Numerical Investigation into 18650 Li-Ion Battery Temperature Control Applying Immersion Cooling with FC-40 Dielectric Fluid

Abstract

1. Introduction

2. Methodology

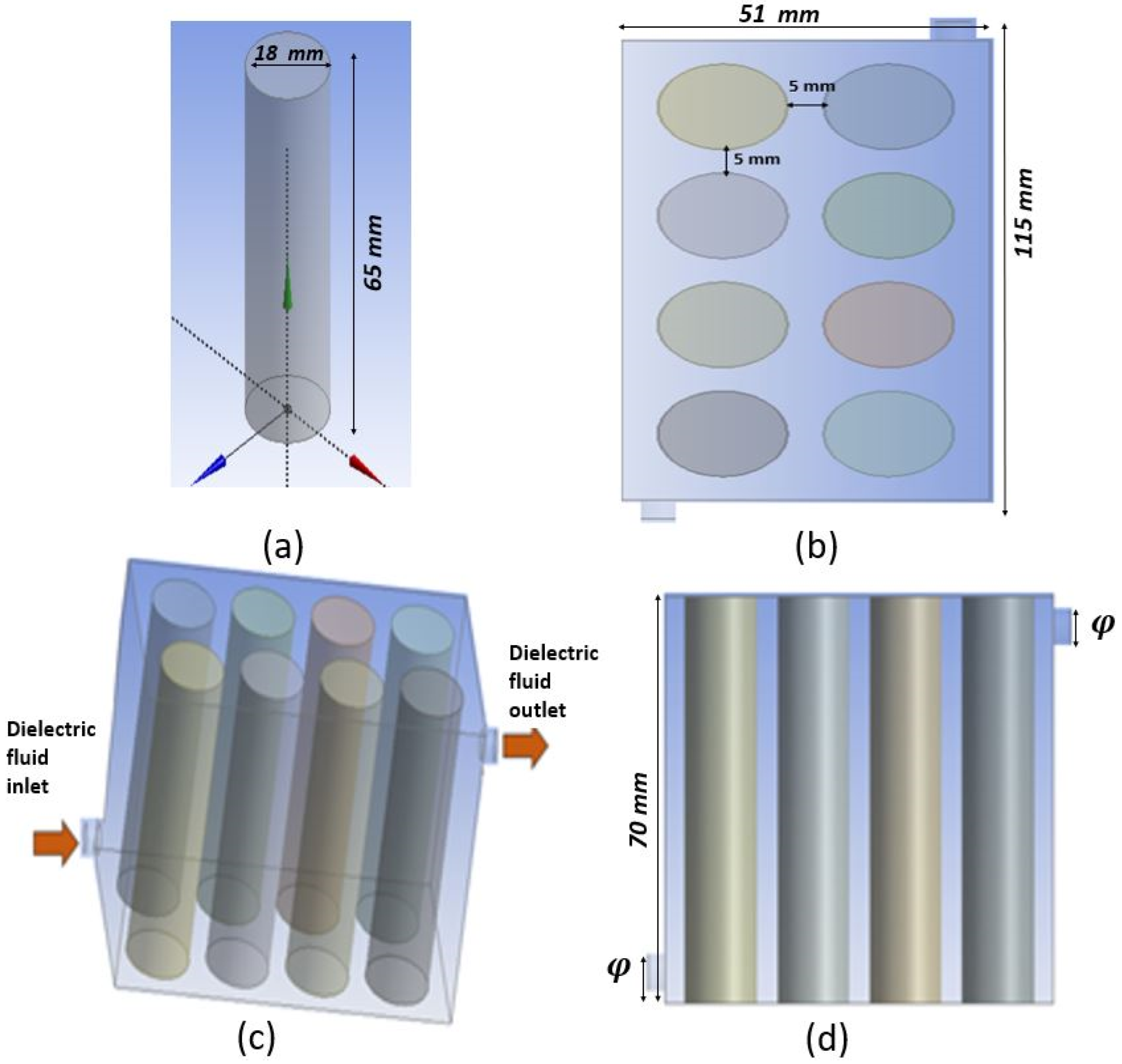

2.1. Geometry Description

2.2. Assumption

2.3. Governing Equations

2.3.1. Thermal Generation Inside the Battery Cells

2.3.2. Energy Conservation Equation

2.3.3. Governing Equations for the Coolant’s Behaviour

- Continuity equation:

- Momentum conservation equation.where corresponds to the velocity vector, μ is dynamic viscosity, P signifies pressure, is gravity, β is the thermal expansion coefficient, is the reference temperature, and is the momentum term source.

