Abstract

Tomatoes are one of the most important vegetables in every home, especially in South Asian countries, used as a vegetable, ketchup, and condiment in many kitchen recipes. It is a good source of calcium, potassium, folate, vitamin A, vitamin K, and lycopene, which are beneficial for the human body and protect it against different diseases. Nutrient management is a key factor for the best quality production of tomato fruit. The present study was conducted to compare the efficiency of different calcium salts (calcium sulphate, calcium carbonate, calcium nitrate, and calcium chloride) in improving the growth, yield, and other quality-related parameters of tomatoes. A single field experiment was conducted and laid out according to the Randomized Complete Block Design (RCBD) with a single factor in the field and a Complete Randomized Design (CRD)) for postharvest fruit storage. The results obtained from this experiment suggest that plants treated with 2% calcium chloride solution exhibited the greatest plant height (85.27 cm), number of leaves (221), yield per plant (2.3 kg), ascorbate peroxidase (290.75 m mol s−1 kg−1), superoxide dismutase (7.13 m mol s−1 kg−1), catalase (18.74 m mol s−1 kg−1), total phenolics (2.44 mg g−1), and β carotene (0.48 µg g−1). During postharvest storage, the maximum shelf life (18 days), minimum disease incidence (4.78%), weight loss (6.61%), and ethylene production (119.6 µL C2H4 kg−1h−1) rate were also observed in calcium-treated fruits.

1. Introduction

Tomato (Lycopersicon esculentum L.) belongs to the family Solanaceae and is one of the most important and top ten widely cultivated crops, which include cassava, soybean, potatoes, wheat, rice, and maize [1]. Tomato fruit is enriched with nutrition and energy, containing a distinct amount of water, carbohydrates, proteins, fibre, vitamins, and almost 37 types of minerals [2]. Its role as an antioxidant has also been identified as it protects people from cancer and optical disease risks, lowers blood pressure, reduces kidney stone risk, and also helps with weight loss and skin health [3]. According to the Food and Agriculture Organization (FAO) of the United Nations, the total world tomato production in 2021 amounted to just over 189.1 million metric tonnes for both fresh consumption and processing [4]. With an increasing population, tomato consumption at the local level is also increasing day by day in Pakistan. The average tomato production in Pakistan is about 9.6 tonnes per hectare, which is much less than in other countries, with 35–40% losses during postharvest handling [5]. Tomato production and fruit quality (both pre- and postharvest) are affected worldwide by many factors, including high- or low-temperature exposure, the cultivated variety, moisture availability, increased ethylene production, respiration, and physical injuries [6]. A decline in preharvest fruit quality ultimately leads to higher quantitative and qualitative postharvest losses, resulting in minimum revenues and foreign exchange [7]. Optimum tomato production depends upon several biotic and abiotic factors, and a lack of technical knowledge among farmers about fertilizer management is one of the major factors in the tomato production decline in our country. The improper timing and method of fertilizer application are also some of the main factors that significantly contribute to the decrease in tomato production [8].

Nutrition is one of the main factors that contribute to the optimum growth and high production levels of tomatoes. Nutrient deficiency in soils is caused by regular and frequent cropping and the inappropriate management of fertilizer (macro- and micronutrients), which ultimately decreases crop production. Thus, for maximum crop production, synthetic as well as organic fertilizer application is required to overcome this deficiency [9]. Calcium is a vital element responsible for better crop production as it is an important part of the cell wall, maintains fruit quality, increases the absorption of macronutrients in the root zone, and helps in fruit maturation [10,11]. It also has a positive role at the seedling stage in photosynthesis, plant growth rate, and disease incidence in many vegetables like tomatoes and sugar beet. Calcium deficiency in tomato plants can decrease leaf size, lead to necrosis in new leaves, and ultimately cause lower yield [11]. Calcium chloride (CaCl22H2O) application has been shown to be an important method that can extend the shelf life of tomato fruits as well as affect fruit quality and yield [7]. Calcium nitrate application improves root and shoot growth as well as phosphorus and potassium contents in cucumber [10,12]. Proper nutrient management regarding nitrogen, phosphorus, potassium, calcium, and magnesium is also required and is considered a good strategy for the better quality and production of tomatoes [13].

It also plays an important role in preserving/maintaining the structural and functional integrity of plant membranes with stabilized cell wall structures and in regulating enzyme activities within the cell wall [7]. Calcium application could also be helpful to increase yield in saline soils and overcome the negative effects of salinity caused by an imbalanced salt ratio and high sodium contents [13]. The addition of calcium sulphate could offer an economical and simple solution to tomato crop production problems caused by high salinity. Calcium sulphate added to saline nutrient solution significantly improves plant growth, fruit yield, and membrane permeability [14].

The present study was carried out to check the effects of different calcium salts on the pre- and postharvest fruit quality attributes of tomatoes grown under polytunnels, as well as to compare the efficiency of different calcium sources to improve fruit quality. This study also emphasizes a comparison of the efficacy of different calcium sources and recommends the best source to support the better growth and yield of the tomato plant.

2. Materials and Methods

2.1. Experimental Site and Materials

The current experiment was carried out at the Department of Horticulture (vegetable research area), Bahauddin Zakariya University, Multan (30.2° N and 71.45° E), Pakistan, to check and compare the effects of calcium salts on indeterminate tomato plants grown under polytunnels. Healthy and uniform tomato seeds of cv. Sahel were purchased from a local market and treated with different calcium sources, including calcium sulphate (CaSO4), calcium nitrate (Ca(NO3)2), calcium carbonate (CaCO3), and calcium chloride (CaCl2).

2.2. Treatments and Sowing Methodology

Treatments included different calcium sources, i.e., control, (2%) calcium sulphate, (2%) calcium nitrate, (2%) calcium carbonate, and (2%) calcium chloride with pH of 6–7.5. All the treatments were applied in the morning, and spray was mixed with Tween 20 (0.03%, v/v; Sigma, Merck Ltd., Shanghai, China) and applied as a foliar application. Tween 20 is a polyoxyethylene sorbitol ester that belongs to the polysorbate family, and it was added as detergent due to its stability. It is important to mention that salts used were not categorized under substance or mixture [15].

Treatments were applied at three different time intervals as follows: 1st application was performed after 15 days of transplanting; 2nd was performed at the time of fruit set, and last application was applied almost 2 weeks before the harvest of tomato fruit.

The seeds were sown in pots filled with media containing half soil and half leaf manure, covered with a thin layer of leaf manure, and irrigated with the help of hand shower. Immediate irrigation was also applied after germination, while remaining was scheduled according to seedling requirements.

