An Investigation of Several Physicochemical Characteristics, as Well as the Cholesterol and Fatty Acid Profile of Ice Cream Samples Containing Oleogel, Various Stabilizers, and Emulsifiers

Abstract

:1. Introduction

2. Results and Discussion

2.1. Physicochemical Properties of Milk, Cream, Sunflower Oil, and Oleogel

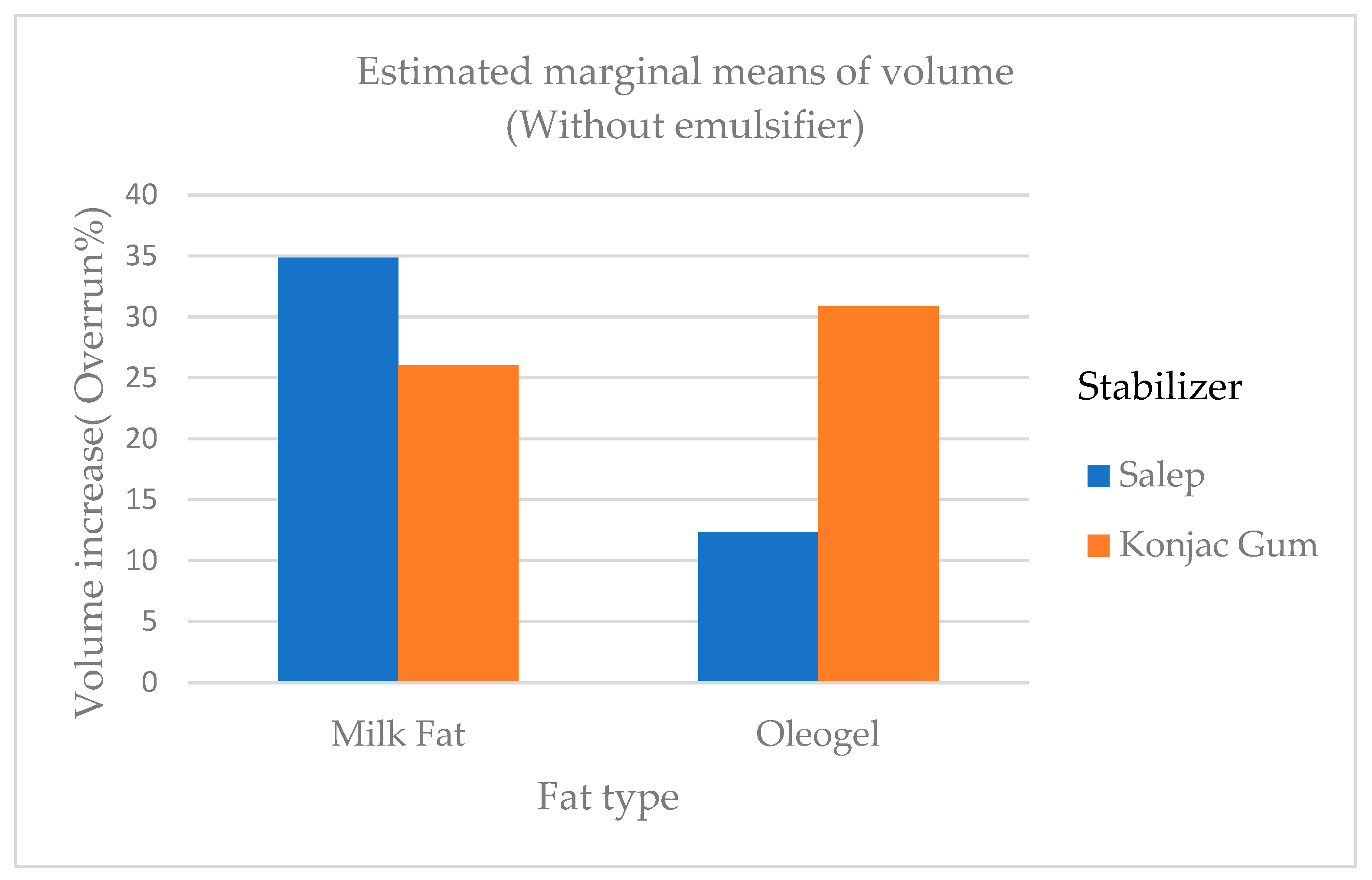

2.2. The Physicochemical Analysis of the Mix and Ice Cream Samples

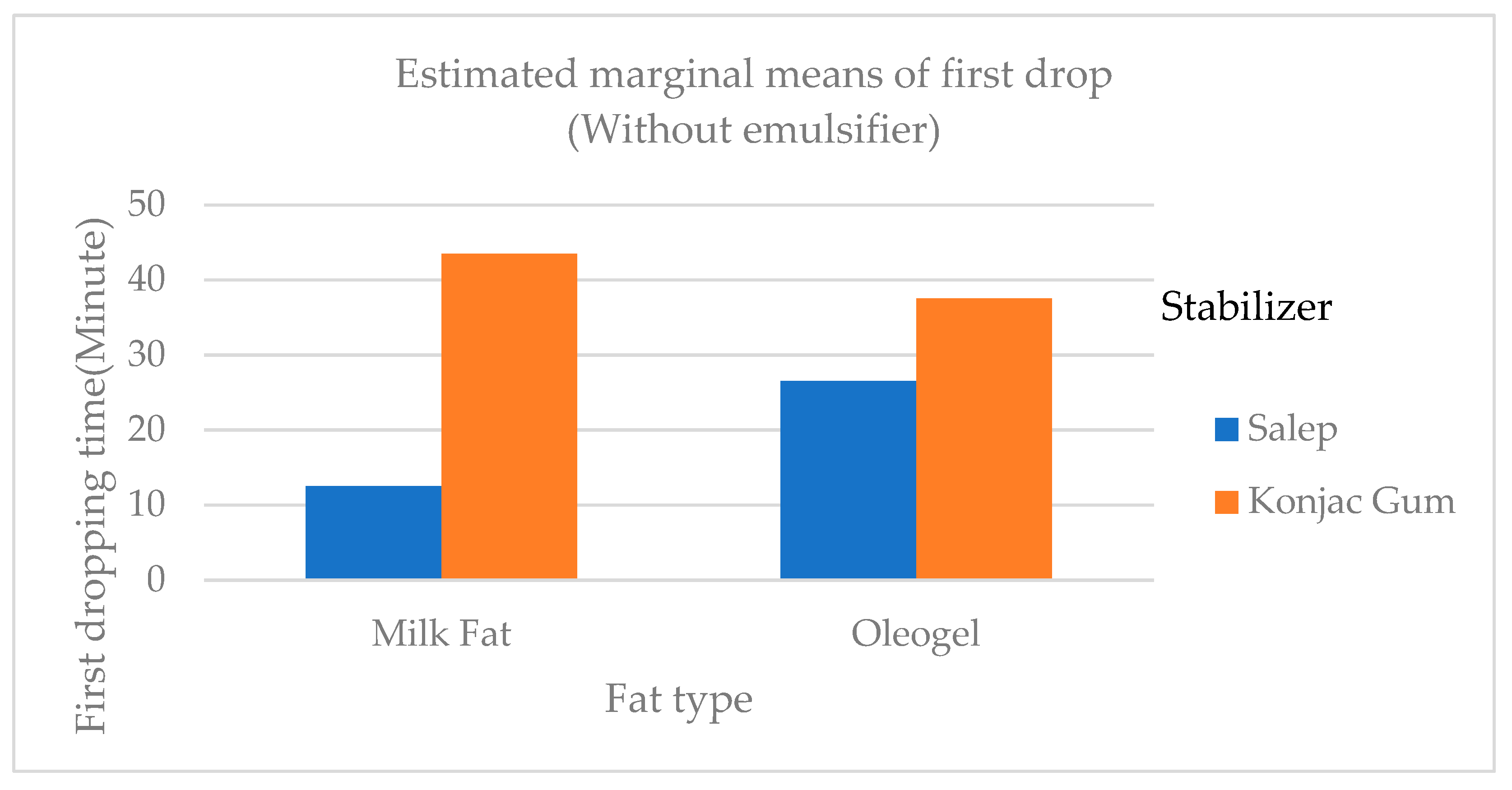

2.3. The Melting Properties and Fat Destabilization of Ice Cream Samples

2.4. The Color Values of Ice Cream Samples

2.5. The Fatty Acid Composition of Ice Cream Samples

2.6. The Microscopic Appearance of the Samples of Ice Cream

2.7. Separation of Ice Cream Samples Using PCA (Principal Component Analysis)

2.8. Results of Sensory Analysis of Ice Cream Samples

3. Conclusions

4. Materials and Methods

4.1. Material

4.2. Methods

4.2.1. Beeswax Oleogel Preparation

4.2.2. Ice Cream Manufacture and Sampling

4.2.3. Physicochemical Analysis

The Physicochemical Analysis of Milk, Cream, Sunflower Oil, and Oleogel Used in Ice Cream Making

Physicochemical Analysis of Ice Cream Samples

4.2.4. Fatty Acid Analysis of Ice Cream Samples

Lipid Extraction: Removing Fat and Oil from Ice Cream Sample

Preparation of Fatty Acid Methyl Esters

Analysis of Fatty Acid Methyl Esters in Gas Chromatography (GC)

4.2.5. Optical Microscopy

4.2.6. Sensory Assessment

4.2.7. Statistical Analysis

