Parameter Optimization of the Harvest Method in the Standardized Hedge Cultivation Mode of Lycium barbarum Using Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

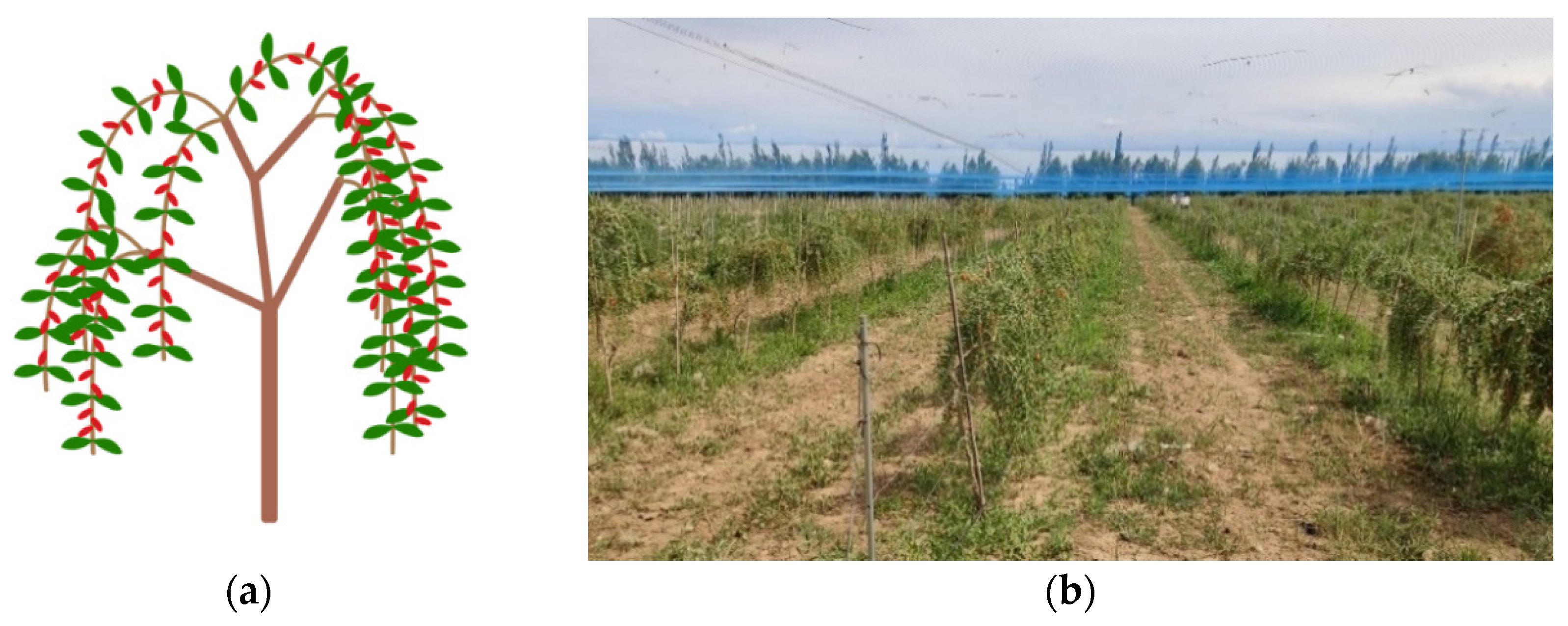

2.1. Standardized Hedge Cultivation Mode

2.2. Overall Structure and Operating Principle

2.2.1. Overall Structure

2.2.2. Operating Principle

2.3. Design of Key Systems

2.3.1. Execution System

2.3.2. Motion System

2.3.3. Control System

2.4. Performance Experiment

3. Results and Discussion

3.1. Regression Analysis

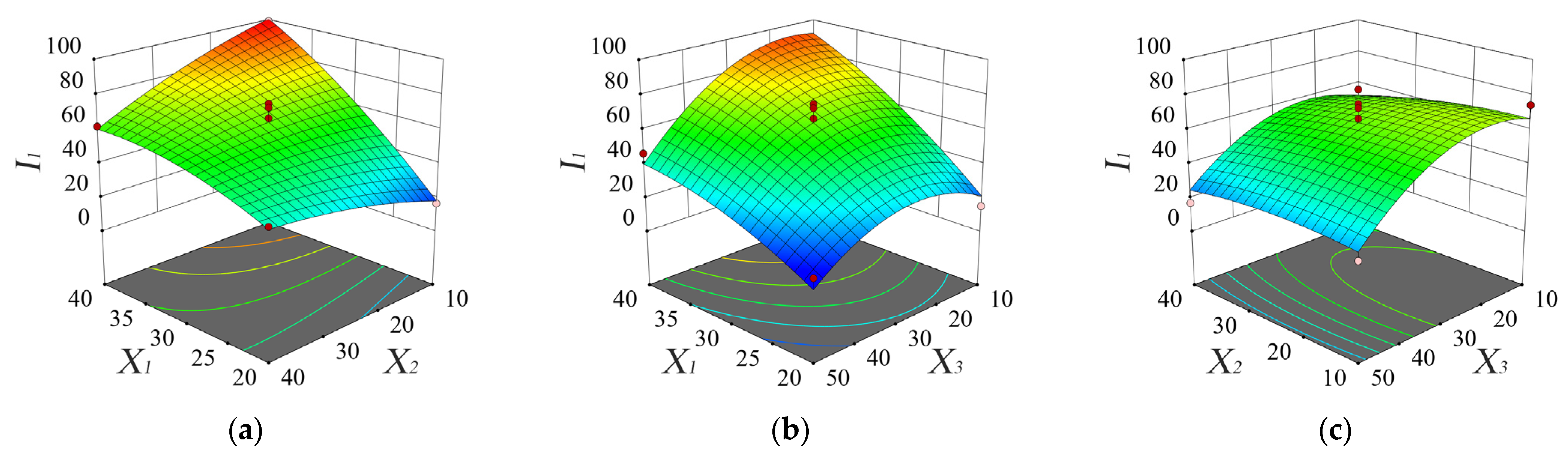

3.2. Response Surface Analysis

3.3. Field Experiment Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, L.; Chen, J.; Wu, G.; Yuan, Q.; Ma, S.; Yu, C.; Duan, Z.; Xing, J.; Liu, X. Design and operating parameter optimization of comb brush vibratory harvesting device for wolfberry. Trans. CSAE 2018, 34, 75–82. [Google Scholar] [CrossRef]

