The Ultraviolet-Induced Functionalization of Multi-Walled Carbon Nanotubes with Polymer Radicals Generated from Polyvinyl Benzoate Derivatives

Abstract

:1. Introduction

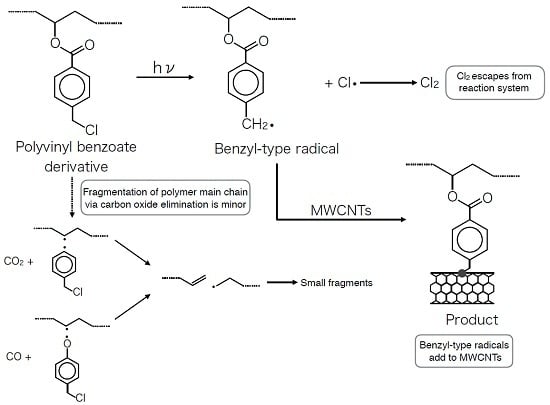

2. Results and Discussion

2.1. Photoinduced Bond Dissociation of Polymer Side Chains Observed by X-ray Photoelectron Spectroscopy (XPS)

2.2. Structural Change of MWCNTs Observed by Raman Spectroscopy

2.3. Photothermal Conversion Characteristics of the Prepared Materials

3. Materials and Methods

3.1. Materials

3.2. Preparation of Polyvinyl 4-(Chloromethyl)Benzoate

3.3. Determination of Degree of Esterification

3.4. Irradiation of Polymer/MWCNT Mixtures with UV Light

3.5. Spectroscopic Analysis of the Samples

3.6. Observation of Temperature Change of the Samples Induced by Infrared Irradiation

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Kaempgen, M.; Duesberg, G.S.; Roth, S. Transparent carbon nanotube coatings. App. Surf. Sci. 2005, 252, 425–429. [Google Scholar] [CrossRef]

- Hu, G.; Zhao, C.; Zhang, S.; Yang, M.; Wang, Z. Low Percolation thresholds of electrical conductivity and rheology in poly(ethylene terephthalate) through the networks of multi-walled carbon nanotubes. Polymer 2006, 47, 480–488. [Google Scholar] [CrossRef]

- Kim, D.O.; Lee, M.H.; Lee, J.H.; Lee, T.W.; Kim, K.J.; Lee, Y.K.; Kim, T.; Choi, H.R.; Koo, J.C.; Nam, J.D. Transparent flexible conductor of poly(methyl methacrylate) containing highly-dispersed multiwalled carbon nanotube. Org. Electron. 2008, 9, 1–13. [Google Scholar] [CrossRef]

- Park, H.J.; Kim, J.; Chang, J.Y.; Theato, P. Preparation of Transparent Conductive Multilayered Films Using Active Pentafluorophenyl Ester Modified Multiwalled Carbon Nanotubes. Langmuir 2008, 24, 10467–10473. [Google Scholar] [CrossRef] [PubMed]

- Logakis, E.; Pissis, P.; Pospiech, D.; Korwitz, A.; Krause, B.; Reuter, U.; Pötschke, P. Low electrical percolation threshold in poly(ethylene terephthalate)/multi-walled carbon nanotube nanocomposites. Eur. Polym. J. 2010, 46, 928–936. [Google Scholar] [CrossRef]

- Logakis, E.; Pandis, C.; Pissis, P.; Pionteck, J.; Pötschke, P. Highly conducting poly(methyl methacrylate)/carbon nanotube composites: Investigation on their thermal, dynamic-mechanical, electrical and dielectric properties. Comp. Sci. Technol. 2011, 71, 854–862. [Google Scholar] [CrossRef]

- Zhao, L.; Kiu, W.L.; Zhang, L.D.; Yao, J.S.; Xu, W.H.; Wang, X.Q.; Wu, Y.Z. Fabrication of superhydrophobic and conductive surface based on carbon nanotubes. Colloids Surf. A 2013, 423, 69–76. [Google Scholar] [CrossRef]

