Abstract

Simulated impact damage testing was investigated by fractal image analysis using response surface methodology (RSM) with a central composite design (CCF) on quality of ‘Glom Sali’ guava for drop heights (0.2, 0.4, and 0.6 m), number of drops (1, 3, and 5) and storage temperature conditions (10, 20, and 30 °C). After 48 h, impacted fruit were determined and analyzed for bruise area (BA), bruise volume (BV), browning index (BI), total color difference (∆E), image analysis for bruise area (BAI), and fractal dimension (FD) at the bruising region on peeled guava. Results showed that the correlation coefficient (r = −0.6055) between ∆E and FD value was higher than ∆E and either BA (r = 0.3132) or BV (r = 0.2095). The FD variable was determined as a better indicator than conventional measurement (BA or BV) for pulp browning and impact bruising susceptibility. The FD variable also exhibited highest R2adj value (81.69%) among the other five variables, as the highest precision model with high determination coefficient value (R2adj) (>0.8) for impact bruising prediction. Recommended condition of the FD variable to minimize impact bruising was drop height of 0.53 m for five drops under storage at 30 °C. FD variable assessed by image analysis was shown to be a highly capable measurement to determine impact bruising susceptibility in guava fruit.

1. Introduction

Guava (Psidium guajava L.) is one of the most famous and economically important fruits in Thailand, with an export value in 2020 worth 5.50 million USD [1]. Guava is a climacteric fruit with a round shape and thin skin that bruises easily. To maintain fruit quality and shelf life and minimize losses, guava fruit needs proper postharvest handling practices [2]. Thai agriculture and ASEAN standards of guava require slight defects on the skin not exceeding 10% of the total surface area of guava fruit [3,4]. Bruising effects can be distinguished from quality changes in guava such as browning, softening of the fruit peel, cell destruction, and reduction in intercellular air spaces resulting in the bruised tissue losing moisture and becoming desiccated [5]. Impact damage to fruit is more severe than vibration and compression damages. When a fruit falls with sufficient force against a surface, impact damage occurs, while dynamic damage of a single fruit occurs through fruit-to-fruit impact between packaging. Fruit dropping from trees to the ground during harvesting, dynamic impact between single fruit, and between the fruit and packaging or containers are all causes of impact damage [6].

Most previous researchers studied independent factors such as drop height, number of drops, and storage temperature. Drop heights of 0.04 to 0.75 m were investigated in fruit such as guava [5], apple [7,8,9], pomegranate [10,11,12], peach [13], and pear [14,15]. In apple, bruise volume (BV) increased linearly with an increase of drop height level [16], while different storage temperatures were investigated in apple [9], pomegranate [11,17,18], and pear [14,15]. However, few studies have investigated the number of drops on fruit found that the fourth drop of apple resulted in an irreversible change in cell damage that stabilized the bruise energy [19]. Previous studies on impact bruise damage investigated two independent variables as drop height and storage temperature, with a fixed number of drops by using a completely randomized design (CRD) experiment in apple [9], pomegranate [11,18], and pear [14,15]. Impact bruising area of ‘Pink Lady’ apple was affected by both drop height and storage temperature [9], bruise damage of pomegranate fruit increased at higher drop height with lower storage temperature (5 °C) [18], while in pears bruising was affected by storage temperature with increased susceptibility to bruising at 22 °C [15]. For impact testing of guava, different drop heights and numbers of drop were currently examined in a CRD experiment with a fixed storage temperature of 25 °C [20]. Thus, most studies investigated either individual factors or the combination between drop height and storage temperature as independent variables for impact testing. Few studies have investigated number of drops combined with either drop height or storage temperature.

Response surface methodology (RSM) was used to identify the relationship between independent and response variables to assess the influences of the many factors and their interactions [21]. RSM utilizes a set of mathematical and statistical methods that fit polynomial equations to the experimental data, hence explaining how the data set behaves [22]. Advantages of using RSM were reducing in the number of experimental treatments to evaluate multiple variables and the ability of the statistical tool to identify interaction of independent variable [23,24]. Several researchers used this method for various aspects of experimental design involving extraction process, food preservation, and fruit coating applications [25]. In postharvest research, many studies investigated fruit coating in various fruit such as guava [26], banana [27], pear [28], apple [29], and in postharvest treatment for storage period in lychee [30]. Recently, the number of drops for five times from either 0.3 m or 0.6 m from CRD experiment exhibited the same BA, BV, and bruise susceptibility levels. Also, the number of drops was assumed a major independent variable of impact bruising in ‘Gim Ju’ guava [20]. Thus, influences of environmental factors such as drop height, number of drops, and storage temperature also remain unclear for impact bruising with a limit of different conditions.

Bruise area (BA) and bruise volume (BV) are most commonly used to measure the amount of impact bruise damage in fruit such as apples [8,31,32], pomegranate [10,33], and peach [13]. Browning index (BI) and total color difference (∆E) both showed highest values for medium and high drop impact bruise damage after 48 h incubation time in pomegranate fruit [11]. Increase in skin tissue browning appeared to be correlated with higher storage temperature in persimmon [34]. Fractal dimension (FD) is an image analysis technique used to explain the texture features of the image [35]. Previously, most researchers used image textural features as FD to assess color change in pulp, internal browning incidence, and fruit defects in pear [36], apple [37], banana [38], and cucumber [39] to evaluate fruit quality. Recently, FD analysis has exhibited high potential and accuracy for vibration bruising of guava under simulated transportation utilizing RSM design [40]. Only one study of fractal image analysis has been conducted to determine impact bruising in guava [20]. The recent study in impact bruise testing with different drop heights and number of drops was examined. Results showed that FD calculated by image analysis presented higher potential for bruise assessment in guava fruit. The efficiency of FD analysis showed potential when comparing BA with BV (conventional technique) for impact and vibration bruising assessments [20,40].

Interestingly, there has been no previous studies that applied RSM to examine three independent variables as drop height, number of drops, and storage temperature, with three factor levels for free fall drop testing in guava and other fruit. Therefore, this study (1) examined the optimal impact condition from treatment combinations of drop height, number of drops and storage temperature, and (2) applied fractal image analysis to assess impact bruising in guava fruit utilizing RSM design.

2. Materials and Methods

2.1. Plant Materials and Sample Preparation

Guava fruit cv. ‘Glom Sali’ were randomly collected from Pangha Homestay Orchard, Mae Sai District, Chiang Rai Province, Thailand (latitude 20°24′22.7″ N longitude 100°00′23.9″ E). The guava fruit were harvested at the mature green stage (approximately 100 days after fruit set) having a light green skin color and carefully handled to avoid mechanical injuries. The fruit were packed into plastic baskets and covered with two material layers of foam net and polythene bags as cushioning materials to protect against mechanical injuries during transportation to the laboratory S7 building at Mae Fah Luang University within 3 h. The fruit were sorted for uniformity of size (approximately 250 to 300 g), color, and if they were free of distinct signs of bruising and disease with a smooth and clean peduncle cut surface.

The random ‘Glom Sali’ guava fruit (15 fruits) were selected and examined for fruit properties by checking uniformity, guava maturity, fruit weight, volume, density, diameter, radius of curvature, firmness, total soluble solids (TSS), and dry matter. Average weight of guava and density fruit were 250.26 g and 0.98 g mL−1 (Table 1). Fruit density at <1.0 indicates top quality at the mature stage for harvesting and optimal consumer acceptability. The highest bruise susceptibility was occurred in the cheek region of the fruit [17], while the middle and top regions of apple showed higher bruise sensitivity than the bottom region for fruit-to-fruit bruising [41]. In this study, the cheek region was exposed to the highest impact under free fall drop test. The averaged radius of curvature at the cheek region of this guava fruit was 50.94 mm (Table 1).

Table 1.

Fruit characteristics of ‘Glom Sali’ guava subjected to simulated impact testing.

