Recent Advancements in Battery Thermal Management Systems for Enhanced Performance of Li-Ion Batteries: A Comprehensive Review

Abstract

:1. Introduction

1.1. Importance of BTMS

1.2. Recent Advances and Critical Analysis of BTMS

1.3. The Motivation for This Work

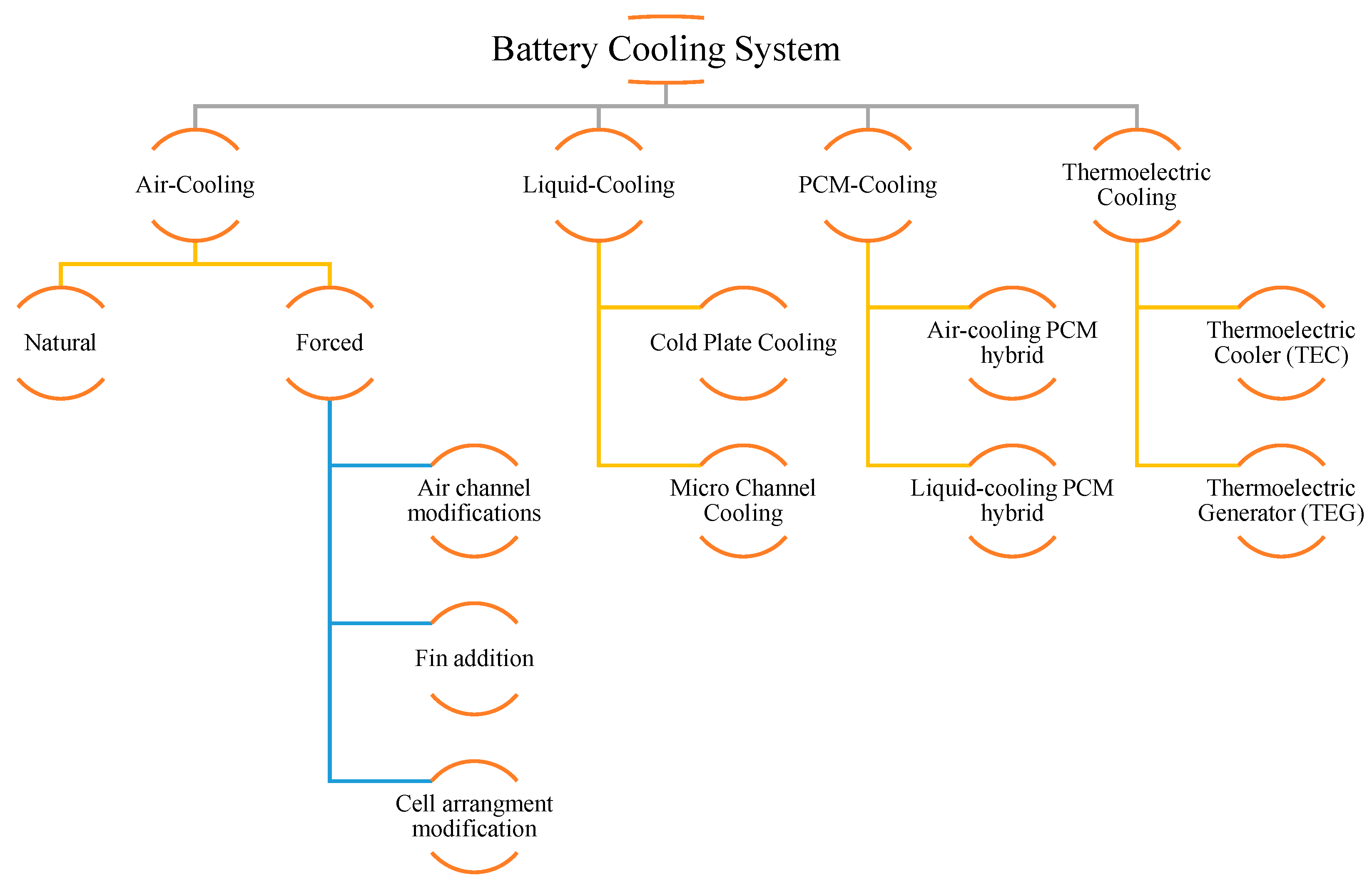

2. Recent Progress in BTMS Studies

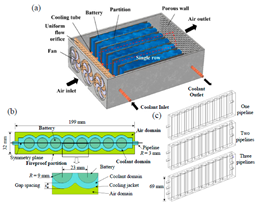

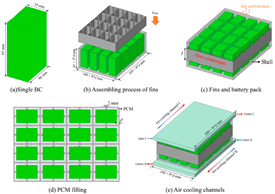

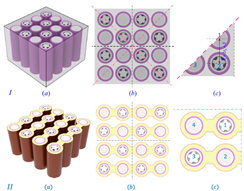

2.1. Air-Cooled BTMS

| No. | Modification/ Novelty | Type of Study | Remarks | Geometry | Ref. | Modification Method |

|---|---|---|---|---|---|---|

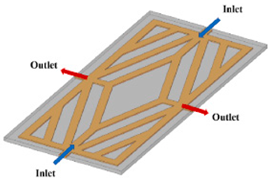

| 1 | X-type double inlet and outlet BP is used. | CFD | and are deceased 4.33 K and 74% respectively. A heat transfer correlation is obtained. |  | [5,13] | Air channel |

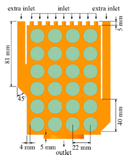

| 2 | A new design with two extra inlets is used. | CFD | Maximum temperature and temperature difference are decreased by 17.93% and 12.22%, respectively. |  | [14] | Air channel |

| 3 | A spoiler is used in the air inlet manifold in U and Z-type BPs. | CFD | Maximum temperature and temperature difference are decreased by 2.97 K and 4.98 K, respectively. |  | [15] | Air channel |

| 4 | A Z-type BP with a new stepwise divergence plenum is suggested. | CFD | Maximum temperature and temperature difference are decreased by 34.65% and 77.51%, respectively. The optimum height for each step and velocity is h = 0.125 mm and v = 3 m/s. |  | [16] | Air channel |

| 5 | A BTMS in dry-out condition is compared with a simple one. | Exp. | Maximum temperature and temperature difference are decreased by 0.31% and 0.48%, respectively. |  | [17] | Air channel |

| 6 | A bypass cold-air channel is added to BP. | CFD | Temperature difference in the BP is decreased from 31.2 °C to 3.2 °C, and maximum temperature is decreased from 30.5 °C to 24.7 °C. |  | [18] | Air channel |

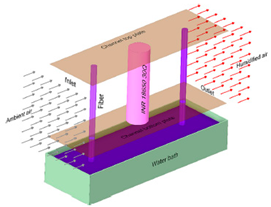

| 7 | A multiple inlet/outlet air-cooling frame is used for pouch Li-ion BP. | Exp. | This method reduces the module maximum temperature Tmax and temperature differential ΔTmax, which will be beneficial for the cost of small logistical vehicles, thus improving the cooling performance of the LIB module. |  | [7] | Air channel |

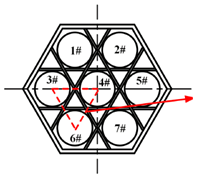

| 8 | A honeycomb-type, cylindrical BP air distribution design. | CFD | Maximum temperature and temperature difference are decreased by 1.7 K and 7.0 K, respectively. |  | [6] | Air channel |

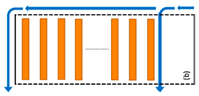

| 9 | Air-flow pattern is changed, based on Z-type and U-type BPs. | CFD | Maximum temperature and temperature difference are decreased by 0.8 K and 2.4 K, respectively. |  | [19] | Air channel |

| 10 | A vortex generator is placed in the air channel. | CFD | Maximum temperature and temperature difference are decreased by 0.85 K and 0.77 K, respectively. Pressure drop in air channel is increased by 17.88 Pa. |  | [20] | Air channel |

| 11 | A J-type BP is proposed | CFD | Maximum temperature and temperature difference are decreased by 1.57 K and 0.80 K, respectively. |  | [21] | Air channel |

| 12 | A modified Z-type BP is proposed, which tilts the arrangement of battery packs. | CFD | Maximum temperature and temperature difference are decreased by 10.5% and 23.9%, respectively. |  | [9] | Air channel |