- Lin, W.Y.; Shih, Y.F.; Lin, C.H.; Lee, C.C.; Yu, Y.H. The preparation of multi-walled carbon nanotube/poly (lactic acid) composites with excellent conductivity. J. Taiwan Inst. Chem. Eng. 2013, 44, 489–496. [Google Scholar] [CrossRef]

- Shi, Y.D.; Lei, M.; Chen, Y.F.; Zhang, K.; Zeng, J.B.; Wang, M. Ultralow Percolation Threshold in Poly(l-lactide)/(ε-caprolactone)/Multiwall Carbon Nanotubes Composites with a Segregated Electrically Conductive Network. J. Phys. Chem. C 2017, 121, 3087–3098. [Google Scholar] [CrossRef]

- Paszkiewics, S。; Szymcsik, A.; Sui, X.M.; Wagner, H.D.; Linares, A.; Cirera, A.; Varea, A.; Ezquerra, T.A.; Rosłaniec, Z. Electrical conductivity and transparency of polymer hybrid nancomposites based on poly(trimethylene terephthalate) containing single walled carbon nanotubes and expanded graphite. J. Appl. Polym. Sci. 2017, 134, 44370. [Google Scholar] [CrossRef]

- Taraghi, I.; Fereidoon, A.; Paszkiewicz, S.; Rosłaniec, Z. Electrically conductive polycarbonate/ethylene-propylene copolymer/multi-walled carbon nanotubes nanocomposites with improved mechanical properties. J. Appl. Polym. Sci. 2017, 134, 44661. [Google Scholar] [CrossRef]

- Zhang, K.; Li, G.H.; Feng, L.M.; Wang., N.; Guo, J.; Sun, K.; Yu, K.X.; Zeng, J.B.; Li, T.; Guo, Z.; et al. Ultralow percolation threshold and enhanced electromagnetic interference shielding in poly(l-lactide)/multi-walled carbon nanotube nanocomposites with electrically conductive segregated networks. J. Mater. Chem. C 2017, in press. [Google Scholar] [CrossRef]

- Sun, K.; Xie, P.; Wang, Z.; Su, T.; Shao, Q.; Ryu, J.; Zhang, X.; Guo, J.; Shankar, A.; Li, J.; et al. Flexible polydimethylsiloxane/multi-walled carbon nanotubes membranous metacomposites with negative permittivity. Polymer 2017, 125, 50–57. [Google Scholar] [CrossRef]

- Zhang, L.; Yu, W.; Han, C.; Guo, J.; Zhang, Q.; Xie, H.; Shao, Q.; Sun, Z.; Guo, Z. Large Scaled Synthesis of Heterostructured Electrospun TiO2/SnO2 Nanofibers with an Enhanced Photocatalytic Activity. J. Electrochem. Soc. 2017, 164, H651–H656. [Google Scholar] [CrossRef]

- Liu, P. Modifications of carbon nanotubes with polymers. Eur. Polym. Sci. 2005, 41, 2693–2703. [Google Scholar] [CrossRef]

- Wu, H.X.; Tong, R.; Qiu, X.Q.; Yang, H.F.; Lin, Y.H.; Cai, R.F.; Qian, S.X. Functionalization of multiwalled carbon nanotubes with polystyrene under atom transfer radical polymerization conditions. Carbon 2007, 45, 152–159. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Composite A 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube-polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Sahoo, N.G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functional carbon nanotubes. Prog. Polym. Sci. 2010, 35, 837–867. [Google Scholar] [CrossRef]

- Khan, M.U.; Gomes, V.G.; Altawawneh, I.S. Synthesizing polystyrene/carbon nanotube composites by emulsion polymerization with non-covalent and covalent functionalization. Carbon 2010, 48, 2925–2933. [Google Scholar] [CrossRef]