2.2. Bruise Susceptibility Testing of Guava Fruit

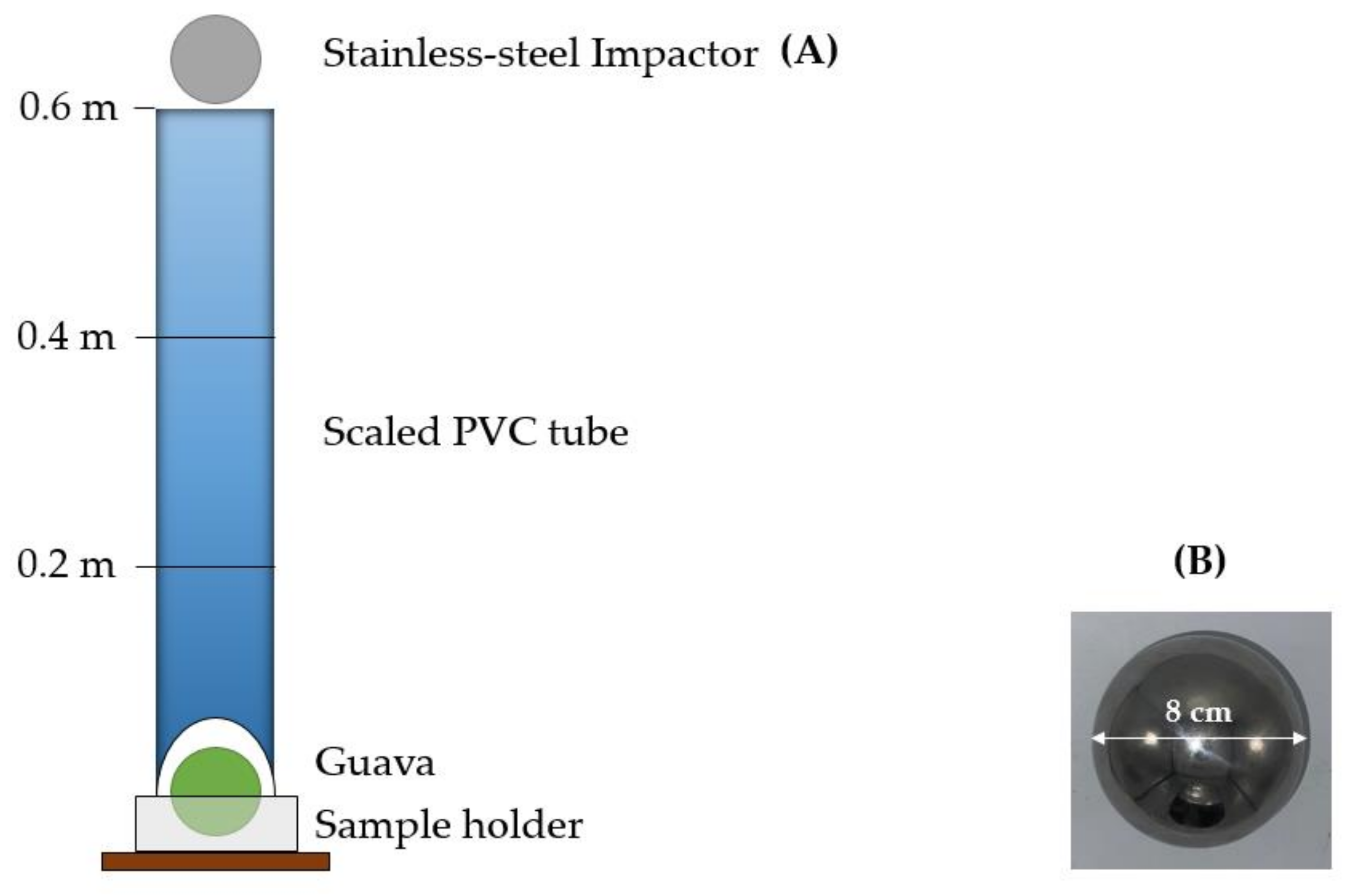

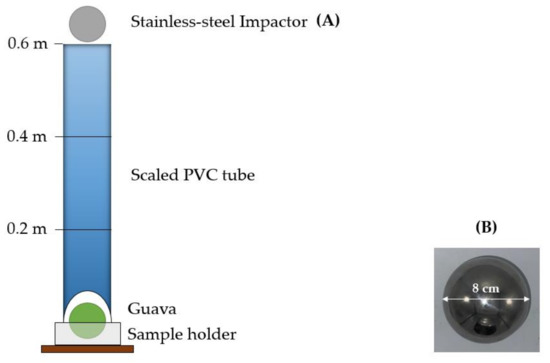

Simulated impact testing was set up utilizing a 9 cm-diameter pipe, following the method of Hussein et al. [33] for pomegranate impact testing. As shown in Figure 1, each fruit was located over a shallow depression (8 cm diameter) in a foam sheet material with dimensions 20 × 23 × 2 cm. A stainless-steel ball (diameter 8 cm and weight 250 g) of equal size and weight to a guava fruit was dropped on each guava fruit from three different drop heights (0.2, 0.4, and 0.6 m) for 1, 3, and 5 drops at each drop height.

Figure 1.

Experimental setup of simulated impact testing in guava (A) with stainless-steel ball (250 g, diameter 8 cm) (B), adapted following the method of [33].

The impact energy (E) was calculated using the equation of E = mgh, where m is the guava mass, g is the gravitational constant (9.81 m s−2), and h is the drop height (m) [33]. As shown in Table 2, the impact energy of a stainless-steel ball for 1, 3, and 5 drops at each of the three drop heights ranged from 507.05 to 7273.60 J. After impact testing, the fruit were stored at three temperature conditions (10, 20, and 30 °C under 90% RH) and checked for quality measurement after 48 h (see Section 2.3 for more information).

Table 2.

Impact energy for three drop heights (0.2, 0.4, and 0.6 m) and number of drops (1, 3, and 5 times).

After simulated impact testing, the bruised guava sample was peeled using a sharp knife with peel thickness of 0.9 mm to reveal browning of the flesh before impact bruising was determined.

2.3. Experimental Design by Response Surface Methodology (RSM)

RSM with central composite face-centered design (CCF) was examined to evaluate the main interaction and quadratic effects of drop height, number of drops, and temperature on impact bruising and color change of the guava fruit (Table 3).

Table 3.

Coded independent variables of drop height, number of drops, and storage temperature for RSM with central composite face-centered design (CCF).

As shown in Table 4, the three independent variables of CCF design with 20 treatments (runs) were coded as −1 (lowest level), 0 (middle level), and +1 (highest level), and applied with the cube point for 8 times, axial point for 6 times, and the repeated center point (0.0.0) for 6 times. The three independent variables were drop height (X1) (0.2, 0.4, and 0.6 m), number of drops (X2) (1, 3, and 5 times), and storage temperature (X3) (10, 20, and 30 °C). In this study, drop heights (0.2, 0.4, and 0.6 m) were compared with a range of drop heights (0.04 to 0.6 m) onto a rigid impact surface in previous studies on pomegranate [11,12,18], apple [7], and pear [14,15]. Five drops were assumed to be the maximum number throughout the guava supply chain [42]. The optimal storage temperature for guava was recommended at 10 °C [43], while temperature during road transportation in open trucks was estimated to average 30 °C. The response function was determined as bruise area (BA), bruise volume (BV), browning index (BI), total color difference (∆E), bruise area by image analysis (BAI), and fractal dimension (FD). The response function value (Y) was related to the coded three independent variables (Xi, 1, 2, and 3) following Equation (1).

Table 4.

RSM with central composite face-centered design (CCF) to optimize simulated impact conditions of ‘Glom Sali’ guava.

Response data of the three independent variables to the six dependent variables as BA, BV, BI, ∆E, BAI, and FD were examined, and the quadratic polynomial fitting was accomplished. The equation of the prediction model is shown as polynomial Equation (1).

where, Y is the representation of the predicted response functions (BA, BV, BI, ∆E, BAI, and FD), X1, X2, and X3 are the three independent variables (drop heights, number of drops, and storage temperature), X12, X22 and X32 are the square of each independent variables. The coefficients of the polynomial were denoted by b0 (constant term), b1, b2 and b3 (linear effects), b11, b22 and b33 (quadratic effects), and b12, b13 and b23 (interaction effects).

Y = b0 + b1X1 + b2X2 + b3X3 + b11X12 + b22X22 + b33X32 + b12X1X2 + b23X2X3 + b13X1X3

2.4. Quality Measurements

2.4.1. Bruise Determination of the Guava Fruit

After impact testing, the guava fruit were stored at 10, 20, and 30 °C with 90% RH (Constant climate chamber, HPP750, Memmert GmbH + Co. KG, Schwabach, Germany) and checked for quality measurement after 48 h when the bruised tissues had turned pale [44]. BA and BV, commonly used to measure the amount of fruit bruise damage, were determined for fruit damage in apple [32]. BA and BV of each fruit were calculated by Equations (2) and (3).

