Liquid-Solid Interaction to Evaluate Thermal Aging Effects on Carbon Fiber-Reinforced Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composite Fabrication and Thermal Aging

2.2. Weight Change and Optical Microscopy

2.3. Characterization of Flexural Properties

2.4. Characterization of Contact Angle, Contact Angle Hysteresis, and Droplet Impact

3. Results and Discussions

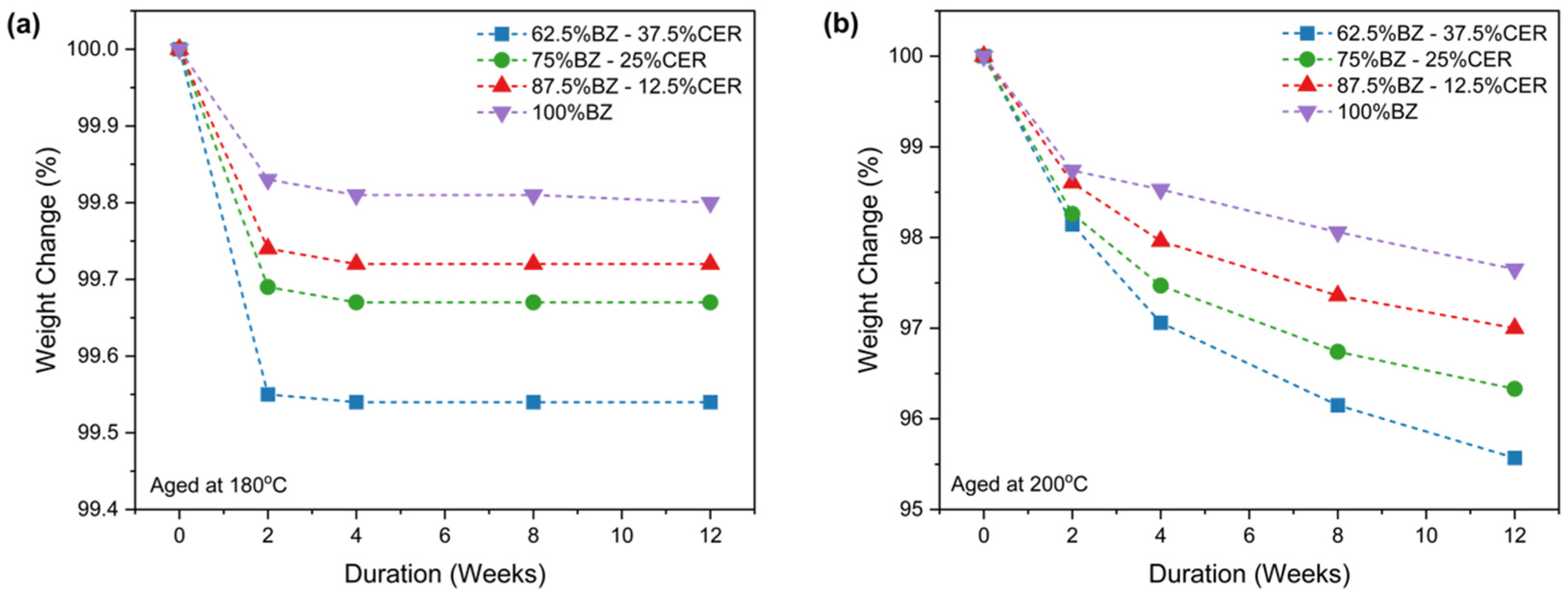

3.1. Weight Change

3.2. Flexural Properties

3.3. Microscopic Analysis

3.4. Static Contact Angle

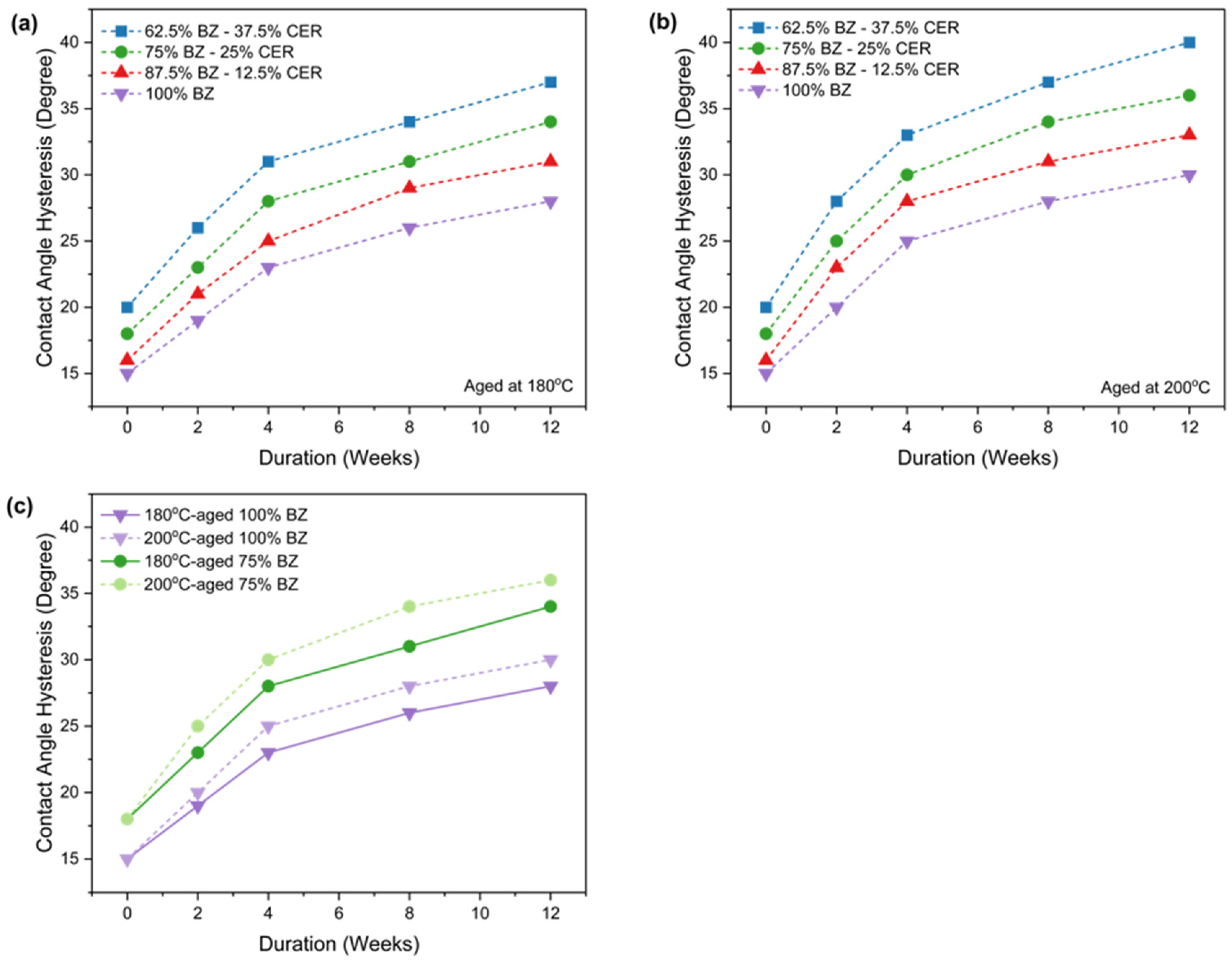

3.5. Contact Angle Hysteresis

