bacterial Cellulose from Industrial Wastes: A Review. Cellulose 2019, 26, 2895–2911. [Google Scholar] [CrossRef]

- Phisalaphong, M.; Tran, T.-K.; Taokaew, S.; Budiraharjo, R.; Febriana, G.G.; Nguyen, D.-N.; Chu-Ky, S.; Dourado, F. Chapter 14—Nata de Coco Industry in Vietnam, Thailand, and IndonesiaaaMuenduen Phisalaphong, Tien-Khai Tran, Son Chu-Ky, and Fernando Dourado Have Contributed Equally to This Work. In Bacterial Nanocellulose; Gama, M., Dourado, F., Bielecki, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 231–236. ISBN 978-0-444-63458-0. [Google Scholar]

- Behera, B.; Laavanya, D.; Balasubramanian, P. Techno-Economic Feasibility Assessment of Bacterial Cellulose Biofilm Production during the Kombucha Fermentation Process. Bioresour. Technol. 2022, 346, 126659. [Google Scholar] [CrossRef]

- Dourado, F.; Fontão, A.; Leal, M.; Rodrigues, A.C.; Gama, M. Process Modeling and Techno-Economic Evaluation of an Industrial Bacterial Nanocellulose Fermentation Process. In Bacterial Nanocellulose; Elsevier: Amsterdam, The Netherlands, 2016; pp. 199–214. [Google Scholar]

- Keshk, S.M.; Razek, T.M.; Sameshima, K. Bacterial Cellulose Production from Beet Molasses. Afr. J. Biotechnol. 2006, 5, 1519–1523. [Google Scholar] [CrossRef]

- Petersen, N.; Gatenholm, P. Bacterial Cellulose-Based Materials and Medical Devices: Current State and Perspectives. Appl. Microbiol. Biotechnol. 2011, 91, 1277–1286. [Google Scholar] [CrossRef]

- Sun, D.-P.; Ma, B.; Zhu, C.-L.; Liu, C.-S.; Yang, J.-Z. Novel Nitrocellulose Made from Bacterial Cellulose. J. Energ. Mater. 2010, 28, 85–97. [Google Scholar] [CrossRef]

- Mormino, R.; Bungay, H. Composites of Bacterial Cellulose and Paper Made with a Rotating Disk Bioreactor. Appl. Microbiol. Biotechnol. 2003, 62, 503–506. [Google Scholar] [CrossRef]

- Zhou, M.; Qi, W.; Hu, Z.; Cheng, M.; Zhao, X.; Xiong, P.; Su, H.; Li, M.; Hu, J.; Xu, Y. Highly Potassiophilic Carbon Nanofiber Paper Derived from Bacterial Cellulose Enables Ultra-Stable Dendrite-Free Potassium Metal Anodes. ACS Appl. Mater. Interfaces 2021, 13, 17629–17638. [Google Scholar] [CrossRef] [PubMed]

- Cheng, K.-C.; Catchmark, J.M.; Demirci, A. Effects of CMC Addition on Bacterial Cellulose Production in a Biofilm Reactor and Its Paper Sheets Analysis. Biomacromolecules 2011, 12, 730–736. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, M.; Gama, M.; Dourado, F.; Souto, A.P. Development of Novel Bacterial Cellulose Composites for the Textile and Shoe Industry. Microb. Biotechnol. 2019, 12, 650–661. [Google Scholar] [CrossRef]

- Ullah, H.; Wahid, F.; Santos, H.A.; Khan, T. Advances in Biomedical and Pharmaceutical Applications of Functional Bacterial Cellulose-Based Nanocomposites. Carbohydr. Polym. 2016, 150, 330–352. [Google Scholar] [CrossRef] [PubMed]

- Badshah, M.; Ullah, H.; Wahid, F.; Khan, T. Bacterial Cellulose-Based Metallic Green Nanocomposites for Biomedical and Pharmaceutical Applications. Curr. Pharm. Des. 2020, 26, 5866–5880. [Google Scholar] [CrossRef]

- Meneguin, A.B.; da Silva Barud, H.; Sábio, R.M.; de Sousa, P.Z.; Manieri, K.F.; de Freitas, L.A.P.; Pacheco, G.; Alonso, J.D.; Chorilli, M. Spray-Dried Bacterial Cellulose Nanofibers: A New Generation of Pharmaceutical Excipient Intended for Intestinal Drug Delivery. Carbohydr. Polym. 2020, 249, 116838. [Google Scholar] [CrossRef]

