Study of Energy Saving Using Silica Aerogel Insulation in a Residential Building

Abstract

:1. Introduction

2. Results and Discussion

3. Conclusions from Simulation Study

- The multiphysics model was confirmed to be a promising tool for predicting room-temperature decay.

- Multiphysics simulations can be used to accurately predict the temperature, heat flux, and energy loss through the windows, walls, floors, doors, ceilings, and their combination under various insulation conditions that are difficult to create using experiments.

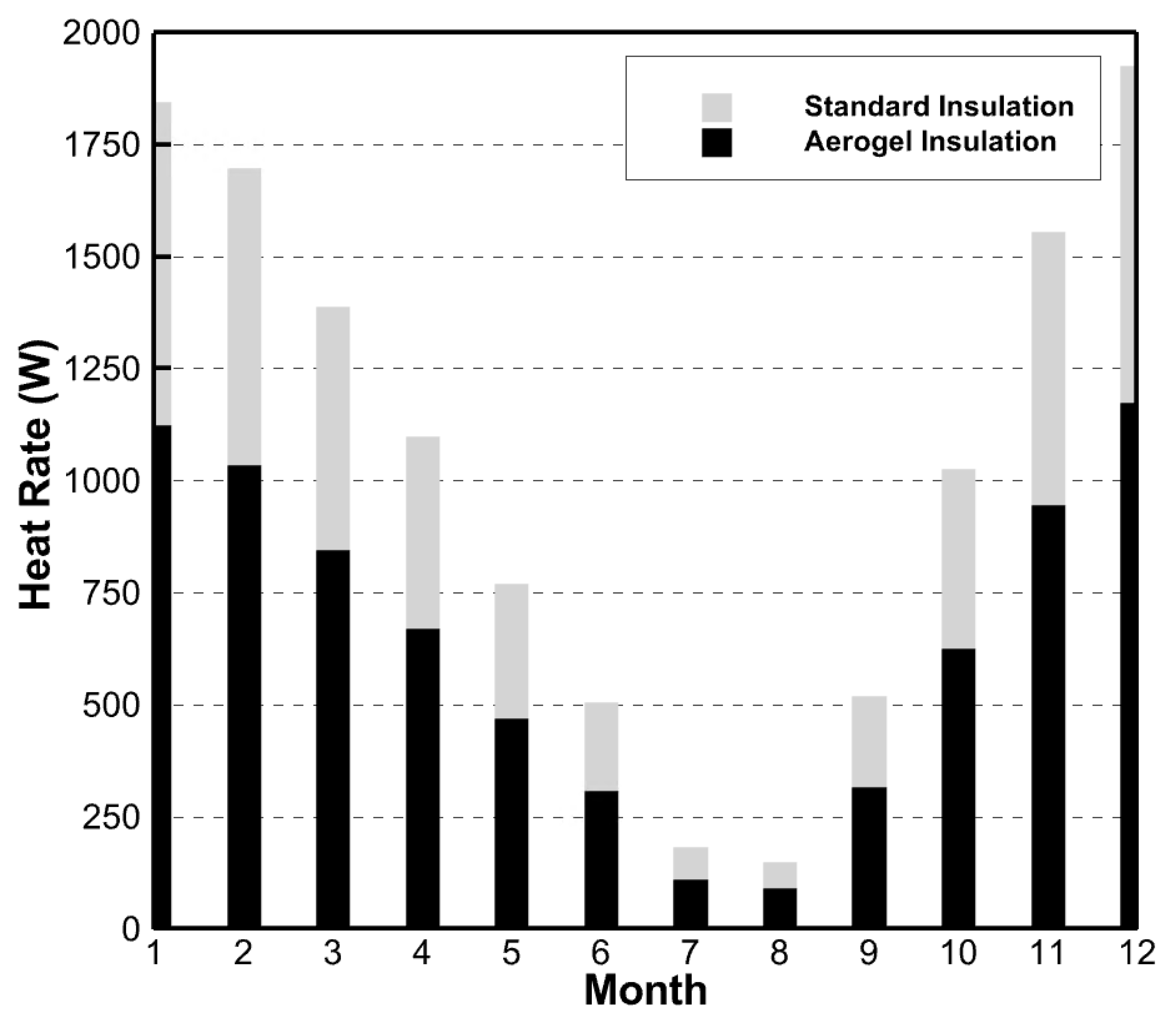

- The energy lost through the walls of a house is potentially 13.3% lower when using a ½ inch layer of aerogels as insulation.

