Aerogels for Thermal Protection and Their Application in Aerospace

Abstract

:1. Introduction

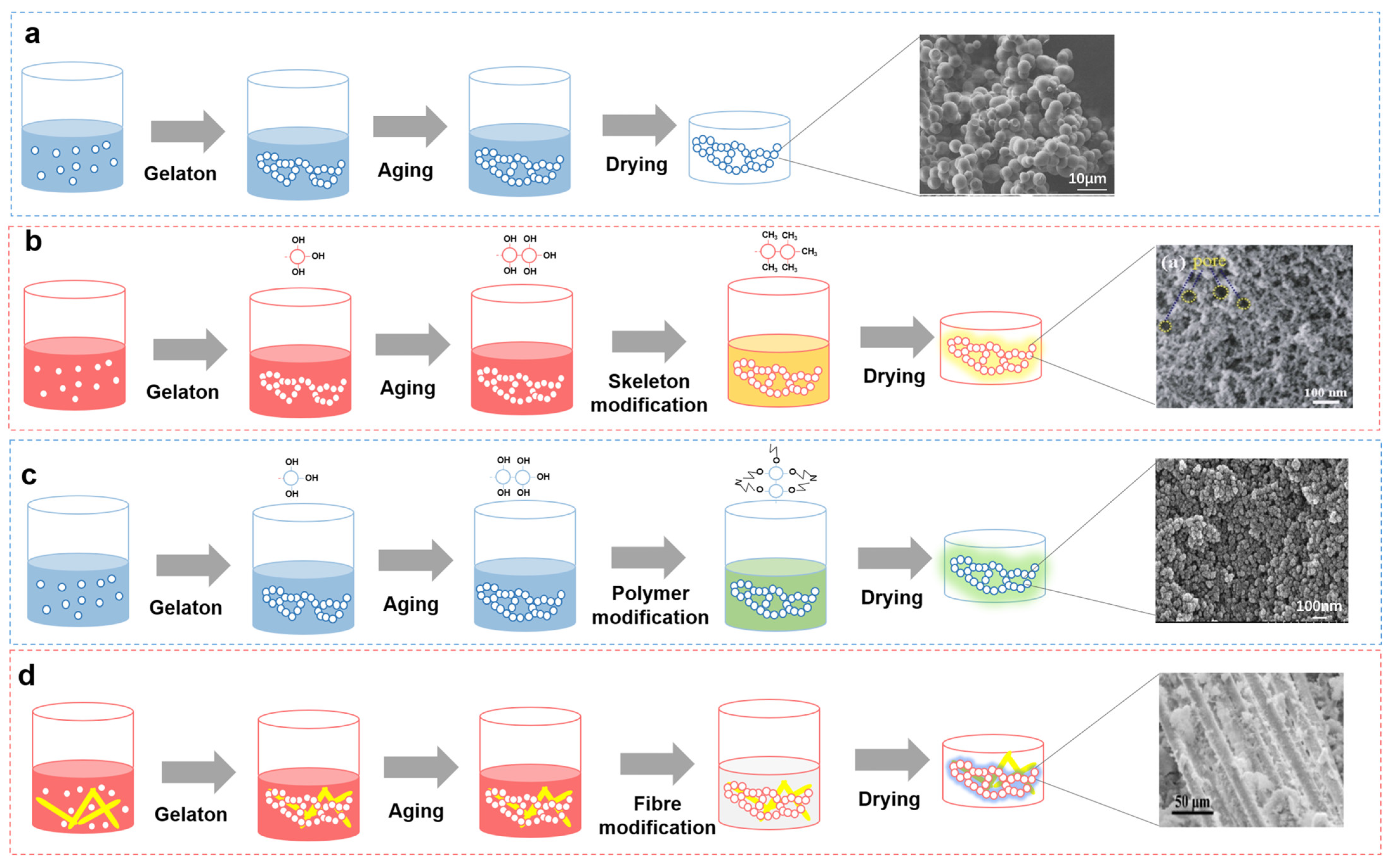

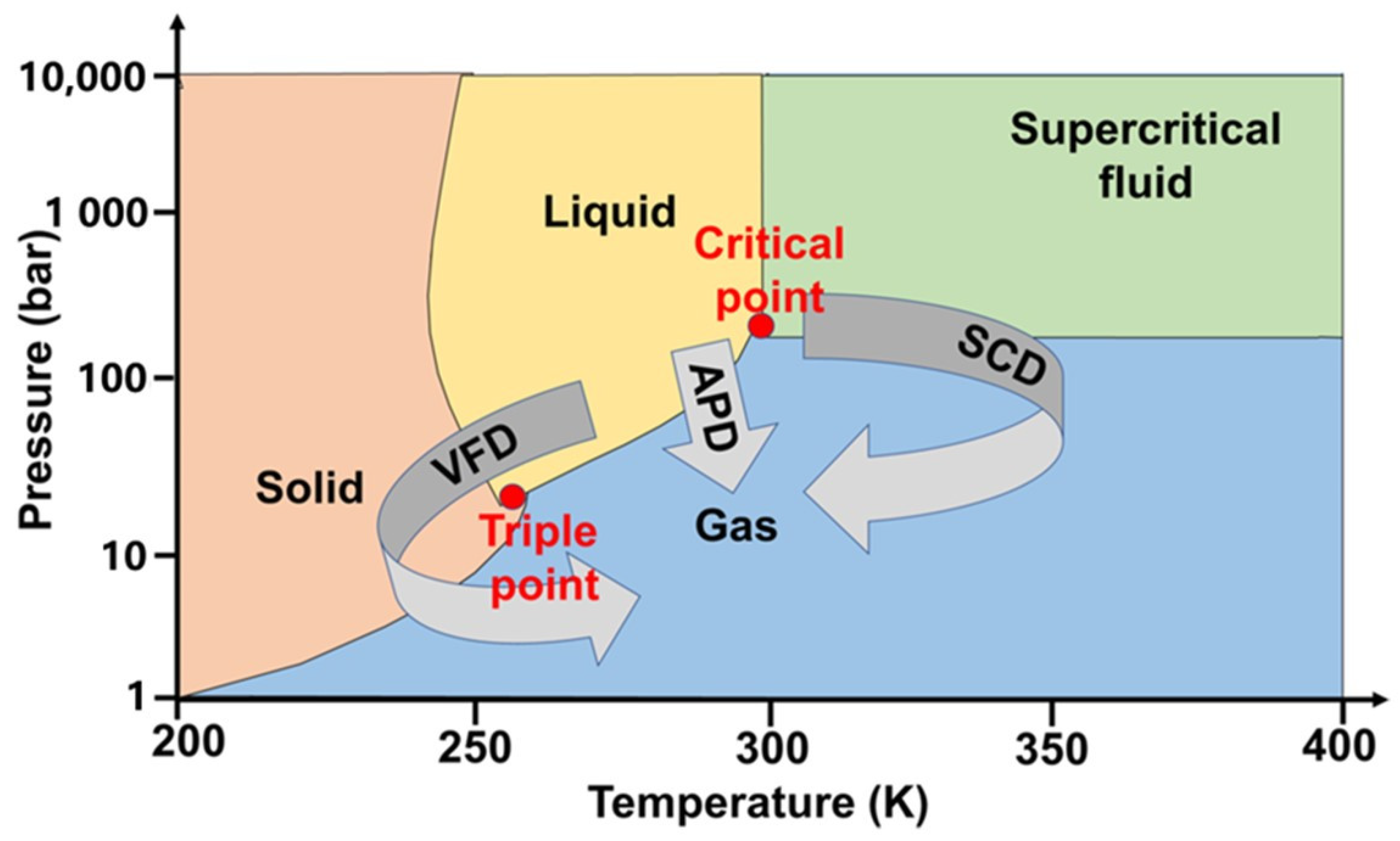

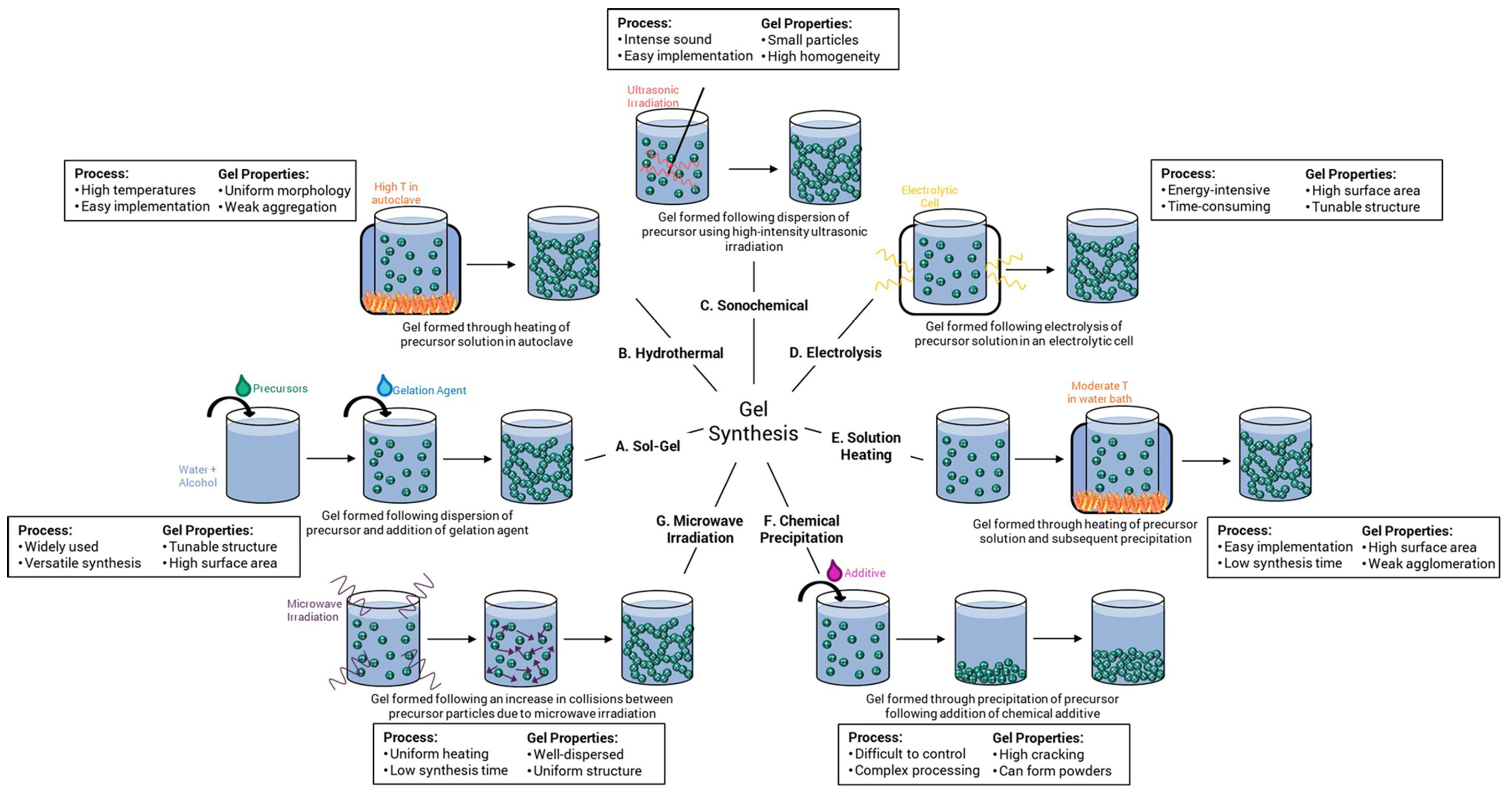

2. Process and Performance of the Aerogel for Thermal Protection

2.1. Inorganic Oxide Aerogels and Composites for Thermal Protection

2.1.1. Single-Component Oxide Aerogels and Composites for Thermal Protection

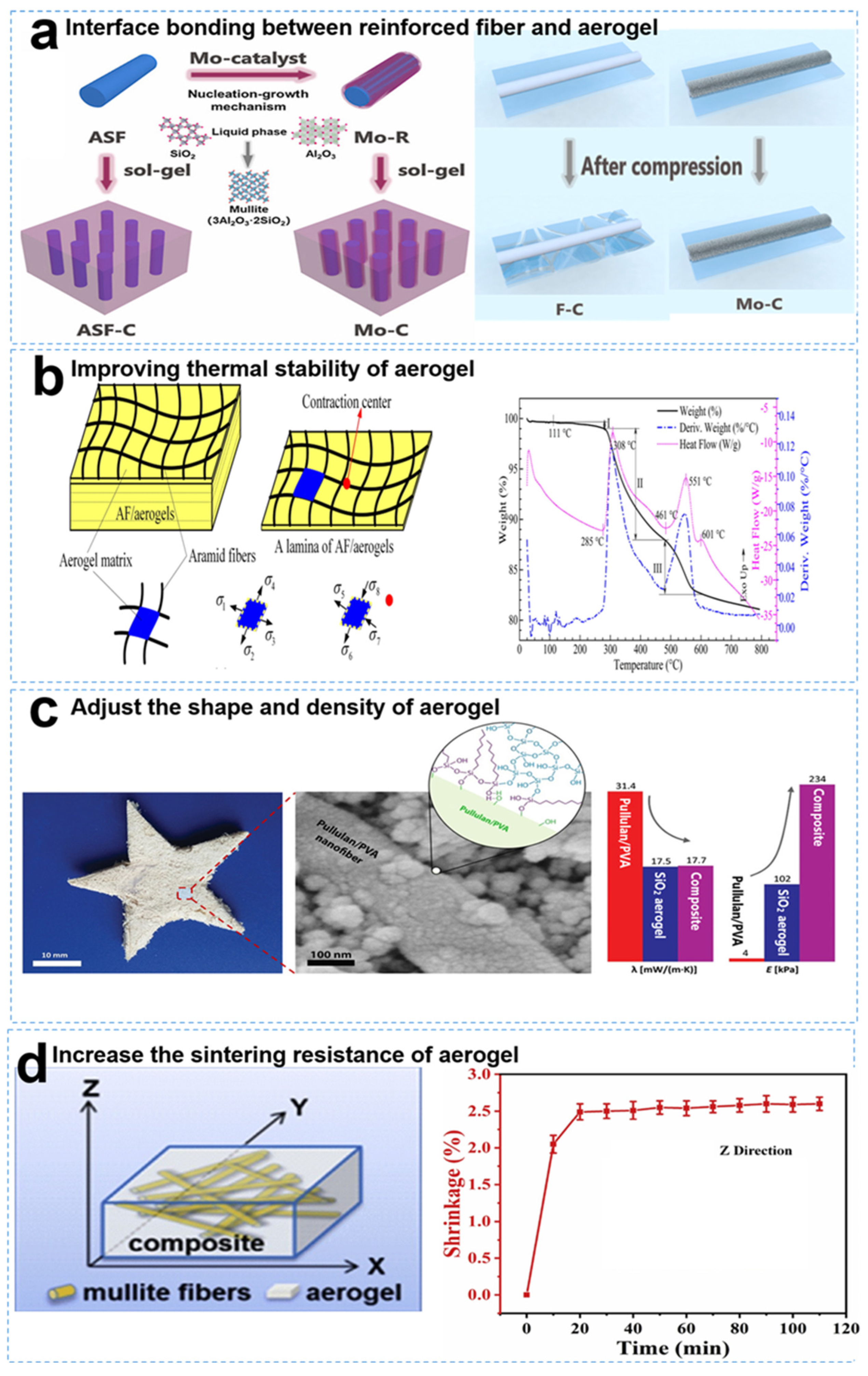

SiO2 Aerogel and Composites for Thermal Protection

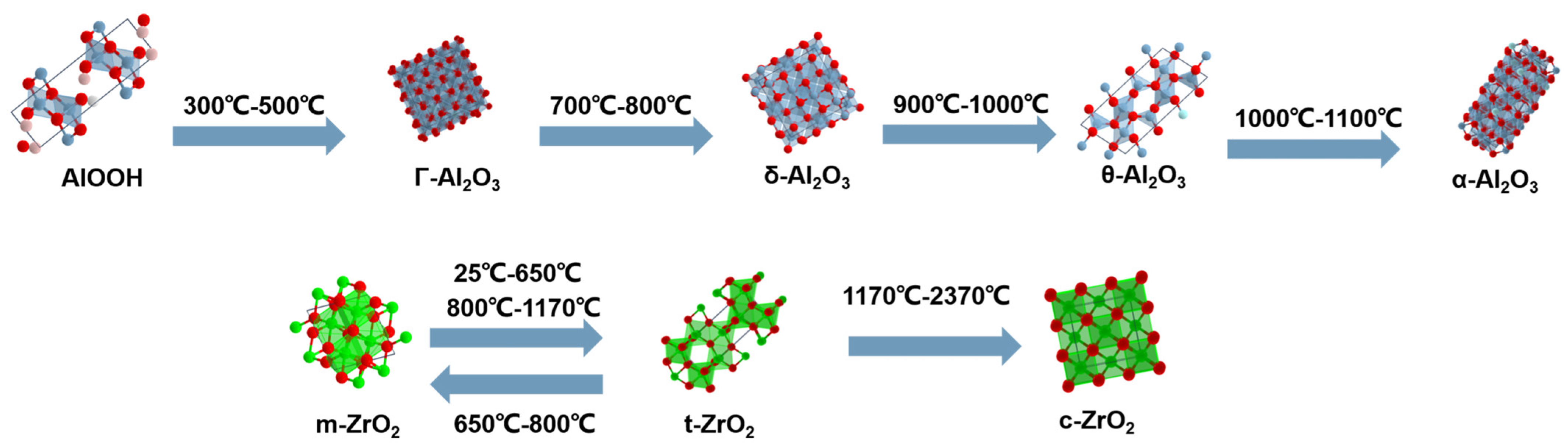

Al2O3 Aerogel and Composites for Thermal Protection

ZrO2 Aerogel and Composites for Thermal Protection

2.1.2. Multioxide Aerogels and Composites for Thermal Protection

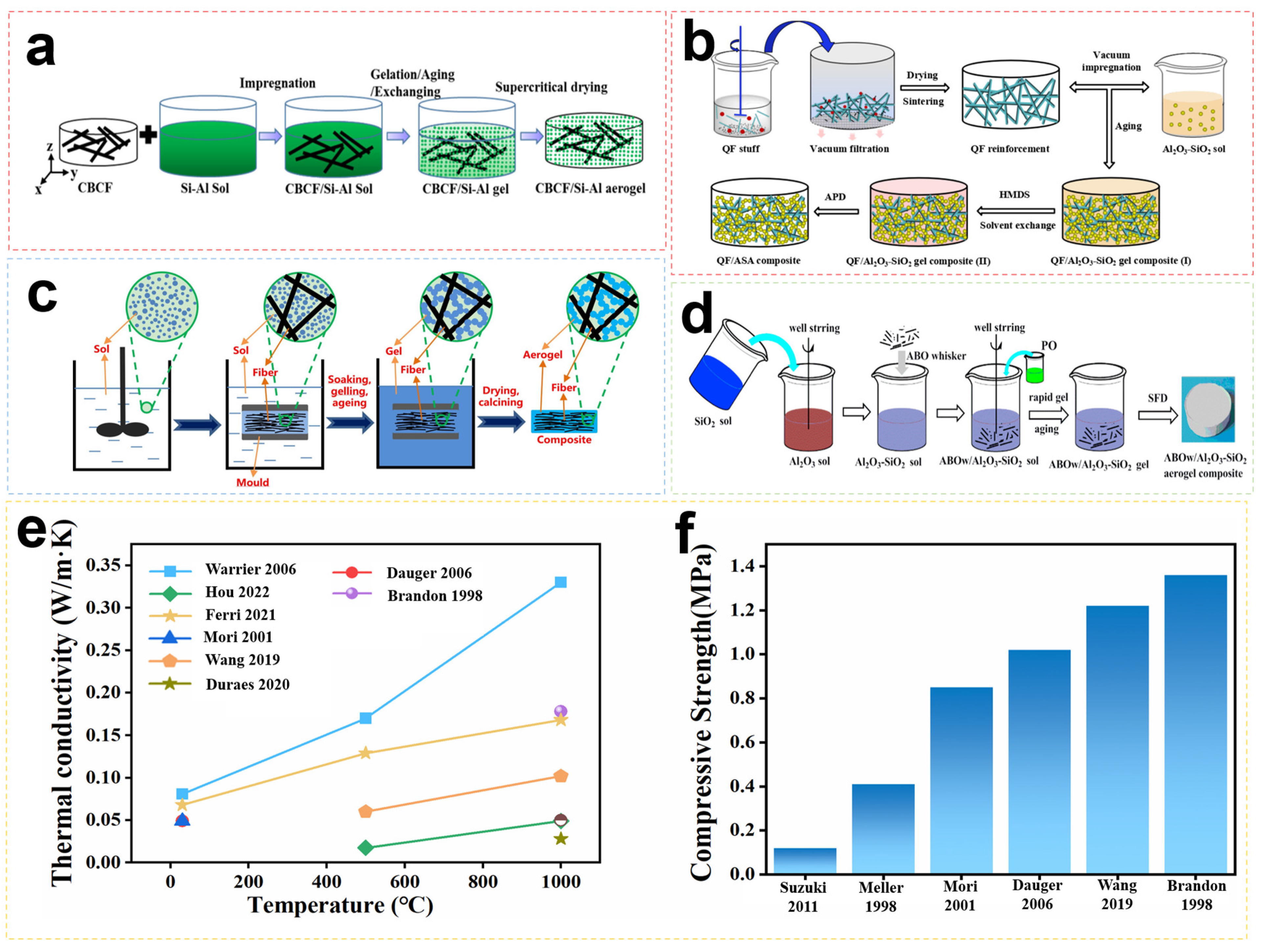

Al2O3-SiO2 Aerogel and Composites for Thermal Protection

ZrO2-SiO2 Aerogel and Composites for Thermal Protection

2.2. Organic Aerogels and Composites for Thermal Protection

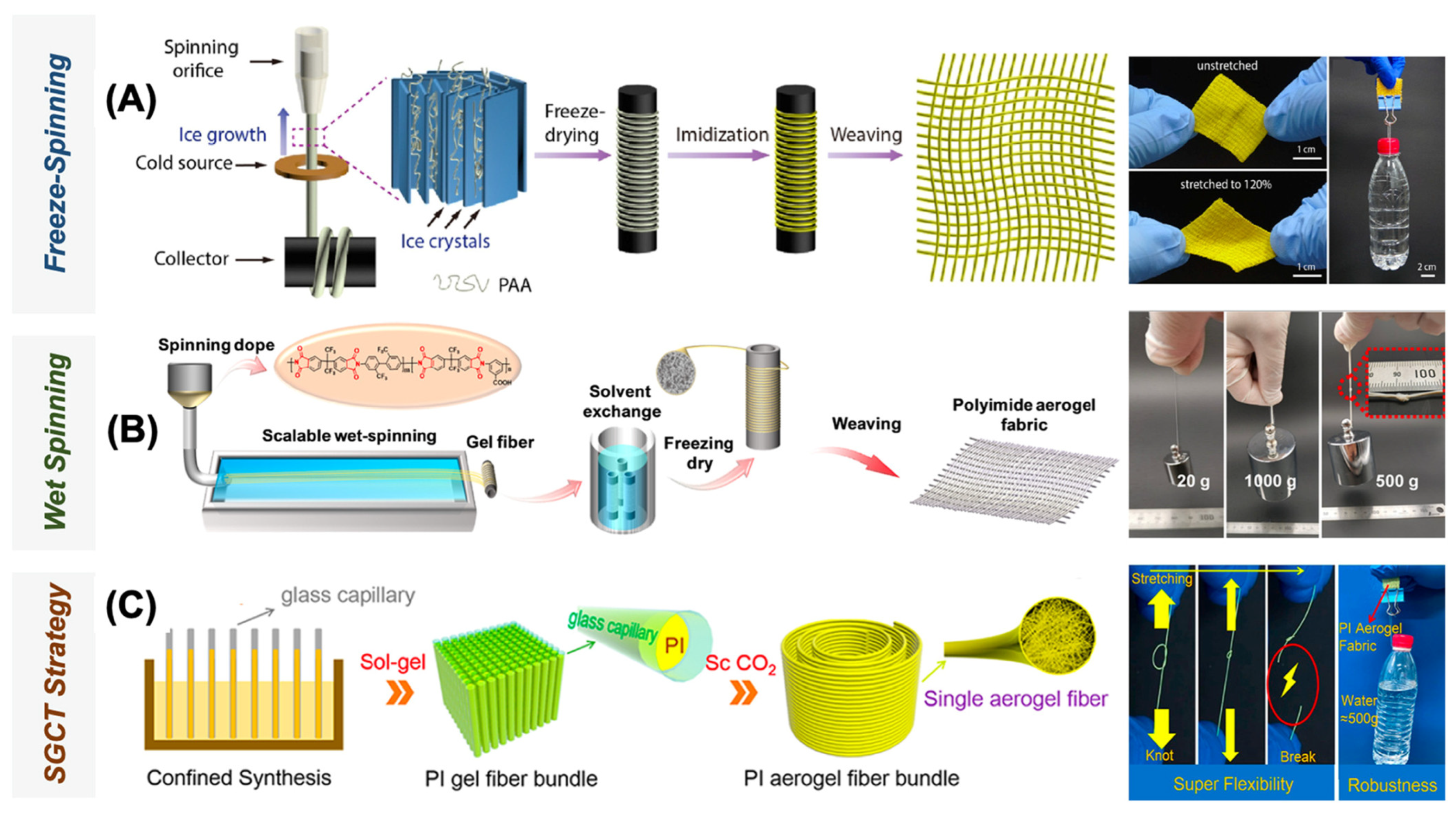

2.2.1. Polyimide Aerogels and Composites for Thermal Protection

| Raw Materials | Enhancement Phase | Density/g·cm−3 | Thermal Conductivity/W·(m·K)−1 | Shrinkage/% | Reference |

|---|---|---|---|---|---|

| NMP 4, ODA 1, BPDA 2 | SiO2 aerogel-powders | 0.020 | 0.028 | 7.5 | [87] |

| DMAc 3, BPDA 2, ODA 1, TEA | SiO2 nanoparticles | 0.080 | 0.020 | 9.0 | [88] |

| DMAc 3, ODA 1, PAA | FHal 8 | 0.065 | 0.039 | 21.9 | [90] |

