Influence of Processing Parameters on Fibre Properties during Twin-Screw Extrusion of Poplar Wood Chips

Abstract

:1. Introduction

1.1. State of Research of Peat Substitution with Fibre

1.2. State of Research on the Extrusion of Biomass

1.3. Hypotheses

- Dry extruded poplar wood chips have a higher fine fraction due to increased friction in the extrusion process as a result of the absence of lubricant (water).

- Poplar fibre with a high fine fraction results in high water holding capacity (WHC).

- A high moisture content during extrusion leads to reduced specific energy demand (SED) because more water decreases friction and therefore comminution.

2. Materials and Methods

2.1. General Information

2.2. Raw Materials

- -

- 60% of the wood chips must be between 3.15 mm and 31.5 mm in size

- -

- fine fraction (<3.15 mm) cannot exceed 10%

- -

- coarse fraction (>45 mm) cannot exceed 6%

- -

- maximum length of the particle cannot exceed 150 mm

- -

- cross-section of oversized particles cannot exceed 4 cm2

2.3. Experimental Setup

2.4. Specific Energy Demand (SED)

2.5. Water Holding Capacity

2.6. Sieving Analysis

2.7. Statistical Analysis

3. Results

3.1. Volume-Based Water Holding Capacity

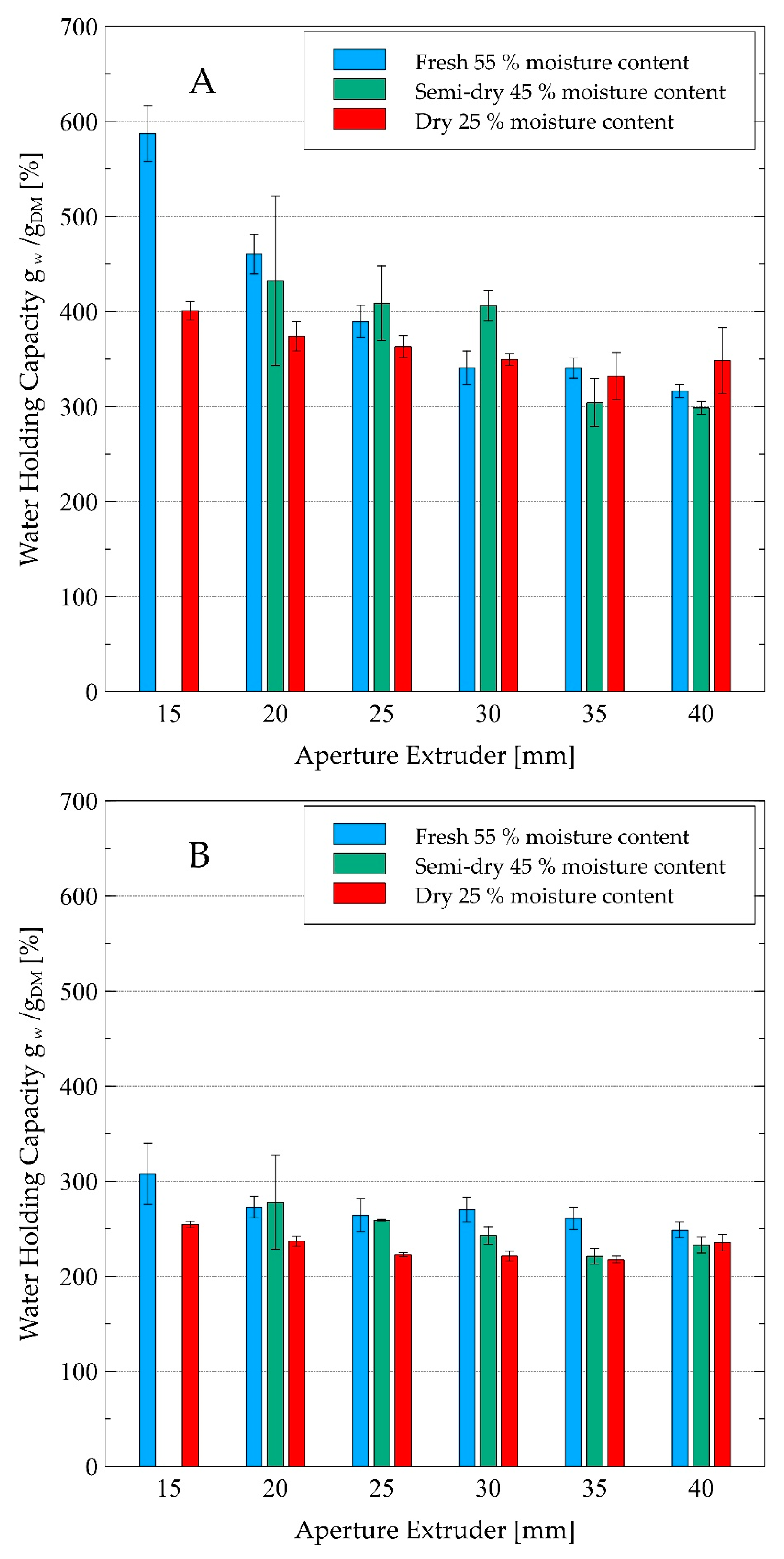

3.2. Mass-Based Water Holding Capacity

3.3. Specific Energy Demand

3.4. Mass Flow

3.5. Sieving Analysis

3.6. X-50 Value

3.7. Decrease in Moisture Content

4. Discussion

4.1. Water Holding Capacity

4.2. Specific Energy Demand

4.3. WHC and X-50 Correlation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| F_15 | F_20 | F_25 | F_30 | F_35 | F_40 | SD_20 | SD_25 | SD_30 | SD_35 | SD_40 | D_15 | D_20 | D_25 | D_30 | D_35 | D_40 | |