- Energy conservation equation:where is the thermal conductivity of the coolant and is the specific heat capacity.

2.3.4. Initial and Boundary Conditions

- a-

- Initial conditions.

- b-

- Boundary conditions.

2.3.5. Solution Procedure and Meshing

3. Results

3.1. Model Verification

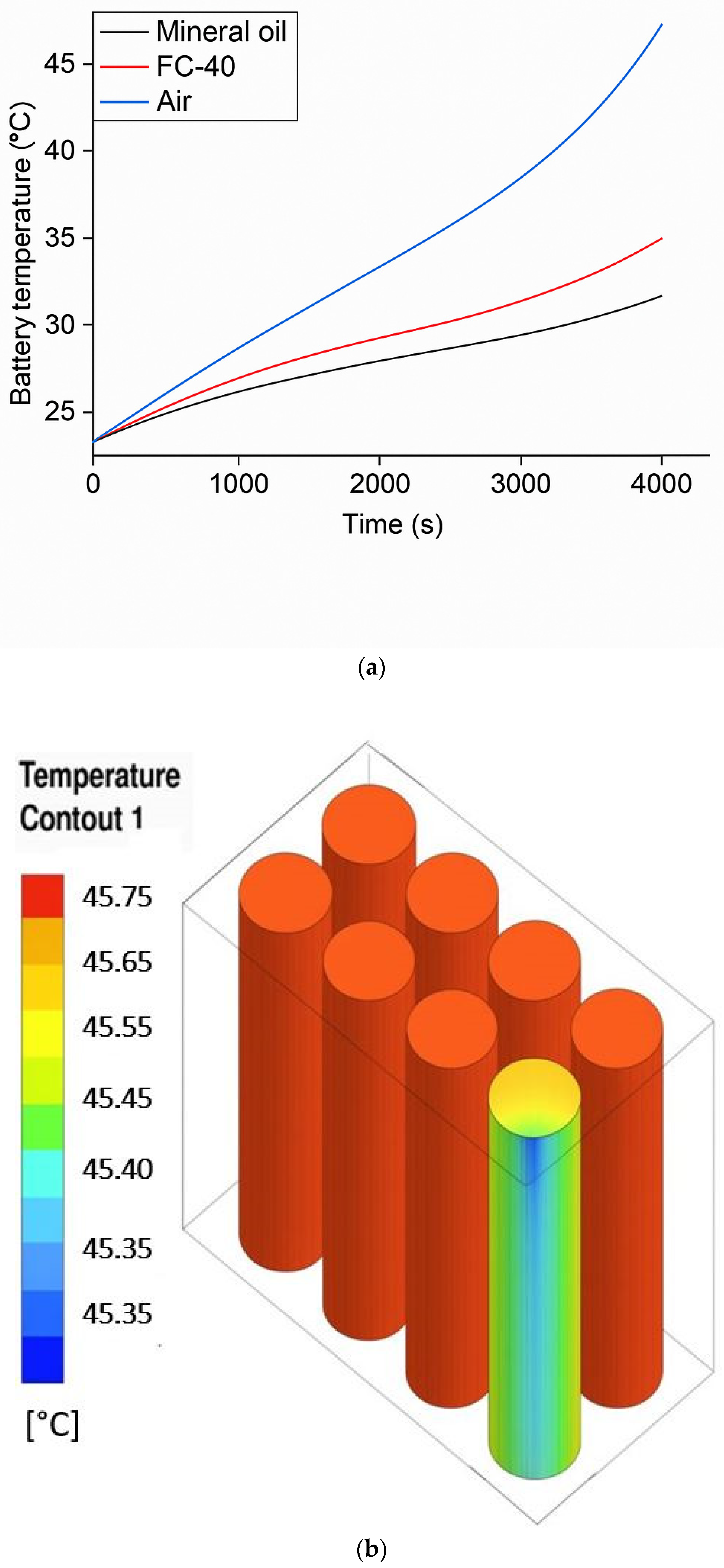

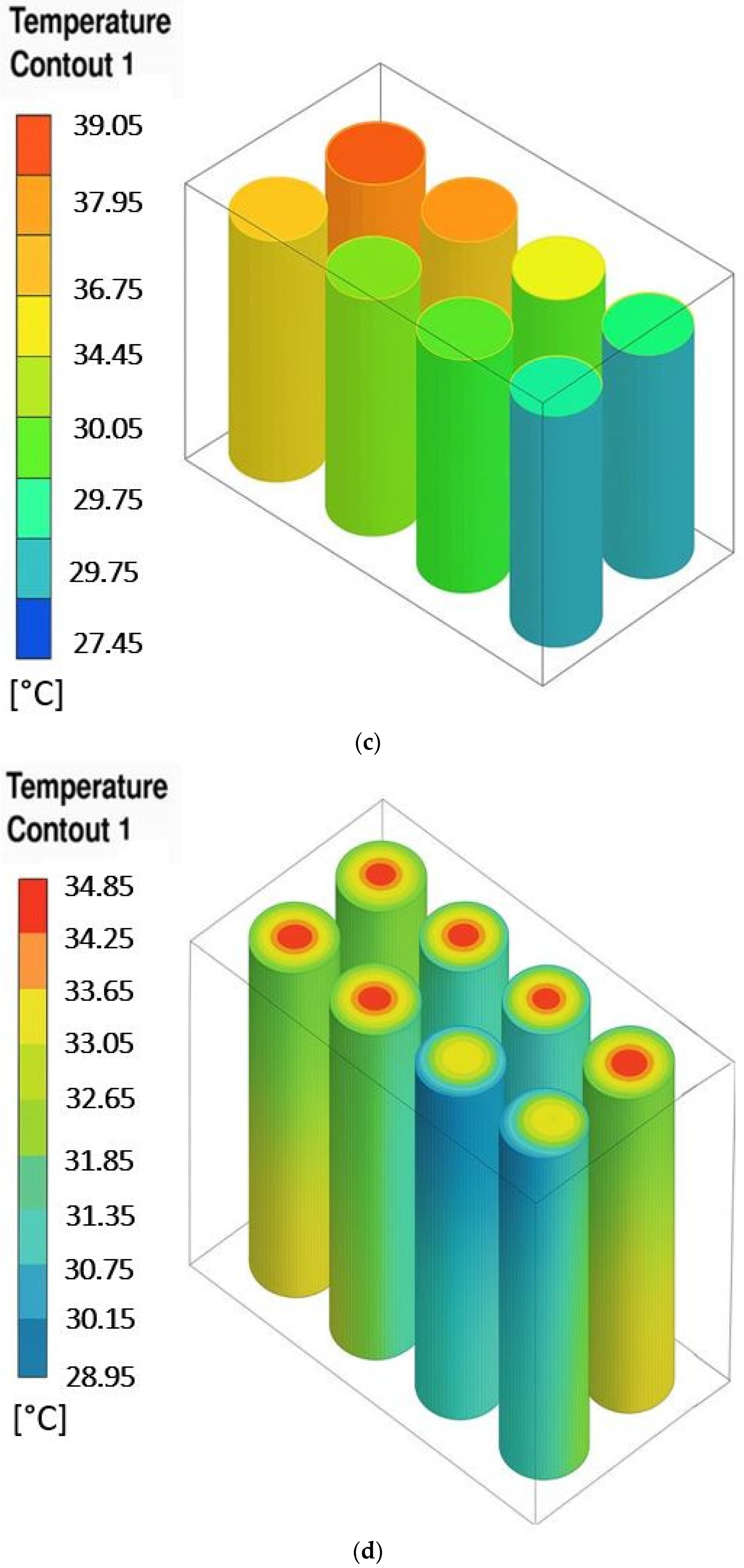

3.2. Comparative Study of FC-40 and Alternative Coolants in Battery Immersion Cooling

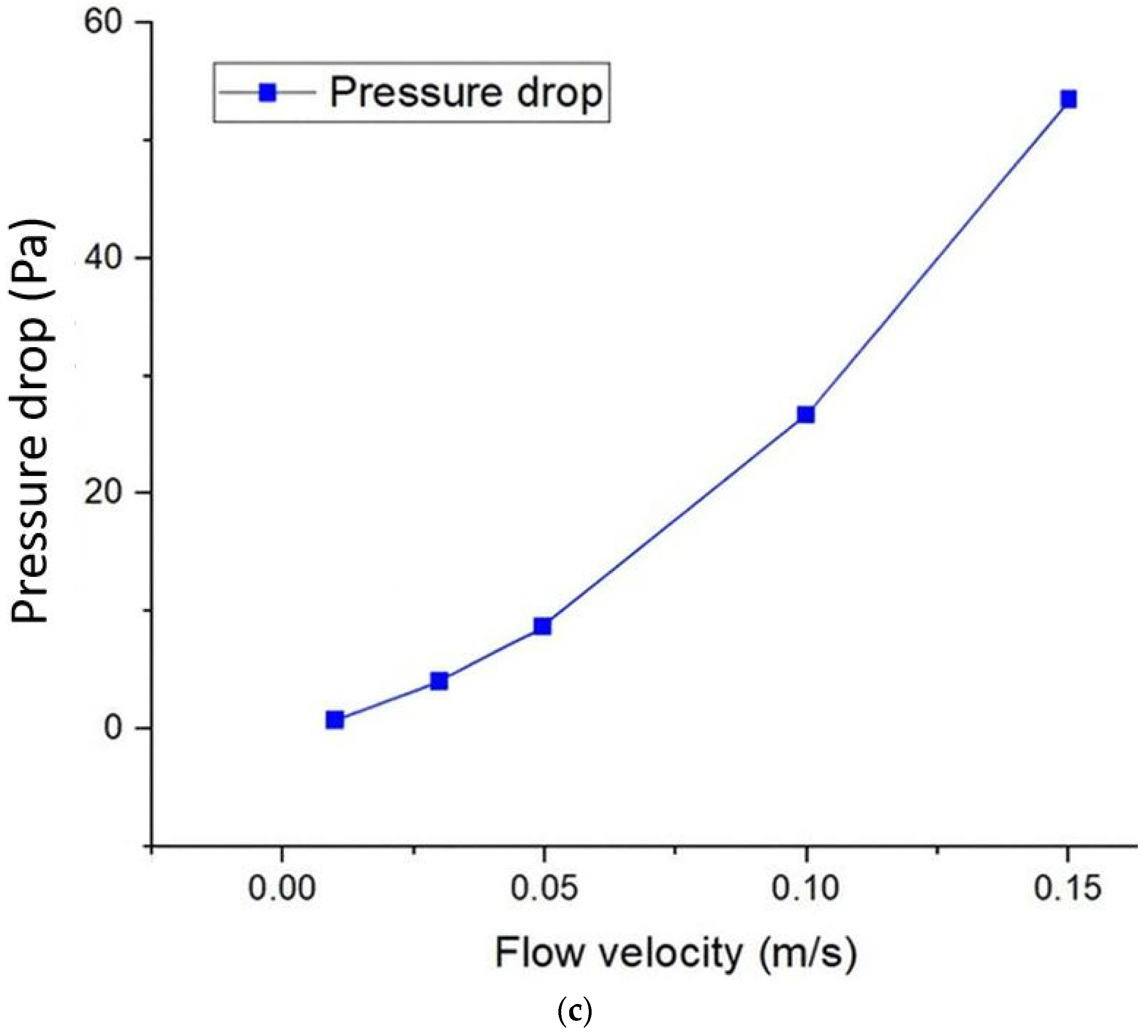