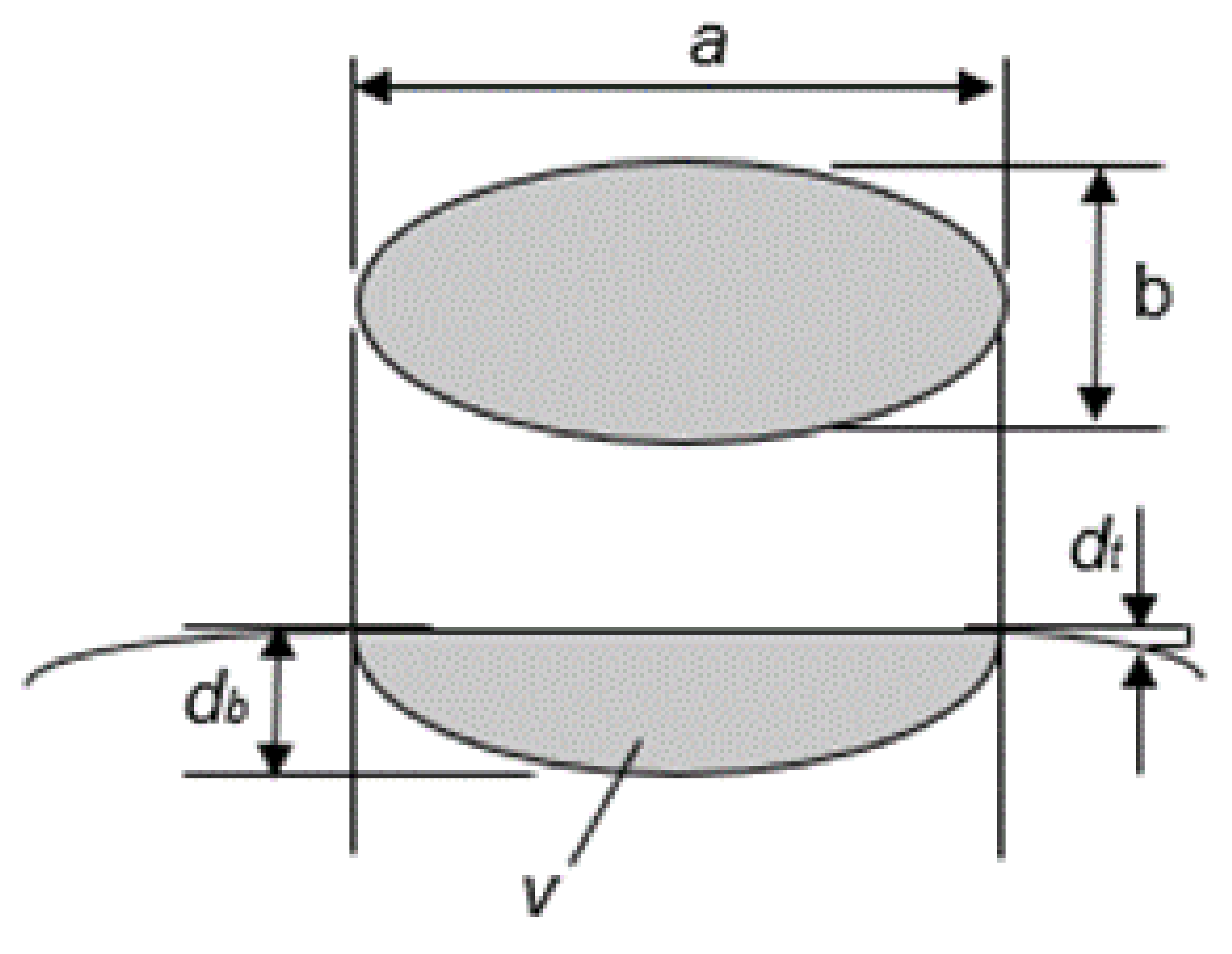

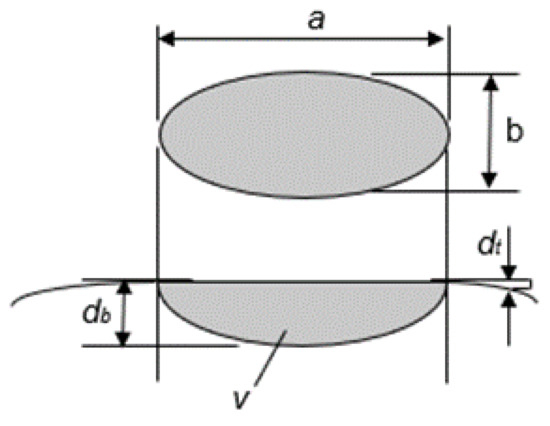

where, a and b are the major axes of the bruise elliptical and d is bruise depth measured by peel thickness [10]. These bruise parameters were measured by a digital caliper (RS PRO 150 mm, RS Components Pte Ltd., Clarke Quay, Singapore) with ±0.01 (mm) accuracy in Figure 2.

BA = π/4 (ab)

BV = πd/24 (3ab + 4d2)

Figure 2.

Determining bruise area and volume by using the elliptical method [10].

2.4.2. Pulp Color at Bruise Area

The guava was peeled to reveal either wet bruising (translucent) or browning incidence at four positions with three positions at no bruising region and one position at middle of bruising region that were measured in the equation zone for each fruit by a CIE-Lab color colorimeter (Konica Minolta, Color Reader CR-10, Osaka, Japan) to determine bruise lightness (L*), redness (a*), yellowish (b*). Browning index (BI) was calculated to represent purity of the brown color [45] using Equations (4) and (5). Total color difference (∆E) was calculated using different color levels on fruit peel (L*, a*, and b* values) between initial (before impact bruise) [46] and after impact damage for 48 h at the bruise area using Equation (6).

where, L0*, a0*, and b0* are the initial color values of the peeled fruit, L*, a*, and b* are the final values at bruised area after storage at 10, 20, and 30 °C with 90% RH for 48 h.

BI = [100 * (X − 0.31)]/0.172

When, X = (a* + 1.75L*)/(5.645L* + a* − 3.012b*)