- Hu, H.; Hui, K.N.; Hui, K.S.; Lee, S.K.; Zhou, W. Facile and green method for polystyrene grafted multi-walled carbon nanotubes and their electroresponse. Colloids Surf. A 2012, 396, 177–181. [Google Scholar] [CrossRef]

- Takada, T.; Baba, T.; Abe, S. Simple Process for Sidewall Modification of Multi-Walled Carbon Nanotubes with Polymer Side Chain Radicals Generated by Ultraviolet-Induced C-Cl Bond Dissociation of Polystyrene Derivatives. C 2016, 2, 20. [Google Scholar] [CrossRef]

- Giménez, V.; Mantecón, A.; Cádiz, V. Modification of poly(vinyl alcohol) with acid chlorides and crosslinking with difunctional hardeners. J. Polym. Sci. A Polym. Chem. 1996, 34, 925–934. [Google Scholar] [CrossRef]

- Porter, G.; Wright, F.J. Primary photochemical processes in aromatic molecules. Part 3. Absorption spectra of benzyl, anilino, phenoxy and related free radicals. Trans. Faraday Soc. 1955, 51, 1469–1474. [Google Scholar] [CrossRef]

- Peng, H.; Alemany, L.B.; Margrave, J.L.; Khabashesku, V.N. Sidewall Carboxylic Acid Functionalization of Single-Walled Carbon Nanotubes. J. Am. Chem. Soc. 2003, 125, 15174–15182. [Google Scholar] [CrossRef] [PubMed]

- Tsubokawa, N. Preparation and Properties of Polymer-grafted Carbon Nanotubes and Nanofibers. Polym. J. 2005, 37, 637–655. [Google Scholar] [CrossRef]

- Fenoglio, I.; Tomatis, M.; Lison, D.; Muller, J.; Fonseca, A.; Nagy, J.B.; Fubini, B. Reactivity of carbon nanotubes: Free radical generation or scavenging activity? Free Radic. Biol. Med. 2006, 40, 1227–1233. [Google Scholar] [CrossRef] [PubMed]

- Galano, A. Carbon Nanotubes as Free-Radical Scavengers. J. Phys. Chem. C 2008, 112, 8922–8927. [Google Scholar] [CrossRef]

- Nakamura, T.; Ishihara, M.; Ohana, T.; Tanaka, A.; Koga, Y. Sidewall modification of single-walled carbon nanotubes using photolysis of perfluroroazooctane. Diam. Relat. Mater. 2004, 13, 1971–1974. [Google Scholar] [CrossRef]

- Nakamura, T.; Ishihara, M.; Ohana, T.; Tanaka, A.; Koga, Y. Sidewall modification of single-walled carbon nanotubes using photolysis of perfluroroazooctane. Chem. Commun. 2004, 11, 1336–1337. [Google Scholar] [CrossRef] [PubMed]

- Baker, S.E.; Tse, K.Y.; Hindin, E.; Nichols, B.M.; Clare, T.L.; Hamers, R.J. Covalent Functionalization for Biomolecular recognition on Vertically Aligned Carbon Nanfibers. Chem. Mater. 2005, 17, 4971–4978. [Google Scholar] [CrossRef]

- Nakamura, T.; Ohana, T.; Ishihara, M.; Hasegawa, M.; Koga, Y. Photochemical modification of single-walled carbon nanotubes with amino functionalities and their metal nanoparticles attachment. Diam. Relat. Mater. 2008, 17, 559–562. [Google Scholar] [CrossRef]

- Kosaka, T.; Ohgami, A.; Nakamura, T.; Ohana, T.; Ishihara, M. The Preparation of Ag Nanoparticle-Modified Single-Walled Carbon Nanotubes and Their Antibacterial Activity. Biocontrol Sci. 2009, 14, 133–138. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, T. Photochemical modification and functionalization of carbon surfaces with fluorine moieties. Diam. Relat. Mater. 2010, 19, 374–381. [Google Scholar] [CrossRef]