- Islam, S.U.; Ul-Islam, M.; Ahsan, H.; Ahmed, M.B.; Shehzad, A.; Fatima, A.; Sonn, J.K.; Lee, Y.S. Potential Applications of Bacterial Cellulose and Its Composites for Cancer Treatment. Int. J. Biol. Macromol. 2021, 168, 301–309. [Google Scholar] [CrossRef]

- Ul-Islam, M.; Ul-Islam, S.; Yasir, S.; Fatima, A.; Ahmed, M.W.; Lee, Y.S.; Manan, S.; Wajid Ullah, M. Potential Applications of Bacterial Cellulose in Environmental and Pharmaceutical Sectors. Curr. Pharm. Des. 2020, 26, 5793–5806. [Google Scholar] [CrossRef]

- Weyell, P.; Beekmann, U.; Küpper, C.; Dederichs, M.; Thamm, J.; Fischer, D.; Kralisch, D. Tailor-Made Material Characteristics of Bacterial Cellulose for Drug Delivery Applications in Dentistry. Carbohydr. Polym. 2019, 207, 1–10. [Google Scholar] [CrossRef]

- Bianchet, R.T.; Vieira Cubas, A.L.; Machado, M.M.; Siegel Moecke, E.H. Applicability of Bacterial Cellulose in Cosmetics—Bibliometric Review. Biotechnol. Rep. 2020, 27, e00502. [Google Scholar] [CrossRef]

- Chen, L.; Cao, X.; Gao, J.; He, W.; Liu, J.; Wang, Y.; Zhou, X.; Shen, J.; Wang, B.; He, Y.; et al. Nitrated Bacterial Cellulose-Based Energetic Nanocomposites as Propellants and Explosives for Military Applications. ACS Appl. Nano Mater. 2021, 4, 1906–1915. [Google Scholar] [CrossRef]

- Iguchi, M.; Yamanaka, S.; Budhiono, A. Bacterial Cellulose—A Masterpiece of Nature’s Arts. J. Mater. Sci. 2000, 35, 261–270. [Google Scholar] [CrossRef]

- Jozala, A.F.; de Lencastre-Novaes, L.C.; Lopes, A.M.; de Carvalho Santos-Ebinuma, V.; Mazzola, P.G.; Pessoa, A., Jr.; Grotto, D.; Gerenutti, M.; Chaud, M.V. Bacterial Nanocellulose Production and Application: A 10-Year Overview. Appl. Microbiol. Biotechnol. 2016, 100, 2063–2072. [Google Scholar] [CrossRef] [PubMed]

- Piadozo, M. Nata de Coco Industry in the Philippines. Bact. Nanocellulose 2016, 215–229. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Barud, H.; Farinas, C.S.; Vasconcellos, V.M.; Claro, A.M. Bacterial Cellulose as a Raw Material for Food and Food Packaging Applications. Front. Sustain. Food Syst. 2019, 3, 7. [Google Scholar] [CrossRef]

- Casaburi, A.; Montoya Rojo, Ú.; Cerrutti, P.; Vázquez, A.; Foresti, M.L. Carboxymethyl Cellulose with Tailored Degree of Substitution Obtained from Bacterial Cellulose. Food Hydrocoll. 2018, 75, 147–156. [Google Scholar] [CrossRef]

- Cho, S.; Almeida, N. Dietary Fiber and Health; CRC Press: Boca Raton, FL, USA, 2012; ISBN 978-1-4398-9937-3. [Google Scholar]

- Paximada, P.; Koutinas, A.A.; Scholten, E.; Mandala, I.G. Effect of Bacterial Cellulose Addition on Physical Properties of WPI Emulsions. Comparison with Common Thickeners. Food Hydrocoll. 2016, 54, 245–254. [Google Scholar] [CrossRef]

- Okiyama, A.; Motoki, M.; Yamanaka, S. Bacterial Cellulose IV. Application to Processed Foods. Food Hydrocoll. 1993, 6, 503–511. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, Y.; Phillips, G.O.; Yang, G. Utilization of Bacterial Cellulose in Food. Food Hydrocoll. 2014, 35, 539–545. [Google Scholar] [CrossRef]

- Tekin, E.; Sahin, S.; Sumnu, G. Physicochemical, Rheological, and Sensory Properties of Low-Fat Ice Cream Designed by Double Emulsions. Eur. J. Lipid Sci. Technol. 2017, 119, 1600505. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, X.; Hao, W.; Xie, Y.; Chen, L.; Li, Z.; Zhu, B.; Feng, X. Nano-Bacterial Cellulose/Soy Protein Isolate Complex Gel as Fat Substitutes in Ice Cream Model. Carbohydr. Polym. 2018, 198, 620–630. [Google Scholar] [CrossRef] [PubMed]