| NMP 4, ODA 1, PMDA | SiC whisker | 0.238 | 0.036 | 16.2 | [94] |

| ODA 1, BPDA 2, PAA 5 | CNT | 0.107 | 0.023 | 6.2 | [92] |

| PAA, LDH 6 | GO 9 | 0.052 | 0.036 | 29 | [93] |

| ODA 1, PPDA 7 | Glass fiber | 0.143–0.177 | 0.023–0.029 | - | [89] |

2.2.2. Phenolic Aerogels and Composites for Thermal Protection

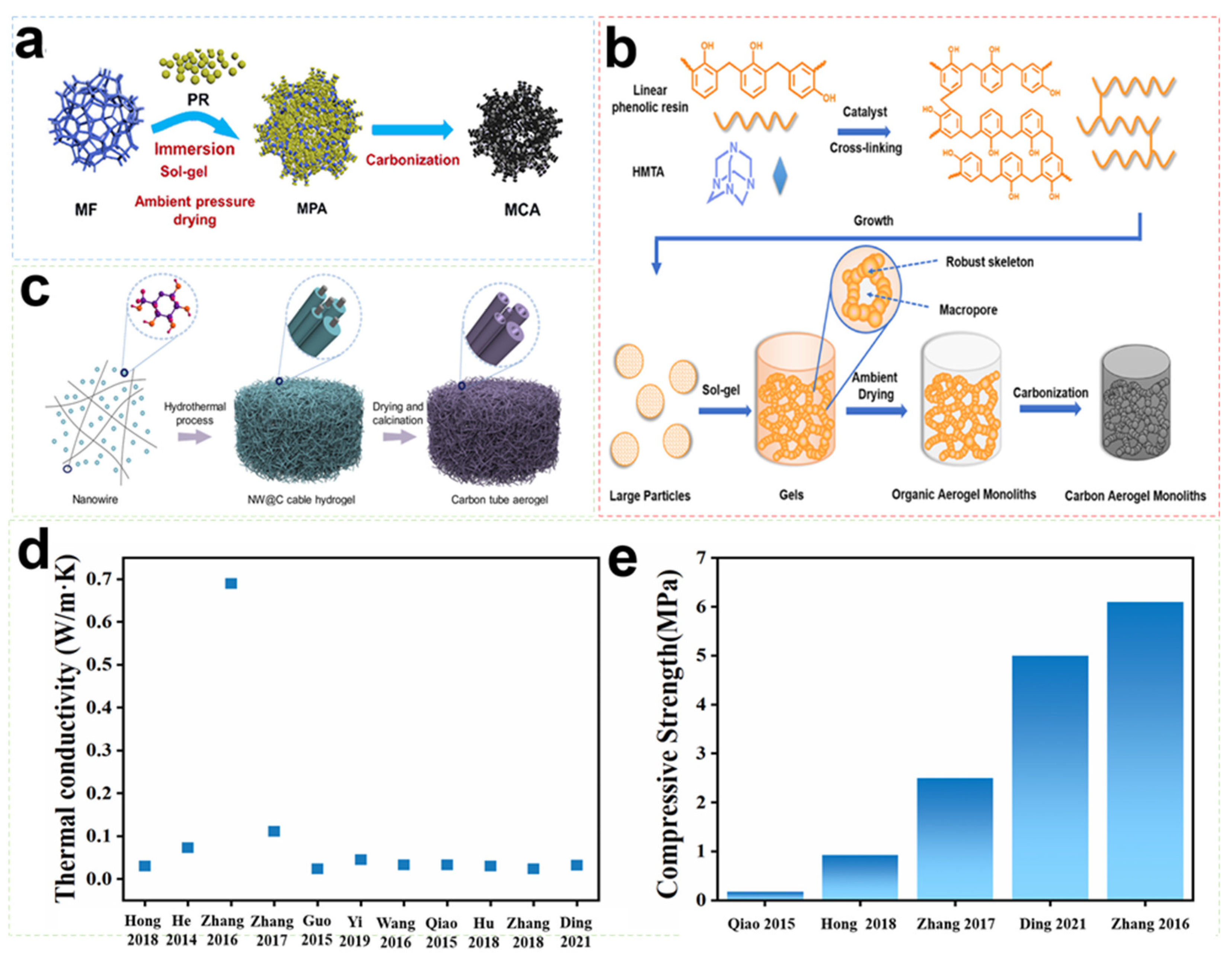

2.3. Carbon Aerogels and Carbide Aerogels and Composites for Thermal Protection

2.3.1. Carbon Aerogels and Composites for Thermal Protection

2.3.2. Carbide Aerogels and Composites for Thermal Protection

SiC Aerogels and Composites for Thermal Protection

| Raw Materials | Density/g·cm−3 | Specific Surface Area/m2·g−1 | Thermal Conductivity/W·(m·K)−1 | Reference |

|---|---|---|---|---|

| PAN 1, SiO2 | 0.500 | 20 | - | [138] |

| PAN 1, TMOS | 0.320 | 20 | - | [139] |

| APTES 2 | 0.29 | 251 | - | [140] |

| SMP-10 3 | 0.170 | 444 | - | [141] |

| PCS-800 4, KIT-6 | - | 942 | - | [142] |

| Siloxane gel | 0.005 | 78 | 0.026 | [143] |

| Graphene foam | 0.017 | - | 0.160 | [144] |

| SiO powder, Balsa wood | - | - | 0.019 | [145] |

| SiC Nanowire | 0.007 | - | 0.014 | [133] |

| SiC fiber | 0.039 | - | 0.025 | [146] |

| Si powder, SiO2 powder | 0.076 | - | 0.035 | [140] |

Other Carbide Aerogels and Composites for Thermal Protection

3. Application of Aerogels for Thermal Protection in the Aerospace Field

