Improving LiFe0.4Mn0.6PO4 Nanoplate Performance by a Dual Modification Strategy toward the Practical Application of Li-Ion Batteries

Abstract

:1. Introduction

2. Experimental Section

2.1. Chemicals

2.2. Material Synthesis

3. Results and Discussion

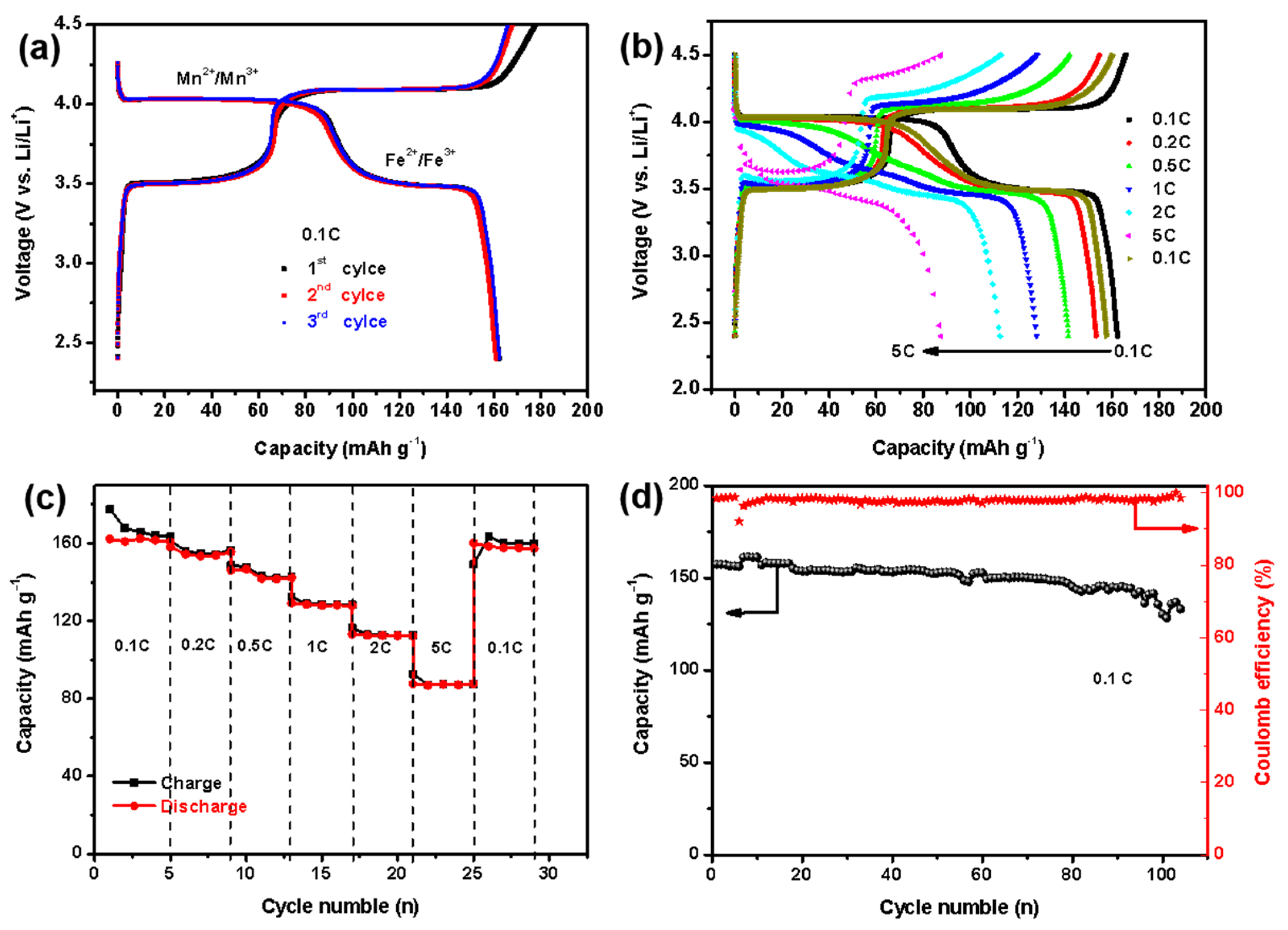