- The energy lost through the windows of a house is potentially 39.1% lower when using a ½ inch layer of aerogels as insulation.

- The potential yearly energy savings using a ½ inch layer of aerogel insulation in the window gaps and walls of a residential building is 4721.8 kWh. This is more than one-fifth the total cost without aerogel insulation.

- The savings potential is greater with the use of aerogel insulation in the windows than in the walls.

- Future work will focus on adding other factors, such as human activities, into the simulations.

4. Materials and Methods

4.1. Mathematical Modeling

4.2. Validation

4.3. Simulation of a Residential House

4.3.1. Geometry and Grid Development

4.3.2. Solver Methods

4.3.3. Boundary Conditions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Berardi, U. A cross-country comparison of the building energy consumptions and their trends. Resour. Conserv. Recycl. 2017, 123, 230–241. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Fantucci, S.; Garbaccio, S.; Lorenzati, A.; Perino, M. Thermo-economic analysis of building energy retrofits using VIP-Vacuum Insulation Panels. Energy Build. 2019, 196, 269–279. [Google Scholar] [CrossRef]

- Sun, Y.; Wilson, R.; Wu, Y. A Review of Transparent Insulation Material (TIM) for building energy saving and daylight comfort. Appl. Energy 2018, 226, 713–729. [Google Scholar] [CrossRef]

- GhaffarianHoseini, A.; Dahlan, N.D.; Berardi, U.; GhaffarianHoseini, A.; Makaremi, N.; GhaffarianHoseini, M. Sustainable energy performances of green buildings: A review of current theories, implementations and challenges. Renew. Sustain. Energy Rev. 2013, 25, 1–17. [Google Scholar] [CrossRef]

- Lyons, A. Materials for Architects and Builders; Routledge, Taylor and Francis: Oxfordshire, UK, 2014; ISBN 9780815363392. [Google Scholar]

- Michalak, J.; Czernik, S.; Marcinek, M.; Michałowski, B. Environmental burdens of external thermal insulation systems. expanded polystyrene vs. mineral wool: Case study from Poland. Sustainability 2020, 12, 4532. [Google Scholar] [CrossRef]

- VIPA International. IEA-EBC Annex 65 Project. Available online: https://vipa-international.org/iea-ebc-annex-65-project/ (accessed on 15 December 2022).

- Kucukpinar, E.; Miesbauer, O.; Carmi, Y.; Fricke, M.; Gullberg, L.; Erkey, C.; Caps, R.; Rochefort, M.; Moreno, A.G.; Delgado, C. Development of transparent and opaque vacuum insulation panels for energy efficient buildings. Energy Procedia 2015, 78, 412–417. [Google Scholar] [CrossRef]

- Lu, X.; Caps, R.; Fricke, J.; Alviso, C.; Pekala, R. Correlation between structure and thermal conductivity of organic aerogels. J. Non-Cryst. Solids 1995, 188, 226–234. [Google Scholar] [CrossRef]

- Uriarte, A.; Garai, I.; Ferdinando, A.; Erkoreka, A.; Nicolas, O.; Barreiro, E. Vacuum insulation panels in construction solutions for energy efficient retrofitting of buildings. Two case studies in Spain and Sweden. Energy Build. 2019, 197, 131–139. [Google Scholar] [CrossRef]

- Jukić, M.; Jordan, S.; Lisičić, D. Novel thermal insulation with gas-filled cavities–assessment of thermal performance of different designs based on numerical simulations of heat transfer. Int. J. Comput. Methods Exp. Meas. 2019, 7, 181–192. [Google Scholar] [CrossRef]