- Zhao, J.; Sugirbay, A.; Liu, F.; Chen, Y.; Hu, G.; Zhang, E.; Chen, J. Parameter optimization of winnowing equipment for machine-harvested Lycium barbarum L. Span. J. Agric. Res. 2019, 17, e0203. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, T.; Inagaki, T.; Chen, Q.; Gao, Z.; Sun, L.; Cai, H.; Chen, C.; Li, C.; Zhang, S.; et al. Finite Element Method Simulations and Experiments of Detachments of Lycium barbarum L. Forests 2021, 12, 699. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, J. Detecting Maturity in Fresh Lycium barbarum L. Fruit Using Color Information. Horticulturae 2021, 7, 108. [Google Scholar] [CrossRef]

- Amagase, H.; Farnsworth, N.R. A review of botanical characteristics, phytochemistry, clinical relevance in efficacy and safety of Lycium barbarum fruit (Goji). Food Res. Int. 2011, 44, 1702–1717. [Google Scholar] [CrossRef]

- Lu, Y.; Guo, S.; Zhang, F.; Yan, H.; Qian, D.-W.; Wang, H.-Q.; Jin, L.; Duan, J.-A. Comparison of Functional Components and Antioxidant Activity of Lycium barbarum L. Fruits from Different Regions in China. Molecules 2019, 24, 2228. [Google Scholar] [CrossRef] [Green Version]