- Perumal, A.B.; Nambiar, R.B.; Moses, J.A.; Anandharamakrishnan, C. Nanocellulose: Recent Trends and Applications in the Food Industry. Food Hydrocoll. 2022, 127, 107484. [Google Scholar] [CrossRef]

- Hu, Z.; Ballinger, S.; Pelton, R.; Cranston, E.D. Surfactant-Enhanced Cellulose Nanocrystal Pickering Emulsions. J. Colloid Interface Sci. 2015, 439, 139–148. [Google Scholar] [CrossRef] [PubMed]

- Zhai, X.; Lin, D.; Liu, D.; Yang, X. Emulsions Stabilized by Nanofibers from Bacterial Cellulose: New Potential Food-Grade Pickering Emulsions. Food Res. Int. 2018, 103, 12–20. [Google Scholar] [CrossRef] [PubMed]

- Chevalier, Y.; Bolzinger, M.-A. Emulsions Stabilized with Solid Nanoparticles: Pickering Emulsions. Colloids Surf. Physicochem. Eng. Asp. 2013, 439, 23–34. [Google Scholar] [CrossRef]

- Kalashnikova, I.; Bizot, H.; Cathala, B.; Capron, I. Modulation of Cellulose Nanocrystals Amphiphilic Properties to Stabilize Oil/Water Interface. Biomacromolecules 2012, 13, 267–275. [Google Scholar] [CrossRef]

- Yan, H.; Chen, X.; Song, H.; Li, J.; Feng, Y.; Shi, Z.; Wang, X.; Lin, Q. Synthesis of Bacterial Cellulose and Bacterial Cellulose Nanocrystals for Their Applications in the Stabilization of Olive Oil Pickering Emulsion. Food Hydrocoll. 2017, 72, 127–135. [Google Scholar] [CrossRef]

- Paximada, P.; Tsouko, E.; Kopsahelis, N.; Koutinas, A.A.; Mandala, I. Bacterial Cellulose as Stabilizer of o/w Emulsions. Food Hydrocoll. 2016, 53, 225–232. [Google Scholar] [CrossRef]

- Goi, Y.; Fujisawa, S.; Saito, T.; Yamane, K.; Kuroda, K.; Isogai, A. Dual Functions of TEMPO-Oxidized Cellulose Nanofibers in Oil-in-Water Emulsions: A Pickering Emulsifier and a Unique Dispersion Stabilizer. Langmuir 2019, 35, 10920–10926. [Google Scholar] [CrossRef]

- Kalashnikova, I.; Bizot, H.; Cathala, B.; Capron, I. New Pickering Emulsions Stabilized by Bacterial Cellulose Nanocrystals. Langmuir 2011, 27, 7471–7479. [Google Scholar] [CrossRef]

- Martins, D.; Estevinho, B.; Rocha, F.; Dourado, F.; Gama, M. A Dry and Fully Dispersible Bacterial Cellulose Formulation as a Stabilizer for Oil-in-Water Emulsions. Carbohydr. Polym. 2020, 230, 115657. [Google Scholar] [CrossRef] [PubMed]

- Rios, R.V.; Garzón, R.; Lannes, S.C.S.; Rosell, C.M. Use of Succinyl Chitosan as Fat Replacer on Cake Formulations. LWT 2018, 96, 260–265. [Google Scholar] [CrossRef]

- PREDIMED Study Investigators. Dietary Fat Intake and Risk of Cardiovascular Disease and All-Cause Mortality in a Population at High Risk of Cardiovascular Disease. Am. J. Clin. Nutr. 2015, 102, 1563–1573. [Google Scholar] [CrossRef] [PubMed]

- Aydinol, P.; Ozcan, T. Production of Reduced-Fat Labneh Cheese with Inulin and β-Glucan Fibre-Based Fat Replacer. Int. J. Dairy Technol. 2018, 71, 362–371. [Google Scholar] [CrossRef]

- Kumar, Y.; Kairam, N.; Ahmad, T.; Yadav, D.N. Physico Chemical, Microstructural and Sensory Characteristics of Low-Fat Meat Emulsion Containing Aloe Gel as Potential Fat Replacer. Int. J. Food Sci. Technol. 2016, 51, 309–316. [Google Scholar] [CrossRef]

