Abstract

Ultrasound technologies are well-known for their ability to intensify the heat and mass transfer processes. Hence, ultrasonic treatment processes are widely applied for the separation of oil–water emulsions, optimization of oil pumping processes, cleaning the bottomhole zone, etc. However, the main phenomenon under the positive influence of ultrasonic waves on such processes is the cavitation bubbles implosion on the water–oil boundary. It is well-known that ultrasound energy contributes to the reversible viscosity reduction in heavy oil systems. However, it is possible to exhibit chemical destruction of the weakest carbon–heteroatom bonds in the structure of the asphaltenes. This study investigates the influences of controllable ultrasound waves with frequency ranges of 20–60 kHz under the exposure time of 60 s on the rheology of a heavy crude oil sample produced from the Ashalcha reservoir (Tatarstan Republic, Russia). The specific feature of this study is the application of multi-frequency ultrasonic exposure with a wide spectrum of side harmonics with the frequency up to 400 kHz. The results of the Saturates, Aromatics, Resins and Asphaltenes (SARA) analysis method support the chemical consequences of ultrasonication of crude oil. The content of resins under the irradiation of ultrasound waves altered from 32.5 wt.% to 29.4 wt.%, while the number of aromatics hydrocarbons raised from 24.3 wt.% to 34.1 wt.%. The Gas Chromatography—Mass Spectroscopy (GC-MS) analytical analysis method was applied to qualitatively compare the composition of saturated and aromatics fractions between the initial and upgraded heavy crude oil in order to show the chemical destruction of asphaltene bonds after the ultrasonic treatment. It was demonstrated that ultrasound waves allowed chemical conversion of asphaltene fragments that led to irreversible viscosity reduction. The viscosity of the heavy oil sample under the favorable ultrasonic irradiation conditions reduced from 661.2 mPa·s to 178.8 mPa·s. This advantage can be used to develop enhanced oil recovery methods and partial upgrading processes in downstream conditions.

1. Introduction

One of the most important tendencies observed in the global petroleum production industry is the decline in the production rate of conventional light oils [1]. On the contrary, energy demand is rising with such a speed that the supply of crude oil in the near future will fail to meet it. Therefore, alternative hydrocarbon resources are crucial to meet the demand for energy. The hydrocarbon-importing countries are trying to find solution in non-hydrocarbon and renewable resources such as wind, solar and geothermal energies. However, the high initial cost of installation, low efficiency levels and sustainability issues due to the lack of power storage are still challenging. On the other hand, oil-exporting countries are considering unconventional hydrocarbon resources such as shale oil, heavy oil and natural bitumen, shale gas, tight gas and extra-heavy oil as alternative resources to conventional light crude oils. However, the high viscosity and density, as well as the significant content of asphaltenes, metals and sulfur in the composition of hydrocarbons are the main problems, which require practical, novel and cheap technological solutions. Currently, there are many technologies applied to unlock and transport heavy crude oil [2,3,4]. However, the energy required to produce and pump through the pipelines is cost-effective. This is due to the lack of technical means and technological challenges of transportation, which is a prerequisite for the development of emerging methods and technologies for enhancing oil recovery and pumping of abnormally high-viscosity oils. Recently, wave technologies such as electrical and magnetic fields, microwave irradiation and ultrasonic waves have been widely employed to process and transport unconventional heavy crude oils [5,6,7,8]. The application of ultrasonic field is the most promising method, in contrast to the other wave technologies, owing to its low specific power consumption. It is well-known that ultrasound energy contributes to the heat and mass transfer processes, which makes it attractive for the improvement of wellbore damage, demulsification, optimization of oil transfer processes, etc. [9,10]. At the same time, it is believed that ultrasound has positive effects on the processes carried out in the oil–water interphases and the colloidal structure of oil. When powerful acoustic oscillations propagate through the liquid medium, non-linear effects are observed, which depend on the amplitude of acoustic waves. Such secondary order effects can be applied to improve heavy oil recovery [11]. Moreover, acoustic waves contribute to the formation, growth and collapse of bubbles in oil-phase medium, and therefore ponderomotive forces arise in its vicinity [12].

Ultrasound can improve the mass-transfer and kinetics of oxidative desulfurization processes due to the formation of surfaces in liquid fuels [13]. It is proposed that desulfurization efficiency of oil and its products is increased. Stepwise periodic processing under ultrasonic field in the presence of a catalyst and an oxidizing agent is used, followed by the removal of the purified part of the oil product [14,15,16]. Gildo et al. reported the results of their experiments on ultrasound-assisted oxidative desulfurization using a catalyst. The authors imply that desulfurization degree in the presence of 984 mg of the catalyst reached 95%. The ultrasonic treatment time was 76 min [16]. Similarly, Jalali et al. carried out oxidative desulfurization of gasoil under ultrasonic treatment. The authors used formic acid as a catalyst. The influence of ultrasonic parameters and the ratio of the catalyst to oxidant was also evaluated. The study found that maximum desulfurization was achieved under the optimum conditions of 50 °C temperature, 19.81 min of sonication time, 46.36 oxidant to sulfur molar ratio, 3.22 formic acid to oxidant molar ratio and 7.78 W/mL sonication power [17]. Studies have shown that sonocatalytic oxidative desulfurization is a promising method for reducing the sulfur content of oil distillates [18,19,20]. Unlike conventional hydrodesulfurization methods that require steam generation, sonocatalytic oxidative desulfurization can be performed under mild conditions, making it safe, feasible and green. Moreover, using low range ultrasonic power makes this method attractive for industrial-scale applications.

In addition to the physical consequences such as heat, cavitation and emulsification, the ultrasonication of crude oil can have chemical consequences as well. The composition of crude oil can be significantly changed due to the destruction of high-molecular components of oil such as resins and asphaltenes [21]. The influence mechanisms of ultrasound on paraffinic and highly paraffinic dispersed oil systems are well-established [22,23,24,25]. Ultrasonic treatment of crude oil has a strong influence on the structure of asphaltenes. The efficiency of such treatment primarily depends on the time of treatment, physical parameters of the ultrasound wave, temperature of the medium and concentration of the asphaltenes. It is reported that the size of asphaltene cluster decreases in the structure of the oil dispersed system under ultrasonic irradiation [26,27]. According to the experiments carried out by some scholars, the destruction of asphaltene structures leads to the reorganization of aggregates that contributes to more condensed and larger aggregates [28].

It is reported that the dispersity degree of asphaltene aggregates increases under the irradiation of ultrasonic waves with the frequency of 22 kHz for 10 min. Moreover, sedimentation stability increases, and the relative content of aliphatic fragments decreases. The number of rings in the structure of naphtene aromatics, the heteroatom fragments and the number of blocks in the mean asphaltene molecules also decreases [29]. There is a vast amount of literature on the capability of ultrasonic cavitation to inhibit the sedimentation of asphaltenes, which improves the characteristics of crude oil [30]. The dispersion degree of asphaltene aggregates increases after the ultrasonic treatment. Therefore, their sedimentation stability in the dispersion medium also increases [31].

The destruction of the molecules is carried out where the energy of the valence bonds is less than the acting forces on it. In normal alkanes, this is typical for the C–C bonds located closer to the center, while for aromatic hydrocarbons with an alkyl substitute this is seen with the β-bond of the peripheral chains. The new hydrocarbon molecules formed after ultrasonic treatment can join both the composition of the core and shell of the Complex Structural Unit [32].

In general, the application of ultrasounds is a promising technology to solve several problems raised in the petroleum industry. However, the reviewed literatures demonstrated weak practice results of ultrasound waves, probably due to the long treatment duration required to efficiently upgrade heavy crude oil. Few researchers have addressed the chemical transformation of crude oil under the impact of ultrasound energy. This study aims to investigate the chemical transformations that occur in the composition of heavy crude oil after multi-frequency ultrasonic wave treatment with the main harmonics of 20–60 kHz, which successfully improved the rheology of the hydrocarbon fluid.

2. Materials and Methods

The object of this study was a heavy oil sample produced from the Ashalcha field, located in the Republic of Tatarstan, Russia. The development of the field was actively initiated in 2006 year. The crude oil from Ashalcha is characterized by high viscosity and density equal to 2676 mPa·s (at a temperature of 20 °C) and 959.7 kg/m3 (at a temperature of 20 °C). The elemental composition of the crude oil was as follows: carbon—83.9 wt.%, hydrogen—11.3 wt.%, oxygen—1.2 wt.%, sulfur—3.2 wt.%, nitrogen—0.4 wt.%.