3.3. Flow Velocity Effects on FC-40 Dielectric Fluid in Battery Immersion Cooling

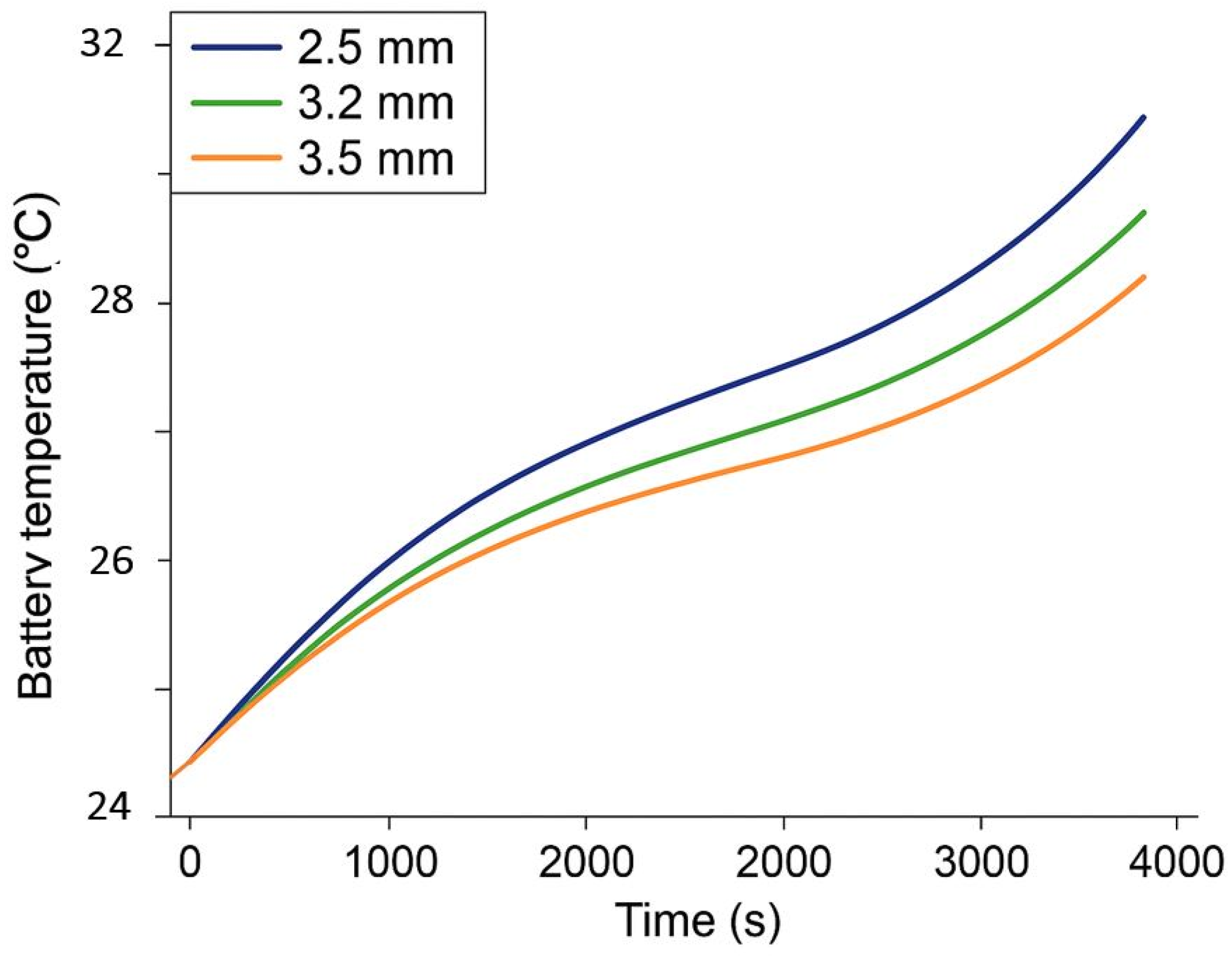

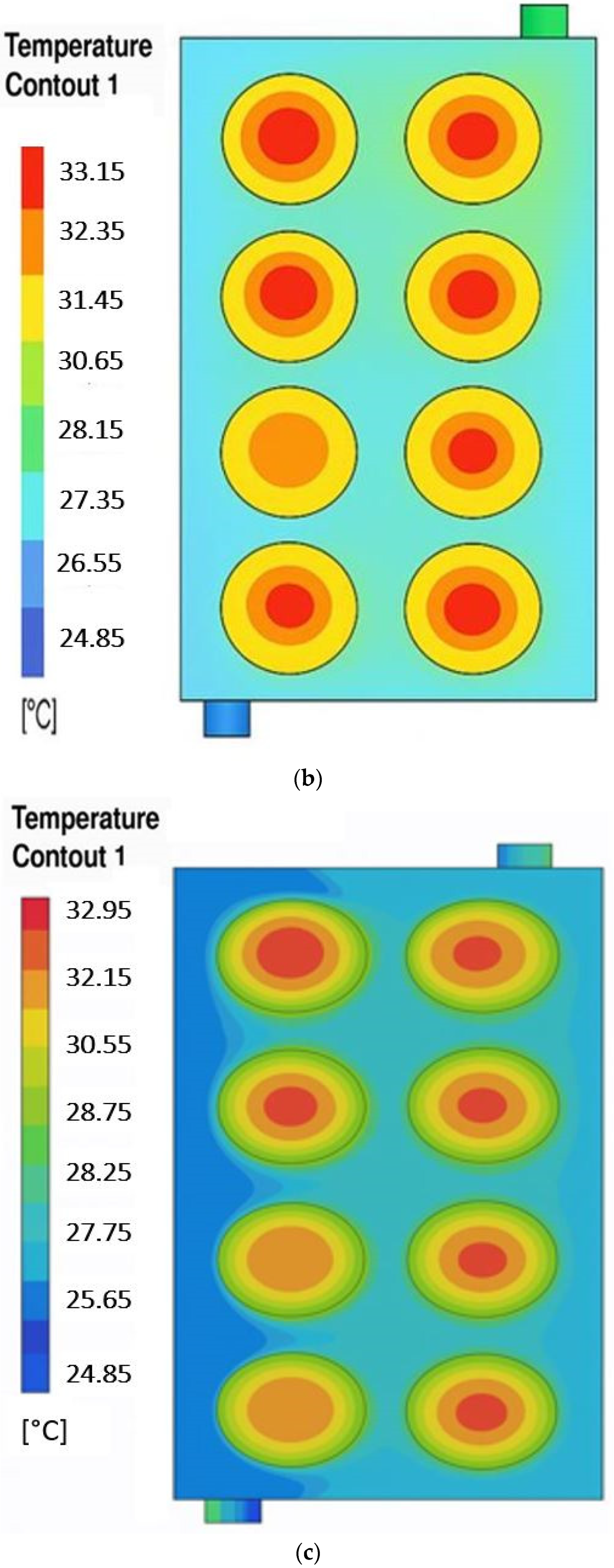

3.4. Impact of Inlet/Outlet Diameter on the Battery’s Thermal Performance with FC-40 Immersion Cooling

3.5. Effect of Discharge Rate on the Battery’s Thermal Performance with FC-40 Immersion Cooling

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | Nomenclature | ||

| BTMS | Battery Thermal Management System | Heat generation | |