| F_15 | |||||||||||||||||

| F_20 | - | ||||||||||||||||

| F_25 | + | + | |||||||||||||||

| F_30 | + | + | - | ||||||||||||||

| F_35 | + | + | + | - | |||||||||||||

| F_40 | + | + | - | - | - | ||||||||||||

| SD_20 | - | ||||||||||||||||

| SD_25 | - | + | |||||||||||||||

| SD_30 | - | + | - | ||||||||||||||

| SD_35 | - | + | + | - | |||||||||||||

| SD_40 | - | + | + | + | + | ||||||||||||

| D_15 | - | ||||||||||||||||

| D_20 | - | + | - | ||||||||||||||

| D_25 | - | - | - | - | |||||||||||||

| D_30 | - | - | - | - | - | ||||||||||||

| D_35 | - | + | - | - | - | - | |||||||||||

| D_40 | - | + | - | - | - | + | + |

| F_15 | F_20 | F_25 | F_30 | F_35 | F_40 | SD_20 | SD_25 | SD_30 | SD_35 | SD_40 | D_15 | D_20 | D_25 | D_30 | D_35 | D_40 | |

| F_15 | |||||||||||||||||

| F_20 | - | ||||||||||||||||

| F_25 | + | - | |||||||||||||||

| F_30 | + | - | - | ||||||||||||||

| F_35 | + | - | - | - | |||||||||||||

| F_40 | + | - | - | - | - | ||||||||||||

| SD_20 | - | ||||||||||||||||

| SD_25 | - | - | |||||||||||||||

| SD_30 | - | - | - | ||||||||||||||

| SD_35 | - | + | + | - | |||||||||||||

| SD_40 | - | + | + | - | - | ||||||||||||

| D_15 | - | ||||||||||||||||

| D_20 | - | - | - | ||||||||||||||

| D_25 | - | - | - | - | |||||||||||||

| D_30 | - | - | - | - | - | ||||||||||||

| D_35 | - | + | - | - | - | - | |||||||||||

| D_40 | - | + | - | - | - | - | - |

| F_15 | F_20 | F_25 | F_30 | F_35 | F_40 | SD_20 | SD_25 | SD_30 | SD_35 | SD_40 | D_15 | D_20 | D_25 | D_30 | D_35 | D_40 | |

