Investigation of the Effects of Multi-Wall and Single-Wall Carbon Nanotubes Concentration on the Properties of ABS Nanocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Material Processing and Sample Preparation

2.2.1. Compounding

2.2.2. Compression Moulding (CM)

2.2.3. Filament Extrusion

2.3. Testing Techniques

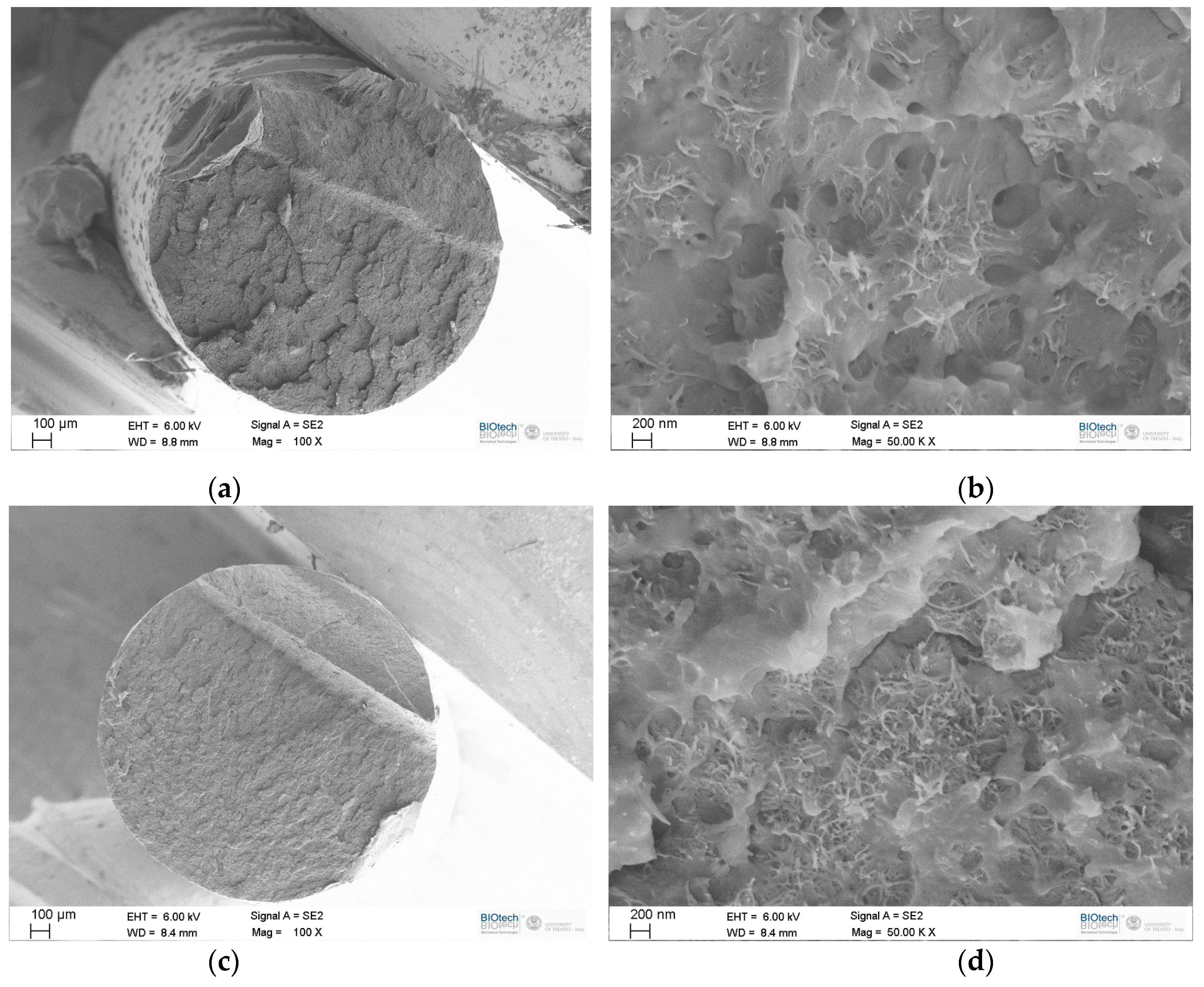

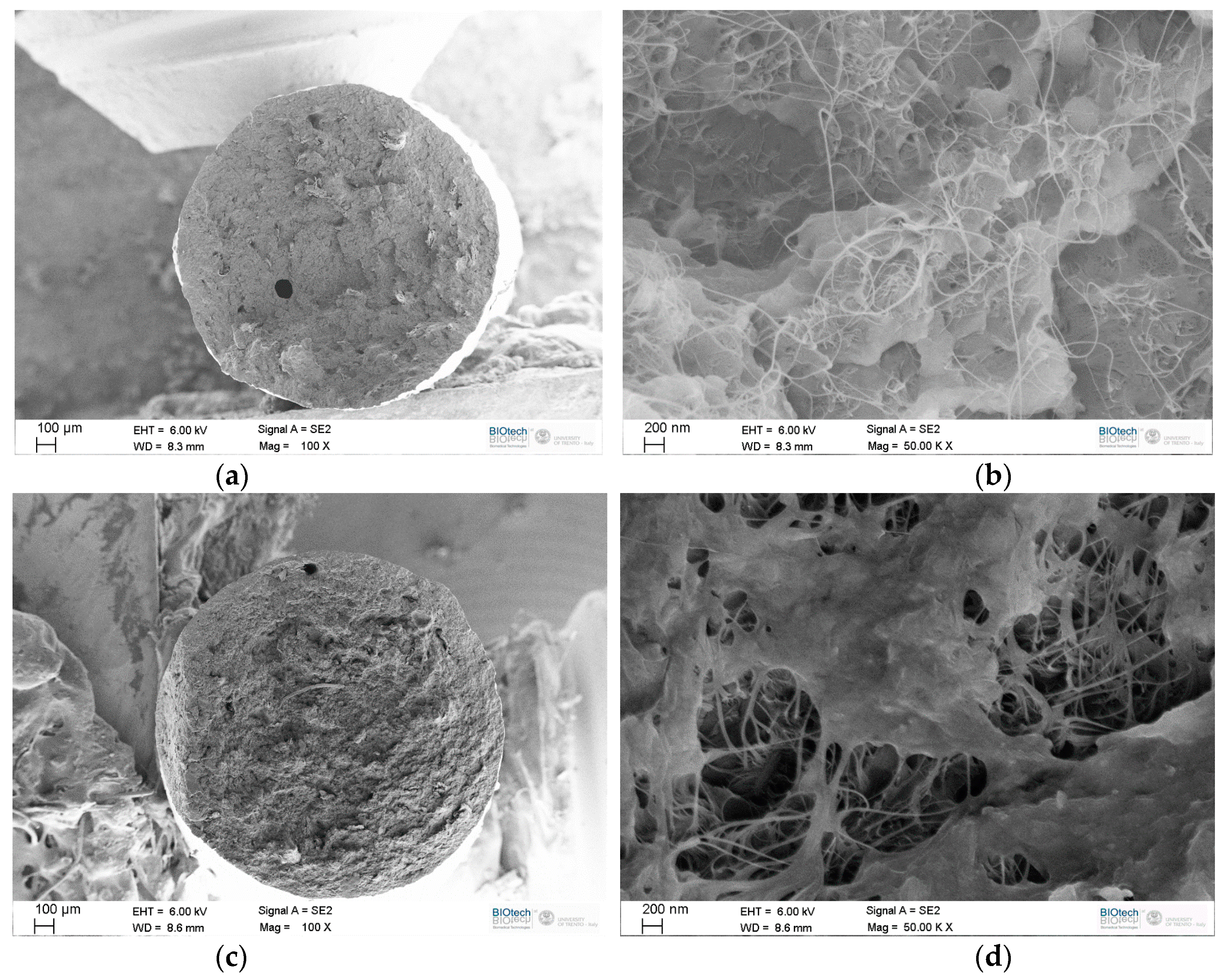

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. Density Measurement

2.3.3. Shore Hardness Test

2.3.4. Vicat Softening Temperature (VST)

2.3.5. Melt Flow Index (MFI)

2.3.6. Thermogravimetric Analysis (TGA)

2.3.7. Differential Scanning Calorimetry (DSC)

2.3.8. Mechanical Test

2.3.9. Electrical Resistivity Measurement

3. Results and Discussion

3.1. Compression Moulding

3.1.1. Density and Morphology

3.1.2. Shore Hardness and Maximum Using Temperature (VST).

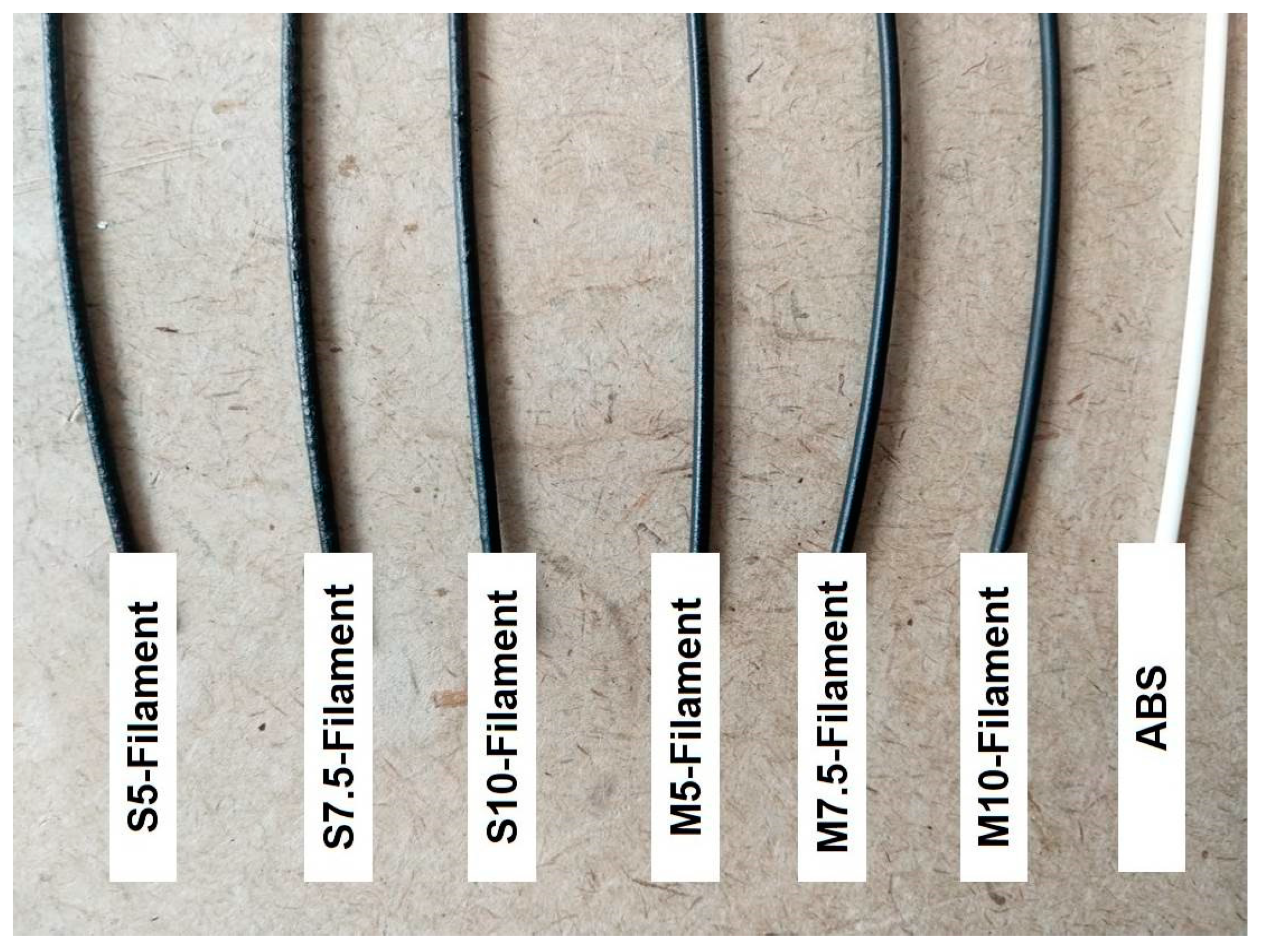