3.1. Electrochemical Performance and Analysis

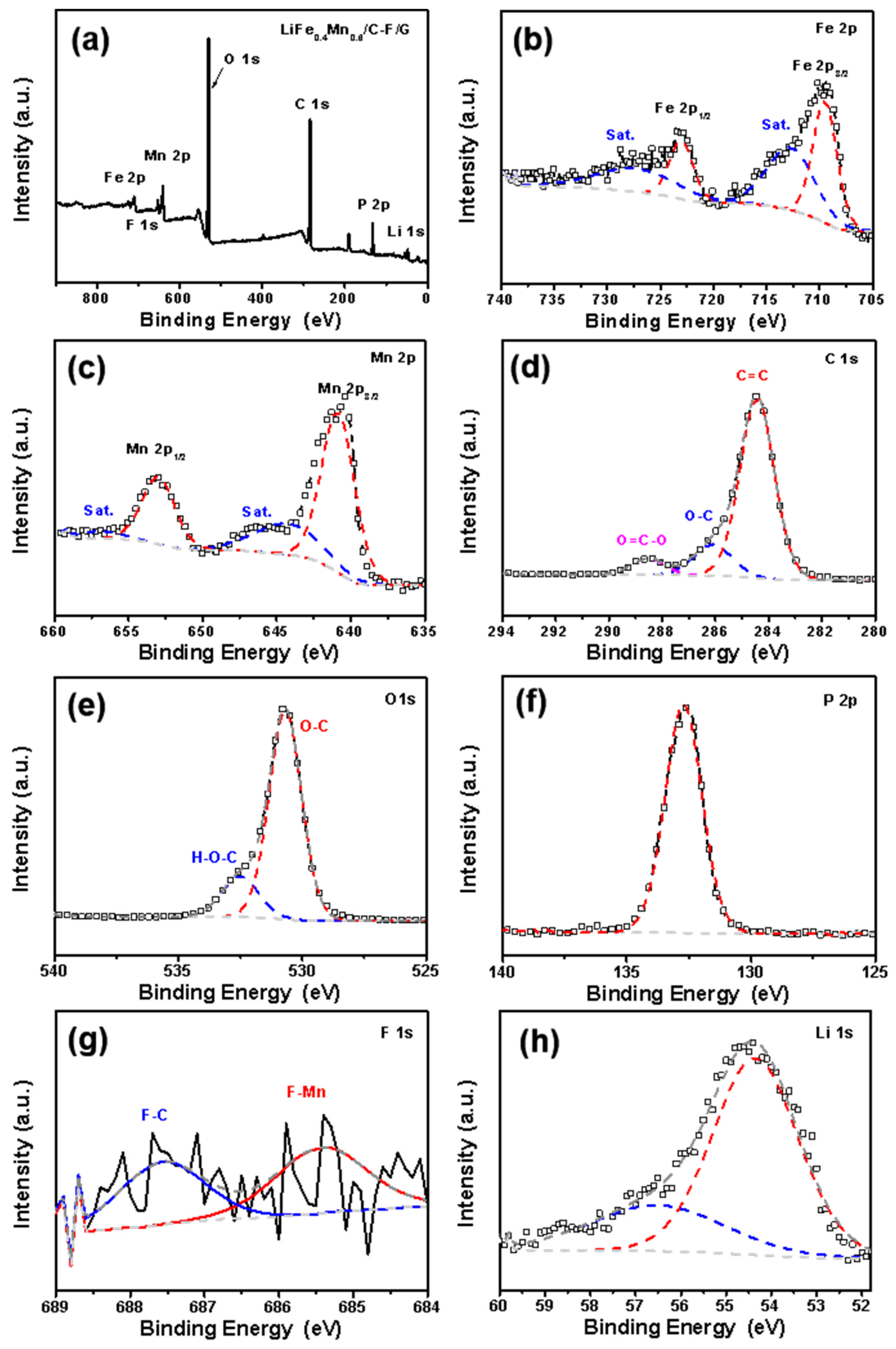

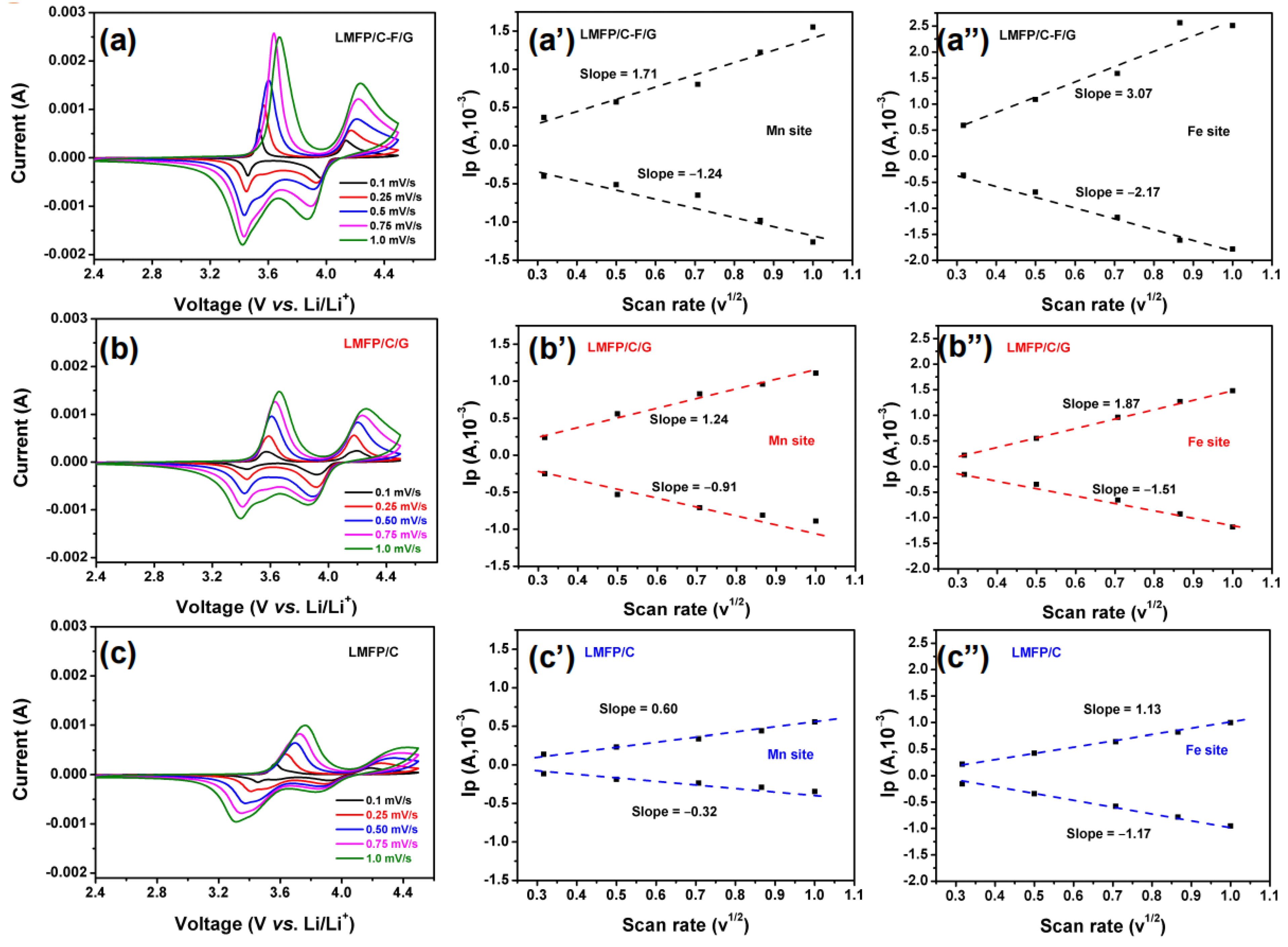

3.2. Mechanism Analysis of the Electrocatalytic Activity Enhancement

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Armand, M.; Tarascon, J.M. Building better batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; He, J.; Liu, J.; Wu, M.; Hou, Y.; Wang, H.; Qi, S.; Liu, Q.; Hu, J.; Ma, J. Gradient Solid Electrolyte Interphase and Lithium-Ion Solvation Regulated by Bisfluoroacetamide for Stable Lithium Metal Batteries. Angew. Chem. Int. Ed. 2021, 60, 6600–6608. [Google Scholar] [CrossRef]