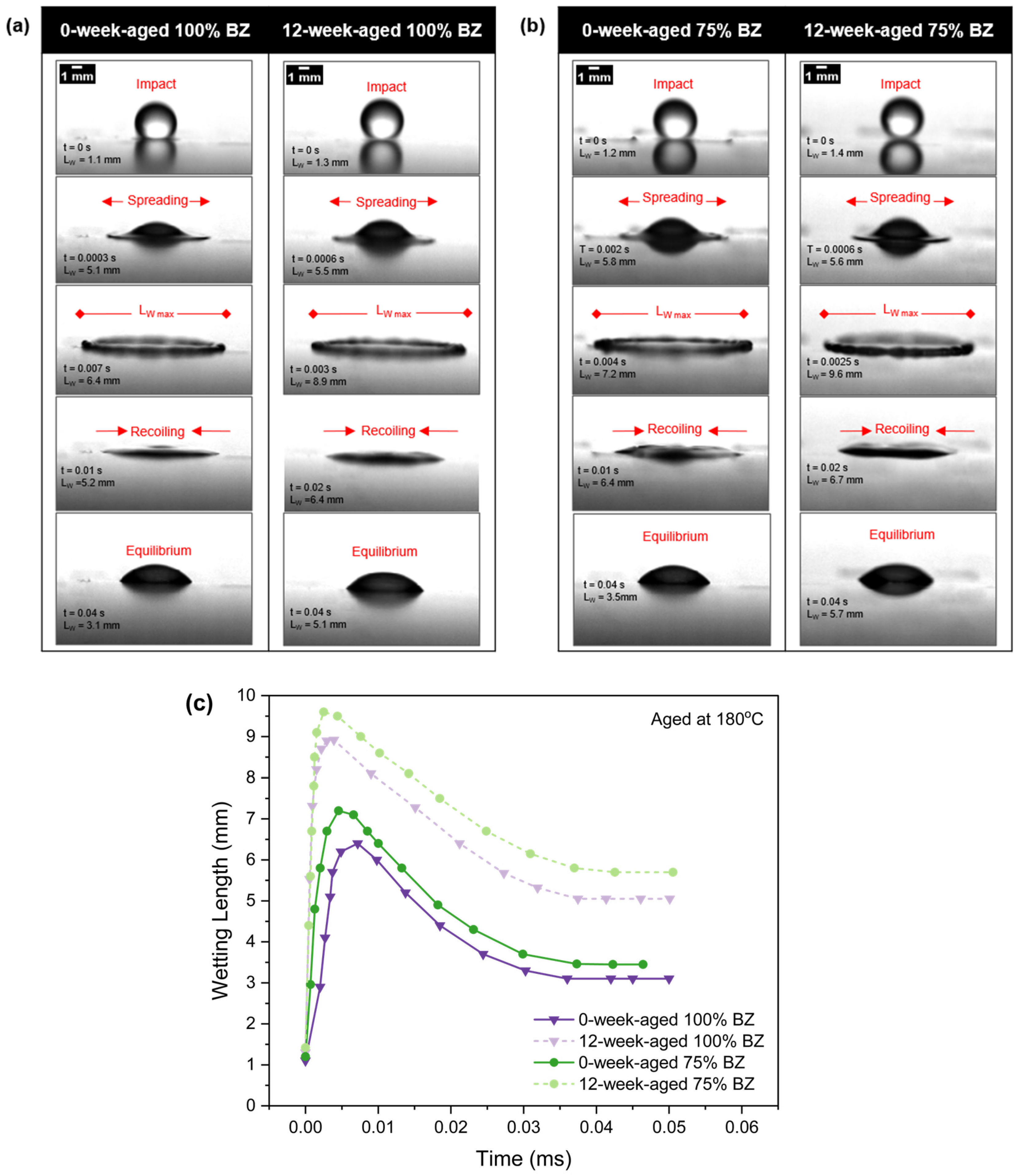

3.6. Static Droplet Impact

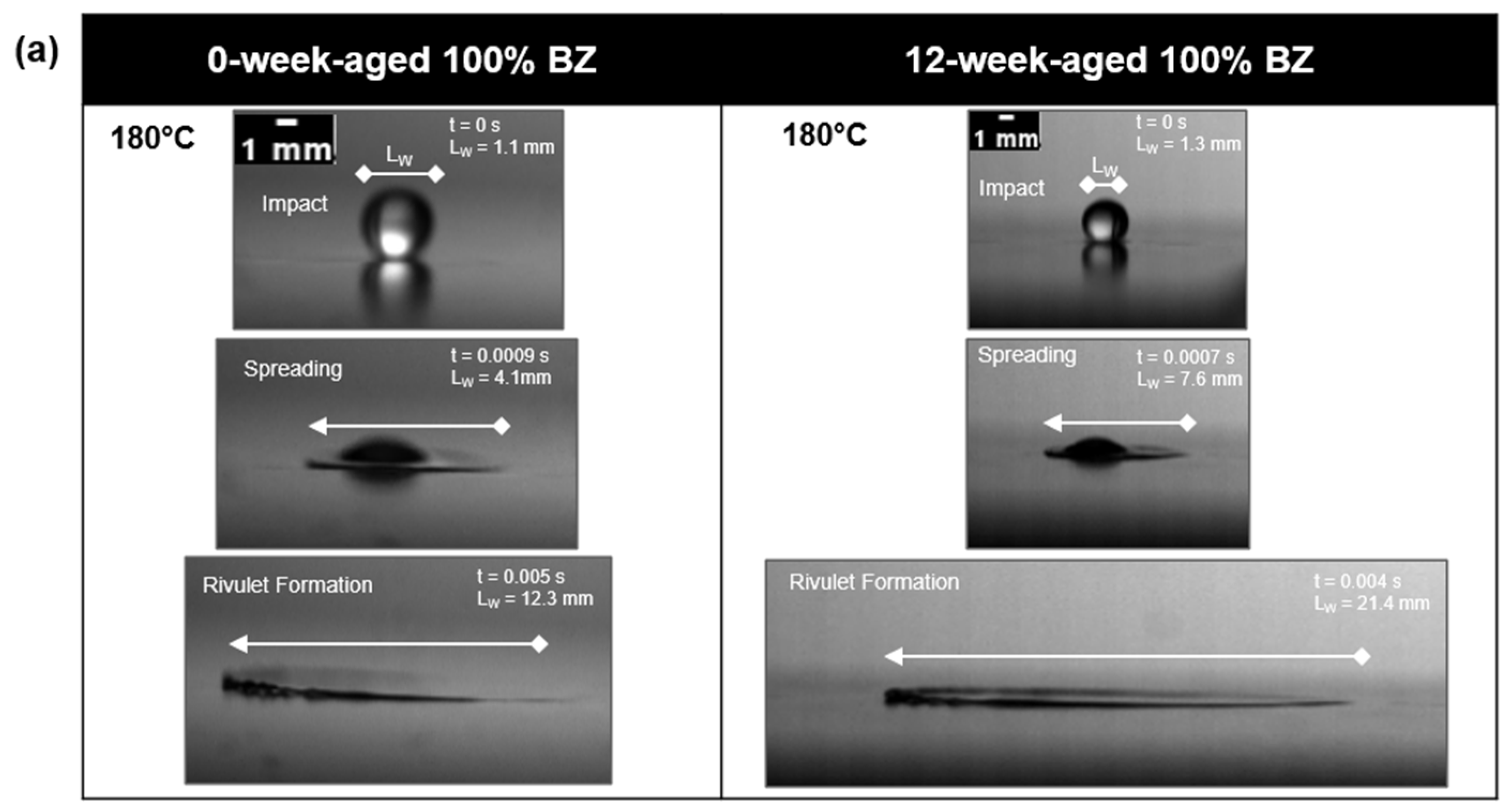

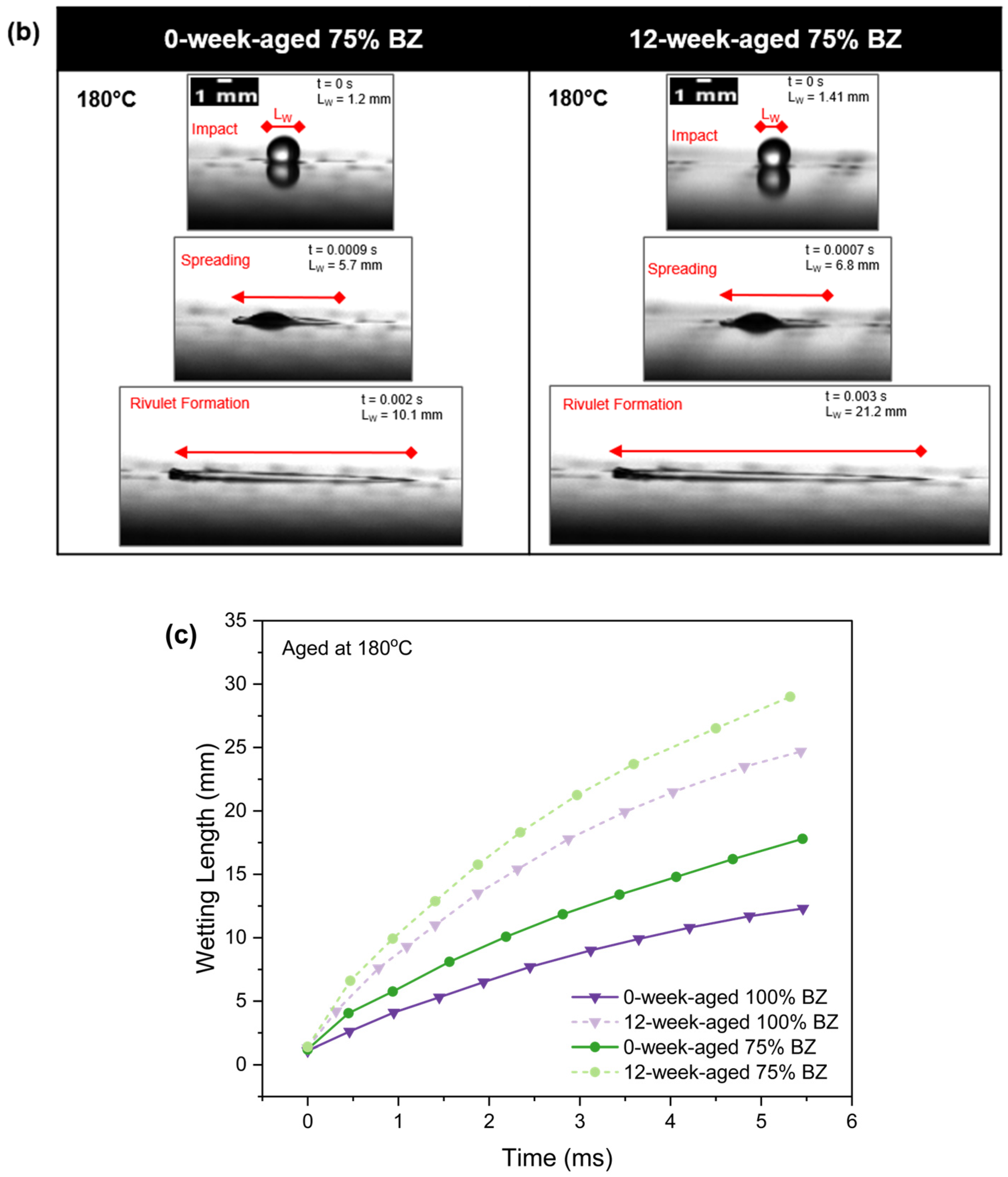

3.7. Dynamic Droplet Impact

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taylor, T.; Zhang, J.; Yanagimoto, J. Evaluation of a concept out-of-autoclave process for manufacturing carbon fibre reinforced polymer automotive parts. Procedia CIRP 2019, 86, 162–166. [Google Scholar] [CrossRef]

- Jia, Z.; Li, T.; Chiang, F.; Wang, L. An experimental investigation of the temperature effect on the mechanics of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2018, 154, 53–63. [Google Scholar] [CrossRef]

- Zavatta, N.; Rondina, F.; Falaschetti, M.P.; Donati, L. Effect of Thermal Ageing on the Mechanical Strength of Carbon Fibre Reinforced Epoxy Composites. Polymers 2021, 13, 2006. [Google Scholar] [CrossRef]

