Thermo-Environmental Performance of Four Different Shapes of Solar Greenhouse Dryer with Free Convection Operating Principle and No Load on Product

Abstract

:1. Introduction

2. Materials and Methods

2.1. CFD Simulation

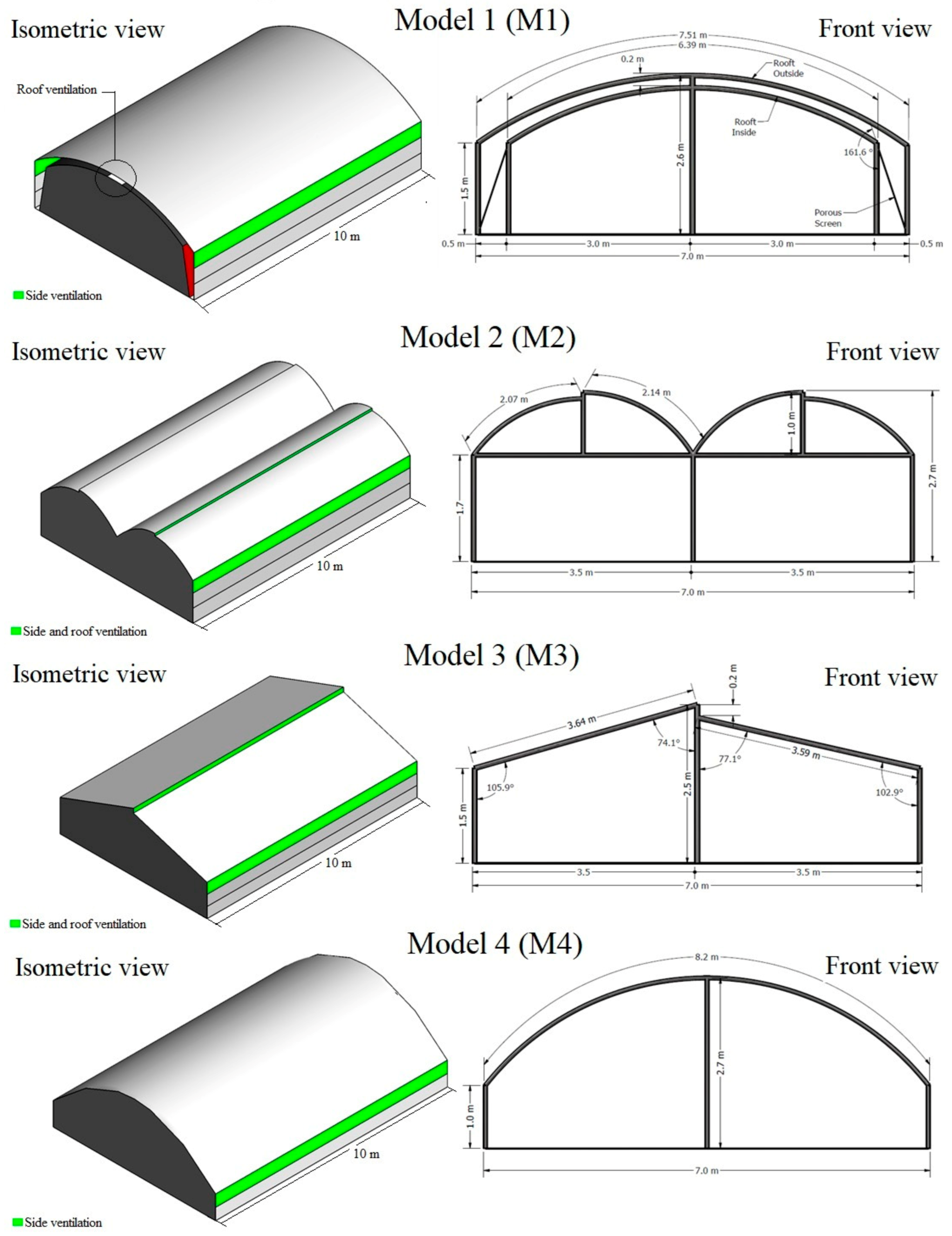

2.2. Description of the Dryer Designs Evaluated

2.3. Numerical Model

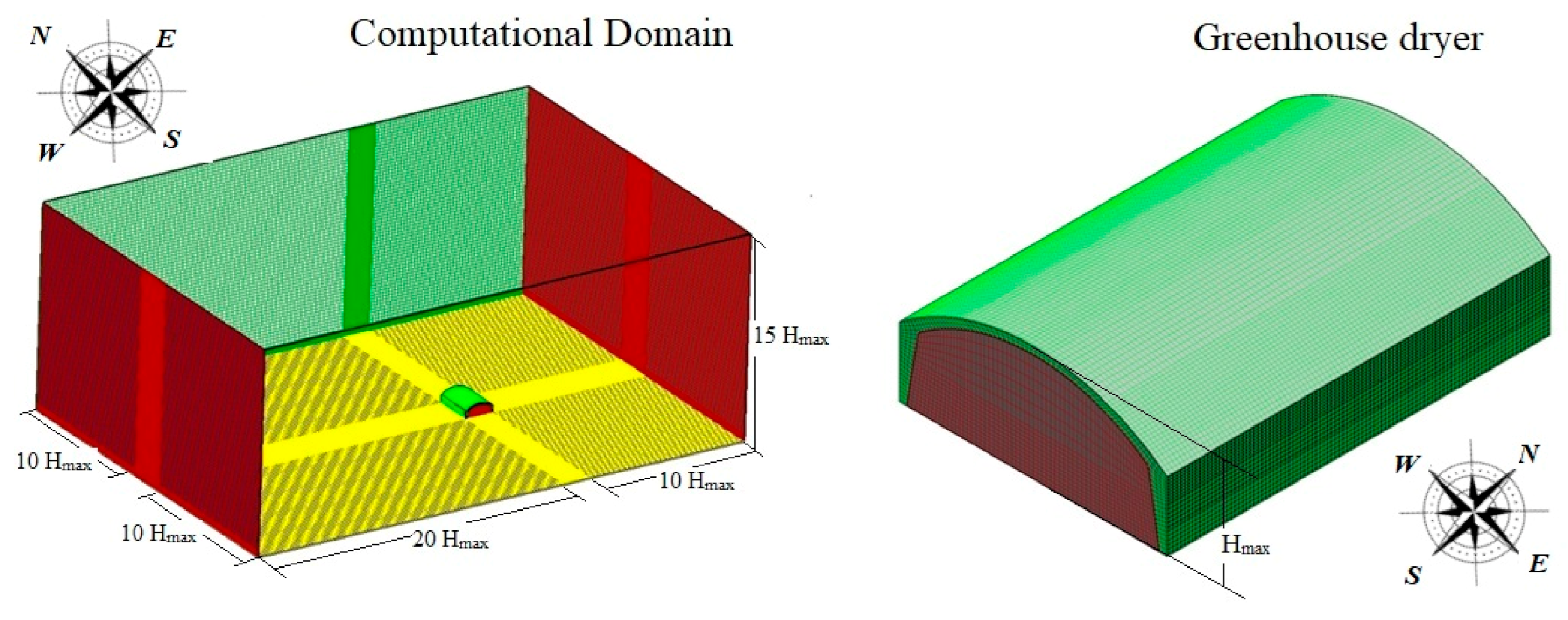

2.4. Discretization of the Computer Domain and Boundary Conditions

2.5. Climate Performance of the Study Region and Simulated Scenarios

3. Results and Discussion

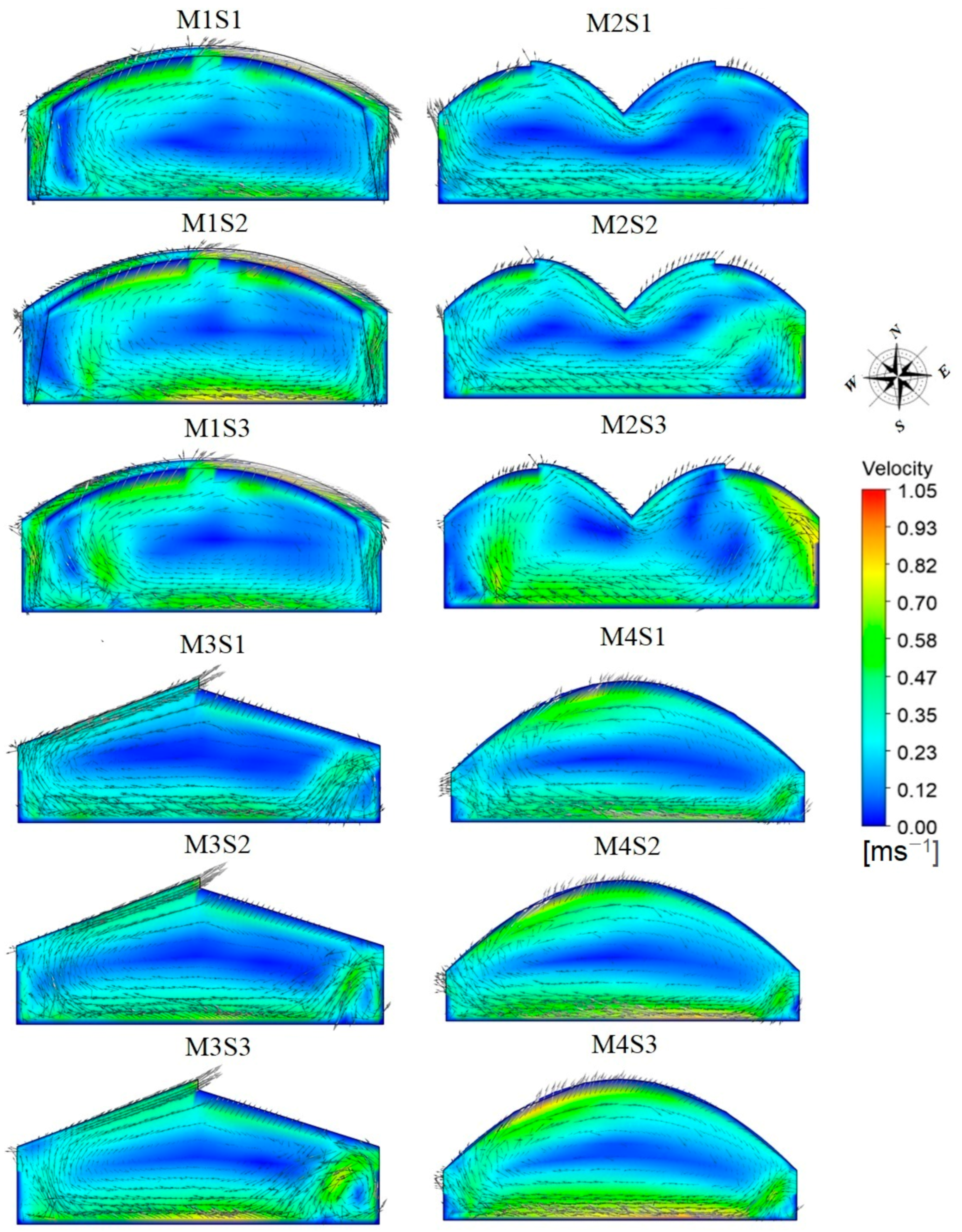

3.1. Effect of Dryer Design on Airflow Patterns

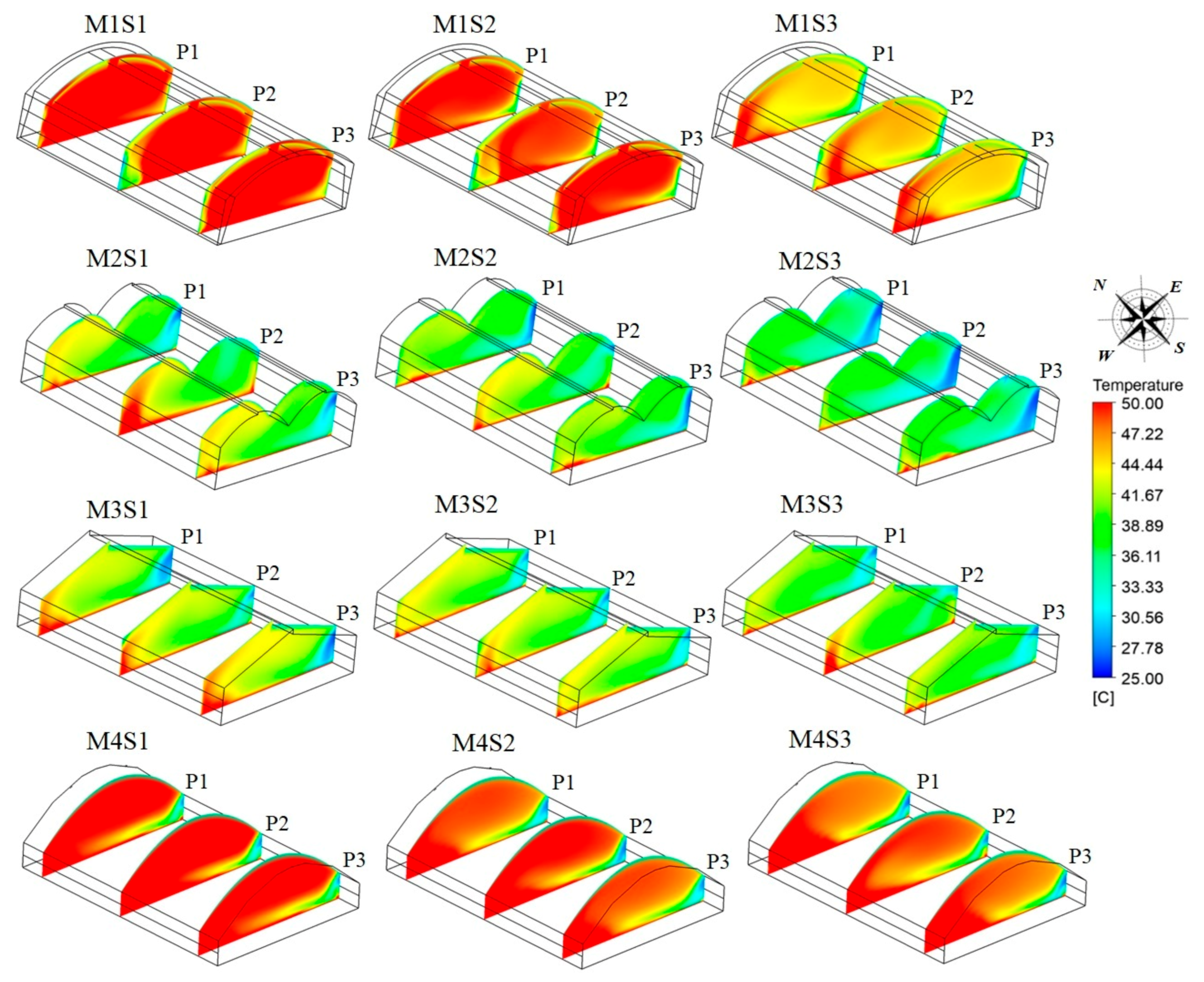

3.2. Effect of Dryer Design on Spatial Temperature Distribution

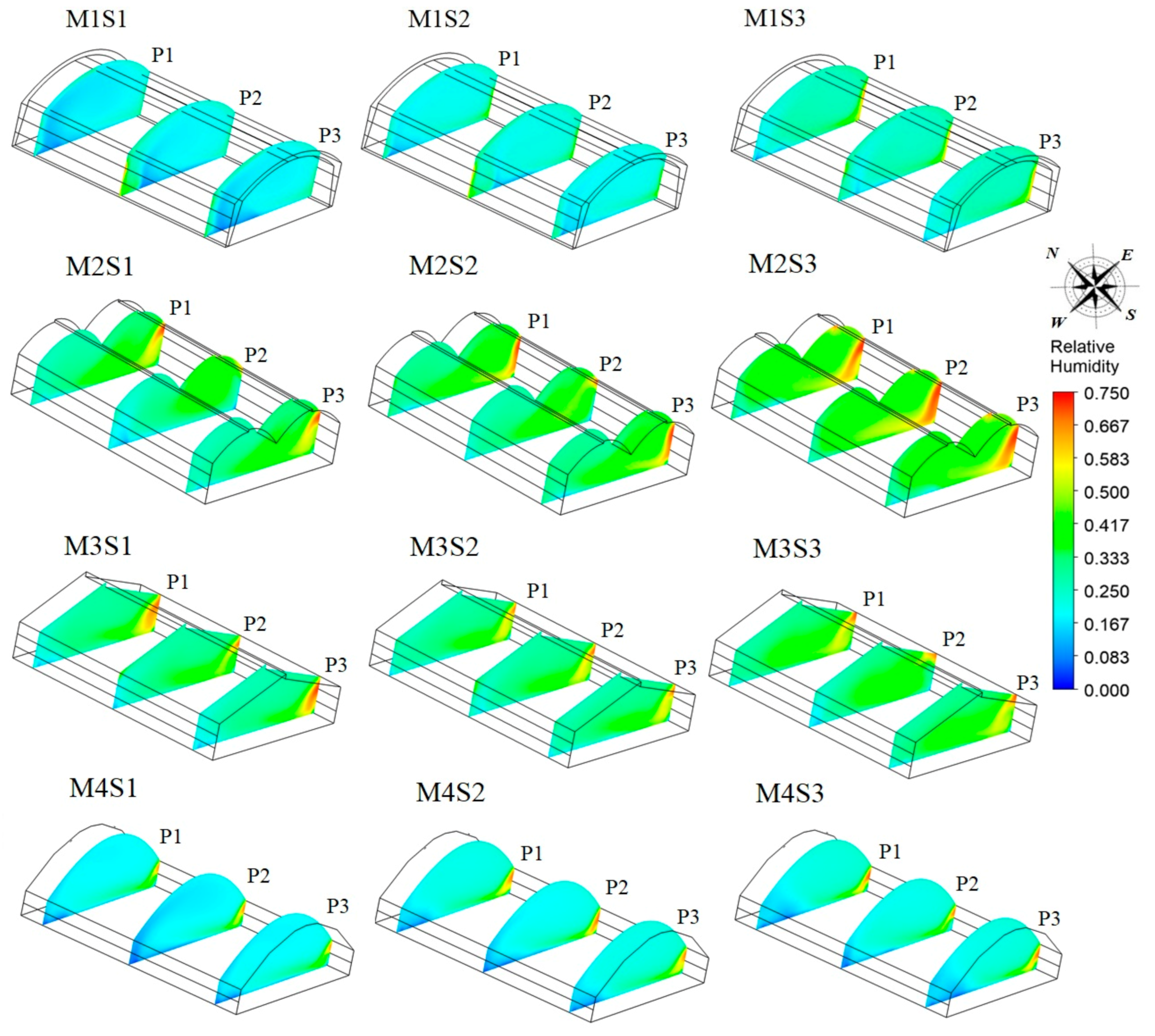

3.3. Effect of Dryer Design on Spatial Distribution of Relative Humidity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prakash, O.; Kumar, A. Solar greenhouse drying: A review. Renew. Sustain. Energy Rev. 2014, 29, 905–910. [Google Scholar] [CrossRef]