- Karimi, R.; Azizi, M.H.; Ghasemlou, M.; Vaziri, M. Application of Inulin in Cheese as Prebiotic, Fat Replacer and Texturizer: A Review. Carbohydr. Polym. 2015, 119, 85–100. [Google Scholar] [CrossRef]

- Kocer, D.; Hicsasmaz, Z.; Bayindirli, A.; Katnas, S. Bubble and Pore Formation of the High-Ratio Cake Formulation with Polydextrose as a Sugar- and Fat-Replacer. J. Food Eng. 2007, 78, 953–964. [Google Scholar] [CrossRef]

- Oh, I.; Lee, J.; Lee, H.G.; Lee, S. Feasibility of Hydroxypropyl Methylcellulose Oleogel as an Animal Fat Replacer for Meat Patties. Food Res. Int. 2019, 122, 566–572. [Google Scholar] [CrossRef]

- Lin, S.-B.; Chen, L.-C.; Chen, H.-H. Physical Characteristics of Surimi and Bacterial Cellulose Composite Gel. J. Food Process Eng. 2011, 34, 1363–1379. [Google Scholar] [CrossRef]

- Karahan, A.G.; Kart, A.; Akoğlu, A.; Çakmakçı, M.L. Physicochemical Properties of Low-Fat Soft Cheese Turkish Beyaz Made with Bacterial Cellulose as Fat Mimetic. Int. J. Dairy Technol. 2011, 64, 502–508. [Google Scholar] [CrossRef]

- Akoğlu, A.; Çakır, İ.; Akoğlu, I.; Karahan, A.; Çakmakçı, M.L. Yağı Azaltılmış Sucuğun Bazı Kalite Özellikleri Üzerine Yağ İkame Maddesi Olarak Kullanılan Bakteriyel Selülozun Etkisi. GIDA J. Food 2015, 40, 133–140. [Google Scholar] [CrossRef]

- Akoğlu, A.; Cakir, I.; Karahan, A.G.; Lutfu, M. Effects of Bacterial Cellulose as a Fat Replacer on Some Properties of Fat-Reduced Mayonnaise. Rom. Biotechnol. Lett. 2018, 23, 13674–13680. [Google Scholar]

- Oliveira, A.A.N.; Marques de Mesquita, E.d.F.; Furtado, A.A.L. Use of Bacterial Cellulose as a Fat Replacer in Emulsified Meat Products: Review. Food Sci. Technol. 2021, 42, e42621. [Google Scholar] [CrossRef]

- Sheu, F.; Wang, C.L.; Shyu, Y.T. Fermentation of Monascus purpureus on Bacterial Cellulose-Nata and the Color Stability of Monascus-Nata Complex. J. Food Sci. 2000, 65, 342–345. [Google Scholar] [CrossRef]

- Purwadaria, T.; Gunawan, L.; Gunawan, A.W. The Production of Nata Colored by Monascus purpureus J1 Pigments as Functional Foods. J. Microbiol. Indones. 2010, 4, 6–10. [Google Scholar] [CrossRef]

- Kim, D.; Ku, S. Beneficial Effects of Monascus Sp. KCCM 10093 Pigments and Derivatives: A Mini Review. Molecules 2018, 23, 98. [Google Scholar] [CrossRef]

- Ochaikul*, D.; Chotirittikrai, K.; Chantra, J.; Wutigornsombatkul, S. Studies on Fermentation of Monascus purpureus TISTR 3090 With Bacterial Cellulose from Acetobacter Xylinum TISTR 967. Curr. Appl. Sci. Technol. 2006, 6, 13–17. [Google Scholar]

- Ullah, H.; Santos, H.A.; Khan, T. Applications of Bacterial Cellulose in Food, Cosmetics and Drug Delivery. Cellulose 2016, 23, 2291–2314. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M. Bacterial Cellulose as a Biodegradable Food Packaging Material: A Review. Food Hydrocoll. 2021, 113, 106530. [Google Scholar] [CrossRef]

- Isopencu, G.O.; Stoica-Guzun, A.; Busuioc, C.; Stroescu, M.; Deleanu, I.M. Development of Antioxidant and Antimicrobial Edible Coatings Incorporating Bacterial Cellulose, Pectin, and Blackberry Pomace. Carbohydr. Polym. Technol. Appl. 2021, 2, 100057. [Google Scholar] [CrossRef]

- Videira-Quintela, D.; Martin, O.; Montalvo, G. Recent Advances in Polymer-Metallic Composites for Food Packaging Applications. Trends Food Sci. Technol. 2021, 109, 230–244. [Google Scholar] [CrossRef]