3.2. Filament Extrusion and Properties

3.2.1. Morphology and Density

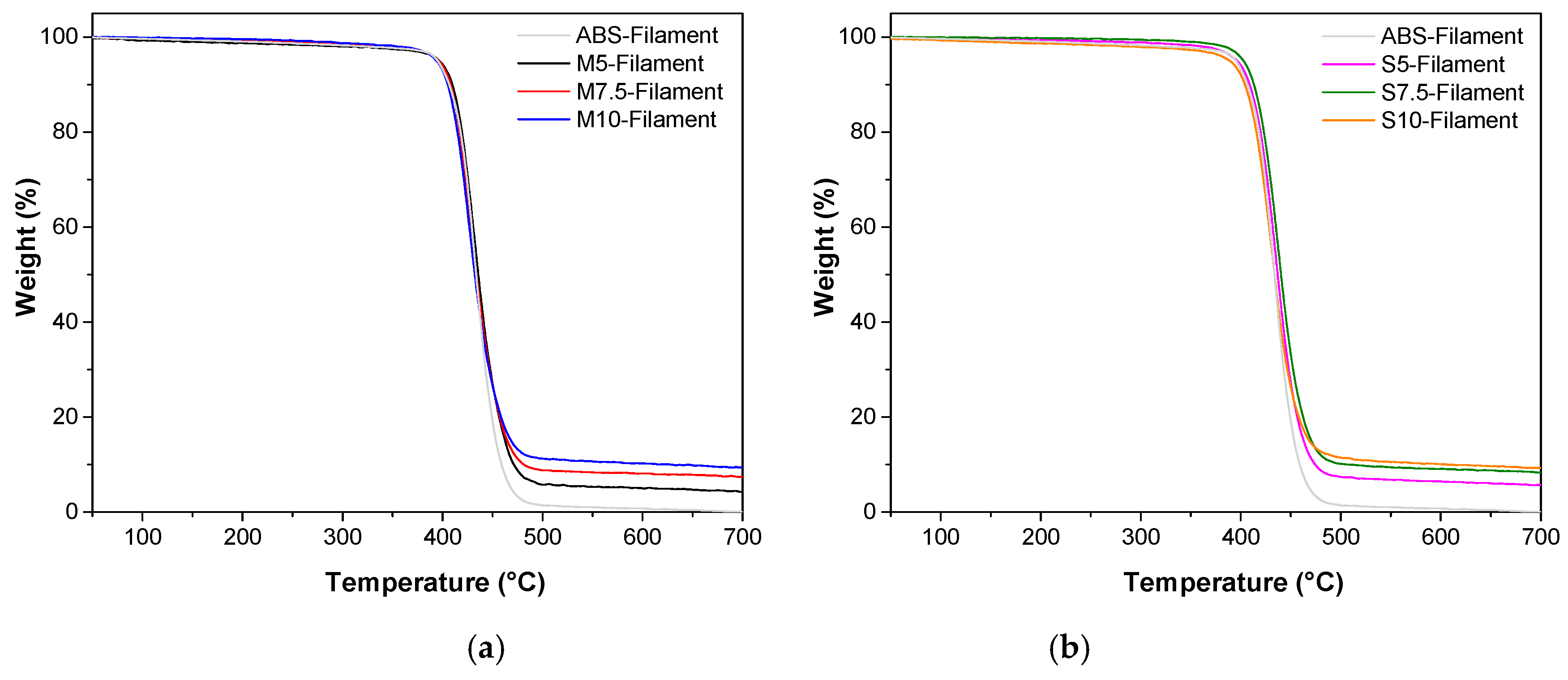

3.2.2. Thermal Properties

3.2.3. Melt Flow Index

3.2.4. Tensile Properties of Filaments

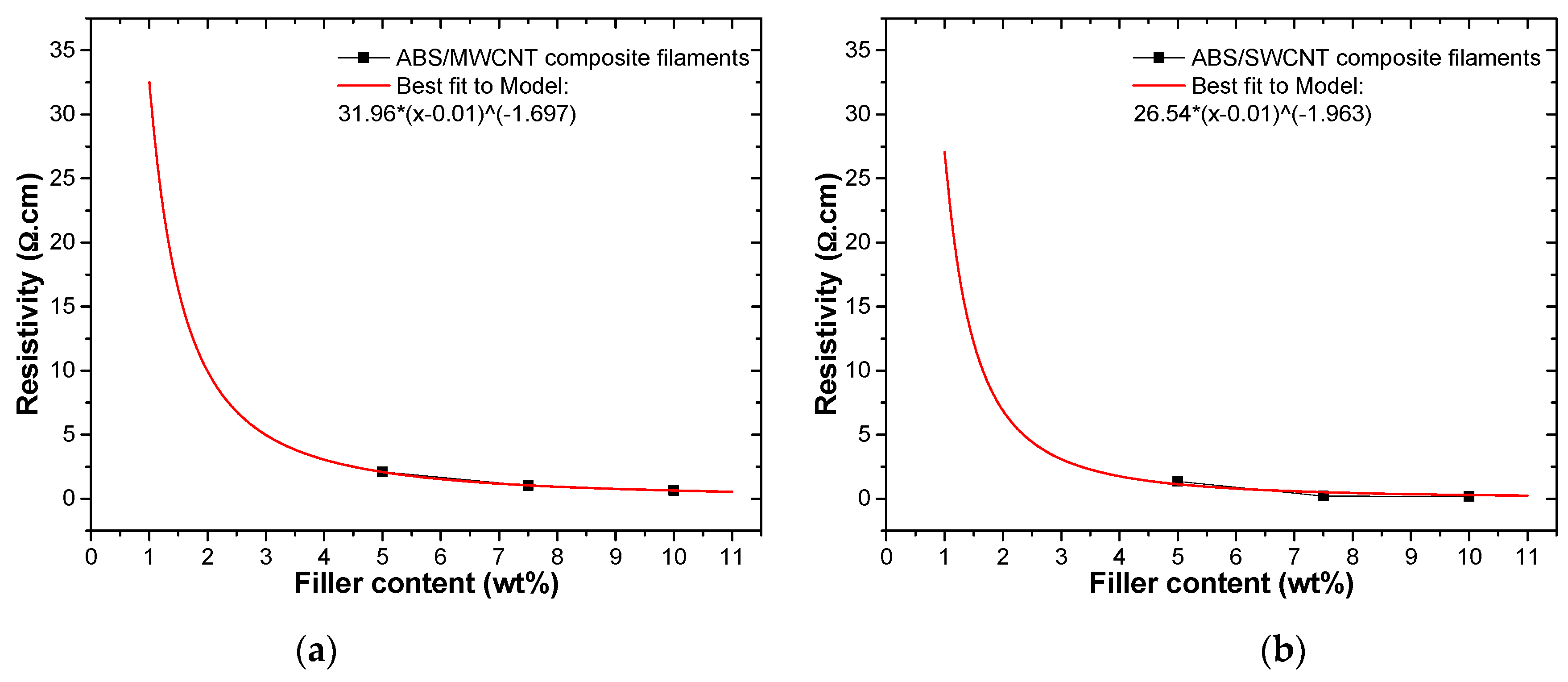

3.2.5. Electrical Resistivity

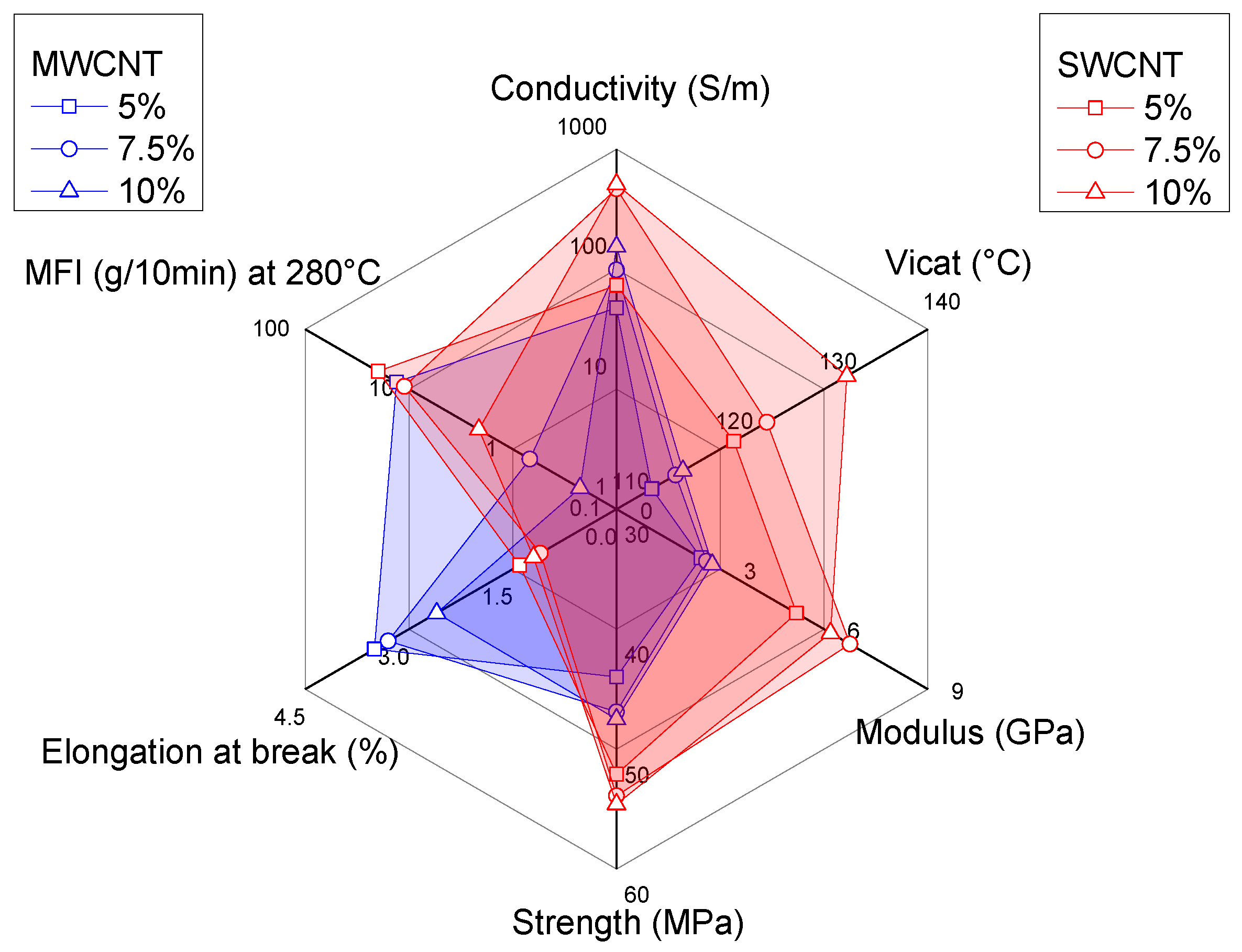

3.3. Comparative Effects of MWCNT and SWCNT

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile Butadiene Styrene |

| ASTM | American Society for Testing and Materials |

| CNT | Carbon Nanotubes |

| CM | Compression Moulding |

| DSC | Differential Scanning Calorimetry |

| FFF | Fused Filament Fabrication |

| MFI | Melt Flow Index |

| MWCNT | Multi-Wall Carbon Nanotubes |

| SEM | Scanning Electron Microscopy |

| SWCNT | Single-Wall Carbon Nanotubes |

| Tg | Glass transition temperature |

| TGA | Thermogravimetric Analysis |

| VST | Vicat Softening Temperature |