- Di Lecce, D.; Hassoun, J. Lithium Transport Properties in LiMn1−αFeαPO4 Olivine Cathodes. J. Phys. Chem. C 2015, 119, 20855–20863. [Google Scholar] [CrossRef]

- Padhi, A.K.; Nanjundaswamy, K.S.; Goodenough, J.B. Phospho-olivines as Positive-Electrode Materials for Rechargeable Lithium Batteries. J. Electrochem. Soc. 1997, 144, 1188. [Google Scholar] [CrossRef]

- Guo, H.; Liu, R.; Li, W.; Gu, H.; Cao, J.; Gong, D.; Liang, G. Site Selection of Niobium-Doped LiMn0.6Fe0.4PO4 and Effect on Electrochemical Properties. J. Electrochem. Soc. 2023, 170, 030542. [Google Scholar] [CrossRef]

- Gao, C.; Zhou, J.; Liu, G.; Wang, L. Synthesis of F-doped LiFePO4/C Cathode Materials for High Performance Lithium-ion Batteries using Co-Precipitation Method with Hydrofluoric Acid Source. J. Alloys Compd. 2017, 727, 501–513. [Google Scholar] [CrossRef]

- Gangaraju, V.; Shastri, M.; Shetty, K.; Marilingaiah, N.R.; Anantharaju, K.S.; Shivaramu, P.D.; Rangappa, D. In-situ Preparation of Silk-Cocoon Derived Carbon and LiFePO4 Nanocomposite as Cathode Material for Li-ion Battery. Ceram. Int. 2022, 48, 35657–35665. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, J.; Zhang, J.; Wang, J.; Nie, N.; Fu, Y.; Li, W.; Yu, F. Controllable Synthesis of Nano-Sized LiFePO4/C via a High Shear Mixer Facilitated Hydrothermal Method for High Rate Li-ion Batteries. Electrochim. Acta 2015, 173, 448–457. [Google Scholar] [CrossRef]

- Zhang, W.J. Structure and Performance of LiFePO4 Cathode Materials: A Review. J. Power Sources 2011, 196, 2962–2970. [Google Scholar] [CrossRef]

- Jiang, F.; Qu, K.; Wang, M.S.; Chen, J.C.; Liu, Y.; Xu, H.; Huang, Y.; Li, J.Y.; Gao, P.; Zheng, J.M.; et al. Atomic Scale Insight into the Fundamental Mechanism of Mn Doped LiFePO4. Sustain. Energy Fuels 2020, 4, 2741–2751. [Google Scholar] [CrossRef]

- Luo, T.; Zeng, T.T.; Chen, S.L.; Li, R.; Fan, R.Z.; Chen, H.; Han, S.C.; Fan, C.L. Structure, Performance, Morphology and Component Transformation Mechanism of LiMn0·8Fe0·2PO4/C Nanocrystal with Excellent Stability. J. Alloys Compd. 2020, 834, 155143. [Google Scholar] [CrossRef]

- Oh, S.M.; Myung, S.T.; Park, J.B.; Scrosati, B.; Amine, K.; Sun, Y.K. Double-Structured LiMn0.85Fe0.15PO4 Coordinated with LiFePO4 for Rechargeable Lithium Batteries. Angew. Chem. Int. Ed. 2012, 51, 1853–1856. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Tan, R.; Li, D.; Ma, J.M.; Duan, X.C. Ionic Liquid Assisted Electrospinning of Porous LiFe0.4Mn0.6PO4/CNFs as Free-Standing Cathodes with a Pseudocapacitive Contribution for High-Performance Lithium-Ion Batteries. Chem.—A Eur. J. 2020, 26, 5341–5346. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Yang, C.; Zou, K.; Qin, X.; Zhao, Z.; Chen, G. Recent Advances of Mn-Rich LiFe1-yMnyPO4 (0.5 ≤ y < 1.0) Cathode Materials for High Energy Density Lithium Ion Batteries. Adv. Energy Mater. 2017, 7, 1601958. [Google Scholar]