- Wen, Y.; Liu, J.; Jiang, L.; Zhu, Z.; He, S.; He, S.; Shao, W. Development of Intelligent/Active Food Packaging Film Based on TEMPO-Oxidized Bacterial Cellulose Containing Thymol and Anthocyanin-Rich Purple Potato Extract for Shelf Life Extension of Shrimp. Food Packag. Shelf Life 2021, 29, 100709. [Google Scholar] [CrossRef]

- Silva, S.M.F.; Ribeiro, H.L.; Mattos, A.L.A.; Borges, M.d.F.; Rosa, M.d.F.; de Azeredo, H.M.C. Films from Cashew Byproducts: Cashew Gum and Bacterial Cellulose from Cashew Apple Juice. J. Food Sci. Technol. 2021, 58, 1979–1986. [Google Scholar] [CrossRef] [PubMed]

- Nunes, S.B.; Hodel, K.V.S.; Sacramento, G.d.C.; Melo, P.d.S.; Pessoa, F.L.P.; Barbosa, J.D.V.; Badaró, R.; Machado, B.A.S. Development of Bacterial Cellulose Biocomposites Combined with Starch and Collagen and Evaluation of Their Properties. Materials 2021, 14, 458. [Google Scholar] [CrossRef]

- Nanofibrillated Bacterial Cellulose and Pectin Edible Films Added with Fruit Purees—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0144861718305411?casa_token=R1fLVJLUIZ0AAAAA:PicpHuMIulxmELVEOJWBcPbsY2kuMGy46qUbJ95kUvS-hzvRcwRFmQiJaJbUmizE6f7NXT7qUow (accessed on 18 August 2021).

- Adepu, S.; Khandelwal, M. Broad-Spectrum Antimicrobial Activity of Bacterial Cellulose Silver Nanocomposites with Sustained Release. J. Mater. Sci. 2018, 53, 1596–1609. [Google Scholar] [CrossRef]

- Buruaga-Ramiro, C.; Valenzuela, S.V.; Valls, C.; Roncero, M.B.; Pastor, F.I.J.; Díaz, P.; Martinez, J. Development of an Antimicrobial Bioactive Paper Made from Bacterial Cellulose. Int. J. Biol. Macromol. 2020, 158, 587–594. [Google Scholar] [CrossRef] [PubMed]

- Abral, H.; Pratama, A.B.; Handayani, D.; Mahardika, M.; Aminah, I.; Sandrawati, N.; Sugiarti, E.; Muslimin, A.N.; Sapuan, S.M.; Ilyas, R.A. Antimicrobial Edible Film Prepared from Bacterial Cellulose Nanofibers/Starch/Chitosan for a Food Packaging Alternative. Int. J. Polym. Sci. 2021, 2021, e6641284. [Google Scholar] [CrossRef]

- Gedarawatte, S.T.G.; Ravensdale, J.T.; Al-Salami, H.; Dykes, G.A.; Coorey, R. Antimicrobial Efficacy of Nisin-Loaded Bacterial Cellulose Nanocrystals against Selected Meat Spoilage Lactic Acid Bacteria. Carbohydr. Polym. 2021, 251, 117096. [Google Scholar] [CrossRef]

- Padrão, J.; Gonçalves, S.; Silva, J.P.; Sencadas, V.; Lanceros-Méndez, S.; Pinheiro, A.C.; Vicente, A.A.; Rodrigues, L.R.; Dourado, F. Bacterial Cellulose-Lactoferrin as an Antimicrobial Edible Packaging. Food Hydrocoll. 2016, 58, 126–140. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Gidley, M.J.; Dykes, G.A. Potential of a Nisin-Containing Bacterial Cellulose Film to Inhibit Listeria Monocytogenes on Processed Meats. Food Microbiol. 2008, 25, 471–478. [Google Scholar] [CrossRef]

- Rollini, M.; Musatti, A.; Cavicchioli, D.; Bussini, D.; Farris, S.; Rovera, C.; Romano, D.; De Benedetti, S.; Barbiroli, A. From Cheese Whey Permeate to Sakacin-A/Bacterial Cellulose Nanocrystal Conjugates for Antimicrobial Food Packaging Applications: A Circular Economy Case Study. Sci. Rep. 2020, 10, 21358. [Google Scholar] [CrossRef] [PubMed]