- Skenderidis, P.; Lampakis, D.; Giavasis, I.; Leontopoulos, S.; Petrotos, K.; Hadjichristodoulou, C.; Tsakalof, A. Chemical Properties, Fatty-Acid Composition, and Antioxidant Activity of Goji Berry (Lycium barbarum L. and Lycium chinense Mill.) Fruits. Antioxidants 2019, 8, 60. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Z.; Deng, Q.; Zhou, W.; Zhang, Y. Immune activities of polysaccharides isolated from Lycium barbarum L. What do we know so far? Pharmacol. Ther. 2022, 229, 107921. [Google Scholar] [CrossRef]

- Zhao, Q.; Li, J.; Yan, J.; Liu, S.; Guo, Y.; Chen, D.; Luo, Q. Lycium barbarum polysaccharides ameliorates renal injury and inflammatory reaction in alloxan-induced diabetic nephropathy rabbits. Life Sci. 2016, 157, 82–90. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, J.; Hu, G.; Chen, J. Design and Testing of a Pneumatic Oscillating Chinese Wolfberry Harvester. Horticulturae 2021, 7, 214. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, H.; Ding, W.; Mei, S. Machanism simulation analysis and prototype experiment of Lycium barbarum harvest by vibration mode. Trans. CSAE 2015, 31, 20–28. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, J.; Chen, Y.; Bu, L.; Hu, G.; Zhang, E. Design and experiment on vibrating and comb brushing harvester for Lycium barbarum. Trans. CSAM 2019, 50, 152–161. [Google Scholar] [CrossRef]

- So, J.D. Vibration characteristics of boxthorn (Lycium chinense Mill) branches. Appl. Eng. Agric. 2001, 17, 755–760. [Google Scholar] [CrossRef]

- So, J.D. Vibratory harvesting machine for boxthorn (Lycium chinense Mill.) berries. Trans. ASAE 2003, 46, 211–221. [Google Scholar] [CrossRef]

- Jinpeng, W.; Song, M.; Hongru, X.; Ying, Z.; Hongping, Z. Research on Mechanized Harvesting Methods of Lycium barbarum Fruit. IFAC-PapersOnLine 2018, 51, 223–226. [Google Scholar] [CrossRef]

- Yun, C.; Yalei, W.; Jian, Z.; Jun, C. Recognition of the position of Chinese wolfberry branches under the artificial background. IFAC-PapersOnLine 2018, 51, 321–325. [Google Scholar] [CrossRef]

- He, M.; Kan, Z.; Li, C.; Wang, L.; Yang, L.; Wang, Z. Mechanism analysis and experiment on vibration harvesting of wolfberry. Trans. CSAE 2017, 33, 47–53. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Han, B.; Chen, J. Research on laws of wolfberry dropping based on high-speed camera. J. Agric. Mech. Res. 2018, 40, 166–170. [Google Scholar] [CrossRef]

- Wang, Y. Research on Key Technology of Wolfberry Vibration Harvest. Master’s Thesis, Northwest A&F University, Xianyang, China, 2018. [Google Scholar]

- Zhao, J.; Chen, Y.; Wang, Y.; Chen, J. Experimental research on parameter optimization of portable vibrating and harvesting device of Chinese wolfberry. J. Agric. Mech. Res. 2019, 41, 176–182. [Google Scholar] [CrossRef]

- Zhao, J.; Sugirbay, A.; Chen, Y.; Zhang, S.; Liu, F.; Bu, L.; Wang, Z.; Chen, J. FEM explicit dynamics simulation and NIR hyperspectral reflectance imaging for determination of impact bruises of Lycium barbarum L. Postharvest Biol. Technol. 2019, 155, 102–110. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, J.; Chen, Q.; Chen, J. Simulation for Fitting the Bending Shape of Fruit Branches of Lycium barbarum Based on the Finite Element Method. Horticulturae 2021, 7, 434. [Google Scholar] [CrossRef]

