“Gloppiness” Phenomena and a Computer Vision Method to Quantify It

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Shear Rheology Tests

2.2.1. Flow Curve

2.2.2. Small Amplitude Oscillatory Shear (SAOS)

2.3. “Gloppiness” Degrees Evaluations by Trained Panelists

2.4. Jetting Flow Test

- is the pressure difference,

- is the dynamic viscosity of the fluid,

- L is the length of the pipe,

- Q is the volumetric flow rate, and

- r is the radius of the pipe.

- Record the videos of the jet experiment with a high-speed camera. One needs to carefully adjust the frame rate (FPS) and the field of view (FoV) to get a suitable video for future data analysis.

- Inputs the video to a Python-based algorithm. The packages used here are OpenCV, Numpy, and Pandas.

- Applied OpenCV canny function to detect the edge of the jet in the video. The details of the canny function can be found in this link: https://docs.opencv.org/3.4/da/d22/tutorial_py_canny.html (accessed on 1 March 2023)

- Save the edge position for the whole video as a panda DataFrame. The details about the panda DataFrame can be found in this link: https://www.geeksforgeeks.org/pandas-tutorial/ (accessed on 1 March 2023)

- Find the local and global minimum value for each frame. The reason that we also want to find the local minimum is that the global minimum is not always the breakage(rupture) location.

- Select the right local and global minimum value for each frame with the Algorithm. Normalize it and plot it as shown in Section 3.2.

