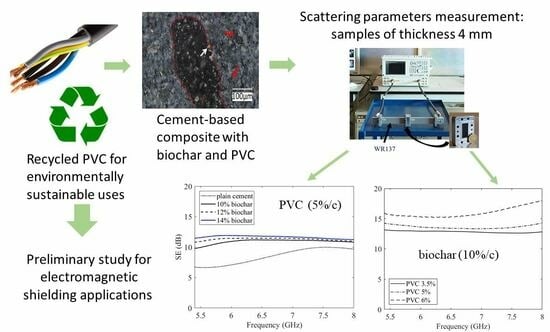

Analysis of Electromagnetic Shielding Properties of Cement-Based Composites with Biochar and PVC as Fillers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

- -

- Commercial biochar from Carlo Erba Reagents, originated from wood pyrolysis. Before use, biochar was thermally treated (reactivation process) in the oven for four hours at C in a covered alumina crucible, filled to the brim so as to avoid combustion in presence of oxygen (see Figure 1a).

- -

- PVC was obtained from the sheathing of electrical cables by a granulating procedure, and sieved to separate the fraction with dimensions smaller than m. Since PVC is derived from waste, the presence of a small amount of copper fragments can be observed, together with a filler mainly constituted by , as discussed in Section 3.1. The size of the resulting PVC particles, after sifting, was below m (see Figure 1b).

2.2. Composite Preparation

2.3. Microstructural Analysis

2.4. Shielding Effectiveness Definition

2.5. Scattering Parameter Measurement Setup

3. Results

3.1. Microstructural Analysis

3.2. Influence of Biochar on the Cementitious Paste

3.3. Evaluation of the Shielding Effectiveness

3.3.1. Analysis with Different Concentration of Biochar

3.3.2. Analysis of PVC Variation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aqeeli, M.; Leng, T.; Huang, X.; Chen, J.; Chang, K.; Alburaikan, A.; Hu, Z. Electromagnetic interference shielding based on highly flexible and conductive graphene laminate. Electron. Lett. 2015, 51, 1350–1352. [Google Scholar] [CrossRef]

- Jamshed, M.A.; Heliot, F.; Brown, T.W. A survey on electromagnetic risk assessment and evaluation mechanism for future wireless communication systems. IEEE J. Electromagn. RF Microw. Med. Biol. 2019, 4, 24–36. [Google Scholar] [CrossRef]

- Carlberg, M.; Koppel, T.; Hedendahl, L.K.; Hardell, L. Is the increasing incidence of thyroid cancer in the Nordic countries caused by use of mobile phones? Int. J. Environ. Res. Public Health 2020, 17, 9129. [Google Scholar] [CrossRef] [PubMed]

- Ravaioli, F.; Bacalini, M.G.; Giuliani, C.; Pellegrini, C.; D’Silva, C.; De Fanti, S.; Pirazzini, C.; Giorgi, G.; Del Re, B. Evaluation of DNA Methylation Profiles of LINE-1, Alu and Ribosomal DNA Repeats in Human Cell Lines Exposed to Radiofrequency Radiation. Int. J. Mol. Sci. 2023, 24, 9380. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Lee, J.K.; Kim, H.G.; Kim, K.B.; Kim, H.R. Possible effects of radiofrequency electromagnetic field exposure on central nerve system. Biomol. Ther. 2019, 27, 265. [Google Scholar] [CrossRef] [PubMed]

- Banik, S.; Bandyopadhyay, S.; Ganguly, S. Bioeffects of microwave—A brief review. Bioresour. Technol. 2003, 87, 155–159. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Tai, N.H. Carbon materials and their composites for electromagnetic interference shielding effectiveness in X-band. Carbon 2019, 152, 159–187. [Google Scholar] [CrossRef]

- Savi, P.; Yasir, M.; Bartoli, M.; Giorcelli, M.; Longo, M. Electrical and microwave characterization of thermal annealed sewage sludge derived biochar composites. Appl. Sci. 2020, 10, 1334. [Google Scholar] [CrossRef]

- Savi, P.; Yasir, M.; Giorcelli, M.; Tagliaferro, A. The effect of carbon nanotubes concentration on complex permittivity of nanocomposites. Prog. Electromagn. Res. M 2017, 55, 203–209. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Ahmad, S.; Savi, P.; Tulliani, J.M.; Giorcelli, M.; Ferro, G.A. Improvement in electromagnetic interference shielding effectiveness of cement composites using carbonaceous nano/micro inerts. Constr. Build. Mater. 2015, 85, 208–216. [Google Scholar] [CrossRef]