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Goff, H.D.; Hartel, R.W. Analyzing Frozen Desserts, Sensory Analyses. In Ice Cream; Springer: Boston, MA, USA, 2013; pp. 423–431. [Google Scholar]

- Aime, D.B.; Arntfield, S.D.; Malcolmson, L.J.; Ryland, D. Textural analysis of fat reduced vanilla ice cream products. Food Res. Int. 2001, 34, 237–246. [Google Scholar] [CrossRef]

- Marshall, R.T.; Goff, H.D.; Hartel, R.W. Ice Cream, 6th ed.; Kluwer Academic/Plenum Publishers: New York, NY, USA, 2003; p. 371. [Google Scholar]

- Anonymous. [USDA and US HHS] U.S. Department of Agriculture and U.S. Department of Health and Human Services. In Dietary Guidelines for Americans; Government Printing Office: Washington, DC, USA, 2011. [Google Scholar]

- Corradini, S.A.S.; Madrona, G.S.; Visentainer, J.V.; Bonafe, E.G.; Carvalho, C.B.P.M.; Roche, P.M.; Prado, I.N. Sensorial and fatty acid profile of ice cream manufactured with milk of crossbred cows fed palm oil and coconut fat. J. Dairy Sci. 2014, 97, 6745–6753. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fredrick, E.; Walstra, P.; Dewettinck, K. Factors governing partial coalescence in oil-in-water emulsions. Adv. Colloid Interfac. 2010, 153, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Zetzl, A.K.; Marangoni, A.G.; Barbut, S. Mechanical properties of ethylcellulose oleogels and their potential for saturated fat reduction in comminuted meat products. Food Funct. 2012, 3, 327–337. [Google Scholar] [CrossRef]

