Enhancing Rheological and Textural Properties of Gelatin-Based Composite Gels through Incorporation of Sesame Seed Oleosome-Protein Fillers

Abstract

:1. Introduction

2. Results and Discussion

2.1. Chemical Properties of Sesame Seeds

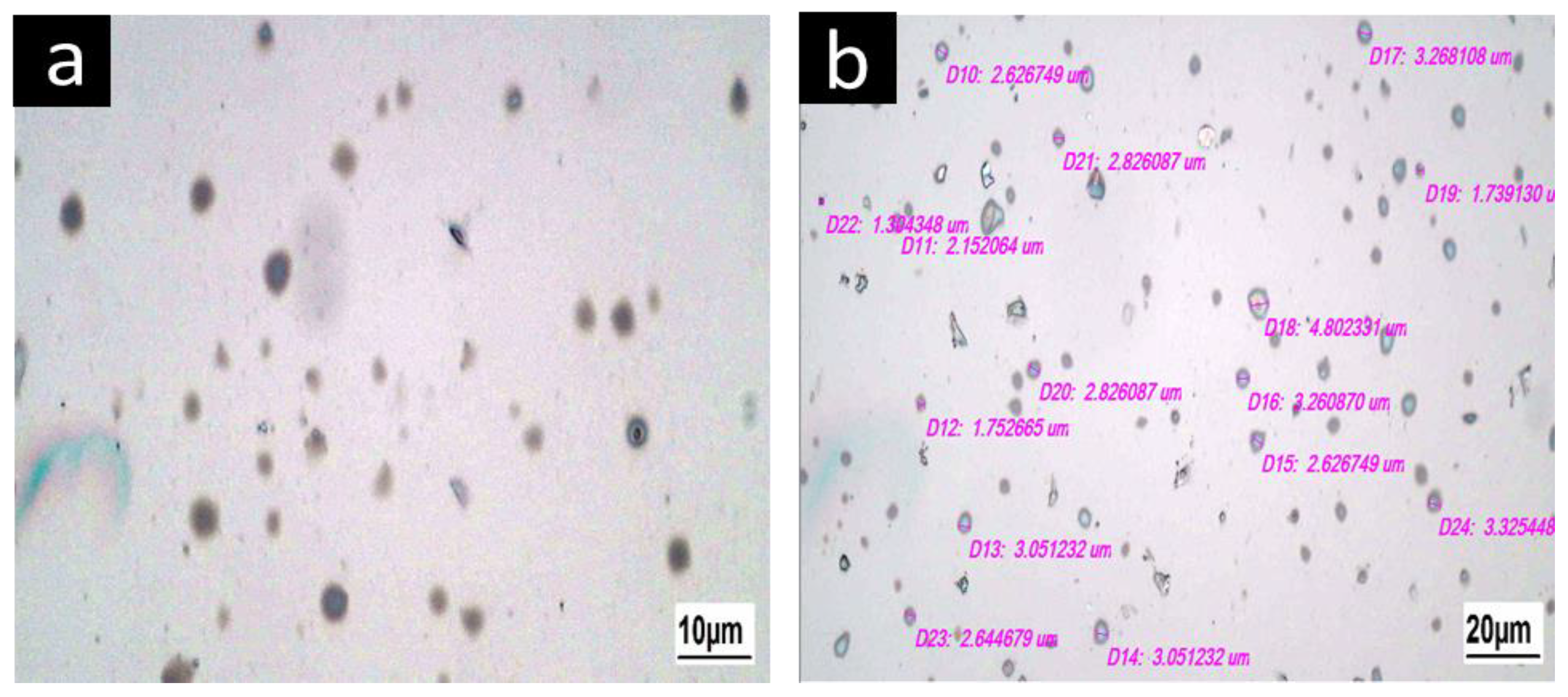