- de Castro, D.O.; Tabary, N.; Martel, B.; Gandini, A.; Belgacem, N.; Bras, J. Controlled Release of Carvacrol and Curcumin: Bio-Based Food Packaging by Synergism Action of TEMPO-Oxidized Cellulose Nanocrystals and Cyclodextrin. Cellulose 2018, 25, 1249–1263. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Ionita, E.R.; Nicolae, C.-A.; Gabor, A.R.; Ionita, M.D.; Trusca, R.; Lixandru, B.-E.; Codita, I.; Dinescu, G. Poly(3-Hydroxybutyrate) Modified by Nanocellulose and Plasma Treatment for Packaging Applications. Polymers 2018, 10, 1249. [Google Scholar] [CrossRef] [PubMed]

- Tsai, Y.-H.; Yang, Y.-N.; Ho, Y.-C.; Tsai, M.-L.; Mi, F.-L. Drug Release and Antioxidant/Antibacterial Activities of Silymarin-Zein Nanoparticle/Bacterial Cellulose Nanofiber Composite Films. Carbohydr. Polym. 2018, 180, 286–296. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Xie, J.; Deng, Y.; Bian, Y.; Hong, F. Hydrothermal Synthesis of Bacterial Cellulose/AgNPs Composite: A “Green” Route for Antibacterial Application. Carbohydr. Polym. 2012, 87, 2482–2487. [Google Scholar] [CrossRef]

- Wang, Y.; Yadav, S.; Heinlein, T.; Konjik, V.; Breitzke, H.; Buntkowsky, G.; Schneider, J.J.; Zhang, K. Ultra-Light Nanocomposite Aerogels of Bacterial Cellulose and Reduced Graphene Oxide for Specific Absorption and Separation of Organic Liquids. RSC Adv. 2014, 4, 21553–21558. [Google Scholar] [CrossRef]

- Thaveemas, P.; Chuenchom, L.; Kaowphong, S.; Techasakul, S.; Saparpakorn, P.; Dechtrirat, D. Magnetic Carbon Nanofiber Composite Adsorbent through Green In-Situ Conversion of Bacterial Cellulose for Highly Efficient Removal of Bisphenol A. Bioresour. Technol. 2021, 333, 125184. [Google Scholar] [CrossRef]

- Khamkeaw, A.; Phisalaphong, M.; Jongsomjit, B.; Lin, K.-Y.A.; Yip, A.C.K. Synthesis of Mesoporous MFI Zeolite via Bacterial Cellulose-Derived Carbon Templating for Fast Adsorption of Formaldehyde. J. Hazard. Mater. 2020, 384, 121161. [Google Scholar] [CrossRef]

- Pereira, A.L.S.; Feitosa, J.P.A.; Morais, J.P.S.; de Freitas, R.M. Bacterial Cellulose Aerogels: Influence of Oxidation and Silanization on Mechanical and Absorption Properties. Carbohydr. Polym. 2020, 250, 116927. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, S.; Liu, J.; Sun, J.; Zhang, Z.; Zhu, Q. Sustainable Cellulose Nanomaterials for Environmental Remediation—Achieving Clean Air, Water, and Energy: A Review. Carbohydr. Polym. 2022, 285, 119251. [Google Scholar] [CrossRef]

- Liu, X.; Souzandeh, H.; Zheng, Y.; Xie, Y.; Zhong, W.-H.; Wang, C. Soy Protein Isolate/Bacterial Cellulose Composite Membranes for High Efficiency Particulate Air Filtration. Compos. Sci. Technol. 2017, 138, 124–133. [Google Scholar] [CrossRef]

- Wu, A.; Hu, X.; Ao, H.; Chen, Z.; Chu, Z.; Jiang, T.; Deng, X.; Wan, Y. Rational Design of Bacterial Cellulose-Based Air Filter with Antibacterial Activity for Highly Efficient Particulate Matters Removal. Nano Sel. 2022, 3, 201–211. [Google Scholar] [CrossRef]

- HE, W.; LIU, X.; ZHENG, Y.; WANG, H.; XIE, Y.; FENG, Z.; WANG, Y.; LIU, X. Preparation and Properties of Modified Soy Protein-Bacterial Cellulose Composites for Air Filtration. Acta Mater. Compos. Sin. 2021, 38, 843–853. [Google Scholar] [CrossRef]

- Sai, H.; Fu, R.; Xing, L.; Xiang, J.; Li, Z.; Li, F.; Zhang, T. Surface Modification of Bacterial Cellulose Aerogels’ Web-like Skeleton for Oil/Water Separation. ACS Appl. Mater. Interfaces 2015, 7, 7373–7381. [Google Scholar] [CrossRef] [PubMed]