- Co, E.; Marangoni, A.G. Organogels: An alternative edible oil-structuring method. J. Amer. Oil Chem. Soc. 2012, 89, 749–780. [Google Scholar]

- Dassanayake, L.S.K.; Kodali, D.R.; Sato, S.U.K. Physical properties of organogels made of rice bran wax and vegetable oils. In Edible Oleogels; AOCS Press: Urbana, 2011; pp. 149–172. [Google Scholar]

- Goff, H.D. Colloidal aspects of ice cream—A review Int. Dairy J. 1997, 7, 363–373. [Google Scholar] [CrossRef]

- Zulim Botega, D.C.; Marangoni, A.G.; Smith, A.K.; Goff, H.G. The potential application of rice bran wax oleogel to replace solid fat and enhance unsaturated fat content in ıce cream. J. Food Sci. 2013, 78, 1334–1339. [Google Scholar] [CrossRef]

- Akesowan, A. Optimization of textural properties of konjac gels formed with κ-carrageenan or xanthan and xylitol as ıngredients in jelly drink. J. Food Process. Preserv. 2015, 39, 1745–1749. [Google Scholar] [CrossRef]

- Jaberi, R.; Pedram Nia, A.; Naji-Tabasi, S.; Elhamirad, A.H.; Shafafi Zenoozian, M. Rheological and structural prop-erties of oleogel base on soluble complex of egg white protein and xanthan gum. J. Texture Stud. 2020, 51, 925–936. [Google Scholar] [CrossRef]

- Tekinșen, K.K.; Bİçer, Y.; Akkemik, Y. The effect of the stabilizer mixture containing konjac gum on the some quality properties of Kahramanmaraș type ice cream. Eurasian J. Vet. Sci. 2017, 33, 113–119. [Google Scholar] [CrossRef]

- Wu, B.; Freire, D.O.; Hartel, R.W. The effect of overrun, fat destabilization, and ice cream mix viscosity on entire meltdown behavior. J. Food Sci. 2019, 84, 2562–2571. [Google Scholar] [CrossRef] [PubMed]

- Goff, H.D.; Jordan, W.K. Action of emulsifiers in promoting fat destabilization during the manufacture of ice cream. J. Dairy Sci. 1989, 72, 18–29. [Google Scholar] [CrossRef]

- Mendez-Velasco, C.; Goff, H.D. Fat aggregation in ice cream: A study on the types of fat interactions. Food Hydrocoll. 2012, 29, 152–159. [Google Scholar] [CrossRef]

- Metwaly, E.A.; EmaraTalaat, H.; EL-Sawah, T.H. Impact of Konjac Glucomannan on Ice Cream-like Properties. Int. J. Dairy Sci. 2017, 12, 177–183. [Google Scholar]

- Guven, M.; Karaca, O.B. Effects of using different emulsifiers on properties of ice cream in production of low fat Kahramanmaraș type ice cream. GIDA-J. Food. 2010, 35, 97–104. [Google Scholar]

- Sulejmani, E.; Demiri, M. The effect of stevia, emulsifier and milk powder on melting rate, hardness and overrun of ice cream formulations during storage. Mljekarstvo 2020, 70, 120–130. [Google Scholar] [CrossRef]

- AL- Assar, M.A. Impact of replacement milk fat with vegetable oils on the quality of ice cream. J. Agric. Sci. 2009, 34, 1735–1744. [Google Scholar] [CrossRef]

- Mariano, E.M.; Alamprese, C. Honey, trehalose and erythritol as sucrose-alternative sweeteners for artisanal ice-cream: A pilot study. LWT–Food Sci. Technol. 2017, 75, 329–334. [Google Scholar] [CrossRef]

- Ozdemir, C.; Dagdemir, E.; Ozdemir, S.; Sagdıc, O. The effects of using alternative sweeteners to sucrose on ice cream quality. J. Food Qual. 2008, 31, 415–428. [Google Scholar] [CrossRef]

- Minhas, K.S.; Sidhu, J.S.; Mudahar, G.S.; Sinngh, A.K. Flow behavior characteristics of ice cream mix made with buffalo milk and various stabilizers. Plant Foods Hum. Nutr. 2002, 57, 25–40. [Google Scholar] [CrossRef]

- Guven, M.; Karaca, O.B.; Kacar, A. The effects of the combined use of stabilizers containing locust bean gum and of the storage time on Kahramanmaraş type ice creams. Int. J. Dairy Technol. 2003, 56, 223–228. [Google Scholar] [CrossRef]

- Çetin Abay, S.E.D.A. Dondurma Üretiminde Stabilizör Olarak Konjak Bitkisi (amorphophallus konjac) Sakızının Salep (orchidaceae) Yerine Kullanılabilme Olanaklarının Araştırılmasıı/Investigation of the Usage Possibilities of Konjac Plant (Amorphophallus konjac) Gum as a Stabilizer Instead of Salep (Orchidaceae) in Ice Cream Production. Ph.D. Thesis, Harran Üniversitesi Fen Bilimleri Enstitüsü, Urfa, Turkey, 2017. [Google Scholar]

