Pulsed Electric Field as a Novel Technology for Fresh Barhi Date Shelf-Life Extension: Process Optimization Using Response Surface Methodology

Abstract

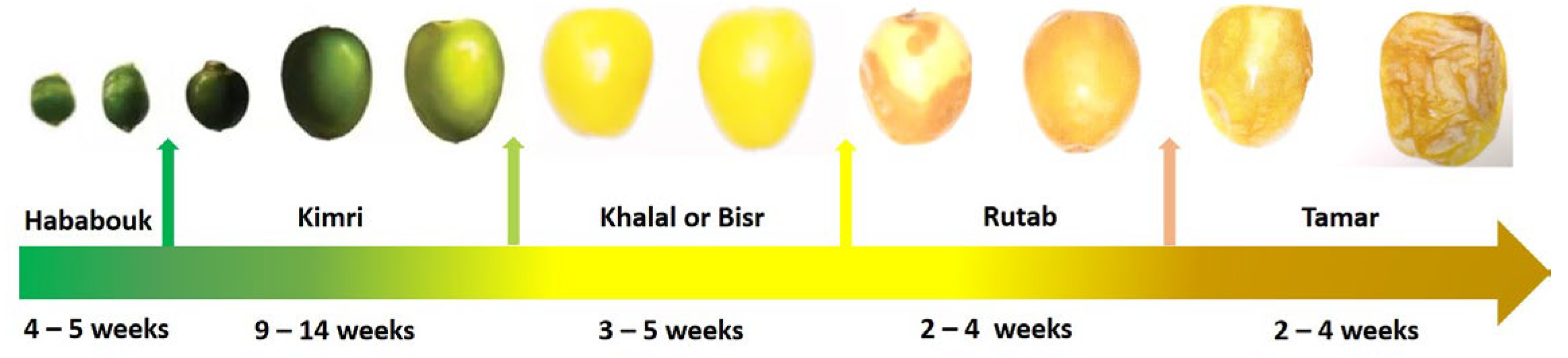

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. PEF Treatment

2.3. Experimental Design

2.4. Measurement of Mositure Content and Total Soluble Solids (TSS)

2.5. Determination of Physical Properties (Firmness and Color) of Barhi Dates

2.6. Microbial Quality [Total Viable Count (TVC) and Yeast Enumeration (YE) of Barhi Dates]

2.7. Determination of Bioactive Properties of Barhi Dates

2.8. Determination of Glucose and Fructose

2.9. Statistical Analysis

3. Results and Discussion