2.2. Physicochemical Properties of Oleosomes Extracted from Sesame Seeds

2.3. Sesame Oleosome Proteins and Their Properties

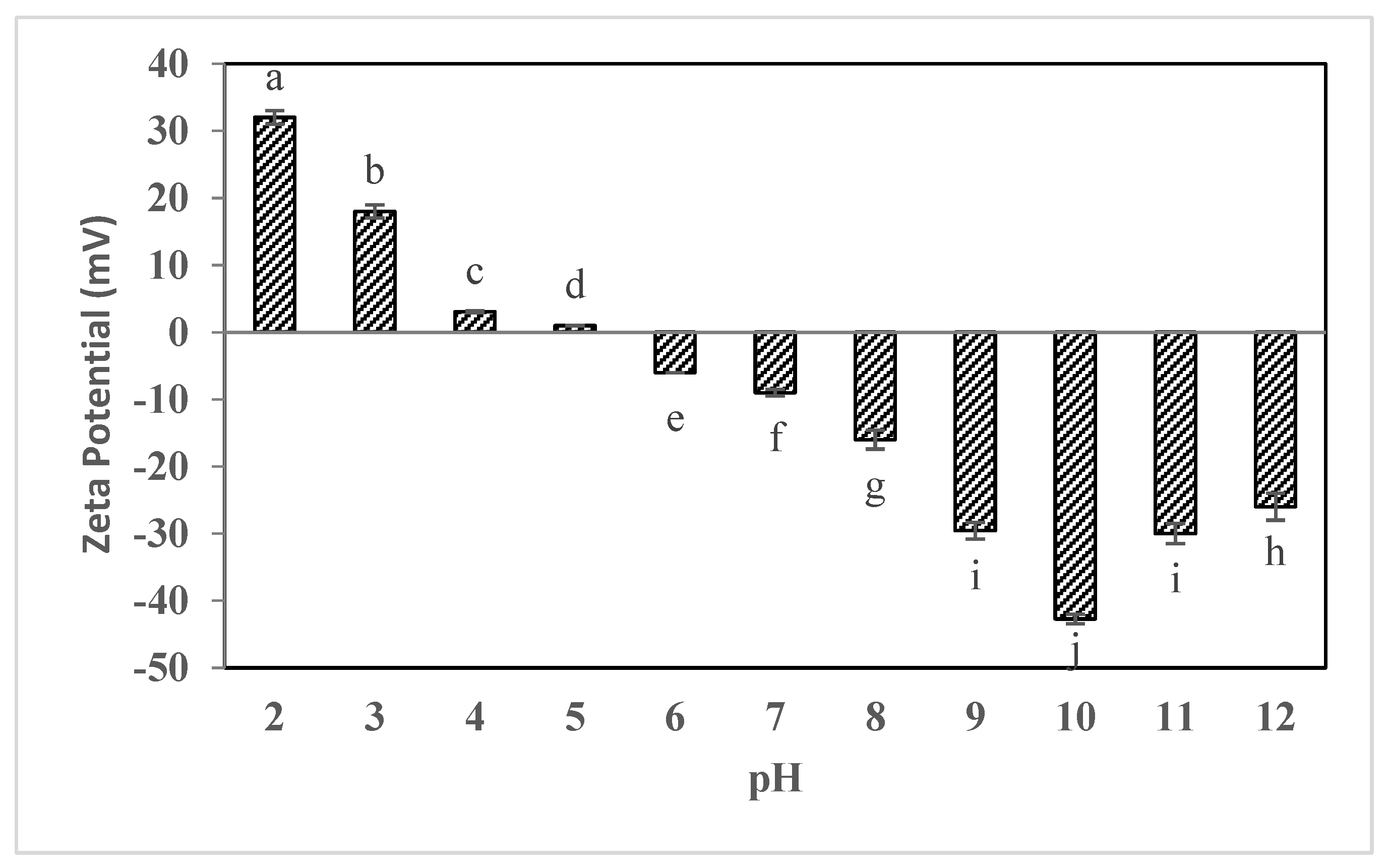

2.4. Zeta Potential of Sesame Seed Oleosomes

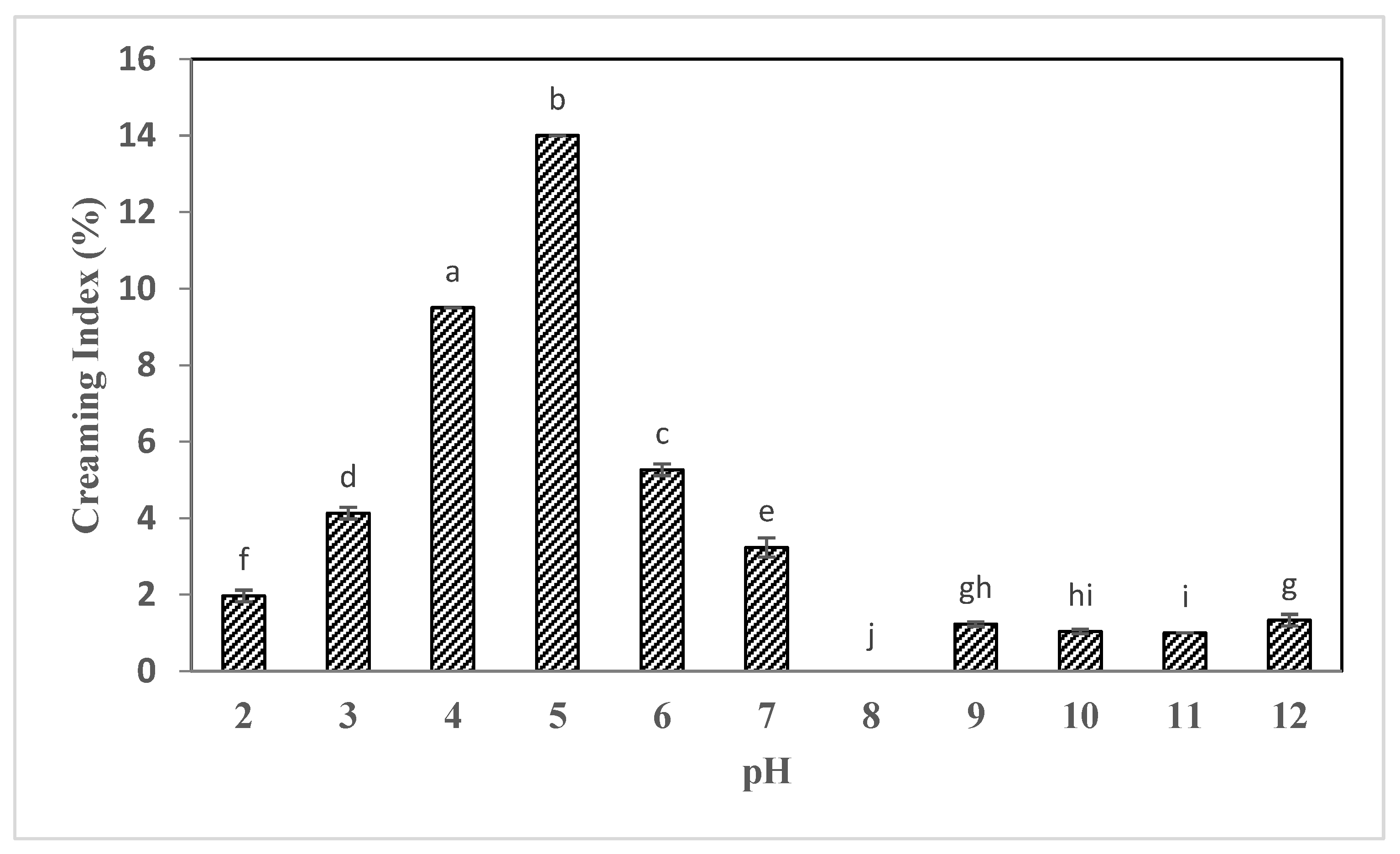

2.5. Creaming Index of Sesame Seed Oleosomes

2.6. Analysis of the Properties of Composite Gels