- Zhang, W.; Li, Z.; Tan, Y.; Li, W. Optimal design and experiment on variable pacing combing brush picking device for Lycium barbarum. Trans. CSAM 2018, 49, 83–90. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, M.; Zhang, J.; Li, W. Design and experiment of vibrating wolfberry harvester. Trans. CSAM 2018, 49, 97–102. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, T.; Inagaki, T.; Chen, Y.; Hu, G.; Wang, Z.; Chen, Q.; Gao, Z.; Zhou, J.; Wang, M.; et al. Parameter Optimization of Vibrating and Comb-Brushing Harvesting of Lycium barbarum L. Based on FEM and RSM. Horticulturae 2021, 7, 286. [Google Scholar] [CrossRef]

- Liu, X.; Fan, G.; Zhang, D.; Wang, Z. Effects of Hedgerow Cultivation on Leaf and Fruit Phenotypic and Yield of Lycium bar-barum L. North. Hortic. 2021, 1, 122–126. [Google Scholar] [CrossRef]

- Ghanbari, M.; Mozafari-Vanani, L.; Dehghani-Soufi, M.; Jahanbakhshi, A. Effect of alumina nanoparticles as additive with diesel–biodiesel blends on performance and emission characteristic of a six-cylinder diesel engine using response surface methodology (RSM). Energy Convers. Manag. X 2021, 11, 100091. [Google Scholar] [CrossRef]

- Liu, C.; Chen, Z.; Mao, Y.; Yao, Z.; Zhang, W.; Ye, W.; Duan, Y.; Xie, Q. Analysis and Optimization of Grinding Performance of Vertical Roller Mill Based on Experimental Method. Minerals 2022, 12, 133. [Google Scholar] [CrossRef]

- Karganroudi, S.S.; Moradi, M.; Attar, M.A.; Rasouli, S.A.; Ghoreishi, M.; Lawrence, J.; Ibrahim, H. Experimental and Numerical Analysis on TIG Arc Welding of Stainless Steel Using RSM Approach. Metals 2021, 11, 1659. [Google Scholar] [CrossRef]

| Name | Mean Value | Standard Deviation |

|---|---|---|

| Distance between shrubs/cm | 118.10 | 7.82 |

| Height of shrubs/cm | 186.50 | 26.92 |

| Width of the shrubs/cm | 147.25 | 26.56 |

| Height of first-floor hedge frame/cm | 71.68 | 12.05 |

| Height of second-floor hedge frame/cm | 121.59 | 18.58 |

| Height of first-floor wire rope/cm | 63 | - |

| Height of second-floor wire rope/cm | 122 | - |

| Codes | Vibration Frequency (Hz) | Brush Speed (mm·s−1) | Insertion Depth (mm) |

|---|---|---|---|

| −1 | 20 | 10 | 10 |

| 0 | 30 | 25 | 30 |

| 1 | 40 | 40 | 50 |

| NO. | X1 | X2 | X3 | n1 | n2 | n3 | n4 | n5 | I1/% | I2/% | I3/% | I |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | −1 | −1 | 0 | 26 | 132 | 2 | 95 | 1 | 16.46 | 2.06 | 3.85 | 64.81 |

