A Comparative Assessment of Different Aerogel-Insulated Building Walls for Enhanced Thermal Insulation Performance

Abstract

:1. Introduction

2. Results and Discussion

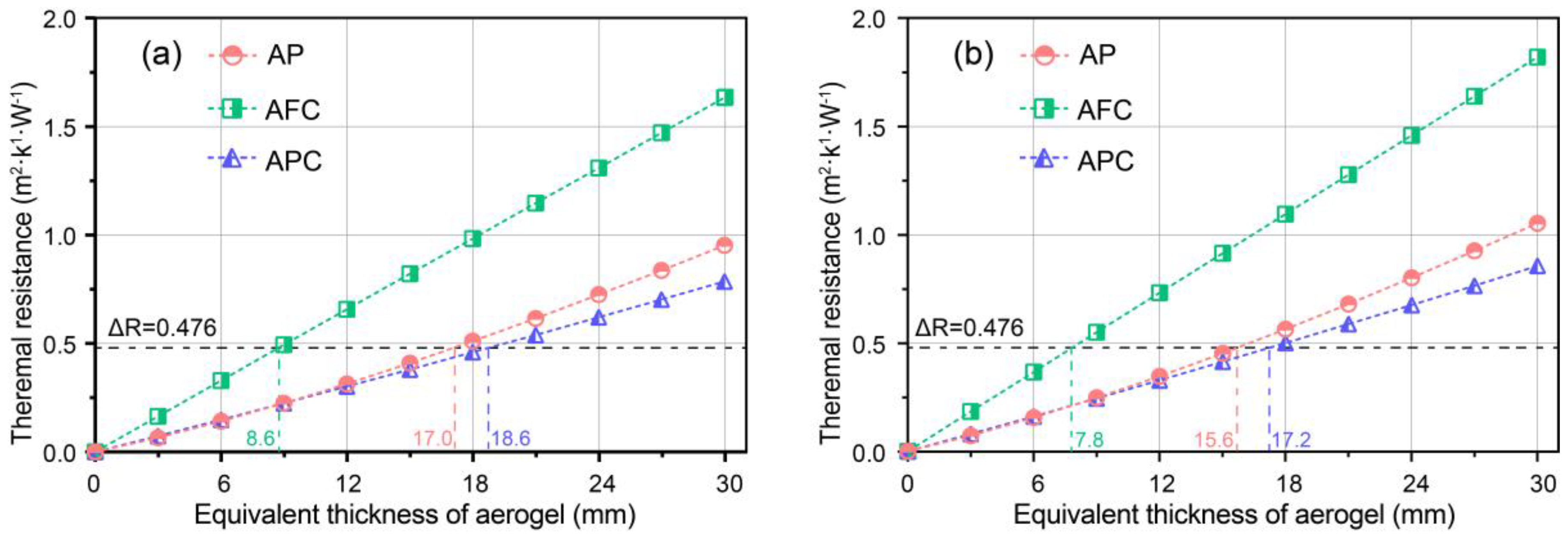

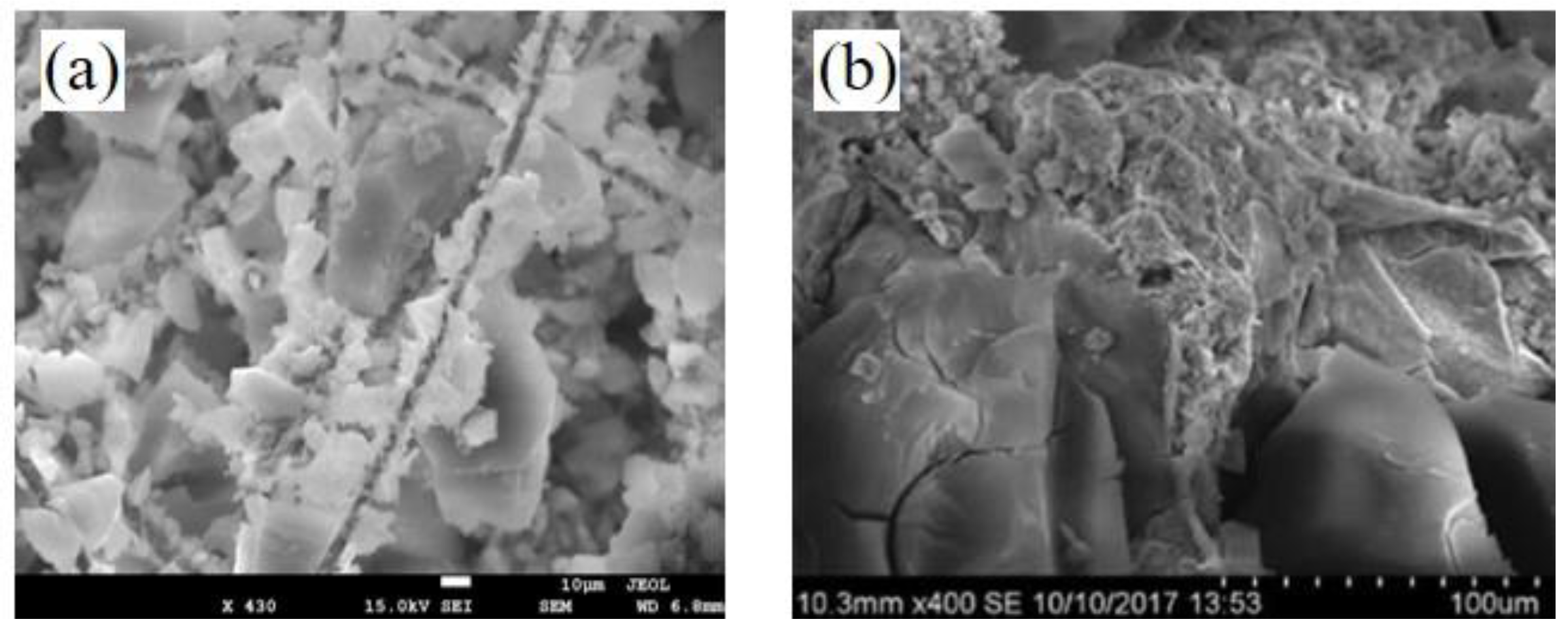