- Xiong, J.W.; Wang, Y.Z.; Wang, Y.Y.; Zhang, J.X. PVP-Assisted Solvothermal Synthesis of LiMn0.8Fe0.2PO4/C Nanorods as Cathode Material for Lithium Ion Batteries. Ceram. Int. 2016, 42, 9018–9024. [Google Scholar] [CrossRef]

- Peng, Z.D.; Zhang, B.C.; Hu, G.R.; Du, K.; Xie, X.M.; Wu, K.P.; Wu, J.H.; Gong, Y.F.; Shu, Y.M.; Cao, Y.B. Green and Efficient Synthesis of Micro-Nano LiMn0.8Fe0.2PO4/C Composite with High-Rate Performance for Li-ion Battery. Electrochim. Acta 2021, 387, 138456. [Google Scholar] [CrossRef]

- Yang, S.C.; Zhou, C.C.; Wang, Q.; Chen, B.B.; Zhao, Y.; Guo, B.; Zhang, Z.J.; Gao, X.L.; Chowdhury, R.; Wang, H.Z.; et al. Highly Aligned Ultra-Thick Gel-Based Cathodes Unlocking Ultra-High Energy Density Batteries. Energy Environ. Mater. 2022, 5, 1332–1339. [Google Scholar] [CrossRef]

- Wang, Y.; Niu, P.; Li, J.Z.; Wang, S.L.; Li, L. Recent Progress of Phosphorus Composite Anodes for Sodium/Potassium Ion Batteries. Energy Storage Mater. 2021, 34, 436–460. [Google Scholar] [CrossRef]

- Hu, H.; Li, H.; Lei, Y.; Liu, J.; Liu, X.; Wang, R.; Peng, J.; Wang, X. Mg-doped LiMn0.8Fe0.2PO4/C Nano-Plate as a High-Performance Cathode Material for Lithium-ion Batteries. J. Energy Storage 2023, 73, 109006. [Google Scholar] [CrossRef]

- Wu, R.; Drozdov, I.K.; Eltinge, S.; Zahl, P.; Ismail-Beigi, S.; Bozovic, I.; Gozar, A. Large-Area Single-Crystal Sheets of Borophene on Cu(111) Surfaces. Nat. Nanotechnol. 2019, 14, 44–49. [Google Scholar] [CrossRef]

- Karimzadeh, S.; Safaei, B.; Huang, W.; Jen, T.C. Theoretical Investigation on Niobium Doped LiFePO4 Cathode Material for High Performance Lithium-ion Batteries. J. Energy Storage 2023, 67, 107572. [Google Scholar] [CrossRef]

- Sahoo, P.K.; Memaran, S.; Xin, Y.; Balicas, L.; Gutierrez, H.R. One-pot growth of two-dimensional lateral heterostructures via sequential edge-epitaxy. Nature 2018, 553, 63–67. [Google Scholar] [CrossRef]

- Yang, L.; Deng, W.; Xu, W.; Tian, Y.; Wang, A.; Wang, B.; Zou, G.; Hou, H.; Deng, W.; Ji, X. Olivine LiMnxFe1−xPO4 Cathode Materials for Lithium Ion Batteries: Restricted Factors of Rate Performances. J. Mater. Chem. A 2021, 9, 14214–14232. [Google Scholar] [CrossRef]

- Luo, C.; Jiang, Y.; Zhang, X.X.; Ouyang, C.Y.; Niu, X.B.; Wang, L.P. Misfit Strains Inducing Voltage Decay in LiMnyFe1−yPO4/C. J. Energy Chem. 2022, 68, 206–212. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Y.; Ou, X. Heat-Rate-Controlled Hydrothermal Crystallization of High-Performance LiMn0.7Fe0.3PO4 Cathode Material for Lithium-ion Batteries. Ceram. Int. 2020, 46, 5069–5076. [Google Scholar] [CrossRef]