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kistler, S.S. Coherent Expanded Aerogels and Jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Sert Çok, S.; Gizli, N. Microstructural Properties and Heat Transfer Characteristics of In-Situ Modified Silica Aerogels Prepared with Different Organosilanes. Int. J. Heat. Mass. Transf. 2022, 188, 122618. [Google Scholar] [CrossRef]

- Su, L.; Niu, M.; Lu, D.; Cai, Z.; Li, M.; Wang, H. A Review on the Emerging Resilient and Multifunctional Ceramic Aerogels. J. Mater. Sci. Technol. 2021, 75, 1–13. [Google Scholar] [CrossRef]

- Du, A.; Zhou, B.; Zhang, Z.; Shen, J. A Special Material or a New State of Matter: A Review and Reconsideration of the Aerogel. Materials 2013, 6, 941–968. [Google Scholar] [CrossRef] [Green Version]

- Tang, G.H.; Zhao, Y.; Guo, J.F. Multi-Layer Graded Doping in Silica Aerogel Insulation with Temperature Gradient. Int. J. Heat. Mass. Transf. 2016, 99, 192–200. [Google Scholar] [CrossRef]

- El Mel, A.A.; Angleraud, B.; Gautron, E. Preparation and surface modification mechanism of silica aerogels via ambient pressure drying. Mater. Chem. Phys. 2011, 129, 308–314. [Google Scholar] [CrossRef]

- Meador, M.A.B.; Weber, A.S.; Hindi, A.; Naumenko, M.; McCorkle, L.; Quade, D.; Vivod, S.L.; Gould, G.L.; White, S.; Deshpande, K. Structure−Property Relationships in Porous 3D Nanostructures: Epoxy-Cross-Linked Silica Aerogels Produced Using Ethanol as the Solvent. ACS Appl. Mater. Interfaces 2009, 1, 894–906. [Google Scholar] [CrossRef]