- Amador, J.; Hartel, R.; Rankin, S. The effects of fat structures and ice cream mix viscosity on physical and sensory properties of ice cream. J. Food Sci. 2017, 82, 1851–1860. [Google Scholar] [CrossRef] [PubMed]

- Nazarewicz, S.; Kozłowicz, K.; Kobus, Z.; Gładyszewska, B.; Matwijczuk, A.; Ślusarczyk, L.; Kozłowicz, N. The use of ultrasound in shaping the properties of ice cream with oleogel based on oil extracted from tomato seeds. Appl. Sci. 2022, 12, 9165. [Google Scholar] [CrossRef]

- Muse, M.R.; Hartel, R.W. Ice cream structural elements that affect melting rate and hardness. J. Dairy Sci. 2004, 87, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Güven, M.; Karaca, O.B.; Yaşar, K. Düşük yağ oranlı Kahramanmaraş tipi dondurma üretiminde farklı emülgatörlerin kullanımının dondurmaların özellikleri üzerine etkileri. Gıda 2010, 35, 97–104. [Google Scholar]

- Hatipoglu, A. Bazı Yağ Ikame Maddeleri Kullanılarak Yapılan Yağ Oranı Düşürülmüş Dondurmaların Kalite Özelliklerinin Araştırılması. Ph.D. Thesis, Harran Üniversitesi/Fen Bilimleri Enstitüsü/Gıda Mühendisliği Anabilim Dalı, Urfa, Turkey, 2007. [Google Scholar]

- Toro-Vazquez, J.F.; Morales-Rueda, J.A.; Dibildox-Alvarado, E.; Charó-Alonso, M.; Alonzo-Macias, M.; Gonzá-lez-Chávez, M.M. Thermal and textural properties of organogels developed by candelilla wax in sanflower oil. J. Am. Oil Chem. Soc. 2007, 84, 989–1000. [Google Scholar] [CrossRef]

- Bradley, R.L.; Arnold, E.; Barbano, D.M.; Semerad, R.G.; Smith, D.E.; Vines, B.K. Chemical and physical methods. In Standard Methods for the Examination of Dairy Products; Marshall, R.T., Ed.; American Public Health Association: Washington, DC, USA, 1992; pp. 433–531. [Google Scholar]

- Oner, Z.; Şanlıdere-Aloğlu, H. Süt ve Süt Ürünleri Analiz Yöntemleri; Sidas Medya Ltd. Şti. Çankaya: İzmir, Turkey, 2018. [Google Scholar]

- Abdel-Aal, E.M.; Ziena, H.M.; Youssef, M., M. Adulteration of honey with high-fructose corn syrup:Detection by different methods. Food Chem. 1993, 48, 209–212. [Google Scholar] [CrossRef]

- Association of Analytical Chemists [AOAC]. In Official Methods of Analysis, 17th ed.; International, Inc.: Arlington, TX, USA, 2000.

- Karshenas, M.; Goli, M.; Zamindar, N. The effect of replacing egg yolk with sesame peanut defatted meal milk on the physicocturehemical, colorimetry, and rheological properties of low cholesterol mayonnaise. Food Sci. Nutr. 2018, 6, 824. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Florez, R.; Klipfel, N.J.; Tobias, J. Ice-cream and frozen desserts. In Dairy Science and Technology Handbook. 2. Product Manufacturing; Hui, Y.H., Ed.; VCH Publishers: New York, NY, USA, 1993. [Google Scholar]

- Cotrell, J.F.L.; Pass, G.; Phillips, G.O. Assessment of polysaccharides as ice cream stabilizers. J. Sci. Food Agric. 1979, 30, 1085–1089. [Google Scholar] [CrossRef]

- Sukhija, P.S.; Palmquist, D.L. Rapid method for determination of total fatty acid content and composition of feedstuffs and feces. J. Agrie, Food Chem. 1988, 36, 1202–1206. [Google Scholar] [CrossRef]

- Deeth, H.C.; Fitz-Gerald, C.H.; Snow, A.J. A GC method for the quantitative assay of free fatty acids. New Zealand J. Sci. Technol. 1983, 18, 13–20. [Google Scholar]

- Satchithanandam, S.; Fritsche, J.; Rader, J.I. Extension of AOAC official method 996.01 to the analysis of standard reference material (SRM) 1846 and infant formulas. J. AOAC Int. 2001, 84, 805–814.e31. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tan, H.W.; Misran., M. Characterization of fatty acid liposome coated with low-molecular-weight chitosan. J. Liposome Res. 2012, 22, 329–335. [Google Scholar] [CrossRef] [PubMed]

- Bodyfelt, F.W.; Tobias, J.; Trout, G.M. The Sensory Evaluation of Dairy Products. New York. AVI Book 1988, 166–226. [Google Scholar]

| Samples | Dry Matter (%) | Fat and Oil Ratio (%) | Ash (%) | Sspecific Gravity | Acidity (%) | pH | Viscosity (Pa.s.) (50 rpm) |

|---|---|---|---|---|---|---|---|

| Milk (all fat) | 12.70 | 3.30 | 0.75 | 1.028 | 0.19 | 6.47 | - |

| Cream | 55.50 | 66.80 | 0.55 | - | 1.19 | 6.51 | 1.32 |

| Milk (no fat) | 10.03 | 0.10 | 0.72 | 1.036 | 0.16 | 6.13 | - |

| Sunflower oil (refined) | - | 99.75 | - | 0.918 | 0.51 | 6.81 | 1.15 |

| Oleogel | - | 95.25 | - | - | 0.43 | 6.34 | 1.61 |

| Sample | Dry Matter (%) | Milk Fat/ Oil Ratios (%) | Ash (%) | pH | Acidity (%) | Overrun (%) | Mix Viscosity (Pa.s.) | |