3.1. Model Fitting

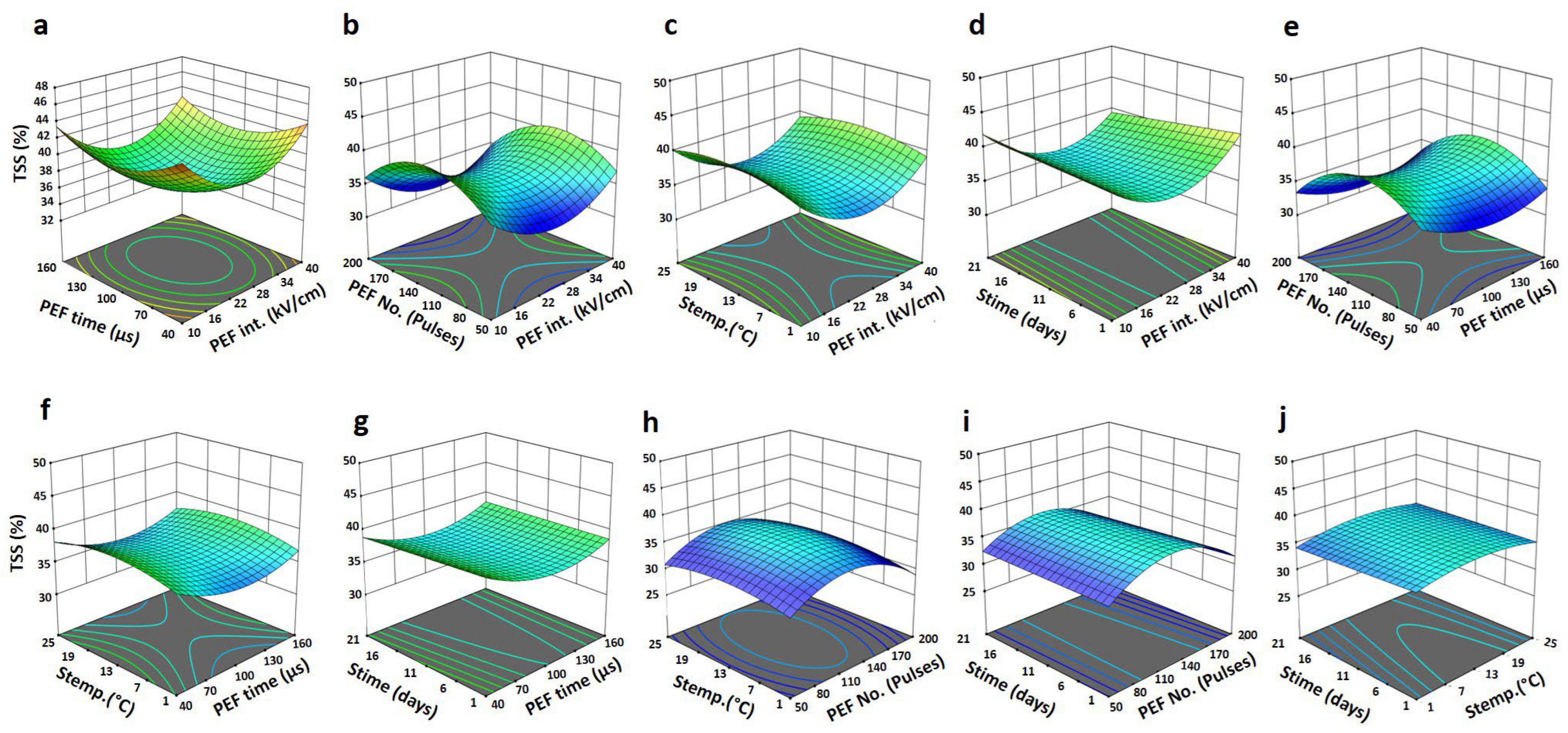

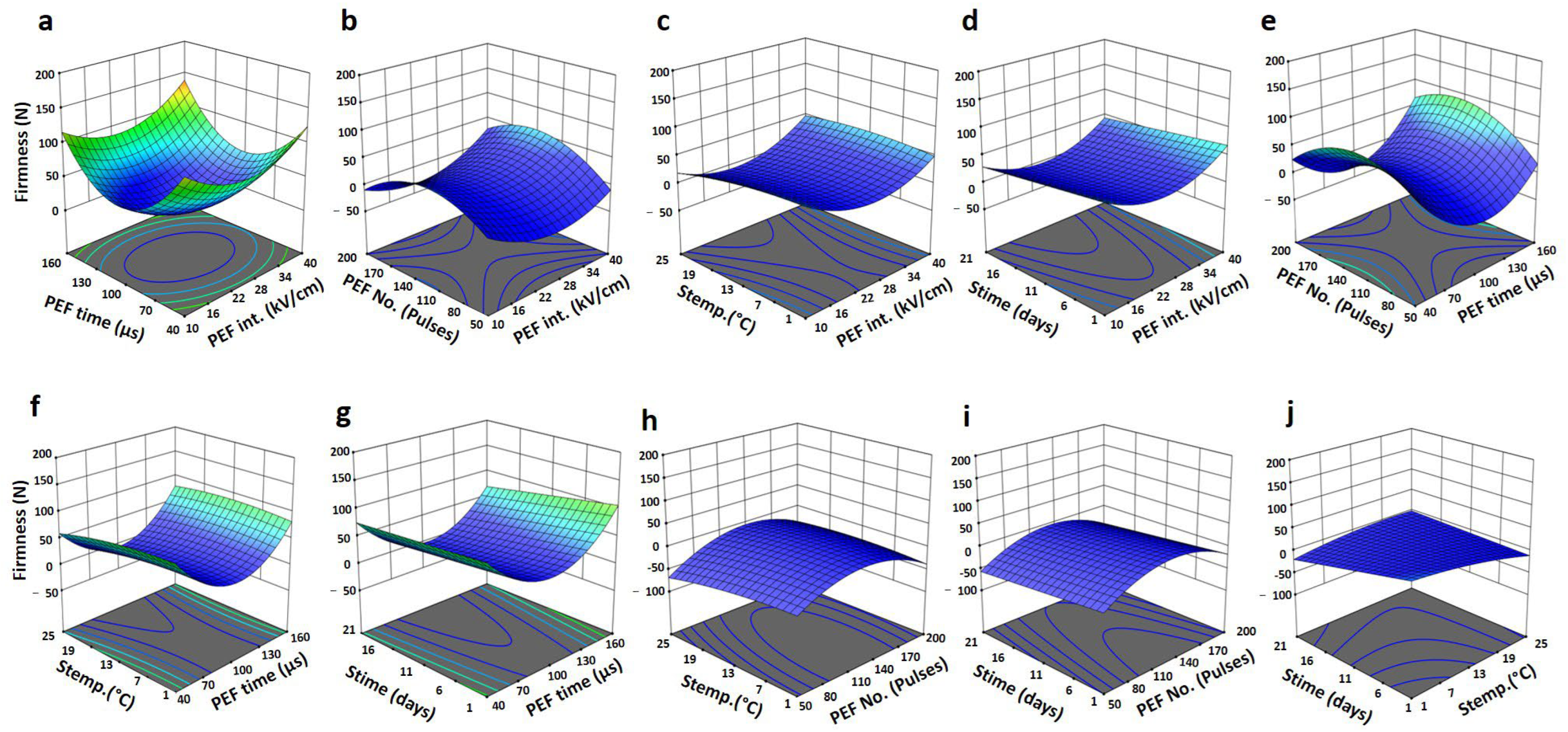

3.2. Physicochemical Properties (TSS, Firmness, and ΔE) as Influenced by PEF Treatment and Storage Conditions

3.3. Total Viable Count (TVC) of Barhi Dates as Influenced by PEF Treatment and Storage Conditions

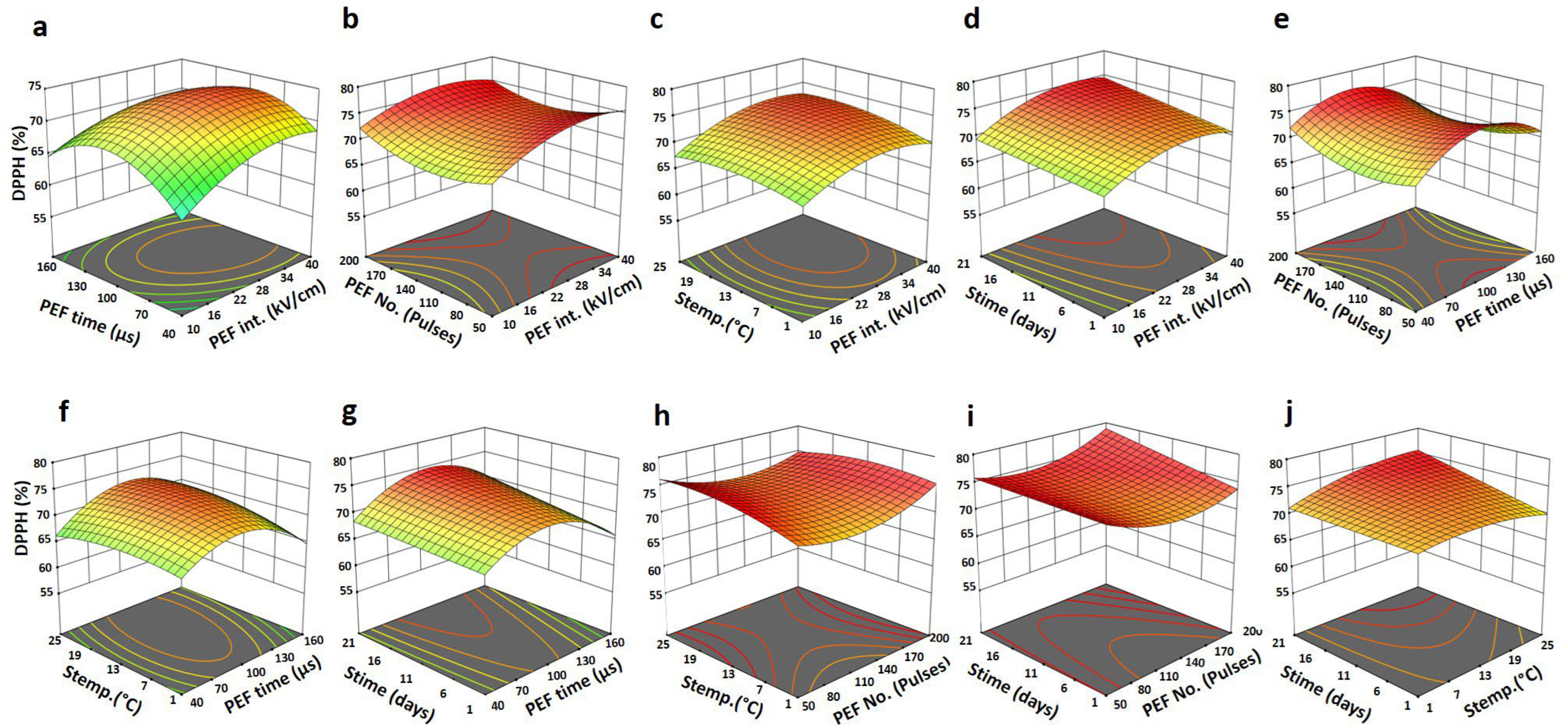

3.4. Bioactive Properties (TPC and DPPH) of Barhi Dates as Influenced by PEF Treatment and Storage Conditions

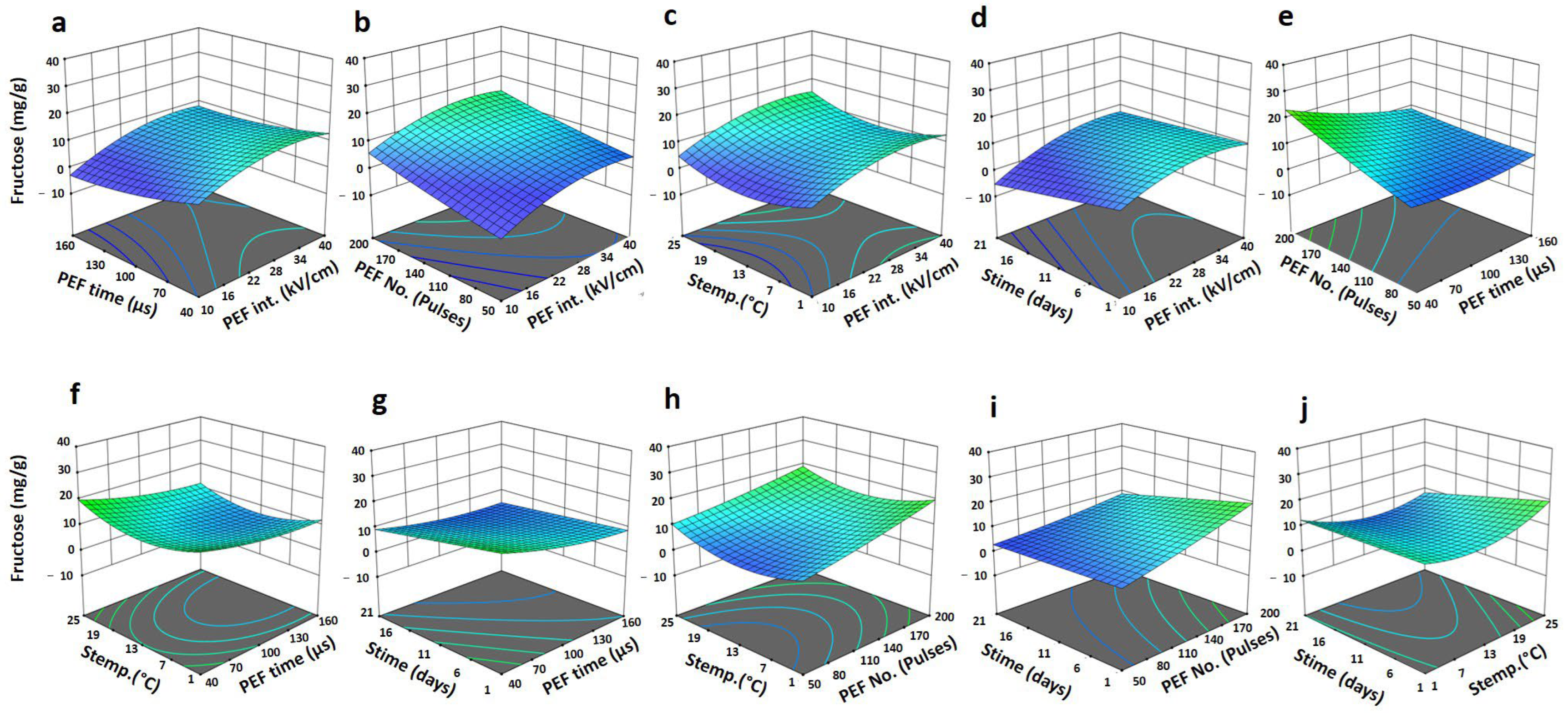

3.5. Glucose and Fructose Contents of Barhi Dates as Influenced by PEF Treatment and Storage Conditions