- Zhou, T.; Cheng, X.; Pan, Y.; Li, C.; Gong, L.; Zhang, H. Mechanical Performance and Thermal Stability of Glass Fiber Reinforced Silica Aerogel Composites Based on Co-Precursor Method by Freeze Drying. Appl. Surf. Sci. 2018, 437, 321–328. [Google Scholar] [CrossRef]

- Vareda, J.P.; Matias, T.; Durães, L. Facile Preparation of Ambient Pressure Dried Aerogel-like Monoliths with Reduced Shrinkage Based on Vinyl-Modified Silica Networks. Ceram. Int. 2018, 44, 17453–17458. [Google Scholar] [CrossRef]

- Ismail, A.A.; Ibrahim, I.A. Impact of Supercritical Drying and Heat Treatment on Physical Properties of Titania/Silica Aerogel Monolithic and Its Applications. Appl. Catal. A Gen. Gen. 2008, 346, 200–205. [Google Scholar] [CrossRef]

- Stojanovic, A.; Paz Comesaña, S.; Rentsch, D.; Koebel, M.M.; Malfait, W.J. Ambient Pressure Drying of Silica Aerogels after Hydrophobization with Mono-, Di- and Tri-Functional Silanes and Mixtures Thereof. Microporous Mesoporous Mater. 2019, 284, 289–295. [Google Scholar] [CrossRef]

- He, F.; Zhao, H.; Qu, X.; Zhang, C.; Qiu, W. Modified Aging Process for Silica Aerogel. J. Mater. Process. Technol. 2009, 209, 1621–1626. [Google Scholar] [CrossRef]

- Duan, Y.; Jana, S.C.; Reinsel, A.M.; Lama, B.; Espe, M.P. Surface Modification and Reinforcement of Silica Aerogels Using Polyhedral Oligomeric Silsesquioxanes. Langmuir 2012, 28, 15362–15371. [Google Scholar] [CrossRef]

- Leventis, N.; Sotiriou-Leventis, C.; Zhang, G.; Rawashdeh, A.-M.M. Nanoengineering Strong Silica Aerogels. Nano Lett. 2002, 2, 957–960. [Google Scholar] [CrossRef]

- Wei, T.-Y.; Lu, S.-Y.; Chang, Y.-C. Transparent, Hydrophobic Composite Aerogels with High Mechanical Strength and Low High-Temperature Thermal Conductivities. J. Phys. Chem. B 2008, 112, 11881–11886. [Google Scholar] [CrossRef]

- Randall, J.P.; Meador, M.A.B.; Jana, S.C. Tailoring Mechanical Properties of Aerogels for Aerospace Applications. ACS Appl. Mater. Interfaces 2011, 3, 613–626. [Google Scholar] [CrossRef]

- Feng, J.; Chen, D.; Ni, W.; Yang, S.; Hu, Z. Study of IR Absorption Properties of Fumed Silica-Opacifier Composites. J. Non-Cryst. Solids 2010, 356, 480–483. [Google Scholar] [CrossRef]

- Yuan, B.; Ding, S.; Wang, D.; Wang, G.; Li, H. Heat Insulation Properties of Silica Aerogel/Glass Fiber Composites Fabricated by Press Forming. Mater. Lett. 2012, 75, 204–206. [Google Scholar] [CrossRef]

- Erden, S.; Ho, K. 3—Fiber Reinforced Composites. In Fiber Technology for Fiber-Reinforced Composites; Seydibeyoğlu, M.Ö., Mohanty, A.K., Misra, M., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2017; pp. 51–79. ISBN 978-0-08-101871-2. [Google Scholar]

- Liao, Y.; Wu, H.; Ding, Y.; Yin, S.; Wang, M.; Cao, A. Engineering Thermal and Mechanical Properties of Flexible Fiber-Reinforced Aerogel Composites. J. Sol-Gel. Sci. Technol. 2012, 63, 445–456. [Google Scholar] [CrossRef]

- Wu, Q.; Yang, L.; Chen, Z.; Yang, M.; Liu, T.; Li, M.; Mukhopadhyaya, P. SiO2 Aerogel Multiscale Reinforced by Glass Fibers and SiC Nanowhiskers for Thermal Insulation. J. Porous Mater. 2023. ahead of print. [Google Scholar] [CrossRef]

- Li, Z.; Gong, L.; Cheng, X.; He, S.; Li, C.; Zhang, H. Flexible Silica Aerogel Composites Strengthened with Aramid Fibers and Their Thermal Behavior. Mater. Des. 2016, 99, 349–355. [Google Scholar] [CrossRef]

- Moretto, L.M.; Kalcher, K. (Eds.) Environmental Analysis by Electrochemical Sensors and Biosensors: Fundamentals; Nanostructure Science and Technology; Springer: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Zhao, S.; Emery, O.; Wohlhauser, A.; Koebel, M.M.; Adlhart, C.; Malfait, W.J. Merging Flexibility with Superinsulation: Machinable, Nanofibrous Pullulan-Silica Aerogel Composites. Mater. Des. 2018, 160, 294–302. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Z.; Kong, Y.; Chu, C.; Tang, J.; Ren, J.; Shen, X. Facile Preparation of Nano-SiO2 Composites with Excellent High-Temperature Thermal Insulation Performance. Ceram. Int. 2022, 48, 27486–27492. [Google Scholar] [CrossRef]

- Cai, H.; Jiang, Y.; Chen, Q.; Zhang, S.; Li, L.; Feng, J.; Feng, J. Sintering Behavior of SiO2 Aerogel Composites Reinforced by Mullite Fibers via In-Situ Rapid Heating TEM Observations. J. Eur. Ceram. Soc. 2020, 40, 127–135. [Google Scholar] [CrossRef]

- Yi, Z.; Zhang, X.; Yan, L.; Huyan, X.; Zhang, T.; Liu, S.; Guo, A.; Liu, J.; Hou, F. Super-Insulated, Flexible, and High Resilient Mullite Fiber Reinforced Silica Aerogel Composites by Interfacial Modification with Nanoscale Mullite Whisker. Compos. Part. B Eng. 2022, 230, 109549. [Google Scholar] [CrossRef]

- Pierre, A.; Begag, R.; Pajonk, G. Structure and Texture of Alumina Aerogel Monoliths Made by Complexation with Ethyl Acetoacetate. J. Mater. Sci. 1999, 34, 4937–4944. [Google Scholar] [CrossRef]

- Pakharukova, V.P.; Shalygin, A.S.; Gerasimov, E.Y.; Tsybulya, S.V.; Martyanov, O.N. Structure and Morphology Evolution of Silica-Modified Pseudoboehmite Aerogels during Heat Treatment. J. Solid State Chem. 2016, 233, 294–302. [Google Scholar] [CrossRef]

- Baumann, T.F.; Gash, A.E.; Chinn, S.C.; Sawvel, A.M.; Maxwell, R.S.; Satcher, J.H. Synthesis of High-Surface-Area Alumina Aerogels without the Use of Alkoxide Precursors. Chem. Mater. 2005, 17, 395–401. [Google Scholar] [CrossRef] [Green Version]

- Mazrouei-Sebdani, Z.; Naeimirad, M.; Peterek, S.; Begum, H.; Galmarini, S.; Pursche, F.; Baskin, E.; Zhao, S.; Gries, T.; Malfait, W.J. Multiple Assembly Strategies for Silica Aerogel-Fiber Combinations—A Review. Mater. Des. 2022, 223, 111228. [Google Scholar] [CrossRef]

- Xu, L.; Jiang, Y.; Feng, J.; Feng, J.; Yue, C. Infrared-Opacified Al2O3–SiO2 Aerogel Composites Reinforced by SiC-Coated Mullite Fibers for Thermal Insulations. Ceram. Int. 2015, 41, 437–442. [Google Scholar] [CrossRef]

- Mizushima, Y.; Hori, M. Preparation of an Alumina Aerogel with SiC Whisker Inclusion. J. Eur. Ceram. Soc. 1994, 14, 117–121. [Google Scholar] [CrossRef]

- Gao, M.; Liu, B.; Zhao, P.; Yi, X.; Shen, X.; Xu, Y. Mechanical Strengths and Thermal Properties of Titania-Doped Alumina Aerogels and the Application as High-Temperature Thermal Insulator. J. Sol-Gel Sci. Technol. 2019, 91, 514–522. [Google Scholar] [CrossRef]

- Zu, G.; Shen, J.; Zou, L.; Wang, W.; Lian, Y.; Zhang, Z.; Du, A. Nanoengineering Super Heat-Resistant, Strong Alumina Aerogels. Chem. Mater. 2013, 25, 4757–4764. [Google Scholar] [CrossRef]

- Zhang, R.; Ye, C.; Wang, B. Novel Al2O3–SiO2 Aerogel/Porous Zirconia Composite with Ultra-Low Thermal Conductivity. J. Porous Mater. 2018, 25, 171–178. [Google Scholar] [CrossRef]

- Zu, G.; Shen, J.; Wang, W.; Zou, L.; Lian, Y.; Zhang, Z.; Liu, B.; Zhang, F. Robust, Highly Thermally Stable, Core–Shell Nanostructured Metal Oxide Aerogels as High-Temperature Thermal Superinsulators, Adsorbents, and Catalysts. Chem. Mater. 2014, 26, 5761–5772. [Google Scholar] [CrossRef]

- Teichner, S.J.; Nicolaon, G.A.; Vicarini, M.A.; Gardes, G.E.E. Inorganic Oxide Aerogels. Adv. Colloid. Interface Sci. 1976, 5, 245–273. [Google Scholar] [CrossRef]

- Hetrick, R.E.; Schamp, A.L. Capacitive Air-Fuel Ratio Sensor. Sens. Actuators B Chem. 1994, 21, 5–10. [Google Scholar] [CrossRef]

- Tanabe, K. Surface and Catalytic Properties of ZrO2. Mater. Chem. Phys. 1985, 13, 347–364. [Google Scholar] [CrossRef]

- Bedilo, A.F.; Klabunde, K.J. Synthesis of High Surface Area Zirconia Aerogels Using High Temperature Supercritical Drying. Nanostruct. Mater. 1997, 8, 119–135. [Google Scholar] [CrossRef]

- Cao, Y.; Hu, J.-C.; Hong, Z.-S.; Deng, J.-F.; Fan, K.-N. Characterization of High-Surface-Area Zirconia Aerogel Synthesized from Combined Alcohothermal and Supercritical Fluid Drying Techniques. Catal. Lett. 2002, 81, 107–112. [Google Scholar] [CrossRef]

- Guo, J.; Xin, X.; Zhang, X.; Zhang, S. Ultrasonic-Induced Synthesis of High Surface Area Colloids CeO2–ZrO2. J. Nanopart. Res. 2009, 11, 737–741. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, D.; Jiao, X. Zirconia Aerogels with High Surface Area Derived from Sols Prepared by Electrolyzing Zirconium Oxychloride Solution: Comparison of Aerogels Prepared by Freeze-Drying and Supercritical CO2(l) Extraction. J. Phys. Chem. C 2007, 111, 18738–18743. [Google Scholar] [CrossRef]

- Wu, Z.G.; Zhao, Y.X.; Xu, L.P.; Liu, D.S. Preparation of Zirconia Aerogel by Heating of Alcohol–Aqueous Salt Solution. J. Non-Cryst. Solids 2003, 330, 274–277. [Google Scholar] [CrossRef]