- Jelle, B.P.; Baetens, R.; Gustavsen, A. Aerogel insulation for building applications. Sol-Gel. Handb. 2015, 43, 1385–1412. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Balaji, D. Aerogels for insulation applications. Mater. Res. Found. 2021, 98, 57–76. [Google Scholar] [CrossRef]

- Wang, L.; Feng, J.; Luo, Y.; Zhou, Z.; Jiang, Y.; Luo, X.; Xu, L.; Li, L.; Feng, J. Three-Dimensional-Printed Silica Aerogels for Thermal Insulation by Directly Writing Temperature-Induced Solidifiable Inks. ACS Appl. Mater. Interfaces 2021, 13, 40964–40975. [Google Scholar] [CrossRef] [PubMed]

- da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Incorporation of phase change materials into building envelope for thermal comfort and energy saving: A comprehensive analysis. J. Build. Eng. 2021, 36, 102122. [Google Scholar] [CrossRef]

- Shah, S.N.; Mo, K.H.; Yap, S.P.; Radwan, M.K. Towards an energy efficient cement composite incorporating silica aerogel: A state of the art review. J. Build. Eng. 2021, 44, 103227. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef] [Green Version]

- Adhikary, S.K.; Ashish, D.K.; Rudžionis, Ž. Aerogel based thermal insulating cementitious composites: A review. Energy Build. 2021, 245, 111058. [Google Scholar] [CrossRef]

- Bashir, A.W.; Leite, B.C.C. Performance of aerogel as a thermal insulation material towards a sustainable design of residential buildings for tropical climates in Nigeria. Energy Built Environ. 2022, 3, 291–315. [Google Scholar] [CrossRef]

- Ganobjak, M.; Malfait, W.J.; Just, J.; Käppeli, M.; Mancebo, F.; Brunner, S.; Wernery, J. Get the light & keep the warmth-A highly insulating, translucent aerogel glass brick for building envelopes. J. Build. Eng. 2022, 64, 105600. [Google Scholar] [CrossRef]

- Xue, R.; Liu, G.; Liu, F. A simple and efficient method for the preparation of SiO2/PI/AF aerogel composite fabrics and their thermal insulation performance. Ceram. Int. 2023, 49, 210–215. [Google Scholar] [CrossRef]

- Carroll, M.K.; Anderson, A.M.; Mangu, S.T.; Hajjaj, Z.; Capron, M. Aesthetic Aerogel Window Design for Sustainable Buildings. Sustainability 2022, 14, 2887. [Google Scholar] [CrossRef]

- Balaji, D.; Sivalingam, S.; Bhuvaneswari, V.; Amarnath, V.; Adithya, J.; Balavignesh, V. Aerogels as alternatives for thermal insulation in buildings—A comparative teeny review. Mater. Today: Proc. 2022, 62, 5371–5377. [Google Scholar] [CrossRef]

- Chen, Y.; Klima, K.; Brouwers, H.; Yu, Q. Effect of silica aerogel on thermal insulation and acoustic absorption of geopolymer foam composites: The role of aerogel particle size. Compos. Part B: Eng. 2022, 242, 110048. [Google Scholar] [CrossRef]

- Yin, Y.; Song, Y.; Chen, W.; Yan, Y.; Wang, X.; Hu, J.; Zhao, B.; Ren, S. Thermal environment analysis of enclosed dome with double-layered PTFE fabric roof integrated with aerogel-glass wool insulation mats: On-site test and numerical simulation. Energy Build. 2022, 254, 111621. [Google Scholar] [CrossRef]

- Song, Z.; Zhao, Y.; Yuan, M.; Huang, L.; Yuan, M.; Cui, S. Thermal Insulation and Moisture Resistance of High-Performance Silicon Aerogel Composite Foam Ceramic and Foam Glass. Adv. Eng. Mater. 2022, 24, 2101508. [Google Scholar] [CrossRef]