2.1. Predicting Effective Thermal Conductivity and Thermal Resistance of Aerogel-Insulated Structures

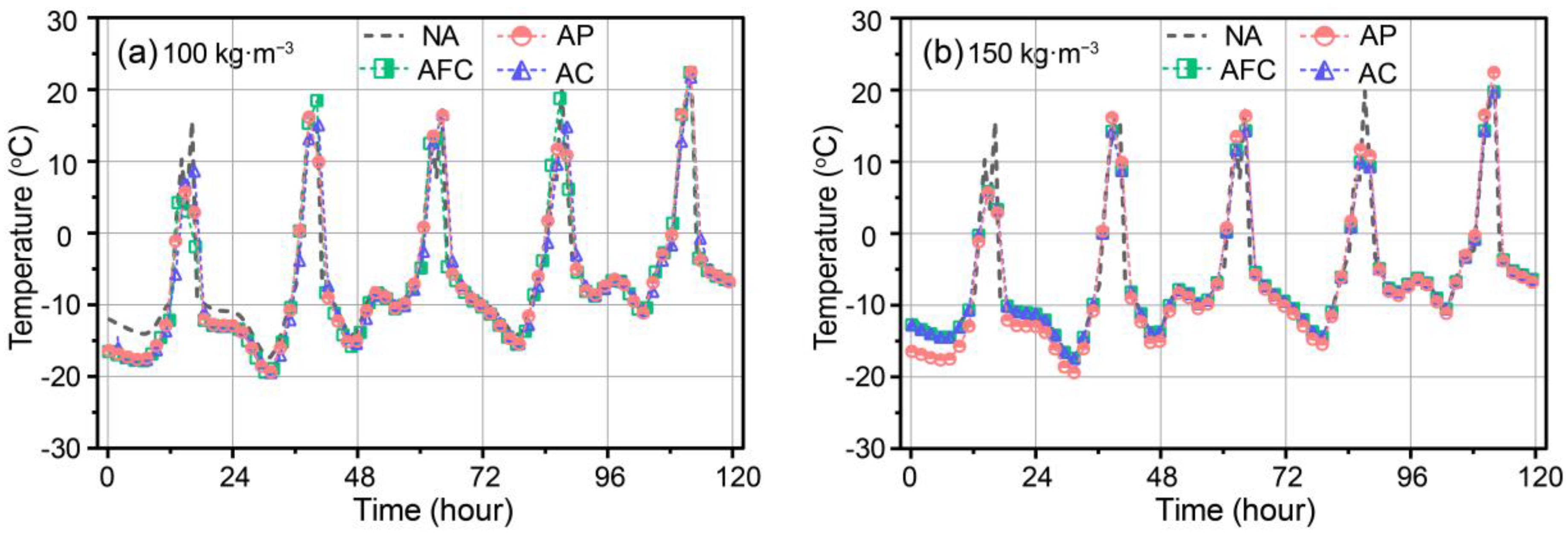

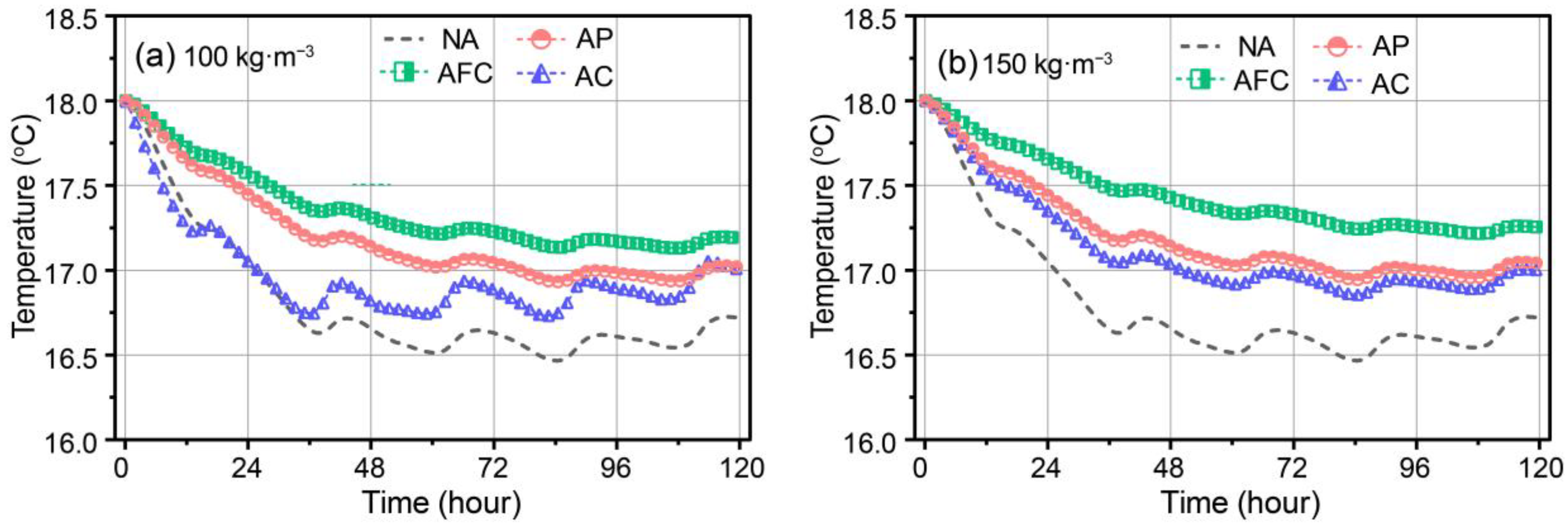

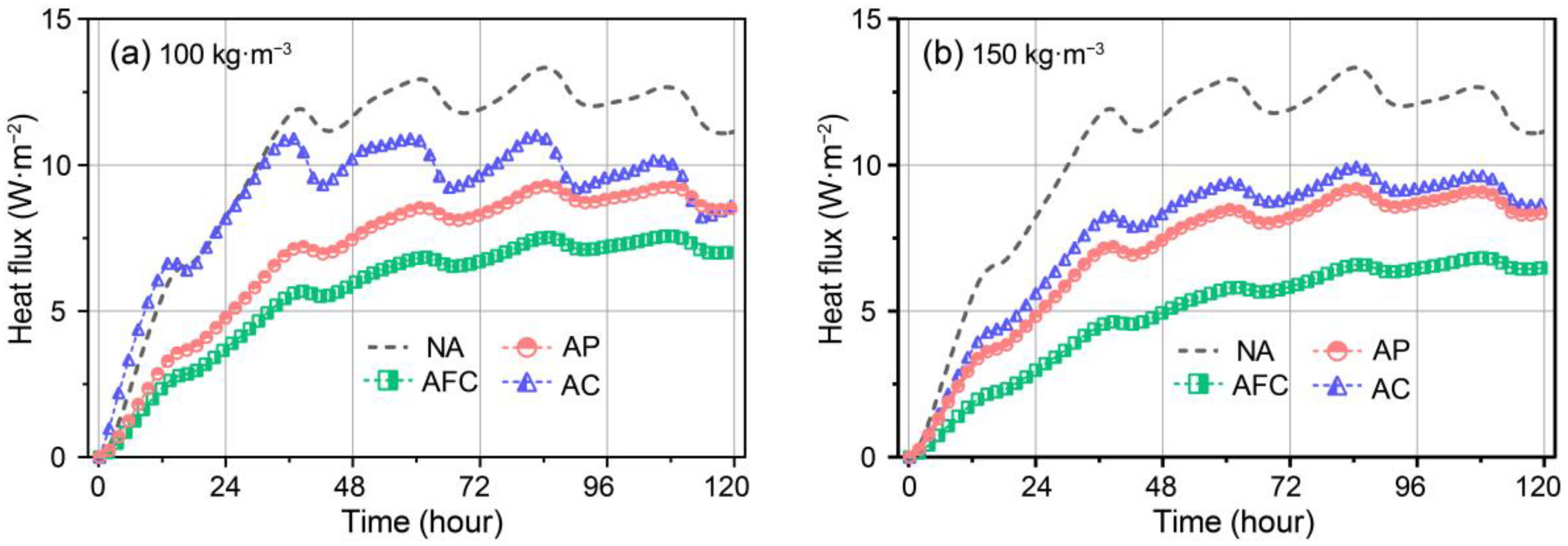