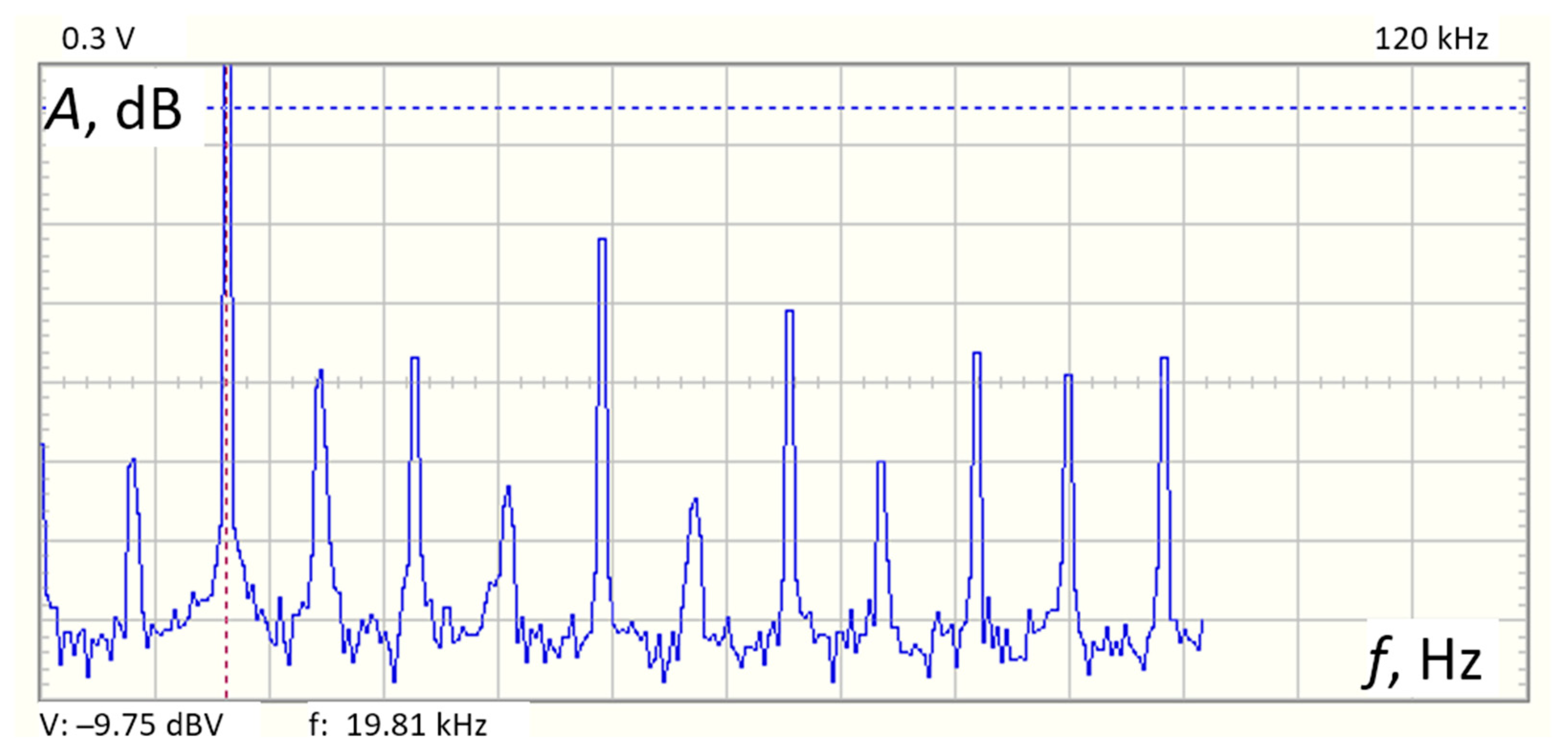

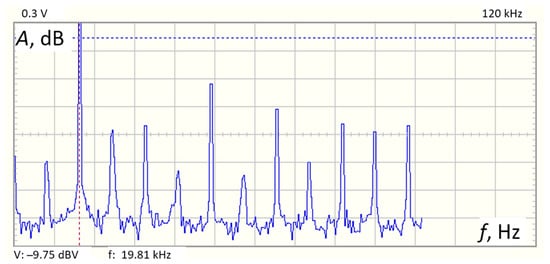

The ultrasonic treatment of the given sample was carried out by a Complex Ultrasonic Instrument developed by LLC Scientific Production Association «VOLNA», Moscow, Russia. The specific feature of the instrument is the possibility to employ controllable acoustic multifrequency fields with the given amplitudes [25,26]. By controllable multifrequency acoustic fields, we mean the generation of multifrequency wave energy at each moment of time in the treated liquid medium, which promotes physical and chemical processes in the treated liquid, and hence leads to new technological solutions. In Figure 1, we demonstrate an example of the multi-frequency ultrasonic exposure spectrum tested in a closed cylindrical metal vessel with a main harmonic of 19.8 kHz. The wave propagation pattern in the liquid bulk was different in each moment of time, which exhibits a superposition of wave series with different frequencies. In Figure 1, the waves have the upper frequency of 120 kHz, and this was not the limit.

Figure 1.

Ultrasonic multifrequency specter for the frequency of 19.8 kHz: A—amplitude; f—frequency.