- Moghtadernejad, S.; Barjasteh, E.; Johnson, Z.; Stolpe, T.; Banuelos, J. Effect of thermo-oxidative aging on surface characteristics of benzoxazine and epoxy copolymer. J. Appl. Polym. Sci. 2021, 138, 50211. [Google Scholar] [CrossRef]

- Barjasteh, E.; Gouni, S.; Sutanto, C.; Narongdej, P. Bisphenol-A benzoxazine and cycloaliphatic epoxy copolymer for composite processing by resin infusion. J. Compos. Mater. 2019, 53, 1777–1790. [Google Scholar] [CrossRef]

- Navarro, C.A.; Kedzie, E.A.; Ma, Y.; Michael, K.H.; Nutt, S.R.; Williams, T.J. Mechanism and catalysis of oxidative degradation of fiber-reinforced epoxy composites. Top. Catal. 2018, 61, 704–709. [Google Scholar] [CrossRef] [PubMed]

- Barjasteh, E.; Kar, N.; Nutt, S.R. Effect of filler on thermal aging of composites for next-generation power lines. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1873–1882. [Google Scholar] [CrossRef]

- Crane, R.I. Droplet deposition in steam turbines. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2004, 218, 859–870. [Google Scholar] [CrossRef]

- Sun, L.; Zheng, Q.; Luo, M.; Li, Y.; Bhargava, R. On the Behavior of Water Droplets When Moving onto Blade Surface in a Wet Compression Transonic Compressor. J. Eng. Gas Turbines Power 2011, 133, 082001. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, N.; Chen, X.; Xu, T.; Hui, S.; Zhang, D. Analysis of water drop erosion on turbine blades based on a nonlinear liquid–solid impact model. Int. J. Impact Eng. 2009, 36, 1156–1171. [Google Scholar] [CrossRef]

- Dunn, T.A.; Loth, E.; Bragg, M.B. Computational Investigation of Simulated Large-Droplet Ice Shapes on Airfoil Aerodynamics. J. Aircr. 1999, 36, 836–843. [Google Scholar] [CrossRef]

- Cebeci, T.; Kafyeke, F. Aircraft Icing. Annu. Rev. Fluid Mech. 2003, 35, 11–21. [Google Scholar] [CrossRef]

- Thomas, S.K.; Cassoni, R.P.; MacArthur, C.D. Aircraft anti-icing and de-icing techniques and modeling. J. Aircr. 1996, 33, 841–854. [Google Scholar] [CrossRef]

- Antonini, C.; Carmona, F.J.; Pierce, E.; Marengo, M.; Amirfazli, A. General Methodology for Evaluating the Adhesion Force of Drops and Bubbles on Solid Surfaces. Langmuir 2009, 25, 6143–6154. [Google Scholar] [CrossRef] [PubMed]

- Schleizer, A.D.; Bonnecaze, R.T. Displacement of a two-dimensional immiscible droplet adhering to a wall in shear and pressure-driven flows. J. Fluid Mech. 1999, 383, 29–54. [Google Scholar] [CrossRef]

- Li, J.Y.; Yuan, X.F.; Han, Q.; Xi, G. Impact patterns and temporal evolutions of water drops impinging on a rotating disc. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 226, 956–967. [Google Scholar] [CrossRef]

- Hung, Y.L.; Wang, M.J.; Huang, J.W.; Lin, S.Y. A study on the impact velocity and drop size for the occurrence of entrapped air bubbles-Water on parafilm. Exp. Therm. Fluid Sci. 2013, 48, 102–109. [Google Scholar] [CrossRef]

- Yarin, A.L. Drop impact dynamics: Splashing, spreading, receding, bouncing…. Annu. Rev. Fluid Mech. 2006, 38, 159–192. [Google Scholar] [CrossRef]

- Khojasteh, D.; Kazerooni, M.; Salarian, S.; Kamali, R. Droplet impact on superhydrophobic surfaces: A review of recent developments. J. Ind. Eng. Chem. 2016, 42, 1–14. [Google Scholar] [CrossRef]