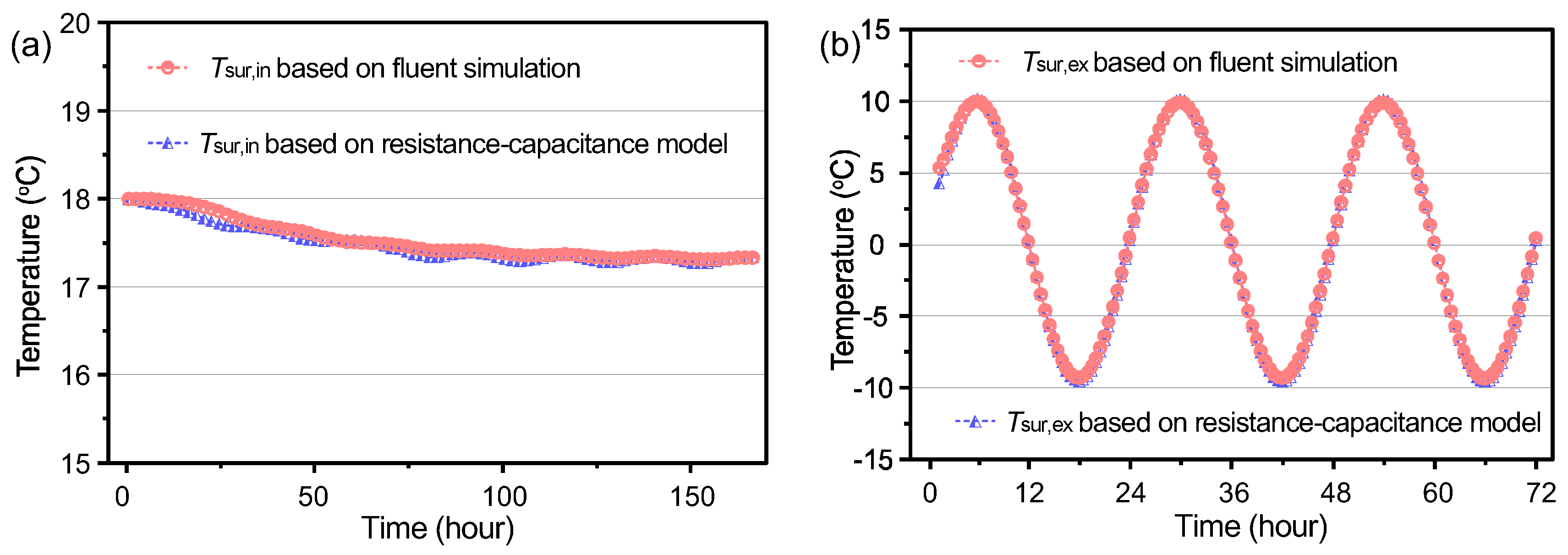

2.2. Modelling Transient Thermal Performance of Aerogel-Insulated Walls

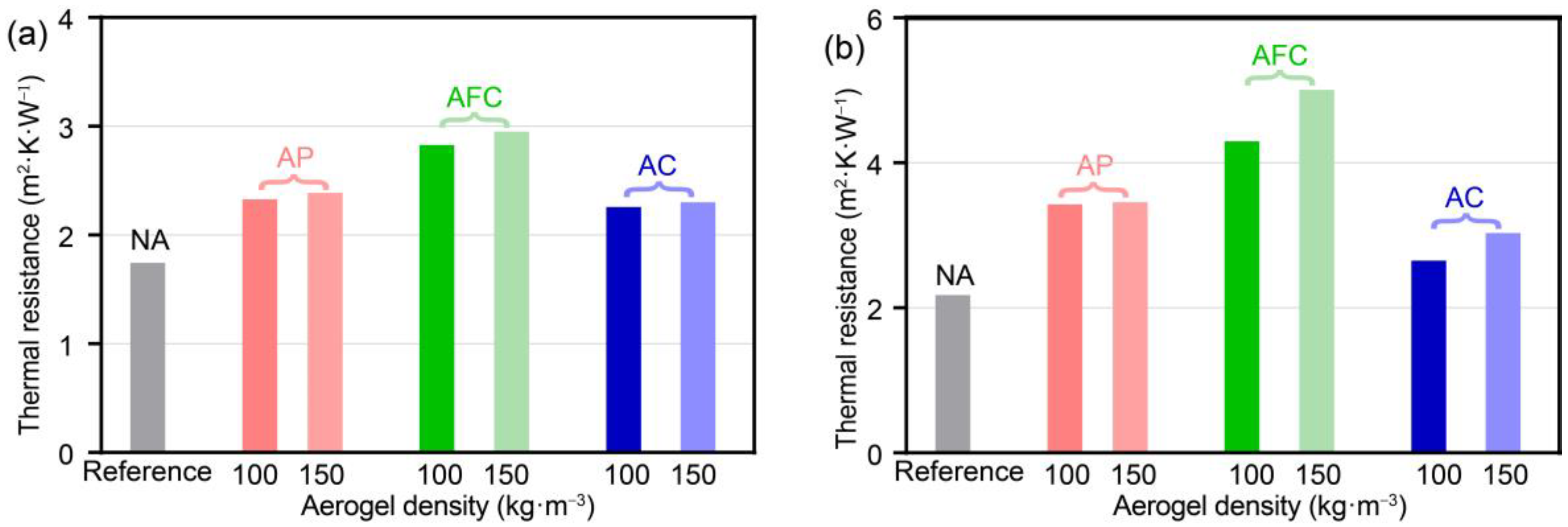

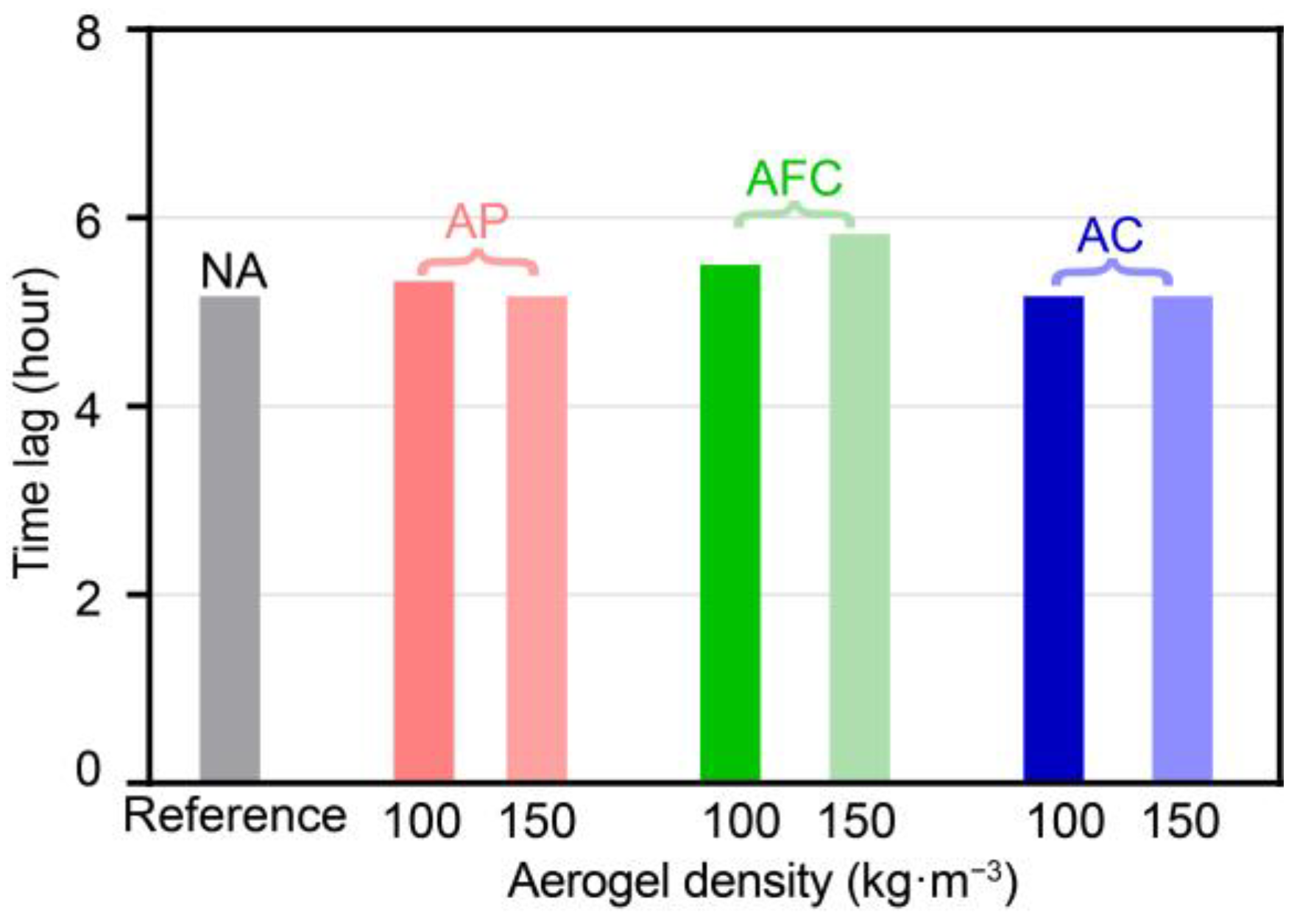

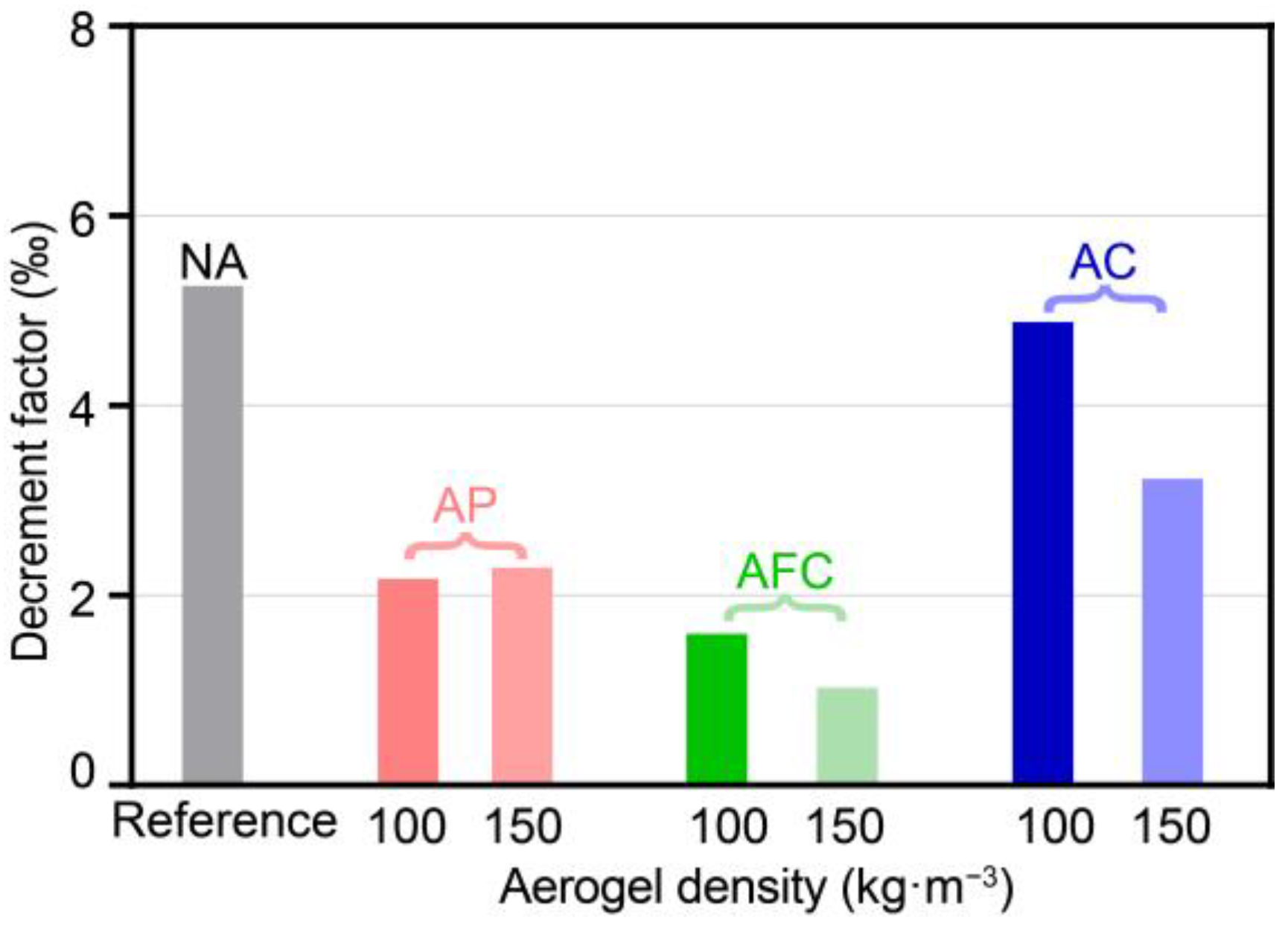