- Galdino, C.J.S.; Maia, A.D.; Meira, H.M.; Souza, T.C.; Amorim, J.D.P.; Almeida, F.C.G.; Costa, A.F.S.; Sarubbo, L.A. Use of a Bacterial Cellulose Filter for the Removal of Oil from Wastewater. Process Biochem. 2020, 91, 288–296. [Google Scholar] [CrossRef]

- Hassan, E.; Hassan, M.; Abou-zeid, R.; Berglund, L.; Oksman, K. Use of Bacterial Cellulose and Crosslinked Cellulose Nanofibers Membranes for Removal of Oil from Oil-in-Water Emulsions. Polymers 2017, 9, 388. [Google Scholar] [CrossRef]

- Wahid, F.; Zhao, X.-J.; Duan, Y.-X.; Zhao, X.-Q.; Jia, S.-R.; Zhong, C. Designing of Bacterial Cellulose-Based Superhydrophilic/Underwater Superoleophobic Membrane for Oil/Water Separation. Carbohydr. Polym. 2021, 257, 117611. [Google Scholar] [CrossRef]

- Hu, Y.; Yue, M.; Yuan, F.; Yang, L.; Chen, C.; Sun, D. Bio-Inspired Fabrication of Highly Permeable and Anti-Fouling Ultrafiltration Membranes Based on Bacterial Cellulose for Efficient Removal of Soluble Dyes and Insoluble Oils. J. Membr. Sci. 2021, 621, 118982. [Google Scholar] [CrossRef]

- Alves, A.A.; Silva, W.E.; Belian, M.F.; Lins, L.S.G.; Galembeck, A. Bacterial Cellulose Membranes for Environmental Water Remediation and Industrial Wastewater Treatment. Int. J. Environ. Sci. Technol. 2020, 17, 3997–4008. [Google Scholar] [CrossRef]

- Chen, S.; Zou, Y.; Yan, Z.; Shen, W.; Shi, S.; Zhang, X.; Wang, H. Carboxymethylated-Bacterial Cellulose for Copper and Lead Ion Removal. J. Hazard. Mater. 2009, 161, 1355–1359. [Google Scholar] [CrossRef]

- Qin, D.; Hu, X.; Dong, Y.; Mamat, X.; Li, Y.; Wågberg, T.; Hu, G. An Electrochemical Sensor Based on Green γ-AlOOH-Carbonated Bacterial Cellulose Hybrids for Simultaneous Determination Trace Levels of Cd(II) and Pb(II) in Drinking Water. J. Electrochem. Soc. 2018, 165, B328. [Google Scholar] [CrossRef]

- Hassan, A.; Sorour, N.M.; El-Baz, A.; Shetaia, Y. Simple Synthesis of Bacterial Cellulose/Magnetite Nanoparticles Composite for the Removal of Antimony from Aqueous Solution. Int. J. Environ. Sci. Technol. 2019, 16, 1433–1448. [Google Scholar] [CrossRef]

- Jin, X.; Xiang, Z.; Liu, Q.; Chen, Y.; Lu, F. Polyethyleneimine-Bacterial Cellulose Bioadsorbent for Effective Removal of Copper and Lead Ions from Aqueous Solution. Bioresour. Technol. 2017, 244, 844–849. [Google Scholar] [CrossRef]

- Mohite, B.V.; Patil, S.V. Bacterial Cellulose of Gluconoacetobacter Hansenii as a Potential Bioadsorption Agent for Its Green Environment Applications. J. Biomater. Sci. Polym. Ed. 2014, 25, 2053–2065. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Ye, M.; Zhang, X.; Zhang, H.; Wang, G.; Zhang, Y. Hierarchically Porous Poly(Amidoxime)/Bacterial Cellulose Composite Aerogel for Highly Efficient Scavenging of Heavy Metals. J. Colloid Interface Sci. 2021, 600, 752–763. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, H.; Mousavi, S.M. Bacterial Cellulose/Polyaniline Nanocomposite Aerogels as Novel Bioadsorbents for Removal of Hexavalent Chromium: Experimental and Simulation Study. J. Clean. Prod. 2021, 278, 123817. [Google Scholar] [CrossRef]

- Ougiya, H.; Hioki, N.; Watanabe, K.; Morinaga, Y.; Yoshinaga, F.; Samejima, M. Relationship between the Physical Properties and Surface Area of Cellulose Derived from Adsorbates of Various Molecular Sizes. Biosci. Biotechnol. Biochem. 1998, 62, 1880–1884. [Google Scholar] [CrossRef] [PubMed]