|---|---|---|---|---|---|---|---|---|

| (20 rpm) | (50 rpm) | |||||||

| A | 31.37 ± 1.1 a | 5.05 ± 0.1 e (MF) | 0.96 ± 0.2 a | 6.71 ± 0.4 a | 0.14 ± 0.01 c | 34.84 ± 5.1 b | 12.68 ± 1.4 d | 8.07 ± 0.8 cd |

| B | 29.87 ± 1.8 b | 5.10± 0.4 e (MF) | 0.83 ± 0.1 ab | 6.17 ± 0.3 b | 0.18 ± 0.02 a | 42.10 ± 8.2 a | 14.71 ± 2.1 c | 9.21 ± 1.5 c |

| C | 32.35 ± 0. 7 a | 4.65 ± 0.1 f (MF) | 0.75 ± 0.01 c | 6.66 ± 0.08 a | 0.15 ± 0.01 b | 30.67 ± 3.4 bc | 11.72 ± 8.9 d | 7.19 ± 4.1 d |

| D | 31.50 ± 1.9 a | 5.10 ± 0.1 e (MF) | 0.81 ± 0.03 b | 6.64 ± 0.6 a | 0.14 ± 0.10 c | 26.03 ± 4.5 c | 24.32 ± 2.5 a | 13.03 ± 1.4 a |

| E | 28.98 ± 2.9 c | 5.07 ± 0.1 e (MF) | 0.80 ± 0.1 b | 5.98 ± 0.4 c | 0.16 ± 0.01 b | 32.49 ± 1.9 b | 20.69 ± 4.0 b | 11.08 ± 0.1 ab |

| F | 33.13 ± 2.4 a | 5.00± 0.8 e (MF) | 0.86 ± 0.9 a | 6.70 ± 0.5 a | 0.14 ± 0.04 c | 29.83 ± 12.4 b c | 26.33 ± 10.3 a | 11.26 ± 3.0 ab |

| G | 29.89 ± 0.1 b | 6.28 ± 0.2 c (oil) | 0.79 ± 0.05 b | 6.02 ± 0.1 c | 0.18 ± 0.0 a | 12.35 ± 3.6 e | 11.82 ± 1.3 d | 7.00 ± 0.3 d |

| H | 29.82 ± 0.5 b | 6.55 ± 0.2 a (oil) | 0.90 ± 0.1 a | 6.25 ± 0.1 b | 0.14 ± 0.01 c | 17.56 ± 7.9 de | 10.06 ± 6.0 d | 6.58 ± 2.0 d |

| I | 30.65 ± 0.6 b | 6.30 ± 0.3 c (oil) | 0.82 ± 0.6 ab | 6.55 ± 0.1 ab | 0.14 ± 0.03 c | 6.50 ± 17.1 f | 18.61 ± 2.7 b | 9.50 ± 1.7 b |

| J | 31.58 ± 0.3 a | 6.15 ± 0.07 d (oil) | 0.97 ± 0.2 a | 6.48 ± 0.5 ab | 0.13 ± 0.02 cd | 30.87 ± 14.0 bc | 22.40 ± 3.4 ab | 11.96 ± 1.2 ab |

| K | 32.20 ± 0.7 a | 6.50 ± 0.2 a (oil) | 0.72 ± 0.01 d | 5.91 ± 0.3 c | 0.16 ± 0.03 b | 11.18 ± 7.8 e | 17.69 b ± 7.28 | 10.42 ± 3.1 b |

| L | 31.26 ± 0.01 a | 6.45 ± 0.01 b (oil) | 0.80 ± 0.01 b | 6.51 ± 0.01 ab | 0.12 ± 0.01 d | 22.35 ± 0.01 d | 28.00 a ± 0.01 | 14.70 ± 0.01 a |

| Samples | First Drop. Time (min.) | Complete Melting Time (min.) | Melting Ratio (%) | Fat Destabilization (%) |