2.3. Comparing Thermal Insulation Index of Different Aerogel-Insulated Walls

3. Conclusions

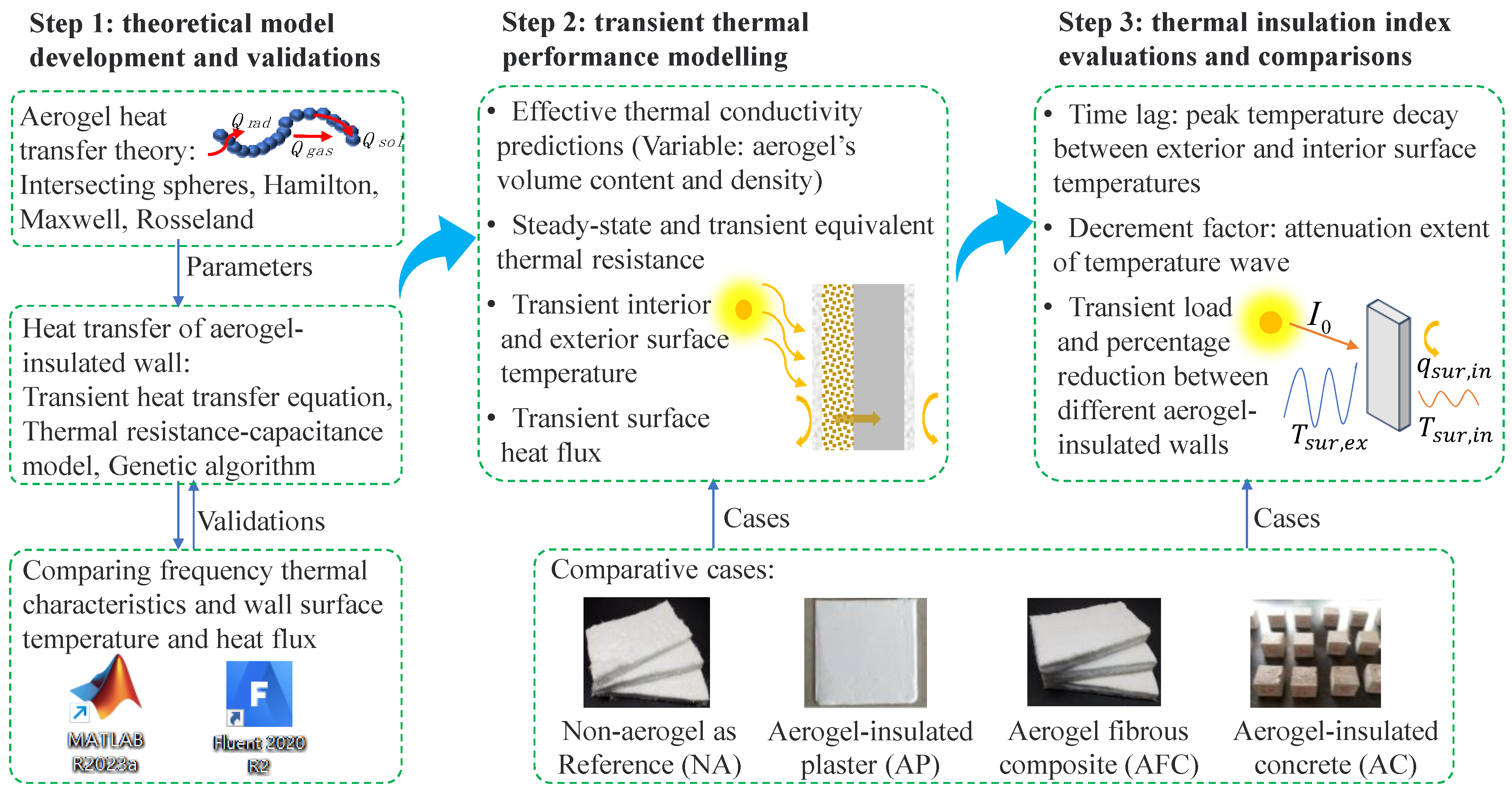

4. Methodology

4.1. Overview of the Methodology

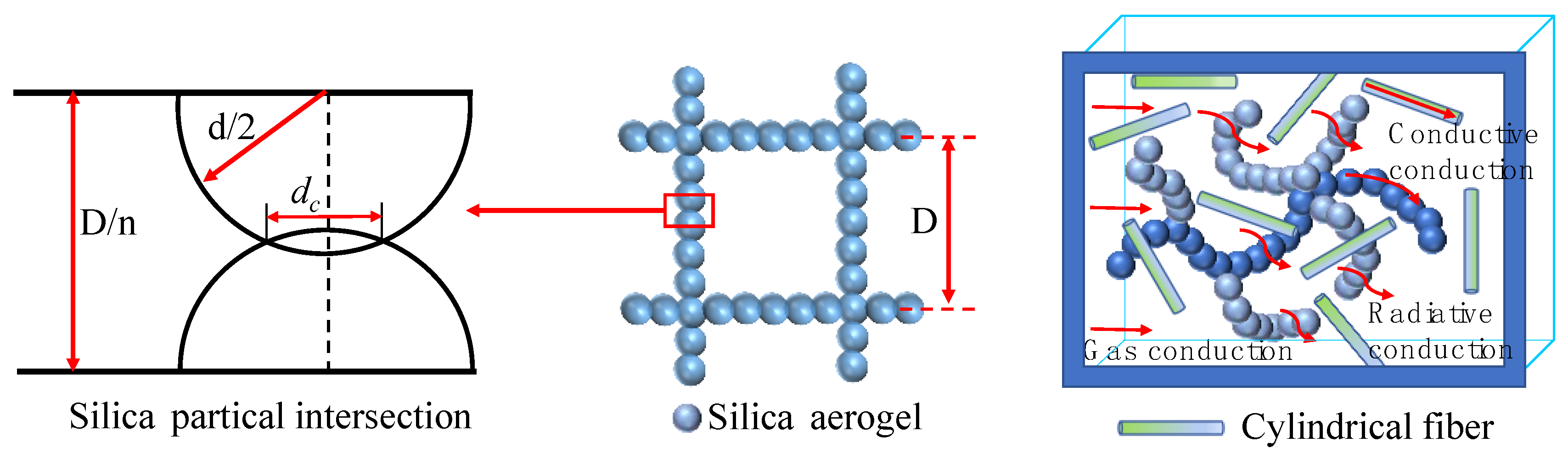