- Daş, M.; Alıç, E.; Kavak Akpinar, E. Numerical and experimental analysis of heat and mass transfer in the drying process of the solar drying system. Eng. Sci. Technol. Int. J. 2021, 24, 236–246. [Google Scholar]

- Motahayyer, M.; Arabhosseini, A.; Samimi-Akhijahani, H. Numerical analysis of thermal performance of a solar dryer and validated with experimental and thermo-graphical data. Sol. Energy 2019, 193, 692–705. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A.; Gupta, B. A review on thermal models for greenhouse dryers. Renew. Sustain. Energy Rev. 2017, 75, 548–558. [Google Scholar] [CrossRef]

- Singh, P.; Shrivastava, V.; Kumar, A. Recent developments in greenhouse solar drying: A review. Renew. Sustain. Energy Rev. 2018, 82, 3250–3262. [Google Scholar] [CrossRef]

- Nimnuan, P.; Nabnean, S. Experimental and simulated investigations of the performance of the solar greenhouse dryer for drying cassumunar ginger (Zingiber cassumunar Roxb.). Case Stud. Therm. Eng. 2020, 22, 100745. [Google Scholar] [CrossRef]

- Chauhan, P.S.; Kumar, A. Performance analysis of greenhouse dryer by using insulated north-wall under natural convection mode. Energy Rep. 2016, 2, 107–116. [Google Scholar] [CrossRef] [Green Version]

- Patil, R.; Gawande, R. A review on solar tunnel greenhouse drying system. Renew. Sustain. Energy Rev. 2016, 56, 196–214. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Design, development, and testing of a modified greenhouse dryer under conditions of natural convection. Heat Transf. Res. 2014, 45, 433–451. [Google Scholar] [CrossRef]

- Anil, K.; Tiwari, G.; Subodh, K.; Mukesh, P. Role of greenhouse technology in agricultural engineering. Int. J. Agric. Res. 2010, 5, 779–787. [Google Scholar]

- Nayak, S.; Tiwari, G.N. Energy and exergy analysis of photovoltaic/thermal integrated with a solar greenhouse. Energy Build. 2008, 40, 2015–2021. [Google Scholar] [CrossRef]

- Rocha, R.; Melo, E. Influence of drying process on the quality of medicinal plants: A review. J. Med. Plants Res. 2011, 5, 7076–7084. [Google Scholar] [CrossRef]

- García Navarrete, F.J. Evaluation of the Effects of the Drying Process on the Quality of Stevia (Stevia Rebaudiana Bertoni) and Peppermint (Mentha Spicata). Master’s Thesis, Universidad Nacional de Colombia Headquarters Bogotá Faculty of Engineering Department of Civil and Agricultural Engineering, Montevideo, Uruguay, 2014. [Google Scholar]

- Sahdev, R.K. Open sun and greenhouse drying of agricultural and food products: A review. Int. J. Eng. Res. 2014, 3, 1053–1066. [Google Scholar]

- Munar, E.A.V.; Aldana, C.R.B. Avaliação numérica de estratégias passivas para a otimização climática noturna de uma estufa projetada para a produção de rosas. (Rosa spp.). Ornam. Hortic. 2019, 25, 351–364. [Google Scholar] [CrossRef] [Green Version]