2.3. Construction of Plastic Tunnel and Beds

For transplantation, land was prepared thoroughly with 2–3 deep ploughings. The position of tunnel was marked, and beds were prepared with maintained bed height of around 20 cm and bed-to-bed distance of 100 cm in walk-in tunnel. Mulching was performed by covering the soil beds with black polythene before transplanting seedlings. Seedlings were removed from the pots, followed by fungicide treatment, and transplantation on both sides of the raised bed. The gaps were filled after 10 days of transplantation to maintain the plant population.

Furrows were kept moist during whole growing season and summer season; irrigation was applied twice a week and fortnightly during the winter season. Mulching and cultural practices were performed as per routine, and after 1½ months of transplantation, side dressings of potash (KCl) and potash and urea (50 and 25 kg/acre) were performed. Moreover, after every 15 days, same amount of these fertilizers was applied until fruit harvesting.

After 3 weeks, healthy and vigorous seedlings were transplanted following the standard spacing of 60 cm between plants and 75 cm between rows. After 20 days of transplantation, the side branches of plants were removed, and plastic strings were used to train the plants in upward direction.

Tomato fruits were harvested manually in the red ripe stage (stage 6), and fruits of uniform size, and colour, undamaged and free from disease and bruises, were selected for data analysis. Fresh fruit was used to measure some quality parameters, while to measure bioactive components, the refrigerated samples were used.

2.4. Postharvest Storage of Fruits

Ten fruits from each replication were selected for postharvest storage and quality evaluation and stored in plastic baskets at a low temperature (at 10 °C with 85 ± 2%)). The temperature and humidity were measured using a digital in/out thermo-hygrometer (MEXTECH, Mumbai, India). The fruits were observed on a daily basis, and all the rotted and disease-ridden fruits were discarded immediately. However, for statistical analysis, data were recorded up to 15 days with 5-day intervals.

2.5. Data Collection

2.5.1. Preharvest Quality Parameters

Plant Height, Root Length, and Shoot Length (cm)

Five plants from each treatment were selected randomly and tagged to measure plant height. Plant height of each plant was measured from the uppermost shoot of the plant to the soil surface with the help of measuring tape. The data regarding plant height were collected after 80 days of transplantation, and the average plant height of five plants was expressed in cm. In the same way, root length and shoot length of each selected branch from each treatment were measured, average values were calculated, and reading was expressed in cm.

No. of Leaves per Plant, Leaf Chlorophyll Content (SPAD Value), and Leaf Area (cm2/Plant)

Five plants from each replication of all treatments were selected randomly and labelled for data collection. Each leaf SPAD value obtained was the average of 10 readings on each side of leaf midrib. No. of leaves were calculated to compare the effect of treatments, and average values were used for data analysis. Relative leaf chlorophyll content was measured with the help of chlorophyll meter after 80 days of transplantation. Leaf area from selected plants was measured to check and compare the efficiency of treatments.

Number of Flowers, Number of Fruits, and Fruit Yield per Plant (g)

The number of flowers and number of fruits from tagged plants were counted, and average values were calculated to check the effects of treatments. At harvesting, total number of fruits harvested at every picking from each tagged tomato plant was weighed at electronic balance to measure fruit yield (kg). After complete harvesting, average fruit yield per plant was calculated.

Shoot Fresh and Dry Weight; Root Fresh and Dry Weight (g)

The plants were uprooted after harvest to calculate fresh and dry weight of shoot and root. For easy uprooting, irrigation was applied one day before plant uprooting, and tagged plants were uprooted from the soil softly. The roots were cut with the help of a sharp knife, fresh weight of both shoots and roots was recorded using digital balance, and average values were calculated for data analysis. After calculating fresh weight, the shoots and roots were kept in oven for three days at 65 °C for drying, and dry weight was calculated using a digital electronic balance.

Total Soluble Solids (°Brix); Titratable Acidity (%) and Ripening Index

To check total soluble solids/soluble solid contents, 2–3 drops of extracted tomato juice were put in the prism of refractometer (Model; PAL-1, Atago, Tokyo, Japan), and reading was noted. A total of 10 mL of tomato juice was titrated with NaOH (0.1 N), and the final reading was determined according to the following formula [16].

To find out the ripening index, average values of total soluble solids (°Brix) were divided with the values of titratable acidity (%).

DPPH Scavenging Activity (%); Ascorbic Acid Contents (mg100 g−1) and Ascorbate Peroxidase (mmoles−1kg−1)

DPPH-scavenging activity of fruit was determined by using 2, 2-diphenyl-1-picrylhydrazyl radical (DPPH) assay, as prescribed by [17] with slight modifications, and following formula was used to express final values:

where

To determine ascorbic acid contents (g kg−1), the method given by [18] was followed with slight modifications.

To assess ascorbate peroxidase, the enzyme extract was supplemented with phosphate buffer and L-ascorbic acid, followed by addition of hydrogen peroxide and transfer to check absorbance at 290 nm at 0, 30, 60, and 90 s [19].

Beta-Carotene (µg g−1) and Phenolic Contents (mg g−1 FW)

To determine carotene contents, method given by [20] was used. A total of 1 g of samples was homogenized using pestle and mortar and mixed with 20 mL of petroleum and 20 mL of sodium sulfate (5%) in a separate funnel. The extract was transferred, and the absorbance was measured for beta-carotene at 453 nm using a UV spectrophotometer (HACH, Model; LBDI-UV58000, Bengaluru, India).

For total phenolic content determination, juice (1 mL) was taken and treated with liquid nitrogen, followed by storage at −80 °C. After completing all steps, samples were centrifuged (13,000× g) for 180 s at ambient temperature, and the supernatant was used for its evaluation. A spectrophotometer was used to evaluate its absorbance (at 765 nm and 517 nm), respectively [21].

Catalase, Peroxidase, Superoxide Dismutase (mmole s−1 kg−1), and Lycopene Contents (mg 100 g−1)

To extract enzymes, 1 g sample was taken with 2 mL of phosphate buffer with pH of 7.2 and homogenized, followed by centrifugation at 12,000 rpm for 5 min.

To determine catalase, peroxidase, and superoxide dismutase, the protocol given by Liu et al., 2009 [22], was followed after slight modifications. Absorbance for catalase, peroxidase, and dismutase was recorded on spectrophotometer (HACH, Model; LBDI-UV58000, Bengaluru, India) at 240 nm, 470 nm, and 560 nm, respectively, at 0, 30, 60, 90, and 120 s, and mean values was used for final calculations using following formula [22].

where A0 is the absorbance in the absence of SOD. A1 is the absorbance in the presence of SOD, and the enzymatic activity that causes 50% inhibition in the system is defined as 1 unit (U).