3.6. Optimal PEF Treatment and Storage Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdelkarim, D.O.; Ahmed, K.A.; Younis, M.; Yehia, H.M.; El-Abedein, A.I.Z.; Alhamdan, A.; Ahmed, I.A.M. Optimization of Infrared Postharvest Treatment of Barhi Dates Using Response Surface Methodology (RSM). Horticulturae 2022, 8, 342. [Google Scholar] [CrossRef]

- Ahmed, Z.F.R.; Al Shaibani, F.Y.Y.; Kaur, N.; Maqsood, S.; Schmeda-Hirschmann, G. Improving fruit quality, bioactive compounds, and storage life of date palm (Phoenix dactylifera L., cv. Barhi) using natural elicitors. Horticulturae 2021, 7, 293. [Google Scholar] [CrossRef]

- Fernández-López, J.; Viuda-Martos, M.; Sayas-Barberá, E.; Navarro-Rodríguez de Vera, C.; Pérez-Álvarez, J.Á. Biological, Nutritive, Functional and Healthy Potential of Date Palm Fruit (Phoenix dactylifera L.): Current Research and Future Prospects. Agronomy 2022, 12, 876. [Google Scholar] [CrossRef]

- Younis, M.; Mohamed Ahmed, I.A.; Ahmed, K.A.; Yehia, H.M.; Abdelkarim, D.O.; El-Abedein, A.I.Z.; Alhamdan, A. Response Surface Methodology (RSM) Optimization of the Physicochemical Quality Attributes of Ultraviolet (UV-C)-Treated Barhi Dates. Plants 2022, 11, 2322. [Google Scholar] [CrossRef]

- Alhamdan, A.M.; Fickak, A.; Atia, A.R. Evaluation of sensory and texture profile analysis properties of stored Khalal Barhi dates nondestructively using Vis/NIR spectroscopy. J. Food Process Eng. 2019, 42, e13215. [Google Scholar] [CrossRef]