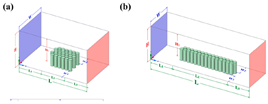

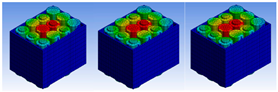

| 13 | A staggered-arranged BTMS | GA optimization CFD | The optimum architecture is found, which decreases maximum temperature by 49.18% and temperature difference by 102.37%. |  | [10] | Cell arrangement |

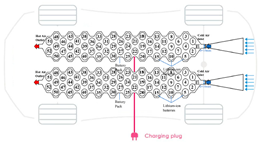

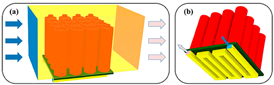

| 14 | An innovative cell arrangement for an EV is proposed. | CFD | The average temperature drop of lithium-ion batteries’ cell surface temperature is 5.6% to 7.8% when cold fluid is flowed through them. |  | [22] | Cell arrangement |

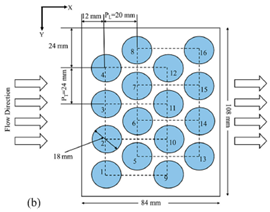

| 15 | The effect of different cell arrangements is evaluated for a 30-cell battery pack. | CFD Exp. | The 5 × 6 BP works better than 15 × 2 BP, and offers better heat dissipation. |  | [23] | Cell arrangement |

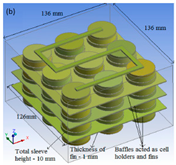

| 16 | Innovative cell holders are used to act as a fin | CFD | Maximum temperatures for the basic model are 301.5, 303.9, and 308.8 K; for the modified model, they are 300.6, 302.1, and 304 K. |  | [24] | Adding fin |

| 17 | An innovative circular fin is used around cells. | Exp. | Maximum temperature is decreased by 27.26%. |  | [12] | Adding fin |

| 18 | Innovative bod baffles for EV are used. | CFD | For 3C discharge, the new design results in a maximum temperature of 24.7 °C and temperature difference of 2.7 °C. |  | [13] | Adding fin |

| 19 | A separator plate with fish-shaped holes is used between batteries. | CFD | The new design results in a maximum temperature drop of 9.2% and temperature difference drop of 12.2%. |  | [25] | Adding fin |

| 20 | A helical coil is coupled with air jet in LIB. | Exp. | The new design results in a maximum temperature drop of 5.7 °C and temperature difference drop of 4 °C. |  | [26] | Adding fin |

2.2. Liquid-Cooled BTMS

| No. | Modification/Novelty | Type of Study | Remarks | Geometry | Ref. | Modification Method |

|---|---|---|---|---|---|---|

| 1 | A spider web liquid channel is designed. This innovation increases the area surface in contact. | CFD | The novel design maintains the maximum battery temperature below 40 °C, even under high discharge rates. |  | [27] | Cooling channel |

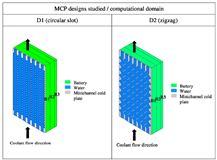

| 2 | A novel mini channel cold plate (MCP) with circular slot and zigzag channel is designed. | Exp. | Using this design can decrease maximum temperature by up to 5 °C. |  | [32] | Cooling channel |

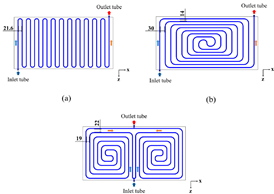

| 3 | A new inlet/outlet layout is proposed. | CFD | An optimal BTMS scheme that utilizes aluminium cooling plates with a serpentine flow channel and an inlet flow velocity of 0.5 m/s achieves the best cooling performance, energy efficiency, and material cost-effectiveness. |  | [33] | Cold plate |

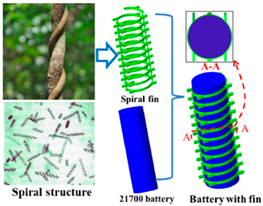

| 4 | A novel BTMS that integrates bionic spiral fins wrapped with phase change material (PCM) and embedded in a liquid cooling plate is designed. | CFD | This design significantly reduces the maximum battery temperature by 3.1 °C and increases preheating efficiency by 5.6 °C, compared to BTMS without fins |  | [30] | Cooling channel |

| 5 | A diamond flow-type channel cold plate is designed. | CFD | In comparison with usual cold plates, maximum temperature decreases from 313.33 K to 308.98 K, and pressure loss decreases from 1708 Pa to 1180 Pa. |  | [28] | Cold plate |

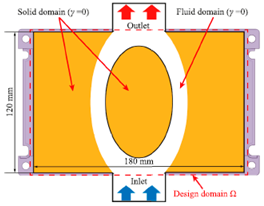

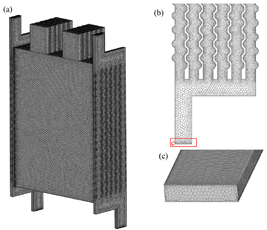

| 6 | Five different cold plates are compared, and the optimal one is found. | CFD Topology optimization method | The optimum design can decrease maximum temperature and temperature difference by 51% and 42%, respectively. |  | [34] | Cold plate |

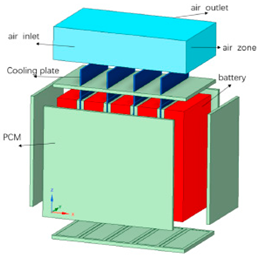

| 7 | A composite battery thermal management system that integrates both air-cooling and liquid-cooling methods is presented | CFD | The composite thermal management system reduced the highest battery temperature to 317.38 K. It minimized the temperature difference to 3.73 K, and significantly decreased entropy production. This improvement was achieved with increased air and liquid flow rates. |  | [35] | Cold plate |

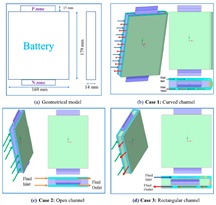

| 8 | The paper investigates various cooling configurations’ impact on LIB temperature behavior and heat transfer, advancing optimal BTMS for EVs. | CFD | The study demonstrates that liquid cooling significantly enhances the thermal performance of the battery pack (BP). Curved channels showed the most promising results, achieving a temperature reduction to 317.38 K and a minimum temperature difference of 3.73 K among the configurations tested. |  | [36] | Cold plate |

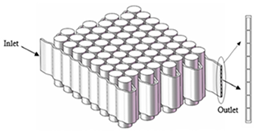

| 9 | This study investigates a hybrid battery thermal management system (BTMS) that integrates phase change material/copper foam with air jet pipe and liquid channel to enhance the thermal performance of cylindrical lithium-ion batteries (LIBs). | Exp. | The BTMS reduces the maximum temperature and temperature difference of LIBs by 14.6% and 64.7%, respectively, |  | [37] | Cooling channel |

| 10 | A hybrid battery thermal management system combining phase change material and copper foam with air jet pipe and liquid channel is designed. | CFD | The indirect liquid cooling microchannel BTMS with nanofluids achieves superior temperature uniformity and rapid cooling, significantly enhancing the thermal performance of the battery module. |  | [38] | Cooling channel |

| 11 | Many liquid circulation types are compared to minimize energy consumption. | CFD | The reciprocating flow approach reduces the temperature differential and energy consumption by 55.3% and 15.6%, respectively. |  | [39] | Cooling channel |

| 12 | Innovative Hybrid Nano/Dielectric Fluid Cooling System for Cylindrical Li-Ion Batteries: Enhanced Thermal Management Across Operational Conditions | CFD | This system exhibits excellent thermal efficiency at high discharge rates, particularly when using a 4% Alumina nanofluid and high input velocities. Thermal management was further improved with the addition of curved cooling channels and separator plates. These enhancements effectively lowered both maximum and non-homogeneity temperatures. |  | [40] | Cooling channel |

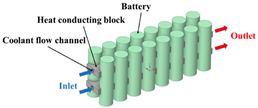

| 13 | Hybrid BTMS for Cylindrical Lithium-Ion Batteries: Optimizing Thermal Performance and Ensuring Cell Temperature Uniformity | CFD Exp. | Three heat-conducting blocks (HCBs) and 6 mm cooling channels for excellent cooling efficiency and lightweight construction were used. Periodic air cooling might save energy and preserve battery safety. |  | [41] | Cooling channel |