4.2. Heat Transfer Model of Aerogel-Insulated Structures

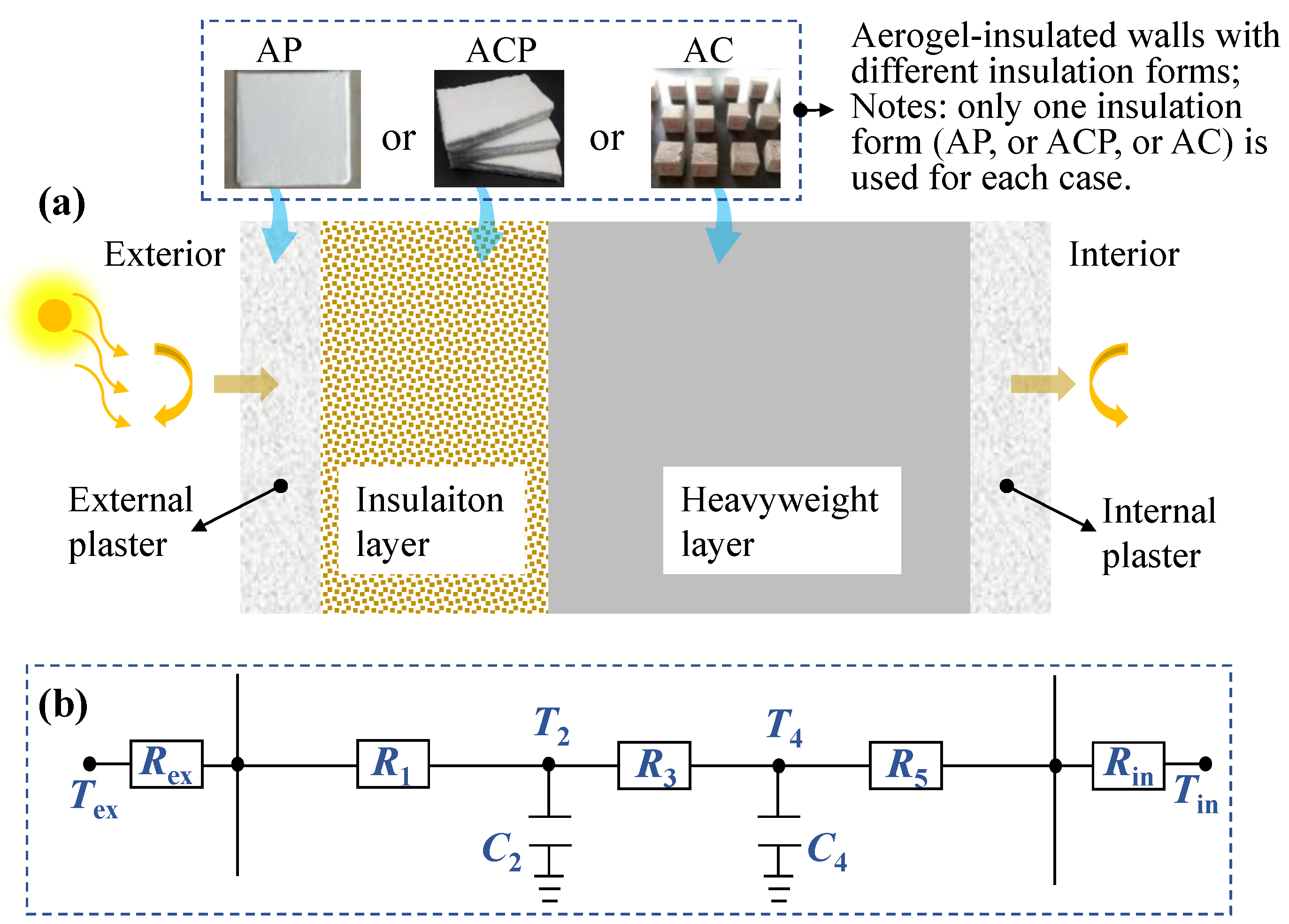

4.3. Development of Thermal Resistance-Capacitance Model for Insulation Performance of Aerogel-Insulated Walls

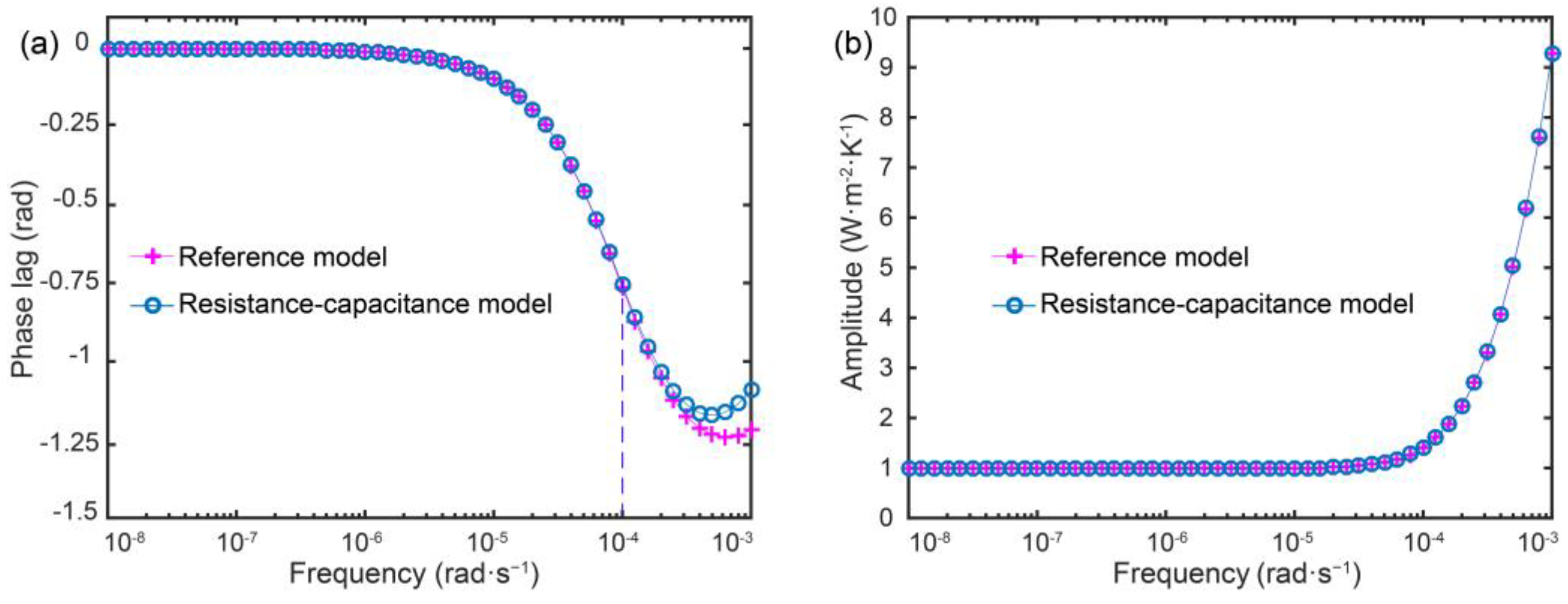

5. Validation of the Theoretical Method

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Booten, C.; Rao, P.; Rapp, V.; Jackson, R.; Prasher, R. Theoretical minimum thermal load in buildings. Joule 2021, 5, 24–46. [Google Scholar] [CrossRef]