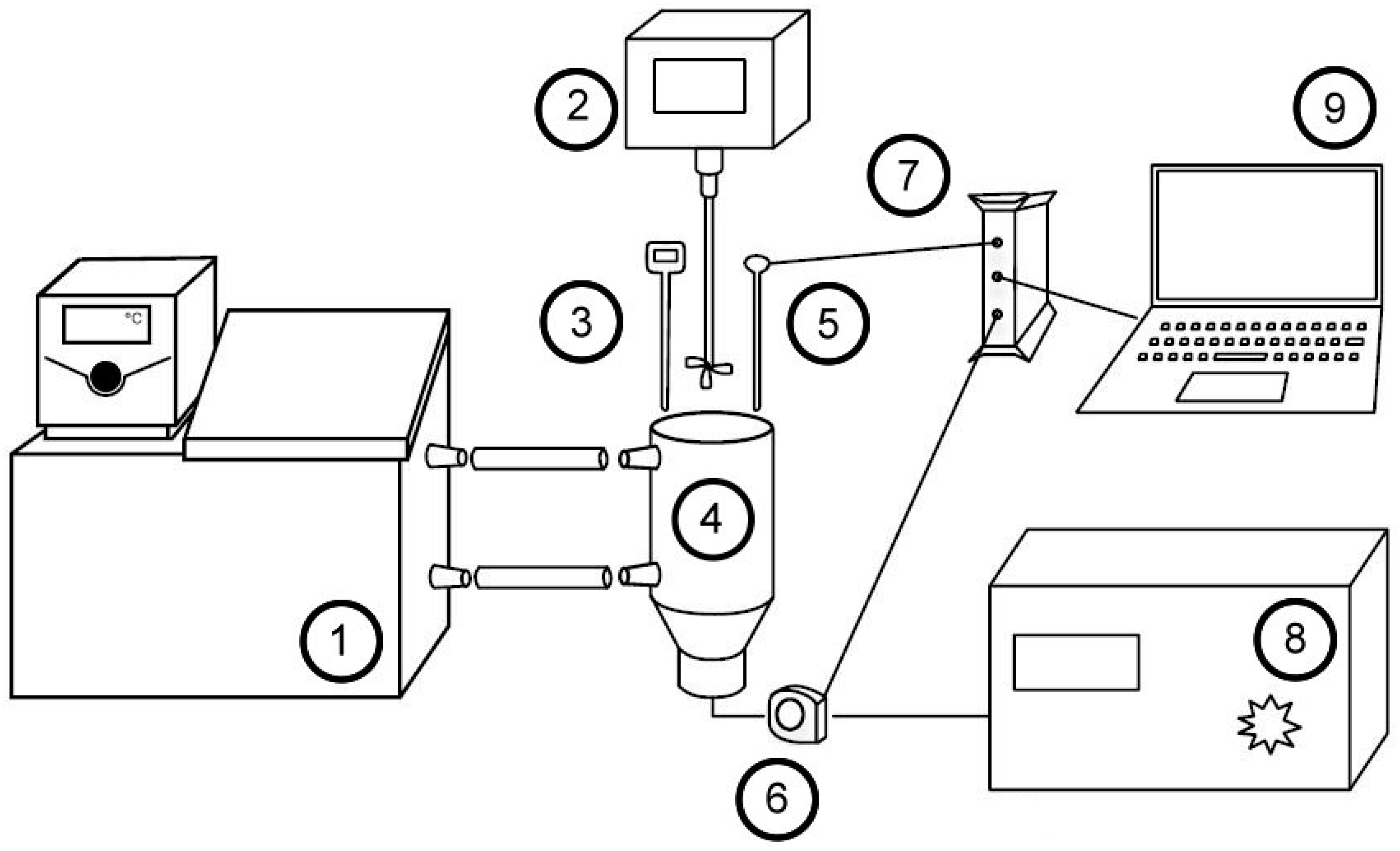

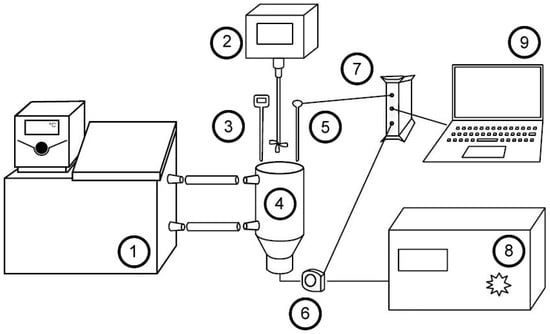

The developed experimental set-up is presented in Figure 2. The experiments were carried out according to the following method. Oil sample with a volume of 100 mL was introduced into a thermostatically controlled reactor vessel (4). The oil sample was kept under the given temperature (in our study the supplied temperature was 40 °C) for 24 h. The reactor vessel (4) was covered by thermostatic jacket that allowed us to reduce the heat loss during the experiments. The given temperature during the process was supplied by the circulating thermostat (1). During the experiment, the apparent temperature of the fluid bulk was controlled by thermocouples (3). In this study, three types of reactor vessels with different ultrasonic (US) stimulators with main harmonics of 19.8 kHz, 42.1 kHz and 62.2 kHz (for oil) were used. Industrial piezoceramic emitters (Figure 3) with resonance frequencies of 22 kHz, 40 kHz and 70 kHz were used as an ultrasonic stimulator. The amplitude of acoustic waves was determined mainly by the amplitude of signals from the generators of ultrasonic frequency (8). Multifrequency specter of ultrasonic oscillations was regulated by hydrophones (5), and the signal was graphically displayed on the computer screen (9) using an oscilloscope (7). The actual voltage consumed was also recorded through a two-channel oscilloscope. A transformer (6) was used to measure the level of the consumed current.

Figure 2.

Experimental set-up for ultrasonic upgrading of heavy oil in laboratory conditions. 1—circulating thermostat; 2—rotational viscosimeter; 3—thermocouples; 4—reactor vessels with heat jackets; 5—hydrophones; 6—current transformer; 7—digital oscilloscope; 8—industrial ultrasound generator UZG-22; 9—computer.

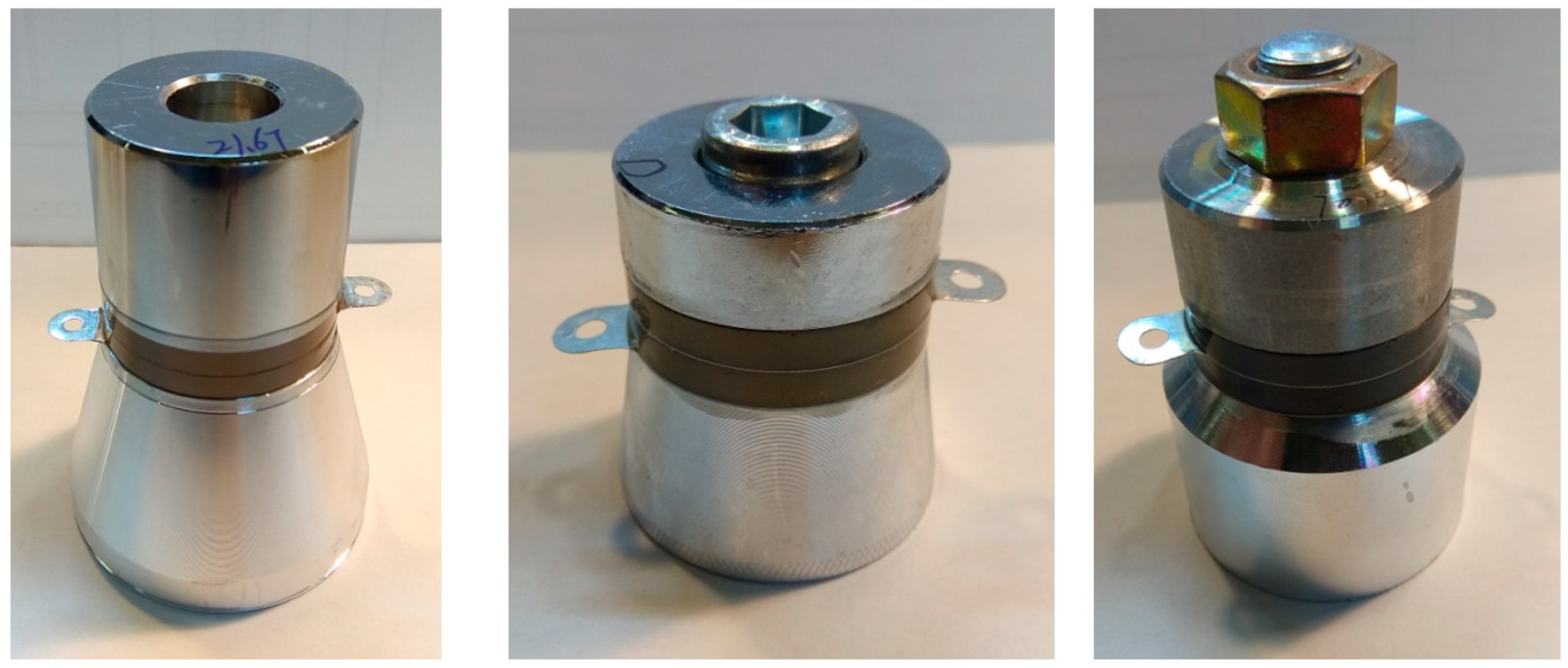

Figure 3.

Applied piezoceramic ultrasound transducers (22 kHz, 40 kHz and 70 kHz).

The dynamic viscosity of the heavy oil sample before and after the ultrasonic treatment was carried out by rotational viscosimeter (2) according to the Brookfield principles. The ultrasonic treatment of the heavy oil sample was initiated after reaching constant viscosity values at the given temperature (40 °C). The applied shear rate was 12 rpm and the volume of the heavy oil sample was 100 mL. The changes in the rheology characteristics were observed for 60 min after the ultrasonic irradiation. During observation, the constant temperature of the bulk medium was supplied via a jacket of vessels heated/cooled by circulating thermostat.

The duration of ultrasonic treatment was the same in all experiments—3 min. The treatment time was chosen according to the experimental results reported in the literature review. Almost all the authors used an ultrasonic exposure time in the range of 100 s—360 s [27,28]. The test modes on different reactors were chosen for the following acoustic wave fluxes with energies 0.14, 0.41 and 0.7 W/mL. The rotation speed during ultrasonic treatment process was adjusted at 50 rpm.

The changes in the composition of heavy oil after ultrasonic upgrading, which explain the improvement in the rheological characteristics of crude oil, were investigated by SARA analysis method. This method determines the changes in the group composition of crude oil after upgrading processes. The asphaltene fraction was precipitated from the oil bulk by dissolving a gram of oil sample in 40 g of petroleum ether, the boiling temperature of which ranges between 30 and 70 °C. The maltenes (de-asphalted oil sample) were separated by liquid adsorption chromatography on silica gel. The chromatography column, with a diameter and length of 20 × 500 mm, was filled with adsorbent—neutral aluminum oxide (as per TU 6-09-3916) with the fractions of 0.04–0.16 mm. The aluminum oxide was previously calcined at temperature of 450 °C for 3 h.