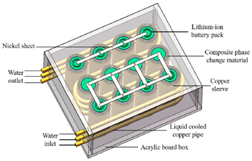

| 14 | Battery Pack with 6 × 8 Cell Configuration: Cooling Jacket with Aluminum Plates and Transformer Oil for Direct Liquid Cooling | CFD | A two-pipeline liquid-cooling structure provides the best balance of cooling performance and energy consumption. This structure achieved effective temperature reduction and improved uniformity under high-rate discharge conditions with the hybrid system. |  | [42] | Cooling channel |

| 15 | BTMS with Hollow Copper Sleeves and Bent Liquid Copper Pipes for Cooling: Micro-Controller Optimization for Enhanced Performance | Exp. | the novel Battery Thermal Management System (BTMS), combining CPCM and liquid cooling, effectively controlled battery temperatures. It maintained a maximum temperature below 44.8 °C and a temperature difference under 2 °C. The optimal coolant flow rate was identified as 250 mL/min, balancing cooling efficiency and energy use. The system’s design is scalable, making it applicable to various battery types for enhanced thermal management. |  | [43] | Cooling channel |

| 16 | Hybrid BTMS for Superior Thermal Management: Integrating PCM Modules with Copper and Graphite, Micro Cooling Plates, and Interconnected Cooling Channels. | Exp. | The hybrid Battery Thermal Management System (BTMS) reduced the maximum battery temperature by 13.78%. It also maintained the temperature difference below 3.9 °C and increased energy density by 11.23%. The optimal cooling configuration combined PCM, MHPA, and liquid cooling. This combination outperformed single-method cooling systems in both thermal performance and energy efficiency. |  | [44] | Cooling channel |

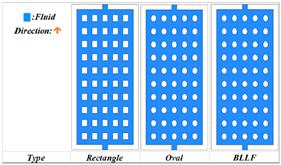

| 17 | Comparative Study of Four Designs with Various Inlet/Outlet Positions: Design D Features Circular Slots for Enhanced Heat Transfer and Optimized Channels for Higher Discharge Rates. | CFD | It was found that Design D demonstrated superior comprehensive performance compared to other designs. This design significantly lowered the maximum temperature of the battery pack and improved temperature uniformity. These features make Design D particularly suitable for high discharge-rate conditions. |  | [45] | Cooling channel |

| 18 | Optimized Bionic Limulus-Like Fins for Liquid-Cooled Plates: Enhanced Heat Dissipation and Reduced Pressure Loss Compared to Conventional Designs. | CFD | The key finding of this work is that the optimized bionic limulus-like fin design significantly reduced the average temperature by 1.69 °C (4.61%). It also decreased the pressure drop by 6.81 Pa (54.26%). These improvements enhanced overall cooling performance compared to the initial model. |  | [46] | Cold plate |

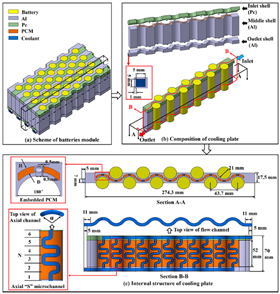

| 19 | Innovative Battery Pack Cold Plates: Radial Inlet/Outlet Flow Channels and Axial Microchannel Shell with S-Shaped Metal Tubes for Enhanced Cooling and Heat Dissipation. | Exp. Multi objective optimization | The study optimized a hybrid cooling plate with axial S-shaped microchannels, which enhanced thermal management and energy efficiency in EV batteries. Key findings include improved temperature uniformity, reduced energy consumption, and effective performance in both high-temperature and cold environments. A delayed cooling strategy was also used to save energy. Increasing the delay time before activating liquid cooling significantly decreased energy consumption. A delay of 300 s reduced energy consumption by 46.3% while maintaining a maximum temperature below 40 °C and a temperature difference within 5 °C. |  | [47] | Cooling channel |

| 20 | Novel Parallel Sandwich Cooling Structure: Enhancing Thermal Uniformity and Reducing Pressure Loss in Lithium-Ion Battery Packs | CFD | The parallel sandwich cooling structure significantly enhanced thermal uniformity in battery packs. It reduced the average temperature by 26.2% and the maximum temperature by 26.9%, compared to series cooling systems. The new model also achieved a 62% decrease in temperature difference within the battery pack, demonstrating improved thermal uniformity over series cooling structures. |  | [31] | Cooling channel |

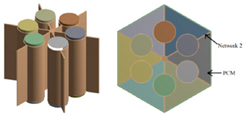

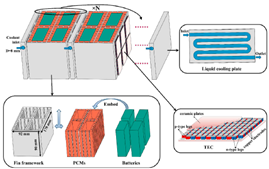

2.3. PCM-Cooled BTMS

| No. | Modification/Novelty | Type of Study | Remarks | Geometry | Ref. | Modification Method |

|---|---|---|---|---|---|---|

| 1 | Lithium-ion (LIB)-PCM Configurations: Square, Circular, Rectangular. | CFD | PCM-RT35 is ideal for temperatures of 20–30 °C. PCM-RT50 is optimal for 40 °C. Copper shells provide superior temperature control. Aluminium shells are more practical. Higher heat transfer coefficients improve temperature stabilization. Rectangular battery packs offer the best thermal management. |  | [57] | PCM-air |

| 2 | Biomimetic Fin with PCM and Delayed Air Cooling | Exp. | Maximum temperature reduced by 3.4 °C using fins. Power consumption reduced by 33% with beak fins. Optimal fin parameters: 75° angle, 40 mm length. Delayed air-cooling reduces power consumption by 59%. |  | [50] | PCM-air |

| 3 | Hybrid PCM with Secondary Air and Liquid Coolants | Exp. | With a discharge rate of 7C, the paraffin with copper foam showed a phase-change percentage of only 6.87%. This suggests effective thermal management without excessive phase change, resulting in reduced pumping power requirements and improved energy efficiency. |  | [58] | PCM- liquid |

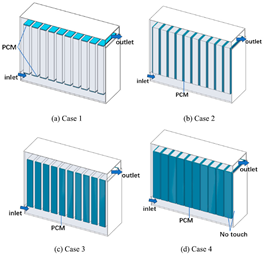

| 4 | Optimized PCM Configurations for Prismatic Batteries | CFD | PCM significantly enhances thermal performance. Case 4 saves PCM while maintaining thermal efficiency. Optimized PCM proportion is 64%. |  | [52] | PCM-air |

| 5 | Hybrid PCM-Air/Fluid Coolants for Enhanced Thermal Performance | CFD | Hybrid strategy with paraffin, air, and fluid coolants significantly improves thermal performance. Eliminates need for pumps. Achieves high temperature uniformity. |  | [59] | PCM-air |

| 6 | Graphene-Enhanced Paraffin PCM | Exp. | In higher temperature scenarios, researchers have found that a hybrid cooling system that combines phase-change material (PCM) with other cooling methods like forced-air or thermoelectric module cooling may be more effective. The inclusion of graphene-enhanced paraffin as a phase-change material (PCM) has a substantial impact on lowering the temperature of the lithium-ion battery pack. It was shown in the study that as the thickness of the PCM layer increases, the maximum temperature decreases. |  | [60] | PCM-air |

| 7 | Dual PCM System with Petal Design and Optimized Fins | CFD | The optimized solution with an asymmetric fin arrangement significantly decreases the maximum temperature difference (ΔT_max) by 5.53% at 30 °C. The optimized solution decreases the maximum temperature difference (ΔT_max) by 29.19% at 40 °C. It reduces the maximum temperature rise (ΔT_(m-rise)) by 36.15% at 30 °C. It reduces the maximum temperature rise (ΔT_(m-rise)) by 42.76% at 40 °C. |  | [61] | PCM-air |

| 8 | PCM-Based BTMS with Air-Cooling and Cold Plate | CFD | Throughout January, the battery temperature was carefully regulated with the help of a BTMS, staying consistently between 20–28 °C. The maximum temperature difference (ΔT) was only 2.6 °C. This demonstrates the successful implementation of efficient thermal management. |  | [62] | PCM-air |

| 9 | Hybrid PCM with Wavy Microchannel Cold Plate (HWMCP) | CFD | In cold weather, HWMCP helps prevent battery temperature loss, allowing for longer battery temperature maintenance during short-term parking, compared to WMCP. By reducing the weight of HWMCP by 45%, the system’s energy efficiency is significantly improved. |  | [54] | PCM- liquid |

| 10 | Nine Innovative Branch-Fin Designs for Enhanced PCM Thermal Management | CFD | The study presents nine new branch-fin designs for battery thermal management, showing superior thermal performance. These designs increase heat transfer efficiency by 14.98%. They extend operating time by 131.5%. The new designs reduce system weight by 10.28%, compared to conventional designs. |  | [63] | PCM-air |