- Alhamdan, A.; Hassan, B.; Alkahtani, H.; Abdelkarim, D.; Younis, M. Cryogenic freezing of fresh date fruits for quality preservation during frozen storage. J. Saudi Soc. Agric. Sci. 2018, 17, 9–16. [Google Scholar] [CrossRef] [Green Version]

- Atia, A.; Abdelkarim, D.; Younis, M.; Alhamdan, A. Effects of calcium chloride and salicylic acid postharvest treatments on the quality of Khalal Barhi dates at different ripening levels during cold storage. J. Food Meas. Character. 2018, 12, 1156–1166. [Google Scholar] [CrossRef]

- Atia, A.; Abdelkarim, D.; Younis, M.; Alhamdan, A. Effects of pre-storage dipping in calcium chloride and salicylic acid on the quality attributes of stored Khalal Barhi dates. Int. J. Agric. Biol. Eng. 2020, 13, 206–212. [Google Scholar] [CrossRef]

- Alhamdan, A.; Hassan, B.; Alkahtani, H.; Abdelkarim, D.; Younis, M. Freezing of fresh Barhi dates for quality preservation during frozen storage. Saudi J. Biol. Sci. 2018, 25, 1552–1561. [Google Scholar] [CrossRef] [Green Version]

- Al-Redhaiman, K.N. Chemical changes during storage of Barhi dates under controlled atmospheric conditions. Hortic. Sci. 2005, 40, 1413–1415. [Google Scholar]

- Alsawmahi, O.N.; Al-Juhaimi, F.Y.; Alhamdan, A.M.; Ghafoor, K.; Adiamo, O.Q.; Mohamed Ahmed, I.A.; Hassan, B.H.; Ehmed, K.A.; Babiker, E.E.; Abdelkarim, D.; et al. Phenolic, tannin, antioxidant, color, and sensory attributes of Barhi date (Phoenix dactylifera) fruit stored in modified atmosphere packages. J. Food Biochem. 2018, 42, e12576. [Google Scholar] [CrossRef]

- Alsawmahi, O.N.; Al-Juhaimi, F.Y.; Alhamdan, A.M.; Ghafoor, K.; Mohamed Ahmed, I.A.; Hassan, B.H.; Ehmed, K.A.; Abdelkarim, D.; Younis, M.; Alashmawe, N.; et al. Enzyme activity, sugar composition, microbial growth and texture of fresh Barhi dates as affected by modified atmosphere packaging. J. Food Sci. Technol. 2018, 55, 4492–4504. [Google Scholar] [CrossRef] [PubMed]

- El-Gioushy, S.F.; El-Masry, A.M.; Fikry, M.; El-Kholy, M.F.; Shaban, A.E.; Sami, R.; Algarni, E.; Alshehry, G.; Aljumayi, H.; Benajiba, N.; et al. Utilization of Active Edible Films (Chitosan, Chitosan Nanoparticle, and CaCl2) for Enhancing the Quality Properties and the Shelf Life of Date Palm Fruits (Barhi Cultivar) during Cold Storage. Coatings 2022, 12, 255. [Google Scholar] [CrossRef]

- Ghafoor, K.; Al-Juhaimi, F.Y.; Babiker, E.E.; Mohamed Ahmed, I.A.; Shahzad, S.A.; Alsawmahi, O.N. Quality Attributes of Refrigerated Barhi Dates Coated with Edible Chitosan Containing Natural Functional Ingredients. Foods 2022, 11, 1584. [Google Scholar] [CrossRef] [PubMed]

- Abdelkarim, D.O.; Mohamed Ahmed, I.A.; Ahmed, K.A.; Younis, M.; Yehia, H.M.; Zein El-Abedein, A.I.; Alhamdan, A. Extending the Shelf Life of Fresh Khalal Barhi Dates via an Optimized Postharvest Ultrasonic Treatment. Plants 2022, 11, 2029. [Google Scholar] [CrossRef] [PubMed]

- Yolmeh, M.; Jafari, S.M. Applications of Response Surface Methodology in the Food Industry Processes. Food Bioprocess Technol. 2017, 10, 413–433. [Google Scholar] [CrossRef]

- Weremfo, A.; Abassah-Oppong, S.; Adulley, F.; Dabie, K.; Seidu-Larry, S. Response Surface Methodology as a Tool to Optimize the Extraction of Bioactive Compounds from Plant Sources. J. Sci. Food Agric. 2023, 103, 26–36. [Google Scholar] [CrossRef]

- Frontuto, D.; Carullo, D.; Harrison, S.M.; Brunton, N.P.; Ferrari, G.; Lyng, J.G.; Pataro, G. Optimization of Pulsed Electric Fields-Assisted Extraction of Polyphenols from Potato Peels Using Response Surface Methodology. Food Bioprocess Technol. 2019, 12, 1708–1720. [Google Scholar] [CrossRef]

- Chen, B.-K.; Chang, C.-K.; Cheng, K.-C.; Hou, C.-Y.; Lin, J.-A.; Chen, M.-H.; Santoso, S.P.; Chen, C.-P.; Hsieh, C.-W. Using the response surface methodology to establish the optimal conditions for preserving bananas (Musa acuminata) in a pulsed electric field and to decrease browning induced by storage at a low temperature. Food Packag. Shelf Life 2022, 31, 100804. [Google Scholar] [CrossRef]