|---|---|---|---|---|

| A | 12.50 ± 3.5 g | 64.50 ± 2.1 e | 96.05 ± 1.9 a | 27.30 ± 1.5 b |

| B | 19.00 ± 4.2 ef | 64.00 ± 4.2 e | 90.12 ± 0.3 b | 21.15 ± 0.9 e |

| C | 17.00 ± 0.01 f | 63.50 ± 1.4 e | 95.78 ± 3.1 a | 37.50 ± 1.4 a |

| D | 43.50 ± 2.1 bc | 66.00 ± 1.4 e | 81.96 ± 7.4 c | 31.11 ± 0.9 b |

| E | 32.50 ± 3.5 d | 77.00 ± 4.2 c | 79.68 ± 10.5 c | 23.32 ± 2.2 d |

| F | 35.00 ± 5.7 c | 79.50 ± 2.1 c | 66.96 ± 0.3 d | 28.90 ± 0.6 b |

| G | 26.50 ± 0.7 e | 94.50 ± 2.1 a | 66.69 ± 1.4 d | 22.59 ± 1.4 d |

| H | 16.50 ± 0.7 f | 72.00 ± 2.8 d | 95.74 ± 5.2 a | 24.79 ± 0.9 c |

| I | 31.00 ± 0.01 d | 93.50 ± 2.1 a | 66.81 ± 1.6 d | 20.84 ± 1.1 e |

| J | 37.50 ± 0.7 c | 84.50 ± 3.5 b | 68.02 ± 5.6 d | 18.71 ± 0.2 f |

| K | 49.00 ± 1.4 b | 89.00 ± 1.4 a | 47.71 ± 1.4 e | 19.36 ± 0.1 f |

| L | 60.50 ± 0.7 a | 88.50 ± 0.7 a | 82.00 ± 0.3 c | 21.20 ± 0.5 e |

| Samples | L* Color | a* Color | b* Color |

|---|---|---|---|

| A | 85.47 ± 4.1 a | −2.88 ± 0.3 c | 9.56 ± 1.05 a |

| B | 80.88 ± 0.8 c | −2.36 ± 0.04 c | 8.06 ± 0.6 bc |

| C | 80.83 ± 3.9 c | −2.72 ± 0.2 c | 8.70 ± 0.7 ab |

| D | 81.33 ± 0.9 c | −2.65 ± 0.1 c | 8.76 ± 1.1 ab |

| E | 86.76 ± 5.3 a | −2.08 ± 0.02 b | 7.50 ± 0.04 c |

| F | 86.05 ± 0.9 a | −3.08 ± 0.09 c | 8.22 ± 0.01 b |

| G | 83.61 ± 6.4 b | −3.13 ± 0.2 c | 8.33 ± 0.2 b |

| H | 83.14 ± 5.1 b | −3.02 ± 0.2 c | 7.96 ± 0.4 bc |

| I | 80.66 ± 7.1 c | −2.77 ± 0.2 c | 7.03 ± 0.3 d |

| J | 81.16 ± 5.2 c | −3.34 ± 0.2 d | 8.14 ± 0.3 b |

| K | 87.15 ± 1.6 a | −3.30 ± 0.1 d | 8.64 ± 0.1 ab |

| L | 83.94 ± 2.7 b | −1.84 ± 0.04 a | 7.00 ± 0.6 d |

| Samples | C4:0 | C6:0 | C14:0 | C16:0 | C18:0 | C18:1 | C18:2 | C18:3 |

|---|---|---|---|---|---|---|---|---|

| A | 2.25 ± 0.10 a | 1.67 ± 0.03 a | 12.32 ± 0.03 a | 35.85 ± 0.10 a | 10.33 ± 0.04 c | 22.25 ± 0.10 a | 1.51 ± 0.01 bc | nd b |

| B | 2.25 ± 0.10 a | 1.55 ± 0.10 a | 10.40 ± 0.07 b | 35.23 ± 0.04 a | 13.03 ± 0.04 a | 21.46 ± 0.10 b | 3.03 ± 0.04 b | nd b |

| C | 2.01 ± 0.01 a | 1.50 ± 0.10 a | 12.11 ± 0.01 a | 34.77 ± 0.10 a | 11.41 ± 0.01 b | 22.50 ± 0.10 a | 1.03 ± 0.04 bc | nd b |

| D | 2.16 ± 0.10 a | 1.50 ± 0.10 a | 10.29 ± 0.10 b | 34.34 ± 0.10 a | 12.19 ± 0.10 b | 22.19 ± 0.10 a | 3.91 ± 0.01 b | nd b |

| E | 2.08 ± 0.03 a | 1.50 ± 0.10 a | 12.47 ± 0.10 a | 36.09 ± 0.00 a | 10.61 ± 0.01 c | 22.11 ± 0.00 a | 2.71 ± 0.01 b | nd b |

| F | 1.77 ± 0.10 b | 1.35 ± 0.10 b | 11.63 ± 0.04 a | 35.12 ± 0.10 a | 10.86 ± 0.10 c | 22.75 ± 0.10 a | 2.84 ± 0.10 b | nd b |

| G | nd c | nd c | 0.180 ± 0.04 c | 6.480 ± 0.10 c | 4.110 ± 0.01 d | 23.37 ± 0.10 a | 65.75 ± 0.10 a | 0.10 ± 0.01 a |

| H | nd c | nd c | 0.230 ± 0.04 c | 8.300 ± 0.03 b | 5.040 ± 0.10 d | 22.05 ± 0.10 a | 64.04 ± 0.10 a | 0.12 ± 0.03 a |

| I | nd c | nd c | 0.250 ± 0.10 c | 6.620 ± 0.04 c | 4.210 ± 0.01 d | 23.68 ± 0.10 a | 64.23 ± 0.04 a | 0.14 ± 0.03 a |

| J | nd c | nd c | 0.210 ± 0.00 c | 7.830 ± 0.10 b | 4.840 ± 0.10 d | 22.26 ± 0.10 a | 64.52 ± 0.03 a | 0.12 ± 0.03 a |

| K | nd c | nd c | 0.220 ± 0.03 c | 6.440 ± 0.10 c | 4.120 ± 0.03 d | 22.96 ± 0.10 a | 65.80 ± 0.10 a | 0.13 ± 0.03 a |

| L | nd c | nd c | 0.170 ± 0.03 c | 6.630 ± 0.04 c | 4.160 ± 0.10 d | 23.47 ± 0.00 a | 65.19 ± 0.01 a | 0.14 ± 0.03 a |