3. Results

3.1. Shear Rheology

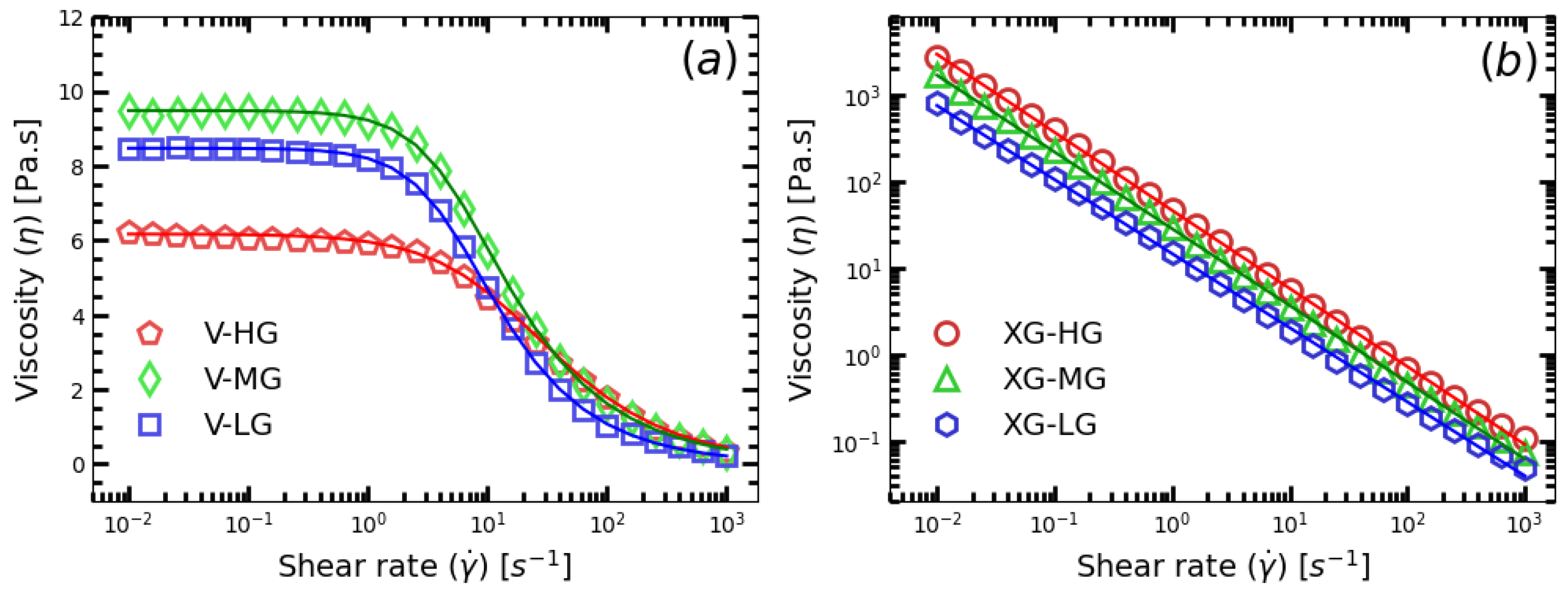

3.1.1. Flow Curve

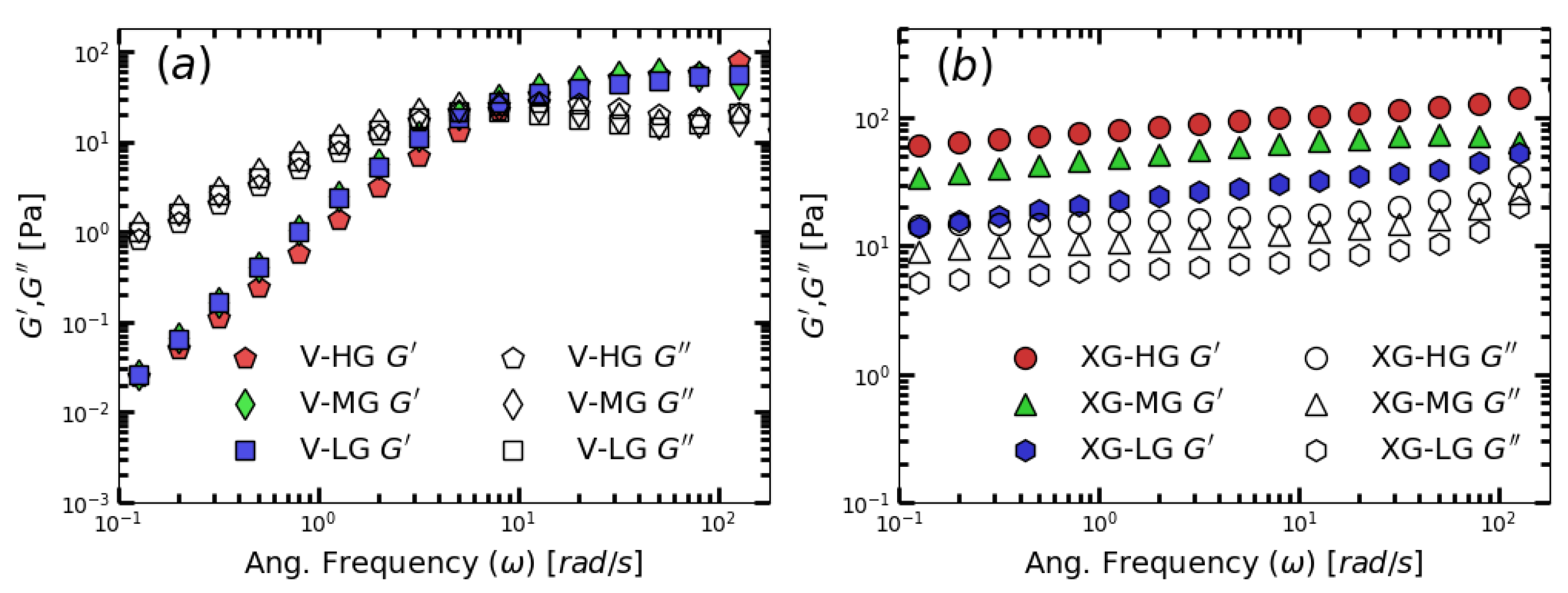

3.1.2. Small Amplitude Oscillatory Shear Test

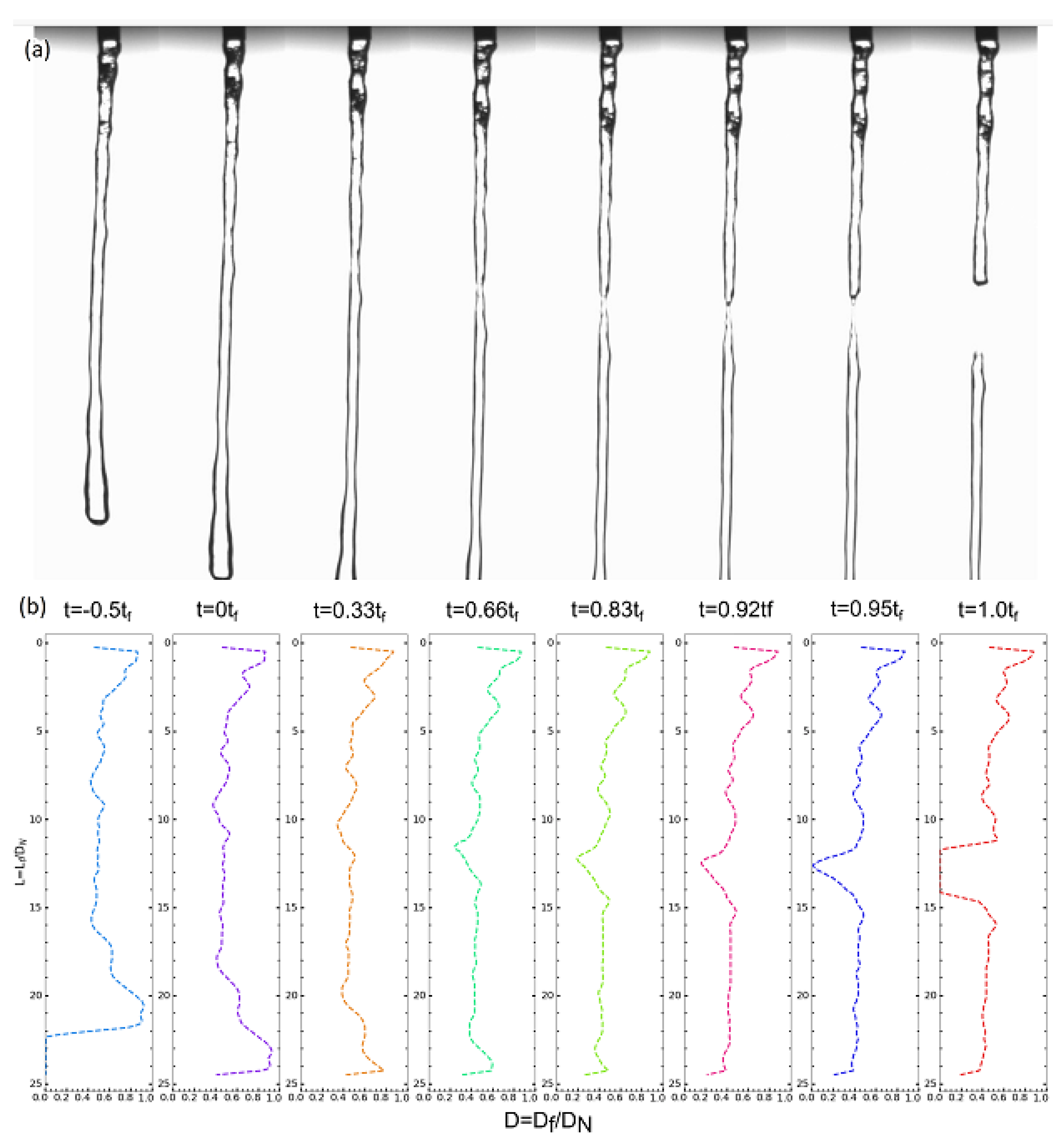

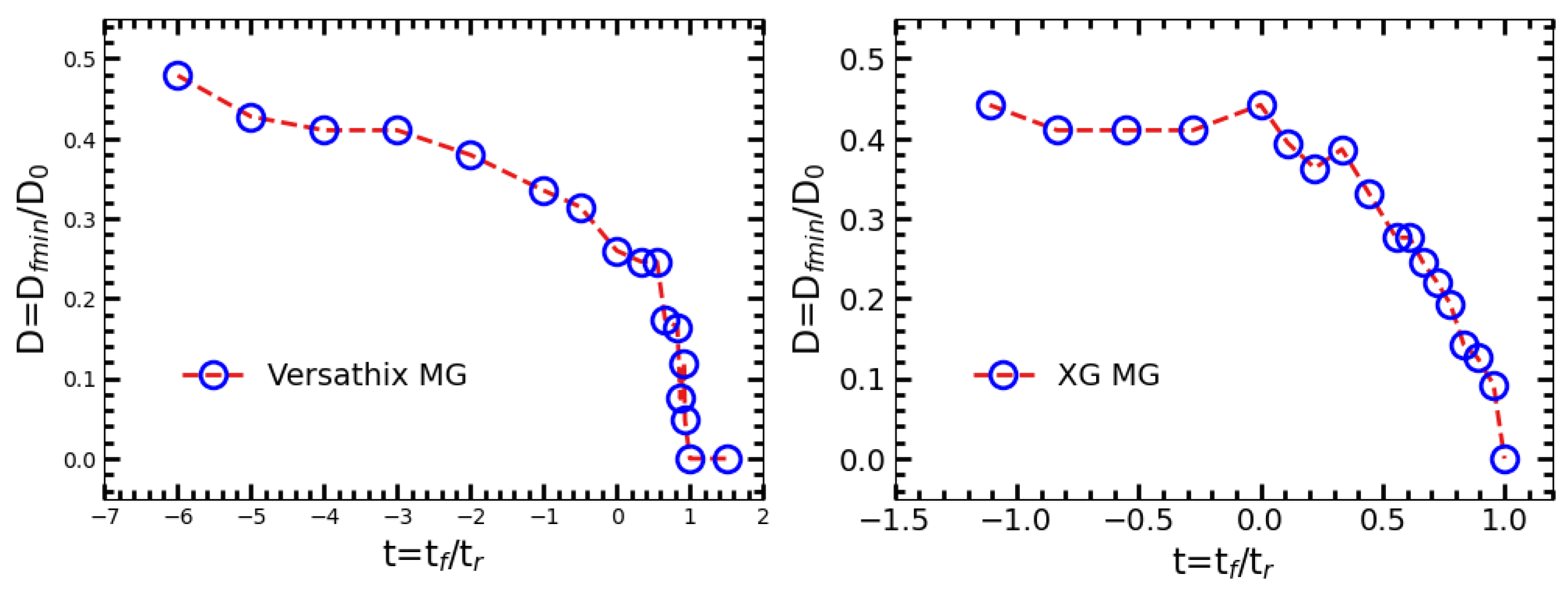

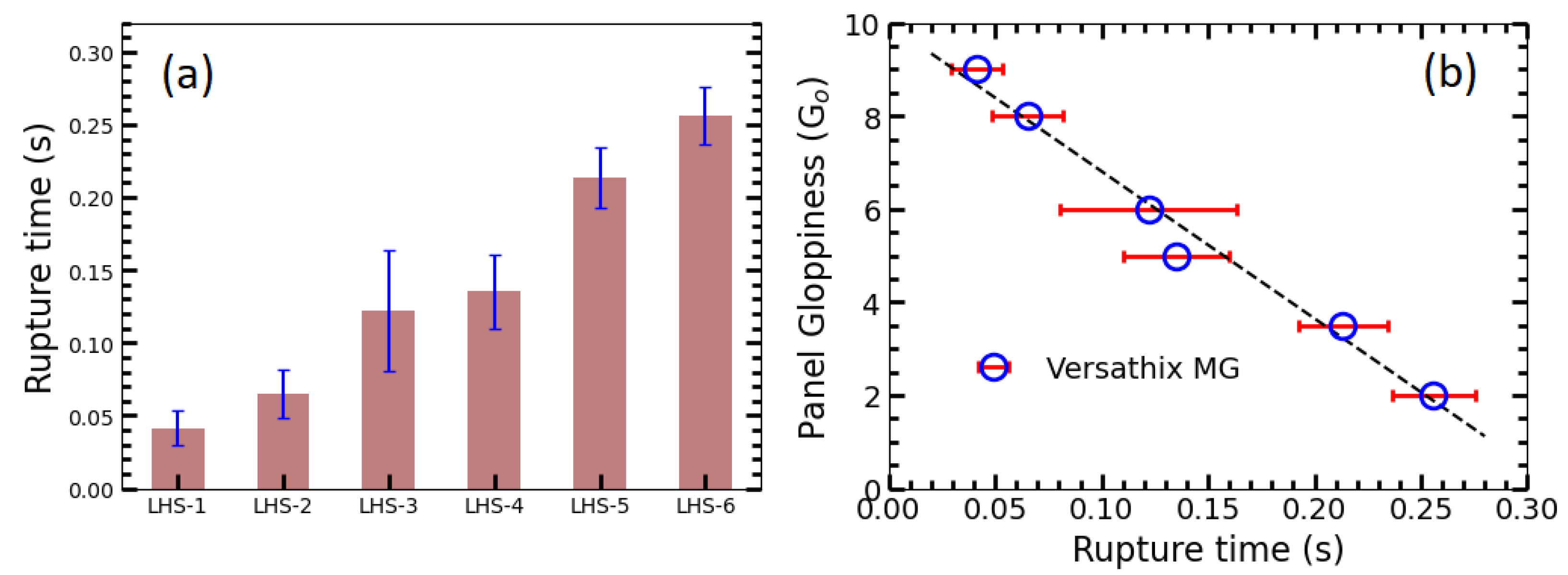

3.2. Jet Flow of Complex Fluids

4. Discussion

4.1. Shear Rheology

4.2. The Effect of “Gloppiness”

4.3. Jetting Flow under Gravity

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, J. Viscoelastic wormlike micelles and their applications. Curr. Opin. Colloid Interface Sci. 2002, 7, 276–281. [Google Scholar] [CrossRef]