∆E = ((L0* − L*)2 + (a0* − a*)2 + (b0* − b*)2)1/2

2.4.3. Image Analysis

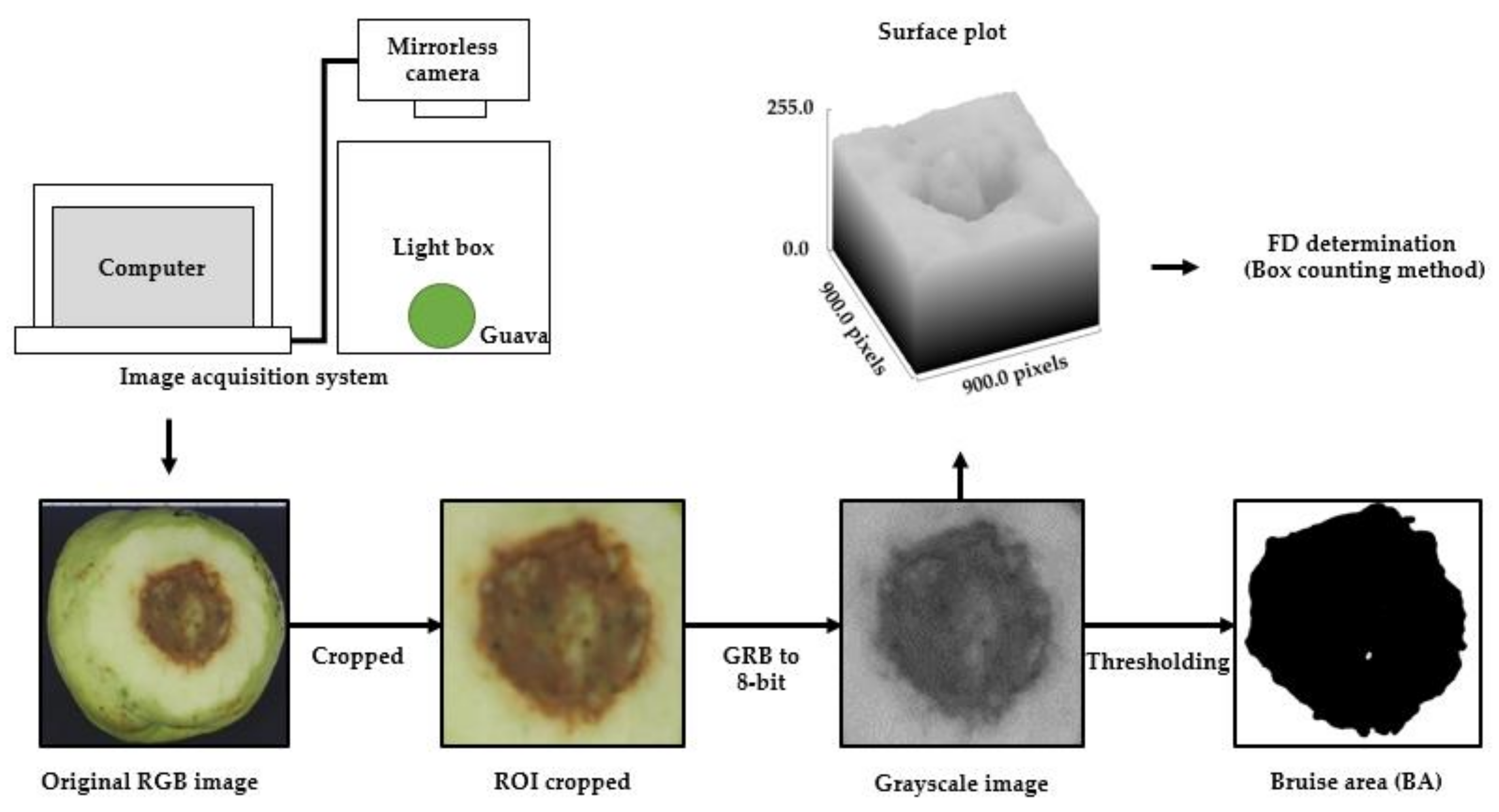

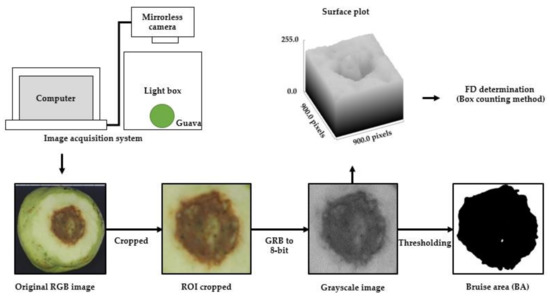

The bruise region on the fruit surface after impact testing was placed under a square light box (UDIOBIZ 40D, size 40 × 40 × 40 cm, adjustable light, pocket studio with 4 rows of LED as light source intensity 9.6 × 105 lux using a light meter (Tenmars TM-204, Taipei, Taiwan). Guava images were taken at a uniform distance of 40 cm, with camera settings on manual mode, autofocus, lens capture f 7.1, 1/250 shutter speed, and ISO 100 using a digital mirrorless camera (Canon EOS M50, 15–45 mm, Tokyo, Japan). The original image files (6000 × 3368 pixels) were saved in JPEG format with 72-dpi resolution. Guava bruise damage images were analyzed by ImageJ software (version 1.51j8, NIH, Bethesda, MD, USA) following the method of Chaiwong et al. [40]. All original images were pre-processed and resized. The image analysis procedure is shown in Figure 3. The resized image was cropped around the bruising area, which is the region of interest (ROI). After that, the RGB image was converted into an 8-bit image (grayscale), then the surface plot of bruising image was determined by plotting the grayscale values (z-axis) of each pixel in the image (x- and y-axis). The surface plot showed the roughness of bruise surface texture due to the variation of grayscale level in each pixel of the image. Moreover, the 8-bit image was thresholded to convert to be the binary image. Then, the binary image of bruising was computed as a percentage of the bruise region corresponding to the entire flesh area.

Figure 3.

Image acquisition system and image analysis procedure for impact bruise determination.

The intensity of fruit bruise damage was estimated using the binary image. The Fractal dimension (FD) values of the bruise images were then determined using the fractal box counting technique by intercepting N number of various box size r (2–128 pixels) with the binary image. FD value was calculated as FD = log(Nr)/log(1/r) [40].

2.5. Statistical Analysis

The effect of each of the three independent factors, lack-of-fit, and regression coefficients (R2) in individual linear, quadratic, and interaction terms was determined in analysis of variance (ANOVA) tables and generated to establish the model equation by Minitab version 19 (Minitab, LLC, State college, PA, USA). Three-dimensional response surface plots were created using the overlaid contour plot feature in MATLAB software version R2018a (MathWorks Inc., Natick, MA, USA). Predictive equations for the thirteen treatments within the experimental range conditions were checked for correctness (Table 5). To generate a matrix plot using PAST 4.05 software, all variables were evaluated using Pearson’s correlation (p < 0.05).

Table 5.

Thirteen treatments to verify the predictive model in ‘Glom Sali’ guava impact bruising by simulated impact testing.

3. Results and Discussion

3.1. Fractal Image Analysis and Correlation between Bruise Susceptibility and Color

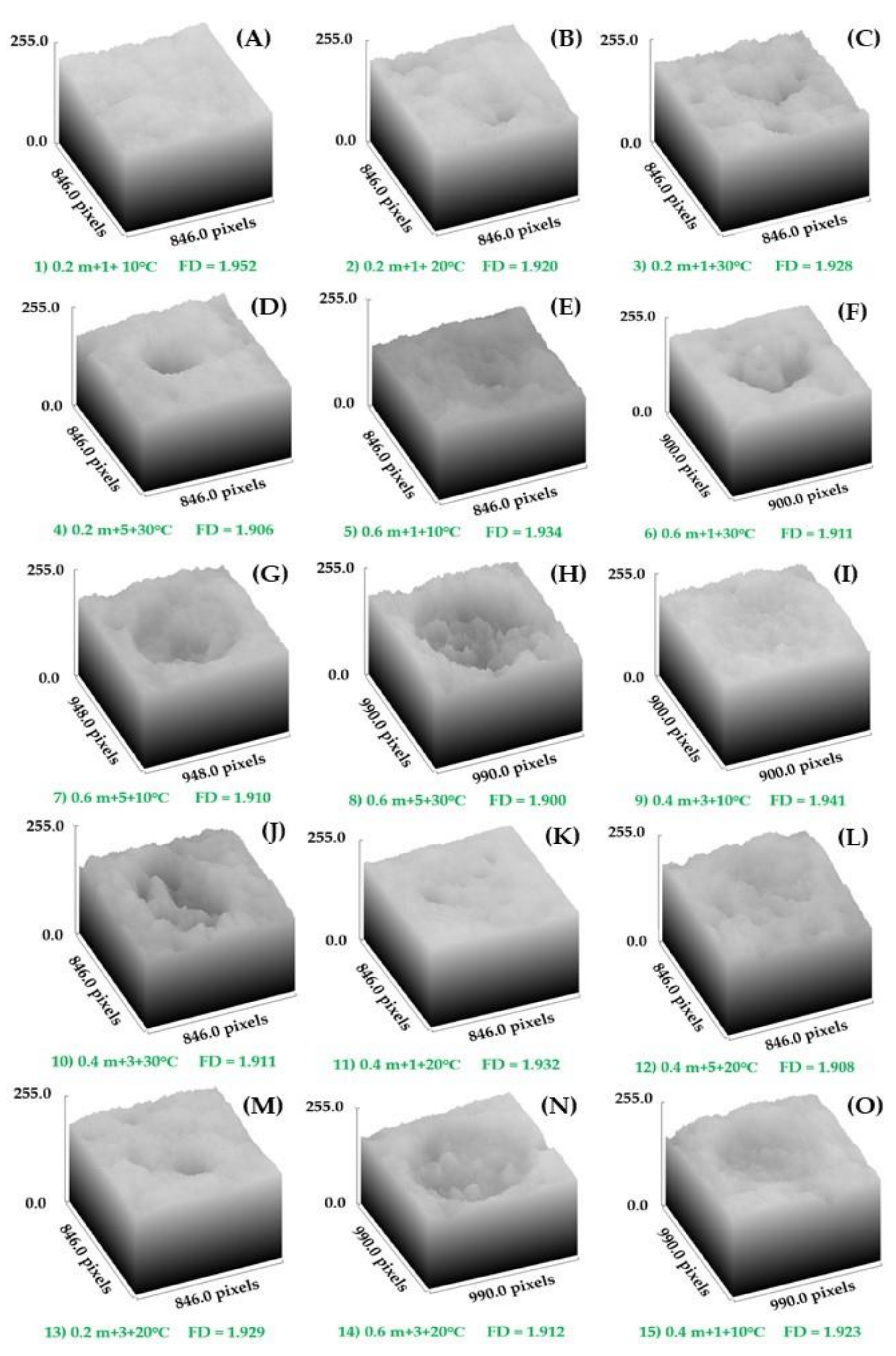

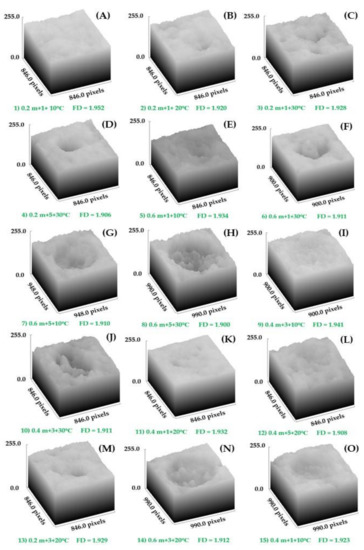

The intensity of fruit bruise damage was analyzed by converting cropped RGB images and calculating the FD values. Using the threshold method, the bruise damage region was cropped and then separated. Before applying a box counting method to determine FD values, the selected BA was transformed into a binary image (Figure 4). Fractal image analysis of guava impact bruising was varied in the drop test under RSM design (Table 4). Image analysis revealed visible damage to the peeled guava surface. A greater impact bruise with lower FD value exhibited as a significantly deeper surface plot image, which related to the low value of grayscale that came from the dark brown color of bruising, relating to increase in drop height, number of drops, and storage temperature. For example, the deepest surface plot image with the lowest FD value (1.900) was a drop height of 0.6 m for five drops (E = 7273.60 J) (Table 2) for storage condition at 30 °C (Figure 4H). Lower storage temperature at 10 °C with drop height (0.6 m) and five drops (E = 7273.60 J) (Table 2) exhibited the deepest surface with FD value (1.910) (Figure 4G), while the shallowest surface with the highest FD value (1.952) was a drop height of 0.2 m for one drop and storage at 10 °C (Figure 4A). In previous studies, image analysis was used to obtain FD values for lightness and darkness of the surface to assess bruising or browning of banana [38]. Fractal modeling was used to assess the intensity of flesh browning and its color change to acquire improved knowledge of the enzymatic chemical changes and their location within the apple fruit [37]. Recently, it was found that higher impact bruising for both drop heights of 0.3 and 0.6 m repeated five times. Results showed a deeper surface plot with lower FD values of 1.937 and 1.930, respectively, after storage at 25 °C for 48 h [20]. Therefore, fractal image analysis in this study successfully performed impact bruising severity of guava under different drop test conditions utilizing RSM design. Recently, the advanced techniques, i.e., hyperspectral, computerized, and X-ray imaging had successfully achieved assessing bruise severity accurately; however, these techniques required higher invest in the machine and complex computational processes to interpret the data. Although, application of FD was only suitable for characterizing the external bruising such as vibrational bruising damage [40], this technique using simple equipment and data processing technique that may have a change to apply for various commodities.