- Holl, M.; Patek, Z.; Smrcek, L. Wind tunnel testing of performance degradation of ice contaminated airfoils. ICAS Tech. Paper 2000, 3, 2000. [Google Scholar]

- Li, R.; Ashgriz, N.; Chandra, S.; Andrews, J.R.; Drappel, S. Coalescence of two droplets impacting a solid surface. Exp. Fluids 2010, 48, 1025–1035. [Google Scholar] [CrossRef]

- Cao, L.; Jones, A.K.; Sikka, V.K.; Wu, J.; Gao, D. Anti-Icing Superhydrophobic Coatings. Langmuir 2009, 25, 12444–12448. [Google Scholar] [CrossRef]

- Chen, X.; Wang, P.; Zhang, D.; Ou, J. Rational fabrication of superhydrophobic surfaces with coalescence-induced droplet jumping behavior for atmospheric corrosion protection. Chem. Eng. J. 2021, 428, 132029. [Google Scholar] [CrossRef]

- Pan, R.; Zhang, H.; Zhong, M. Triple-Scale Superhydrophobic Surface with Excellent Anti-Icing and Icephobic Performance via Ultrafast Laser Hybrid Fabrication. ACS Appl. Mater. Interfaces 2021, 13, 1743–1753. [Google Scholar] [CrossRef]

- Barjasteh, E.; Bosze, E.J.; Tsai, Y.I.; Nutt, S.R. Thermal aging of fiberglass/carbon-fiber hybrid composites. Compos.-A Appl. Sci. Manuf. 2009, 40, 2038–2045. [Google Scholar] [CrossRef]

- Bhargava, R.; Wang, S.Q.; Koenig, J.L. FTIR microspectroscopy of polymeric systems. Adv. Polym. Sci. 2003, 163, 137–191. [Google Scholar]

- Ernault, E.; Richaud, E.; Fayolle, B. Thermal oxidation of epoxies: Influence of diamine hardener. Polym. Degrad. Stab. 2016, 134, 76–86. [Google Scholar] [CrossRef]

- Minervino, M.; Gigliotti, M.; Lafarie-Frenot, M.C.; Grandidier, J.C. The effect of thermo-oxidation on the mechanical behaviour of polymer epoxy materials. Polym. Test. 2013, 32, 1020–1028. [Google Scholar] [CrossRef]

- Chernykh, A.; Agag, T.; Ishida, H. Synthesis of linear polymers containing benzoxazine moieties in the main chain with high molecular design versatility via click reaction. Polymer 2009, 50, 382–390. [Google Scholar] [CrossRef]

- Zhou, C.; Xin, Z. Polybenzoxazine-based coatings for corrosion protection. Adv. Emerg. Polybenzoxazine Sci. Technol. 2017, 1003–1017. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Ding, Y.F.; Li, S.J.; Luo, X.W.; Zhou, W.F. Effect of polymeric structure on the corrosion protection of epoxy coatings. Corros. Sci. 2002, 44, 861–869. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narongdej, P.; Hanson, J.; Barjasteh, E.; Moghtadernejad, S. Liquid-Solid Interaction to Evaluate Thermal Aging Effects on Carbon Fiber-Reinforced Composites. Fluids 2024, 9, 100. https://doi.org/10.3390/fluids9050100

Narongdej P, Hanson J, Barjasteh E, Moghtadernejad S. Liquid-Solid Interaction to Evaluate Thermal Aging Effects on Carbon Fiber-Reinforced Composites. Fluids. 2024; 9(5):100. https://doi.org/10.3390/fluids9050100

Chicago/Turabian StyleNarongdej, Poom, Jack Hanson, Ehsan Barjasteh, and Sara Moghtadernejad. 2024. "Liquid-Solid Interaction to Evaluate Thermal Aging Effects on Carbon Fiber-Reinforced Composites" Fluids 9, no. 5: 100. https://doi.org/10.3390/fluids9050100