| EV | Electric Vehicle | Irreversible heat | |

| CFD | Computational Fluid Dynamics | Reversible heat | |

| LIBs | Lithium-Ion Batteries | I | Current |

| PCM | Phase Change Material | E | Voltage |

| I/O | Inlet and Outlet | Internal resistance | |

| SOC | State of Charge | T | Temperature |

| Greek Symbols | t | Time | |

| Ҩ | Diameter of the fluid inlet and outlet | Battery surface heat dissipation | |

| Density | Volumetric heat generation rate | ||

| Thermal conductivity of the coolant | Specific heat capacity | ||

| Thermal conductivity of the battery cell | Reference temperature | ||

| Velocity vector | P | Pressure | |

| Dynamic viscosity | g | Gravity | |

| β | Thermal expansion coefficient | Reynolds number | |

References

- U.S. Environmental Protection Agency. Fast Facts on Transportation Greenhouse Gas Emissions. Available online: https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions (accessed on 25 August 2025).

- Alanazi, F. Electric vehicles: Benefits, challenges, and potential solutions for widespread adaptation. Appl. Sci. 2023, 13, 6016. [Google Scholar] [CrossRef]

- Tan, Y.; Li, Y.; Gu, Y.; Liu, W.; Fang, J.; Pan, C. Numerical study on heat generation characteristics of charge and discharge cycle of the Lithium-Ion battery. Energies 2023, 17, 178. [Google Scholar] [CrossRef]

- Afia, S.E.; Cano, A.; Arévalo, P.; Jurado, F. Energy Sources and Battery Thermal Energy Management Technologies for Electrical Vehicles: A Technical Comprehensive Review. Energies 2024, 17, 5634. [Google Scholar] [CrossRef]