- Verma, S.; Amritphale, S.S.; Das, S. Synchronising Effect of Microwave and Cytosine for the Synthesis of Hybrid Homogenised Nanosized Cerium Oxide and Cerium Oxycarbonate Hydrate Material. J. Chem. Res. 2016, 40, 321–325. [Google Scholar] [CrossRef]

- Siddiquey, I.A.; Furusawa, T.; Sato, M.; Bahadur, N.M.; Uddin, M.N.; Suzuki, N. A Rapid Method for the Preparation of Silica-Coated ZrO2 Nanoparticles by Microwave Irradiation. Ceram. Int. 2011, 37, 1755–1760. [Google Scholar] [CrossRef]

- Walker, R.C.; Potochniak, A.E.; Hyer, A.P.; Ferri, J.K. Zirconia Aerogels for Thermal Management: Review of Synthesis, Processing, and Properties Information Architecture. Adv. Colloid Interface Sci. 2021, 295, 102464. [Google Scholar] [CrossRef]

- Levin, I.; Brandon, D. Metastable Alumina Polymorphs: Crystal Structures and Transition Sequences. J. Am. Ceram. Soc. 1998, 81, 1995–2012. [Google Scholar] [CrossRef]

- Lenormand, P.; Lecomte, A.; Babonneau, D.; Dauger, A. X-Ray Reflectivity, Diffraction and Grazing Incidence Small Angle X-Ray Scattering as Complementary Methods in the Microstructural Study of Sol–Gel Zirconia Thin Films. Thin Solid Films 2006, 495, 224–231. [Google Scholar] [CrossRef] [Green Version]

- Almeida, C.M.R.; Ghica, M.E.; Durães, L. An Overview on Alumina-Silica-Based Aerogels. Adv. Colloid. Interface Sci. 2020, 282, 102189. [Google Scholar] [CrossRef]

- Horiuchi, T.; Osaki, T.; Sugiyama, T.; Suzuki, K.; Mori, T. Maintenance of Large Surface Area of Alumina Heated at Elevated Temperatures above 1300 °C by Preparing Silica-Containing Pseudoboehmite Aerogel. J. Non-Cryst. Solids 2001, 291, 187–198. [Google Scholar] [CrossRef]

- Miller, J. A Homogeneously Dispersed Silica Dopant for Control of the Textural and Structural Evolution of an Alumina Aerogel. Catal. Today 1998, 43, 51–67. [Google Scholar] [CrossRef]

- Aravind, P.R.; Mukundan, P.; Krishna Pillai, P.; Warrier, K.G.K. Mesoporous Silica–Alumina Aerogels with High Thermal Pore Stability through Hybrid Sol–Gel Route Followed by Subcritical Drying. Microporous Mesoporous Mater. 2006, 96, 14–20. [Google Scholar] [CrossRef]

- Peng, F.; Jiang, Y.; Feng, J.; Liu, F.; Feng, J.; Li, L. Novel Silica-Modified Boehmite Aerogels and Fiber-Reinforced Insulation Composites with Ultra-High Thermal Stability and Low Thermal Conductivity. J. Eur. Ceram. Soc. 2022, 42, 6684–6702. [Google Scholar] [CrossRef]

- Peng, F.; Jiang, Y.; Feng, J.; Li, L.; Cai, H.; Feng, J. A Facile Method to Fabricate Monolithic Alumina–Silica Aerogels with High Surface Areas and Good Mechanical Properties. J. Eur. Ceram. Soc. 2020, 40, 2480–2488. [Google Scholar] [CrossRef]

- Ji, X.; Zhou, Q.; Qiu, G.; Peng, B.; Guo, M.; Zhang, M. Synthesis of an Alumina Enriched Al2O3-SiO2 Aerogel: Reinforcement and Ambient Pressure Drying. J. Non-Cryst. Solids 2017, 471, 160–168. [Google Scholar] [CrossRef]

- Wu, X.; Shao, G.; Cui, S.; Wang, L.; Shen, X. Synthesis of a Novel Al2O3–SiO2 Composite Aerogel with High Specific Surface Area at Elevated Temperatures Using Inexpensive Inorganic Salt of Aluminum. Ceram. Int. 2016, 42, 874–882. [Google Scholar] [CrossRef]

- Yu, H.; Tong, Z.; Yue, S.; Li, X.; Su, D.; Ji, H. Effect of SiO2 Deposition on Thermal Stability of Al2O3-SiO2 Aerogel. J. Eur. Ceram. Soc. 2021, 41, 580–589. [Google Scholar] [CrossRef]

- Zou, W.; Wang, X.; Wu, Y.; Zu, G.; Zou, L.; Zhang, R.; Yao, X.; Shen, J. Highly Thermally Stable Alumina-Based Aerogels Modified by Partially Hydrolyzed Aluminum Tri-Sec-Butoxide. J. Sol-Gel Sci. Technol. 2017, 84, 507–514. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, X.; Liu, L.; Zhang, Z.; Shen, J. Alumina-Doped Silica Aerogels for High-Temperature Thermal Insulation. Gels 2021, 7, 122. [Google Scholar] [CrossRef]

- Zhang, E.; Zhang, W.; Iv, T.; Li, J.; Dai, J.; Zhang, F.; Zhao, Y.; Yang, J.; Li, W.; Zhang, H. Insulating and Robust Ceramic Nanorod Aerogels with High-Temperature Resistance over 1400 °C. ACS Appl. Mater. Interfaces 2021, 13, 20548–20558. [Google Scholar] [CrossRef]

- Li, H.; Chen, Y.; Wang, P.; Xu, B.; Ma, Y.; Wen, W.; Yang, Y.; Fang, D. Porous Carbon-Bonded Carbon Fiber Composites Impregnated with SiO2-Al2O3 Aerogel with Enhanced Thermal Insulation and Mechanical Properties. Ceram. Int. 2018, 44, 3484–3487. [Google Scholar] [CrossRef]

- Yu, H.; Jiang, Y.; Lu, Y.; Li, X.; Zhao, H.; Ji, Y.; Wang, M. Quartz Fiber Reinforced Al2O3-SiO2 Aerogel Composite with Highly Thermal Stability by Ambient Pressure Drying. J. Non-Cryst. Solids 2019, 505, 79–86. [Google Scholar] [CrossRef]

- Chen, F.; Ma, L.; Shen, Q.; Zhang, L. Thermally insulating, fiber-reinforced alumina–silica aerogel composites with ultra-low shrinkage up to 1500 °C. Chem. Eng. J. 2021, 411, 128402. [Google Scholar] [CrossRef]

- Novel whisker-reinforced Al2O3-SiO2 aerogel composites with ultra-low thermal conductivity. Ceram. Int. 2017, 43, 9547–9551. [CrossRef]

- Zou, W.; Wang, X.; Wu, Y.; Zou, L.; Zu, G.; Chen, D.; Shen, J. Opacifier Embedded and Fiber Reinforced Alumina-Based Aerogel Composites for Ultra-High Temperature Thermal Insulation. Ceram. Int. 2019, 45, 644–650. [Google Scholar] [CrossRef]

- Jiang, D.; Qin, J.; Zhou, X.; Li, Q.; Yi, D.; Wang, B. Improvement of Thermal Insulation and Compressive Performance of Al2O3-SiO2 Aerogel by Doping Carbon Nanotubes. Ceram. Int. 2022, 48, 16290–16299. [Google Scholar] [CrossRef]

- Ghica, M.E.; Almeida, C.M.R.; Rebelo, L.S.D.; Cathoud-Pinheiro, G.C.; Costa, B.F.O.; Durães, L. Novel Kevlar® Pulp-Reinforced Alumina-Silica Aerogel Composites for Thermal Insulation at High Temperature. J. Sol-Gel Sci. Technol. 2022, 101, 87–102. [Google Scholar] [CrossRef]

- Yu, Y.; Peng, K.; Fang, J.; Zhang, R.; Wang, G.; Peng, X. Mechanical and Thermal Conductive Properties of Fiber-Reinforced Silica-Alumina Aerogels. Int. J. Appl. Ceram. Technol. 2018, 15, 1138–1145. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, Z.; Shi, Z.; Zhang, J.; Zhi, M.; Hong, Z. Synthesis of High-Temperature Resistant Monolithic Zirconia-Based Aerogel via Facile Water Glass Assisted Sol–Gel Method. J. Sol-Gel Sci. Technol. 2018, 85, 567–573. [Google Scholar] [CrossRef]

- Xiong, R.; Li, X.; Ji, H.; Sun, X.; He, J. Thermal Stability of ZrO2–SiO2 Aerogel Modified by Fe(III) Ion. J. Sol-Gel Sci. Technol. 2014, 72, 496–501. [Google Scholar] [CrossRef]

- He, J.; Li, X.; Su, D.; Ji, H.; Zhang, X.; Zhang, W. Super-Hydrophobic Hexamethyl-Disilazane Modified ZrO2–SiO2 Aerogels with Excellent Thermal Stability. J. Mater. Chem. A 2016, 4, 5632–5638. [Google Scholar] [CrossRef]

- Zu, G.; Shen, J.; Zou, L.; Zou, W.; Guan, D.; Wu, Y.; Zhang, Y. Highly Thermally Stable Zirconia/Silica Composite Aerogels Prepared by Supercritical Deposition. Microporous Mesoporous Mater. 2017, 238, 90–96. [Google Scholar] [CrossRef]

- Ren, J.; Cai, X.; Yang, H.; Guo, X. Preparation and Characterization of High Surface Area ZrO2 Aerogel Modified by SiO2. J. Porous. Mater. 2015, 22, 973–978. [Google Scholar] [CrossRef]

- Liu, B.; Gao, M.; Liu, X.; Zhao, X.; Zhang, J.; Yi, X. Thermally Stable Nanoporous ZrO2/SiO2 Hybrid Aerogels for Thermal Insulation. ACS Appl. Nano Mater. 2019, 2, 7299–7310. [Google Scholar] [CrossRef]

- He, J.; Li, X.; Su, D.; Ji, H.; Wang, X. Ultra-Low Thermal Conductivity and High Strength of Aerogels/Fibrous Ceramic Composites. J. Eur. Ceram. Soc. 2016, 36, 1487–1493. [Google Scholar] [CrossRef]

- He, J.; Li, X.; Su, D.; Ji, H.; Qiao, Y. High-Strength Mullite Fibers Reinforced ZrO2–SiO2 Aerogels Fabricated by Rapid Gel Method. J. Mater. Sci. 2015, 50, 7488–7494. [Google Scholar] [CrossRef]

- He, J.; Zhao, H.; Li, X.; Su, D.; Ji, H.; Yu, H.; Hu, Z. Large-Scale and Ultra-Low Thermal Conductivity of ZrO2 Fibrofelt/ZrO2-SiO2 Aerogels Composites for Thermal Insulation. Ceram. Int. 2018, 44, 8742–8748. [Google Scholar] [CrossRef]

- Hou, X.; Zhang, R.; Fang, D. An ultralight silica-modified ZrO2–SiO2 aerogel composite with ultra-low thermal conductivity and enhanced mechanical strength. Scr. Mater. 2018, 143, 113–116. [Google Scholar] [CrossRef]