| 2 | 1 | −1 | 0 | 94 | 1 | 6 | 45 | 17 | 98.95 | 11.76 | 18.09 | 90.62 |

| 3 | −1 | 1 | 0 | 48 | 69 | 1 | 63 | 3 | 41.03 | 1.56 | 6.25 | 74.07 |

| 4 | 1 | 1 | 0 | 94 | 58 | 3 | 80 | 12 | 61.84 | 3.61 | 12.77 | 79.82 |

| 5 | −1 | 0 | −1 | 30 | 168 | 5 | 114 | 2 | 15.15 | 4.2 | 6.67 | 62.80 |

| 6 | 1 | 0 | −1 | 64 | 11 | 6 | 57 | 11 | 85.33 | 9.52 | 17.19 | 86.12 |

| 7 | −1 | 0 | 1 | 36 | 225 | 2 | 203 | 1 | 13.79 | 0.98 | 2.78 | 64.39 |

| 8 | 1 | 0 | 1 | 64 | 74 | 4 | 107 | 7 | 46.38 | 3.6 | 10.94 | 74.19 |

| 9 | 0 | −1 | −1 | 84 | 29 | 5 | 76 | 16 | 74.34 | 6.17 | 19.05 | 82.17 |

| 10 | 0 | 1 | −1 | 84 | 66 | 7 | 119 | 7 | 56 | 5.56 | 8.33 | 78.23 |

| 11 | 0 | −1 | 1 | 37 | 123 | 3 | 73 | 5 | 23.13 | 3.95 | 13.51 | 64.01 |

| 12 | 0 | 1 | 1 | 32 | 156 | 5 | 182 | 2 | 17.02 | 2.67 | 6.25 | 64.13 |

| 13 | 0 | 0 | 0 | 68 | 81 | 3 | 144 | 9 | 45.64 | 2.04 | 13.24 | 73.67 |

| 14 | 0 | 0 | 0 | 63 | 39 | 3 | 68 | 8 | 61.76 | 4.23 | 12.7 | 79.63 |

| 15 | 0 | 0 | 0 | 84 | 28 | 1 | 75 | 8 | 75 | 1.32 | 9.52 | 86.75 |

| 16 | 0 | 0 | 0 | 90 | 45 | 3 | 95 | 11 | 66.67 | 3.06 | 12.22 | 82.08 |

| 17 | 0 | 0 | 0 | 61 | 23 | 4 | 145 | 9 | 72.62 | 2.68 | 14.75 | 83.82 |

| Sources | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 10,639.70 | 9 | 1182.19 | 9.48 | 0.0036 |

| X1 | 5308.11 | 1 | 5308.11 | 42.57 | 0.0003 |

| X2 | 171.03 | 1 | 171.03 | 1.37 | 0.2798 |

| X3 | 2128.78 | 1 | 2128.78 | 17.07 | 0.0044 |

| X1X2 | 951.11 | 1 | 951.11 | 7.63 | 0.0280 |

| X1X3 | 353.25 | 1 | 353.25 | 2.83 | 0.1362 |

| X2X3 | 37.39 | 1 | 37.39 | 0.2999 | 0.6009 |

| X12 | 157.39 | 1 | 157.39 | 1.26 | 0.2982 |

| X22 | 56.22 | 1 | 56.22 | 0.4509 | 0.5234 |

| X32 | 1373.55 | 1 | 1373.55 | 11.02 | 0.0128 |

| Residual | 872.74 | 7 | 124.68 | ||

| Lack of fit | 328.77 | 3 | 109.59 | 0.8058 | 0.5526 |

| Pure error | 543.97 | 4 | 135.99 | ||

| Total | 11,512.44 | 16 |

| Sources | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 118.08 | 9 | 13.12 | 6.39 | 0.0115 |

| X1 | 48.46 | 1 | 48.46 | 23.62 | 0.0018 |

| X2 | 13.89 | 1 | 13.89 | 6.77 | 0.0353 |

| X3 | 25.38 | 1 | 25.38 | 12.37 | 0.0098 |

| X1X2 | 14.63 | 1 | 14.63 | 7.13 | 0.0320 |

| X1X3 | 1.82 | 1 | 1.82 | 0.8883 | 0.3773 |

| X2X3 | 0.1122 | 1 | 0.1122 | 0.0547 | 0.8218 |

| X12 | 4.51 | 1 | 4.51 | 2.20 | 0.1819 |

| X22 | 4.62 | 1 | 4.62 | 2.25 | 0.1773 |

| X32 | 3.22 | 1 | 3.22 | 1.57 | 0.2505 |

| Residual | 14.36 | 7 | 2.05 | ||

| Lack of fit | 9.56 | 3 | 3.19 | 2.65 | 0.1848 |

| Pure error | 4.81 | 4 | 1.20 | ||

| Total | 132.44 | 16 |

| Sources | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 333.80 | 9 | 37.09 | 5.86 | 0.0147 |