To determine the lycopene contents in tomato fruit, the method given by [19] was used. A total of 1 g of samples was homogenized using pestle and mortar, and for lycopene pigment determination, it was dissolved in 10 mL of acetone. A total of 20 mL of petroleum and sodium sulfate (5%) was added in reaction mixture in a separate funnel. The extract was transferred, and the absorbance was measured at 503 using a UV spectrophotometer to determine lycopene content [19].

Sensory Evaluation (Score)

A total of 10 fruits per treatment were used, and fruit colour, taste, texture, and flavour were determined; 5 fruits were used for tasting by a panel of 10 judges, who were asked to perform a sensory/organoleptic assessment following the Hedonic scales [22].

2.5.2. Postharvest Quality Parameters

Fruit Shelf Life (Days), Weight Loss, and Disease Incidence (%)

To determine fruit shelf life, the days were counted for each treatment at which the fruits retained their quality during storage.

The following equation was used to measure weight loss.

Disease incidence (%) was calculated using the following formula:

Ethylene Production (µLC2H4/kg/h) and Respiration Rate (mL of CO2/kg/h)

The harvested tomato fruits were placed in an airtight container, and after 2 h, the respiration rate was checked at room temperature by measuring the CO2. Gas chromatography (Clarus 500, PerkinElmer instrument, Waltham, MA, USA) was used for CO2 determination to estimate respiration and ethylene production [7,23].

2.6. Statistical Analysis

The present study was carried out under Randomized Complete Block Design (RCBD) for field trial using statistix version 8.1 software with three replications and a single factor. Five plants were used as experimental units in each replication. However, the experiment regarding fruit shelf life was laid out under Complete Randomized Design (CRD) with three replications of each factor. The data were analyzed by using Analysis of Variance (ANOVA) technique, and Least Significant Difference (LSD) test was used to compare the treatment means [24].

3. Results and Discussion

3.1. Preharvest Quality and Yield Parameters

3.1.1. Plant Height, Root Length, and Shoot Length (cm)

The results (p ≤ 0.01) suggested that plants sprayed with calcium chloride exhibited a maximum plant height (85.27 cm), followed by calcium carbonate (83.23 cm), calcium sulphate (81.51 cm), calcium nitrate (77.51 cm), and the control (60.87 cm), respectively (Table 1).

Different sources of calcium (p ≤ 0.01) also resulted in a significant increase in the shoot length of tomato plants grown in field conditions. The results revealed that the maximum shoot length (68.87 cm) was recorded in the plants treated with calcium chloride solution, followed by calcium nitrate (64.93 cm), calcium carbonate (60.07 cm), calcium sulphate (59.01 cm), and the control (45.17 cm), respectively (Table 1).

It was observed that all calcium sources significantly (p ≤ 0.01) affected the root length of tomato plants. The plants treated with calcium carbonate exhibited the maximum root length (23.16 cm), followed by calcium sulphate (18.50 cm), calcium chloride (16.4 cm), and calcium nitrate (15.16 cm), and the control (15.07 cm), respectively (Table 1).

3.1.2. No. of Flowers, No. of Fruits, and Fruit Yield per Plant (kg)

The plants treated with calcium chloride had the maximum number of flowers (42.66), followed by calcium carbonate (36.33), calcium sulphate (32.99), the control (32), and calcium nitrate (28.66), respectively. The plants treated with calcium chloride exhibited the maximum No. of fruits (34.51), followed by calcium carbonate (29.44), calcium sulphate (28.11), calcium nitrate (26.66), and the control (23.87), respectively (Table 1).

Table 1.

Effects of different calcium salts on preharvest quality parameters of tomato fruits.

Table 1.

Effects of different calcium salts on preharvest quality parameters of tomato fruits.

| Treatments | Plant Height (cm) | Root Length (cm) | Shoot Length (cm) | No. of Leaves | No. of Fruits | No. of Flowers | Leaf Chlorophyll Contents (SPAD) | Leaf Area (cm2/Plant) | Fruit Yield per Plant (kg) | Shoot Fresh Weight (g) | Root Fresh Weight (g) | Shoot Dry Weight (g) | Root Dry Weight (g) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 60.87 E | 15.07 D | 45.8 D | 177.0 D | 23.88 E | 32.0 D | 44.11 B | 28.98 C | 1.28 E | 55.63 D | 12.66 E | 10.76 E | 0.95 B |

| Calcium Sulphate (2%) | 77.51 D | 18.5 B | 59.01 C | 220.0 A | 28.11 C | 32.99 C | 48.93 A | 34.76 A | 2.16 B | 66.787 B | 13.16 D | 14.12 D | 2.1 A |

| Calcium Nitrate (2%) | 80.09 C | 15.16 D | 64.93 B | 215.0 B | 26.66 D | 28.66 E | 47.9 AB | 31.26 B | 1.56 D | 61.58 C | 17.66 C | 14.67 B | 2.30 A |

| Calcium Carbonate (2%) | 83.23 B | 23.16 A | 60.07 C | 212.0 C | 29.44 B | 36.33 B | 47.5 AB | 31.98 B | 1.95C | 68.68 AB | 20.83 A | 17.98 C | 2.34 A |

| Calcium Chloride (2%) | 85.27 A | 16.4 C | 68.87 A | 221.7 A | 34.51 A | 42.66 A | 48.8 A | 34.81 A | 2.36 A | 69.16 A | 18.0 B | 18.43 A | 2.01 A |

Means sharing same letter (p ≤ 0.01) are non-significant to each other.

It was also observed that the application of calcium chloride increased the fruit yield (kg) per plant (2.36 kg), calcium sulphate (2.16 kg), calcium carbonate (1.95 kg), calcium nitrate (1.56 kg), and the control (1.28 kg), respectively (Table 1)

3.1.3. No. of Leaves per Plant, Leaf Chlorophyll Content (SPAD), and Leaf Area (cm2/Plant)

The results revealed significant differences (p ≤ 0.01), and it was observed that the maximum No. of leaves (221.76) was found in the plants treated with calcium chloride, followed by calcium sulphate (220), calcium nitrate (215), calcium carbonate (212), and the control (177), respectively (Table 1).

Maximum chlorophyll contents (49.11) were recorded in the plants treated with calcium sulphate solution (48.9), calcium chloride (48.8), calcium nitrate (47.9), calcium carbonate (47.5), and the control (44.11), respectively. The plants treated with CaCl2 solution exhibited the maximum leaf area (34.81 cm2/plant), followed by calcium sulphate (34.76 cm2/plant), calcium carbonate (31.98 cm2/plant), calcium nitrate (31.26 cm2/plant), and the control (28.98 cm2/plant), respectively (Table 1).