- Ibrahim, M.; Biwole, P.H.; Achard, P.; Wurtz, E.; Ansart, G. Building envelope with a new aerogel-based insulating rendering: Experimental and numerical study, cost analysis, and thickness optimization. Appl. Energy 2015, 159, 490–501. [Google Scholar] [CrossRef]

- Elshazli, M.T.; Mudaqiq, M.; Xing, T.; Ibrahim, A.; Johnson, B.; Yuan, J. Experimental study of using Aerogel insulation for residential buildings. Adv. Build. Energy Res. 2021, 16, 569–588. [Google Scholar] [CrossRef]

- Sakiyama, N.; Frick, J.; Stipetic, M.; Oertel, T.; Garrecht, H. Hygrothermal performance of a new aerogel-based insulating render through weathering: Impact on building energy efficiency. Build. Environ. 2021, 202, 108004. [Google Scholar] [CrossRef]

- National Centers for Environmental Information. Climate Data Online Search. Available online: https://www.ncdc.noaa.gov/cdo-web/search (accessed on 4 May 2021).

- ANSYS. Fluent User’s Guide, Release V19.0; Ansys Inc.: Canonsburg, PA, USA, 2018. [Google Scholar]

- Berardi, U. Development of glazing systems with silica aerogel. Energy Procedia 2015, 78, 394–399. [Google Scholar] [CrossRef]

| Study Type | Aerogels in Window | Aerogels in Walls |

|---|---|---|

| Control | No | No |

| Walls Only | No | Yes |

| Windows Only | Yes | No |

| Both | Yes | Yes |

| Month | January | February | March | April | May | June | July | August | September | October | November | December |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean Temperature (°F) | 31.2 | 34.3 | 40.8 | 46.9 | 53.8 | 59.4 | 66.2 | 66.9 | 59.1 | 48.4 | 37.3 | 29.5 |

| Material | Location | Density kg/m3 | Specific Heat J/(kg·K) | Thermal Conductivity W/(m·K) |

|---|---|---|---|---|

| Wood | Walls and roof | 700 | 2310 | 0.173 |

| Vinyl | Siding | 125 | 1200 | 0.17 |

| Sheathing | Roof | 6 | 1300 | 0.055 |

| Insulation Composite | Walls | 73.1875 | 1062.8 | 0.045 |

| Gypsum | Walls | 800 | 1100 | 0.17 |

| Glass | Windows | 2500 | 800 | 0.8 |

| Concrete | Foundation | 2300 | 880 | 1.4 |

| Aerogel | Windows and Walls | 120 | 1050 | 0.014 |

| Air | N/A | 1.225 | 1006 | 0.0242 |

| Model | Setting |

|---|---|

| Space | 3D |

| Time | Steady |

| Viscous | Laminar |

| Heat Transfer | Enabled |

| Solidification and Melting | Disabled |

| Radiation | None |

| Species | Disabled |

| Coupled Dispersed Phase | Disabled |

| NOx Pollutants | Disabled |

| SOx Pollutants | Disabled |

| Soot | Disabled |

| Mercury Pollutants | Disabled |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thie, C.; Quallen, S.; Ibrahim, A.; Xing, T.; Johnson, B. Study of Energy Saving Using Silica Aerogel Insulation in a Residential Building. Gels 2023, 9, 86. https://doi.org/10.3390/gels9020086

Thie C, Quallen S, Ibrahim A, Xing T, Johnson B. Study of Energy Saving Using Silica Aerogel Insulation in a Residential Building. Gels. 2023; 9(2):86. https://doi.org/10.3390/gels9020086

Chicago/Turabian StyleThie, Conal, Sean Quallen, Ahmed Ibrahim, Tao Xing, and Brian Johnson. 2023. "Study of Energy Saving Using Silica Aerogel Insulation in a Residential Building" Gels 9, no. 2: 86. https://doi.org/10.3390/gels9020086

APA StyleThie, C., Quallen, S., Ibrahim, A., Xing, T., & Johnson, B. (2023). Study of Energy Saving Using Silica Aerogel Insulation in a Residential Building. Gels, 9(2), 86. https://doi.org/10.3390/gels9020086