| F_15 | |||||||||||||||||

| F_20 | - | ||||||||||||||||

| F_25 | - | - | |||||||||||||||

| F_30 | - | - | - | ||||||||||||||

| F_35 | - | - | - | - | |||||||||||||

| F_40 | - | - | - | - | - | ||||||||||||

| SD_20 | - | ||||||||||||||||

| SD_25 | - | - | |||||||||||||||

| SD_30 | - | - | - | ||||||||||||||

| SD_35 | - | + | - | - | |||||||||||||

| SD_40 | - | - | - | - | - | ||||||||||||

| D_15 | - | ||||||||||||||||

| D_20 | - | - | - | ||||||||||||||

| D_25 | - | - | - | - | |||||||||||||

| D_30 | - | - | - | - | - | ||||||||||||

| D_35 | - | - | - | - | - | - | |||||||||||

| D_40 | - | - | - | - | - | - |

| F_15 | F_20 | F_25 | F_30 | F_35 | F_40 | SD_20 | SD_25 | SD_30 | SD_35 | SD_40 | D_15 | D_20 | D_25 | D_30 | D_35 | D_40 | |

| F_15 | |||||||||||||||||

| F_20 | + | ||||||||||||||||

| F_25 | + | - | |||||||||||||||

| F_30 | + | + | - | ||||||||||||||

| F_35 | + | + | - | - | |||||||||||||

| F_40 | + | + | - | - | - | ||||||||||||

| SD_20 | - | ||||||||||||||||

| SD_25 | - | - | |||||||||||||||

| SD_30 | - | - | - | ||||||||||||||

| SD_35 | - | + | + | + | |||||||||||||

| SD_40 | - | + | + | + | - | ||||||||||||

| D_15 | + | ||||||||||||||||

| D_20 | - | + | - | ||||||||||||||

| D_25 | - | + | - | - | |||||||||||||

| D_30 | - | - | - | - | - | ||||||||||||

| D_35 | - | - | - | - | - | - | |||||||||||

| D_40 | - | - | - | - | - | - | - |

| F_15 | F_20 | F_25 | F_30 | F_35 | F_40 | SD_20 | SD_25 | SD_30 | SD_35 | SD_40 | D_15 | D_20 | D_25 | D_30 | D_35 | D_40 | |

| F_15 | |||||||||||||||||

| F_20 | - | ||||||||||||||||

| F_25 | - | - | |||||||||||||||

| F_30 | - | - | - | ||||||||||||||

| F_35 | - | - | - | - | |||||||||||||

| F_40 | - | - | - | - | - | ||||||||||||

| SD_20 | - | ||||||||||||||||

| SD_25 | - | - | |||||||||||||||

| SD_30 | - | - | - | ||||||||||||||

| SD_35 | - | + | - | - | |||||||||||||

| SD_40 | - | + | - | - | - | ||||||||||||

| D_15 | - | ||||||||||||||||

| D_20 | - | + | - | ||||||||||||||

| D_25 | - | - | - | - | |||||||||||||

| D_30 | - | - | - | - | - | ||||||||||||

| D_35 | - | - | - | - | - | - | |||||||||||

| D_40 | - | - | - | - | - | - | - |

References

- Albrecht, J. Das Klimaschutzgesetz des Bundes–neue Ansätze für den Naturschutz? Nat. Recht 2020, 42, 513–518. [Google Scholar] [CrossRef]

- Gaudig, G. Sphagnum Growth and Its Perspectives for Sphagnum Farming; University Greifswald: Greifswald, Germany, 2020. [Google Scholar]