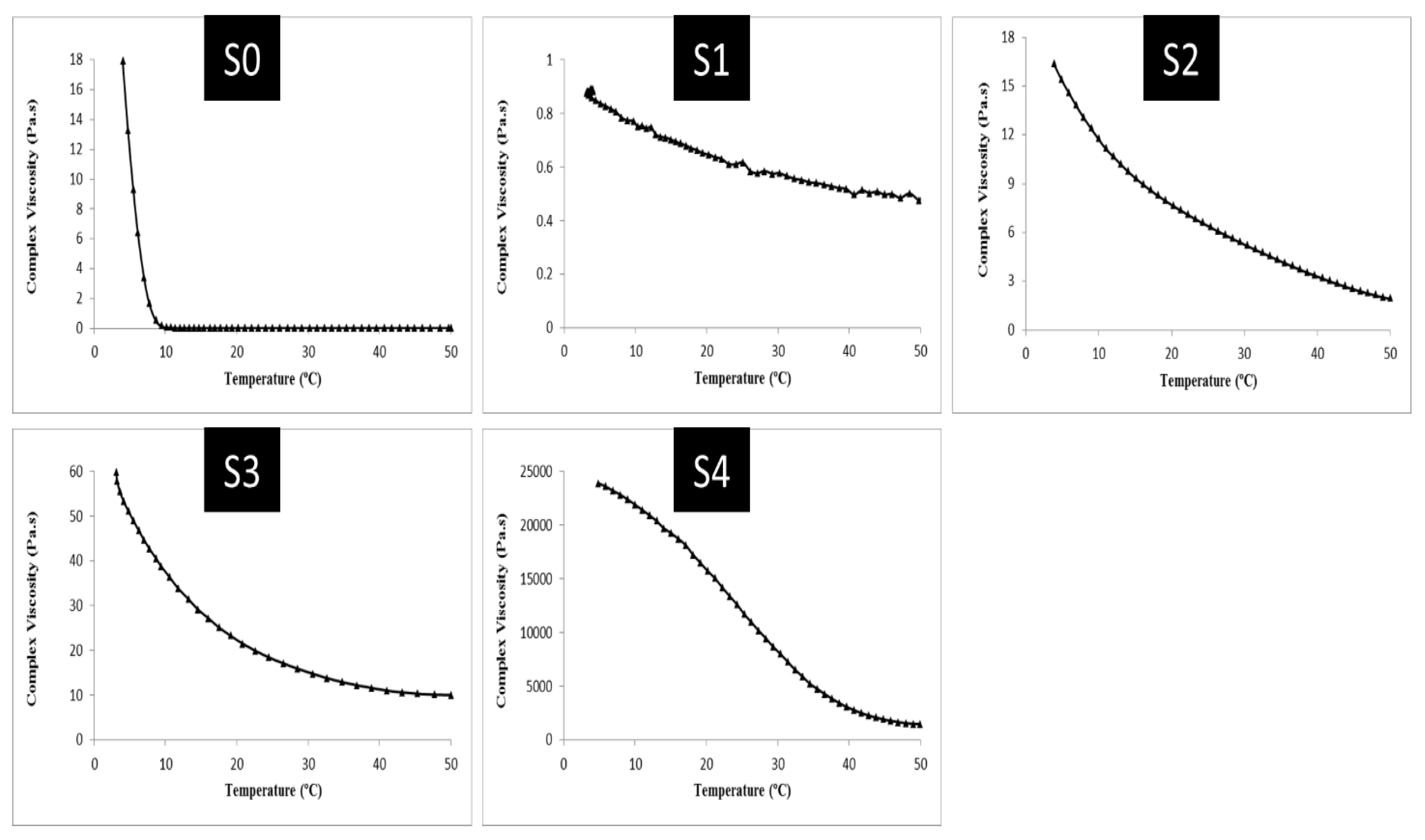

2.6.1. Rheological Properties of Composite Gels

2.6.2. Gel Texture

2.6.3. Microstructural Properties

3. Conclusions

4. Materials and Methods

4.1. Materials and Equipment

4.2. Physicochemical Characteristics of Sesame Seeds

4.3. Extraction of Sesame Seeds Protein and Determination of the Extraction Efficiency

4.4. Extraction of Sesame Seeds Oleosome and Extraction Efficiency

4.4.1. Determination of Oleosomes Protein

- VC = The volume of acid consumed for the control sample (mL)

- VS = The volume of acid consumed for the sample (mL)

