Packaging Design to Protect Hongmeiren Orange Fruit from Mechanical Damage during Simulated and Road Transportation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Packaging Formats

2.1.1. Format of Packaging A

2.1.2. Format of Packaging B

2.1.3. Format of Packaging C

2.2. Transportation Experiment

2.2.1. Simulated Transportation

2.2.2. Road Transportation

2.3. Fruit Supply

2.4. Damage Rate and Decay Rate Statistics

2.5. Vibration Transmissibility

2.6. Software and Statistical Analyses

3. Results

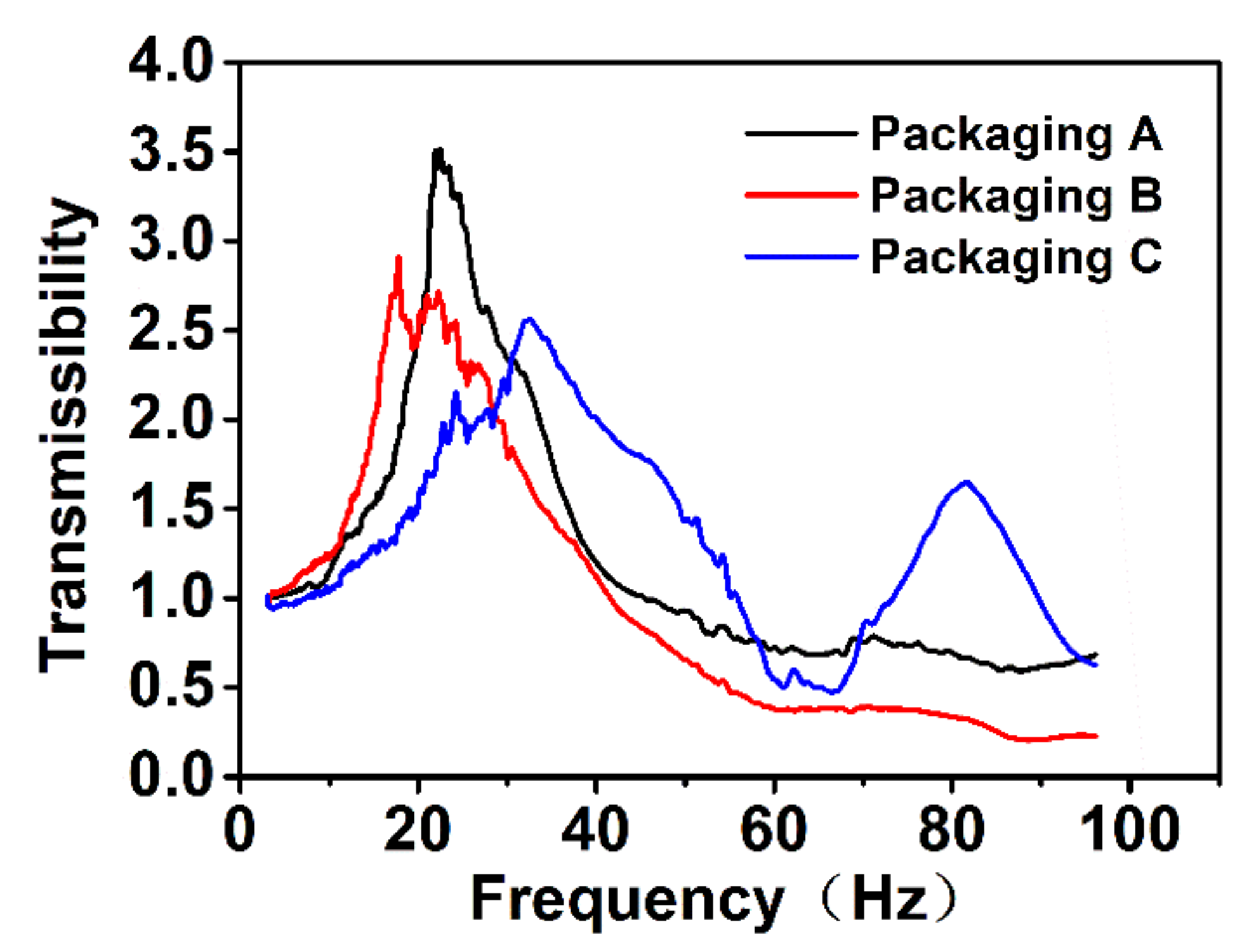

3.1. Vibration Transmissibility and Response Acceleration

3.2. Protective Performance of Three Packaging Formats in Simulated Transportation with Two Distances

3.2.1. Simulated Transportation for 3 h

3.2.2. Simulated Transportation for 10 h

3.2.3. Analysis of Protective Capabilities of Packaging B and C

3.3. Effect of Temperature and Humidity on Susceptibility to Mechanical Damage of Fruit Packaged by Packaging C during Simulated Transportation

3.3.1. Analysis of Different Transportation Temperatures

3.3.2. Analysis of Different Transportation Humidity

3.4. Road Transportation

3.4.1. Comparison of Packaging A and C in Road Test A

3.4.2. Effect of Packaging C at Different Stack Positions and Heights on A Lorry in Road Test B

3.4.3. Results of Acceleration Measurements in Road Test C

4. Discussion

4.1. Discussion on Packaging for Transportation of the Citrus Susceptible to Mechanical Damage

4.2. Discussion on the Delicate Balance between Fruit Decay and Internal Packaging Waste

4.3. Discussion on the Effect of Transport Environment on the Susceptibility of Fruits to Mechanical Damage

4.4. Discussion on the Effect of Position and Height of Fruits in the Truck to the Susceptibility to Mechanical Damage

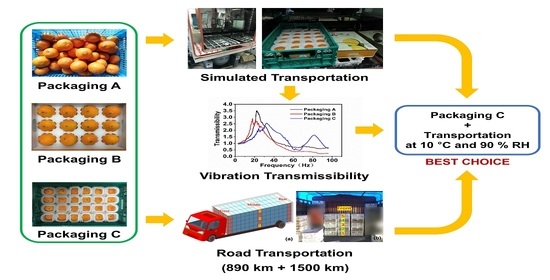