The Gas Chromatography and Mass Spectroscopy (GC-MS) analysis of aromatic fractions separated by SARA analysis method were carried out in a Crystal 5000.2 instrument produced by “Chromatec” (Yoshkar-Ala, Russia) coupled with mass spectrometer 214.2.840.083-10 (ions source ADVIS). The Xcalibur software was used for processing the results. The chromatograph was fitted with a capillary column, 30 m long, with a diameter of 0.25 mm. The speed of the flow of carrier gas (helium) was 1 mL/min. The temperature of the injector was 310 °C. The temperature program of the thermostat was as follows: temperature increase from 100 to 150 °C at a speed of 3 °C/min and from 150 to 300 °C at a speed of 12 °C/min, followed by its isotherm to the end of the analysis. Electron energy of the mass detector was 70 eV; the temperature of ion source was 250 °C. The compounds were identified through the electronic library of the NIST spectra database and according to the data of the literary sources.

3. Results and Discussion

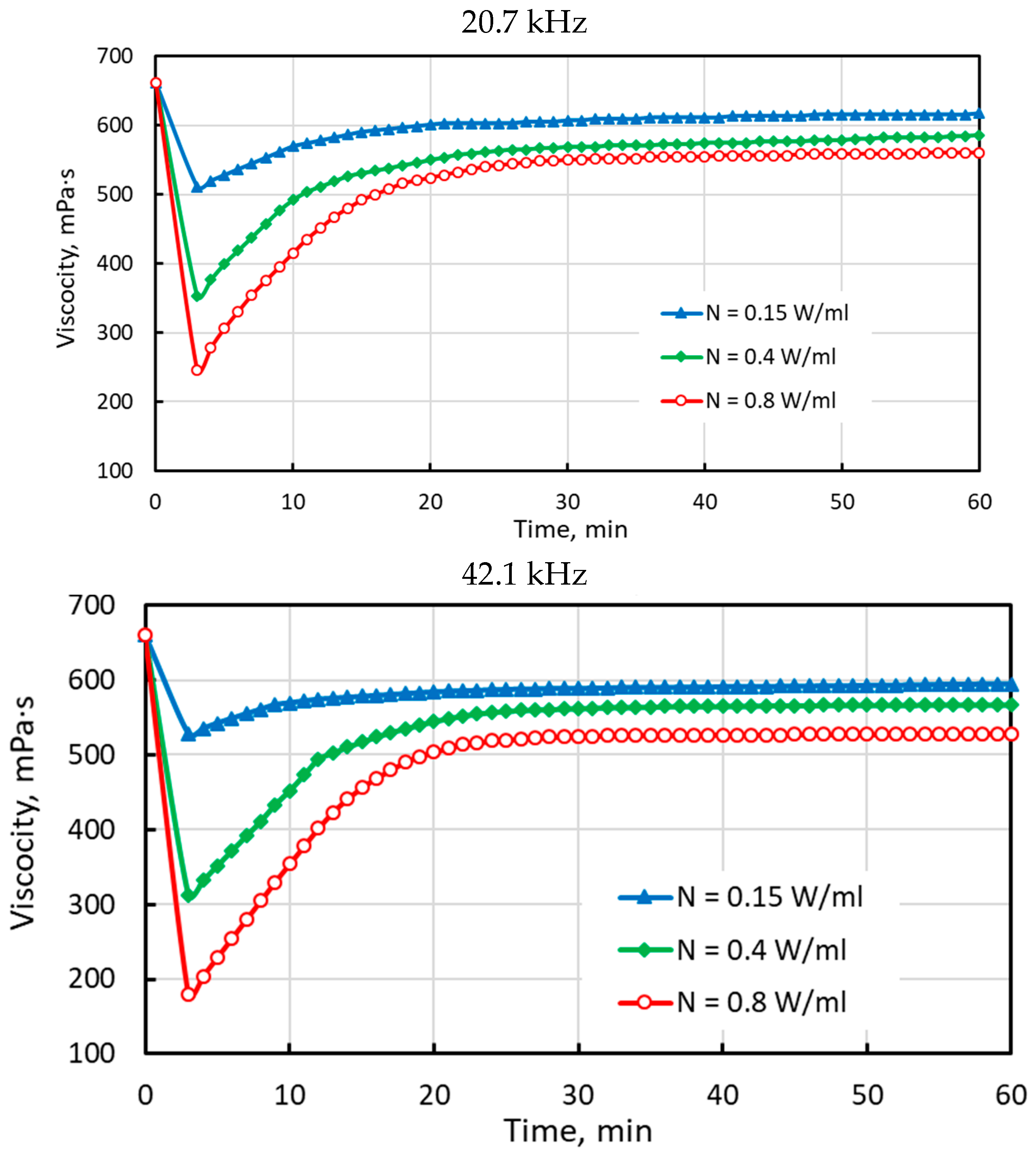

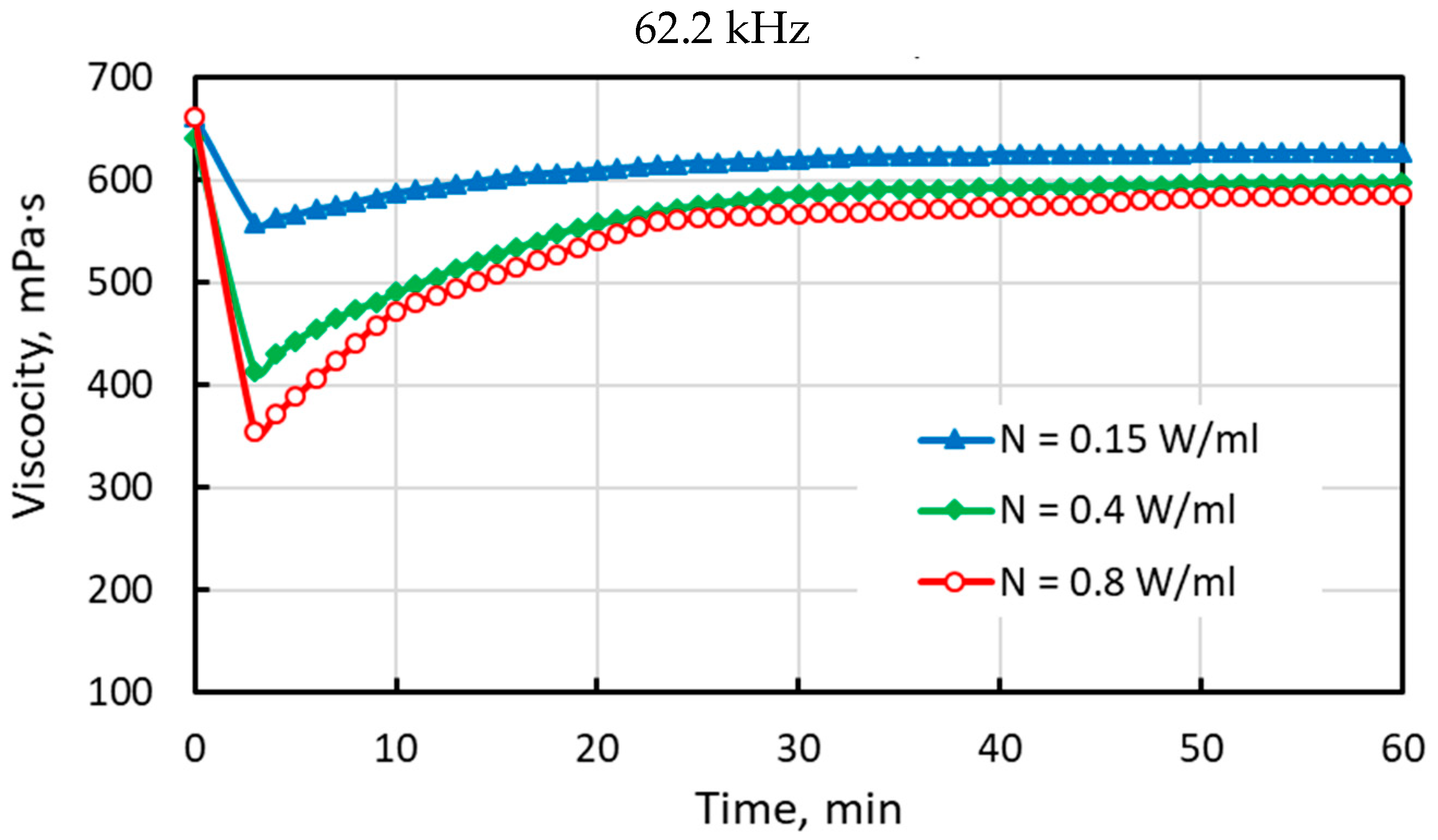

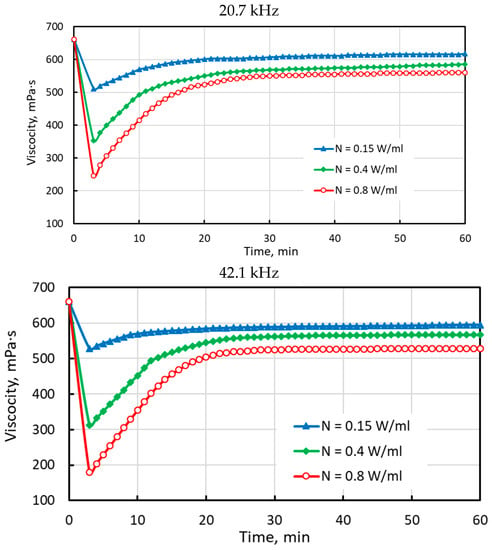

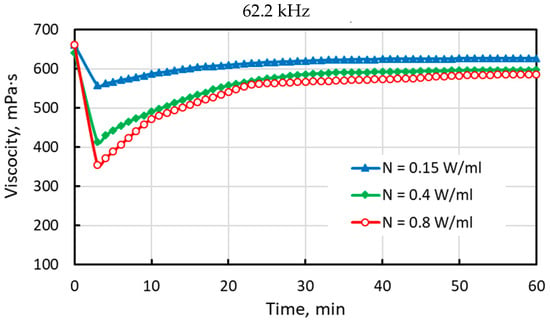

Heavy oil samples were sonicated for 3 min under various acoustic frequencies (20.7 kHz; 42.1 kHz and 62.2 kHz) and power (0.15 W/mL; 0.4 W/mL and 0.8 W/mL), with measuring the viscosity of the samples up to 60 min (Figure 4) in order to evaluate the relaxation of viscosity values, which is very common for ultrasonic treatment processes. One can observe that viscosity values for the whole sample increased just after termination of sonication, but were still lower than the initial viscosity values. The plateau phase for the whole sample initiated after 20 min. The increase in the viscosity values after termination of ultrasonic irradiation, or, in another words, relaxation phenomenon, can be explained by the changes in the colloidal structure of dispersed oil systems. The viscosity relaxation of heavy crude oil samples can be attributed either to the polymerization of the cracked fragments of asphaltene molecules or