- Noh, A.M.; Mat, S.; Ruslan, M.H.; Sciences, T. CFD simulation of temperature and air flow distribution inside industrial scale solar dryer. J. Adv. Res. Fluid Mech. 2018, 45, 156–164. [Google Scholar]

- Ramachandran, R.P.; Akbarzadeh, M.; Paliwal, J.; Cenkowski, S. Computational fluid dynamics in drying process modelling—a technical review. Food Bioprocess Technol. 2018, 11, 271–292. [Google Scholar] [CrossRef]

- Vélez-Piedrahita, S.; Ciro-Velásquez, H.; Osorio-Saráz, J.; Largo-Ávila, E. Estudio del efecto de la geometría de un secador solar típico para café con CFD. Rev. Ing. Univ. Medellin 2019, 18, 149–161. [Google Scholar] [CrossRef]

- Sanghi, A.; Ambrose, R.K.; Maier, D. CFD simulation of corn drying in a natural convection solar dryer. Dry. Technol. 2018, 36, 859–870. [Google Scholar] [CrossRef]

- Obayopo, S.O.; Oluwasanmi, A. CFD and experimental analysis of direct solar dryer for fish. Agric. Eng. Int. Cigr. J. 2019, 21, 108–117. [Google Scholar]

- Vivekanandan, M.; Periasamy, K.; Dinesh Babu, C.; Selvakumar, G.; Arivazhagan, R. Experimental and CFD investigation of six shapes of solar greenhouse dryer in no load conditions to identify the ideal shape of dryer. Mater. Today Proc. 2021, 37, 1409–1416. [Google Scholar] [CrossRef]

- Villagran, E.; Leon, R.; Rodriguez, A.; Jaramillo, J. 3D Numerical Analysis of the Natural Ventilation Behavior in a Colombian Greenhouse Established in Warm Climate Conditions. Sustainability 2020, 12, 8101. [Google Scholar] [CrossRef]

- Senhaji, A.; Mouqallid, M.; Majdoubi, H. Cfd assisted study of multi-chapels greenhouse vents openings effect on inside airflow circulation and microclimate patterns. Open J. Fluid Dyn. 2019, 9, 119–139. [Google Scholar] [CrossRef] [Green Version]

- Villagran Munar, E.A.; Bojacá Aldana, C.R. CFD simulation of the increase of the roof ventilation area in a traditional Colombian greenhouse: Effect on air flow patterns and thermal behavior. Int. J. Heat Technol 2019, 37, 881–892. [Google Scholar] [CrossRef]

- Srichat, A.; Vengsungnle, P.; Hongtong, K.; Kaewka, W.; Jongpluempiti, J. A Comparison of Temperature for Parabola and Sinusoidal Greenhouse Solar Dryer by CFD. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Singapore, 5–7 December 2019; p. 012006. [Google Scholar]

- User’s Guide, A.-F. ANSYS FLUENT theory guide. CanonsburgPa 2013, 794. [Google Scholar] [CrossRef]

- Tomasello, N.; Valenti, F.; Cascone, G.; Porto, S.M.C. Development of a CFD Model to Simulate Natural Ventilation in a Semi-Open Free-Stall Barn for Dairy Cows. Buildings 2019, 9, 183. [Google Scholar] [CrossRef] [Green Version]

- Villagran, E.A.; Noreña, J.E.J. Microclimatic behavior of a screen house proposed for horticultural production in low-altitude tropical climate conditions. Comun. Sci. 2020, 11, e3350. [Google Scholar] [CrossRef]

- Baxevanou, C.; Fidaros, D.; Bartzanas, T.; Kittas, C. Yearly numerical evaluation of greenhouse cover materials. Comput. Electron. Agric. 2018, 149, 54–70. [Google Scholar] [CrossRef]

- Odhiambo, M.R.O.; Abbas, A.; Wang, X.; Elahi, E. Thermo-environmental assessment of a heated venlo-type greenhouse in the yangtze river delta region. Sustainability 2020, 12, 412. [Google Scholar] [CrossRef]

- Esquivel, R.S.; Vindas, M.R.; Treto, P.C.; Ramírez, K.S. Cfd Applied in the optimization of a dryer for parchment coffee drying (Coffeaarabica L.) by forced ventilation. Am. J. Eng. Res. 2018, 7, 221–229. [Google Scholar]

- Román-Roldán, N.-I.; López-Ortiz, A.; Ituna-Yudonago, J.-F.; García-Valladares, O.; Pilatowsky-Figueroa, I. Computational fluid dynamics analysis of heat transfer in a greenhouse solar dryer “chapel-type” coupled to an air solar heating system. Energy Sci. Eng. 2019, 7, 1123–1139. [Google Scholar] [CrossRef]

- Tominaga, Y.; Mochida, A.; Yoshie, R.; Kataoka, H.; Nozu, T.; Yoshikawa, M.; Shirasawa, T. AIJ guidelines for practical applications of CFD to pedestrian wind environment around buildings. J. Wind Eng. Ind. Aerodyn. 2008, 96, 1749–1761. [Google Scholar] [CrossRef]

- Perén, J.I.; van Hooff, T.; Leite, B.C.C.; Blocken, B. CFD simulation of wind-driven upward cross ventilation and its enhancement in long buildings: Impact of single-span versus double-span leeward sawtooth roof and opening ratio. Build. Environ. 2016, 96, 142–156. [Google Scholar] [CrossRef] [Green Version]

- Villagrán, E.A.; Bojacá, C.R. Effects of surrounding objects on the thermal performance of passively ventilated greenhouses. J. Agric. Eng. 2019, 50, 20–27. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Yue, X.; Liu, X.; Tian, S.; Li, T. Evaluation of airflow pattern and thermal behavior of the arched greenhouses with designed roof ventilation scenarios using CFD simulation. PLoS ONE 2020, 15, e0239851. [Google Scholar] [CrossRef]