3.1.4. Shoot Fresh Weight, Root Fresh Weight, Shoot Dry Weight, and Root Dry Weight (g)

The maximum shoot fresh and dry weight (69.16; 17.98 g) was noticed in plants treated with calcium chloride solution, followed by calcium carbonate (68.68; 18.43 g), calcium sulphate (66.78; 14.12 g), calcium nitrate (61.58; 14.67 g), and control plants (55.63; 10.76 g), respectively (Table 1). The maximum root fresh and dry weight (20.83; 2.34 g) was observed in the plants treated with calcium carbonate solution, followed by calcium chloride (18.0; 2.01 g), calcium nitrate (17.66; 2.3 g), calcium sulphate (13.16; 2.11 g), and the control (12.66; 0.95 g), respectively (Table 1).

3.1.5. Total Soluble Solids (°Brix); Titratable Acidity (%) and Ripening Index

After harvesting, fruit analysis showed that plants sprayed with calcium sulfate had maximum (7.5 °Brix) soluble solid contents (SSC) followed by calcium carbonate (6.3 °Brix), control (6.1 °Brix), calcium nitrate (6.0 °Brix) and calcium chloride (5.5 °Brix), respectively. However, maximum titratable acidity (0.66%) was found in plants treated with calcium carbonate solution followed by calcium sulphate (0.65%), calcium nitrate (0.63%), control (0.58%) and calcium chloride (0.54%), respectively. It was observed that maximum value of SSC: TA ratio/ripening index (11.53) was found in plants sprayed with calcium sulphate solution followed by control (10.51), calcium chloride (10.18), calcium carbonate (9.54), and calcium nitrate (9.52), respectively (Table 2).

Table 2.

Effects of different calcium salts on SSC; TA (%); Ripening Index of tomato fruit.

3.1.6. Antioxidant Activities and Enzymes

DPPH Scavenging Activity (%); Ascorbic Acid Contents (g kg−1) and Ascorbate Peroxidase (mmol s−1kg−1)

It was observed that plants treated with calcium chloride solution exhibited maximum DPPH scavenging activity (61.25%) followed by calcium carbonate (59.0%), calcium nitrate (58.13%), calcium sulphate (55.62%), and the control (45.99%), respectively (Table 3).

Table 3.

Effects of different calcium salts on antioxidants and enzymatic activities of tomato fruits.

The results revealed non-significant differences (p ≤ 0.01) among different calcium treatments but significant differences with control plants for ascorbic acid contents in tomato fruit. It was observed that maximum vitamin/ascorbic acid content (259.78 g kg−1) was found in plants treated with 2% calcium chloride solution followed by calcium nitrate (253.91 g kg−1), calcium sulphate (252.65 g kg−1), and control plants (237.65 g kg−1), respectively. The plants treated with 2% calcium chloride solution exhibited maximum (290.75 mmol s−1kg−1) ascorbate peroxidase (APX) activity, followed by calcium sulphate (277.58 mmol s−1kg−1), carbonate (261.38 mmol s−1kg−1), calcium nitrate (261.27 mmol s−1kg−1), and the control (255.15 mmol s−1kg−1), respectively (Table 3).

Beta-Carotene (µg g−1) and Phenolic Contents (mg g−1 FW)

The results (p ≤ 0.01) suggested that all the calcium sources/treatments were helpful in increasing total phenolic contents and beta-carotene in tomato fruit. The plants treated with 2% calcium chloride exhibited maximum beta-carotene (0.48 µg g−1), followed by calcium nitrate (0.47 µg g−1), calcium sulphate (0.41 µg g−1), calcium carbonate (0.39 µg g−1), and the control (0.37 µg g−1), respectively The fruit analysis (p ≤ 0.01) showed that maximum TPC (2.45 mg g−1 FW) was recorded in the plants treated with calcium carbonate solution (2.45 mg g−1 FW), followed by calcium chloride solution (2.44 mg g−1 FW), calcium sulphate (2.39 mg g−1 FW), calcium nitrate (2.37 mg g−1 FW), and the control (1.31 mg g−1 FW), respectively. (Table 3).

Catalase, Peroxidase, Superoxide Dismutase (mmole s−1kg−1), and Lycopene (mg 100 g−1)

The overall results suggested that all calcium salts were effective (p ≤ 0.01) in increasing antioxidative enzyme activities in tomato fruit. The maximum catalase activity (18.71 mmole s−1kg−1) was recorded in the plants treated with calcium chloride, followed by calcium carbonate (18.0), calcium nitrate (17.44 mmole s−1kg−1), calcium sulphate (17.3 mmole s−1kg−1), and the control (16.49 mmole s−1kg−1), respectively (Table 3). Similarly, maximum peroxidase, SOD, and lycopene activities were also found to be higher (7.82, 7.13, and 16.07) in the plants treated with calcium chloride solution. Other sources also performed well compared to the control treatment, as peroxidase, SOD, and lycopene contents found in calcium carbonate were (5.97, 6.23, and 14.98), followed by calcium nitrate (6.04, 6.17, and 14.87), calcium sulphate (4.29, 5.65, and 13.78), and the control (4.71, 5.53, and 9.98), respectively (Table 3).