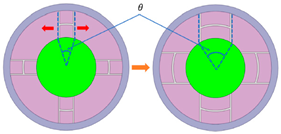

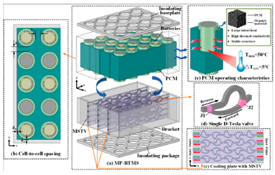

| 11 | Hybrid PCM with Multi-Stage Tesla Liquid Valve-Cooling | Exp. CFD | The hybrid battery thermal management system with PCM and multistage Tesla valve-cooling significantly decreases energy consumption by 79.9%, compared to traditional systems. It also proves to be more efficient at maintaining battery temperature, especially during cold stops. This results in a doubling of warmth-retention time. |  | [64] | PCM- liquid |

| 12 | Novel BTMS with PCM, Air Cooling, and Fin Structures | Optimal BTMS parameters are d = 8.125 mm and l = 65 mm, with Tmax = 318.01 K, ΔT = 0.0135 K, and W = 5.13 kg. Increasing fin height from 5 mm to 65 mm enhances PCM utilization by 20.4% and reduces Tmax by 9.3 K. As d increases from 5 mm to 20 mm, PCM utilization decreases by 90.9% and BTMS weight increases by 146.7%. Fin addition improves thermal efficiency and compactness, significantly lowering battery temperature. |  | [65] | PCM-air | |

| 13 | BTMS with PCM and Optimized Aluminium Fins | CFD | The identified optimal parameters are d = 8.125 mm and l = 65 mm, resulting in Tmax = 318.01 K, ΔT = 0.0135 K, and W = 5.13 kg. By increasing the fin height, the utilization of PCM is improved by 20.4% and the maximum temperature (Tmax) is reduced by 9.3 K. On the other hand, increasing the PCM thickness results in a significant decrease in utilization by 90.9% and a substantial increase in weight by 146.7%. |  | [66] | PCM-air |

| 14 | Innovative BTMS with PCM, Metal Foam, and Fin Shapes | CFD | The fourth case of the BTMS, which combines PCM, metal foam, and fins, exhibited the best thermal performance, keeping the battery surface temperature at the lowest level. This design achieved a maximum reduction of 3 K in battery surface temperature compared to pure PCM systems. Different fin shapes (rectangular, triangular, trapezoidal, I-shape, and wavy) were analyzed. The results showed that, while the triangular fins were most effective before the PCM melting began, the I-shape fins provided the lowest battery surface temperature after the PCM started melting. |  | [67] | PCM-air |

| 15 | Hybrid BTMS with U-Shaped Micro Heat Pipe Array and Composite PCM | Exp. | The hybrid Battery Thermal Management System (BTMS), which combines a U-shaped micro heat pipe array (U-MHPA), composite phase change material (cPCM), and liquid cooling, significantly improves cooling performance. It effectively controls the maximum temperature and temperature difference within the battery module, even under extreme conditions. The system maintains the maximum temperature below 50 °C and the temperature difference below 5 °C. |  | [68] | PCM- liquid |

| 16 | Comparison of Hydrogel and PCM-Based BTMS | CFD | Hydrogel-based BTMS demonstrated superior cooling performance compared to PCM-based systems. It showed a significant decrease of 5.27 °C in maximum temperature under specific conditions. |  | [69] | PCM-air |

| 17 | Electrochemical–Thermal Modeling of Li-ion Batteries with Fin-Intensified PCM BTMS | CFD | Without any thermal management system (TMS), the peak temperature during a 4C discharge reached 336 K. The use of base PCM alone reduced the peak temperature increase by almost 71%. The finned designs further improved this, with Design D1 reducing the temperature increase by 72% and Design D2 by 75.58%. |  | [70] | PCM-air |

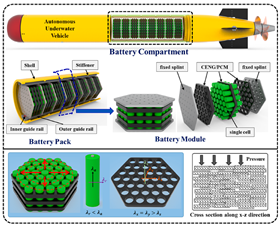

| 18 | High-Performance Anisotropic CPCM Composite for Thermal Management | Exp. | The CPCM showed excellent thermal management performance. Under a 2C high discharge rate, the maximum temperature of the battery module with CPCM decreased by 21.9 °C (29.9%). The temperature difference decreased by 7.8 °C (55.3%), compared to modules without CPCM. |  | [71] | PCM- liquid |

| 19 | Aluminium Nitride Enhanced PCM for Superior Passive Cooling | Exp. | Managing battery temperatures within the range of 25 °C to 45 °C is crucial for optimizing the performance of the thermal regulator. When the temperature is below 30 °C, the batteries can function without the need for active cooling methods, thanks to the use of PCM or cPCM. When the ambient temperature reaches 35 °C, it is important to use a thermal regulator with cooling water to ensure that the battery temperature remains below 38.13 °C. When the ambient temperature exceeds 40 °C, the thermal regulator equipped with cPCM can lower the battery temperature to 35.02 °C. |  | [55] | PCM- liquid |

| 20 | Snowflake Fin Design for Enhanced PCM Heat Transfer | CFD | With the addition of snowflake fins, the heat-transfer efficiency of PCM is greatly improved, resulting in a noticeable reduction in battery temperatures. With a 3C discharge rate, the Batteries–PCM–Fins design effectively keeps the battery module temperature below 45 °C, regardless of whether the ambient temperatures are 25 °C or 40 °C. The temperature difference remains less than 3 °C, ensuring optimal performance. These snowflake fins are designed to enhance thermal management efficiency, particularly during the initial cycles. They achieve this by minimizing the maximum temperature and temperature difference within the battery module. |  | [72] | PCM- liquid |

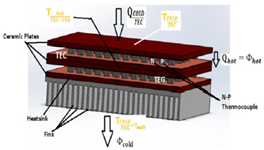

2.4. Thermoelectric Cooler BTMS

3. Discussion and Conclusions

3.1. Summary of Key Findings

- Air channel modifications are the most impactful, with designs like the X-type, honeycomb structures, and multiple inlet/outlet air cooling significantly improving temperature management.

- Cell arrangement modifications also contribute to better thermal performance, with innovative designs such as the modified Z-shaped system and the staggered-arranged system.

- Adding fin structures greatly enhances cooling efficiency by increasing the heat-dissipation surface area using radial fins for air-cooling and direct cooling with baffles.

- Cold plate modifications show significant improvements in cooling efficiency, with designs like the spider web liquid channel, mini channel plates with circular and zigzag channels, and the diamond flow type channel maintaining optimal temperatures under high-load conditions.

- Cooling channel modifications enhance thermal management by optimizing fluid flow, wavy microchannels, increasing surface area for heat dissipation, and using advanced materials such as nanofluids and dielectric fluids.

- Hybrid systems combining PCM and liquid-cooling methods provide superior temperature control, ensuring consistent battery performance, even under extreme conditions.

- PCM configurations such as square, circular, and rectangular designs optimize thermal management for specific temperature ranges, with materials like copper shells providing enhanced temperature control.

- Hybrid PCM systems that integrate PCM with air- or liquid-cooling methods offer improved temperature regulation and energy efficiency. These systems are particularly effective at managing thermal loads during high discharge rates.

- Innovative PCM designs featuring advanced fin structures and optimized configurations significantly enhance heat-transfer efficiency, reduce temperature differences, and extend battery operating time.

- Hybrid TEC–TEG systems demonstrate substantial improvements in cooling efficiency by leveraging the benefits of both TEC and TEG. These systems are effective at significantly reducing battery temperatures.