- Toghraie, D.; Abdollah, M.M.D.; Pourfattah, F.; Akbari, O.A.; Ruhani, B. Numerical investigation of flow and heat transfer characteristics in smooth, sinusoidal and zigzag-shaped microchannel with and without nanofluid. J. Therm. Anal. Calorim. 2018, 131, 1757–1766. [Google Scholar] [CrossRef]

- Osorio Hernandez, R.; Guerra Garcia, L.M.; Tinôco, I.F.; Martins, J.H.; Souza, C.d.F.; Osorio Saraz, J.A. Simulation of the internal environment of a post-harvest installation and a solar dryer of coffee. Rev. Bras. Eng. Agric. Ambient. 2016, 20, 163–168. [Google Scholar] [CrossRef] [Green Version]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Köppen-Geiger climate classification. Hydrol. Earth Syst. Sci. Discuss. 2007, 4, 439–473. [Google Scholar]

- Mesmoudi, K.; Meguallati, K.; Bournet, P.-E. Effect of the greenhouse design on the thermal behavior and microclimate distribution in greenhouses installed under semi-arid climate. Heat Transf. Asian Res. 2017, 46, 1294–1311. [Google Scholar] [CrossRef]

- Teitel, M.; Liran, O.; Barak, M.; Tanny, J. Air velocities in a naturally ventilated greenhouse. In Proceedings of the International Symposium on Greenhouse Cooling 719, Almeria, Spain, 24–27 April 2006; pp. 189–196. [Google Scholar]

- Baeza, E.J.; Pérez-Parra, J.J.; Montero, J.I.; Bailey, B.J.; López, J.C.; Gázquez, J.C. Analysis of the role of sidewall vents on buoyancy-driven natural ventilation in parral-type greenhouses with and without insect screens using computational fluid dynamics. Biosyst. Eng. 2009, 104, 86–96. [Google Scholar] [CrossRef]

- Molina-Aiz, F.D.; Valera, D.L.; Peña, A.A.; Gil, J.A.; López, A. A study of natural ventilation in an Almería-type greenhouse with insect screens by means of tri-sonic anemometry. Biosyst. Eng. 2009, 104, 224–242. [Google Scholar] [CrossRef]

- Lebbal, C.; Bougoul, S.; Zeroual, S. Simulation of natural ventilation inside tunnel greenhouse. Int. J. Heat Technol. 2020, 38, 752–757. [Google Scholar] [CrossRef]

- Elings, A.; Kempkes, F.; Kaarsemaker, R.; Ruijs, M.; Van de Braak, N.; Dueck, T. The energy balance and energy-saving measures in greenhouse tomato cultivation. In Proceedings of the International Conference on Sustainable Greenhouse Systems-Greensys2004 691, Leuven, Belgium, 12–16 September 2004; pp. 67–74. [Google Scholar]

- Villagrán, E.A.; Gil, R.; Acuña, J.F.; Bojacá, C.R. Optimization of ventilation and its effect on the microclimate of a colombian multispan greenhouse. Agron. Colomb. 2012, 30, 282–288. [Google Scholar]

- Bournet, P.E.; Ould Khaoua, S.A.; Boulard, T. Numerical prediction of the effect of vent arrangements on the ventilation and energy transfer in a multi-span glasshouse using a bi-band radiation model. Biosyst. Eng. 2007, 98, 224–234. [Google Scholar] [CrossRef]

- Bournet, P.-E.; Boulard, T. Effect of ventilator configuration on the distributed climate of greenhouses: A review of experimental and CFD studies. Comput. Electron. Agric. 2010, 74, 195–217. [Google Scholar] [CrossRef]

- Bartzanas, T.; Boulard, T.; Kittas, C. Effect of vent arrangement on windward ventilation of a tunnel greenhouse. Biosyst. Eng. 2004, 88, 479–490. [Google Scholar] [CrossRef]

- Mistriotis, A.; Arcidiacono, C.; Picuno, P.; Bot, G.P.A.; Scarascia-Mugnozza, G. Computational analysis of ventilation in greenhouses at zero- and low-wind-speeds. Agric. For. Meteorol. 1997, 88, 121–135. [Google Scholar] [CrossRef]

- Perén, J.I.; van Hooff, T.; Leite, B.C.C.; Blocken, B. CFD analysis of cross-ventilation of a generic isolated building with asymmetric opening positions: Impact of roof angle and opening location. Build. Environ. 2015, 85, 263–276. [Google Scholar] [CrossRef] [Green Version]

- Akrami, M.; Javadi, A.A.; Hassanein, M.J.; Farmani, R.; Dibaj, M.; Tabor, G.R.; Negm, A. study of the effects of vent configuration on mono-span greenhouse ventilation using computational fluid dynamics. Sustainability 2020, 12, 986. [Google Scholar] [CrossRef] [Green Version]

- Couto, N.; Rouboa, A.; Monteiro, E.; Viera, J. Computational fluid dynamics analysis of greenhouses with artificial heat tube. World J. Mech. 2012. [Google Scholar] [CrossRef] [Green Version]

- Prada, Á.; Vela, C.P.; Bardález, G.; Saavedra, J. Efectividad de un proceso de secado de café usando secadores solares con sistema de flujo de aire continuo impulsado por energía fotovoltaica, en la Región San Martín, Perú. Inf. Tecnológica 2019, 30, 85–92. [Google Scholar] [CrossRef]

- Boulard, T.; Kittas, C.; Roy, J.C.; Wang, S. SE—Structures and Environment: Convective and Ventilation Transfers in Greenhouses, Part 2: Determination of the Distributed Greenhouse Climate. Biosyst. Eng. 2002, 83, 129–147. [Google Scholar] [CrossRef] [Green Version]