3.2. Postharvest Storage and Quality Parameters

3.2.1. Sensory Evaluation (Score)

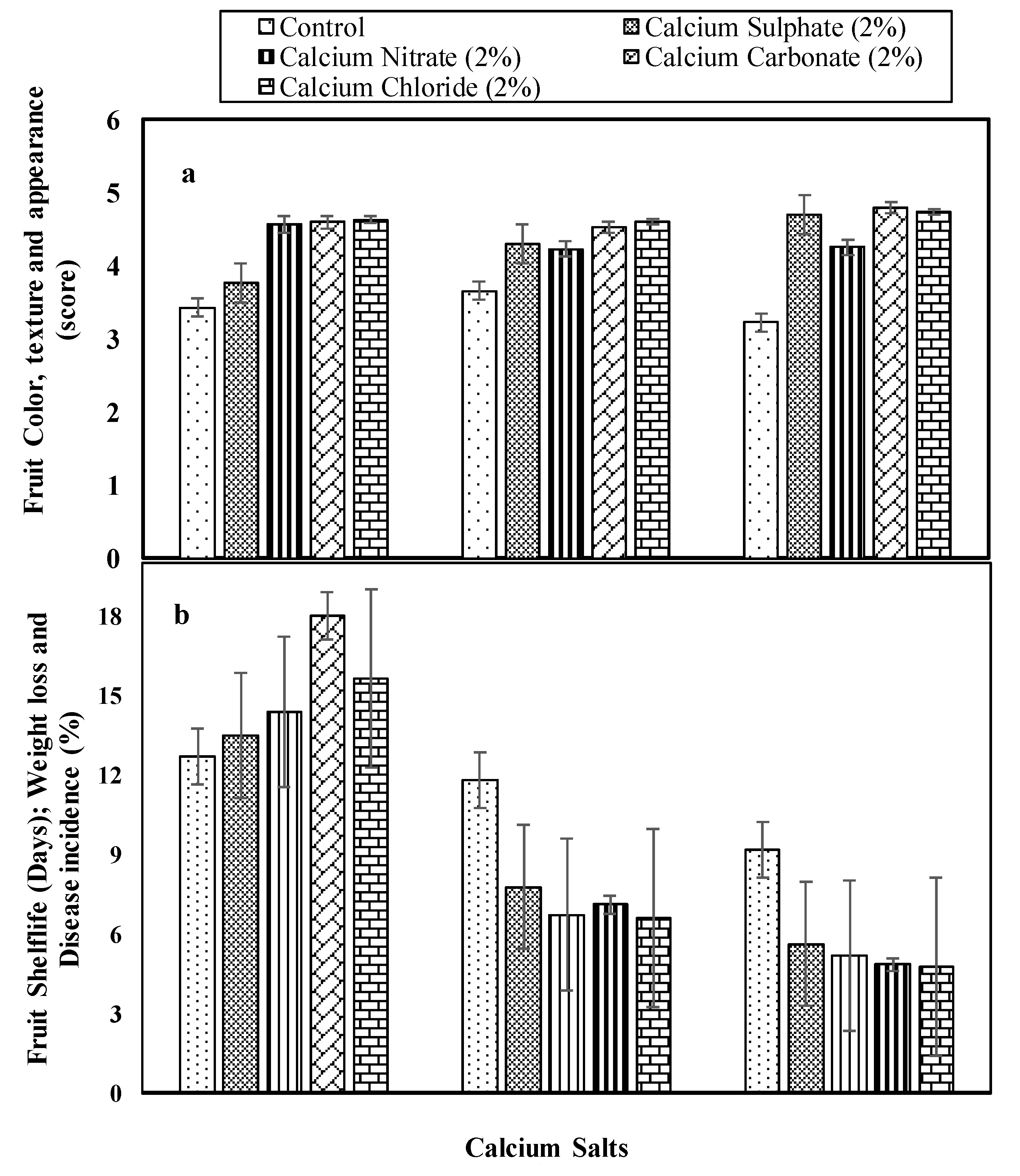

The organoleptic evaluation was assessed by evaluating fruit colour, texture, taste, and aroma. It was observed that all calcium salts were helpful in maintaining fruit quality, texture, and taste. All the treatments exhibited satisfactory results of sensory evaluation in tomato fruit. However, the maximum red colour was developed in plants treated with calcium sulphate, calcium nitrate, calcium chloride and calcium carbonate, and the control, respectively (Figure 1a).

Figure 1.

(a) Effects of different calcium salts on sensory evaluation (score), (b) fruit shelf life (days), weight Loss (%), and disease incidence (%).

3.2.2. Fruit Shelf Life (Days), Weight Loss, and Disease Incidence (%)

The results revealed that (p ≤ 0.01) the maximum shelf life (18 days) at ambient room temperature was observed in the fruits harvested from plants with the foliar application of calcium carbonate, followed by calcium chloride (15.63 days), calcium nitrate (14.4 days), calcium sulphate (13.5 days), and the control (12.7 days), respectively (Figure 1b). All calcium treatments were also effective in minimizing the weight loss disease incidence percentage in stored tomato fruits. The maximum weight loss and disease incidence (11.8, 9.1%) was recorded in control fruits, followed by calcium sulphate (7.78, 5.63%), calcium nitrate (6.74, 5.2%), calcium carbonate (7.12, 4.86%), and calcium chloride (6.61, 4.78%), respectively (Figure 1b).