- Salehi, F. Physico-chemical properties of fruit and vegetable juices as affected by pulsed electric field: A review. Inter. J. Food Proper. 2020, 23, 1036–1050. [Google Scholar] [CrossRef]

- Koch, Y.; Witt, J.; Lammerskitten, A.; Siemer, C.; Toepfl, S. The influence of Pulsed Electric Fields (PEF) on the peeling ability of different fruits and vegetables. J. Food Eng. 2022, 322, 110938. [Google Scholar] [CrossRef]

- Pataro, G.; Ferrari, G. Limitations of pulsed electric field utilization in food industry. In Pulsed Electric Fields to Obtain Healthier and Sustainable Food for Tomorrow; Barba, F.J., Parniakov, O., Wiktor, A., Eds.; Academic Press: London, UK, 2020; pp. 283–310. [Google Scholar]

- Mohammed, M.E.A.; Eissa, A.H.A.; Aleid, S.M. Application of Pulsed Electric Field for Microorganisms Inactivation in Date palm Fruits. J. Food Nutr. Res. 2016, 4, 646–652. [Google Scholar]

- Siddeeg, A.; Manzoor, M.F.; Ahmad, M.H.; Ahmad, N.; Ahmed, Z.; Khan, M.K.I.; Maan, A.A.; Mahr-Un-Nisa; Zeng, X.-A.; Rahaman, A.; et al. Pulsed Electric Field-Assisted Ethanolic Extraction of Date Palm Fruits: Bioactive Compounds, Antioxidant Activity and Physicochemical Properties. Processes 2019, 7, 585. [Google Scholar] [CrossRef] [Green Version]

- Siddeeg, A.; Zeng, X.-A.; Rahaman, A.; Manzoor, M.F.; Ahmed, Z.; Al-Farga, A. Effect of Pulsed Electric Field Pretreatment of Date Palm Fruits on Free Amino Acids, Bioactive Components, and Physicochemical Characteristics of the Alcoholic Beverage. J. Food Sci. 2019, 84, 3156–3162. [Google Scholar] [CrossRef] [PubMed]

- Siddeeg, A.; Zeng, X.-A.; Rahaman, A.; Manzoor, M.F.; Ahmed, Z.; Al-Farga, A. Quality characteristics of the processed dates vinegar under influence of ultrasound and pulsed electric field treatments. J. Food Sci. Technol. 2019, 56, 4380–4389. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists—International. Official Methods of Analysis, 18th ed.; AOAC: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Bouhlali, E.T.; Derouich, M.; Meziani, R.; Bourkhis, B.; Filali-Zegzouti, Y.; Alem, C. Nutritional, mineral and organic acid composition of syrups produced from six Moroccan date fruit (Phoenix dactylifera L.) varieties. J. Food Comp. Anal. 2020, 93, 103591. [Google Scholar] [CrossRef]

- Almusallam, I.A.; Mohamed Ahmed, I.A.; Babiker, E.E.; Al Juhaimi, F.Y.; Fadimu, G.J.; Osman, M.A.; Al Maiman, S.A.; Ghafoor, K.; Alqah, H.A.S. Optimization of ultrasound-assisted extraction of bioactive properties from date palm (Phoenix dactylifera L.) spikelets using response surface methodology. LWT-Food Sci. Technol. 2021, 140, 110816. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, S.; Wu, M.; Yang, S. Phenolic compounds from date pits: Ultrasonic-assisted extraction, antioxidant activity and component identification. J. Food Measur. Character. 2018, 12, 967–973. [Google Scholar] [CrossRef]

- Erbay, Z.; Icier, F. Optimization of hot air drying of olive leaves using response surface methodology. J. Food Eng. 2009, 91, 533–541. [Google Scholar] [CrossRef]

- Martín-Belloso, O.; Elez-Martínez, P. Enzymatic Inactivation by Pulsed Electric Fields. In Emerging Technologies for Food Processing; Sun, D.-W., Ed.; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2005; pp. 155–181. [Google Scholar]

- Rios-Corripio, G.; Morales-de la Peña, M.; Welti-Chanes, J.; Guerrero-Beltran, J.A. Pulsed electric field processing of a pomegranate (Punica granatum L.) fermented beverage. Inno. Food Sci. Emerg. Technol. 2022, 79, 103045. [Google Scholar] [CrossRef]

- Buitimea-Cantúa, G.V.; Rico-Alderete, I.A.; de Jesus Rostro-Alanís, M.; Welti-Chanes, J.; Escobedo-Avellaneda, Z.J.; Soto-Caballero, M.C. Effect of High Hydrostatic Pressure and Pulsed Electric Fields Processes on Microbial Safety and Quality of Black/Red Raspberry Juice. Foods 2022, 11, 2342. [Google Scholar] [CrossRef] [PubMed]