Figure 4.

Fifteen pictures of fractal dimension (FD) of surface plots in impact bruising of guava for different drop heights, number of drops, and storage temperature variables under RSM design from fifteen runs (treatments) after storage for 48 h. The fifteen runs were 0.2 m + 1 drop + 10 °C (A), 0.2 m + 1 drop + 20 °C (B), 0.2 m + 1 drop + 30 °C (C), 0.2 m + 5 drops + 30 °C (D), 0.6 m + 1 drop + 10 °C (E), 0.6 m + 1 drop + 20 °C (F), 0.6 m + 5 drops + 10 °C (G), 0.6 m + 5 drops + 30 °C (H), 0.4 m + 3 drops + 10 °C (I), 0.4 m + 3 drops + 30 °C (J), 0.4 m + 1 drop + 20 °C (K), 0.4 m + 5 drops + 20 °C (L), 0.2 m + 3 drops + 20 °C (M), 0.6 m + 3 drops + 20 °C (N), 0.4 m + 1 drop + 10 °C (O).

Guava fruit peel is thin and delicate and easily damaged by rough handling during harvest and postharvest [2]. In this study, Pearson’s correlation was performed to establish the relationship between the six measured dependent variables BA, BV, BI, ∆E, BAI, and FD. The FD variable showed good agreement with the ∆E parameter (r = −0.6055) when compared with BA, BV, BI, and BAI, while color measurement and analysis of BI and ∆E parameters for impact guava bruising correlated poorly with bruise damages (BA and BV) as well as FD. Thus, image analysis (FD) was a good indicator to respond to browning incidence of impact guava bruising as the ∆E variable from 20 different impact conditions (Table 6). Heterogeneous changes of fruit and vegetable surfaces such as color intensity and enzymatic browning reaction had a strong correlation with FD value variations [47]. For bruise formation of fresh-cut apple, the higher potential of image analysis detected that ∆E value correlated to color changes [48]. Image analysis by the FD method offers great potential for application where color intensity has a non-homogenous color surface [36]. Increase in the FD value in the selected area indicated major complexity in color distribution during the enzymatic browning kinetic for banana [38]. For vibration bruising of guava, FD analysis exhibited high potential and accuracy under frequency, acceleration, and time duration of vibration testing [40]. For impact bruising of guava, FD analysis showed higher potential than color measurements to evaluate impact bruise damage under testing conditions such as drop height, number of drops, and storage temperature [20]. Thus, the FD variable was a good indicator for impact bruising of guava under varying conditions of drop height, number of drops, and storage temperature. Therefore, high efficacy of the FD technique was suggested to assess mechanical damages in guava, with applications on other sensitive fruit from impact and vibration forces.

Table 6.

Bruise assessment parameters of guava fruit stored at 25 °C under 70% RH for four days.

In this study, ∆E was a better indicator for impact bruising damage of guava than BI and showed high correlation with the FD variable. Both browning scores and ∆E parameters revealed highest values in pomegranate corresponding to medium and high drop impact bruise damage [11]. At medium and maximum drop levels, a high ∆E value indicated impact bruising of pomegranate [18]. Variations in ∆E value correlated to changes in color of fresh-cut apple over time [48]. Interestingly, the BAI parameter from the image analysis technique showed positive correlation with BA (r = 0.9975). Bruise area by image analysis was suggested to apply for BA measurement as a conventional technique, with calculation as Equation (2) to determine the impact bruising area of guava.

3.2. Model Fitting and Statistical Analysis of CCF

RSM values utilizing CCF from 20 treatments (runs) performed the correlation of the response data between three independent variables and six dependent variables (BA, BV, BI, ∆E, BAI, and FD) (Table 4) by quadratic multiple regression equations as follows (Equations (7) to (12)).

Y1 (BA) = 219.8 − 2.3X1 + 57.7X2 + 117.1X3 − 7.1X12 − 107.6X22 + 47.5X32 − 2.0X1X2 + 4.3X1X3 + 29.0X2X3

Y2 (BV) = 2559 + 1525X1 + 386X2 + 862X3 + 4895X12 − 3977X22 − 2294X32 + 4X1X2 + 25X1X3 + 372X2X3

Y3 (BI) = 97.42 + 4.72X1 − 3.50X2 + 1.06X3 + 4.72X12 + 5.03X22 − 0.35X32 − 5.48X1X2 − 0.90X1X3 − 1.64X2X3

Y4 (∆E) = 4.159 + 2.183X1 + 0.491X2 + 0.775X3 + 1.140X12 − 0.927X22 + 0.567X32 − 0.106X1X2 + 0.666X1X3 + 0.007X2X3

Y5 (BAI) = 233.5 + 0.3X1 + 56.6X2 + 117.1X3 − 7.3X12 − 108.6X22 + 48.5X32 − 4.1X1X2 + 0.3X1X3 + 28.1X2X3

Y6 (FD) = 1.9177 − 0.0117X1 − 0.0097X2 − 0.0068X3 + 0.0049X12 − 0.0011X22 − 0.0006X32 + 0.0029 X1X2 + 0.0026X1X3 + 0.0004X2X3

Table 7 shows the coefficient results of RSM regression equations generated from the ANOVA analysis of BA, BV, BI, ∆E, BAI, and FD models. The predicted six models (BA, BV, BI, ∆E, BAI, and FD) provided the determination coefficient (R2adj) values of 0.5304, 0.0868, 0.2227, 0.5751, 0.4960, and 0.8169, respectively. These findings indicated that the FD model provided higher response performance than the BA, BV, BI, ∆E, and BAI model predictions. The lack of fit values of the five models (BA, BI, ∆E, BAI, and FD) were not remarkable, except that the BV model showed low levels of reliability and repeatability, with significant lack of fit and R2adj (8.68%). The FD variable exhibited the highest R2adj value (81.69%), representing the highest precision model for impact bruising prediction among the other five variables. Also, the ∆E model with R2adj value (57.51%) exhibited greater liability for impact bruising prediction than BI with R2adj value (22.27%). In this study, FD exhibited the highest dependent variable for impact damage of guava due to a significant correlation with ∆E (Table 6) as well as the highest levels of reliability and repeatability (Table 7).

Table 7.

ANOVA results of each drop height (X1) (m), number of drops (X2) (times), and temperature (X3) (°C) factors as response surface models for BA, BV, BI, ∆E, BAI, and FD values of impact bruise of ‘Glom Sali’ guava fruit.

Until recently, no RSM experiments investigating free fall or impact testing had been conducted for impact bruising susceptibility at various drop heights, number of drops and temperature conditions to simulate the effects on guava and other sensitive fruit. Only two RSM studies on vibration testing for fruit bruising used two independent variables to design vibration conditions of tomato [49] and three independent variables to design vibration conditions of guava [40]. Most studies on simulated impact bruise damage only focused on experimental designs by fixing one or two variables. With their fruit size and spherical shape similar to guava fruit, pomegranate and apple were tested under two variables of three drop heights and two storage temperature conditions with a fixed number of drops [9,11,17], while pear bruises were determined using two variables with three drop heights and two storage temperature conditions with a fixed number of drops [14,15]. Recently, impact bruising using two variables of three drop heights and member of drops (one and five times) on bruise assessment in guava fruit was examined [20]. Thus, no clear factor analysis has demonstrated impact fruit bruising under three independent variables.

In this study, an RSM design for simulated impact testing identified three major independent variables in guava bruising with both individual and combined effects. The ANOVA result showed that all linear coefficients (drop height (X1), number of drops (X2), and temperature (X3)) affected the FD model. The linear coefficients (X1) and (X3) also affected color changes (∆E) and both BA and BAI models, respectively. The quadratic drop height (X12) only had an effect on the BV model (Table 7). Most previous studies focused on two independent variables (drop height and storage temperature) with a fixed number of drop heights using CRD design in pomegranate [11,18], ‘Pink Lady’ apple [9], and pear [14,15]. For example, in the study of pomegranate fruit, storage temperature factors affected impact bruising with higher refrigerated storage temperature reducing bruise damage [17]. The drop height factor combined with impact materials affected bruise area measurement in apples [9], while the combination of drop height and storage temperature showed the highest increase in bruise area, bruise volume, and color measurements in pear fruit [14,15]. Recently, the number of drops (five drops) from different heights (0.3 and 0.6 m) affected impact bruising of guava more than the same drop height (0.3 and 0.6 m) with a single drop [20]. Therefore, this is the first study to undertake impact test by RSM experiment for this bruising in guava and other fruit. However, this study of RSM design did not exhibit significant cross-product coefficients among the three independent variables from six dependent variables. Therefore, the linear model was suggested as optimal to predict impact bruising of guava compared with the quadratic model (Table 7). Previous studies investigated impact bruising volume of apple, with impact energy ranging 0 to 2.25 J. Results showed that linear regression fitted the impact energy for apple sizes of 180 and 240 g, with high coefficient of determination (R2) values at 0.94 and 0.93, respectively [50]. There was also a high linear relationship (R2 = 0.94) between BV and drop height for BV of apple [16]. Recently, a strong linear regression between impact bruise susceptibility and color parameters in pear at different drop heights and storage temperatures was found by Pathare [14].