- Active and passive hybrid systems that integrate TEC with PCM or fins show enhanced temperature regulation and energy efficiency. These systems are particularly effective at managing thermal loads during high discharge rates.

- Innovative TEC designs offer advanced solutions for thermal management, such as dual active cooling systems and TEC with cold plates. These designs provide efficient cooling, and maintain battery temperatures within optimal ranges, even under extreme conditions.

3.2. Techno-Economic Comparative Analysis of Cooling Methods

- Cooling Efficiency (CE): measures how effectively a cooling method maintains the battery temperature within the optimal range.

- Temperature Uniformity (TU): assesses the ability of the cooling method to maintain a uniform temperature distribution across the battery pack.

- Maximum Temperature Reduction (MTR): the extent to which the cooling method can lower the maximum temperature of the battery.

- Energy Consumption (EC): the amount of energy required by the cooling method to maintain optimal battery temperatures.

- System Complexity (SC): the level of complexity involved in implementing and maintaining the cooling method.

- Response Time (RT): the speed at which the cooling method can adapt to changes in thermal load.

- Cost-Effectiveness (C-E): the overall cost of implementing and operating the cooling method, relative to its performance benefits.

- Scalability (S): the ease with which the cooling method can be scaled up or down to accommodate different battery sizes and configurations.

- Safety and Reliability (SR): the degree to which the cooling method enhances battery safety and operational reliability.

4. Future Directions and Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ali, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Rallabandi, S.; Selvaraj, R.V.I. Advancements in Battery Cooling Techniques for Enhanced Performance and Safety in Electric Vehicles: A Comprehensive Review; John Wiley and Sons Inc.: Hoboken, NJ, USA, 2024. [Google Scholar] [CrossRef]

- Li, K.; Sun, C.; Zhang, M.; Wang, S.; Wei, B.; Cheng, Y.; Ju, X.; Xu, C. A Study of the Thermal Management and Discharge Strategies of Lithium-Ion Batteries in a Wide Temperature Range. Energies 2024, 17, 2319. [Google Scholar] [CrossRef]

- Li, J.-X.; Li, P.-Z.; Wang, M.; Chen, C.; Gao, Y.; Yan, L.-Y.; Yang, S.-C.; Zhao, C.; Chen, M.-M.; Zhang, J.-S.; et al. Study on the temperature rise characteristics of aging lithium-ion batteries under different cooling methods. Appl. Therm. Eng. 2024, 240, 122235. [Google Scholar] [CrossRef]

- Luo, L.; Liu, Y.; Liao, Z.; Zhong, J. Optimal structure design and heat transfer characteristic analysis of X-type air-cooled battery thermal management system. J. Energy Storage 2023, 67, 107681. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, F.; Chen, X.; Li, K.; Shen, J. Thermal performance of honeycomb-type cylindrical lithium-ion battery pack with air distribution plate and bionic heat sinks. Appl. Therm. Eng. 2023, 218, 119299. [Google Scholar] [CrossRef]

- Duan, L.; Zhou, H.; Xu, W.; Li, L.; Liu, X.; Du, Z.; Jiang, H. Design method of multiple inlet/outlet air cooling frame of pouch lithium-ion battery based on thermal-fluid coupling topology optimization. Int. J. Heat Mass Transf. 2023, 215, 124496. [Google Scholar] [CrossRef]

- Jilte, R.D.; Kumar, R.; Ahmadi, M.H.; Chen, L. Battery Thermal Management System Employing Phase Change Material with Cell-To-Cell Air Cooling; Elsevier Ltd.: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Shen, X.; Cai, T.; He, C.; Yang, Y.; Chen, M. Thermal analysis of modified Z-shaped air-cooled battery thermal management system for electric vehicles. J. Energy Storage 2023, 58, 106356. [Google Scholar] [CrossRef]

- Kashyap, P.; Panda, B.; Gao, L.; Garg, A. Design optimization of staggered-arranged battery thermal management system using an integrated approach of physics-based simulations and evolutionary algorithms. J. Energy Storage 2024, 79, 110229. [Google Scholar] [CrossRef]

- Ahmad, S.; Liu, Y.; Khan, S.A.; Hao, M.; Huang, X. Hybrid battery thermal management by coupling fin intensified phase change material with air cooling. J. Energy Storage 2023, 64, 107167. [Google Scholar] [CrossRef]

- Chaudhari, J.; Singh, G.K.; Rathod, M.K.; Ali, H.M. Experimental and computational analysis on lithium-ion battery thermal management system utilizing air cooling with radial fins. J. Therm. Anal. Calorim. 2024, 149, 203–218. [Google Scholar] [CrossRef]

- Luo, Y.; Qiu, X.; Wang, S.; Jia, Z. Optimizing a direct flow cooling battery thermal management with bod baffles for electric vehicles: An experimental and simulation study. J. Energy Storage 2023, 74, 109410. [Google Scholar] [CrossRef]

- Tuğan, V.; Yardımcı, U. Numerical study for battery thermal management system improvement with air channel in electric vehicles. J. Energy Storage 2023, 72, 108515. [Google Scholar] [CrossRef]

- Yang, C.; Xi, H.; Wang, M. Structure optimization of air cooling battery thermal management system based on lithium-ion battery. J. Energy Storage 2023, 59, 106538. [Google Scholar] [CrossRef]

- Suo, Y.; Tang, C.; Yang, H. Optimization design of the forced air-cooled battery thermal management system with a stepped divergence plenum. J. Energy Storage 2023, 73, 108904. [Google Scholar] [CrossRef]

- Sutheesh, P.; Atul, A.; Rohinikumar, B. Numerical and experimental investigations of thermal performance of lithium-ion battery with hybrid cooling system under dry-out condition. J. Energy Storage 2024, 84, 110889. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, Y.-W.; Yang, J.-T. Optimized thermal management of a battery energy-storage system (BESS) inspired by air-cooling inefficiency factor of data centers. Int. J. Heat Mass Transf. 2023, 200, 123388. [Google Scholar] [CrossRef]

- Zhang, S.-B.; He, X.; Long, N.-C.; Shen, Y.-J.; Gao, Q. Improving the air-cooling performance for lithium-ion battery packs by changing the air flow pattern. Appl. Therm. Eng. 2023, 221, 119825. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Li, C.; Zhang, H.; Cheng, Y. A High-Performance Vortex Adjustment Design for an Air-Cooling Battery Thermal Management System in Electric Vehicles. Batteries 2023, 9, 208. [Google Scholar] [CrossRef]

- Fan, H.; Wang, L.; Chen, W.; Liu, B.; Wang, P. A J-Type Air-Cooled Battery Thermal Management System Design and Optimization Based on the Electro-Thermal Coupled Model. Energies 2023, 16, 5962. [Google Scholar] [CrossRef]

- Hasan, H.A.; Togun, H.; Abed, A.M.; Biswas, N.; Mohammed, H.I. Thermal performance assessment for an array of cylindrical Lithium-Ion battery cells using an Air-Cooling system. Appl. Energy 2023, 346, 121354. [Google Scholar] [CrossRef]

- Yang, T.-F.; Yan, W.-M.; Lin, P.-Y.; Lin, C.-Y.; Yang, C.-C.; Sajjad, U. Thermal management of 21700 Li-ion battery packs: Experimental and numerical investigations. Appl. Therm. Eng. 2024, 236, 121518. [Google Scholar] [CrossRef]

- Kummitha, O.R. Thermal cooling of li-ion cylindrical cells battery module with baffles arrangement for airflow cooling numerical analysis. J. Energy Storage 2023, 59, 106474. [Google Scholar] [CrossRef]

- Gao, Q.; Lei, Z.; Huang, Y.; Zhang, C.; Chen, Y. Performance investigation of a liquid immersion cooling system with fish-shaped bionic structure for Lithium-ion battery pack. Int. J. Heat Mass Transf. 2024, 222, 125156. [Google Scholar] [CrossRef]

- Zhou, H.; Niu, J.; Guo, X.; Xu, L.; Song, Z.; Yin, X. Thermal performance of a hybrid thermal management system based on the half helical coil coupled with air jet cooling for cylindrical Lithium-ion battery. Appl. Therm. Eng. 2023, 225, 120231. [Google Scholar] [CrossRef]