References

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Gao, X.; Xu, D. A review of the interfacial characteristics of polymer nanocomposites containing carbon nanotubes. RSC Adv. 2018, 8, 28048–28085. [Google Scholar] [CrossRef]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef] [PubMed]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D Printing of Strain Sensors within Highly Stretchable Elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef]

- Sun, K.; Wei, T.-S.; Ahn, B.Y.; Seo, J.Y.; Dillon, S.J.; Lewis, J.A. 3D Printing of Interdigitated Li-Ion Microbattery Architectures. Adv. Mater. 2013, 25, 4539–4543. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 217, 79–86. [Google Scholar] [CrossRef]

- Chizari, K.; Arjmand, M.; Liu, Z.; Sundararaj, U.; Therriault, D. Three-dimensional printing of highly conductive polymer nanocomposites for EMI shielding applications. Mater. Today Commun. 2017, 11, 112–118. [Google Scholar] [CrossRef]

- Crawford, R. Plastics Engineering, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 1998; Available online: https://www.elsevier.com/books/plastics-engineering/crawford/978-0-7506-3764-0 (accessed on 18 January 2021).

- Moniruzzaman, M.; Winey, K.I. Polymer Nanocomposites Containing Carbon Nanotubes. Macromolecules 2006, 39, 5194–5205. [Google Scholar] [CrossRef]

- Li, B.; Zhong, W.-H. Review on polymer/graphite nanoplatelet nanocomposites. J. Mater. Sci. 2011, 46, 5595–5614. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Pandey, G.; Thostenson, E.T. Carbon Nanotube-Based Multifunctional Polymer Nanocomposites. Polym. Rev. 2012, 52, 355–416. [Google Scholar] [CrossRef]

- Baker, R.T.K.; Barber, M.A.; Harris, P.S.; Feates, F.S.; Waite, R.J. Nucleation and growth of carbon deposits from the nickel catalyzed decomposition of acetylene. J. Catal. 1972, 26, 51–62. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nat. Cell Biol. 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Aqel, A.; El-Nour, K.M.A.; Ammar, R.A.; Al-Warthan, A. Carbon nanotubes, science and technology part (I) structure, synthesis and characterisation. Arab. J. Chem. 2012, 5, 1–23. [Google Scholar] [CrossRef]

- Dul, S.; Pegoretti, A.; Fambri, L. Effects of the nanofillers on physical properties of acrylonitrile-butadiene-styrene nano-composites: Comparison of graphene nanoplatelets and multiwall carbon nanotubes. Nanomaterials 2018, 8, 674. [Google Scholar] [CrossRef]

- Gupta, R.K.; Kennel, E.; Kim, K.-J. Polymer Nanocomposites Handbook; CRC Press: Boca Raton, FL, USA, 2009; Available online: https://www.taylorfrancis.com/books/edit/10.1201/9781420009804/polymer-nanocomposites-handbook-rakesh-gupta-elliot-kennel-kwang-jea-kim (accessed on 18 January 2021).