- Hidalgo, J.; An, Y.; Yehorova, D.; Li, R.; Breternitz, J.; Perini, C.A.R.; Hoell, A.; Boix, P.P.; Schorr, S.; Kretchmer, J.S.; et al. Solvent and A-Site Cation Control Preferred Crystallographic Orientation in Bromine-Based Perovskite Thin Films. Chem. Mater. 2023, 35, 4181–4191. [Google Scholar] [CrossRef]

- Yan, X.; Sun, D.; Wang, Y.; Zhang, Z.; Yan, W.; Jiang, J.; Ma, F.; Liu, J.; Jin, Y.; Kanamura, K. Enhanced Electrochemical Performance of LiMn0.75Fe0.25PO4 Nanoplates from Multiple Interface Modification by Using Fluorine-Doped Carbon Coating. ACS Sustain. Chem. Eng. 2017, 5, 4637–4644. [Google Scholar] [CrossRef]

- Ming, L.; Zhang, B.; Cao, Y.; Zhang, J.F.; Wang, C.H.; Wang, X.W.; Li, H. Effect of Nb and F Co-doping on Li1.2Mn0.54Ni0.13Co0.13O2 Cathode Material for High-Performance Lithium-Ion Batteries. Front. Chem. 2018, 6, 76. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Feng, Z.; Huang, J.; Deng, W.; Li, X.; Zhang, H.; Wen, Z. Graphene-Decorated Carbon-Coated LiFePO4 Nanospheres as a High-Performance Cathode Material for Lithium-Ion Batteries. Carbon 2018, 127, 149–157. [Google Scholar] [CrossRef]

- Ding, D.; Maeyoshi, Y.; Kubota, M.; Wakasugi, J.; Kanamura, K.; Abe, H. Highly Improved Performances of LiMn0.7Fe0.3PO4 Cathode with in Situ Electrochemically Reduced Graphene Oxide. J. Alloys Compd. 2019, 793, 627–634. [Google Scholar] [CrossRef]

- Ding, D.; Maeyoshi, Y.; Kubota, M.; Wakasugi, J.; Kanamura, K.; Abe, H. Holey Reduced Graphene Oxide/Carbon Nanotube/LiMn0.7Fe0.3PO4 Composite Cathode for High-Performance Lithium Batteries. J. Power Sources 2020, 449, 227553. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, X.; He, P.; Zhang, X.; Wang, P.; Zhou, H. Synthesis of Hierarchical and Bridging Carbon-Coated LiMn0.9Fe0.1PO4 Nanostructure as Cathode Material with Improved Performance for Lithium Ion Battery. J. Power Sources 2017, 359, 408–414. [Google Scholar] [CrossRef]

- Wang, B.; Liu, A.; Abdulla, W.A.; Wang, D.; Zhao, X.S. Desired Crystal oriented LiFePO4 Nanoplatelets in Situ Anchored on a Graphene Cross-Linked Conductive Network for Fast Lithium Storage. Nanoscale 2015, 7, 8819–8828. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.L.; Tan, A.D.; Hu, S.Z.; Piao, J.H.; Fu, Z.Y. Efficient Spinel Iron-Cobalt Oxide/Nitrogen-Doped Ordered Mesoporous Carbon Catalyst for Rechargeable Zinc-Air Batteries. Chin. J. Catal. 2021, 42, 1451–1458. [Google Scholar] [CrossRef]

- Lv, X.Y.; Huang, Q.Y.; Wu, Z.; Su, J.; Long, Y.F.; Wen, Y.X. Li0.995Nb0.005Mn0.85Fe0.15PO4/C as a High-Performance Cathode Material for Lithium-Ion Batteries. J. Solid State Electrochem. 2017, 21, 1499–1507. [Google Scholar] [CrossRef]

- Zhang, K.; Lee, J.T.; Li, P.; Kang, B.; Kim, J.H.; Yi, G.-R.; Park, J.H. Conformal Coating Strategy Comprising N-doped Carbon and Conventional Graphene for Achieving Ultrahigh Power and Cyclability of LiFePO4. Nano Lett. 2015, 15, 6756–6763. [Google Scholar] [CrossRef] [PubMed]