- Karanafti, A.; Theodosiou, T.; Tsikaloudaki, K. Assessment of buildings’ dynamic thermal insulation technologies—A review. Appl. Energy 2022, 326, 119985. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, K.; Wang, X.; Huan, S.; Yang, H.; Wang, C. Low-cost, superhydrophobic, flame-retardant sunflower straw-based xerogel as thermal insulation materials for energy-efficient buildings. Sustain. Mater. Technol. 2023, 38, e00748. [Google Scholar] [CrossRef]

- Pontinha, A.D.R.; Mäntyneva, J.; Santos, P.; Durães, L. Thermomechanical Performance Assessment of Sustainable Buildings: Insulating Materials under Accelerated Ageing Conditions. Gels 2023, 9, 241. [Google Scholar] [CrossRef]

- De Guinoa, A.S.; Zambrana-Vasquez, D.; Alcalde, A.; Corradini, M.; Zabalza-Bribián, I. Environmental assessment of a nano-technological aerogel-based panel for building insulation. J. Clean. Prod. 2017, 161, 1404–1415. [Google Scholar] [CrossRef]

- Zhao, S.; Siqueira, G.; Drdova, S.; Norris, D.; Ubert, C.; Bonnin, A.; Galmarini, S.; Ganobjak, M.; Pan, Z.; Brunner, S. Additive manufacturing of silica aerogels. Nature 2020, 584, 387–392. [Google Scholar] [CrossRef]

- Aegerter, M.A.; Leventis, N.; Koebel, M.M. Aerogels Handbook; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Thie, C.; Quallen, S.; Ibrahim, A.; Xing, T.; Johnson, B. Study of Energy Saving Using Silica Aerogel Insulation in a Residential Building. Gels 2023, 9, 86. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Z.; Song, S.; You, Q.; Cui, S.; Shen, W.; Wang, G.; Zhang, X.; Zhu, X. Facile Preparation of a Novel HfC Aerogel with Low Thermal Conductivity and Excellent Mechanical Properties. Gels 2023, 9, 839. [Google Scholar] [CrossRef]

- Berardi, U. Aerogel-enhanced systems for building energy retrofits: Insights from a case study. Energy Build. 2018, 159, 370–381. [Google Scholar] [CrossRef]

- He, S.; Wu, X.; Zhang, X.; Sun, J.; Tian, F.; Guo, S.; Du, H.; Li, P.; Huang, Y. Preparation and properties of thermal insulation coating based on silica aerogel. Energy Build. 2023, 298, 113556. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; Huang, G.; Liang, Y.; Liao, Y. Modeling and coupling effect evaluation of thermal conductivity of ternary opacifier/fiber/aerogel composites for super-thermal insulation. Mater. Des. 2017, 133, 224–236. [Google Scholar] [CrossRef]

- Rong, X.; Zhang, X.; Zhang, J.; Xu, W.; Zhang, Z. Study on mechanical and thermal properties of alkali-excited fly ash aerogel foam concrete. Constr. Build. Mater. 2023, 408, 133770. [Google Scholar] [CrossRef]

- Lamy-Mendes, A.; Pontinha, A.D.R.; Alves, P.; Santos, P.; Durães, L. Progress in silica aerogel-containing materials for buildings’ thermal insulation. Constr. Build. Mater. 2021, 286, 122815. [Google Scholar] [CrossRef]

- Pedroso, M.; Silvestre, J.D.; Gomes, M.G.; Bersch, J.D.; Flores-Colen, I. Application of Silica-Aerogel-Fibre-Based Thermal Renders for Retrofits in Building Walls: A Comparative Assessment with Benchmark Solutions. Gels 2023, 9, 861. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.; Biwole, P.H.; Wurtz, E.; Achard, P. A study on the thermal performance of exterior walls covered with a recently patented silica-aerogel-based insulating coating. Build. Environ. 2014, 81, 112–122. [Google Scholar] [CrossRef]

- Ibrahim, M.; Biwole, P.H.; Achard, P.; Wurtz, E.; Ansart, G. Building envelope with a new aerogel-based insulating rendering: Experimental and numerical study, cost analysis, and thickness optimization. Appl. Energy 2015, 159, 490–501. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; He, S.; Wang, M. Prediction of thermal conductivity of fiber/aerogel composites for optimal thermal insulation. J. Porous Media 2015, 18, 971–984. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Zhang, Z.; Shi, Y.; Zhao, Y.; Shen, S.; Yao, X.; Shen, J. A Facile Method for Fabricating a Monolithic Mullite Fiber-Reinforced Alumina Aerogel with Excellent Mechanical and Thermal Properties. Gels 2022, 8, 380. [Google Scholar] [CrossRef]

- Zhou, J.; Hsieh, Y.-L. Nanocellulose aerogel-based porous coaxial fibers for thermal insulation. Nano Energy 2020, 68, 104305. [Google Scholar] [CrossRef]

- Joly, M.; Bourdoukan, P.; Ibrahim, M.; Stipetic, M.; Dantz, S.; Nocentini, K.; Aulagnier, M.; Caiazzo, F.G.; Fiorentino, B. Competitive high performance Aerogel-Based Composite material for the European insulation market. Energy Procedia 2017, 122, 859–864. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; Xu, X.; Huang, G.; Xu, T.; Guo, S.; Liang, Y. Numerical and experimental study on the thermal performance of aerogel insulating panels for building energy efficiency. Renew. Energy 2019, 138, 445–457. [Google Scholar] [CrossRef]

- Welsch, T.; Vievers, Y.; Schnellenbach-Held, M.; Bialuschewski, D.; Milow, B. Comparison of Different Aerogel Granules for Use as Aggregate in Concrete. Gels 2023, 9, 406. [Google Scholar] [CrossRef] [PubMed]

- Fickler, S.; Milow, B.; Ratke, L.; Schnellenbach-Held, M.; Welsch, T. Development of High Performance Aerogel Concrete. Energy Procedia 2015, 78, 406–411. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, K.; Cui, S.; Shen, X.; Tan, G. A novel building material with low thermal conductivity: Rapid synthesis of foam concrete reinforced silica aerogel and energy performance simulation. Energy Build. 2018, 177, 385–393. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Yang, J.M.; Wu, H.J.; Fu, P.; Liu, Y.C.; Yang, W.B. Dynamic thermal performance of ultra-light and thermal-insulative aerogel foamed concrete for building energy efficiency. Sol. Energy 2020, 204, 569–576. [Google Scholar] [CrossRef]