- MS = Mass of sample in grams

4.4.2. Protein Characterization by Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

4.4.3. Measurement of Oleosome Fat

- MO = grams of oil extracted

- MS = weight of the sample in grams

4.4.4. Determination of Oleosome Moisture

4.4.5. Measurement of Oil Droplet Size and Polydispersity Index (PDI)

4.4.6. Determining the Zeta Potential of Oleosomes Surface

4.4.7. Determination of Creaming Indexes

4.4.8. Oleosomes Morphology

4.5. Preparation of Gel-Forming Samples

4.5.1. Temperature Scanning Test

4.5.2. Texture Analysis

4.5.3. Study of Gel Structure

4.6. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, J.; Wen, J.; Wang, J.; Tian, R.; Yu, L.; Jiang, L.; Zhang, Y.; Sui, X. The physicochemical properties and gastrointestinal fate of oleosomes from non-heated and heated soymilk. Food Hydrocoll. 2020, 100, 105418. [Google Scholar] [CrossRef]

- Abdullah, J.; Weiss, H.; Zhang, H. Recent advances in the composition, extraction and food applications of plant-derived oleosomes. Trends Food Sci. Technol. 2020, 106, 322–332. [Google Scholar] [CrossRef]

- Peng, C.C.; Lin, I.; Lin, C.K.; Tzen, J.T. Size and stability of reconstituted sesame oil bodies. Biotechnol. Prog. 2003, 19, 1623–1626. [Google Scholar] [CrossRef] [PubMed]

- Kirimlidou, M.; Matsakidou, A.; Scholten, E.; Nikiforidis, C.V.; Kiosseoglou, V. Composite gels structured by a gelatin protein matrix filled with oil bodies. Food Struct. 2017, 14, 46–51. [Google Scholar] [CrossRef]

- White, D.; Fisk, I.; Mitchell, J.; Wolf, B.; Hill, S.; Gray, D. Sunflower-seed oil body emulsions: Rheology and stability assessment of a natural emulsion. Food Hydrocoll. 2008, 22, 1224–1232. [Google Scholar] [CrossRef]

- Sala, G.; Van Aken, G.A.; Stuart, M.A.C.; Van De Velde, F. Effect of droplet– matrix interactions on large deformation properties of emulsion-filled gels. J. Texture Stud. 2007, 38, 511–535. [Google Scholar] [CrossRef]

- Oliver, L.; Wieck, L.; Scholten, E. Influence of matrix inhomogeneity on the rheological properties of emulsion-filled gels. Food Hydrocoll. 2016, 52, 116–125. [Google Scholar] [CrossRef]

- Chang, M.T.; Chen, C.R.; Liu, T.H.; Lee, C.P.; Tzen, J.T. Development of a protocol to solidify native and artificial oil bodies for long-term storage at room temperature. J. Sci. Food Agric. 2013, 93, 1516–1519. [Google Scholar] [CrossRef]

- Matsakidou, A.; Mantzouridou, F.T.; Kiosseoglou, V. Optimization of water extraction of naturally emulsified oil from maize germ. LWT-Food Sci. Technol. 2015, 63, 206–213. [Google Scholar] [CrossRef]

- Gallier, S.; Singh, H. Behavior of almond oil bodies during in vitro gastric and intestinal digestion. Food Funct. 2012, 3, 547–555. [Google Scholar] [CrossRef]

- Nikiforidis, C.V.; Matsakidou, A.; Kiosseoglou, V. Composition, properties and potential food applications of natural emulsions and cream materials based on oil bodies. RSC Adv. 2014, 4, 25067–25078. [Google Scholar] [CrossRef]

- Lopez, C.; Sotin, H.; Rabesona, H.; Novales, B.; Le Quéré, J.M.; Froissard, M.; Faure, J.D.; Guyot, S.; Anton, M. Oil Bodies from Chia (Salvia hispanica L.) and Camelina (Camelina sativa L.) Seeds for Innovative Food Applications: Microstructure, Composition and Physical Stability. Foods 2023, 12, 211. [Google Scholar] [CrossRef] [PubMed]