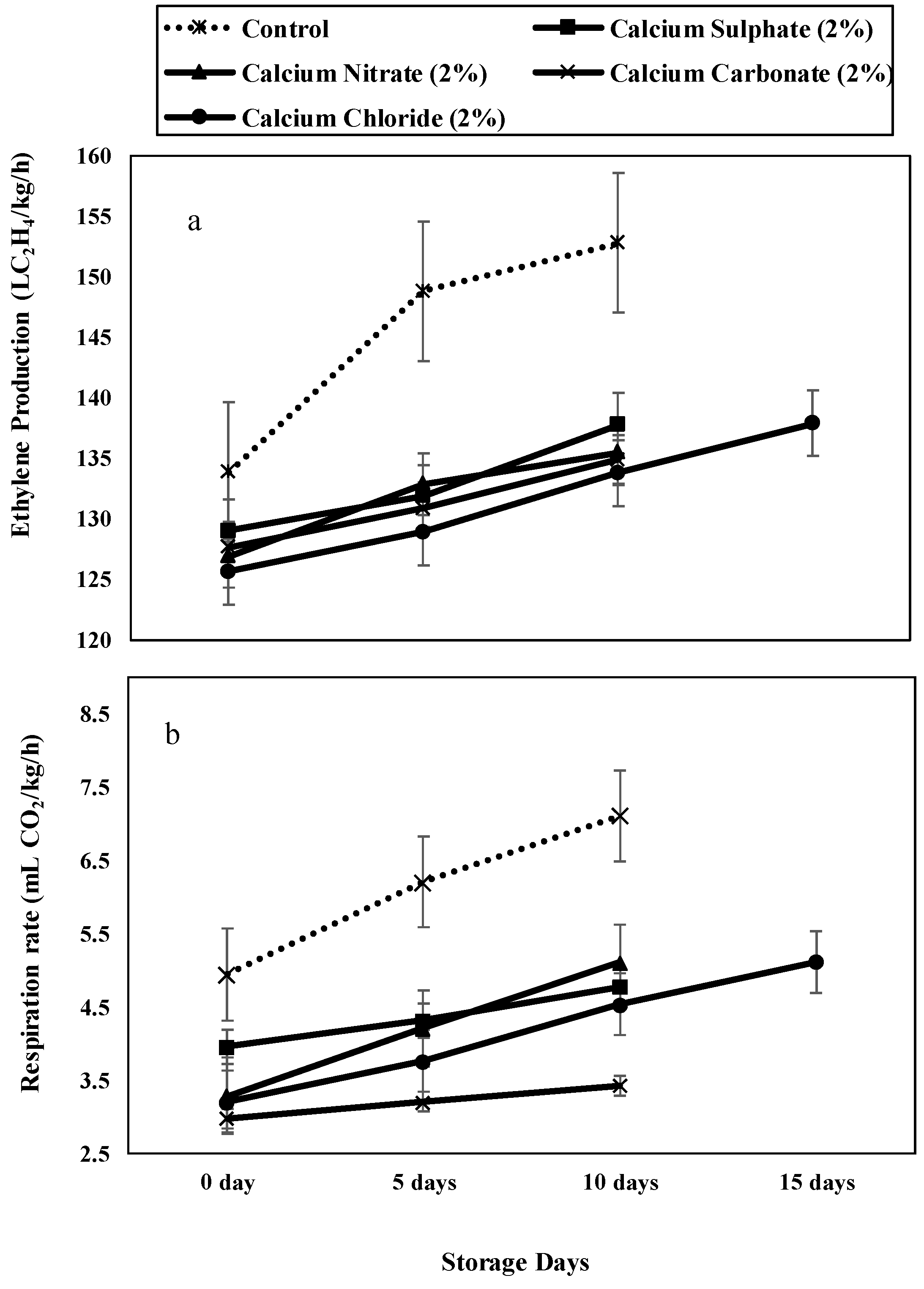

3.2.3. Ethylene Production (µLC2H4/kg/h) and Respiration Rate (mL of CO2/kg/h)

All calcium salts were significantly effective (p ≤ 0.01) in controlling ethylene rise and the respiration rate during the storage of tomato fruit. Irrespective of treatments, both ethylene production and the respiration rate were increased with increasing storage time (Figure 2a).

Figure 2.

(a) Effects of different calcium salts on ethylene production (µLC2H4/kg/h) and (b) respiration rate (mL of CO2/kg/h) of tomato fruit during storage (Horizontal lines represent different calcium salts while vertical bars in each graph represent ±SE of means).

At the end of storage, it was observed that the control fruit exhibited maximum ethylene production and respiration rate (152.76 µLC2H4/kg/h, 7.11 mL of CO2/kg/h), followed by calcium sulphate (137.76 µLC2H4/kg/h, 5.11 mL of CO2/kg/h), calcium nitrate (135.47 µLC2H4/kg/h, 4.78 mL of CO2/kg/h), calcium carbonate (134.87 µLC2H4/kg/h, 3.43 mL of CO2/kg/h), and calcium chloride (137.87 µLC2H4/kg/h, 5.12 mL of CO2/kg/h), respectively (Figure 2b).

4. Discussions

Calcium plays an important role in maintaining the overall quality of horticultural crops, including fruits and vegetables. It is considered the main element that determines the structure of cell walls and stabilizes cell membranes. It also directly affects salt balance within plant cells and helps in water movement from the plant by triggering potassium salts to regulate the stomatal movement (opening and closing). It has been reported that calcium application in plants increases pollen germination, regulates different enzymes, and affects cell growth and development [25].

In our study, maximum fruit number and size were observed in the plants treated with different calcium salts when compared to the control. The maximum fruit set (%) could be positively correlated with controlled metabolism and nutrient uptake in the calcium-treated plants [26]. However, the increased fruit size might be due to the role of Ca in the preservation of cell integrity and its relation with pectic enzymes. It has been reported that calcium application at high levels is helpful in increasing fruit size by constraining the activity of pectic enzymes in tomato fruit, while low calcium levels minimize fruit size with the increase in pectic enzyme activity [27,28].

The better values of TSS in calcium-treated tomato fruit might be due to the slow metabolic activity and slow respiration rates [28]. It has been reported that the synthesis and use of metabolites are decreased because of slower respiration rates, which ultimately result in balanced fruit TSS. The increase in the calcium contents of fruit after calcium application could also be helpful in controlling physiochemical changes associated with ripening.

The sugar and acid ratio is very important to determine fruit ripening as it is directly linked with fruit taste and flavour, which is regulated by having an optimum amount of titratable acidity. It has been reported that the reduced metabolic activities of organic acid in water and CO2 result in producing better retention in fruit acidity [29].

Photosynthetic pigments in any crop are very important in determining the photosynthetic efficiency and plant growth. In our study, all calcium salts had a positive effect on the photosynthetic rate as well as the No. of leaves in comparison to the control. A greater number of leaves in calcium-treated plants might be due to increased calcium levels. However, a greater chlorophyll ratio might be due to the effect of calcium salts that directly improve the cell wall absorption capacity, which results in an increased photosynthetic process and, ultimately, a greater number of leaves [30]. These results are also supported by previous studies that reported that the supplemental addition of calcium sulphate in nutrient solution containing salt significantly improved growth and physiological variables affected by salt stress, including plant growth, fruit yield, and membrane permeability [31].

In our study, maximum ascorbic acid contents, phenolics, and antioxidative enzymes were found in calcium-treated fruits. Ascorbic acid contents or vit C in tomato fruit possess antioxidant properties, with a main role in regulating cell division, as well as cell expansion, and also acts as a cofactor for different enzymes [31]. Preharvest calcium application has been reported to increase ascorbic acid contents as well as help minimize its losses during the storage of fruits and vegetables. The calcium delays the rapid oxidation of ascorbic acid, and the increase in contents after calcium application may be due to the regulation of oxidative processes in the cytosol [32]. The maximum ascorbic acid contents recorded in calcium-treated fruits may be due to the role of calcium in countering the ascorbic acid degradation due to extreme light exposure and increased fruit temperature [32]. Previous studies also suggest that tomato plants treated with calcium carbonate exhibited better firmness, higher contents of vitamin C and total phenols (+12%), and higher antioxidant activity [31,33].

Calcium chloride has been widely used to improve fruit quality and delay ripening and skin shrinkage during storage to extend their shelf life [34]. In our study, all calcium sources significantly increased the shelf life of tomato fruits, which might be due to the fact that calcium may inhibit fruit ripening in tomatoes by avoiding cell wall breakdown enzyme release, as well as by directly minimizing respiration [25].

The physiological weight loss is usually due to the loss of moisture and respiratory losses occurring during storage in horticultural crops. The application of calcium significantly reduces physiological weight loss (%) during storage. Fruits with higher calcium contents may have better transportation and maintain their quality for a longer time because calcium is involved in minimizing the respiration rate, maintaining fruit firmness, and delaying senescence [24]. Our results are also in line with the results of many other scientists who reported that different calcium sources significantly increase shelf life and decrease weight loss during the storage of fruits and vegetables [3,35].