| X1 | 194.44 | 1 | 194.44 | 30.73 | 0.0009 |

| X2 | 54.60 | 1 | 54.60 | 8.63 | 0.0218 |

| X3 | 39.43 | 1 | 39.43 | 6.23 | 0.0412 |

| X1X2 | 14.90 | 1 | 14.90 | 2.35 | 0.1688 |

| X1X3 | 1.39 | 1 | 1.39 | 0.2201 | 0.6533 |

| X2X3 | 2.99 | 1 | 2.99 | 0.473 | 0.5137 |

| X12 | 22.62 | 1 | 22.62 | 3.58 | 0.1005 |

| X22 | 0.0218 | 1 | 0.0218 | 0.0034 | 0.9548 |

| X32 | 2.52 | 1 | 2.52 | 0.3976 | 0.5484 |

| Residual | 44.29 | 7 | 6.33 | ||

| Lack of fit | 29.69 | 3 | 9.90 | 2.71 | 0.1799 |

| Pure error | 14.61 | 4 | 3.65 | ||

| Total | 378.09 | 16 |

| Sources | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 1173.34 | 9 | 130.37 | 5.75 | 0.0155 |

| X1 | 522.94 | 1 | 522.94 | 23.08 | 0.0020 |

| X2 | 3.59 | 1 | 3.59 | 0.1585 | 0.7024 |

| X3 | 226.85 | 1 | 226.85 | 10.01 | 0.0158 |

| X1X2 | 100.60 | 1 | 100.60 | 4.44 | 0.0731 |

| X1X3 | 45.70 | 1 | 45.70 | 2.02 | 0.1986 |

| X2X3 | 4.12 | 1 | 4.12 | 0.1819 | 0.6826 |

| X12 | 17.87 | 1 | 17.87 | 0.7885 | 0.4040 |

| X22 | 13.64 | 1 | 13.64 | 0.602 | 0.4632 |

| X32 | 221.62 | 1 | 221.62 | 9.78 | 0.0167 |

| Residual | 158.62 | 7 | 22.66 | ||

| Lack of fit | 61.01 | 3 | 20.34 | 0.8335 | 0.5412 |

| Pure error | 97.61 | 4 | 24.40 | ||

| Total | 1331.96 | 16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Zhang, S.; Hu, G.; Zhou, J.; Zhao, J.; Chen, Y.; Chen, J.; Gao, S.; Chen, Y.; Shi, T. Parameter Optimization of the Harvest Method in the Standardized Hedge Cultivation Mode of Lycium barbarum Using Response Surface Methodology. Horticulturae 2022, 8, 308. https://doi.org/10.3390/horticulturae8040308

Chen Q, Zhang S, Hu G, Zhou J, Zhao J, Chen Y, Chen J, Gao S, Chen Y, Shi T. Parameter Optimization of the Harvest Method in the Standardized Hedge Cultivation Mode of Lycium barbarum Using Response Surface Methodology. Horticulturae. 2022; 8(4):308. https://doi.org/10.3390/horticulturae8040308

Chicago/Turabian StyleChen, Qingyu, Shixia Zhang, Guangrui Hu, Jianguo Zhou, Jian Zhao, Yu Chen, Jun Chen, Sen Gao, Yun Chen, and Tengfei Shi. 2022. "Parameter Optimization of the Harvest Method in the Standardized Hedge Cultivation Mode of Lycium barbarum Using Response Surface Methodology" Horticulturae 8, no. 4: 308. https://doi.org/10.3390/horticulturae8040308

APA StyleChen, Q., Zhang, S., Hu, G., Zhou, J., Zhao, J., Chen, Y., Chen, J., Gao, S., Chen, Y., & Shi, T. (2022). Parameter Optimization of the Harvest Method in the Standardized Hedge Cultivation Mode of Lycium barbarum Using Response Surface Methodology. Horticulturae, 8(4), 308. https://doi.org/10.3390/horticulturae8040308