- Laba, D. Rheological Properties of Cosmetics and Toiletries; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Lochhead, R.Y. The Role of Polymers in Cosmetics: Recent Trends; American Chemical Society: Washington, DC, USA, 2007. [Google Scholar]

- Lochhead, R.Y. A review of recent advances in the polymeric delivery of attributes in cosmetics and personal care products. Polym. Deliv. Ther. 2010, 1053, 3–22. [Google Scholar]

- Garcıa-Ochoa, F.; Santos, V.; Casas, J.; Gómez, E. Xanthan gum: Production, recovery, and properties. Biotechnol. Adv. 2000, 18, 549–579. [Google Scholar] [CrossRef] [PubMed]

- Macosko, C.W. Rheology: Principles, Measurements, and Applications; Wiley: Hoboken, NJ, USA, 1994. [Google Scholar]

- Larson, R.G. The Structure and Rheology of Complex Fluids; Oxford University Press: New York, NY, USA, 1999; Volume 150. [Google Scholar]

- Munoz, J.; Rincon, F.; Alfaro, M.C.; Zapata, I.; de la Fuente, J.; Beltrán, O.; de Pinto, G.L. Rheological properties and surface tension of Acacia tortuosa gum exudate aqueous dispersions. Carbohydr. Polym. 2007, 70, 198–205. [Google Scholar] [CrossRef]

- Eggers, J.; Villermaux, E. Physics of liquid jets. Rep. Prog. Phys. 2008, 71, 036601. [Google Scholar] [CrossRef] [Green Version]

- Ahuja, A.; Potanin, A. Rheological predictions of sensory attributes of lotions. J. Texture Stud. 2018, 50, 295–305. [Google Scholar] [CrossRef] [PubMed]

- Huang, Q.; Hassager, O. Polymer liquids fracture like solids. Soft Matter 2017, 13, 3470–3474. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Subbotin, A.V.; Skvortsov, I.Y.; Kuzin, M.S.; Gerasimenko, P.S.; Kulichikhin, V.G.; Malkin, A.Y. The shape of a falling jet formed by concentrated polymer solutions. Phys. Fluids 2021, 33, 083108. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Petrie, C.J.S. Some conditions for rupture of polymer liquids in extension. J. Rheol. 1997, 41, 1–25. [Google Scholar] [CrossRef]

- Vinogradov, G.V.; Malkin, A.Y.; Volosevitch, V.V.; Shatalov, V.P.; Yudin, V.P. Flow, high-elastic (recoverable) deformation, and rupture of uncured high molecular weight linear polymers in uniaxial extension. J. Polym. Sci. Polym. Phys. Ed. 1975, 13, 1721–1735. [Google Scholar] [CrossRef]