- Ma, J.; Meng, Q.; Zaman, I.; Zhu, S.; Michelmore, A.; Kawashima, N.; Wang, C.H.; Kuan, H.-C. Development of polymer composites using modified, high-structural integrity graphene platelets. Compos. Sci. Technol. 2014, 91, 82–90. [Google Scholar] [CrossRef]

- Askeland, P.A.; Fukushima, H.; Do, I.; Kalaitzidou, K.; Drzal, L.T. Exfoliated graphite nanoplatelets [2] surface treatment. In Proceedings of the Technical Proceedings of NSTI Nanotechnology Conference and Trade Show (NSTI Nanotech 2006), Boston, MA, USA, 7–11 May 2006; Volume 1, pp. 76–78. [Google Scholar]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review article: Polymer-matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Yildirir, E.; Miskolczi, N.; Onwudili, J.A.; Németh, K.E.; Williams, P.T.; Sója, J. Evaluating the mechanical properties of rein-forced ldpe composites made with carbon fibres recovered via solvothermal processing. Composites Part. B 2015, 78, 393–400. [Google Scholar] [CrossRef]

- Li, J.; Wong, P.-S.; Kim, J.-K. Hybrid nanocomposites containing carbon nanotubes and graphite nanoplatelets. Mater. Sci. Eng. A 2008, 483–484, 660–663. [Google Scholar] [CrossRef]

- Yang, S.-Y.; Lin, W.-N.; Huang, Y.-L.; Tien, H.-W.; Wang, J.-Y.; Ma, C.-C.M.; Li, S.-M.; Wang, Y.-S. Synergetic effects of gra-phene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Wang, P.-N.; Hsieh, T.-H.; Chiang, C.-L.; Shen, M.-Y. Synergetic Effects of Mechanical Properties on Graphene Nanoplatelet and Multiwalled Carbon Nanotube Hybrids Reinforced Epoxy/Carbon Fiber Composites. J. Nanomater. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.K.; Donato, K.; Godoy, A.P.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. Pla/graphene/mwcnt composites with improved electrical and thermal properties suitable for fdm 3d printing applica-tions. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Kotsilkova, R.; Tabakova, S.; Ivanova, R.; Angelova, P.; Angelov, V.; Ivanov, E.; Di Maio, R.; et al. Morphological, Rheological and Electromagnetic Properties of Nanocarbon/Poly(lactic) Acid for 3D Printing: Solution Blending vs. Melt Mixing. Materials 2018, 11, 2256. [Google Scholar] [CrossRef] [PubMed]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Kotsilkova, R.; Ivanov, E.; Menseidov, D.; Naddeo, C.; Romano, V.; Guadagno, L.; Adami, R.; et al. Nanocarbon/Poly(Lactic) Acid for 3D Printing: Effect of Fillers Content on Electromagnetic and Thermal Properties. Materials 2019, 12, 2369. [Google Scholar] [CrossRef] [PubMed]

- Yuan, D.; Pedrazzoli, D.; Manas-Zloczower, I. Synergistic Effects in Thermoplastic Polyurethanes Incorporating Hybrid Carbon Nanofillers. Int. Polym. Process. 2016, 31, 554–561. [Google Scholar] [CrossRef]

- Gonçalves, J.; Lima, P.; Krause, B.; Pötschke, P.; Lafont, U.; Gomes, J.R.; Abreu, C.S.; Paiva, M.C.; Covas, J.A. Electrically Conductive Polyetheretherketone Nanocomposite Filaments: From Production to Fused Deposition Modeling. Polymer 2018, 10, 925. [Google Scholar] [CrossRef] [PubMed]

- Dul, S.; Fambri, L.; Pegoretti, A. Fused deposition modelling with ABS–graphene nanocomposites. Compos. Part. A Appl. Sci. Manuf. 2016, 85, 181–191. [Google Scholar] [CrossRef]

- Ecco, L.; Dul, S.; Schmitz, D.; Barra, G.; Soares, B.; Fambri, L.; Pegoretti, A. Rapid prototyping of efficient electromagnetic in-terference shielding polymer composites via fused deposition modeling. Appl. Sci. 2019, 9, 37. [Google Scholar] [CrossRef]

- Schmitz, D.P.; Ecco, L.G.; Dul, S.; Pereira, E.C.L.; Soares, B.G.; Barra, G.M.O.; Pegoretti, A. Electromagnetic interference shield-ing effectiveness of abs carbon-based composites manufactured via fused deposition modelling. Mater. Today. 2018, 15, 70–80. [Google Scholar]

- Dul, S.; Fambri, L.; Pegoretti, A. Filaments Production and Fused Deposition Modelling of ABS/Carbon Nanotubes Composites. Nanomaterials 2018, 8, 49. [Google Scholar] [CrossRef]

- Dul, S.; Ecco, L.G.; Pegoretti, A.; Fambri, L. Graphene/carbon nanotube hybrid nanocomposites: Effect of compression mold-ing and fused filament fabrication on properties. Polymers 2020, 12, 101. [Google Scholar] [CrossRef]

- Nanocyl®nc7000tm (2016) Multiwall Carbon Nanotubes Product. Available online: http://www.Nanocyl.Com/wp-content/uploads/2016/07/dm-ti-02-tds-nc7000-v08.Pdfxg (accessed on 15 April 2019).