- González-Casado, S.; Martín-Belloso, O.; Elez-Martínez, P.; Soliva-Fortuny, R. Induced accumulation of individual carotenoids and quality changes in tomato fruits treated with pulsed electric fields and stored at different post-treatments temperatures. Posthar. Biol. Technol. 2018, 146, 117–123. [Google Scholar] [CrossRef]

- Shayanfar, S.; Chauhan, O.; Toepfl, S.; Heinz, V. The interaction of pulsed electric fields and texturizing—Antifreezing agents in quality retention of defrosted potato strips. Int. J. Food Sci. Technol. 2013, 48, 1289–1295. [Google Scholar] [CrossRef]

- Bi, X.; Liu, F.; Rao, L.; Li, J.; Liu, B.; Liao, X.; Wu, J. Effects of electric field strength and pulse rise time on physicochemical and sensory properties of apple juice by pulsed electric field. Innov. Food Sci. Emerg. Technol. 2013, 17, 85–92. [Google Scholar] [CrossRef]

- Ramadan, B.R.; Selim, M.A.A.; Nagy, K.S.A.; Mohamed, Z.S. Influence of Packaging and Cold Storage Conditions on the Physiochemical Properties of Barhi Date Fruits. Assiut J. Agric. Sci. 2020, 51, 79–91. [Google Scholar]

- López-Gámez, G.; Elez-Martínez, P.; Martín-Belloso, O.; Soliva-Fortuny, R. Enhancing phenolic content in carrots by pulsed electric fields during post-treatment time: Effects on cell viability and quality attributes. Innov. Food Sci. Emerg. Technol. 2020, 59, 102252. [Google Scholar] [CrossRef]

- Gagneten, M.; Leiva, G.; Salvatori, D.; Schebor, C.; Olaiz, N. Optimization of Pulsed Electric Field Treatment for the Extraction of Bioactive Compounds from Blackcurrant. Food Bioprocess Technol. 2019, 12, 1102–1109. [Google Scholar] [CrossRef]

- Mahnič-Kalamiza, S.; Vorobiev, E.; Miklavčič, D. Electroporation in food processing and biorefinery. J. Membr. Biol. 2014, 247, 1279–1304. [Google Scholar] [CrossRef]

- Janositz, A.; Noack, A.-K.; Knorr, D. Pulsed electric fields and their impact on the diffusion characteristics of potato slices. LWT-Food Sci. Technol. 2011, 44, 1939–1945. [Google Scholar] [CrossRef]

- Oziembłowski, M.; Trenka, M.; Czaplicka, M.; Maksimowski, D.; Nawirska-Olszánska, A. Selected Properties of Juices from Black Chokeberry (Aronia melanocarpa L.) Fruits Preserved Using the PEF Method. Appl. Sci. 2022, 12, 7008. [Google Scholar]

| Independent Variables | Level | ||||

|---|---|---|---|---|---|

| PEF intensity, kV/cm (X1) | 10 (−1) | 20 (−0.333) | 30 (0.333) | 40 (1) | |

| PEF exposure time, μs (X2) | 40 (−1) | 80 (−0.333) | 120 (0.333) | 160 (1) | |

| PEF No. of Pulses, (X3) | 50 (−1) | 100 (−0.333) | 150 (0.333) | 200 (1) | |

| Storage temperature, °C (X4) | 1 (−1) | 5 (−0.667) | 15 (0.167) | 25 (1) | |

| Storage time, days (X5) | 1 (−1) | 6 (−0.5) | 11 (0) | 16 (0.5) | 21 (1) |

| Factors | TSS | Hardness | ΔE | TVC | TPC | DPPH | Glucose | Fructose |

|---|---|---|---|---|---|---|---|---|

| Intercept | ||||||||

| β0 | 40.420 ** | 322.682 * | 2.940 ** | 0.724 * | 0.537 *** | 59.121 ** | 10.177 * | 7.949 * |

| Linear | ||||||||

| X1 (β1) | −0.362 | 10.835 | 0.113 | 0.555 | 0.144 | −0.956 | 0.607 * | 0.949 ** |

| X2 (β2) | −0.110 * | −4.441 | −0.952 | −0.017 * | −0.068 ** | 0.507 * | −0.112 | −0.134 |

| X3 (β3) | 0.108 | −1.603 | −0.033 | 0.025 | 0.081 | −0.066 | 0.259 * | 0.304 ** |

| X4 (β4) | −0.129 | −19.757 * | −0.732 * | 0.025 * | −0.189 | −1.807 * | −0.450 ** | −1.647 *** |

| X5 (β5) | 0.341 ** | 9.831 * | −0.030 ** | −0.809 * | 0.102 * | 2.188 * | 0.267 | 1.817 |

| Interaction | ||||||||

| X1X2 (β12) | 0.014 | 0.012 | −0.337 | −0.038 | −0.021 | −0.055 | 0.056 | 0.015 |

| X1X3 (β13) | −0.012 * | 0.014 | 0.333 | 0.030 * | 0.066 | 0.019 | 0.032 * | 0.019 * |