- Reynafarje, X.; Villagrán, E.; Bojacá, C.; Gil, R.; Schrevens, E. Simulation and validation of the airflow inside a naturally ventilated greenhouse designed for tropical conditions. In Proceedings of the XXX International Horticultural Congress IHC2018: III International Symposium on Innovation and New Technologies in Protected 1271, Istanbul, Turkey, 12–16 August 2018; pp. 55–62. [Google Scholar]

- Gupta, V.; Sharma, A.; Gupta, K.S. Numerical analysis of direct type greenhouse dryer. In Proceedings of the Gas Turbine India Conference, Bangalore, India, 7–8 December 2017; p. V002T006A008. [Google Scholar]

- Purusothaman, M.; Valarmathi, T.N. Computational fluid dynamics analysis of greenhouse solar dryer. Int. J. Ambient Energy 2019, 40, 894–900. [Google Scholar] [CrossRef]

- Prakash, O.; Kumar, A. Thermal performance evaluation of modified active greenhouse dryer. J. Build. Phys. 2014, 37, 395–402. [Google Scholar] [CrossRef]

- Purusothaman, M.; Valarmathi, T.; sai Santhosh, P. CFD Analysis of greenhouse solar dryer with different roof shapes. In Proceedings of the 2019 Fifth International Conference on Science Technology Engineering and Mathematics (ICONSTEM), Chennai, India, 14–15 March 2019; pp. 408–412. [Google Scholar]

- Anil, K.; Om, P.; Ajay, K.; Abhishek, T. Experimental analysis of greenhouse dryer in no-load conditions. J. Environ. Res. Dev. 2013, 7, 1399. [Google Scholar]

- Wisaiprom, N.; Kasayapanand, N.; Pratinthong, N.; Songprakorp, R.; Thepa, S.; Deeto, S. The study ofshrimp drying by greenhouse drying combined with low humidity air. Int. J. Smart Grid Clean Energy 2018. [Google Scholar] [CrossRef]

- Costales, R. Aplicación de la energía renovable en el secado. Estado del arte y su potencial en las producciones agrícolas. Icidca. Sobre Los Deriv. Cana Azucar 2010, 44, 47–53. [Google Scholar]

- Kripanand, S.; Guruguntla, S. Effect of various drying methods on quality and flavor characteristics of mint leaves (Mentha spicata L.). J. Food Pharm. Sci. 2015, 3, 38–45. [Google Scholar]

- Nayak, S.; Kumar, A.; Mishra, J.; Tiwari, G.N. Drying and Testing of Mint (Mentha piperita) by a Hybrid Photovoltaic-Thermal (PVT)-Based Greenhouse Dryer. Dry. Technol. 2011, 29, 1002–1009. [Google Scholar] [CrossRef]

- Nour-Eddine, B.; Belkacem, Z.; Abdellah, K. Experimental study and simulation of a solar dryer for spearmint leaves (Mentha spicata). Int. J. Ambient Energy 2015, 36, 50–61. [Google Scholar] [CrossRef]

| Variable | Relaxation Factors |

|---|---|

| Density | 1.0 |

| Body force | 0.9 |

| Pressure | 0.3 |

| Momentum | 0.7 |

| DO | 0.8 |

| Energy | 0.8 |

| k and ε | 0.7 |

| Water vapor | 0.7 |

| Turbulent viscosity | 0.8 |

| Model | Number of Elements of the Numerical Grid | Quality of Numerical Grid |

|---|---|---|

| M1 | 3.928.756 | Average: 0.94; maximum: 0.97; minimum: 0.76. |

| M2 | 3.872.906 | Average: 0.93; maximum: 0.98; minimum: 0.74. |

| M3 | 3.956.191 | Average: 0.95; maximum: 0.99; minimum: 0.79. |

| M4 | 3.741.873 | Average: 0.93; maximum: 0.98; minimum: 0.73. |

| Variable | Concrete | Black Plastic Cover | Clear Plastic Cover |

|---|---|---|---|

| Density (ρ) (kg m−3) | 2100 | 920 | 920 |

| Thermal conductivity (k) (W m−1 K−1) | 1.41 | 0.30 | 0.30 |

| Specific heat (Cp) (J K−1 kg−1) | 880 | 1800 | 1900 |

| Absorptivity coefficient (1/m) | 0.60 | 9.9 | 0.10 |

| Refractive index | 1.00 | 1.79 | 1.00 |

| Emissivity | 0.71 | 0.95 | 0.90 |

| Scattering coefficient (1/m) | −10 | 0.00 | 0.00 |

| Scenario | Temperature (°C) | Relative Humidity (%) | Wind Speed (ms−1) | Wind Direction | Solar Radiation (wm−2) |