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Porat, R.; Lichter, A.; Terry, L.A.; Harker, R.; Buzby, J. Postharvest losses of fruit and vegetables during retail and in consumers’ homes: Quantifications, causes, and means of prevention. Postharvest Biol. Technol. 2018, 139, 135–149. [Google Scholar] [CrossRef] [Green Version]

- Nattaporn, J.; Krittika, T. Effect of storage time and relative humidity on transportability of sweet tamarind. Acta Hortic. 2010, 151–156. [Google Scholar] [CrossRef]

- Golombek, S.D.; Blanke, M.M. Orchard management strategies to reduce bruises on apples in India: A review. Vegetos 2022. [Google Scholar] [CrossRef]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Fernando, I.; Fei, J.; Stanley, R.; Enshaei, H.; Eyles, A. Quality deterioration of bananas in the post-harvest supply chain—An empirical study. Mod. Supply Chain Res. Appl. 2019, 1, 135–154. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Singh, S.P.; Singh, J.J.; Sittipod, S.; Swasdee, D.; Pratheepthinthong, S. Measurement and analysis of truck and rail vibration levels in Thailand. Packag. Technol. Sci. 2010, 23, 91–100. [Google Scholar] [CrossRef] [Green Version]

- Shigematsu, Y.; Kita, K.; Yakushiji, H.; Ishikawa, K.; Inoue, H. The new citrus cultivar ‘Ehime Kashi No. 28′. Bull. Ehime Fruit Tree Exp. Stn. (Jpn.) 2005, 19, 1–6. [Google Scholar]

- Hurst, P.; Termine, P.; Karl, M. Agricultural Workers and Their Contribution to Sustainable Agriculture and Rural Development; International Labour Organization (ILO), Food and Agriculture Organization of the United Nations (FAO), International Union of Food, Agricultural, Hotel, Restaurant, Catering, Tobacco and Allied Workers’ Associations (IUF): Genève, Switzerland, 2007. [Google Scholar]

- Okudai, N.; Matsumoto, R.; Oiyama, I.; Takahara, T.; Ishiuchi, D.; Asada, K.; Murata, H. New citrus [Citrus reticulata] cultivar “Nankou” [Japan]. Bull. Fruit Tree Res. Stn. (Jpn.) 1991, 20, 71–77. [Google Scholar]