- Graphene Nanotubes Tuballtm Product. Available online: https://tuball.Com/additives/tuball/ (accessed on 18 January 2021).

- Versalis s.P.A sinkral® f 322- abs Product. Available online: https://www.Materialdatacenter.Com/ms/en/tradenames/sinkral/versalis+s%252ep%252ea/sinkral%c2%ae+f+332/c6da6726/1895 (accessed on 18 January 2021).

- ASTM D 792—13. Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM D 2240—05. Standard Test Method for Rubber Property—Durometer Hardness; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM D1525—09. Standard Test Method for Vicat Softening Temperature of Plastics; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D1238—10. Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ASTM D4496—04. Standard Test Method for D-C Resistance or Conductance of Moderately Conductive Materials; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Savin, A.; Korznikova, E.; Dmitriev, S. Improving bending rigidity of graphene nanoribbons by twisting. Mech. Mater. 2019, 137, 103123. [Google Scholar] [CrossRef]

- Evazzade, I.; Lobzenko, I.P.; Saadatmand, D.A.; Korznikova, E.; Zhou, K.; Liu, B.; Dmitriev, S.V. Graphene nanoribbon as an elastic damper. Nanotechnology 2018, 29, 215704. [Google Scholar] [CrossRef] [PubMed]

- Bao, H.-D.; Guo, Z.-X.; Yu, J. Effect of electrically inert particulate filler on electrical resistivity of polymer/multi-walled car-bon nanotube composites. Polymer 2008, 49, 3826–3831. [Google Scholar] [CrossRef]

- Weber, M.; Kamal, M.R. Estimation of the volume resistivity of electrically conductive composites. Polym. Compos. 1997, 18, 711–725. [Google Scholar] [CrossRef]

- Park, S.-H.; Hwang, J.; Park, G.-S.; Ha, J.-H.; Zhang, M.; Kim, D.; Yun, D.-J.; Lee, S.; Lee, S.H. Modeling the electrical resistivity of polymer composites with segregated structures. Nat. Commun. 2019, 10, 1–11. [Google Scholar] [CrossRef]

| Nanotubes | Carbon Purity (%) | Density (g/cm3) | Length (μm) | Diameter (nm) | Aspect Ratio | Surface Area (m2/g) | Manufacturer |

|---|---|---|---|---|---|---|---|

| MWCNT-NC7000 | >90 | 2.15 ± 0.03 * | 1.5 | 9.5 | 158 | 250–300 | Nanocyl, Belgium |

| SWCNT-TUBALL | >80 | 1.877 ** | 5 | 1.6 ± 0.4 | 313 | >300 | TUBALL, USA |

| Samples | Experimental Density (g/cm3) | CNT Vol (%) | Theoretical Density (g/cm3) | VVCM (%) | Shore D (Hs) | VST (°C) |

|---|---|---|---|---|---|---|

| ABS-CM | 1.043 ± 0.001 | 0 | 1.043 | 0 | 78.8 ± 0.4 | 111.5 ± 0.7 |

| M5-CM | 1.069 ± 0.001 | 2.49 | 1.071 | 0.2% | 79.3 ± 0.4 | 113.4 ± 1.0 |

| M7.5-CM | 1.081 ± 0.001 | 3.78 | 1.085 | 0.4% | 79.6 ± 0.7 | 115.7 ± 0.8 |

| M10-CM | 1.096 ± 0.001 | 5.11 | 1.100 | 0.3% | 80.0 ± 0.4 | 116.4 ± 0.5 |

| S5-CM | 1.066 ± 0.001 | 2.84 | 1.067 | 0.1% | 79.8 ± 0.8 | 121.3 ± 2.1 |

| S7.5-CM | 1.070 ± 0.002 | 4.31 | 1.079 | 0.8% | 78.4 ± 0.7 | 124.5 ± 2.6 |

| S10-CM | 1.086 ± 0.001 | 5.82 | 1.092 | 0.5% | 80.5 ± 0.5 | 132.2 ± 0.6 |

| Samples | Experimental Density (g/cm3) | CNT Volume (%) | Theoretical Density (g/cm3) | VVF (%) |

|---|---|---|---|---|

| ABS-Filament | 1.041 ± 0.005 | 0 | 1.041 | 0 |

| M5-Filament | 1.069 ± 0.001 | 2.48 | 1.069 | 0.0% |

| M7.5-Filament | 1.073 ± 0.001 | 3.78 | 1.083 | 1.0% |

| M10-Filament | 1.094 ± 0.004 | 5.10 | 1.098 | 0.4% |

| S5-Filament | 1.060 ± 0.004 | 2.84 | 1.065 | 0.4% |

| S7.5-Filament | 1.070 ± 0.003 | 4.30 | 1.077 | 0.7% |

| S10-Filament | 1.076 ± 0.007 | 5.80 | 1.090 | 1.3% |

| Samples | First Heating | Cooling | Second Heating | Tg Comparison Tg2 − Tg1 | ||