The preharvest application of calcium chloride in immature fruits is also helpful in increasing the postharvest storage life of tomato fruits as it affects firmness and fruit colour development and inhibits fungal attack during storage [36].

Lycopene is one of the most important and potential natural antioxidants present in fruits and vegetables, and it has a higher nutritional status and health benefits. During fruit ripening, the degradation of chlorophyll and the synthesis and storage of carotenoids occurs [37,38]. This might be due to higher activities of the enzyme phytoene synthase and accumulation as precursors of lycopene [39]. However, calcium application may decrease lycopene and beta-carotene to delay the ripening process, chlorophyll degradation, as well as carotenoid development [38,40,41].

5. Conclusions

Therefore, it is concluded that all calcium salts were effective in improving the pre- and postharvest fruit quality of tomato fruits. However, among all sources, calcium chloride was more effective in maintaining fruit quality parameters after harvest as well as during storage. This recommendation is based on the results of all parameters collected, as maximum parameters were found in the plants sprayed with calcium chloride. However, these results are obtained from a single experiment and will be confirmed through confirmatory trials in related studies. Moreover, the salts used were not categorized under substance or mixture according to FAO and European parliament and council regulations.

Author Contributions

Conceptualization, S.T.-A.H. and M.A.A.; Methodology, M.A.A. and A.U.H.; Software, A.U.H. and M.P.; Investigation, M.N.S. and M.P.; Writing—original draft, A.U.H.; Writing—review & editing, A.U.H., S.D., S.A.A. and S.A.; Supervision, S.T.-A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research did not receive any external funding.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kimura, S.; Sinha, N. Tomato (Solanum lycopersicum): A Model Fruit-Bearing Crop. Cold Spring Harb. Protoc. 2008, 11, pdb-emo105. [Google Scholar] [CrossRef] [PubMed]

- Quinet, M.; Angosto, T.; Yuste-Lisbona, F.J.; Blanchard, G.R.; Bigot, S.; Martinez, J.; Lutts, S. Tomato Fruit Development and Metabolism. Front. Plant Sci. 2019, 10, 01554. [Google Scholar] [CrossRef] [PubMed]

- Cogswell, M.E.; Zhang, Z.; Carriquiry, A.L.; Gunn, J.P.; Kuklina, E.V.; Saydah, S.H.; Yang, Q.; Moshfegh, A.J. Sodium and Potassium Intakes among US Adults: NHANES 2003–2008. Am. J. Clin. Nutr. 2012, 96, 647–657. [Google Scholar] [CrossRef] [PubMed]

- FAO. Production: Crops and Livestock Products. In FAOSTAT; Food and Agriculture Organization of the United Nations: Rome, Italy, 2023; Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 13 January 2024).

- Munhuewyi, K. Postharvest Losses and Changes in Quality of Vegetables from Retail to Consumer: A Case Study of Tomato, Cabbage and Carrot. Ph.D. Dissertation, Stellenbosch University, Stellenbosch, South Africa, 2012. [Google Scholar]

- Rehman, M.; Khan, N.; Jan, I. Postharvest Losses in Tomato Crop (A Case Study of Peshawar Valley). Sarhad J. Agric. 2021, 23, 1279–1284. [Google Scholar]

- Mazumder, M.N.; Azizah, M.; Phebe, D.; Puter, E.M.W.; Azhar, M. Preharvest Foliar Spray of Calcium Chloride on Growth, Yield, Quality, and Shelflife Extension of Different Lowland Tomato Varieties in Malaysia. Horticulturae 2021, 7, 466. [Google Scholar] [CrossRef]

- Pervaiz, U.; Salam, A.; Jan, D.; Khan, A.; Iqbal, M. Adoption Constraints of Improved Technologies Regarding Tomato Cultivation in District Mardan, KP. Sarhad J. Agric. 2018, 34, 428–434. [Google Scholar] [CrossRef]

- Weerasinghe, P. Best Practices of Integrated Plant Nutrition System in Sri Lanka. In Best Practices of Integrated Plant Nutrition System in SAARC Countries; Fatema, N.J., Tayan, R.J., Eds.; SAARC Agriculture Centre: Dhaka, Bangladesh, 2014; pp. 143–168. [Google Scholar]

- Chauhan, S.; Deependra, Y.; Kumar, S.; Kumar, R.; Kumar, A. Effect of Calcium on the Growth and Yield of Tomato (Solanum lycopersicum L.). Biol. Forum. 2023, 15, 1162–1166. [Google Scholar]

- Hao, X.; Papadopoulos, A.P. Effects of Calcium and Magnesium on Plant Growth, Biomass Partitioning, and Fruit Yield of Winter Greenhouse Tomato. HortScience 2004, 39, 512–515. [Google Scholar] [CrossRef]

- Shafeek, M.R.; Helmy, Y.I.; El-Tohamy, W.A.; El-Abagy, H.M. Changes in Growth, Yield and Fruit Quality of Cucumber (Cucumis sativus L.) in Response to Foliar Application of Calcium and Potassium Nitrate under Plastic House Conditions. Res. J. Agric. Biol. Sci. 2013, 9, 114–118. [Google Scholar]

- Olaniyi, J.O.; Ajibola, A. Effects of Inorganic and Organic Fertilizers Application on the Growth, Fruit Yield and Quality of Tomato (Lycopersicon lycopersicum). J. Appl. Biosci. 2008, 8, 236–242. [Google Scholar]

- Tuna, A.L. Influence of Foliarly Applied Different Triazole Compounds on Growth, Nutrition, and Antioxidant Enzyme Activities in Tomato (Solanum lycopersicum L.) under Salt Stress. Aust. J. Crop Sci. 2014, 8, 71–79. [Google Scholar]

- EU. Regulation (EC) No. 1272/2008 of the European Parliament and of the Council on Classification, Labelling and PACKAGING of Substances and Mixtures, Amending and Repealing Directives 67/548/EEC and 1999/45/EC, and Amending Regulation (EC) No 1907/2006. 2008. Available online: https://www.fao.org/faolex/results/details/en/c/LEX-FAOC089390 (accessed on 3 September 2024).