- Yao, F.; Guan, X.; Chen, Q.; Lin, L. Research on thermal management system of lithium-ion battery with a new type of spider web liquid cooling channel and phase change materials. J. Energy Storage 2024, 81, 110447. [Google Scholar] [CrossRef]

- Li, W.; Wang, Y.; Yang, W.; Zhang, K. Design and optimization of an integrated liquid cooling thermal management system with a diamond-type channel. Therm. Sci. Eng. Prog. 2024, 47, 102325. [Google Scholar] [CrossRef]

- Yates, M.; Akrami, M.; Javadi, A.A. Analysing the performance of liquid cooling designs in cylindrical lithium-ion batteries. J. Energy Storage 2021, 33, 100913. [Google Scholar] [CrossRef]

- Chen, X.; Shen, J.; Xu, X.; Wang, X.; Su, Y.; Qian, J.; Zhou, F. Performance of thermal management system for cylindrical battery containing bionic spiral fin wrapped with phase change material and embedded in liquid cooling plate. Renew. Energy 2024, 223, 120087. [Google Scholar] [CrossRef]

- Zhao, J.; Du, W.; Xiang, H.; Gu, L. Heat transfer characteristics of liquid cooling system for lithium-ion battery pack. Proc. Inst. Mech. Eng. Part. D J. Automob. Eng. 2024, 09544070231220750. [Google Scholar] [CrossRef]

- Amalesh, T.; Narasimhan, N.L.; Reddy, G.R. Numerical and experimental studies on novel minichannel cold plates for lithium-ion battery thermal management. J. Energy Storage 2023, 73, 109167. [Google Scholar] [CrossRef]

- Feng, Z.; Shen, X.; Li, P.; Zhao, J.; Zhang, H.; Xu, Y.; Yuan, J. Performance optimization and scheme evaluation of liquid cooling battery thermal management systems based on the entropy weight method. J. Energy Storage 2024, 80, 110329. [Google Scholar] [CrossRef]

- Zhong, Q.; Chandra, P.K.; Li, W.; Gao, L.; Garg, A.; Lv, S.; Tai, K. A comprehensive numerical study based on topology optimization for cooling plates thermal design of battery packs. Appl. Therm. Eng. 2024, 236, 121918. [Google Scholar] [CrossRef]

- Ye, J.; Aldaher, A.Y.M.; Tan, G. Thermal performance analysis of 18,650 battery thermal management system integrated with liquid-cooling and air-cooling. J. Energy Storage 2023, 72, 108766. [Google Scholar] [CrossRef]

- Chavan, S.; Liu, J.; Venkateswarlu, B.; Joo, S.W.; Kim, S.C. Numerical simulation of lithium-ion battery thermal management systems: A comparison of fluid flow channels and cooling fluids. J. Energy Storage 2023, 73, 108940. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, X.; Xu, L.; Cui, Y.; Guo, S.; Song, Z. Thermal performance of a hybrid thermal management system that couples PCM/copper foam composite with air-jet and liquid cooling. J. Energy Storage 2023, 74, 109408. [Google Scholar] [CrossRef]

- Kumar, K.; Sarkar, J.; Mondal, S.S. Multi-scale-multi-domain simulation of novel microchannel-integrated cylindrical Li-ion battery thermal management: Nanoparticle shape effect. J. Energy Storage 2024, 84, 110824. [Google Scholar] [CrossRef]

- Zeng, W.; Ma, C.; Hu, S.; Li, S.; Zhang, Y. The performance investigation and optimization of reciprocating flow applied for liquid-cooling-based battery thermal management system. Energy Convers. Manag. 2023, 292, 117378. [Google Scholar] [CrossRef]

- Tousi, M.; Najafi, M. Innovative hybrid nano/dielectric fluid cooling system for the new cylindrical shaped Li-ion batteries. Int. J. Therm. Sci. 2024, 195, 108634. [Google Scholar] [CrossRef]

- Xin, S.; Wang, C.; Xi, H. Thermal management scheme and optimization of cylindrical lithium-ion battery pack based on air cooling and liquid cooling. Appl. Therm. Eng. 2023, 224, 120100. [Google Scholar] [CrossRef]

- Zhao, L.; Li, W.; Wang, G.; Cheng, W.; Chen, M. A novel thermal management system for lithium-ion battery modules combining direct liquid-cooling with forced air-cooling. Appl. Therm. Eng. 2023, 232, 120992. [Google Scholar] [CrossRef]

- Wang, J.; Mei, W.; Mao, B.; Wang, Q. Investigation on the temperature control performance and optimization strategy of a battery thermal management system combining phase change and liquid cooling. Appl. Therm. Eng. 2023, 232, 121080. [Google Scholar] [CrossRef]

- Xie, N.; Zhang, Y.; Liu, X.; Luo, R.; Liu, Y.; Ma, C. Thermal performance and structural optimization of a hybrid thermal management system based on MHPA/PCM/liquid cooling for lithium-ion battery. Appl. Therm. Eng. 2023, 235, 121341. [Google Scholar] [CrossRef]

- Dai, W.; Lai, H. Comparative study of flow-channel layout schemes in liquid cooling plates of a prismatic battery module. Appl. Therm. Eng. 2024, 236, 121501. [Google Scholar] [CrossRef]

- Zhang, F.; Huang, Z.; Li, S.; Sun, S.; Zhao, H. Design and thermal performance analysis of a new micro-fin liquid cooling plate based on liquid cooling channel finning and bionic limulus-like fins. Appl. Therm. Eng. 2024, 237, 121597. [Google Scholar] [CrossRef]

- Shen, J.; Chen, X.; Xu, X.; Kong, J.; Song, Z.; Wang, X.; Zhou, F. Thermal performance of a hybrid cooling plate integrated with microchannels and PCM. Appl. Therm. Eng. 2024, 236, 121917. [Google Scholar] [CrossRef]

- Yan, G.; Alizadeh, A.; Rahmani, A.; Zarringhalam, M.; Shamsborhan, M.; Nasajpour-Esfahani, N.; Akrami, M. Natural convection of rectangular cavity enhanced by obstacle and fin to simulate phase change material melting process using Lattice Boltzmann method. Alex. Eng. J. 2023, 81, 319–336. [Google Scholar] [CrossRef]

- Rahmani, A.; Dibaj, M.; Akrami, M. Computational investigation of magnetohydrodynamic flow and melting process of phase change material in a battery pack using the lattice Boltzmann method. J. Energy Storage 2024, 78, 110046. [Google Scholar] [CrossRef]

- Chen, X.; Yang, W.; Shen, J.; Xu, X.; Zhou, F. Thermal performance of hybrid battery thermal management system with air cooling and phase change material embedding biomimetic variable section fins. Appl. Therm. Eng. 2023, 231, 120985. [Google Scholar] [CrossRef]

- Rahmani, A.; Dibaj, M.; Akrami, M. Enhancing Heat Storage Cooling Systems via the Implementation of Honeycomb-Inspired Design: Investigating Efficiency and Performance. Energies 2024, 17, 351. [Google Scholar] [CrossRef]

- Suo, Y.; Tang, C.; Jia, Q.; Zhao, W. Influence of PCM configuration and optimization of PCM proportion on the thermal management of a prismatic battery with a combined PCM and air cooling structure. J. Energy Storage 2024, 80, 110340. [Google Scholar] [CrossRef]

- Tang, H.; Wang, S.; Li, H. Flexibility Categorization, Sources, Capabilities and Technologies for Energy-Flexible and Grid-Responsive Buildings: State-Of-The-Art and Future Perspective; Elsevier Ltd.: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, T.; Zhou, L.; Gong, J.; Li, J. A parametric study of a hybrid battery thermal management system that couples PCM with wavy microchannel cold plate. Appl. Therm. Eng. 2023, 219, 119625. [Google Scholar] [CrossRef]

- Li, K.; Yao, X.; Li, Z.; Gao, T.; Zhang, W.; Liao, Z.; Ju, X.; Xu, C. Thermal management of Li-ion batteries with passive thermal regulators based on composite PCM materials. J. Energy Storage 2024, 89, 111661. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Yang, B.; Cai, S. A Review of Battery Thermal Management Systems Using Liquid Cooling and PCM; Elsevier Ltd.: Amsterdam, The Netherlands, 2024. [Google Scholar] [CrossRef]