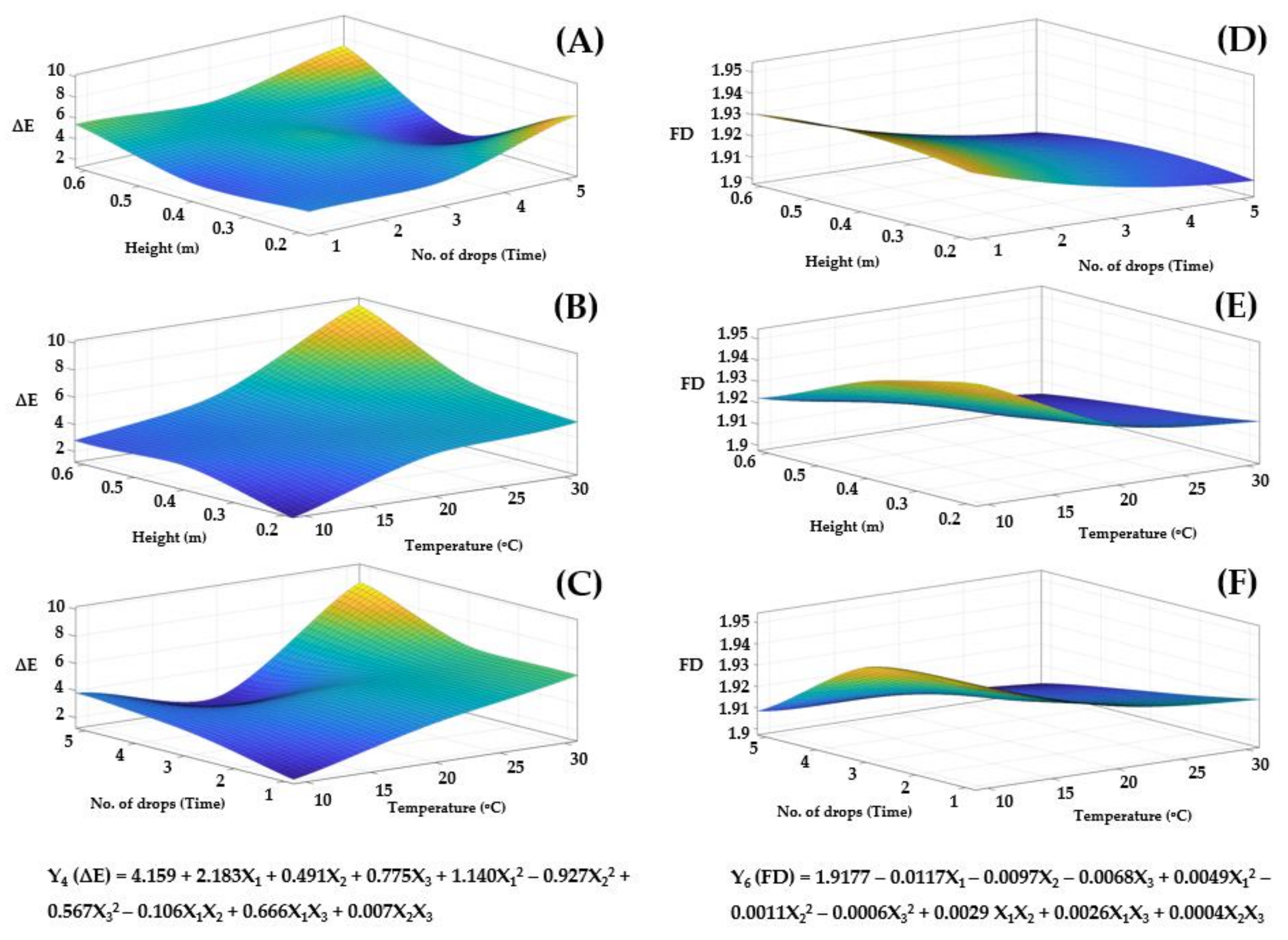

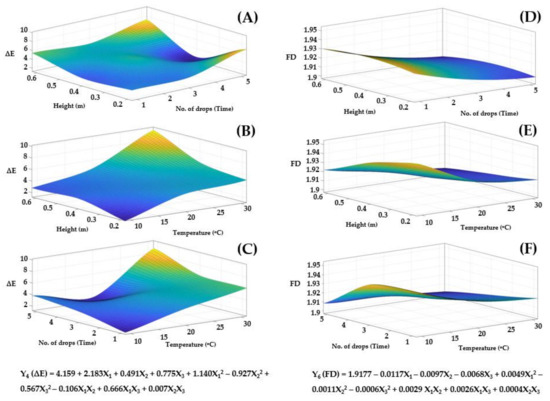

The FD model was optimized by setting minimum conditions as drop height of 0.53 m for five drops under storage temperature of 30 °C (Equation (12)). To minimize the FD value, postharvest handling of guava must be gentle to avoid impact bruising, coupled with a cool storage temperature. Response surface analysis of CCF (Figure 5) showed that surfaces of the BA, BV, BI, and BAI models for drop height, number of drops, and storage temperature showed no interaction between X1X2, X2X3, and X1X3 (Table 6), while the ∆E model became steeper with increasing number of drops and storage temperature. The 3D graphs of FD model indicated that increasing number of drops and storage temperature in the slope of the curved surface and lower steepness (Figure 5F), giving linear model (p < 0.05) (Table 7) when compared with ∆E response surface with a non-significant impact in both number of drops and storage temperature (p > 0.05) (Figure 5C) (Table 7).

Figure 5.

Response surface plot graphs of ∆E and FD variables were created from Equations (10) and (12), respectively. Response surface plots demonstrating effects of drop height, number of drops, and storage temperature on total color difference (∆E) and fractal dimension (FD) (D–F) in ‘Glom Sali’ guava impact bruising at various drop heights and number of drops (A,D), different drop heights and temperature (B,E), and different number of drops and storage temperature (C,F).