- Pekala, R.W.; Kong, F.M. A Synthetic Route to Organic Aerogels—Mechanism, Structure, and Properties. J. Phys. Colloq. 1989, 50, C4–C40. [Google Scholar] [CrossRef]

- Xiong, S.; Yang, Y.; Zhang, S.; Xiao, Y.; Ji, H.; Yang, Z.; Ding, F. Nanoporous Polybenzoxazine Aerogels for Thermally Insulating and Self-Extinguishing Materials in Aerospace Applications. ACS Appl. Nano Mater. 2021, 4, 7280–7288. [Google Scholar] [CrossRef]

- Yan, M.; Cheng, X.; Shi, L.; Pan, Y.; He, P.; Zhang, Z.; Lun, Z.; Fu, Y.; Zhang, H. Bioinspired SiC Aerogels for Super Thermal Insulation and Adsorption with Super-Elasticity over 100,000 Times Compressions. Chem. Eng. J. 2023, 455, 140616. [Google Scholar] [CrossRef]

- Civioc, R.; Lattuada, M.; Koebel, M.M.; Galmarini, S. Monolithic Resorcinol–Formaldehyde Alcogels and Their Corresponding Nitrogen-Doped Activated Carbons. J. Sol-Gel Sci. Technol. 2020, 95, 719–732. [Google Scholar] [CrossRef]

- Meador, M.A.B.; Wright, S.; Sandberg, A.; Nguyen, B.N.; Van Keuls, F.W.; Mueller, C.H.; Rodríguez-Solís, R.; Miranda, F.A. Low Dielectric Polyimide Aerogels as Substrates for Lightweight Patch Antennas. ACS Appl. Mater. Interfaces 2012, 4, 6346–6353. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Meador, M.A.B.; McCorkle, L.; Quade, D.J.; Guo, J.; Hamilton, B.; Cakmak, M.; Sprowl, G. Polyimide Aerogels Cross-Linked through Amine Functionalized Polyoligomeric Silsesquioxane. ACS Appl. Mater. Interfaces 2011, 3, 546–552. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Du, A.; Xiang, Y.; Liu, M.; Li, T.; Shen, J.; Zhang, Z.; Li, C.; Zhou, B. Silica-Aerogel-Powders “Jammed” Polyimide Aerogels with Excellent Hydrophobicity and Conversion to Ultra-Light Polyimide Aerogel. RSC Adv. 2016, 6, 58268–58278. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, Y.; Li, X.; Ma, X.; Li, S.; Sun, M.; Liu, H.; Wang, K. Ultralight and Heat-Insulating Mesoporous Polyimide Aerogels Cross-Linked with Aminated SiO2 Nanoparticles. Microporous Mesoporous Mater. 2021, 319, 111074. [Google Scholar] [CrossRef]

- Zhu, Z.; Yao, H.; Wang, F.; Dong, J.; Wu, K.; Cao, J.; Long, D. Fiber Reinforced Polyimide Aerogel Composites with High Mechanical Strength for High Temperature Insulation. Macromol. Mater. Eng. 2019, 304, 1800676. [Google Scholar] [CrossRef]

- Zhao, F.; Zhu, J.; Peng, T.; Liu, H.; Ge, S.; Xie, H.; Xie, L.; Jiang, C. Preparation of Functionalized Halloysite Reinforced Polyimide Composite Aerogels with Excellent Thermal Insulation Properties. Appl. Clay Sci. 2021, 211, 106200. [Google Scholar] [CrossRef]

- Zhu, C.; Xue, T.; Ma, Z.; Fan, W.; Liu, T. Mechanically Strong and Thermally Insulating Polyimide Aerogel Fibers Reinforced by Prefabricated Long Polyimide Fibers. ACS Appl. Mater. Interfaces 2023, 15, 12443–12452. [Google Scholar] [CrossRef]

- Zhu, Z.; Yao, H.; Dong, J.; Qian, Z.; Dong, W.; Long, D. High-Mechanical-Strength Polyimide Aerogels Crosslinked with 4, 4′-Oxydianiline-Functionalized Carbon Nanotubes. Carbon 2019, 144, 24–31. [Google Scholar] [CrossRef]

- Xue, T.; Fan, W.; Zhang, X.; Zhao, X.; Yang, F.; Liu, T. Layered Double Hydroxide/Graphene Oxide Synergistically Enhanced Polyimide Aerogels for Thermal Insulation and Fire-Retardancy. Compos. Part. B Eng. 2021, 219, 108963. [Google Scholar] [CrossRef]

- Hou, X.; Li, Y.; Luo, X.; Zhang, R. SiC Whiskers-Reinforced Polyimide Aerogel Composites with Robust Compressive Properties and Efficient Thermal Insulation Performance. J. Appl. Polym. Sci. 2021, 138, 49892. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, Y.; Shao, Z.; Gao, W.; Fan, W.; Liu, T.; Bai, H. Multifunctional Polyimide Aerogel Textile Inspired by Polar Bear Hair for Thermoregulation in Extreme Environments. Chem. Eng. J. 2020, 390, 124623. [Google Scholar] [CrossRef]

- Li, M.; Gan, F.; Dong, J.; Fang, Y.; Zhao, X.; Zhang, Q. Facile Preparation of Continuous and Porous Polyimide Aerogel Fibers for Multifunctional Applications. ACS Appl. Mater. Interfaces 2021, 13, 10416–10427. [Google Scholar] [CrossRef]

- Li, X.; Dong, G.; Liu, Z.; Zhang, X. Polyimide Aerogel Fibers with Superior Flame Resistance, Strength, Hydrophobicity, and Flexibility Made via a Universal Sol–Gel Confined Transition Strategy. ACS Nano 2021, 15, 4759–4768. [Google Scholar] [CrossRef]

- Ghaffari-Mosanenzadeh, S.; Aghababaei Tafreshi, O.; Karamikamkar, S.; Saadatnia, Z.; Rad, E.; Meysami, M.; Naguib, H.E. Recent Advances in Tailoring and Improving the Properties of Polyimide Aerogels and Their Application. Adv. Colloid. Interface Sci. 2022, 304, 102646. [Google Scholar] [CrossRef]

- Jin, X.; Liu, C.; Huang, H.; Pan, R.; Wu, C.; Yan, X.; Wang, H.; Pan, Y.; Hong, C.; Zhang, X. Multiscale, Elastic, and Low-Density Carbon Fibre / Siliconoxycarbide-Phenolic Interpenetrating Aerogel Nanocomposite for Ablative Thermal Protection. Compos. Part B Eng. 2022, 245, 110212. [Google Scholar] [CrossRef]

- Wang, H.; Quan, X.; Yin, L.; Jin, X.; Pan, Y.; Wu, C.; Huang, H.; Hong, C.; Zhang, X. Lightweight Quartz Fiber Fabric Reinforced Phenolic Aerogel with Surface Densified and Graded Structure for High Temperature Thermal Protection. Compos. Part A Appl. Sci. Manuf. 2022, 159, 107022. [Google Scholar] [CrossRef]

- Jin, X.; Xu, J.; Pan, Y.; Wang, H.; Ma, B.; Liu, F.; Yan, X.; Wu, C.; Huang, H.; Cheng, H.; et al. Lightweight and Multiscale Needle Quartz Fiber Felt Reinforced Siliconoxycarbide Modified Phenolic Aerogel Nanocomposite with Enhanced Mechanical, Insulative and Flame-Resistant Properties. Compos. Sci. Technol. 2022, 217, 109100. [Google Scholar] [CrossRef]

- Cheng, H.; Xue, H.; Hong, C.; Zhang, X. Preparation, Mechanical, Thermal and Ablative Properties of Lightweight Needled Carbon Fibre Felt/Phenolic Resin Aerogel Composite with a Bird’s Nest Structure. Compos. Sci. Technol. 2017, 140, 63–72. [Google Scholar] [CrossRef]

- Wang, H.; Yan, X.; Jin, X.; Pan, Y.; Wu, C.; Huang, H.; Hong, C.; Zhang, X. Mechanical and Thermal Ablative Behavior of Ceramic-Modified Lightweight Quartz Felt Reinforced Phenolic Aerogel. Compos. Commun. 2022, 35, 101285. [Google Scholar] [CrossRef]

- Jin, X.; Wu, C.; Wang, H.; Pan, Y.; Huang, H.; Wang, W.; Fan, J.; Yan, X.; Hong, C.; Zhang, X. Synergistic Reinforcement and Multiscaled Design of Lightweight Heat Protection and Insulation Integrated Composite with Outstanding High-Temperature Resistance up to 2500 °C. Compos. Sci. Technol. 2023, 232, 109878. [Google Scholar] [CrossRef]

- Wu, C.; Chen, Z.; Wang, F.; Hu, Y.; Rao, Z.; Wang, E.; Zhang, X. Preparation and Characterization of Ultralight Glass Fiber Wool/Phenolic Resin Aerogels with a Spring-like Structure. Compos. Sci. Technol. 2019, 179, 125–133. [Google Scholar] [CrossRef]

- Wu, K.; Dong, W.; Pan, Y.; Cao, J.; Zhang, Y.; Long, D. Lightweight and Flexible Phenolic Aerogels with Three-Dimensional Foam Reinforcement for Acoustic and Thermal Insulation. Ind. Eng. Chem. Res. 2021, 60, 1241–1249. [Google Scholar] [CrossRef]

- Wang, H.; Pan, Y.; Jin, X.; Wu, C.; Huang, H.; Yan, X.; Hong, C.; Zhang, X. Gradient Fiber-Reinforced Aerogel Composites Using Surface Ceramicizable-Resin Densification with Outstanding Ablation Resistance for High-Temperature Thermal Protection. Compos. Sci. Technol. 2022, 230, 109798. [Google Scholar] [CrossRef]

- Noroozi, M.; Panahi-Sarmad, M.; Bahramian, A.R. Thermal Insulation Behavior of Functionally Graded Aerogel: The Role of Novolac Molecular-Weight. Polymers 2019, 178, 121575. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, H.; Hong, C.; Zhang, X.; Zeng, T. Lightweight Chopped Carbon Fibre Reinforced Silica-Phenolic Resin Aerogel Nanocomposite: Facile Preparation, Properties and Application to Thermal Protection. Compos. Part A Appl. Sci. Manuf. 2018, 112, 81–90. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, L.; Cai, H.; Liu, F.; Zhang, S.; Feng, J.; Jiang, Y.; Feng, J. In Situ Co-Polymerization of High-Performance Polybenzoxazine/Silica Aerogels for Flame-Retardancy and Thermal Insulation. J. Appl. Polym. Sci. 2021, 138, 50333. [Google Scholar] [CrossRef]

- Ma, J.; Li, J.; Guo, P.; Pang, S.; Hu, C.; Zhao, R.; Tang, S.; Cheng, H.M. Tailoring Microstructures of Carbon Fiber Reinforced Carbon Aerogel-like Matrix Composites by Carbonization to Modulate Their Mechanical Properties and Thermal Conductivities. Carbon 2022, 196, 807–818. [Google Scholar] [CrossRef]

- Hu, L.; He, R.; Lei, H.; Fang, D. Carbon Aerogel for Insulation Applications: A Review. Int. J. Thermophys. 2019, 40, 1–25. [Google Scholar] [CrossRef]

- Wu, D.; Fu, R. Requirements of Organic Gels for a Successful Ambient Pressure Drying Preparation of Carbon Aerogels. J. Porous Mater. 2008, 15, 29–34. [Google Scholar] [CrossRef]