|---|---|---|---|---|---|---|

| Tg1 (°C) | ΔCP1 (J/g.K) | TgC (°C) | Tg2 (°C) | ΔCP2 (J/g.K) | ΔTg (°C) | |

| ABS-Filament | 106.1 | 0.38 | 102.1 | 108.0 | 0.39 | +1.9 |

| M5-Filament | 108.4 | 0.34 | 99.0 | 109.7 | 0.35 | +1.3 |

| M7.5-Filament | 108.6 | 0.33 | 98.7 | 109.5 | 0.32 | +0.9 |

| M10-Filament | 108.5 | 0.25 | 98.1 | 110.9 | 0.32 | +2.4 |

| S5-Filament | 109.1 | 0.31 | 104.5 | 109.9 | 0.33 | +0.8 |

| S7.5-Filament | 108.9 | 0.27 | 101.3 | 110.0 | 0.36 | +1.1 |

| S10-Filament | 108.2 | 0.30 | 99.3 | 109.4 | 0.34 | +1.2 |

| Samples | Mass Loss at 280 °C (%) | Tonset (°C) | Td,max (°C) | Residue at Selected Temperature (wt%) | ||

|---|---|---|---|---|---|---|

| 475 °C | 575 °C | 700 °C | ||||

| ABS-Filament | 1.6 | 398.2 | 433.5 | 3.3 | 0.8 | 0.0 |

| M5-Filament | 1.8 | 399.4 | 432.2 | 8.8 | 5.2 | 4.2 |

| M7.5-Filament | 1.1 | 394.8 | 428.7 | 11.2 | 8.2 | 7.4 |

| M10-Filament | 1.0 | 382.3 | 427.3 | 13.2 | 10.5 | 9.4 |

| S5-Filament | 1.0 | 377.7 | 435.8 | 9.8 | 6.6 | 5.7 |

| S7.5-Filament | 0.5 | 384.0 | 438.0 | 13.3 | 9.2 | 8.4 |

| S10-Filament | 1.9 | 372.6 | 435.0 | 13.5 | 10.3 | 9.2 |

| Samples | Tensile Modulus E (MPa) | Yield Stress σy (MPa) | Yield Strain εy (%) | Stress at Break σb (MPa) | Elongation at Break εb (%) | Tensile Energy at Break TEB (MJ mm−3) |

|---|---|---|---|---|---|---|

| ABS-Filament * | 2207 ± 65 | 42.8 ± 1.9 | 2.6 ± 0.1 | 35.0 ± 0.4 | 25.6 ± 15.8 | 8.94 ± 5.61 |

| M5-Filament | 2438 ± 142 | 44.0 ± 1.3 | 2.5 ± 0.2 | 40.2 ± 1.6 | 3.5 ± 1.3 | 1.10 ± 0.39 |

| M7.5-Filament | 2602 ± 218 | 46.9 ± 0.8 | 2.5 ± 0.2 | 44.5 ± 1.4 | 3.3 ± 0.8 | 1.06 ± 0.35 |

| M10-Filament | 2771 ± 155 | - | - | 47.5 ± 1.8 | 2.6 ± 0.2 | 0.84 ± 0.12 |

| S5-Filament | 5204 ± 275 | - | - | 52.1 ± 3.3 | 1.4 ± 0.2 | 0.44 ± 0.10 |

| S7.5-Filament | 6751 ± 506 | - | - | 53.9 ± 9.8 | 1.1 ± 0.3 | 0.37 ± 0.18 |

| S10-Filament | 6190 ± 362 | - | - | 54.6 ± 6.1 | 1.2 ± 0.2 | 0.37 ± 0.13 |

| Samples | Resistivity (Ω.cm) |

|---|---|

| M5-Filament | 2.10 ± 0.12 |

| M7.5-Filament | 1.02 ± 0.04 |

| M10-Filament | 0.65 ± 0.04 |

| S5-Filament | 1.36 ± 0.10 |

| S7.5-Filament | 0.21 ± 0.02 |

| S10-Filament | 0.19 ± 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gutierrez, B.J.A.; Dul, S.; Pegoretti, A.; Alvarez-Quintana, J.; Fambri, L. Investigation of the Effects of Multi-Wall and Single-Wall Carbon Nanotubes Concentration on the Properties of ABS Nanocomposites. C 2021, 7, 33. https://doi.org/10.3390/c7020033

Gutierrez BJA, Dul S, Pegoretti A, Alvarez-Quintana J, Fambri L. Investigation of the Effects of Multi-Wall and Single-Wall Carbon Nanotubes Concentration on the Properties of ABS Nanocomposites. C. 2021; 7(2):33. https://doi.org/10.3390/c7020033

Chicago/Turabian StyleGutierrez, Brenda Janett Alonso, Sithiprumnea Dul, Alessandro Pegoretti, Jaime Alvarez-Quintana, and Luca Fambri. 2021. "Investigation of the Effects of Multi-Wall and Single-Wall Carbon Nanotubes Concentration on the Properties of ABS Nanocomposites" C 7, no. 2: 33. https://doi.org/10.3390/c7020033

APA StyleGutierrez, B. J. A., Dul, S., Pegoretti, A., Alvarez-Quintana, J., & Fambri, L. (2021). Investigation of the Effects of Multi-Wall and Single-Wall Carbon Nanotubes Concentration on the Properties of ABS Nanocomposites. C, 7(2), 33. https://doi.org/10.3390/c7020033