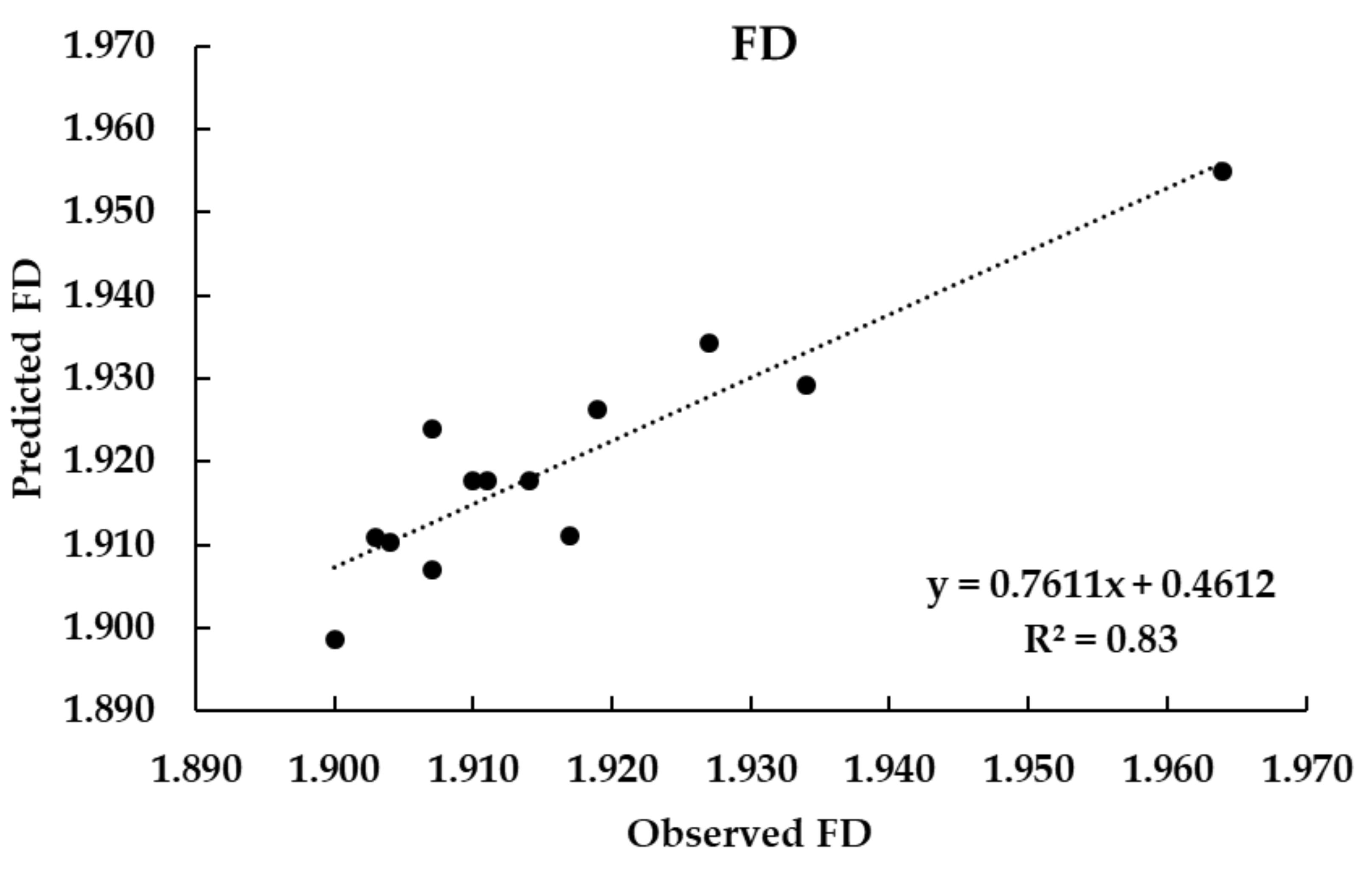

3.3. Validation Testing of CCF

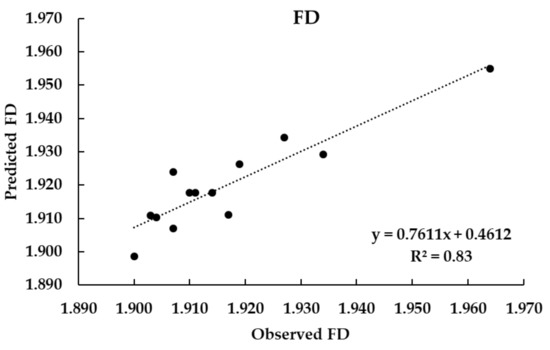

Validation of impact bruise damage of guava fruit focused on image analysis by FD (0.82) variables, with higher determination coefficient (R2adj) value of the predicted model compared to ∆E (0.57), BA (0.53), BAI (0.50), BI (0.2227), and BV (0.09) (Table 7). To evaluate and confirm the predicted FD model value for impact bruising (Equation (12)), the model was verified using thirteen treatments in a range of 20 RSM conditions with three independent variables. As shown in Figure 6, the predicted value of FD exhibited a high linear correlation with the observed value of FD (R2 = 0.83) for impact bruise assessment of guava. Thus, FD by image analysis was proven to predict impact bruising of guava with high determination coefficient value (R2adj) (>0.8) of the predicted model, with no significant lack of fit compared to the validated model. In a previous study, high values of both R2 and R2val were recorded for a polynomial equation (plotting between drop height and storage period) at five drop times, with drop heights of 0.3 (0.95 and 0.88) and 0.6 m (0.99 and 0.92), respectively. The FD value exhibited a higher accuracy for impact bruise prediction with greater bruise susceptibility in guava fruit [20]. Most previous researchers conducted fruit quality evaluation using the FD method to assess internal browning and color change in the flesh [36,38], including fruit bruising [51]. Classification models based on the FD parameter attained a total accuracy rate of 100%, while the support vector machine model based on RGB values only realized 85.29% for bruising detection on red bayberries [51].

Figure 6.

Verification of predictive model equations for fractal dimension (FD) values in ‘Glom Sali’ bruised guava by impact testing for 48 h.

4. Conclusions

Impact bruising of ‘Glom Sali’ guava was evaluated using fractal image analysis and RSM design. The FD variable of peeled guava exhibited good agreement with ∆E, indicating that impact bruising browning incidence compared well with BI. Lower FD value correlated with higher impact bruising severity of guava and supported conventional bruise determination. This study represents the first report applying RSM design to assess impact bruising of guava and other fruit. RSM performed for drop height, number of drops, and storage temperature factors showed individual effects on impact bruising of guava. The recommended condition to minimize impact bruising was drop height of 0.53 m for five drops coupled with storage temperature at 30 °C. To reduce impact bruising incidence of guava throughout its supply chain, careful handling to reduce impact energy is suggested, with storage under cool conditions. Impact bruising of guava can be ameliorated by cushioning material to protect fruit areas with high radius of curvature. Future RSM studies should be performed on spherical or delicate fruit to assess impact bruising related to browning incidence.

Author Contributions

T.H. conducted experiments, analyzed data, interpreted results, and assisted manuscript writing; R.S. was the co-investigator of the research, interpreted results, and assisted image data analysis; N.A. assisted data analysis; K.T. provided comments and suggestions for the final draft of the manuscript; S.C. was the principal investigator of the research, responsible for the overall research management, interpretation of results, and manuscript writing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Thailand International Cooperation Agency (TICA) and Mae Fah Luang University, Chiang Rai, Thailand.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request corresponding author.

Acknowledgments

The authors gratefully acknowledge the Thailand International Cooperation Agency (TICA) and the Integrated AgriTech Ecosystem Research Group (IATE), Scientific and Technological Instruments Center, Mae Fah Luang University for financial and equipment support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Thai Customs. The Exported Guava from Thailand from 2015–2019. 2021. Available online: http://www.customs.go.th/statistic_report.php?lang=en&ini_content=statistics_report&fbclid=IwAR3fgvhby1iB4O9LUuMedqNtqYNS_ZfyBOOqjPJnBGQlXT6zEWd18v577YQ (accessed on 12 February 2021).

- Singh, S.P. Guava (Psidium guajava L.). In Postharvest Biology and Technology of Tropical and Subtropical Fruits Volume 3: Cocona to Mango; Yahia, E.M., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 213–245. [Google Scholar]

- ASEAN Stan 7:2008. ASEAN Standard for Guava. 2008. Available online: https://asean.org/storage/2012/05/7-ASEAN-STANDARD-FOR-GUAVA-2008.pdf (accessed on 2 February 2021).

- Thai Agricultural Standard TAS 16-2010. Thai Agricultural Standard for Guava. 2020. Available online: https://www.acfs.go.th/standard/download/eng/guava.pdf (accessed on 2 February 2021).

- Nila, I.; Harmoko, A.; Imawan, C. The prediction system of bruising depth of guava (Psidium guajava L.) based on Vis-NIR imaging. In Proceedings of the 2017 International Conference on Sustainable Information Engineering and Technology (SIET), Malang, Indonesia, 24–25 November 2017; pp. 420–424. [Google Scholar]

- Li, Z.; Thomas, C. Quantitative evaluation of mechanical damage to fresh fruits. Trends Food Sci. Technol. 2014, 35, 138–150. [Google Scholar] [CrossRef]

- Lu, L.; Wang, Z.W. Dropping bruise fragility and bruise boundary of apple fruit. Trans. ASABE 2007, 5, 1323–1329. [Google Scholar]

- Lu, F.; Ishikawa, Y.; Kitazawa, H.; Satake, T. Measurement of impact pressure and bruising of apple fruit using pressure-sensitive film technique. J. Food Eng. 2010, 96, 614–620. [Google Scholar] [CrossRef] [Green Version]

- Celik, H.K.; Ustun, H.; Erkan, M.; Rennie, A.E.W.; Akinci, I. Effects of bruising of ‘Pink Lady’ apple under impact loading in drop test on firmness, colour and gas exchange of fruit during long term storage. Postharvest Biol. Technol. 2021, 179, 111561. [Google Scholar] [CrossRef]

- Shafie, M.; Rajabipour, A.; Mobli, H. Determination of bruise incidence of pomegranate fruit under drop case. Int. J. Fruit Sci. 2017, 17, 1–14. [Google Scholar]

- Hussein, Z.; Fawole, O.; Opara, U. Determination of physical, biochemical and microstructural changes in impact-bruise damaged pomegranate fruit. J. Food Meas. Charact. 2019, 13, 2177–2189. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.O. Effects of bruising and storage duration on physiological response and quality attributes of pomegranate fruit. Sci. Hortic. 2020, 267, 109306. [Google Scholar] [CrossRef]

- Tabatabaekoloor, R. Engineering properties and bruise susceptibility of peach fruits (Prunus persica). Agric. Eng. Int. CIGR J. 2013, 15, 244–252. [Google Scholar]

- Pathare, P. Bruise susceptibility and impact on quality parameters of pears during storage. Front. Sustain. Food Syst. 2021, 5, 658132. [Google Scholar] [CrossRef]

- Pathare, P.B.; Al-Dairi, M.; Al-Mahdouri, A. Bruise damage susceptibility and fruit quality assessment of pear. Open Agric. J. 2021, 15, 82–90. [Google Scholar] [CrossRef]

- Aboud, A.J. Study on factors affecting apple bruises under drop loading. In Proceedings of the 14th. Annual Conference of the Misr Society of Agriculture Engineering, Cairo, Egypt, 22 November 2006; pp. 876–887. [Google Scholar]