| X1X4 (β14) | −0.010 | 0.057 * | 0.682 * | 0.038 | −0.016 ** | 0.030 * | −0.024 | 0.012 |

| X1X5 (β15) | −0.064 | 0.089 | −0.136 * | −0.091 * | 0.021 | 0.070 | 0.061 | 0.014 |

| X2X3 (β23) | 0.093 | 0.040 | −0.246 | −0.055 | −0.010 | −0.033 | −0.064 | −0.090 |

| X2X4 (β24) | 0.036 | 0.012 | −0.298 * | −0.041 * | −0.016 | 0.022 * | −0.018 | −0.076 |

| X2X5 (β25) | −0.012 * | −0.018 | 0.041 | 0.069 | 0.065 | 0.053 | 0.016 | 0.020 |

| X3X4 (β34) | 0.015 | 0.060 | 0.072 | 0.080 | 0.040 | −0.024 | −0.091 * | −0.057 * |

| X3X5 (β35) | −0.075 | −0.054 | −0.205 | −0.027 | 0.024 ** | 0.053 * | −0.027 | −0.037 |

| X4X5 (β45) | 0.099 | 0.113 * | 0.378 * | −0.032 * | 0.016 | 0.016 * | −0.016 | −0.016 |

| Quadratic | ||||||||

| X12 (β11) | 0.086 | −0.296 | −2.640 | −0.012 | −0.029 ** | 0.017 | 0.011 ** | 0.013 * |

| X22 (β22) | 0.046 | 0.019 | 0.401 | 0.011 | −0.029 | −0.023 | 0.070 | 0.077 |

| X32 (β33) | −0.046 | 0.035 | −0.572 | −0.012 | 0.069 * | 0.014 | −0.050 | −0.056 |

| X42 (β44) | 0.018 | 0.549 | −0.638 | −0.044 | 0.036 | 0.053 | 0.035 | 0.069 |

| X52 (β55) | −0.057 | −0.408 | 4.080 | 0.041 | 0.011 | −0.119 | −0.099 | −0.080 |

| Model F-value | 0.474 | 1.450 | 0.871 | 0.772 | 3.280 | 2.145 | 1.924 | 2.290 |

| Model p-value | 0.009 | 0.028 | 0.008 | 0.041 | 0.0003 | 0.003 | 0.036 | 0.049 |

| Mean | 38.09 | 91.34 | 3.47 | 3.47 | 1.83 | 66.42 | 18.65 | 11.04 |

| C.V. % | 7.77 | 2.168 | 2.445 | 1.445 | 8.46 | 7.60 | 2.511 | 2.563 |

| Adeq. precision | 10.473 | 6.799 | 9.705 | 5.704 | 11.747 | 8.532 | 8.286 | 6.847 |

| R2 | 0.976 | 0.979 | 0.974 | 0.978 | 0.989 | 0.976 | 0.986 | 0.957 |

| Adjusted R2 | 0.962 | 0.965 | 0.924 | 0.929 | 0.924 | 0.969 | 0.963 | 0.931 |

| Std. Dev. | 2.961 | 18.071 | 1.891 | 1.892 | 0.337 | 5.054 | 5.513 | 5.041 |

| F-value (Lack of Fit) | 12.001 | 17.402 | 21.492 | 11.043 | 22.351 | 1.150 | 15.450 | 12.352 |

| p-value (Lack of Fit) | 0.238 | 0.233 | 1.075 | 1.069 | 0.375 | 0.079 | 0.768 | 0.375 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Younis, M.; Ahmed, I.A.M.; Ahmed, K.A.; Yehia, H.M.; Abdelkarim, D.O.; Fickak, A.; El-Abedein, A.I.Z.; Alhamdan, A.; Elfeky, A. Pulsed Electric Field as a Novel Technology for Fresh Barhi Date Shelf-Life Extension: Process Optimization Using Response Surface Methodology. Horticulturae 2023, 9, 155. https://doi.org/10.3390/horticulturae9020155

Younis M, Ahmed IAM, Ahmed KA, Yehia HM, Abdelkarim DO, Fickak A, El-Abedein AIZ, Alhamdan A, Elfeky A. Pulsed Electric Field as a Novel Technology for Fresh Barhi Date Shelf-Life Extension: Process Optimization Using Response Surface Methodology. Horticulturae. 2023; 9(2):155. https://doi.org/10.3390/horticulturae9020155

Chicago/Turabian StyleYounis, Mahmoud, Isam A. Mohamed Ahmed, Khaled A. Ahmed, Hany M. Yehia, Diaeldin O. Abdelkarim, Adil Fickak, Assem I. Zein El-Abedein, Abdulla Alhamdan, and Ahmed Elfeky. 2023. "Pulsed Electric Field as a Novel Technology for Fresh Barhi Date Shelf-Life Extension: Process Optimization Using Response Surface Methodology" Horticulturae 9, no. 2: 155. https://doi.org/10.3390/horticulturae9020155