- Schmilewski, G.; Nordzieke, B. Researched, developed and commercialized: GreenFiber. In Proceedings of the International Symposium on Growing Media, Soilless Cultivation, and Compost Utilization in Horticulture 1266, Portland, OR, USA, 20–25 August 2017; pp. 361–368. [Google Scholar]

- Dittrich, C.; Pecenka, R.; Løes, A.-K.; Cáceres, R.; Conroy, J.; Rayns, F.; Schmutz, U.; Kir, A.; Kruggel-Emden, H. Extrusion of Different Plants into Fibre for Peat Replacement in Growing Media: Adjustment of Parameters to Achieve Satisfactory Physical Fibre-Properties. Agronomy 2021, 11, 1185. [Google Scholar] [CrossRef]

- Maher, M.; Prasad, M.; Raviv, M. Organic soilless media components. Soil. Cult. Theory Pract. 2008, 11, 459–504. [Google Scholar]

- Agarwal, P.; Saha, S.; Hariprasad, P. Agro-industrial-residues as potting media: Physicochemical and biological characters and their influence on plant growth. Biomass Convers. Biorefinery 2021, 11, 1–24. [Google Scholar] [CrossRef]

- Friis Pedersen, S.; Løes, A.-K. Phasing Out Peat in Growing Media-Results from Scandinavian Studies; Norwegian Institute for Organic Agriculture: Tingvoll, Norway, 2022. [Google Scholar]

- Atzori, G.; Pane, C.; Zaccardelli, M.; Cacini, S.; Massa, D. The Role of Peat-Free Organic Substrates in the Sustainable Management of Soilless Cultivations. Agronomy 2021, 11, 1236. [Google Scholar] [CrossRef]

- Barrett, G.; Alexander, P.; Robinson, J.; Bragg, N. Achieving environmentally sustainable growing media for soilless plant cultivation systems—A review. Sci. Hortic. 2016, 212, 220–234. [Google Scholar] [CrossRef]

- Debode, J.; De Tender, C.; Cremelie, P.; Lee, A.S.; Kyndt, T.; Muylle, H.; De Swaef, T.; Vandecasteele, B. Trichoderma-inoculated miscanthus straw can replace peat in strawberry cultivation, with beneficial effects on disease control. Front. Plant Sci. 2018, 9, 213. [Google Scholar] [CrossRef] [PubMed]

- Grießer, S. Torfersatzsubstrate für den Erwerbsgartenbau-Ein Beitrag für Nachhaltige Landnutzung in Niedersachsen; University Vechta: Vechta, Germany, 2016. [Google Scholar]

- Gruda, N.; Schnitzler, W. Holzfasersubstrate als eine Torfalternative für die Gemüseproduktion. Holz Als Roh- Werkst. 2006, 64, 347–350. [Google Scholar] [CrossRef]

- Kharazipour, A. Herstellung von Holzfasern als Torfersatzstoff; Büsgen-Institut: Göttingen, Germany, 2009. [Google Scholar]

- Kir, A.; Løes, A.K.; Cetinel, B.; Turan, H.S.; Aydogdu, E.; Pecenka, R.; Dittrich, C.; Cáceres, R.; Lennartsson Turner, M.; Rayns, F.; et al. Testing peat-free growing media based on olive wood residues for olive saplings (Olea europaea L., cv. Gemlik). In Proceedings of the II International Symposium on Growing Media, Soilless Cultivation, and Compost Utilization in Horticulture 1317, Ghent, Belgium, 22–27 August 2021. [Google Scholar]

- Koller, M. Test für torfreduzierte und torffreie Substrate. GPlus 2018, 1, 20–21. [Google Scholar]

- König, U.J. Optimisation of Quality of Bio Substrates for Nursery Plants under Ecological Vegetable Production with Special Concern to Transformation to Praxis of Peat Ersatz by Fermented Wood Fibre; Forschungsring e.V.: Darmstadt, Germany, 2006. [Google Scholar]