- Chen, X.; Chen, M.; Xu, C.; Yam, K.L. Critical review of controlled release packaging to improve food safety and quality. Crit. Rev. Food Sci. Nutr. 2019, 59, 2386–2399. [Google Scholar] [CrossRef]

- Fernando, I.; Fei, J.; Stanley, R.; Enshaei, H. Measurement and evaluation of the effect of vibration on fruits in transit—Review. Packag. Technol. Sci. 2018, 31, 723–738. [Google Scholar] [CrossRef]

- Ge, C. Theory and practice of cushion curve: A supplementary discussion. Packag. Technol. Sci. 2019, 32, 185–197. [Google Scholar] [CrossRef]

- Ge, C.; Pan, L. Vibration damage rate curves for quantifying abrasion of printed packaging in accelerated random vibration test. Packag. Technol. Sci. 2018, 31, 71–81. [Google Scholar] [CrossRef]

- Saade, C.; Annous, B.A.; Gualtieri, A.J.; Schaich, K.M.; Liu, L.; Yam, K.L. System feasibility: Designing a chlorine dioxide self-generating package label to improve fresh produce safety part I: Extrusion approach. Innov. Food Sci. Emerg. Technol. 2017, 43, 102–111. [Google Scholar] [CrossRef]

- Saade, C.; Annous, B.A.; Gualtieri, A.J.; Schaich, K.M.; Liu, L.; Yam, K.L. System feasibility: Designing a chlorine dioxide self-generating package label to improve fresh produce safety part II: Solution casting approach. Innov. Food Sci. Emerg. Technol. 2018, 47, 110–119. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Singh, S.P. Testing and comparison of various packages for mango distribution. J. Test. Eval. 2004, 32, 69–72. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Sittipod, S.; Swasdee, D.; Rachtanapun, P.; Singh, S.P.; Singh, J.A. Effect of truck vibration during transport on damage to fresh produce shipments in Thailand. J. Appl. Packag. Res. 2009, 3, 27–38. [Google Scholar]

- Barchi, G.L.; Berardinelli, A.; Guarnieri, A.; Ragni, L.; Fila, C.T. PH—Postharvest Technology: Damage to loquats by vibration-simulating intra-state transport. Biosyst. Eng. 2002, 82, 305–312. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Singh, S.P. Packaging performance comparison for distribution and export of papaya fruit. Packag. Technol. Sci. 2005, 18, 125–131. [Google Scholar] [CrossRef]

- Zhou, R.; Su, S.; Li, Y. Effects of cushioning materials on the firmness of Huanghua pears (Pyrus pyrifolia Nakai cv. Huanghua) during distribution and storage. Packag. Technol. Sci. 2008, 21, 1–11. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Chen, L.; Chukwu, O.; Opara, U.L. Susceptibility of apples to bruising inside ventilated corrugated paperboard packages during simulated transport damage. Postharvest Biol. Technol. 2016, 118, 111–119. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Kamhangwong, D.; Singh, S.P. Comparison of reusable and single-use plastic and paper shipping containers for distribution of fresh pineapples. Packag. Technol. Sci. 2008, 21, 73–83. [Google Scholar] [CrossRef]

- Lin, M.; Chen, J.; Chen, F.; Zhu, C.; Wu, D.; Wang, J.; Chen, K. Effects of cushioning materials and temperature on quality damage of ripe peaches according to the vibration test. Food Packag. Shelf Life 2020, 25, 100518. [Google Scholar] [CrossRef]

- ASTM (ASTM D4169-2016); Standard Practice for Performance Testing of Shipping Containers and Systems. ASTM International: West Conshohocken, PA, USA. [CrossRef]

- Zhang, L.; Yang, C.; Wang, Y.; Pan, D.; Meng, X.; Tong, T. Vibration and impact performance tests of cherry tomato transport packages. Trans. Chin. Soc. Agric. Mach. 2011, 42, 125–130, 155. [Google Scholar]