- Hortwitz, W. Official and Tentative Methods of Analysis, 9th ed.; Association of Official Agricultural Chemists: Washington, DC, USA, 1960; pp. 314–320. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C.L.W.T. Use of a Free Radical Method to Evaluate Antioxidant Activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Ali, S.; Javed, H.U.; Rehman, R.N.U.; Sabir, I.A.; Naeem, M.S.; Siddiqui, M.Z. Foliar Application of Some Macro and Micro Nutrients Improves Tomato Growth, Flowering and Yield. Int. J. Biosci. 2013, 3, 280–287. [Google Scholar]

- Metkar, S.; Saptarshi, S.; Kadam, A. Studies on Extraction, Isolation and Applications of Lycopene. Indo Am. J. Pharm. Res. 2014, 3, 234–242. [Google Scholar]

- Ainsworth, E.A.; Gillespie, K.M. Estimation of Total Phenolic Contents and Other Oxidation Substances in Plant Tissue Using Folin-Ciocalteu Reagent. Nat. Protoc. 2007, 2, 875–877. [Google Scholar] [CrossRef]

- Liu, D.; Zou, J.; Meng, Q.; Zou, J.; Jiang, W. Uptake and Accumulation and Oxidative Stress in Garlic (Allium sativum L.) under Lead Phytotoxicity. Ecotoxicology 2009, 18, 134–143. [Google Scholar] [CrossRef]

- Stone, H.; Bleibaum, R.N.; Thomas, H.A. Sensory Evaluation Practices, 4th ed.; Elsevier: Amsterdam, The Netherlands; Academic Press: London, UK, 2012; p. 448. [Google Scholar]

- Zhu, S.H.; Zhou, J. Effect of Nitric Oxide on Ethylene Production in Strawberry Fruit During Storage. Food Chem. 2007, 100, 1517–1522. [Google Scholar] [CrossRef]

- Steel, R.G.D.; Torrie, J.H.; Dicky, D.A. Principles and Procedures of Statistics: A Biological Approach, 3rd ed.; McGraw Hill Book Co. Inc.: New York, NY, USA, 1997. [Google Scholar]

- Abrol, G.S.; Thakur, K.S.; Pal, R.; Punetha, S. Role of Calcium in Maintenance of Postharvest Quality of Horticultural Crops. Int. J. Econ. Plants. 2017, 4, 88–93. [Google Scholar]

- Kamal, B.A. Physiological Studies on Nutrition Status and Productivity of Olive Tree under New Land Conditions. Ph.D. Thesis, Zagazig University, Zagazig, Egypt, 2000. [Google Scholar]

- Haleema, B.; Rab, A.; Hussain, S.A.; Sajid, M.; Arif, M.; Shah, S.T. Influence of Calcium Concentrations and Sources on the Fruit Quality of Tomato (Lycopersicon esculentum Mill) at Different Storage Conditions. Fresenius Environ. Bull. 2020, 29, 1866–1877. [Google Scholar]

- Tomar, S.; Rajiv; Beniwal, D.; Sourabh. Effect of Transplanting Dates and Mulching on Growth and Yield of Tomato (Solanum lycopersicum L.). Veg. Sci. 2019, 46, 39–43. [Google Scholar] [CrossRef]

- Bhattarai, D.R.; Gautam, D.R. Effect of Harvesting Method and Calcium on Postharvest Physiology of Tomato. Nepal Agric. Res. J. 2006, 7, 37–41. [Google Scholar] [CrossRef]

- Islam, M.M.; Jahan, K.; Sen, A.; Urmi, T.A.; Haque, M.M.; Ali, H.M.; Siddiqui, M.H.; Murata, Y. Exogenous Application of Calcium Ameliorates Salinity Stress Tolerance of Tomato (Solanum lycopersicum L.) and Enhances Fruit Quality. Antioxidants 2023, 12, 558. [Google Scholar] [CrossRef] [PubMed]

- Tuna, A.L.; Kaya, C.; Ashraf, M.; Altunlu, H.; Yokas, I.; Yagmur, B. The effects of calcium sulphate on growth, membrane stability and nutrient uptake of tomato plants grown under salt stress. Environ. Experiment. Bot. 2007, 59, 173–175. [Google Scholar] [CrossRef]

- Safari, Z.S.; Ding, P.; Zahidi, N.M.; Atif, A.; Wafa, S.; Aziz, A.; Yusoff, S.F. Maintenance of Defence Enzyme Activities in Tomato Fruit During Storage by Chitosan and Vanillin Coating. Int. J. Appl. Sci. Res. 2021, 4, 177–188. [Google Scholar]

- Patane, C.; Pellegrino, A.; Silvestro, I.D. Effects of calcium carbonate application on physiology, yield and quality of field-grown tomatoes in a semi-arid Mediterranean climate. Crop Pasture Sci. 2018, 69, 411–418. [Google Scholar] [CrossRef]

- Kushwaha, R.; Singh, M.; Singh, V.; Puranik, V.; Kaur, D. Variation of Bioactive Compounds and Antioxidant Activity During Ripening of Tomato Cultivars. J. Food Agric. Res. 2021, 1, 15–29. [Google Scholar]

- Santhosh, S.; Chitdeshwari, T.; Chinnasamy, K. Calcium Influences Biochemical and Antioxidant Enzymatic Activities in Tomato Fruits During Storage. J. Appl. Biol. Biotechnol. 2023, 11, 158–164. [Google Scholar] [CrossRef]

- Shehata, S.A.; Abdelrahman, S.Z.; Megahed, M.M.A.; Abdeldaym, E.A.; El-Mogy, M.M.; Abdelgawad, K.F. Extending Shelf Life and Maintaining Quality of Tomato Fruit by Calcium Chloride, Hydrogen Peroxide, Chitosan, and Ozonated Water. Horticulturae 2021, 7, 309. [Google Scholar] [CrossRef]

- Navjot, S.; Gurcharan, S. Studies on Storage Behaviour of Peach cv. Earli Grande. Int. J. Agric. Sci. 2006, 2, 541–543. [Google Scholar]

- Manganaris, G.A.; Vasilakakis, M.; Diamantidis; MignaniIlaria, G. Effect of In-Season Calcium Application on Cell Wall Physicochemical Properties of Nectarine Fruit (Prunus persica var. nectarine Ait. Maxim) After Harvest or Cold Storage. J. Sci. Food Agric. 2006, 86, 2597–2602. [Google Scholar] [CrossRef]

- Kumar, N.; Kaur, P.; Devgan, K.; Attkan, A.K. Shelf Life Prolongation of Cherry Tomato Using Magnesium Hydroxide Reinforced Bio-Nanocomposite and Conventional Plastic Films. J. Food Process. Preserv. 2020, 44, e14379. [Google Scholar] [CrossRef]

- Demes, R.; Satheesh, N.; Fanta, S.W. Effect of Different Concentrations of Gibberellic Acid and Calcium Chloride Dipping on Quality and Shelf-Life of Kochoro Variety Tomato. Philipp. J. Sci. 2021, 150, 335–349. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).