- Xiao, P.; Cai, Y.Y.; Chen, X.P.; Sheng, Z.M.; Chang, C.K. Improved Electrochemical Performance of LiFe0.4Mn0.6PO4/C with Cr3+ Doping. RSC Adv. 2017, 7, 31558–31566. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, K.; Li, Y.; Yuan, S.; Huang, G.; Li, X.; Li, N. Activation Engineering on Metallic 1T-MoS2 by Constructing In-Plane Heterostructure for Efficient Hydrogen Generation. Appl. Catal. B Environ. 2022, 300, 120696. [Google Scholar] [CrossRef]

- Ding, D.; Maeyoshi, Y.; Kubota, M.; Wakasugi, J.; Kanamura, K.; Abe, H. A Facile Way To Synthesize Carbon-Coated LiMn0.7Fe0.3PO4/Reduced Graphene Oxide Sandwich-Structured Composite for Lithium-Ion Batteries. ACS Appl. Energy Mater. 2019, 2, 1727–1733. [Google Scholar] [CrossRef]

- Huang, Y.; Ding, R.; Ying, D.; Shi, W.; Huang, Y.; Tan, C.; Sun, X.; Gao, P.; Liu, E. Engineering doping-vacancy double defects and insights into the conversion mechanisms of an Mn–O–F ultrafine nanowire anode for enhanced Li/Na-ion storage and hybrid capacitors. Nanoscale Adv. 2019, 1, 4669–4678. [Google Scholar] [CrossRef]

- Qin, Q.; Deng, N.; Wang, L.; Zhang, L.; Jia, Y.; Dai, Z.; Liu, Y.; Kang, W.; Cheng, B. Novel Flexible Mn-Based Carbon Nanofiber Films as Interlayers for Stable Lithium-Metal Battery. Chem. Eng. J. 2019, 360, 900–911. [Google Scholar] [CrossRef]

- Zhang, K.; Cao, J.; Tian, S.; Guo, H.; Liu, R.; Ren, X.; Wen, L.; Liang, G. The Prepared and Electrochemical Property of Mg-Doped LiMn0.6Fe0.4PO4/C as Cathode Materials for Lithium-Ion Batteries. Ionics 2021, 27, 4629–4637. [Google Scholar] [CrossRef]

- Kou, L.Q.; Chen, F.J.; Tao, F.; Dong, Y.; Chen, L. High Rate Capability and Cycle Performance of Ce-Doped LiMnPO4/C via an Efficient Solvothermal Synthesis in Water/Diethylene Glycol System. Electrochim. Acta 2015, 173, 721–727. [Google Scholar] [CrossRef]

- Li, N.; Xu, Z.; Wang, P.; Zhang, Z.; Hong, B.; Li, J.; Lai, Y. High-Rate Lithium-Sulfur Batteries Enabled via Vanadium Nitride Nanoparticle/3D Porous Graphene through Regulating the Polysulfides Transformation. Chem. Eng. J. 2020, 398, 125432. [Google Scholar] [CrossRef]

- Sun, Z.H.; Wu, X.L.; Peng, Z.Q.; Wang, J.W.; Gan, S.; Zhang, Y.W.; Han, D.X.; Niu, L. Compactly Coupled Nitrogen-Doped Carbon Nanosheets/Molybdenum Phosphide Nanocrystal Hollow Nanospheres as Polysulfide Reservoirs for High-Performance Lithium–Sulfur Chemistry. Small 2019, 15, 1902491. [Google Scholar] [CrossRef] [PubMed]

- Xiang, W.; Wu, Z.G.; Wang, E.H.; Chen, M.Z.; Song, Y.; Zhang, J.B.; Zhong, Y.J.; Chou, S.L.; Luo, J.H.; Guo, X.D. Confined Synthesis of Graphene Wrapped LiMn0.5Fe0.5PO4 Composite Via Two Step Solution Phase Method as High Performance Cathode for Li-ion Batteries. J. Power Sources 2016, 329, 94–103. [Google Scholar] [CrossRef]

- Chi, Z.X.; Zhang, W.; Wang, X.S.; Cheng, F.Q.; Chen, J.T.; Cao, A.M.; Wan, L.J. Accurate Surface Control of Core–Shell Structured LiMn0.5Fe0.5PO4@C for Improved Battery Performance. J. Mater. Chem. A 2014, 2, 17359–17365. [Google Scholar] [CrossRef]