- Park, J.J.; Park, D.M.; York, J.H.; Yu, W.R.; Lee, J. Functionalization of multi-walled carbon nanotubes by free radical graft polymerization initiated from photoinduced surface groups. Carbon 2010, 48, 2899–2905. [Google Scholar] [CrossRef]

- Petrov, P.; Georgiev, G.; Momekova, D.; Momekov, G.; Tsvetanov, C.B. UV-assisted grafting of polymers: A method towards biocompatible carbon nanotubes. Polymer 2010, 51, 2465–2471. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Xie, J.Y.; Ma, Y.H.; Yang, W.T. Surface functionalization of single-walled carbon nanotubes using photolysis for enhanced dispersion in an organic solvent. New Carbon Mater. 2010, 25, 134–140. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Nadeem, M.; Ma, Y.H.; Yang, W.T. Photochemical modification of single-walled carbon nanotubes using HPHMP photoinitiator for enhanced organic solvent dispersion. J. Mater. Sci. 2010, 45, 5591–5597. [Google Scholar] [CrossRef]

- Girard-Lauriault, P.L.; Illgen, R.; Ruiz, J.C.; Wertheimer, M.R.; Unger, W.E.S. Surface functionalization of graphite and carbon nanotubes by vacuum-ultraviolet photochemical reactions. Appl. Surf. Sci. 2012, 258, 8448–8454. [Google Scholar] [CrossRef]

- Liu, T.; Yu, K.; Gao, L.; Wang, N.; Hao, L.; Li, T.; He, H.; Guo, Z. A graphene quantum dot decorated SrRuO3 mesoporous film as an efficient counter electrode for high-performance dye-sensitized solar cells. J. Mater. Chem. A 2017, in press. [Google Scholar] [CrossRef]

- Sabba, Y.; Thomas, E.L. High-Concentration Dispersion of Single-Wall Carbon Nanotubes. Macromolecules 2004, 37, 4815–4820. [Google Scholar] [CrossRef]

- Saito, R.; Hoffmann, M.; Dresselhaus, G.; Jorio, A.; Dresselhaus, M.S. Raman spectroscopy of graphene and carbon nanotubes. Adv. Phys. 2011, 60, 413–550. [Google Scholar] [CrossRef]

- Kam, N.W.; O’Connell, M.; Wisdom, J.A.; Dai, H. Carbon nanotubes as multifunctional biological transporters and near-infrared agents for selective cancer cell destruction. Proc. Natl. Acad. Sci. USA 2005, 102, 11600–11605. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takada, T.; Nishioka, Y.; Baba, T. The Ultraviolet-Induced Functionalization of Multi-Walled Carbon Nanotubes with Polymer Radicals Generated from Polyvinyl Benzoate Derivatives. C 2017, 3, 28. https://doi.org/10.3390/c3030028

Takada T, Nishioka Y, Baba T. The Ultraviolet-Induced Functionalization of Multi-Walled Carbon Nanotubes with Polymer Radicals Generated from Polyvinyl Benzoate Derivatives. C. 2017; 3(3):28. https://doi.org/10.3390/c3030028

Chicago/Turabian StyleTakada, Tomoya, Yuya Nishioka, and Takuma Baba. 2017. "The Ultraviolet-Induced Functionalization of Multi-Walled Carbon Nanotubes with Polymer Radicals Generated from Polyvinyl Benzoate Derivatives" C 3, no. 3: 28. https://doi.org/10.3390/c3030028

APA StyleTakada, T., Nishioka, Y., & Baba, T. (2017). The Ultraviolet-Induced Functionalization of Multi-Walled Carbon Nanotubes with Polymer Radicals Generated from Polyvinyl Benzoate Derivatives. C, 3(3), 28. https://doi.org/10.3390/c3030028