- Wang, H.; Guo, Y.; Ren, Y.; Yeboah, S.; Wang, J.; Long, F.; Zhang, Z.; Jiang, R. Investigation of the thermal management potential of phase change material for lithium-ion battery. Appl. Therm. Eng. 2024, 236, 121590. [Google Scholar] [CrossRef]

- Shahid, S.; Agelin-Chaab, M. Investigation of thermal properties of phase change materials for novel hybrid thermal management strategies for cylindrical Li-ion cells. Appl. Therm. Eng. 2024, 242, 122471. [Google Scholar] [CrossRef]

- Shahid, S.; Agelin-Chaab, M. Investigation of Heat Transfer Enhancement Techniques on a Scalable Novel Hybrid Thermal Management Strategy for Lithium-Ion Battery Packs. Batteries 2024, 10, 32. [Google Scholar] [CrossRef]

- Kadam, G.; Kongi, P. Battery thermal management system based on PCM with addition of nanoparticles. Mater. Today Proc. 2023, 72, 1543–1549. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Feng, Y.; Liu, M.; Kang, C.; Yang, K.; Yuan, J.; Qiu, C.; Shi, H.; Jiang, Y. A novel petal-type battery thermal management system with dual phase change materials. Int. J. Heat Mass Transf. 2023, 207, 123989. [Google Scholar] [CrossRef]

- Xu, B.; Xia, F.; Wang, Y.-L.; Xie, X.; Gan, W.-T. A battery thermal management scheme suited for cold regions based on PCM and aerogel: Demonstration of performance and availability. Appl. Therm. Eng. 2023, 227, 120378. [Google Scholar] [CrossRef]

- Zhang, F.; Lu, F.; Liang, B.; Zhu, Y.; Gou, H.; Xiao, K.; He, Y. Thermal performance analysis of a new type of branch-fin enhanced battery thermal management PCM module. Renew. Energy 2023, 206, 1049–1063. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, Z.; Xiong, X.; Zhu, J.; Gao, Q.; Wang, H.; Wu, H. Novel concept design of low energy hybrid battery thermal management system using PCM and multistage Tesla valve liquid cooling. Appl. Therm. Eng. 2023, 220, 119680. [Google Scholar] [CrossRef]

- Shi, H.; Liu, M.; Li, Y.; Wang, S.; Qiu, C.; Cheng, M.; Yuan, J.; Yang, K.; Kang, C. Multi-objective optimization of integrated lithium-ion battery thermal management system. Appl. Therm. Eng. 2023, 223, 119991. [Google Scholar] [CrossRef]

- Liu, H.; Jin, C.; Li, H.; Ji, Y. A numerical study of PCM battery thermal management performance enhancement with fin structures. Energy Rep. 2023, 9, 1793–1802. [Google Scholar] [CrossRef]

- Khaboshan, H.N.; Jaliliantabar, F.; Abdullah, A.A.; Panchal, S. Improving the cooling performance of cylindrical lithium-ion battery using three passive methods in a battery thermal management system. Appl. Therm. Eng. 2023, 227, 120320. [Google Scholar] [CrossRef]

- Luo, T.; Zhang, Y.; Chen, X.; Jia, T.; Yu, H.; Mao, B.; Ma, C. A hybrid battery thermal management system composed of MHPA/PCM/Liquid with a highly efficient cooling strategy. Appl. Therm. Eng. 2024, 251, 123617. [Google Scholar] [CrossRef]

- Mehryan, S.; Jannesari, H. Analyzing battery thermal management systems: A comparative study of hydrogel and various PCMs in different configurations and convection conditions. J. Energy Storage 2024, 77, 109998. [Google Scholar] [CrossRef]

- Dey, H.; Pati, S.; Randive, P.R.; Baranyi, L. Effect of finned networks on PCM based battery thermal management system for cylindrical Li-ion batteries. Case Stud. Therm. Eng. 2024, 59, 104572. [Google Scholar] [CrossRef]

- Li, B.; Mao, Z.; Song, B.; Wang, X.; Tian, W.; Sun, Q.; Wang, Y.-F.; Jin, Z. Experimental investigation on efficient thermal management of autonomous underwater vehicle battery packs using anisotropic expanded graphite/paraffin composite materials. Appl. Therm. Eng. 2024, 242, 122477. [Google Scholar] [CrossRef]

- Luo, M.; Zhang, Y.; Wang, Z.; Niu, Y.; Lu, B.; Zhu, J.; Zhang, J.; Wang, K. Thermal performance enhancement with snowflake fins and liquid cooling in PCM-based battery thermal management system at high ambient temperature and high discharge rate. J. Energy Storage 2024, 90, 111754. [Google Scholar] [CrossRef]

- Fouladvand, J. Energy Security of Thermal Energy Communities. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2022. [Google Scholar]

- Guclu, T.; Cuce, E. Thermoelectric Coolers (TECs): From Theory to Practice; Springer: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Cheng, K.; Qin, J.; Jiang, Y.; Zhang, S.; Bao, W. Performance comparison of single- and multi-stage onboard thermoelectric generators and stage number optimization at a large temperature difference. Appl. Therm. Eng. 2018, 141, 456–466. [Google Scholar] [CrossRef]

- Lin, S.; Yu, J. Optimization of a trapezoid-type two-stage Peltier couples for thermoelectric cooling applications. Int. J. Refrig. 2016, 65, 103–110. [Google Scholar] [CrossRef]

- Li, X.; Zhong, Z.; Luo, J.; Wang, Z.; Yuan, W.; Zhang, G.; Yang, C.; Yang, C. Experimental Investigation on a Thermoelectric Cooler for Thermal Management of a Lithium-Ion Battery Module. Int. J. Photoenergy 2019, 2019, 3725364. [Google Scholar] [CrossRef]

- Hameed, M.M.; Bin Mansor, M.; Azau, M.A.M.; Alshara, A.K. Computational design and analysis of LiFePO4 battery thermal management system (BTMS) using thermoelectric cooling/thermoelectric generator (TEC–TEG) in electric vehicles (EVs). J. Energy Storage 2023, 72, 108394. [Google Scholar] [CrossRef]

- Luo, D.; Wu, Z.; Yan, Y.; Cao, J.; Yang, X.; Zhao, Y.; Cao, B. Performance investigation and design optimization of a battery thermal management system with thermoelectric coolers and phase change materials. J. Clean. Prod. 2024, 434, 139834. [Google Scholar] [CrossRef]

- Bayendang, N.P.; Balyan, V.; Kahn, M.T. The question of thermoelectric devices (TEDs) in/efficiency—A practical examination considering thermoelectric coolers (TECs). Results Eng. 2024, 21, 101827. [Google Scholar] [CrossRef]

- Luo, D.; Wu, H.; Cao, J.; Yan, Y.; Yang, X.; Cao, B. Numerical investigation of a battery thermal management system integrated with vapor chamber and thermoelectric refrigeration. J. Clean. Prod. 2024, 434, 140089. [Google Scholar] [CrossRef]

- Alghamdi, H.; Rosdi, M.F.M.; Mukhtar, A.; Yasir, A.S.H.M.; Alviz-Meza, A. Controlling thermal runaway by simultaneous use of thermoelectric module and phase change material in the lithium-ion batteries of electric vehicles. Case Stud. Therm. Eng. 2023, 52, 103697. [Google Scholar] [CrossRef]

- Pan, Y.; Tang, A.; Liu, Z.; Shan, C. Experimental analysis of power battery preheating system based on thermoelectric elements. Appl. Therm. Eng. 2023, 230, 120860. [Google Scholar] [CrossRef]

- Liu, X.; Yao, L.-C.; Su, C.-Q.; Xiong, X.; Wang, Y.-P. A hybrid battery thermal management system coupling with PCM and optimized thermoelectric cooling for high-rate discharge condition. Case Stud. Therm. Eng. 2023, 49, 103269. [Google Scholar] [CrossRef]

- Luo, D.; Zhao, Y.; Cao, J.; Chen, W.-H.; Zhao, Y.; Cao, B. Performance analysis of a novel thermoelectric-based battery thermal management system. Renew. Energy 2024, 224, 120193. [Google Scholar] [CrossRef]