- Böröcz, P.; Singh, S.P. Measurement and analysis of delivery van vibration levels to simulate package testing for parcel delivery in Hungary. Packag. Technol. Sci. 2018, 31, 342–352. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Singh, S.P.; Singh, J.J.; Stallings, J.; Grewal, G. Measurement and analysis of vehicle vibration for delivering packages in small-sized and medium-sized trucks and automobiles. Packag. Technol. Sci. 2012, 25, 31–38. [Google Scholar] [CrossRef] [Green Version]

- Jarimopas, B.; Singh, S.P.; Saengnil, W. Measurement and analysis of truck transport vibration levels and damage to packaged tangerines during transit. Packag. Technol. Sci. 2005, 18, 179–188. [Google Scholar] [CrossRef]

- Yam, K.L. Encyclopedia of Packaging Technology; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2009. [Google Scholar]

- CPP Soroka, W. Fundamentals of Packaging Technology; DEStech Publications Inc.: Lancaster, PA, USA, 2009. [Google Scholar]

- Rouillard, V.; Lamb, M. On the effects of sampling parameters when surveying distribution vibrations. Packag. Technol. Sci. 2008, 21, 467–477. [Google Scholar] [CrossRef]

- Vursavuş, K.K.; Özgüven, F. Determining the effects of vibration parameters and packaging method on mechanical damage in golden delicious apples. Turk. J. Agric. For. 2004, 28, 311–320. [Google Scholar] [CrossRef]

- Chen, H.; Yin, Y.; Pan, H.; Bao, X.; Li, S.; Xu, Q.; Xu, X. Loss factor analysis of mechanical damage and cushioning protection measure for Citrus reticulate Blanco. Trans. Chin. Soc. Agric. Eng. 2018, 34, 258–266. [Google Scholar] [CrossRef]

- Fernando, I.; Fei, J.; Stanley, R. Measurement and analysis of vibration and mechanical damage to bananas during long-distance interstate transport by multi-trailer road trains. Postharvest Biol. Technol. 2019, 158, 110977. [Google Scholar] [CrossRef]

- Verghese, K.; Lewis, H.; Lockrey, S.; Williams, H. Packaging’s role in minimizing food loss and waste across the supply chain. Packag. Technol. Sci. 2015, 28, 603–620. [Google Scholar] [CrossRef]

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Zoffoli, J.P.; Rodriguez, J. Fruit temperature affects physical injury sensitivity of sweet cherry during postharvest handling. Acta Hortic. 2014, 1020, 111–114. [Google Scholar] [CrossRef]

- DeMartino, G.; Massantini, R.; Botondi, R.; Mencarelli, F. Temperature affects impact injury on apricot fruit. Postharvest Biol. Technol. 2002, 25, 145–149. [Google Scholar] [CrossRef]

- Crisosto, C.H.; Garner, D.; Doyle, J.; Day, K.R. Relationship between fruit respiration, bruising susceptibility, and temperature in sweet cherries. Hortscience 1993, 28, 132–135. [Google Scholar] [CrossRef] [Green Version]

- Mohammad Shafie, M.; Rajabipour, A.; Castro-García, S.; Jiménez-Jiménez, F.; Mobli, H. Effect of fruit properties on pomegranate bruising. Int. J. Food Prop. 2015, 18, 1837–1846. [Google Scholar] [CrossRef] [Green Version]

- Lu, F.; Xu, F.; Li, Z.; Liu, Y.; Wang, J.; Zhang, L. Effect of vibration on storage quality and ethylene biosynthesis-related enzyme genes expression in harvested apple fruit. Sci. Hortic. 2019, 249, 1–6. [Google Scholar] [CrossRef]

- Berardinelli, A.; Donati, V.; Giunchi, A.; Guarnieri, A.; Ragni, L. Effects of transport vibrations on quality indices of shell eggs. Biosyst. Eng. 2003, 86, 495–502. [Google Scholar] [CrossRef]

- Soleimani, B.; Ahmadi, E. Measurement and analysis of truck vibration levels as a function of packages locations in truck bed and suspension. Comput. Electron. Agric. 2014, 109, 141–147. [Google Scholar] [CrossRef]