- Oshima, T.; Taguchi, S.; Fujiwara, H.; Ohe, K.; Baba, Y. Adsorption Behaviors of Bioactive Amines and Proteins on Phosphorylated Bacterial Cellulose. J. Ion Exch. 2007, 18, 204–207. [Google Scholar] [CrossRef]

- Niide, T.; Shiraki, H.; Oshima, T.; Baba, Y.; Kamiya, N.; Goto, M. Quaternary Ammonium Bacterial Cellulose for Adsorption of Proteins. Solvent Extr. Res. Dev. Jpn. 2010, 17, 73–81. [Google Scholar] [CrossRef][Green Version]

- Oshima, T.; Taguchi, S.; Ohe, K.; Baba, Y. Phosphorylated Bacterial Cellulose for Adsorption of Proteins. Carbohydr. Polym. 2011, 83, 953–958. [Google Scholar] [CrossRef]

- Lin, Q.; Zheng, Y.; Wang, G.; Shi, X.; Zhang, T.; Yu, J.; Sun, J. Protein Adsorption Behaviors of Carboxymethylated Bacterial Cellulose Membranes. Int. J. Biol. Macromol. 2015, 73, 264–269. [Google Scholar] [CrossRef] [PubMed]

- Wibowo, A.; Sihombing, A.R.S.A.; Putra Parmita, A.W.Y.; Triadhi, U.; Ardy, H. The Influence of Hydrogen Peroxide Concentration on Catalytic Activity of Fenton Catalyst@bacterial Cellulose. IOP Conf. Ser. Mater. Sci. Eng. 2019, 509, 012020. [Google Scholar] [CrossRef]

- Song, L.; Shu, L.; Wang, Y.; Zhang, X.-F.; Wang, Z.; Feng, Y.; Yao, J. Metal Nanoparticle-Embedded Bacterial Cellulose Aerogels via Swelling-Induced Adsorption for Nitrophenol Reduction. Int. J. Biol. Macromol. 2020, 143, 922–927. [Google Scholar] [CrossRef] [PubMed]

- Kamal, T.; Ahmad, I.; Khan, S.B.; Ul-Islam, M.; Asiri, A.M. Microwave Assisted Synthesis and Carboxymethyl Cellulose Stabilized Copper Nanoparticles on Bacterial Cellulose Nanofibers Support for Pollutants Degradation. J. Polym. Environ. 2019, 27, 2867–2877. [Google Scholar] [CrossRef]

- Li, G.; Nandgaonkar, A.G.; Wang, Q.; Zhang, J.; Krause, W.E.; Wei, Q.; Lucia, L.A. Laccase-Immobilized Bacterial Cellulose/TiO2 Functionalized Composite Membranes: Evaluation for Photo- and Bio-Catalytic Dye Degradation. J. Membr. Sci. 2017, 525, 89–98. [Google Scholar] [CrossRef]

- Patel, U.D.; Suresh, S. Complete Dechlorination of Pentachlorophenol Using Palladized Bacterial Cellulose in a Rotating Catalyst Contact Reactor. J. Colloid Interface Sci. 2008, 319, 462–469. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, Y.; Chen, J.; Liang, Q.; Xu, S.; Yao, C.; Zhou, M.; Li, Z. Anti-Aggregation and Morphology-Controlled Effects of Bacterial Cellulose Encapsulated BiOBr for Enhanced Photodegradation Efficiency. Cellulose 2020, 27, 8843–8858. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamal, T.; Ul-Islam, M.; Fatima, A.; Ullah, M.W.; Manan, S. Cost-Effective Synthesis of Bacterial Cellulose and Its Applications in the Food and Environmental Sectors. Gels 2022, 8, 552. https://doi.org/10.3390/gels8090552

Kamal T, Ul-Islam M, Fatima A, Ullah MW, Manan S. Cost-Effective Synthesis of Bacterial Cellulose and Its Applications in the Food and Environmental Sectors. Gels. 2022; 8(9):552. https://doi.org/10.3390/gels8090552

Chicago/Turabian StyleKamal, Tahseen, Mazhar Ul-Islam, Atiya Fatima, Muhammad Wajid Ullah, and Sehrish Manan. 2022. "Cost-Effective Synthesis of Bacterial Cellulose and Its Applications in the Food and Environmental Sectors" Gels 8, no. 9: 552. https://doi.org/10.3390/gels8090552

APA StyleKamal, T., Ul-Islam, M., Fatima, A., Ullah, M. W., & Manan, S. (2022). Cost-Effective Synthesis of Bacterial Cellulose and Its Applications in the Food and Environmental Sectors. Gels, 8(9), 552. https://doi.org/10.3390/gels8090552