- An, Z.; Liu, H.; Gao, W.; Gao, Z. Cooling and preheating performance of dual-active lithium-ion battery thermal management system under harsh conditions. Appl. Therm. Eng. 2024, 242, 122421. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.-F.; Zhou, J.-G.; Xiong, X.; Wang, Y.-P. Thermal performance of battery thermal management system using fins to enhance the combination of thermoelectric Cooler and phase change Material. Appl. Energy 2022, 322, 119503. [Google Scholar] [CrossRef]

| No. | Modification/Novelty | Type of Study | Remarks | Geometry | Ref. |

|---|---|---|---|---|---|

| 1 | Enhanced BTMS Cooling: Using TEG to Power TEC for Improved Heat Management | CFD | To increase the heat dissipation of TEC–TEG, high-quality heat sinks are used to make the temperature of BTMS as close to ambient temperature as possible. The findings revealed that the maximum battery surface temperature decreased from 38 °C to 33.1584 °C with the introduced BTMS. |  | [78] |

| 2 | Novel BTMS: Integrating TECs and PCMs with Cooling Plate for Efficient Lithium-Ion Battery Temperature Control | CFD | Optimal fin length and thickness are 7 mm and 3 mm, respectively. At a 3 A TEC input current, the maximum temperature, temperature difference, and PCM liquid fraction were 315.10 K, 2.39 K, and 0.002 in Case 1. At a discharge rate of 5C, the maximum temperature, temperature difference, and PCM liquid fraction were 318.24 K, 3.60 K, and 0.181. |  | [79] |

| 3 | EV BTMS: Efficient Heat Transport from Battery Pack to TEC Cold Side and Release via Heatsink | Exp. | Forced air, and thermoelectric cooling (TEC) and -generation (TEG), are used to reduce the maximum surface temperature of a LiFePO4 battery cell by approximately 7 °C. |  | [80] |

| 4 | Active–Passive Hybrid BTMS: Combining TEC and PCM with CFD Simulation for Optimal Thermal Performance | CFD | The findings reveal that, even under a high discharge rate of 3C, the system can maintain the maximum temperature of batteries below 45 °C, while ensuring that the maximum temperature difference during the discharge process remains within 3 °C. |  | [81] |

| 5 | Hybrid TEC–PCM BTMS with Circular and Axial Fin Arrangements: Evaluating Temperature in Middle and Top Sections of Battery | Exp. | The use of aluminium circular fins, PCM, and a thermoelectric cooling system significantly reduced battery temperature to 65 °C. Changing the fin configuration from circular to axial led to an average temperature of 48 °C. This study found that axial fins regulate LIB temperature better than ring fins. The battery body’s top temperature is always higher than the middle, regardless of mode or time interval. |  | [82] |

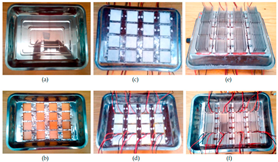

| 6 | BTMS for Battery Module Heating: Dual TECs (6 V Bottom, 9 V Top) and 10 V Fan with Cold Plate Integration | Exp. | The total power consumption of the system is 81.2 W, with the bottom TEC consuming 31.21 W, the top TEC using 47 W, and the electronic fan requiring 2.994 W. This demonstrates the overall effectiveness and energy efficiency of the system. The battery capacity increases by 9.1% as the ambient temperature rises from −5 °C to 5 °C. At a bottom TEC voltage of 6 V, it takes 1631 s to heat the battery from −5 °C to 5 °C without top TEC voltage, with a temperature difference normally below 5.5 °C. |  | [83] |

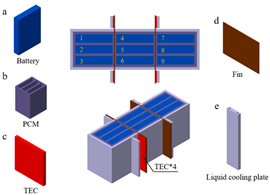

| 7 | BTMS with PC-Wrapped Cells in Aluminum Case: TEC and Fins for Enhanced Heat Transfer, Tested at High Discharge Rates | CFD | Increasing TEC current lowers battery temperature and decreases uniformity and cooling efficiency; a 2A current keeps the battery below 40 °C. Delaying TEC current at 80% PCM melting rate improves temperature homogeneity, while a 2A current maintains a temperature gradient under 5 °C and extends effective temperature-control time. While the transient PCM + TEC model maintains temperature control and uniformity during 4C discharge, pulsed TEC current improves cooling power and thermal performance. |  | [84] |

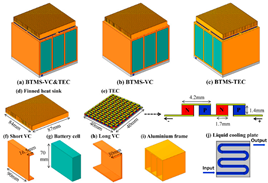

| 8 | Proposed Battery Pack: Four Heat Sinks, 12 TECs, Honeycomb Framework, and Water Channel-Integration | CFD | Thermoelectric coolers (TECs) improve the thermal management of batteries by providing the best cooling performance when a current of 5A is applied. However, the efficiency of TECs decreases when the current exceeds this value. Air and water cooling enhance the efficiency of TEC, with recommended values for optimal performance being 50 W/m2K for air convection and 0.11 m/s for water flow. Optimizing thermal performance and energy efficiency requires precise control strategies to balance TEC input, air cooling, and water cooling-parameters. |  | [85] |

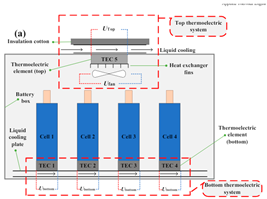

| 9 | Dual Active BTMS: Incorporating Thermal Insulation Plate, TECs, and Liquid Cold Plates for Enhanced Cooling | CFD Exp. | TEC helps batteries maintain a reasonable temperature range in harsh environments and at a 3C discharge rate. Dual active cooling reduces energy consumption more efficiently than pure TEC cooling. Pure liquid cooling uses less energy, but TEC ensures acceptable battery performance under challenging conditions. |  | [86] |

| 10 | Hybrid Active–Passive BTMS: PCM, TEC, Liquid Cooling, and Fins for Enhanced Heat Transfer | CFD | Increasing fin thickness from 2 mm to 8 mm extends temperature control by 12%, enhancing thermoelectric cooler (TEC) cooling power and COP. Fins improve cooling capacity and temperature uniformity, with 4 mm fins being particularly effective. TEC input currents from 1A to 6A boost temperature control by 87.42%. |  | [87] |

| Air Cooling | Liquid Cooling | PCM Cooling | TEC Cooling | |

|---|---|---|---|---|

| CE | Moderate | High | Moderate/High | High |

| TU | Good | Excellent | Good | Excellent |

| MTR | High | High | Moderate | High |

| EC | Low | Moderate | Low | High |

| SC | Low | High | Moderate | High |

| RT | Moderate | Fast | Slow | Fast |

| CE | High | Moderate | High | Moderate |

| S | High | Moderate | High | Moderate |

| SR | Moderate | High | High | High |

| Cooling Method | Advantages | Disadvantages |

|---|---|---|

| Air-cooling | Cost-effective, uncomplicated design and maintenance | Less efficient at high thermal loads |

| Liquid-cooling | Excellent performance, high cooling efficiency | Higher cost, complex design and maintenance |

| PCM-cooling | Satisfactory performance, low energy consumption and cost | Suitable for passive cooling, slower response time |

| TEC-cooling | Precise temperature control, quick response | More expensive, high-energy consumption |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahmani, A.; Dibaj, M.; Akrami, M. Recent Advancements in Battery Thermal Management Systems for Enhanced Performance of Li-Ion Batteries: A Comprehensive Review. Batteries 2024, 10, 265. https://doi.org/10.3390/batteries10080265

Rahmani A, Dibaj M, Akrami M. Recent Advancements in Battery Thermal Management Systems for Enhanced Performance of Li-Ion Batteries: A Comprehensive Review. Batteries. 2024; 10(8):265. https://doi.org/10.3390/batteries10080265

Chicago/Turabian StyleRahmani, Amin, Mahdieh Dibaj, and Mohammad Akrami. 2024. "Recent Advancements in Battery Thermal Management Systems for Enhanced Performance of Li-Ion Batteries: A Comprehensive Review" Batteries 10, no. 8: 265. https://doi.org/10.3390/batteries10080265