- Kunz, G. Torfreduzierte Bio-Anzuchtsubstrate für den Produzierenden Gemüse-und Beerenan-bau: Schlussbericht September 2019; ZHAW LSFM: Wädenswi, Switzerland, 2019. [Google Scholar]

- Eymann, L.; Mathis, A.; Stucki, M.; Amrein, S. Torf und Torfersatzprodukte im Vergleich: Eigenschaften, Verfügbarkeit, Ökologische Nachhaltigkeit und Soziale Auswirkungen; Institut für Umwelt und Natürliche Ressourcen, Zürcher Hochschule für Angewandte Wissenschaften: Wädenswil, Switzerland, 2015. [Google Scholar]

- Stucki, M.; Wettstein, S.; Mathis, A.; Amrein, S. Erweiterung der Studie «Torf und Torfersatzprodukte im Vergleich»: Eigenschaften, Verfügbarkeit, Ökologische Nachhaltigkeit und Soziale Auswirkungen; ZHAW Zürcher Hochschule für Angewandte Wissenschaften: Winterthur, Switzerland, 2019. [Google Scholar]

- Makas, M.; Windeisen, E.; Wegener, G. Substitution von Torf durch Holz in Pflanzsubstraten. Eur. J. Wood Wood Prod. 2000, 58, 125–126. [Google Scholar] [CrossRef]

- Jackson, B.E.; Wright, R.D.; Barnes, M.C. Methods of constructing a pine tree substrate from various wood particle sizes, organic amendments, and sand for desired physical properties and plant growth. HortScience 2010, 45, 103–112. [Google Scholar] [CrossRef]

- Dietrich, T. Untersuchung zur Faserstoffherstellung aus Hanfschäben im Extruderverfahren an einer Pilotanlage; TU Dresden: Dresden, Germany, 2008; p. 94. [Google Scholar]

- Gusovius, H.-J.; Pecenka, R.; Hoffmann, T.; Radosavljevic, L.; Fürll, C. Biologische Bindemittel für die Herstellung von Faserwerkstoffplatten aus konserviertem Hanf. Landtechnik 2009, 64, 281–283. [Google Scholar]

- Pecenka, R.; Furll, C.; Idler, C.; Grundmann, P.; Radosavljevic, L. Fibre boards and composites from wet preserved hemp. Int. J. Mater. Prod. Technol. 2009, 36, 208–220. [Google Scholar] [CrossRef]

- Wallot, G.; Gusovius, H.-J.; Pecenka, R.; Hoffmann, T. Herstellung von Faserwerkstoff aus pflanzlichen Rohstoffen in einer Scheibenmühle. Landtechnik 2011, 66, 100–102. [Google Scholar]

- DIN. 18134-2:2017-05; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. German Version EN ISO 18134-2:2017. AENOR: Madrid, Spain, 2017.

- Kiesewalter, S.; Riehl, G. Nutzungsalternativen von Grünlandaufwüchsen in Sächsischen Vorgebirgslagen–Ein Beitrag zur Erhaltung der Kulturlandschaft und des Ländlichen Raums; Sächsische Landesanstalt für Landwirtschaft: Dresden, Germany, 2007. [Google Scholar]

- Dittrich, C.; Pecenka, R.; Løes, A.-K.; Schmutz, U. Technical Paper on Twin Screw Extruder Processing Technology for Fibres as Raw Material for Peat Substitution; Coventry University: Coventry, UK, 2019. [Google Scholar]

- DIN. 14780:2020-02; Solid Biofuels—Sample Preparation. German version EN ISO 14780:2017 + A1:2019. European Committee for Standardization: Brussels, Belgium, 2020.

- DIN. 13041:2012-01; Soil Improvers and Growing Media—Determination of Physical Properties—Dry Bulk Density, Air Volume, Water Volume, Shrinkage Value and Total Pore Space. German version EN 13041:2011. European Committee for Standardization: Brussels, Belgium, 2012.