- Yang, N.; Feng, Y.; Su, C.; Wang, Q.; Zhang, Y.; Wei, Y.; Zhao, M.; Nishinari, K.; Fang, Y. Structure and tribology of κ-carrageenan gels filled with natural oil bodies. Food Hydrocoll. 2020, 107, 105945. [Google Scholar] [CrossRef]

- Nikiforidis, C.V. Structure and functions of oleosomes (oil bodies). Adv. Colloid Interface Sci. 2019, 274, 102039. [Google Scholar] [CrossRef]

- Hou, J.; Li, T.; Miao, L. Dynamic responses of community structure and microbial functions of periphytic biofilms during chronic exposure to TiO2 NPs. Environ. Sci. Nano 2020, 7, 665–675. [Google Scholar] [CrossRef]

- Cao, Y.; Zhao, L.; Ying, Y.; Kong, X.; Hua, Y.; Chen, Y. The characterization of soybean oil body integral oleosin isoforms and the effects of alkaline pH on them. Food Chem. 2015, 177, 288–294. [Google Scholar] [CrossRef]

- Sukhotu, R.; Guo, S.; Xing, J.; Hu, Q.I.; Wang, R.; Shi, X.; Nishinari, K.; Fang, Y.; Guo, S. Changes in physiochemical properties and stability of peanut oil body emulsions by applying gum arabic. LWT-Food Sci. Technol. 2016, 68, 432–438. [Google Scholar] [CrossRef]

- McClements, D.J. Theoretical analysis of factors affecting the formation and stability of multilayered colloidal dispersions. Langmuir 2005, 21, 9777–9785. [Google Scholar] [CrossRef]

- Wang, W.; Cui, C.; Wang, Q.; Sun, C.; Jiang, L.; Hou, J. Effect of pH on physicochemical properties of oil bodies from different oil crops. J. Food Sci. Technol. 2019, 56, 49–58. [Google Scholar] [CrossRef]

- Iwanaga, D.; Gray, D.A.; Decker, E.A.; Weiss, J.; McClements, D.J. Stabilization of soybean oil bodies using protective pectin coatings formed by electrostatic deposition. J. Agric. Food Chem. 2008, 56, 2240–2245. [Google Scholar] [CrossRef]

- Nantiyakul, N.; Furse, S.; Fisk, I.D.; Tucker, G.; Gray, D.A. Isolation and characterization of oil bodies from Oryza sativa bran and studies of their physical properties. J. Cereal Sci. 2013, 57, 141–145. [Google Scholar] [CrossRef]

- Nikiforidis, C.V.; Kiosseoglou, V. Aqueous extraction of oil bodies from maize germ (Zea mays) and characterization of the resulting natural oil-inwater emulsion. J. Agric. Food Chem. 2009, 57, 5591–5596. [Google Scholar] [CrossRef] [PubMed]

- Sukhotu, R.; Shi, X.; Hu, Q.; Nishinari, K.; Fang, Y.; Guo, S. Aggregation behavior and stability of maize germ oil body suspension. Food Chem. 2014, 164, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Tzen, J.T.C.; Cao, Y.Z.; Laurent, P.; Ratnayaka, C.; Huang, A.H.C. Lipid, proteins, and structure of seed oil bodies from diverse species. Plant Physiol. 1993, 101, 267–276. [Google Scholar] [CrossRef]

- Qi, B.; Ding, J.; Wang, Z.; Li, Y.; Ma, C.; Chen, F.; Sui, X.; Jiang, L. Deciphering the characteristics of soybean oleosome-associated protein in maintaining the stability of oleosomes as affected by pH. Food Res. Int. 2017, 100, 551–557. [Google Scholar] [CrossRef]

- Van Vliet, T. Rheology and Fracture Mechanics of Foods, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013; p. 363. [Google Scholar]

- Abouei, E.; Jafarpour, A.; Motamed zadegan, A. Effects of microbial transglutaminase (MTGase) on functional and rheological properties of big head (Hypophtalmichthys nobilis) fish skin gelatin. J. Food Sci. Technol. 2016, 58, 93–106. [Google Scholar]