- Shafie, M.; Rajabipour, A.; Castro-Garcia, S.; Jiménez-Jiménez, F.; Mobli, H. Effect of fruit properties on pomegranate bruising. Int. J. Food Prop. 2015, 18, 1837–1846. [Google Scholar] [CrossRef] [Green Version]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Bruise damage susceptibility of pomegranates (Punica granatum, L.) and impact on fruit physiological response during short term storage. Sci. Hortic. 2019, 246, 664–674. [Google Scholar] [CrossRef]

- Krzysztof, G.; Paweł, R.; Zbigniew, S. The determination of apples bruise resistance by the multiple impact method. Technol. Sci. 2009, 12, 29–39. [Google Scholar]

- Htike, T.; Saengrayap, R.; Kitazawa, H.; Chaiwong, S. Fractal image analysis and bruise susceptibility evaluation of impact damage in guava. 2021; Manuscript submitted for publication. [Google Scholar]

- Lin, X.; Wang, L.; Hou, Y.; Zheng, Y.; Jin, P. A combination of melatonin and ethanol treatment improves postharvest quality in bitter melon fruit. Foods 2020, 9, 1376. [Google Scholar] [CrossRef]

- Ranade, S.; Thiagarajan, P. Selection of a design for response surface. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 022043. [Google Scholar] [CrossRef] [Green Version]

- Cissé, M.; Montet, D.; Loiseau, G.; Ducamp-Collin, M.-N. Influence of the concentrations of chitosan and glycerol on edible film properties showed by response surface methodology. J. Environ. Polym. Degrad. 2012, 20, 830–837. [Google Scholar] [CrossRef]

- Nandane, A.; Jain, R. Study of mechanical properties of soy protein based edible film as affected by its composition and process parameters by using RSM. J. Food Sci. Technol. 2014, 54, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Said, K.; Afizal, M. Overview on the response surface methodology (RSM) in extraction processes. J. Appl. Sci. Process Eng. 2016, 2, 8–17. [Google Scholar]

- Zahid, M.; Cheow, C.S.; Norizzah, A.R.; Halimahton, M.; Md Sikin, A.; Noorakmar, A.; Ishak, R. Optimization of process conditions for the application of edible coating emulsion on guava (Psidium guajava) using response surface methodology. In Proceedings of the International Conference on Biotechnology and Food Science (IPCBEE), Bali Islan, Singapore, 1–3 April 2011; pp. 61–65. [Google Scholar]

- Jafarizadeh, H.; Osman, A.; Tan, C.; Abdul Rahman, R. Development of an edible coating based on chitosan-glycerol to delay ‘Berangan’ banana (Musa sapientum cv. Berangan) ripening process. Int. Food Res. J. 2011, 18, 989–997. [Google Scholar]

- Nandane, A.S.; Dave, R.K.; Rao, T.V.R. Optimization of edible coating formulations for improving postharvest quality and shelf life of pear fruit using response surface methodology. J. Food Sci. Technol. 2017, 54, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Rashid, F.; Ahmed, Z.; Ameer, K.; Amir, R.A.I.; Khattak, M. Optimization of polysaccharides-based nanoemulsion using response surface methodology and application to improve postharvest storage of apple (Malus domestica). J. Food Meas. Charact. 2020, 14, 2676–2688. [Google Scholar] [CrossRef]

- Tran, D.T.; Hertog, M.; Nicolaï, B.M. Hierarchical response surface methodology for optimization of postharvest treatments to maintain quality of litchi cv. ‘Thieu’ during cold storage. Postharvest Biol. Technol. 2016, 117, 94–101. [Google Scholar] [CrossRef]

- Lewis, R.; Yoxall, A.; Canty, L.A.; Romo, E.R. Development of engineering design tools to help reduce apple bruising. J. Food Eng. 2007, 83, 356–365. [Google Scholar] [CrossRef] [Green Version]

- Gharaghani, A.; Shahkoomahally, S. Cultivar and fruit size influence bruise susceptibility and some physical properties of apple fruit. Iran Agric. Res. 2018, 37, 49–56. [Google Scholar]

- Hussein, Z.; Fawole, O.; Opara, U. Investigating bruise susceptibility of pomegranate cultivars during postharvest handling. J. Rural Dev. 2017, 2, 33–39. [Google Scholar]

- Lee, H.J.; Kim, T.-C.; Kim, S.J.; Park, S.J. Bruising injury of persimmon (Diospyros kaki cv. Fuyu) fruits. Sci. Hortic. 2005, 103, 179–185. [Google Scholar] [CrossRef]

- Zheng, C.; Sun, D.-W.; Zheng, L. Recent developments and applications of image features for food quality evaluation and inspection—A review. Trends Food Sci. Technol. 2006, 17, 642–655. [Google Scholar] [CrossRef]

- Quevedo, R.; Díaz, O.; Caqueo, A.; Ronceros, B.; Aguilera, J.M. Quantification of enzymatic browning kinetics in pear slices using non-homogenous L* color information from digital images. LWT 2009, 42, 1367–1373. [Google Scholar] [CrossRef]

- Quevedo, R.; Jaramillo, M.; Díaz, O.; Pedreschi, F.; Aguilera, J.M. Quantification of enzymatic browning in apple slices applying the fractal texture Fourier image. J. Food Eng. 2009, 95, 285–290. [Google Scholar] [CrossRef]

- Quevedo, R.; Díaz, O.; Ronceros, B.; Pedreschi, F.; Aguilera, J.M. Description of the kinetic enzymatic browning in banana (Musa cavendish) slices using non-uniform color information from digital images. Food Res. Int. 2009, 42, 1309–1314. [Google Scholar] [CrossRef]

- Van Eck, J.W.; van der Heijden, G.W.A.M.; Polder, G. Accurate measurement of size and shape of cucumber fruits with image analysis. J. Agric. Eng. Res. 1998, 70, 335–343. [Google Scholar] [CrossRef]

- Chaiwong, S.; Yoythaisong, P.; Arwatchananukul, S.; Aunsri, N.; Tontiwattanakul, K.; Trongsatitkul, T.; Kitazawa, H.; Saengrayap, R. Vibration damage in guava during simulated transportation assessed by digital image analysis using response surface methodology. Postharvest Biol. Technol. 2021, 181, 111641. [Google Scholar] [CrossRef]

- Fu, H.; Karkee, M.; He, L.; Duan, J.; Li, J.; Zhang, Q. Bruise patterns of fresh market apples caused by fruit-to-fruit impact. Agronomy 2020, 10, 59. [Google Scholar] [CrossRef] [Green Version]

- Kamsiati, E. Postharvest handling practices in maintaining quality and shelf life of guava (Psidium guajava). In Proceedings of the International Conference on Agricultural Postharvest Handling, and Processing, Jakarta, Indonesia, 19–20 November 2013; pp. 363–373. [Google Scholar]

- Urbano, B.; Ribeiro, R.; Cavalini, F.; Pedro, J.; Trevisan, M. Temperature-related changes in respiration and Q10 coefficient of Guava. Sci. Agric. 2005, 62, 458–463. [Google Scholar]

- Komarnicki, P.; Stopa, R.; Kuta, Ł.; Szyjewicz, D. Determination of apple bruise resistance based on the surface pressure and contact area measurements under impact loads. Comput. Electron. Agric. 2017, 142, 155–164. [Google Scholar] [CrossRef]

- Palou, E.; López-Malo, A.; Barbosa-Cánovas, G.; Welti-Chanes, J.; Swanson, B. Polyphenoloxidase activity and color of blanched and high hydrostatic pressure treated banana puree. J. Food Sci. 1999, 64, 42–45. [Google Scholar] [CrossRef]

- Balaban, M.; Aparicio, J.; Zotarelli, M.; Sims, C. Quantifying nonhomogeneous colors in agricultural materials. Part II: Comparison of machine vision and sensory panel evaluations. J. Food Sci. 2008, 73, S438–S442. [Google Scholar] [CrossRef] [PubMed]

- Quevedo, R.; Pedreschi, F.; Bastias, J.M.; Díaz, O. Correlation of the fractal enzymatic browning rate with the temperature in mushroom, pear and apple slices. LWT 2016, 65, 406–413. [Google Scholar] [CrossRef]

- Subhashree, S.N.; Sunoj, S.; Xue, J.; Bora, G.C. Quantification of browning in apples using colour and textural features by image analysis. Food Qual. Saf. 2017, 1, 221–226. [Google Scholar] [CrossRef]

- Widhiantari, I.A.; Sutan, S.M.; Gunomo, D. Optimization of tomato fruit color after simulated transport using response surface methodology (RSM). Int. J. Food Sci. Nutr. Eng. 2016, 6, 42–47. [Google Scholar]

- Jarimopas, B.; Singh, S.; Sayasoonthorn, S.; Singh, J. Comparison of package cushioning materials to protect post-harvest impact damage to apples. Packag. Technol. Sci. 2007, 20, 315–324. [Google Scholar] [CrossRef] [Green Version]

- Lu, H.; Zheng, H.; Hu, Y.; Lou, H.; Kong, X. Bruise detection on red bayberry (Myrica rubra Sieb. & Zucc.) using fractal analysis and support vector machine. J. Food Eng. 2011, 104, 149–153. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).