their self-aggregation. It is well-known that asphaltenes exhibit a tendency toward self-aggregation and can form asphaltene nanoaggregates, which are composed of 6–10 molecules dispersed in crude oil [33]. The further association leads to clusters of asphaltene nanoaggregates, the size of which in crude oil ranges between 2 and 5 nm [34]. Such supramolecular reorganization under the impact of ultrasound waves determines the increase in the viscosity of heavy crude oil.

Figure 4.

Dynamic viscosity of heavy oil sample versus relaxation time for different acoustic frequencies and powers. Sonication time was 3 min.

According to the experimental results provided in Figure 4, acoustic frequency 42.1 kHz exhibited the best performance in terms of viscosity reduction degree, which was considered as a working frequency for further experiments. The measured viscosity of the heavy oil sample at a temperature of 40 °C before ultrasonic treatment was 661.2 mPa·s. The acoustic treatment of the heavy oil sample led to a rise of fluid temperature of up to 1.0 °C. The viscosity of the oil sample heated up to 41 °C (without ultrasound) was 611.8 mPa·s. The ultrasonic treatment of the heavy oil sample reduced its viscosity from 661.2 to 527.4 mPa·s (Figure 4, 42.1 kHz), which corresponds to the viscosity reduction degree of 20.2%. The application of a thermostatically controlled jacket in the reactor makes it possible to quickly restore the temperature of the medium after wave disturbance and to record changes in rheology, mainly focusing on the impact of ultrasonic waves on the viscosity of heavy oil rather than temperature. The temperature recovery time ranges between 12 and 20 min depending on the applied power.

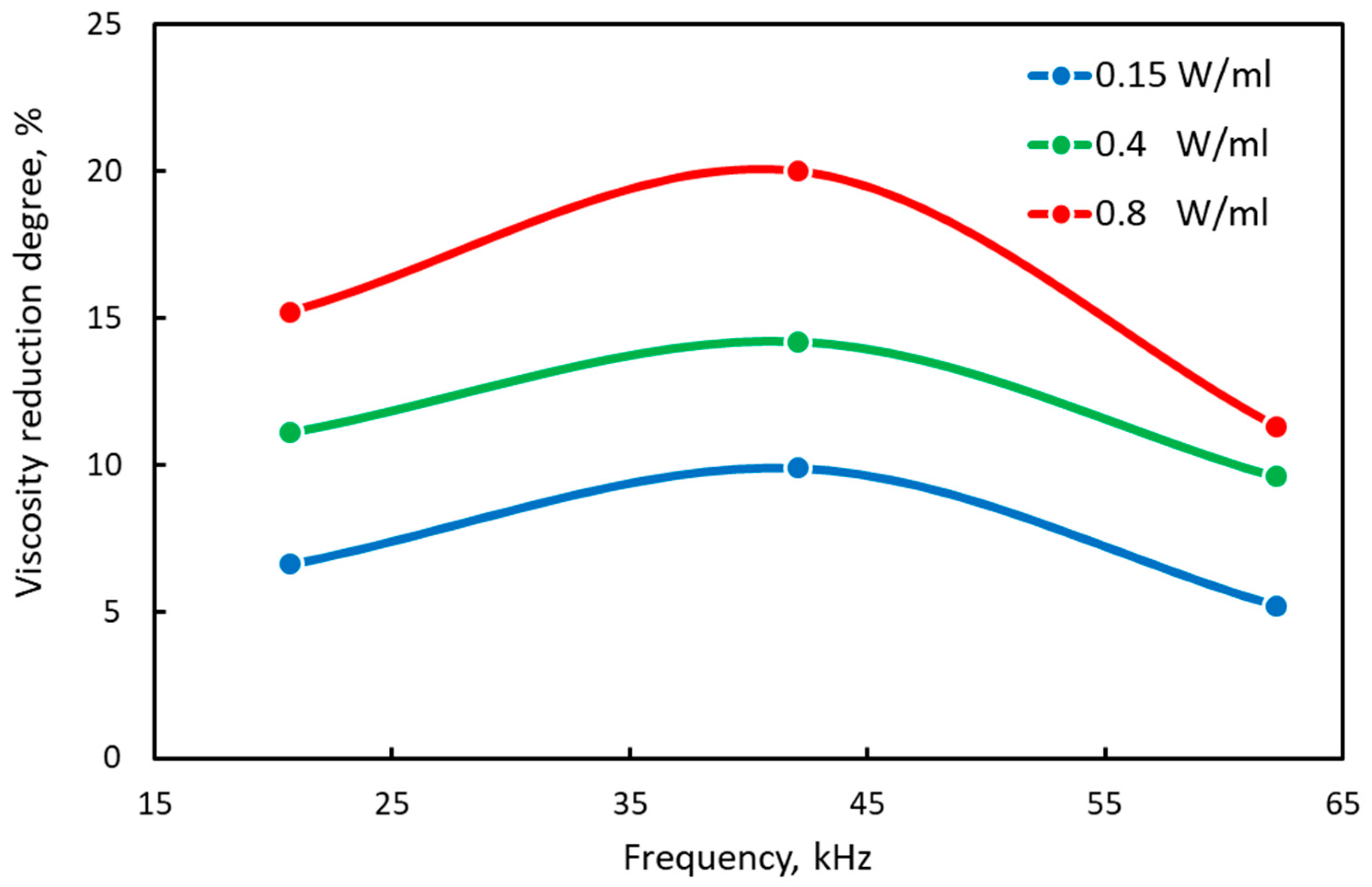

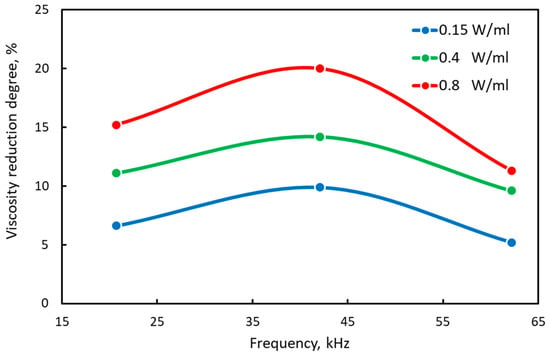

The results of the sonication of oil samples from the Ashalchinskoye field, depending on the applied frequency, are presented in Figure 5. The maximum viscosity reduction degree was obtained at a frequency of 42.1 kHz. The more power was applied, the higher viscosity reduction degree was achieved.