- Geetha, S.; Satheesh Kumar, K.; Rao, C.R.; Vijayan, M.; Trivedi, D. EMI shielding: Methods and materials—A review. J. Appl. Polym. Sci. 2009, 112, 2073–2086. [Google Scholar] [CrossRef]

- Zukowski, B.; dos Santos Mendonça, Y.G.; de Souza, J.V.B.; Filho, R.D.T. Chapter 20—Cement-based EMI shielding materials. In Materials for Potential EMI Shielding Applications; Joseph, K., Wilson, R., George, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 333–340. [Google Scholar] [CrossRef]

- Chung, D. Materials for electromagnetic interference shielding. Mater. Chem. Phys. 2020, 255, 123587. [Google Scholar] [CrossRef]

- Manjunatha, M.; Vijaya Bhaskar Raju, K.; Sivapullaiah, P. Effect of PVC dust on the performance of cement concrete—A sustainable approach. In Recent Developments in Sustainable Infrastructure: Select Proceedings of ICRDSI 2019; Springer: Singapore, 2021; pp. 607–617. [Google Scholar]

- Akyıldız, A.; Durmaz, O. Investigating Electromagnetic Shielding Properties of Building Materials Doped with Carbon Nanomaterials. Buildings 2022, 12, 361. [Google Scholar] [CrossRef]

- Nam, I.; Kim, H.; Lee, H. Influence of silica fume additions on electromagnetic interference shielding effectiveness of multi-walled carbon nanotube/cement composites. Constr. Build. Mater. 2012, 30, 480–487. [Google Scholar] [CrossRef]

- Giorcelli, M.; Savi, P.; Delogu, A.; Miscuglio, M.; Yahya, Y.M.H.; Tagliaferro, A. Microwave absorption properties in epoxy resin Multi Walled Carbon Nanotubes composites. In Proceedings of the 2013 International Conference on Electromagnetics in Advanced Applications (ICEAA), Turin, Italy, 9–13 September 2013; pp. 1139–1141. [Google Scholar] [CrossRef]

- Liu, Z.; Ge, H.; Wu, J.; Chen, J. Enhanced electromagnetic interference shielding of carbon fiber/cement composites by adding ferroferric oxide nanoparticles. Constr. Build. Mater. 2017, 151, 575–581. [Google Scholar] [CrossRef]

- Aradoaei, M.; Ciobanu, R.C.; Schreiner, C.; Ursan, A.G.; Hitruc, E.G.; Aflori, M. Thermoplastic Electromagnetic Shielding Materials from the Integral Recycling of Waste from Electronic Equipment. Polymers 2023, 15, 3859. [Google Scholar] [CrossRef]

- Islam, T.; Safiuddin, M.; Roman, R.A.; Chakma, B.; Al Maroof, A. Mechanical Properties of PVC Fiber-Reinforced Concrete—Effects of Fiber Content and Length. Buildings 2023, 13, 2666. [Google Scholar] [CrossRef]

- Savi, P.; Cirielli, D.; di Summa, D.; Ruscica, G.; Sora, I.N. Analysis of shielding effectiveness of cement composites filled with pyrolyzed biochar. In Proceedings of the 2019 IEEE 5th International Forum on Research and Technology for Society and Industry (RTSI), Florence, Italy, 9–12 September 2019; pp. 376–379. [Google Scholar] [CrossRef]

- Yasir, M.; di Summa, D.; Ruscica, G.; Natali Sora, I.; Savi, P. Shielding properties of cement composites filled with commercial biochar. Electronics 2020, 9, 819. [Google Scholar] [CrossRef]

- di Summa, D.; Ruscica, G.; Savi, P.; Pelosato, R.; Natali Sora, I. Biochar-containing construction materials for electromagnetic shielding in the microwave frequency region: The importance of water content. Clean Technol. Environ. Policy 2023, 25, 1099–1108. [Google Scholar] [CrossRef]

- Giorcelli, M.; Savi, P.; Khan, A.; Tagliaferro, A. Analysis of biochar with different pyrolysis temperatures used as filler in epoxy resin composites. Biomass Bioenergy 2019, 122, 466–471. [Google Scholar] [CrossRef]