|---|---|---|---|---|---|

| M1S1 | 25.4 | 75 | 0.21 | W | 893 |

| M1S2 | 0.62 | ||||

| M1S3 | 1.05 | ||||

| M2S1 | 25.4 | 75 | 0.21 | W | 893 |

| M2S2 | 0.62 | ||||

| M2S3 | 1.05 | ||||

| M3S1 | 25.4 | 75 | 0.21 | W | 893 |

| M3S2 | 0.62 | ||||

| M3S3 | 1.05 | ||||

| M4S1 | 25.4 | 75 | 0.21 | W | 893 |

| M4S2 | 0.62 | ||||

| M4S3 | 1.05 |

| Air Velocity (ms−1) | |||

|---|---|---|---|

| Scenario | Plane 1 (P1) | Plane 2 (P2) | Plane 3 (P3) |

| M1S1 | 0.299 ± 0.184 | 0.308 ± 0.186 | 0.307 ± 0.185 |

| M1S2 | 0.319 ± 0.175 | 0.317 ± 0.173 | 0.314 ± 0.174 |

| M1S3 | 0.336 ± 0.172 | 0.329 ± 0.157 | 0.349 ± 0.167 |

| M2S1 | 0.269 ± 0.141 | 0.256 ± 0.137 | 0.259 ± 0.141 |

| M2S2 | 0.261 ± 0.136 | 0.271 ± 0.110 | 0.262 ± 0.152 |

| M2S3 | 0.302 ± 0.125 | 0.293 ± 0.152 | 0.297 ± 0.123 |

| M3S1 | 0.271 ± 0.156 | 0.275 ± 0.134 | 0.284 ± 0.128 |

| M3S2 | 0.295 ± 0.139 | 0.298 ± 0.141 | 0.288 ± 0.149 |

| M3S3 | 0.324 ± 0.123 | 0.313 ± 0.135 | 0.299 ± 0.136 |

| M4S1 | 0.336 ± 0.218 | 0.331 ± 0.210 | 0.325 ± 0.194 |

| M4S2 | 0.341 ± 0.214 | 0.340 ± 0.214 | 0.336 ± 0.206 |

| M4S3 | 0.346 ± 0.229 | 0.344 ± 0.227 | 0.333 ± 0.203 |

| Temperature (°C) | |||

|---|---|---|---|

| Scenario | Plane 1 (P1) | Plane 2 (P2) | Plane 3 (P3) |

| M1S1 | 49.01 ± 1.31 | 48.43 ± 3.01 | 48.79 ± 2.98 |

| M1S2 | 47.14 ± 2.58 | 45.47 ± 2.71 | 47.18 ± 2.77 |

| M1S3 | 43.38 ± 3.12 | 43.49 ± 2.93 | 43.57 ± 2.96 |

| M2S1 | 39.25 ± 4.24 | 41.10 ± 4.89 | 39.28 ± 4.25 |

| M2S2 | 38.12 ± 3.75 | 39.22 ± 3.73 | 38.20 ± 3.80 |

| M2S3 | 35.83 ± 3.45 | 35.54 ± 3.38 | 35.97 ± 3.60 |

| M3S1 | 40.36 ± 4.03 | 40.36 ± 4.96 | 41.30 ± 5.14 |

| M3S2 | 40.04 ± 4.08 | 40.30 ± 3.91 | 40.06 ± 3.89 |

| M3S3 | 39.96 ± 4.05 | 38.49 ± 3.52 | 38.52 ± 3.57 |

| M4S1 | 46.87 ± 7.50 | 47.03 ± 7.66 | 46.38 ± 6.48 |

| M4S2 | 46.37 ± 7.17 | 46.15 ± 7.14 | 46.52 ± 7.67 |

| M4S3 | 45.96 ± 6.79 | 45.92 ± 6.75 | 45.52 ± 7.98 |

| Scenario | Relative Humidity (%) | ||

|---|---|---|---|

| Plane 1 (P1) | Plane 2 (P2) | Plane 3 (P3) | |

| M1S1 | 19.11 ± 3.61 | 20.33± 4.60 | 22.32 ± 7.31 |

| M1S2 | 21.93 ± 4.10 | 21.75 ± 4.21 | 24.50 ± 6.62 |

| M1S3 | 27.34 ± 5.69 | 26.81 ± 6.71 | 27.11 ± 6.41 |

| M2S1 | 34.70 ± 6.45 | 31.42 ± 7.34 | 34.93 ± 8.49 |

| M2S2 | 36.85 ± 8.32 | 34.52 ± 6.83 | 36.73 ± 8.32 |

| M2S3 | 42.33 ± 8.32 | 43.00 ± 8.96 | 42.16 ± 8.84 |

| M3S1 | 32.45 ± 7.34 | 31.62 ± 9.61 | 32.72 ± 6.63 |

| M3S2 | 33.21 ± 9.51 | 32.81 ± 7.53 | 33.18 ± 7.62 |

| M3S3 | 35.92 ± 7.32 | 36.93 ± 7.42 | 34.33 ± 6.91 |

| M4S1 | 22.21 ± 8.31 | 20.72 ± 9.42 | 22.02 ± 8.23 |

| M4S2 | 24.52 ± 10.3 | 23.31 ± 10.5 | 24.24 ± 10.2 |

| M4S3 | 24.92 ± 10.1 | 24.33 ± 9.42 | 25.03 ± 9.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villagran, E.; Henao-Rojas, J.C.; Franco, G. Thermo-Environmental Performance of Four Different Shapes of Solar Greenhouse Dryer with Free Convection Operating Principle and No Load on Product. Fluids 2021, 6, 183. https://doi.org/10.3390/fluids6050183

Villagran E, Henao-Rojas JC, Franco G. Thermo-Environmental Performance of Four Different Shapes of Solar Greenhouse Dryer with Free Convection Operating Principle and No Load on Product. Fluids. 2021; 6(5):183. https://doi.org/10.3390/fluids6050183

Chicago/Turabian StyleVillagran, Edwin, Juan Camilo Henao-Rojas, and German Franco. 2021. "Thermo-Environmental Performance of Four Different Shapes of Solar Greenhouse Dryer with Free Convection Operating Principle and No Load on Product" Fluids 6, no. 5: 183. https://doi.org/10.3390/fluids6050183

APA StyleVillagran, E., Henao-Rojas, J. C., & Franco, G. (2021). Thermo-Environmental Performance of Four Different Shapes of Solar Greenhouse Dryer with Free Convection Operating Principle and No Load on Product. Fluids, 6(5), 183. https://doi.org/10.3390/fluids6050183