- Paneerselvam, P.; SK, N.; Suyamburajan, V.; Murugaiyan, T.; Shekhawat, K.S.; Rengasamy, G. A review on recent progress in battery thermal management system in electric vehicle application. Mater. Today Proc. 2024. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 2021, 501, 230001. [Google Scholar] [CrossRef]

- Qin, P.; Sun, J.; Yang, X.; Wang, Q. Battery thermal management system based on the forced-air convection: A review. Etransportation 2020, 7, 100097. [Google Scholar] [CrossRef]

- Luo, J.; Zou, D.; Wang, Y.; Wang, S.; Huang, L. Battery thermal management systems (BTMs) based on phase change material (PCM): A comprehensive review. Chem. Eng. J. 2021, 430, 132741. [Google Scholar] [CrossRef]

- Rahmani, A.; Dibaj, M.; Akrami, M. Recent Advancements in battery thermal Management Systems for enhanced performance of Li-Ion Batteries: A Comprehensive review. Batteries 2024, 10, 265. [Google Scholar] [CrossRef]

- Luo, Y.; Zhou, D.; Zou, Z.; Bi, C.; Yang, X.; Li, X.; Yang, X. A battery thermal management system integrating immersion preheating and immersion cooling. ACS Omega 2024, 9, 43523–43533. [Google Scholar] [CrossRef]

- Bao, R.; Wang, Z.; Gao, Q.; Yang, H.; Zhang, B.; Chen, S. Dynamic-static composite immersion cooling for improving thermal equalization behavior in lithium-ion battery packs. Energy 2025, 330, 136774. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, R.; Wang, S.; Huang, D. Heat transfer characteristics and influencing factors of immersion coupled direct cooling for battery thermal management. J. Energy Storage 2023, 62, 106821. [Google Scholar] [CrossRef]

- Zou, Z.; Xie, J.; Luo, Y.; Zhang, G.; Yang, X. Numerical study on a novel thermal management system coupling immersion cooling with cooling tubes for power battery modules. J. Energy Storage 2024, 83, 110634. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, T.; Han, Z.; Chen, H.; Chen, H.; Liu, Z.; Huang, H. Study on the effect of immersion thermal management for high-current rate fast charging of 21700 Li-ion batteries. J. Energy Storage 2024, 85, 111061. [Google Scholar] [CrossRef]

- Hemavathi, S.; Kumaran, A.T.; Srinivas, S.; Prakash, A. Synthetic ester-based forced flow immersion cooling technique for fast discharging lithium-ion battery packs. J. Energy Storage 2024, 97, 112852. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Sun, Z.; Wen, X.; Wu, J.; Feng, L.; Wang, Y.; Cai, W.; Yu, H.; Wang, M.; et al. Two-phase immersion liquid cooling system for 4680 Li-ion battery thermal management. J. Energy Storage 2024, 97, 112952. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Z.; Wu, W.; Wei, L.; Hu, C.; Li, Y.; Huang, H.; Li, Y.; Song, Y. Numerical simulation for comparison of cold plate cooling and HFE-7000 immersion cooling in lithium-ion battery thermal management. J. Energy Storage 2024, 101, 113938. [Google Scholar] [CrossRef]

- He, Q.; Li, X.; Shan, W.; Zhang, W.; Wang, J.; Wang, Z.; Zheng, L. Numerical and experimental investigations on heat transfer characteristics and influencing factors of immersion cooling system for high-capacity prismatic lithium-ion battery. J. Energy Storage 2024, 104, 114518. [Google Scholar] [CrossRef]

- Le, Q.; Shi, Q.; Liu, Q.; Yao, X.; Ju, X.; Xu, C. Numerical investigation on manifold immersion cooling scheme for lithium ion battery thermal management application. Int. J. Heat Mass Transf. 2022, 190, 122750. [Google Scholar] [CrossRef]

- Patil, M.S.; Seo, J.; Lee, M. A novel dielectric fluid immersion cooling technology for Li-ion battery thermal management. Energy Convers. Manag. 2020, 229, 113715. [Google Scholar] [CrossRef]

- Wu, X.; Lu, Y.; Ouyang, H.; Ren, X.; Yang, J.; Guo, H.; Han, X.; Zhang, C.; Wu, Y. Theoretical and experimental investigations on liquid immersion cooling battery packs for electric vehicles based on analysis of battery heat generation characteristics. Energy Convers. Manag. 2024, 310, 118478. [Google Scholar] [CrossRef]