- Bennani, G.; Ndao, A.; Konan, D.; Brassard, P.; Roux, É.L.; Godbout, S.; Adjallé, K. Valorisation of Cranberry Residues through Pyrolysis and Membrane Filtration for the Production of Value-Added Agricultural Products. Energies 2023, 16, 7774. [Google Scholar] [CrossRef]

- Kurup, A.R.; Kumar, K.S. Novel fibrous concrete mixture made from recycled PVC fibers from electronic waste. J. Hazard. Toxic Radioact. Waste 2017, 21, 04016020. [Google Scholar] [CrossRef]

- Kurup, A.R.; Senthil Kumar, K. Effect of recycled PVC fibers from electronic waste and silica powder on shear strength of concrete. J. Hazard. Toxic Radioact. Waste 2017, 21, 06017001. [Google Scholar] [CrossRef]

- Pokorný, J.; Ševčík, R.; Zárybnická, L.; Podolka, L. The Role of High Carbon Additives on Physical–Mechanical Characteristics and Microstructure of Cement-Based Composites. Buildings 2023, 13, 1585. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Klapiszewska, I.; Ślosarczyk, A.; Jesionowski, T. Lignin-based hybrid admixtures and their role in cement composite fabrication. Molecules 2019, 24, 3544. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Dai Pang, S. Effect of biochar on mechanical and permeability properties of concrete exposed to elevated temperature. Constr. Build. Mater. 2020, 234, 117338. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Sciancalepore, C.; Vecchi, F.; Malcevschi, A.; Belletti, B.; Milanese, D. Biochar from wood waste as additive for structural concrete. Constr. Build. Mater. 2021, 303, 124500. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, J.; Tan, K.; Chen, Y. Enhancing Biochar Impact on the Mechanical Properties of Cement-Based Mortar: An Optimization Study Using Response Surface Methodology for Particle Size and Content. Sustainability 2023, 15, 14787. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Falliano, D.; Carvajal, J.F.; Celi, A.C.B.; Ferro, G.A.; Tulliani, J.M.; Lavagna, L.; Restuccia, L. The Effect of Different Biochar on the Mechanical Properties of Cement-Pastes and Mortars. Buildings 2023, 13, 2900. [Google Scholar] [CrossRef]

- Ling, Y.; Wu, X.; Tan, K.; Zou, Z. Effect of Biochar Dosage and Fineness on the Mechanical Properties and Durability of Concrete. Materials 2023, 16, 2809. [Google Scholar] [CrossRef] [PubMed]

- Marcut, L.; Mohan, A.G.; Corneschi, I.; Grosu, E.; Paltanea, G.; Avram, I.; Badaluta, A.V.; Vasilievici, G.; Nicolae, C.A.; Ditu, L.M. Improving the Hydrophobicity of Plasticized Polyvinyl Chloride for Use in an Endotracheal Tube. Materials 2023, 16, 7089. [Google Scholar] [CrossRef] [PubMed]

- Siekierka, P.; Makarewicz, E.; Wilczewski, S.; Lewandowski, K.; Skórczewska, K.; Mirowski, J.; Osial, M. Composite of Poly(Vinyl Chloride) Plastisol and Wood Flour as a Potential Coating Material. Coatings 2023, 13, 1892. [Google Scholar] [CrossRef]

- Kocot, A. Impact of Artificial Waste on the Strength of Cementitious Composites. Multidiscip. Digit. Publ. Inst. Proc. 2019, 34, 11. [Google Scholar]

- Senhadji, Y.; Escadeillas, G.; Benosman, A.; Mouli, M.; Khelafi, H.; Ould Kaci, S. Effect of incorporating PVC waste as aggregate on the physical, mechanical, and chloride ion penetration behavior of concrete. J. Adhes. Sci. Technol. 2015, 29, 625–640. [Google Scholar] [CrossRef]

- Bolat, H.; Erkus, P. Use of polyvinyl chloride (PVC) powder and granules as aggregate replacement in concrete mixtures. Sci. Eng. Compos. Mater. 2016, 23, 209–216. [Google Scholar] [CrossRef]

- Merlo, A.; Lavagna, L.; Suarez-Riera, D.; Pavese, M. Mechanical properties of mortar containing waste plastic (PVC) as aggregate partial replacement. Case Stud. Constr. Mater. 2020, 13, e00467. [Google Scholar] [CrossRef]