Figure 5.

The viscosity reduction degree as a function of ultrasonic frequency and the level of acoustic power.

The obtained results from different ultrasonication modes are presented in Table 1. According to the results, the viscosity reduction depends on the power and frequency of ultrasound waves. When the heavy crude oil sample sonicated under the frequency of 42.1 kHz, the increase in the acoustic power from 0.14 W/mL to 0.41 W/mL provided almost two times increase in the viscosity reduction degree measured at the moment of sonication and after the plateau phase. The thermocouples detected the increase in the temperature of the fluid medium with increasing the acoustic power, which means the influence of heating increases under high acoustic power ranges and the impact of ultrasonic irradiation decreases. However, the best obtained result in terms of viscosity reduction degree during the sonication process was achieved at a frequency of 42.1 kHz with a power of 0.7 W/mL; we are restricted with the less power—0.41 W/mL—to exclude the influence of heating on investigating the chemical consequences of ultrasonic irradiation.

Table 1.

The viscosity of the heavy crude oil sample and change in temperature of the medium under different ultrasonic modes.

Although the still widely accepted view of many scholars is that the primary, if not sole, consequences of the ultrasonic treatment of heavy oil and natural bitumen are physical, such as temperature rise, viscosity reduction and emulsification, we deeply believe that ultrasonic treatment of heavy oil has chemical consequences as well. Therefore, on the basis of experimental evidence such as SARA analysis, we tried to demonstrate the group chemical changes in the composition of a heavy crude oil sample under ultrasound irradiation processes. The SARA fractions of initial crude oil and oil after ultrasonic treatment with various frequencies are summarized in Table 2.

Table 2.

Group composition of crude oil after ultrasonic treatment on various modes.