- Liang, Y.; Wu, H.; Huang, G.; Yang, J.; Wang, H. Thermal performance and service life of vacuum insulation panels with aerogel composite cores. Energy Build. 2017, 154, 606–617. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Lin, D.; Li, Y.; Worsley, M.A. Aerogels, additive manufacturing, and energy storage. Joule 2023, 7, 866–883. [Google Scholar] [CrossRef]

- Feng, J.; Feng, J.; Zhang, C. Thermal conductivity of low density carbon aerogels. J. Porous Mater. 2012, 19, 551–556. [Google Scholar] [CrossRef]

- Acquaroli, L.N.; Newby, P.; Santato, C.; Peter, Y.-A. Thermal properties of methyltrimethoxysilane aerogel thin films. AIP Adv. 2016, 6, 105007. [Google Scholar] [CrossRef]

- Merillas, B.; Villafañe, F.; Rodríguez-Pérez, M.Á. Super-Insulating Transparent Polyisocyanurate-Polyurethane Aerogels: Analysis of Thermal Conductivity and Mechanical Properties. Nanomaterials 2022, 12, 2409. [Google Scholar] [CrossRef]

- Wu, H.; Liang, Y.; Yang, J.; Cen, J.; Zhang, X.; Xiao, L.; Cao, R.; Huang, G. Engineering a superinsulating wall with a beneficial thermal nonuniformity factor to improve building energy efficiency. Energy Build. 2022, 256, 111680. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. An experimental evaluation of thermal behavior of the building envelope using macroencapsulated PCM for energy savings. Renew. Energy 2020, 149, 1300–1313. [Google Scholar] [CrossRef]

- Yang, J.; Lin, Z.; Wu, H.; Chen, Q.; Xu, X.; Huang, G.; Fan, L.; Shen, X.; Gan, K. Inverse optimization of building thermal resistance and capacitance for minimizing air conditioning loads. Renew. Energy 2020, 148, 975–986. [Google Scholar] [CrossRef]

- Lamy-Mendes, A.; Pontinha, A.D.R.; Santos, P.; Durães, L. Aerogel Composites Produced from Silica and Recycled Rubber Sols for Thermal Insulation. Materials 2022, 15, 7897. [Google Scholar] [CrossRef]

- Li, P.; Wu, H.; Liu, Y.; Yang, J.; Fang, Z.; Lin, B. Preparation and optimization of ultra-light and thermal insulative aerogel foam concrete. Constr. Build. Mater. 2019, 205, 529–542. [Google Scholar] [CrossRef]

- Kossecka, E.; Kosny, J. Influence of insulation configuration on heating and cooling loads in a continuously used building. Energy Build. 2002, 34, 321–331. [Google Scholar] [CrossRef]

- Zeng, S.Q.; Hunt, A.; Greif, R. Mean Free Path and Apparent Thermal Conductivity of a Gas in a Porous Medium. J. Heat Transf. 1995, 117, 3. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Tian, Y.; Jiao, J.; Wu, X. Thermal Insulation Performance of Silica Aerogel Composites Doped with Hollow Opacifiers: Theoretical Approach. Gels 2022, 8, 295. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; Wang, M.; Liang, Y. Prediction and optimization of radiative thermal properties of nano TiO2 assembled fibrous insulations. Int. J. Heat Mass Transf. 2018, 117, 729–739. [Google Scholar] [CrossRef]

- Maxwell, J.C. A Treatise on Electricity and Magnetism; Clarendon Press: Oxford, UK, 1873. [Google Scholar]

- Hamilton, R.L.; Crosser, O.K. Thermal conductivity of heterogeneous two-component systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Yang, J.; Wu, H.; Xu, X.; Huang, G.; Cen, J.; Liang, Y. Regional climate effects on the optimal thermal resistance and capacitance of residential building walls. Energy Build. 2021, 244, 111030. [Google Scholar] [CrossRef]

- ASHRAE Engineers. ASHRAE Handbook—Fundamentals; ASHRAE: Atlanta, GA, USA, 2017. [Google Scholar]

- Xu, X.; Wang, S. Optimal simplified thermal models of building envelope based on frequency domain regression using genetic algorithm. Energy Build. 2007, 39, 525–536. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Y. A novel and simple building load calculation model for building and system dynamic simulation. Appl. Therm. Eng. 2001, 21, 683–702. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Z. A neural-network-based experimental technique for determining z-transfer function coefficients of a building envelope. Build. Environ. 2000, 35, 181–189. [Google Scholar] [CrossRef]

- Wang, S.W.; Xu, X.H. Parameter estimation of internal thermal mass of building dynamic models using genetic algorithm. Energy Convers. Manag. 2006, 47, 1927–1941. [Google Scholar] [CrossRef]

- Zhang, G.P.; Wu, H.J.; Liu, J.; Yang, J.M.; Huang, H.K.; Ding, Y.J.; Xie, L. Dynamic performance and energy efficiency of reflective and insulative composite coating on building exterior wall. In Building Simulation; Tsinghua University Press: Beijing, China, 2022; pp. 1–15. [Google Scholar]

- Zhang, L.Y.; Jin, L.W.; Wang, Z.N.; Zhang, J.Y.; Liu, X.; Zhang, L.H. Effects of wall configuration on building energy performance subject to different climatic zones of China. Appl. Energy 2017, 185, 1565–1573. [Google Scholar] [CrossRef]

| Material | Density kg·m−3 | Thermal Conductivity W·m−1·K−1 | Specific Heat kJ·kg−1·K−1 |

|---|---|---|---|

| Internal plaster | 1600 | 0.81 | 1.05 |

| Foam concrete | 900 | 0.22 | 1.05 |

| GF (reference) | 119.7 | 0.0380 | 1.290 |

| AFC | 266.2 | 0.0208 | 1.240 |

| External plaster | 1700 | 0.87 | 1.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Wu, H.; Liang, Y.; Cen, J.; Zhang, X. A Comparative Assessment of Different Aerogel-Insulated Building Walls for Enhanced Thermal Insulation Performance. Gels 2023, 9, 943. https://doi.org/10.3390/gels9120943

Yang J, Wu H, Liang Y, Cen J, Zhang X. A Comparative Assessment of Different Aerogel-Insulated Building Walls for Enhanced Thermal Insulation Performance. Gels. 2023; 9(12):943. https://doi.org/10.3390/gels9120943

Chicago/Turabian StyleYang, Jianming, Huijun Wu, Yuying Liang, Jian Cen, and Xianyong Zhang. 2023. "A Comparative Assessment of Different Aerogel-Insulated Building Walls for Enhanced Thermal Insulation Performance" Gels 9, no. 12: 943. https://doi.org/10.3390/gels9120943