- Valente, R.; De Ruijter, C.; Vlasveld, D.; Van Der Zwaag, S.; Groen, P. Setup for EMI shielding effectiveness tests of electrically conductive polymer composites at frequencies up to 3.0 GHz. IEEE Access 2017, 5, 16665–16675. [Google Scholar] [CrossRef]

- Rudd, M.; Baum, T.C.; Ghorbani, K. Determining high-frequency conductivity based on shielding effectiveness measurement using rectangular waveguides. IEEE Trans. Instrum. Meas. 2019, 69, 155–162. [Google Scholar] [CrossRef]

- Tamburrano, A.; Desideri, D.; Maschio, A.; Sarto, M.S. Coaxial waveguide methods for shielding effectiveness measurement of planar materials up to 18 GHz. IEEE Trans. Electromagn. Compat. 2014, 56, 1386–1395. [Google Scholar] [CrossRef]

- Jung, M.; Lee, Y.S.; Hong, S.G. Effect of incident area size on estimation of EMI shielding effectiveness for ultra-high performance concrete with carbon nanotubes. IEEE Access 2019, 7, 183105–183117. [Google Scholar] [CrossRef]

- Holloway, C.L.; Hill, D.A.; Ladbury, J.; Koepke, G.; Garzia, R. Shielding effectiveness measurements of materials using nested reverberation chambers. IEEE Trans. Electromagn. Compat. 2003, 45, 350–356. [Google Scholar] [CrossRef]

- Clayton, R.P. Shielding. In Introduction to Electromagnetic Compatibility; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2005; pp. 713–752. [Google Scholar] [CrossRef]

- Narayanan, S.; Zhang, Y.; Aslani, F. Prediction Models of Shielding Effectiveness of Carbon Fibre Reinforced Cement-Based Composites against Electromagnetic Interference. Sensors 2023, 23, 2084. [Google Scholar] [CrossRef] [PubMed]

- Wohlfahrt, D.; Peller, H.F.M.; Müller, S.; Modler, N.; Mechtcherine, V. Investigation of helix-pultruded CFRP rebar geometry variants for carbon-reinforced concrete structures. Polymers 2023, 15, 3285. [Google Scholar] [CrossRef] [PubMed]

- Guan, H.; Liu, S.; Duan, Y.; Cheng, J. Cement based electromagnetic shielding and absorbing building materials. Cem. Concr. Compos. 2006, 28, 468–474. [Google Scholar] [CrossRef]

- Chung, D. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Singh, A.P.; Gupta, B.K.; Mishra, M.; Chandra, A.; Mathur, R.; Dhawan, S. Multiwalled carbon nanotube/cement composites with exceptional electromagnetic interference shielding properties. Carbon 2013, 56, 86–96. [Google Scholar] [CrossRef]

- Jiang, A.; Song, Z.; Wang, X.; Zhao, J.; Ren, J. Properties of Concrete Reinforced with a Basalt Fiber Microwave-Absorbing Shielding Layer. Sustainability 2023, 15, 15919. [Google Scholar] [CrossRef]

- Feng, L.; Xin, L.; Yuebo, L.; Zheng, P.; Jie, Y. Attenuation characteristics of high power microwave penetrating through reinforcement nets. High Power Laser Part. Beams 2012, 24, 2713–2717. [Google Scholar] [CrossRef]

- Lee, S.; Kim, G.; Kim, H.; Son, M.; Lee, Y.; Choi, Y.; Woo, J.; Nam, J. Electromagnetic Wave Shielding Properties of Amorphous Metallic Fiber-Reinforced High-Strength Concrete Using Waveguides. Materials 2021, 14, 7052. [Google Scholar] [CrossRef]

- Mann, K.S.; Rani, A.; Heer, M.S. Shielding behaviors of some polymer and plastic materials for gamma-rays. Radiat. Phys. Chem. 2015, 106, 247–254. [Google Scholar] [CrossRef]

- Mahmoud, K.; Lacomme, E.; Sayyed, M.; Özpolat, Ö.; Tashlykov, O. Investigation of the gamma ray shielding properties for polyvinyl chloride reinforced with chalcocite and hematite minerals. Heliyon 2020, 6, e03560. [Google Scholar] [CrossRef]

- Malkapur, S.M.; Ghodke, S.S.; Sujatha, P.; Singh, Y.; Shivakumar, K.; Sen, M.; Narasimhan, M.C.; Pulgur, A.V. Waste-polymer incorporated concrete mixes for neutron and gamma radiation shielding. Prog. Nucl. Energy 2021, 135, 103694. [Google Scholar] [CrossRef]