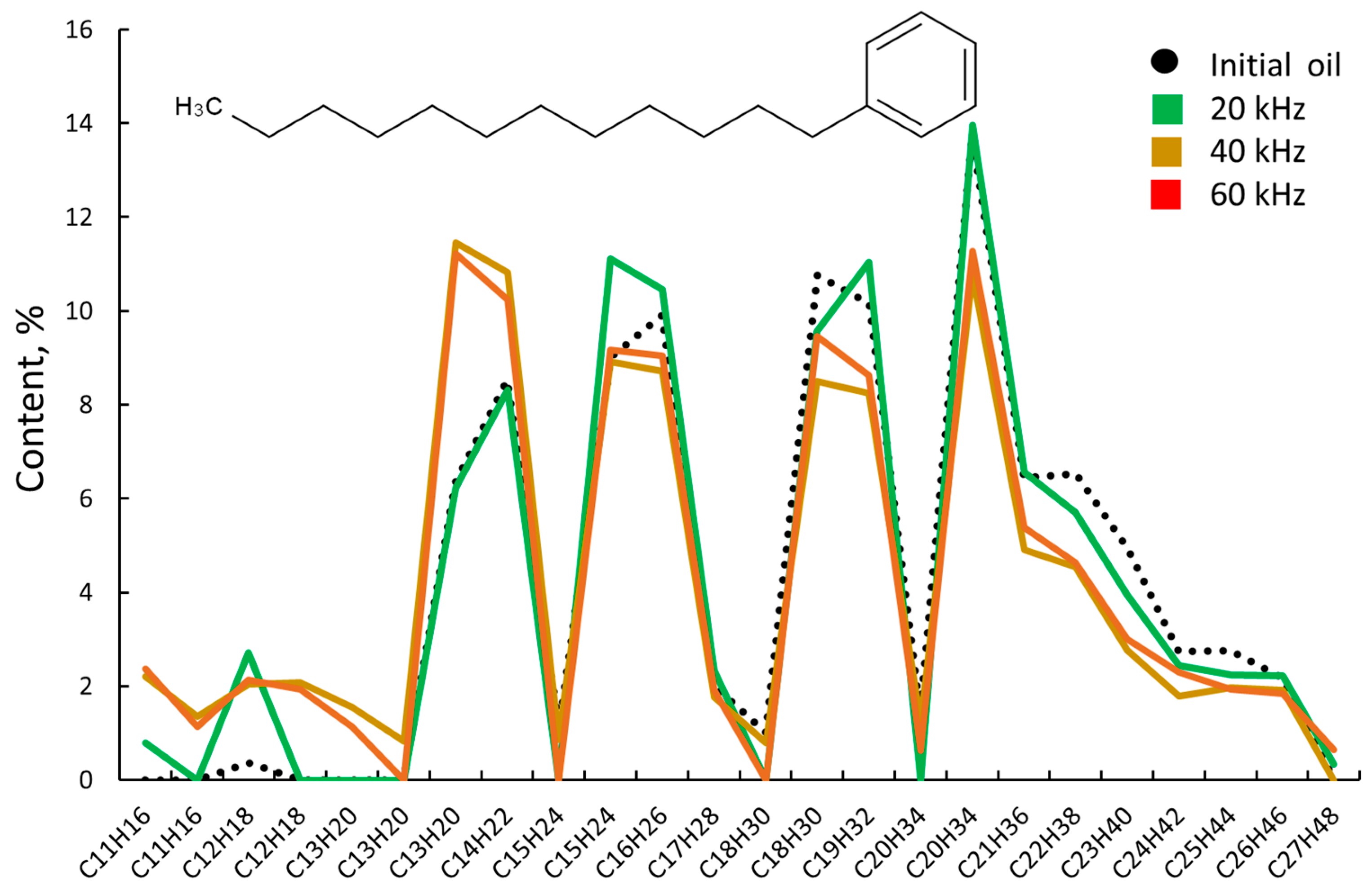

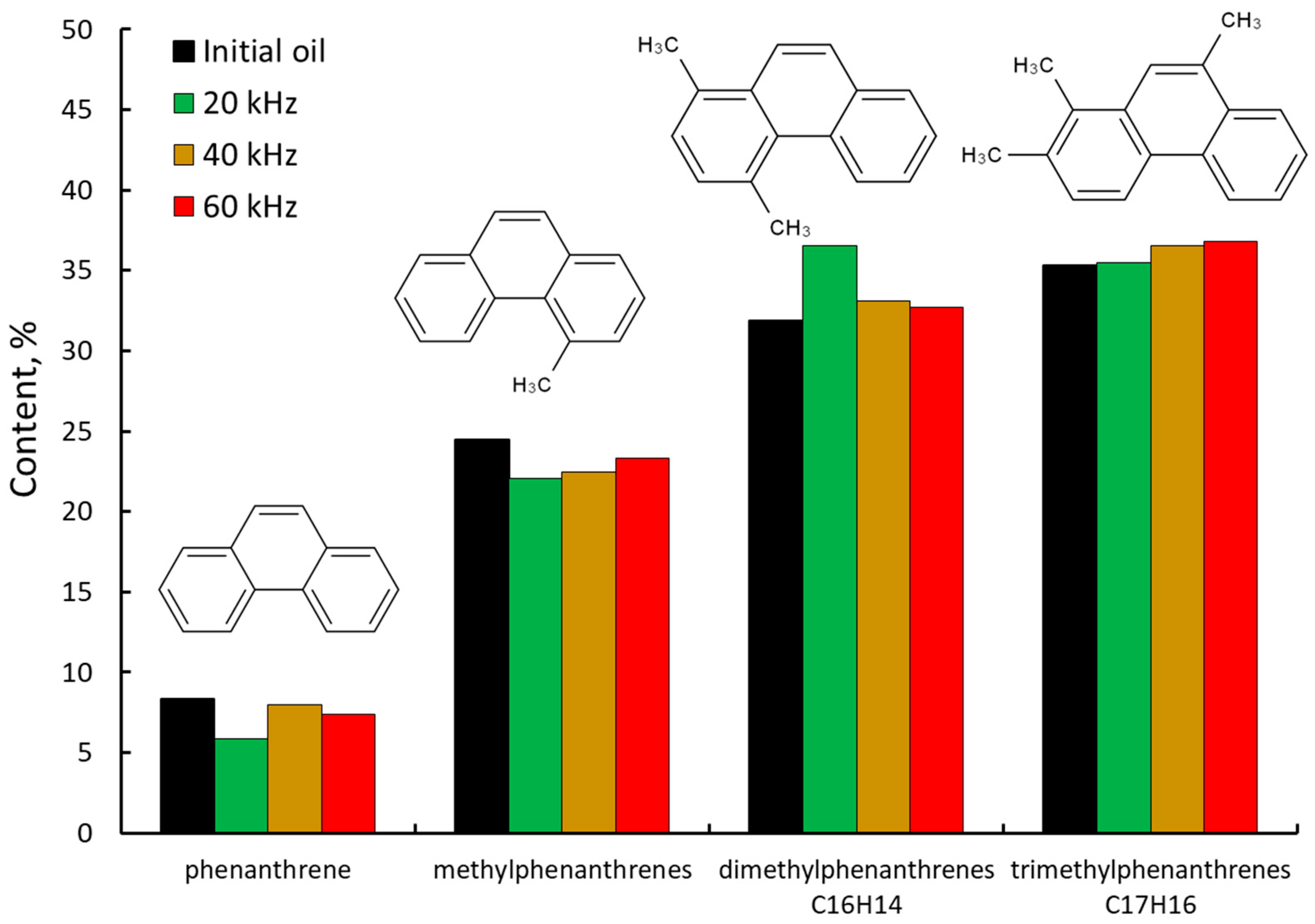

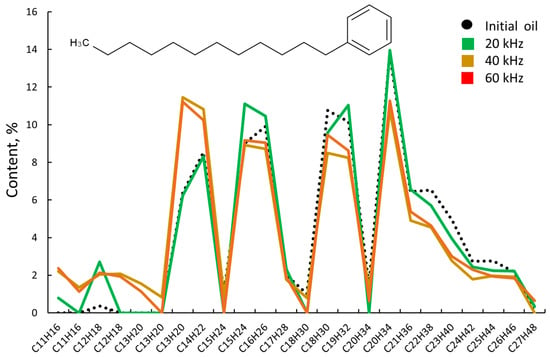

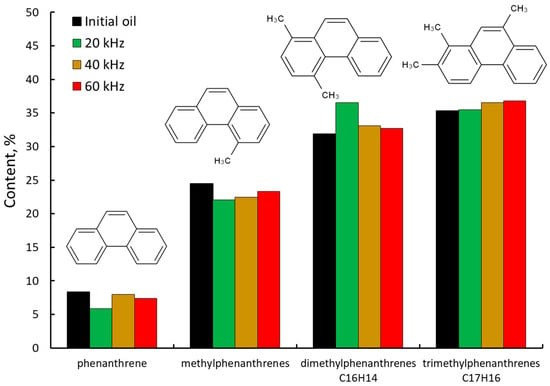

The total content of resins and asphaltenes decreased after ultrasonic treatment with frequencies of 20.7 kHz and 42.1 kHz. The content of resins and asphaltenes significantly increased under the frequency of 62.2 kHz, which contributed to the least viscosity reduction degree. Increase in the content of aromatic hydrocarbons is explained by the depth of destructive hydrogenation reactions of resins and asphaltenes. The Ashalcha heavy oil sample is rich in heteroatoms such as sulfur, nitrogen and oxygen. From the thermodynamical point of view, carbon–heteroatom bonds are considered the weakest bond type and the cleavage of such bonds triggers other chemical reactions, such as decarbonylation, enol rearrangement and polymerization reactions. The destructive processes under the frequency of 62.2 kHz led to the rearrangement of some structures in the composition of aromatics fraction, which increased the content and most probably the molecular mass of resins and asphaltenes. The changes in the chemical composition of the heavy oil sample were justified by the changes in the relative content of alkyl benzenes and phenanthrenes, which are demonstrated in Figure 6 and Figure 7, respectively. These compounds are the destruction products of resins and asphaltenes, which were observed by GC-MS analysis method in aromatics fractions of heavy crude oil samples.

Figure 6.

The relative content of alkyl benzenes in the composition of aromatics fractions of initial oil sample and sonicated oil samples under various wave frequencies.

Figure 7.

The relative content of phenanthrenes in the composition of aromatics fractions of initial oil sample and sonicated oil samples under various wave frequencies.

The content of phenanthrenes is also altered under the impact of ultrasound waves. Phenanthrenes are polycyclic aromatic hydrocarbons (PAHs) composed of three fused benzene rings in the structure of asphaltene agglomerates [35]. The content of phenanthrenes also changes after exposure to ultrasound. The most significant changes were observed in the content of phenanthrene and methylphenanthrene. The changes in the composition of aromatic hydrocarbons confirm the destruction of resins and asphaltenes under the influence of ultrasound. The decrease in the content of resins causes a decrease in viscosity to a greater extent in this case, which is irreversible.

4. Conclusions

The carried-out investigation justifies the possibility of irreversibly reducing the viscosity of heavy oils using multi-frequency ultrasonic waves with the main harmonics of 20–60 kHz. The irreversible viscosity reduction is due to the destruction of resins and asphaltenes. The maximum achieved viscosity reduction degree was 73%.

The ultrasonic waves with the frequencies of 20 kHz and 40 kHz reduced the sum of resins and asphaltenes from 39.3 to 37.3 and 37.2, respectively. However, the ultrasonic wave with the frequency of 60 kHz contributed to the increase in the content of resins and asphaltenes up to 43.1. The observed changes in the relative contents of alkylbenzenes and phenanthrenes let us conclude that destructive hydrogenation processes were carried out in resins and asphaltenes. The destructive processes carried out under the frequency of 60 kHz led to the rearrangement in the structure of aromatic compounds, which resulted in the increase in the content of resins and asphaltenes, rising from 39.3 to 43.1 wt.%.

The correlation between the frequency of ultrasonic waves and the destructive hydrogenation degree of resins and asphaltenes is significant in terms of developing new technologies for the development of heavy oil fields.

Author Contributions

Conceptualization, A.V.D. and A.V.V.; methodology, A.A.G.; validation, B.V.S. and A.F.M.; investigation, A.A.K. and G.F.B.; writing—original draft preparation, F.A.A., A.V.D. and A.V.V.; writing—review and editing, A.V.V. and F.A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation under agreement No. 075-15-2022-299 within the framework of the development program for a world-class Research Center “Efficient development of the global liquid hydrocarbon reserves”.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gately, D. A ten-year retrospective: OPEC and the world oil market. J. Econ. Lit. 1984, 22, 1100–1114. [Google Scholar]

- Rana, M.S.; Sámano, V.; Ancheyta, J.; Diaz, J.A.I. A review of recent advances on process technologies for upgrading of heavy oils and residua. Fuel 2007, 86, 1216–1231. [Google Scholar] [CrossRef]

- Li, H.; Wang, Q.; Wu, Y. Current Status and Development Direction of Low-Carbon Exploitation Technology for Heavy Oil. Energies 2023, 16, 2219. [Google Scholar] [CrossRef]

- Wu, Q. Acidic and basic catalytic cracking technologies and its development prospects for crude oil to chemicals. Fuel 2023, 332, 126132. [Google Scholar] [CrossRef]

- Gao, J.; Wu, P.; Li, C.; Xu, D.; Wang, X. Influence and Mechanism Study of Ultrasonic Electric Power Input on Heavy Oil Viscosity. Energies 2022, 16, 79. [Google Scholar] [CrossRef]

- Li, H.; Gao, H.; Zhao, X.; Xia, Z.; Yu, B.; Sun, D. Experimental study on viscosity reduction of heavy oil with water content by synergistic effect of microwave and nano-catalyst. J. Pet. Sci. Eng. 2022, 208, 109271. [Google Scholar] [CrossRef]

- Hasani, M.; Jafari, A. Electromagnetic field’s effect on enhanced oil recovery using magnetic nanoparticles: Microfluidic experimental approach. Fuel 2022, 307, 121718. [Google Scholar] [CrossRef]