- DIN. 17827-1: 2016-10; Solid Biofuels—Determination of Particle Size Distribution for Uncompressed Fuels—Part 1: Oscillating Screen Method Using Sieves with Apertures of 3.15 mm and above. German version EN ISO 17827-1:2016. European Committee for Standardization: Brussels, Belgium, 2016; Volume 1.

- Schubert, H. Handbuch der Mechanischen Verfahrenstechnik; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Bal, B.C. A comparative study of the physical properties of thermally treated poplar and plane woods. BioResources 2013, 8, 6493–6500. [Google Scholar] [CrossRef]

- Stamm, A.J. Verfahren zur abschätzung der wasserdampfsorption am fasersättigungspunkt von holz und papier. Holz Als Roh- Werkst. 1959, 17, 203–205. [Google Scholar] [CrossRef]

- Almeida, G.; Brito, J.O.; Perre, P. Changes in wood-water relationship due to heat treatment assessed on micro-samples of three eucalyptus species. Holzforschung 2009, 63, 80–88. [Google Scholar] [CrossRef]

- Esteves, B.; Pereira, H. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Sehlstedt-Persson, M. Impact of Drying and Heat Treatment on Physical Properties and Durability of Solid Wood. Doctoral Dissertation, Luleå Tekniska Universitet, Luleå, Sweden, 2008. [Google Scholar]

| Measurement/Trait | Unit | Repetitions/Sample Size | Standard/Method |

|---|---|---|---|

| Specific energy demand at: | kWh t−1 | n = 4 | Calculation with values collected from frequency converter and scale (Equation (1)) |

| mm | ||

| % | ||

| Sieving analysis per aperture | % | n = 4 | ISO 17827 [31] |

| Water holding capacity per aperture | % | n = 4 | DIN EN 13041 [30] |

| Moisture content input material | % | n = 10 | DIN EN ISO 18134–2 [26] |

| Sample preparation | - | n = 1 | DIN EN ISO 14780 [29] |

| X-50 (average particle size) | mm |

| Fresh X-50 | Semi-Dry X-50 | Dry X-50 | |

|---|---|---|---|

| WHC vol −1 kPa | −0.89853 | −0.69404 | −0.82398 |

| p-value | <0.0001 | 0.0007 | <0.0001 |

| WHC vol −5 kPa | −0.44422 | −0.53415 | −0.74877 |

| p-value | 0.0297 | 0.0153 | <0.0001 |

| WHC dm −1 kPa | −0.96333 | −0.69123 | −0.76833 |

| p-value | <0.0001 | 0.0007 | <0.0001 |

| WHC dm −5 kPa | −0.69150 | −0.68993 | −0.75180 |

| p-value | 0.0002 | 0.0008 | <0.0001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dittrich, C.; Pecenka, R.; Selge, B.; Ammon, C.; Kruggel-Emden, H. Influence of Processing Parameters on Fibre Properties during Twin-Screw Extrusion of Poplar Wood Chips. Horticulturae 2022, 8, 762. https://doi.org/10.3390/horticulturae8090762

Dittrich C, Pecenka R, Selge B, Ammon C, Kruggel-Emden H. Influence of Processing Parameters on Fibre Properties during Twin-Screw Extrusion of Poplar Wood Chips. Horticulturae. 2022; 8(9):762. https://doi.org/10.3390/horticulturae8090762

Chicago/Turabian StyleDittrich, Christian, Ralf Pecenka, Benjamin Selge, Christian Ammon, and Harald Kruggel-Emden. 2022. "Influence of Processing Parameters on Fibre Properties during Twin-Screw Extrusion of Poplar Wood Chips" Horticulturae 8, no. 9: 762. https://doi.org/10.3390/horticulturae8090762

APA StyleDittrich, C., Pecenka, R., Selge, B., Ammon, C., & Kruggel-Emden, H. (2022). Influence of Processing Parameters on Fibre Properties during Twin-Screw Extrusion of Poplar Wood Chips. Horticulturae, 8(9), 762. https://doi.org/10.3390/horticulturae8090762