| Samples | First Drop Time | Complete Melting Time | Melting Ratio | Dry Matter | Fat or Oleogel | pH | Overrun | L* | a* | b* | Fat Desatabilization | Viscosity (20 rpm) | Viscosity (50 rpm) | C4:0 | C6:0 | C14:0 | C16:0 | C18:1 | C18:2 | C18:3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| First Drop.Time | 1.00 | 0.534 ** | −0.580 ** | 0.26 | 0.39 | −0.09 | −0.32 | 0.09 | 0.22 | −0.37 | −0.35 | 0.809 ** | 0.856 ** | −0.38 | −0.439 * | −0.39 | −0.39 | 0.37 | 0.38 | 0.419 * |

| Co.Melt.Time | 0.53 ** | 1.00 | −0.752 ** | −0.05 | 0.734 ** | −0.32 | −0.743 ** | −0.16 | −0.17 | −0.467 * | −0.607 ** | 0.27 | 0.20 | −.803 ** | −0.821 ** | −0.754 ** | −0.767 ** | 0.824 ** | 0.780 ** | 0.770 ** |

| Mel.Ratio | −0.58 ** | −0.752 ** | 1.00 | −0.23 | −0.439 * | 0.39 | 0.549 ** | 0.00 | 0.408 * | 0.15 | 0.513 * | −0.36 | −0.30 | 0.510 * | 0.625 ** | 0.472 * | 0.553 ** | −0.468 * | −0.482 * | −0.444 * |

| Dry matter | 0.26 | −0.05 | −0.23 | 1.00 | −0.20 | 0.569 ** | 0.05 | 0.15 | −0.37 | 0.36 | 0.40 | 0.34 | 0.25 | 0.09 | −0.12 | 0.14 | −0.13 | 0.15 | −0.14 | −0.07 |

| Fat/oleogel | 0.39 | 0.734 ** | −0.439 * | −0.20 | 1.00 | −0.37 | −0.751 ** | −0.12 | −0.21 | −0.39 | −0.702 ** | 0.00 | 0.05 | −0.947 ** | −0.809 ** | −0.965 ** | −0.775 ** | 0.554 ** | 0.967 ** | 0.951 ** |

| pH | −0.09 | −0.32 | 0.39 | 0.569 ** | −0.37 | 1.00 | 0.25 | −0.25 | 0.02 | 0.14 | 0.550 ** | 0.28 | 0.18 | 0.31 | 0.19 | 0.33 | 0.19 | 0.02 | −0.34 | −0.23 |

| Overrun | −0.32 | −0.743 ** | 0.549 ** | 0.05 | −0.751 ** | 0.25 | 1.00 | 0.26 | 0.31 | 0.27 | 0.30 | 0.07 | 0.11 | 0.787 ** | 0.698 ** | 0.757 ** | 0.757 ** | −0.715 ** | −0.768 ** | −0.748 ** |

| L* | 0.09 | −0.16 | 0.00 | 0.15 | −0.12 | −0.25 | 0.26 | 1.00 | −0.03 | 0.32 | 0.07 | 0.06 | 0.08 | 0.17 | 0.07 | 0.21 | 0.04 | −0.18 | −0.18 | −0.22 |

| a* | 0.22 | −0.17 | 0.408 * | −0.37 | −0.21 | 0.02 | 0.31 | −0.03 | 1.00 | −0.490 * | 0.01 | 0.30 | 0.40 | 0.32 | 0.38 | 0.28 | 0.30 | −0.06 | −0.29 | −0.20 |

| b* | −0.37 | −0.467 * | 0.15 | 0.36 | −0.39 | 0.14 | 0.27 | 0.32 | −0.490 * | 1.00 | 0.412 * | −0.35 | −0.32 | 0.39 | 0.409 * | 0.38 | 0.38 | −0.31 | −0.38 | −0.444 * |

| Fat Destab. | −0.35 | −0.60 ** | 0.513 * | 0.40 | −0.702 ** | 0.550 ** | 0.30 | 0.07 | 0.01 | 0.412 * | 1.00 | −0.16 | −0.24 | 0.610 ** | 0.528 ** | 0.656 ** | 0.431 * | −0.26 | −0.655 ** | −0.631 ** |

| Visc.(20) | 0.81 ** | 0.27 | −0.36 | 0.34 | 0.00 | 0.28 | 0.07 | 0.06 | 0.30 | −0.35 | −0.16 | 1.00 | 0.953 ** | −0.01 | −0.23 | 0.00 | −0.15 | 0.16 | −0.01 | 0.05 |

| Visc.(50) | 0.85 ** | 0.20 | −0.30 | 0.25 | 0.05 | 0.18 | 0.11 | 0.08 | 0.40 | −0.32 | −0.24 | 0.953 ** | 1.00 | −0.01 | −0.12 | −0.04 | −0.03 | 0.06 | 0.02 | 0.09 |

| C4:0 | −0.38 | −0.803 ** | 0.510 * | 0.09 | −0.947 ** | 0.31 | 0.787 ** | 0.17 | 0.32 | 0.39 | 0.610 ** | −0.01 | −0.01 | 1.00 | 0.890 ** | 0.984 ** | 0.823 ** | −0.627 ** | −0.992 ** | −0.954 ** |

| C6:0 | −0.44 * | −0.821 ** | 0.625 ** | −0.12 | −0.809 ** | 0.19 | 0.698 ** | 0.07 | 0.38 | 0.409 * | 0.528 ** | −0.23 | −0.12 | 0.890 ** | 1.00 | 0.832 ** | 0.949 ** | −0.646 ** | −0.843 ** | −0.818 ** |