- Zhou, R.; Su, S.; Yan, L.; Li, Y. Effect of transport vibration levels on mechanical damage and physiological responses of huanghua pears (Pyrus pyrifolia Nakai cv. Huanghua). Postharvest Biol. Technol. 2007, 46, 20–28. [Google Scholar] [CrossRef]

- Berardinelli, A.; Donati, V.; Giunchi, A.; Guarnieri, A.; Ragni, L. Damage to pears caused by simulated transport. J. Food Eng. 2005, 66, 219–226. [Google Scholar] [CrossRef]

- Slaughter, D.C.; Thompson, J.F.; Hinsch, R.T. Packaging Bartlett pears in polyethylene film bags to reduce vibration injury in transit. Trans. Am. Soc. Agric. Eng. 1998, 41, 107–114. [Google Scholar] [CrossRef]

- Shahbazi, F.; Rajabipour, A.; Mohtasebi, S.; Rafie, S. Simulated in-transit vibration damage to watermelons. J. Agric. Sci. Technol. 2010, 12, 23–34. [Google Scholar] [CrossRef]

| Section | Packaging Format | Temperature (°C) | Humidity (% RH) | Time (h) | |

|---|---|---|---|---|---|

| Materials and Methods | Results | ||||

| Section 2.2.1 | Section 3.2.1 | Packaging A, B, C | 20 | 90 | 3 |

| Section 2.2.1 | Section 3.2.2 | Packaging A, B, C | 20 | 90 | 10 |

| Section 2.2.1 | Section 3.3.1 | Packaging C | 10 and 20 | 90 | 3 and 10 |

| Section 2.2.1 | Section 3.3.2 | Packaging C | 20 | 70 and 90 | 3 and 10 |

| Section | Transportation | Packaging Format | Time (h) | Distance (km) | |

|---|---|---|---|---|---|

| Materials and Methods | Results | ||||

| Section 2.2.2 | Section 3.4.1 | Road Test A | Packaging A and C | 13 | 890 |

| Section 2.2.2 | Section 3.4.2 | Road Test B | Packaging C | 30 | 1500 |

| Package Format | Natural Frequency (Hz) | Maximum Response Acceleration (g) | Maximum Vibration Transmissibility |

|---|---|---|---|

| Packaging A | 21.96 ± 0.47 a | 1.82 ± 0.01 a | 3.62 ± 0.01 a |

| Packaging B | 17.88 ± 1.31 a | 1.70 ± 0.07 a | 2.98 ± 0.12 b |

| Packaging C | 32.67 ± 4.01 b | 1.36 ± 0.04 b | 2.64 ± 0.07 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, D.; Chen, J.; Lin, M.; Wang, D.; Lin, Q.; Cao, J.; Yang, X.; Duan, Y.; Ye, X.; Sun, C.; et al. Packaging Design to Protect Hongmeiren Orange Fruit from Mechanical Damage during Simulated and Road Transportation. Horticulturae 2022, 8, 258. https://doi.org/10.3390/horticulturae8030258

Zheng D, Chen J, Lin M, Wang D, Lin Q, Cao J, Yang X, Duan Y, Ye X, Sun C, et al. Packaging Design to Protect Hongmeiren Orange Fruit from Mechanical Damage during Simulated and Road Transportation. Horticulturae. 2022; 8(3):258. https://doi.org/10.3390/horticulturae8030258

Chicago/Turabian StyleZheng, Dandan, Jiahui Chen, Menghua Lin, Da Wang, Qiong Lin, Jingping Cao, Xiangzheng Yang, Yuquan Duan, Xianming Ye, Chongde Sun, and et al. 2022. "Packaging Design to Protect Hongmeiren Orange Fruit from Mechanical Damage during Simulated and Road Transportation" Horticulturae 8, no. 3: 258. https://doi.org/10.3390/horticulturae8030258

APA StyleZheng, D., Chen, J., Lin, M., Wang, D., Lin, Q., Cao, J., Yang, X., Duan, Y., Ye, X., Sun, C., Wu, D., Wang, J., & Chen, K. (2022). Packaging Design to Protect Hongmeiren Orange Fruit from Mechanical Damage during Simulated and Road Transportation. Horticulturae, 8(3), 258. https://doi.org/10.3390/horticulturae8030258