- Shakir, M.F.; Abdul Rashid, I.; Tariq, A.; Nawab, Y.; Afzal, A.; Nabeel, M.; Naseem, A.; Hamid, U. EMI shielding characteristics of electrically conductive polymer blends of PS/PANI in microwave and IR region. J. Electron. Mater. 2020, 49, 1660–1665. [Google Scholar] [CrossRef]

- Bhavsar, V.; Tripathi, D. Low and high frequency shielding effectiveness of PVC-PPy films. Polym. Bull. 2018, 75, 2085–2104. [Google Scholar] [CrossRef]

- Al-Ghamdi, A.A.; El-Tantawy, F. New electromagnetic wave shielding effectiveness at microwave frequency of polyvinyl chloride reinforced graphite/copper nanoparticles. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1693–1701. [Google Scholar] [CrossRef]

- Matushko, I.P.; Noskov, Y.V.; Moiseienko, V.A.; Malyshev, V.Y.; Grishchenko, L.M. Electromagnetic Microwave Absorption Performances of PVC/AC Composites. Mater. Proc. 2023, 14, 15. [Google Scholar]

- ASTMC150-07; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Savi, P.; Ruscica, G.; di Summa, D.; Natali Sora, I. Shielding Effectiveness Measurements of Drywall Panel Coated with Biochar Layers. Electronics 2022, 11, 2312. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, T.; Yang, J.; Qi, J.; Zhang, L.; Liu, T.; Dai, S.; Zhao, Y.; Huang, Q.; Liu, Z.; et al. A review on the roles of biochar incorporated into cementitious materials: Mechanisms, application and perspectives. Constr. Build. Mater. 2023, 409, 134204. [Google Scholar] [CrossRef]

- Restuccia, L.; Ferro, G.A. Promising low cost carbon-based materials to improve strength and toughness in cement composites. Constr. Build. Mater. 2016, 126, 1034–1043. [Google Scholar] [CrossRef]

| Sample | PVC %/c | Biochar %/c | Water %/c | Superplasticizer %/c |

|---|---|---|---|---|

| reference | - | - | 35 | 1.5 |

| constant PVC | ||||

| B10-P5 | 5 | 10 | 53 | 1.8 |

| B12-P5 | 5 | 12 | 57 | 1.8 |

| B14-P5 | 5 | 14 | 61 | 1.8 |

| constant biochar | ||||

| B10-P3.5 | 3.5 | 10 | 52 | 1.8 |

| B10-P5 | 5 | 10 | 53 | 1.8 |

| B10-P6 | 6 | 10 | 53 | 1.8 |

| Sample | Cement (% m/m) | PVC (% m/m) | Biochar (% m/m) | Water (% m/m) | Superplasticizer (% m/m) |

|---|---|---|---|---|---|

| reference | 73.3 | 0 | 0 | 25.6 | 1.1 |

| constant PVC | |||||

| B10-P5 | 58.9 | 2.9 | 5.9 | 31.2 | 1.1 |

| B12-P5 | 57.2 | 2.9 | 6.9 | 32 | 1.0 |

| B14-P5 | 55 | 2.75 | 7.7 | 33.55 | 1 |

| constant biochar | |||||

| B10-P3.5 | 59.8 | 2.1 | 6 | 31.1 | 1.1 |

| B10-P5 | 58.9 | 2.9 | 5.9 | 31.2 | 1.1 |

| B10-P6 | 58.5 | 3.5 | 5.9 | 31.0 | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruscica, G.; Peinetti, F.; Natali Sora, I.; Savi, P. Analysis of Electromagnetic Shielding Properties of Cement-Based Composites with Biochar and PVC as Fillers. C 2024, 10, 21. https://doi.org/10.3390/c10010021

Ruscica G, Peinetti F, Natali Sora I, Savi P. Analysis of Electromagnetic Shielding Properties of Cement-Based Composites with Biochar and PVC as Fillers. C. 2024; 10(1):21. https://doi.org/10.3390/c10010021

Chicago/Turabian StyleRuscica, Giuseppe, Fabio Peinetti, Isabella Natali Sora, and Patrizia Savi. 2024. "Analysis of Electromagnetic Shielding Properties of Cement-Based Composites with Biochar and PVC as Fillers" C 10, no. 1: 21. https://doi.org/10.3390/c10010021