| C14:0 | −0.39 | −0.754 ** | 0.472 * | 0.14 | −0.965 ** | 0.33 | 0.757 ** | 0.21 | 0.28 | 0.38 | 0.656 ** | 0.00 | −0.04 | 0.984 ** | 0.832 ** | 1.00 | 0.762 ** | −0.558 ** | −0.995 ** | −0.955 ** |

| C16:0 | −0.39 | −0.767 ** | 0.553 ** | −0.13 | −0.775 ** | 0.19 | 0.757 ** | 0.04 | 0.30 | 0.38 | 0.431 * | −0.15 | −0.03 | 0.823 ** | 0.949 ** | 0.762 ** | 1.00 | −0.703 ** | −0.773 ** | −0.760 ** |

| C18:1 | 0.37 | 0.824 ** | −0.468 * | 0.15 | 0.554 ** | 0.02 | −0.715 ** | −0.18 | −0.06 | −0.31 | −0.26 | 0.16 | 0.06 | −0.627 ** | −0.646 ** | −0.558 ** | −0.703 ** | 1.00 | 0.594 ** | 0.632 ** |

| C18:2 | 0.38 | 0.780 ** | 0.482 * | −0.14 | 0.967 ** | −0.34 | −0.768 ** | −0.18 | −0.29 | −0.38 | −0.655 ** | −0.01 | 0.02 | −0.992 ** | −0.843 ** | −0.995 ** | −0.773 ** | 0.594 ** | 1.00 | 0.961 ** |

| C18:3 | 0.42 * | 0.770 ** | −0.444 * | −0.07 | 0.951 ** | −0.23 | −0.748 ** | −0.22 | −0.20 | −0.444 * | −0.631 ** | 0.05 | 0.09 | −0.954 ** | −0.818 ** | −0.955 ** | −0.760 ** | 0.632 ** | 0.961 ** | 1.00 |

| Samples | Color Appearance | Texture Consistency | Gummy | Taste Smell | Sweetness | General Acceptability |

|---|---|---|---|---|---|---|

| A | 8.50 | 8.00 | 8.00 | 8.00 | 7.50 | 8.00 |

| B | 9.00 | 8.00 | 7.00 | 7.50 | 7.50 | 7.00 |

| C | 8.50 | 8.50 | 8.00 | 9.00 | 8.50 | 9.00 |

| D | 8.00 | 8.00 | 7.00 | 7.50 | 6.50 | 6.50 |

| E | 8.00 | 8.00 | 7.00 | 7.00 | 7.00 | 7.00 |

| F | 9.00 | 8.00 | 8.00 | 7.50 | 7.50 | 7.50 |

| G | 8.00 | 7.00 | 7.00 | 5.00 | 6.00 | 5.00 |

| H | 7.50 | 7.50 | 7.00 | 7.00 | 7.50 | 7.00 |

| I | 7.50 | 7.50 | 7.50 | 6.50 | 7.00 | 6.50 |

| J | 8.50 | 8.00 | 8.00 | 7.50 | 7.50 | 7.50 |

| K | 8.50 | 7.50 | 6.50 | 7.00 | 7.50 | 7.00 |

| L | 9.00 | 8.00 | 8.00 | 7.00 | 7.50 | 6.50 |

| Samples | Fat or Oil Sources | Stabilizers | Emulsifiers | Milk | Milk Powder | Raw Cream | Sucrose |

|---|---|---|---|---|---|---|---|

| A | milk fat | Salep | NE | fat | + | + | + |

| B | milk fat | Salep | MG | fat | + | + | + |

| C | milk fat | Salep | PG | fat | + | + | + |

| D | milk fat | KG | NE | fat | + | + | + |

| E | milk fat | KG | MG | fat | + | + | + |

| F | milk fat | KG | PG | fat | + | + | + |

| G | oleogel | Salep | NE | non fat | + | _ | + |

| H | Oleogel | Salep | MG | non fat | + | _ | + |

| I | Oleogel | Salep | PG | non fat | + | _ | + |

| J | Oleogel | KG | NE | non fat | + | _ | + |

| K | Oleogel | KG | MG | non fat | + | _ | + |

| L | Oleogel | KG | PG | non fat | + | _ | + |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozdemir, C. An Investigation of Several Physicochemical Characteristics, as Well as the Cholesterol and Fatty Acid Profile of Ice Cream Samples Containing Oleogel, Various Stabilizers, and Emulsifiers. Gels 2023, 9, 543. https://doi.org/10.3390/gels9070543

Ozdemir C. An Investigation of Several Physicochemical Characteristics, as Well as the Cholesterol and Fatty Acid Profile of Ice Cream Samples Containing Oleogel, Various Stabilizers, and Emulsifiers. Gels. 2023; 9(7):543. https://doi.org/10.3390/gels9070543

Chicago/Turabian StyleOzdemir, Cihat. 2023. "An Investigation of Several Physicochemical Characteristics, as Well as the Cholesterol and Fatty Acid Profile of Ice Cream Samples Containing Oleogel, Various Stabilizers, and Emulsifiers" Gels 9, no. 7: 543. https://doi.org/10.3390/gels9070543

APA StyleOzdemir, C. (2023). An Investigation of Several Physicochemical Characteristics, as Well as the Cholesterol and Fatty Acid Profile of Ice Cream Samples Containing Oleogel, Various Stabilizers, and Emulsifiers. Gels, 9(7), 543. https://doi.org/10.3390/gels9070543