- Fan, Z.; Gong, F.; Nguyen, S.T.; Duong, H.M. Advanced Multifunctional Graphene Aerogel–Poly (Methyl Methacrylate) Composites: Experiments and Modeling. Carbon 2015, 81, 396–404. [Google Scholar] [CrossRef]

- Lee, J.-H.; Park, S.-J. Recent Advances in Preparations and Applications of Carbon Aerogels: A Review. Carbon 2020, 163, 1–18. [Google Scholar] [CrossRef]

- Enterría, M.; Figueiredo, J.L. Nanostructured Mesoporous Carbons: Tuning Texture and Surface Chemistry. Carbon 2016, 108, 79–102. [Google Scholar] [CrossRef]

- Sun, W.; Du, A.; Gao, G.; Shen, J.; Wu, G. Graphene-Templated Carbon Aerogels Combining with Ultra-High Electrical Conductivity and Ultra-Low Thermal Conductivity. Microporous Mesoporous Mater. 2017, 253, 71–79. [Google Scholar] [CrossRef]

- Wu, K.; Cao, J.; Qian, Z.; Luo, Y.; Niu, B.; Zhang, Y.; Long, D. Monolithic Carbon Aerogels within Foam Framework for High-Temperature Thermal Insulation and Organics Absorption. J. Colloid. Interface Sci. 2022, 618, 259–269. [Google Scholar] [CrossRef]

- Jia, X.; Dai, B.; Zhu, Z.; Wang, J.; Qiao, W.; Long, D.; Ling, L. Strong and Machinable Carbon Aerogel Monoliths with Low Thermal Conductivity Prepared via Ambient Pressure Drying. Carbon 2016, 108, 551–560. [Google Scholar] [CrossRef] [Green Version]

- Zhan, H.-J.; Wu, K.-J.; Hu, Y.-L.; Liu, J.-W.; Li, H.; Guo, X.; Xu, J.; Yang, Y.; Yu, Z.-L.; Gao, H.-L.; et al. Biomimetic Carbon Tube Aerogel Enables Super-Elasticity and Thermal Insulation. Chem 2019, 5, 1871–1882. [Google Scholar] [CrossRef]

- Guo, P.; Li, J.; Pang, S.; Hu, C.; Tang, S.; Cheng, H.M. Ultralight Carbon Fiber Felt Reinforced Monolithic Carbon Aerogel Composites with Excellent Thermal Insulation Performance. Carbon 2021, 183, 525–529. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, C.; Feng, J. Carbon Fiber Reinforced Carbon Aerogel Composites for Thermal Insulation Prepared by Soft Reinforcement. Mater. Lett. 2012, 67, 266–268. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, J.; Li, L.; Jiang, Y.; Feng, J. Preparation of a Carbon Fibre-Reinforced Carbon Aerogel and Its Application as a High-Temperature Thermal Insulator. RSC Adv. 2022, 12, 13783–13791. [Google Scholar] [CrossRef] [PubMed]

- Yue, C.; Feng, J.; Feng, J.; Jiang, Y. Low-Thermal-Conductivity Nitrogen-Doped Graphene Aerogels for Thermal Insulation. RSC Adv. 2016, 6, 9396–9401. [Google Scholar] [CrossRef]

- Chen, W.; Liu, S.; Dong, Y.; Zhou, X.; Zhou, F. Poly (m-Phenylene Isophthalamide)/Graphene Composite Aerogels with Enhanced Compressive Shape Stability for Thermal Insulation. J. Sol-Gel Sci. Technol. 2020, 96, 370–381. [Google Scholar] [CrossRef]

- Yue, C.; Feng, J.; Feng, J.; Jiang, Y. Ultralow-Density and High-Strength Graphene Aerogels Composites for Thermal Insulation. Mater. Lett. 2017, 188, 169–171. [Google Scholar] [CrossRef]

- Guo, K.; Hu, Z.; Song, H.; Du, X.; Zhong, L.; Chen, X. Low-Density Graphene/Carbon Composite Aerogels Prepared at Ambient Pressure with High Mechanical Strength and Low Thermal Conductivity. RSC Adv. 2015, 5, 5197–5204. [Google Scholar] [CrossRef]

- Liu, B.-W.; Cao, M.; Zhang, Y.-Y.; Wang, Y.-Z.; Zhao, H.-B. Multifunctional Protective Aerogel with Superelasticity over −196 to 500 °C. Nano Res. 2022, 15, 7797–7805. [Google Scholar] [CrossRef]

- An, Z.; Ye, C.; Zhang, R.; Qu, Q. Multifunctional C/SiO2/SiC-Based Aerogels and Composites for Thermal Insulators and Electromagnetic Interference Shielding. J. Sol-Gel Sci. Technol. 2019, 89, 623–633. [Google Scholar] [CrossRef]

- Yang, H.; Li, C.; Yue, X.; Huo, J.; Ye, F.; Liu, J.; Shi, F.; Ma, J. New BN/SiOC Aerogel Composites Fabricated by the Sol-Gel Method with Excellent Thermal Insulation Performance at High Temperature. Mater. Des. 2020, 185, 108217. [Google Scholar] [CrossRef]

- Han, X.D.; Zhang, Y.F.; Zheng, K.; Zhang, X.N.; Zhang, Z.; Hao, Y.J.; Guo, X.Y.; Yuan, J.; Wang, Z.L. Low-Temperature in Situ Large Strain Plasticity of Ceramic SiC Nanowires and Its Atomic-Scale Mechanism. Nano Lett. 2007, 7, 452–457. [Google Scholar] [CrossRef] [Green Version]

- Song, L.; Fan, B.; Chen, Y.; Gao, Q.; Li, Z.; Wang, H.; Zhang, X.; Guan, L.; Li, H.; Zhang, R. Ultralight and Hyperelastic SiC Nanofiber Aerogel Spring for Personal Thermal Energy Regulation. J. Adv. Ceram. 2022, 11, 1235–1248. [Google Scholar] [CrossRef]

- Su, L.; Wang, H.; Niu, M.; Dai, S.; Cai, Z.; Yang, B.; Huyan, H.; Pan, X. Anisotropic and Hierarchical SiC@SiO2 Nanowire Aerogel with Exceptional Stiffness and Stability for Thermal Superinsulation. Sci. Adv. 2020, 6, eaay6689. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, Z.; Li, X.; Zhao, H.; Hu, Z.; Ji, H.; Qi, T. A Novel Aerogels/Porous Si3N4 Ceramics Composite with High Strength and Improved Thermal Insulation Property. Ceram. Int. 2018, 44, 5233–5237. [Google Scholar] [CrossRef]

- Zhao, J.-J.; Duan, Y.-Y.; Wang, X.-D.; Zhang, X.-R.; Han, Y.-H.; Gao, Y.-B.; Lv, Z.-H.; Yu, H.-T.; Wang, B.-X. Optical and Radiative Properties of Infrared Opacifier Particles Loaded in Silica Aerogels for High Temperature Thermal Insulation. Int. J. Therm. Sci. 2013, 70, 54–64. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Zhang, J.; Wu, C.; Xiang, J. SiC Network Reinforced SiO2 Aerogel with Improved Compressive Strength and Preeminent Microwave Absorption at Elevated Temperatures. Ceram. Int. 2021, 47, 31497–31505. [Google Scholar] [CrossRef]

- Wu, Z.; Cheng, X.; Zhang, L.; Li, J.; Yang, C. Sol-Gel Synthesis of Preceramic Polyphenylsilsesquioxane Aerogels and Their Application toward Monolithic Porous SiOC Ceramics. Ceram. Int. 2018, 44, 14947–14951. [Google Scholar] [CrossRef]

- Wei, B.; Zhou, J.; Yao, Z.; Haidry, A.A.; Guo, X.; Lin, H.; Qian, K.; Chen, W. The Effect of Ag Nanoparticles Content on Dielectric and Microwave Absorption Properties of β-SiC. Ceram. Int. 2020, 46, 5788–5798. [Google Scholar] [CrossRef]

- Leventis, N.; Sadekar, A.; Chandrasekaran, N.; Sotiriou-Leventis, C. Click Synthesis of Monolithic Silicon Carbide Aerogels from Polyacrylonitrile-Coated 3D Silica Networks. Chem. Mater. 2010, 22, 2790–2803. [Google Scholar] [CrossRef]

- Kong, Y.; Zhong, Y.; Shen, X.; Cui, S.; Fan, M. Effect of Silica Sources on Nanostructures of Resorcinol–Formaldehyde/Silica and Carbon/Silicon Carbide Composite Aerogels. Microporous Mesoporous Mater. 2014, 197, 77–82. [Google Scholar] [CrossRef]

- Zera, E.; Campostrini, R.; Aravind, P.R.; Blum, Y.; Sorarù, G.D. Novel SiC/C Aerogels Through Pyrolysis of Polycarbosilane Precursors. Adv. Eng. Mater. 2014, 16, 814–819. [Google Scholar] [CrossRef]

- Wang, J.; Oschatz, M.; Biemelt, T.; Lohe, M.R.; Borchardt, L.; Kaskel, S. Preparation of Cubic Ordered Mesoporous Silicon Carbide Monoliths by Pressure Assisted Preceramic Polymer Nanocasting. Microporous Mesoporous Mater. 2013, 168, 142–147. [Google Scholar] [CrossRef]

- Su, L.; Wang, H.; Niu, M.; Fan, X.; Ma, M.; Shi, Z.; Guo, S.-W. Ultralight, Recoverable, and High-Temperature-Resistant SiC Nanowire Aerogel. ACS Nano 2018, 12, 3103–3111. [Google Scholar] [CrossRef] [PubMed]

- Chabi, S.; Rocha, V.G.; García-Tuñón, E.; Ferraro, C.; Saiz, E.; Xia, Y.; Zhu, Y. Ultralight, Strong, Three-Dimensional SiC Structures. ACS Nano 2016, 10, 1871–1876. [Google Scholar] [CrossRef]

- Yan, M.; Zhang, H.; Fu, Y.; Pan, Y.; Lun, Z.; Zhang, Z.; He, P.; Cheng, X. Implementing an Air Suction Effect Induction Strategy to Create Super Thermally Insulating and Superelastic SiC Aerogels. Small 2022, 18, 2201039. [Google Scholar] [CrossRef]

- An, Z.; Ye, C.; Zhang, R.; Zhou, P. Flexible and Recoverable SiC Nanofiber Aerogels for Electromagnetic Wave Absorption. Ceram. Int. 2019, 45, 22793–22801. [Google Scholar] [CrossRef]

- Moysan, C.; Riedel, R.; Harshe, R.; Rouxel, T.; Augereau, F. Mechanical Characterization of a Polysiloxane-Derived SiOC Glass. J. Eur. Ceram. Soc. 2007, 27, 397–403. [Google Scholar] [CrossRef]

- Suo, H.; Wang, W.; Jiang, S.; Li, Y.; Yu, K.; Huang, S.; Cui, S.; Shen, X.; Xue, J. Preparation of ZrC@Al2O3@Carbon Composite Aerogel with Excellent High Temperature Thermal Insulation Performance. SN Appl. Sci. 2019, 1, 461. [Google Scholar] [CrossRef] [Green Version]