- Sheikh, F.; Hasani, M.; Kiani, H.; Asadollahzadeh, M.J.; Seyfi, J. Evaluation of rheological and textural structure of composite gels using oleosome. and sesame seed protein. Food Eng. Res. 2022, 21, 151–168. [Google Scholar]

- Gómez-Arellano, A.; Jiménez-Islas, H.; Omar Castrejón-González, E.; Medina-Torres, L.; Dendoovenc, L.; Escamilla-Silva, E. Rheological behavior of sesame (Sesamum indicum L.) protein dispersions. Food Bioprod. Process. 2017, 106, 201–208. [Google Scholar] [CrossRef]

- Clark, A.H.; Richardson, R.K.; Robinson, G.; Ross-Murphy, S.B.; Weaver, A.C. Structure and mechanical properties of agar/BSA co-gels. Prog. Food. Nutr. Sci. 1982, 6, 149–160. [Google Scholar]

- Pang, Z.; Deeth, H.; Sopade, P.; Sharma, R.; Bansal, N. Rheology, texture and microstructure of gelatin gels with and without milk proteins. Food Hydrocoll. 2014, 35, 484–493. [Google Scholar] [CrossRef]

- Morris, E.R. Shear-thinning of ‘random coil’ polysaccharides: Characterisation by two parameters from a simple linear plot. Carbohydr. Polym. 1990, 13, 85–96. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Zhao, X.H. Cross-linking of soybean proteins by transglutaminase in the presence of gelatin to improve their rheological properties. In Proceedings of the International Conference on New Technology of Agricultural, Zibo, China, 27 May 2011; pp. 910–913. [Google Scholar]

- Zhou, X.; Chen, H.; Lyu, F.; Lin, H.; Zhang, Q.; Ding, Y. Physicochemical properties and microstructure of fish myofibrillar protein-lipid composite gels: Effects of fat type and concentration. Food Hydrocoll. 2019, 90, 433–442. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Acevedo, N.C. Effects of pre-heating soybean protein isolate and transglutaminase treatments on the properties of egg-soybean protein isolate composite gels. Food Chem. 2020, 318, 126421. [Google Scholar] [CrossRef]

- Liao, Y.; Sun, Y.; Wang, Z.; Zhong, M.; Li, R.; Yan, S.; Qi, B.; Li, Y. Structure, rheology, and functionality of emulsion-filled gels: Effect of various oil body concentrations and interfacial compositions. Food Chem. 2022, 16, 100509. [Google Scholar] [CrossRef]

- Feng, L.; Jia, X.; Yan, J.; Yan, W.; Yin, L. Mechanical, thermal stability and microstructural properties of emulsion-filled gels: Effect of sugar beet pectin/soy protein isolate ratio. LWT 2021, 141, 110917. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis; Association of Official Analytical Chemists: Washington, DC, USA, 2012. [Google Scholar]

- Elleuch, M.; Besbes, S.; Roiseux, O.; Blecker, C.; Hamadi, A. Quality characteristics of sesame seeds and by-products. Food Chem. 2007, 103, 641–650. [Google Scholar] [CrossRef]

- El-Adawy, T. Effect of sesame seed protein supplementation on the nutritional, Physical, chemical and sensory properties of wheat flour bread. Food Chem. 1997, 59, 7–14. [Google Scholar] [CrossRef]

- Ntone, E.; Bitter, J.H.; Nikiforidis, C.V. Not sequentially but simultaneously: Facile extraction of proteins and oleosomes from oilseeds. Food Hydrocoll. 2020, 102, 105598. [Google Scholar] [CrossRef]

- Sheikh, F.; Hasani, M.; Kiani, H.; JavadAsadollahzadeh, M.J.; Seyfi, J. Investigation of textural, rheological and sensory properties of white cheese analog containing sesame seeds oleosome. J. Food Meas. Charact. 2023, 17, 63–74. [Google Scholar] [CrossRef]

- Xu, D.; Gao, Q.; Ma, N.; Yuan, Y.; Zhang, M.; Cao, Y.; Ho, C. Structures and physicochemical characterization of enzyme extracted oil bodies from rice bran. LWT-Food Sci. Technol. 2021, 135, 109982. [Google Scholar] [CrossRef]