- Joshi, Y.M.; Denn, M.M. Rupture of entangled polymeric liquids in elongational flow. J. Rheol. 2003, 47, 291–298. [Google Scholar] [CrossRef] [Green Version]

- Mahmoudabadbozchelou, M.; Kamani, K.M.; Rogers, S.A.; Jamali, S. Digital rheometer twins: Learning the hidden rheology of complex fluids through rheology-informed graph neural networks. Proc. Natl. Acad. Sci. USA 2022, 119, e2202234119. [Google Scholar] [CrossRef] [PubMed]

- Mahmoudabadbozchelou, M.; Caggioni, M.; Shahsavari, S.; Hartt, W.H.; Em Karniadakis, G.; Jamali, S. Data-driven physics-informed constitutive metamodeling of complex fluids: A multifidelity neural network (MFNN) framework. J. Rheol. 2021, 65, 179–198. [Google Scholar] [CrossRef]

- Mahmoudabadbozchelou, M.; Jamali, S. Rheology-Informed Neural Networks (RhINNs) for forward and inverse metamodelling of complex fluids. Sci. Rep. 2021, 11, 12015. [Google Scholar] [CrossRef] [PubMed]

- Saadat, M.; Mahmoudabadbozchelou, M.; Jamali, S. Data-driven selection of constitutive models via rheology-informed neural networks (RhINNs). Rheol. Acta 2022, 61, 721–732. [Google Scholar] [CrossRef]

- Maîtrejean, G.; Samson, A.; Roux, D.; El-Kissi, N. Rheological identification of jetted fluid using machine learning. Phys. Fluids 2022, 34, 093103. [Google Scholar] [CrossRef]

| Gloppiness Level | Low | Middle | High |

|---|---|---|---|

| Ingredient | wt% | wt% | wt% |

| DI water | 84.32 | 84.12 | 83.92 |

| Versathix | 0.20 | 0.40 | 0.60 |

| Other components | 15.48 | 15.48 | 15.48 |

| Gloppiness Level | Low | Middle | High |

|---|---|---|---|

| Ingredient | wt% | wt% | wt% |

| DI water | 71.900 | 71.500 | 71.000 |

| Xanthan Gum | 0.900 | 1.300 | 1.800 |

| Other components | 27.2 | 27.2 | 27.2 |

| ID | Uneven Dispensing | Dispensing Slowness | Consistency | Holds Shape | |

|---|---|---|---|---|---|

| SG-1 | 9.0 | 8.0 | 7.0 | 6.0 | 2.5 |

| SG-2 | 8.0 | 8.5 | 9.0 | 6.0 | 2.5 |

| SG-3 | 6.0 | 7.0 | 6.5 | 4.5 | 2.0 |

| SG-4 | 5.0 | 5.5 | 7.0 | 6.0 | 7.0 |

| SG-5 | 3.5 | 5.0 | 6.5 | 7.0 | 4.0 |

| SG-6 | 2.0 | 3.0 | 3.0 | 2.0 | 7.0 |

| ID | |

|---|---|

| Versathix-HG | 0.12 |

| Versathix-MG | 0.15 |

| Versathix-LG | 0.16 |

| XG-HG | / |

| XG-MG | / |

| XG-LG | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Mintel, M.; Teoman, B.; Jensen, S.; Potanin, A. “Gloppiness” Phenomena and a Computer Vision Method to Quantify It. Gels 2023, 9, 532. https://doi.org/10.3390/gels9070532

Wu S, Mintel M, Teoman B, Jensen S, Potanin A. “Gloppiness” Phenomena and a Computer Vision Method to Quantify It. Gels. 2023; 9(7):532. https://doi.org/10.3390/gels9070532

Chicago/Turabian StyleWu, Shijian, Mark Mintel, Baran Teoman, Stephanie Jensen, and Andrei Potanin. 2023. "“Gloppiness” Phenomena and a Computer Vision Method to Quantify It" Gels 9, no. 7: 532. https://doi.org/10.3390/gels9070532

APA StyleWu, S., Mintel, M., Teoman, B., Jensen, S., & Potanin, A. (2023). “Gloppiness” Phenomena and a Computer Vision Method to Quantify It. Gels, 9(7), 532. https://doi.org/10.3390/gels9070532