- Ye, L.; Qiu, W.; Li, H.; Zhao, A.; Cai, T.; Zhao, T. Preparation and Characterization of ZrCO/C Composite Aerogels. J. Sol-Gel Sci. Technol. 2013, 65, 150–159. [Google Scholar] [CrossRef]

- Yuan, K.; Han, D.; Liang, J.; Zhao, W.; Li, M.; Zhao, B.; Liu, W.; Lu, H.; Wang, H.; Xu, H.; et al. Microwave Induced In-Situ Formation of SiC Nanowires on SiCNO Ceramic Aerogels with Excellent Electromagnetic Wave Absorption Performance. J. Adv. Ceram. 2021, 10, 1140–1151. [Google Scholar] [CrossRef]

- Hickey, G.S. Materials for Thermal Control for Mars Surface Operations. MRS Online Proc. Libr. 1998, 551, 25–31. [Google Scholar] [CrossRef]

- Novak, K.; Phillips, C.; Birur, G.; Sunada, E.; Pauken, M. Development of a Thermal Control Architecture for the Mars Exploration Rovers. Dev. A Therm. Control Archit. Mars Explor. Rovers. 2003, 654, 194–205. [Google Scholar] [CrossRef]

- Jones, S.M.; Sakamoto, J. Applications of Aerogels in Space Exploration. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Advances in Sol-Gel Derived Materials and Technologies; Springer: New York, NY, USA, 2011; pp. 721–746. ISBN 978-1-4419-7589-8. [Google Scholar]

- Trevino, L.; Orndoff, E.; Tang, H.; Gould, G.; Trifu, R. Aerogel-Based Insulation for Advanced Space Suit; SAE International: Warrendale, PA, USA, 2002. [Google Scholar] [CrossRef]

- Del Corso, J.; Cheatwood, F.; Bruce, W.; Hughes, S.; Calomino, A. Advanced High-Temperature Flexible TPS for Inflatable Aerodynamic Decelerators. In Proceedings of the 21st AIAA Aerodynamic Decelerator Systems Technology Conference and Seminar, Dublin, Ireland, 23–26 May 2011. [Google Scholar] [CrossRef] [Green Version]

- Zeng, S.Q.; Hunt, A.; Greif, R. Theoretical Modeling of Carbon Content to Minimize Heat Transfer in Silica Aerogel. J. Non-Cryst. Solids 1995, 186, 271–277. [Google Scholar] [CrossRef]

- Fesmire, J.E.; Sass, J.P. Aerogel Insulation Applications for Liquid Hydrogen Launch Vehicle Tanks. Cryogenics 2008, 48, 223–231. [Google Scholar] [CrossRef] [Green Version]

| Type of Inorganic Fiber | Density/g·cm−1 | Tensile Strength/MPa | Service Temperature/°C |

|---|---|---|---|

| Quartz fiber | 2.20 | 6000 | 1200 |

| Glass fiber | 2.48 | 4800 | 450 |

| Aluminum silicate fiber | 2.20 | 800 | 1260 |

| Mullite fiber | 3.17 | 1400 | 1400 |

| Alumina fiber | 3.70 | 2080 | 1600 |

| Raw Materials | Drying Method | Drying Medium and Operating Conditions | Density/g·cm−3 | Specific Surface Area/m2·g−1 | Shrinkage at High Temperature/% | Thermal Conductivity/W·(m·K)−1 | Reference |

|---|---|---|---|---|---|---|---|

| AIP, TEOS | Supercritical drying | EtOH (10 MPa, 300 °C) | - | 99 (1300 °C) | 14 (1300 °C) | - | [55] |

| ASB, TEOS | Supercritical drying | EtOH (10 MPa, 300 °C) | 0.249 | 120.6 (1200 °C) | - | - | [56] |

| Al (NO3)3, TEOS | Atmospheric drying | 30 °C | 0.5 | 304.2 (1000 °C) | - | - | [57] |

| AlCl3, TEOS | Supercritical drying | EtOH (10 MPa, 300 °C) | 0.053 | 120 (1200 °C) | 40 (1200 °C) | - | [58] |

| AlCl3, TEOS | Supercritical drying | EtOH (10 MPa, 300 °C) | - | 124.2 (1200 °C) | - | 0.0275 | [59] |

| ASB, TMEO | Supercritical drying | EtOH (10 MPa, 300 °C) | - | 72 (1200 °C) | 38 (1200 °C) | - | [60] |

| AlCl3, TEOS | Supercritical drying | EtOH (10 MPa, 260 °C) | - | 234 (1000 °C) | - | 0.05 | [61] |

| γ-AlOOH, TMOS | Supercritical drying | EtOH (10 MPa, 300 °C) | 0.146 | 79 (1200 °C) | 2.5 (1300 °C) | - | [62] |

| Enhancement Phase | Density/g·cm−3 | Room Temperature Thermal Conductivity/W·(m·K)−1 | High Temperature Thermal Conductivity W·(m·K)−1 | Compressive Strength/MPa | Reference |

|---|---|---|---|---|---|

| MF 1 (SiC) | - | - | 0.049 (1000 °C) | - | [32] |

| MF 1 | 0.36 | - | 0.082 (1200 °C) | 0.12 | [65] |

| MF 1 (TiO2) | 0.23 | 0.068 | 0.168 (1050 °C) | [67] | |

| CNT | 0.23 | 0.178 (1000 °C) | 1.36 | [68] | |

| ABOW (30%) 2 | 0.35 | 0.049 | - | 1.02 | [66] |

| Kevlar (R) | 0.12 | 0.028 | - | - | [69] |

| Quartz fiber | 0.36 | 0.049 | - | 0.85 | [64] |

| Al2O3-SiO2 fiber | 0.33 | 0.050 | - | 0.41 | [70] |

| ZrO2 fiber | 0.59 | 0.049 | 0.102 (1000 °C) | 1.22 | [36] |

| Carbon fiber | 0.37 | 0.081 | 0.330 (1000 °C) | - | [63] |

| Raw Materials | Enhancement Phase | Density/g·cm−3 | Specific Surface Area/m2·g−1 | Room Temperature Thermal Conductivity/W·(m·K)−1 | Compressive Strength/MPa | Reference |

|---|---|---|---|---|---|---|

| ZrOCl2, Na2SiO3 | - | 0.136 | 383 (1000 °C) | 0.026 | - | [71] |

| ZrOCl2, TEOS | - | 0.270 | 228 (1000 °C) | - | - | [72] |

| ZrOCl2, TEOS | - | 0.290 | - | 0.027 | - | [73] |

| ZBO 1, TEOS | - | - | 172 (1000 °C) | - | - | [74] |

| ZrO (NO3)2, TEOS | - | 0.202 | - | - | - | [75] |

| PAZ 2, TEOS | - | 0.144 | 214 (1000 °C) | - | - | [76] |

| ZrOCl2, TEOS | PMF | 0.450 | - | 0.052 | 1.05 | [77] |

| ZrOCl2, TEOS | MF | 0.225 | - | 0.027 | 0.438 | [78] |

| ZrOCl2, TEOS | ZrO2 Fiber | 0.302 | - | 0.034 | 0.170 | [79] |

| ZrOCl2, TEOS | ZrO2 Fiber | 0.290 | - | 0.029 | 0.530 | [80] |

| Raw Materials | Enhancement Phase | Density/g·cm−3 | Thermal Conductivity/W·(m·K)−1 | Linear Ablation/mm s−1 | Reference |

|---|---|---|---|---|---|

| PR 1, HMTA 2 | Carbon fiber | 0.270–0.370 | 0.093–0.230 | 0.029 (1.5 MW/m2 33 s) | [102] |

| PR 1, ZrB2, SiB6 | Quartz fiber felt | 0.348 | - | 0.017 | [103] |

| PR 1, HMTA 2, MTMS 3, DMDES 4 | Carbon fiber felt | 0.30–0.35 | 0.068 | 0.019 (1.5 MW/m2 300 s) | [99] |

| PR 1, MTMS 3, DMDES 4, APTES 5 | Quartz/carbon hybrid fiber | 0.310–0.350 | 0.050–0.063 | 0.058 (3.62 MW/m2 300 s) | [104] |

| PR 1, APTES 5, HMTA 2 | Quartz fiber | 0.200 | 0.048 | 0.010 (1.5 MW/m2 180 s) | [100] |

| PR 1, HMTA 2 | Glass fiber wool | 0.036–0.140 | 0.031–0.037 | - | [105] |

| PF, HMTA 2 | - | ~0.112 | 0.021 | - | [106] |

| PR 1, HMTA 2 | Quartz felt | ~0.016 | ~0.030 | 0.003 (1.5 MW/m2 300 s) | [107] |

| Types | Precursors | Properties |

|---|---|---|

| synthetic polymer-based carbon aerogel |

| Textural properties controllable by synthesis conditions Uniform morphology through bottom-up process |

| Applicable to large-scale production | |

| Graphitic materials-based carbon aerogel |

| Crosslinked each other through van der Waals interactions Promising candidates as electrically conductive materials Carbonization process is skippable |

| Biomass-based carbon aerogel |

| Not required for the gelation process |

| Porous structure obtained via sublimation of water in hydrated biomass Inexpensive, abundant, and eco-friendly |

| Raw Materials | Enhancement Phase | Density/g·cm−3 | Thermal Conductivity/W·(m·K)−1 | Compressive Strength/MPa | Reference |

|---|---|---|---|---|---|

| P 1, HMTA 2 | UCF 10 | 0.16 | 0.030 | 0.93 | [121] |

| R 3, F 4 | PAN fiber | 0.17 | 0.073 | - | [122] |

| R 3, F-F 5 | PAN fiber | 0.68 | 0.690 | 6.10 | [123] |

| P 1, MF 6 | - | 0.12 | 0.111 | 2.50 | [118] |

| PPA 7, GO | - | 0.11 | 0.023 | - | [124] |

| DMF 8, PPA 7, GO | - | - | 0.045 | - | [125] |

| GO | Quartz fiber | 0.07 | 0.033 | - | [126] |

| GO | - | 0.13 | 0.033 | 0.18 | [127] |

| MWCNTs | - | - | 0.030 | - | [128] |

| Te NWs 9, glucose | - | - | 0.023 | - | [120] |

| P 1, H | - | 0.07 | 0.032 | 5.00 | [119] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, R.; Zhou, Z.; Liu, J.; Shi, B.; Zhou, N.; Wang, X.; Jia, X.; Guo, D.; Xu, B. Aerogels for Thermal Protection and Their Application in Aerospace. Gels 2023, 9, 606. https://doi.org/10.3390/gels9080606

Jin R, Zhou Z, Liu J, Shi B, Zhou N, Wang X, Jia X, Guo D, Xu B. Aerogels for Thermal Protection and Their Application in Aerospace. Gels. 2023; 9(8):606. https://doi.org/10.3390/gels9080606

Chicago/Turabian StyleJin, Runze, Zihan Zhou, Jia Liu, Baolu Shi, Ning Zhou, Xinqiao Wang, Xinlei Jia, Donghui Guo, and Baosheng Xu. 2023. "Aerogels for Thermal Protection and Their Application in Aerospace" Gels 9, no. 8: 606. https://doi.org/10.3390/gels9080606

APA StyleJin, R., Zhou, Z., Liu, J., Shi, B., Zhou, N., Wang, X., Jia, X., Guo, D., & Xu, B. (2023). Aerogels for Thermal Protection and Their Application in Aerospace. Gels, 9(8), 606. https://doi.org/10.3390/gels9080606