- Wen, F.; Lv, T.a.; Gao, P.; Wu, B.; Liang, Q.; Zhang, Y.; Shu, H.; Yang, X.; Liu, L.; Wang, X. Graphene-Embedded LiMn0.8Fe0.2PO4 Composites with Promoted Electrochemical Performance for Lithium Ion Batteries. Electrochim. Acta 2018, 276, 134–141. [Google Scholar] [CrossRef]

- Li, R.; Fan, C.; Zhang, W.; Tan, M.; Zeng, T.; Han, S. Structure and Performance of Na+ and Fe2+ Co-Doped Li1-xNaxMn0.8Fe0.2PO4/C Nanocapsule Synthesized by a Simple Solvothermal Method for Lithium ion Batteries. Ceram. Int. 2019, 45, 10501–10510. [Google Scholar] [CrossRef]

- Liao, L.; Wang, H.; Guo, H.; Zhu, P.; Xie, J.; Jin, C.; Zhang, S.; Cao, G.; Zhu, T.; Zhao, X. Facile Solvothermal Synthesis of Ultrathin LiFexMn1−xPO4 Nanoplates as Advanced Cathodes with Long Cycle Llife and Superior Rate Capability. J. Mater. Chem. A 2015, 3, 19368–19375. [Google Scholar] [CrossRef]

- Xu, H.; Zong, J.; Ding, F.; Lu, Z.W.; Li, W.; Liu, X.J. Effects of Fe2+ ion Doping on LiMnPO4 Nanomaterial for Lithium ion Batteries. RSC Adv. 2016, 6, 27164–27169. [Google Scholar] [CrossRef]

- Wang, K.; Hou, M.; Yuan, S.; Yu, H.; Wang, Y.; Wang, C.; Xia, Y. An Additional Discharge Plateau of Mn3+ in LiFe0.5Mn0.5PO4 at High Current Rates. Electrochem. Commun. 2015, 55, 6–9. [Google Scholar] [CrossRef]

| Sample | C | O | F | Li | Fe | Mn | P | Fe:Mn |

|---|---|---|---|---|---|---|---|---|

| LMFP/C | 29.55 | 25.83 | -- | 33.92 | 1.53 | 2.42 | 6.75 | 4:6 |

| LMFP/C/G | 49.25 | 22.00 | -- | 50.88 | 1.02 | 1.60 | 4.19 | 4:6 |

| LMFP/C-F/G | 39.38 | 22.40 | 0.28 | 29.33 | 1.28 | 1.94 | 5.38 | 4:6 |

| Sample | Fe3+ | Fe2+ | Mn3+ | Mn2+ | ∆EFe | ∆EMn |

|---|---|---|---|---|---|---|

| LMFP/C | 3.76 | 3.31 | 4.41 | 3.85 | 0.45 | 0.56 |

| LMFP/C/G | 3.66 | 3.39 | 4.26 | 3.86 | 0.27 | 0.40 |

| LMFP/C-F/G | 3.67 | 3.42 | 4.23 | 3.87 | 0.25 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, M.; Wei, H.; Li, Q.; Yu, Z.; Zhang, Q.; Lin, M.; Lin, B. Improving LiFe0.4Mn0.6PO4 Nanoplate Performance by a Dual Modification Strategy toward the Practical Application of Li-Ion Batteries. Batteries 2024, 10, 272. https://doi.org/10.3390/batteries10080272

Tan M, Wei H, Li Q, Yu Z, Zhang Q, Lin M, Lin B. Improving LiFe0.4Mn0.6PO4 Nanoplate Performance by a Dual Modification Strategy toward the Practical Application of Li-Ion Batteries. Batteries. 2024; 10(8):272. https://doi.org/10.3390/batteries10080272

Chicago/Turabian StyleTan, Mingfeng, Helei Wei, Qi Li, Zhipeng Yu, Qiang Zhang, Mingzhi Lin, and Bo Lin. 2024. "Improving LiFe0.4Mn0.6PO4 Nanoplate Performance by a Dual Modification Strategy toward the Practical Application of Li-Ion Batteries" Batteries 10, no. 8: 272. https://doi.org/10.3390/batteries10080272