- Mullakaev, M.S.; Abramov, V.O.; Abramova, A.V. Ultrasonic automated oil well complex and technology for enhancing marginal well productivity and heavy oil recovery. J. Pet. Sci. Eng. 2017, 159, 1–7. [Google Scholar] [CrossRef]

- Gondrexon, N.; Cheze, L.; Jin, Y.; Legay, M.; Tissot, Q.; Hengl, N.; Talansier, E. Intensification of heat and mass transfer by ultrasound: Application to heat exchangers and membrane separation processes. Ultrason. Sonochem. 2015, 25, 40–50. [Google Scholar] [CrossRef]

- Gondrexon, N.; Rousselet, Y.; Legay, M.; Boldo, P.; Le Person, S.; Bontemps, A. Intensification of heat transfer process: Improvement of shell-and-tube heat exchanger performances by means of ultrasound. Chem. Eng. Process. Process Intensif. 2010, 49, 936–942. [Google Scholar] [CrossRef]

- Marfin, E.A.; Gataullin, R.N.; Abdrashitov, A.A. Acoustic stimulation of oil production by a downhole emitter based on a jet-driven helmholtz oscillator. J. Pet. Sci. Eng. 2022, 215, 110705. [Google Scholar] [CrossRef]

- Sokolov, E.; Kaluzhnaya, D.; Shel’deshova, E.; Ryapolov, P. Formation and Behaviour of Active Droplets and Bubbles in a Magnetic Fluid in an Inhomogeneous Magnetic Field. Fluids 2023, 8, 2. [Google Scholar] [CrossRef]

- Bhasarkar, J.B.; Chakma, S.; Moholkar, V.S. Investigations in physical mechanism of the oxidative desulfurization process assisted simultaneously by phase transfer agent and ultrasound. Ultrason. Sonochem. 2015, 24, 98–106. [Google Scholar] [CrossRef]

- Hossain, M.N.; Choi, M.K.; Choi, H.S. A Review of the Desulfurization Processes Used for Waste Tire Pyrolysis Oil. Catalysts 2021, 11, 801. [Google Scholar] [CrossRef]

- Hossain, M.N.; Park, H.C.; Choi, H.S. A Comprehensive Review on Catalytic Oxidative Desulfurization of Liquid Fuel Oil. Catalysts 2019, 9, 229. [Google Scholar] [CrossRef]

- Gildo, P.J.; Dugos, N.; Roces, S.; Wan, M.W. Optimized Ultrasound-Assisted Oxidative Desulfurization Process of Simulated Fuels over Activated Carbon-Supported Phosphotungstic Acid. MATEC Web Conf. 2018, 156, 03045. [Google Scholar] [CrossRef]

- Jalali, M.R.; Sobati, M.A. Intensification of Oxidative Desulfurization of Gas Oil by Ultrasound Irradiation: Optimization Using Box–Behnken Design (BBD). Appl. Therm. Eng. 2017, 111, 1158–1170. [Google Scholar] [CrossRef]

- Margeta, D.; Sertić-Bionda, K.; Foglar, L. Ultrasound Assisted Oxidative Desulfurization of Model Diesel Fuel. Appl. Acoust. 2016, 103, 202–206. [Google Scholar] [CrossRef]

- Akbari, A.; Omidkhah, M.; Towfighi Darian, J. Facilitated and Selective Oxidation of Thiophenic Sulfur Compounds Using MoOx/Al2O3-H2O2 System under Ultrasonic Irradiation. Ultrason. Sonochem. 2015, 23, 231–237. [Google Scholar] [CrossRef]

- Choi, A.E.S.; Roces, S.; Dugos, N.; Futalan, C.M.; Lin, S.S.; Wan, M.W. Optimization of Ultrasound-Assisted Oxidative Desulfurization of Model Sulfur Compounds Using Commercial Ferrate (VI). J. Taiwan Inst. Chem. Eng. 2014, 45, 2935–2942. [Google Scholar]

- Yakovlev, В.А.; Zavarukhin, S.G.; Kuzavov, V.T.; Stebnovskiy, S.I.; Malikh, N.V.; Malsev, L.I.; Parmon, V.N. Investigation of chemical conversions of organic compounds under cavitation influence. Chem. Phys. 2010, 29, 43–51. [Google Scholar]

- Anufriev, R.V.; Volkova, G.I.; Vasilyeva, A.A.; Petukhova, A.V.; Usheva, N.V. The integrated effect on properties and composition of high-paraffin oil sludge. Procedia Chem. 2015, 15, 2–7. [Google Scholar] [CrossRef]

- Mieles-Gómez, L.; Lastra-Ripoll, S.E.; Torregroza-Fuentes, E.; Quintana, S.E.; García-Zapateiro, L.A. Rheological and Microstructural Properties of Oil-in-Water Emulsion Gels Containing Natural Plant Extracts Stabilized with Carboxymethyl Cellulose/Mango (Mangiferaindica) Starch. Fluids 2021, 6, 312. [Google Scholar] [CrossRef]

- Najafi, I.; Amani, M. Asphaltene flocculation inhibition with ultrasonic wave radiation: A detailed experimental study of the governing mechanisms. Adv. Pet. Explor. Dev. 2011, 2, 32–36. [Google Scholar]

- Shedid, A. An ultrasonic irradiation technique for treatment of asphaltenes deposition. J. Pet. Sci. Eng. 2004, 42, 57–70. [Google Scholar] [CrossRef]

- Anufriev, R.V.; Volova, G.I. Changes in the structure-mechanic parameters of hydrocarbons after high frequency acoustic infleunces. Chem. Terms Sustain. Dev. 2014, 22, 307–312. [Google Scholar]

- Anufriev, R.V.; Volkova, G.I. The change of the structural and mechanical properties of the hydrocarbons after high frequency acoustic irradiation. Chem. Sustain. Dev. 2014, 3, 307–312. [Google Scholar]

- Kuryakov, V.N. Influence of ultrasonic treatment on kinetic of asphaltene aggregation in toluene/heptane mixture. J. Phys. Conf. Ser. 2021, 1942, 012035. [Google Scholar] [CrossRef]

- Volkova, G.I.; Morozova, A.V. Structural transformations of bitumen asphaltenes after ultrasonic treatment. Solid Fuel Chem. 2022, 56, 133–137. [Google Scholar] [CrossRef]

- Avvaru, B.; Venkateswaran, N.; Uppara, P.; Iyengar, S.B.; Katti, S.S. Current knowledge and potential applications of cavitation technologies for the petroleum industry. Ultrason. Sonochem. 2018, 42, 493–507. [Google Scholar] [CrossRef]

- Hemmati-Sarapardeh, A.; Dabir, B.; Ahmadi, M.; Mohammadi, A.; Husein, M. Toward mechanistic understanding of asphaltene aggregation behavior in toluene: The roles of asphaltene structure, aging time, temperature, and ultrasonic radiation. J. Mol. Liq. 2018, 264, 410–424. [Google Scholar] [CrossRef]

- Klokova, T.P.; Volodin, Y.u.A.; Glagoleva, O.F. Effect of ultrasound on the colloidal-disperse properties of petroleum systems. Chem. Technol. Fuels Oils 2006, 42, 43–46. [Google Scholar] [CrossRef]

- Gafurov, M.R.; Volodin, M.A.; Rodionov, A.A.; Sorokina, A.T.; Dolomatov MYu Petrov, A.V.; Vakhin, A.V.; Mamin, G.V.; Orlinskii, S.B. EPR study of spectra transformations of the intrinsic vanadyl-porphyrin complexes in heavy crude oils with temperature to probe the asphaltenes' aggregation. J. Pet. Sci. Eng. 2018, 166, 363–368. [Google Scholar]

- Morozov, E.V.; Yushmanov, P.V.; Martyanov, O.N. Temperature-Triggered Rearrangement of Asphaltene Aggregates as Revealed by Pulsed-Field Gradient NMR. Energy Fuels 2019, 33, 6934–6945. [Google Scholar] [CrossRef]

- Derakhshesh, M.; Bergmann, A.; Gray, M.R. Occlusion of polyaromatic compounds in asphaltene precipitates suggests porous nanoaggregates. Energy Fuels 2013, 27, 1748–1751. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).