- Romero-Guzmán, M.J.; Köllmann, N.; Zhang, L.; Boom, R.M.; Nikiforidis, C.V. Controlled oleosome extraction to produce a plant-based mayonnaise-like emulsion using solely rapeseed seeds. LWT-Food Sci. Technol. 2020, 123, 109120. [Google Scholar] [CrossRef]

- Hong, I.K.; Kim, S.I.; Lee, S.B. Effects of HLB value on oil-in-water emulsions: Droplet size, rheological behavior, zeta-potential, and creaming index. J. Ind. Eng. Chem. 2018, 67, 123–131. [Google Scholar] [CrossRef]

- Altuna, F.I.; Pettarin, V.; Williams, R.J. Self-healable polymer networks based on the cross-linking of epoxidised soybean oil by an aqueous citric acid solution. Green Chem. 2013, 15, 3360–3366. [Google Scholar] [CrossRef]

- Motamedzadegan, A.; Shahidi, S.A.; Hosseini parvar, S.H.; Ebdali, S. Evaluation effects of gelatins types on functional properties of fat free set style yogurt. J. Food Sci. Technol. 2015, 12, 221–230. [Google Scholar]

| Parameter | Breaking Force (N) | Adhesiveness (Kgf.s) | Hardness (N) | |

|---|---|---|---|---|

| Treatment | ||||

| S0 | 0.00 b ± 0.05 | 0.00 d ± 0.07 | 0.00 d ± 0.24 | |

| S1 | 0.01 b ± 0.05 | 0.01 c ± 0.08 | 0.01 e ± 0.22 | |

| S2 | 0.02 b ± 0.07 | 0.01 a ± 0.22 | 0.01 c ± 0.44 | |

| S3 | 0.03 b ± 0.08 | 0.01 a ± 0.21 | 0.07 b ± 0.61 | |

| S4 | 0.02 a ± 0.17 | 0.01 b ± 0.18 | 0.02 a ± 1.29 | |

| Samples | Water (g) | Gelatin (g) | Sesame Protein (g) | Sesame Protein/Gelatin | Sesame Seed Oleosome (% Based on Total Mass) |

|---|---|---|---|---|---|

| S0 | 96 | 4 | - | 0:100 | - |

| S1 | 96 | 2 | 2 | 50:50 | - |

| S2 | 86 | 2 | 2 | 50:50 | 10 |

| S3 | 76 | 2 | 2 | 50:50 | 20 |

| S4 | 66 | 2 | 2 | 50:50 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheikh, F.; Hasani, M.; Kiani, H.; Asadollahzadeh, M.J.; Sabbagh, F. Enhancing Rheological and Textural Properties of Gelatin-Based Composite Gels through Incorporation of Sesame Seed Oleosome-Protein Fillers. Gels 2023, 9, 774. https://doi.org/10.3390/gels9100774

Sheikh F, Hasani M, Kiani H, Asadollahzadeh MJ, Sabbagh F. Enhancing Rheological and Textural Properties of Gelatin-Based Composite Gels through Incorporation of Sesame Seed Oleosome-Protein Fillers. Gels. 2023; 9(10):774. https://doi.org/10.3390/gels9100774

Chicago/Turabian StyleSheikh, Fatemeh, Maryam Hasani, Hossein Kiani, Mohammad Javad Asadollahzadeh, and Farzaneh Sabbagh. 2023. "Enhancing Rheological and Textural Properties of Gelatin-Based Composite Gels through Incorporation of Sesame Seed Oleosome-Protein Fillers" Gels 9, no. 10: 774. https://doi.org/10.3390/gels9100774

APA StyleSheikh, F., Hasani, M., Kiani, H., Asadollahzadeh, M. J., & Sabbagh, F. (2023). Enhancing Rheological and Textural Properties of Gelatin-Based Composite Gels through Incorporation of Sesame Seed Oleosome-Protein Fillers. Gels, 9(10), 774. https://doi.org/10.3390/gels9100774