- Kumaran, A.T.; Hemavathi, S. Optimization of Lithium-ion battery thermal performance using dielectric fluid immersion cooling technique. Process Saf. Environ. Prot. 2024, 189, 768–781. [Google Scholar] [CrossRef]

- Zhao, L.; Tong, J.; Zheng, M.; Chen, M.; Li, W. Experimental study on the thermal management performance of immersion cooling for 18650 lithium-ion battery module. Process Saf. Environ. Prot. 2024, 192, 634–642. [Google Scholar] [CrossRef]

- Huang, H.; Li, W.; Xiong, S.; Luo, Z.; Ahmed, M. Single-phase static immersion-cooled battery thermal management system with finned heat pipes. Appl. Therm. Eng. 2024, 254, 123931. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Yue, M.; Chen, J.; Zhu, H.; Deng, Y.; Zhu, Y.; Zhang, F.; Wen, M.; Zhang, B.; Kang, S. Effects of the different air-cooling strategies on cooling performance of a lithium-ion battery module with baffle. Appl. Therm. Eng. 2018, 144, 231–241. [Google Scholar] [CrossRef]

- 3M. 3MTM FluorinertTM Electronic Liquid FC-40. 2019. Available online: https://multimedia.3m.com/mws/media/64888O/3m-fluorinert-electronic-liquid-fc40.pdf (accessed on 1 January 2025).

- Muneeshwaran, M.; Lin, Y.; Wang, C. Performance analysis of single-phase immersion cooling system of data center using FC-40 dielectric fluid. Int. Commun. Heat Mass Transf. 2023, 145, 106843. [Google Scholar] [CrossRef]

- Liu, J.; Ma, Q.; Li, X. Numerical study on heat dissipation performance of a lithium-ion battery module based on immersion cooling. J. Energy Storage 2023, 66, 107511. [Google Scholar] [CrossRef]

- Williams, N.; Trimble, D.; O’Shaughnessy, S. Liquid immersion thermal management of lithium-ion batteries for electric vehicles: An experimental study. J. Energy Storage 2023, 72, 108636. [Google Scholar] [CrossRef]

- Liu, J.; Chen, H.; Yang, M.; Huang, S.; Wang, K. Comparative study of natural ester oil and mineral oil on the applicability of the immersion cooling for a battery module. Renew. Energy 2024, 224, 120187. [Google Scholar] [CrossRef]

- Satyanarayana, G.; Sudhakar, D.R.; Goud, V.M.; Ramesh, J.; Pathanjali, G. Experimental investigation and comparative analysis of immersion cooling of lithium-ion batteries using mineral and therminol oil. Appl. Therm. Eng. 2023, 225, 120187. [Google Scholar] [CrossRef]

| Property | Specification |

|---|---|

| Cathode substance | |

| Anode substance | Graphite |

| Cell length (mm) | 65 |

| Cell diameter (mm) | 18 |

| Nominal voltage (V) | 3.7 |

| Nominal capacity (Ah) | 2.6 |

| Specific heat capacity () | 1200 |

| Mesh Configuration | Number of Elements | Number of Nodes |

|---|---|---|

| Mesh-1 | 514,924 | 208,219 |

| Mesh-2 | 901,284 | 355,905 |

| Mesh-3 | 1,459,459 | 603,667 |

| Case | Coolant | Flow Velocity (m/s) | Discharge Rate | Inlet and Outlet Diameter (mm) |

|---|---|---|---|---|

| 1 | Air | 0.01 | 1C | 2.5 |

| 2 | Mineral oil | 0.01 | 1C | 2.5 |

| 3 | FC-40 | 0.01 | 1C | 2.5 |

| 4 | FC-40 | 0.03 | 1C | 2.5 |

| 5 | FC-40 | 0.05 | 1C | 2.5 |

| 6 | FC-40 | 0.1 | 1C | 2.5 |

| 7 | FC-40 | 0.15 | 1C | 2.5 |

| 8 | FC-40 | 0.01 | 1C | 3.2 |

| 9 | FC-40 | 0.01 | 1C | 3.5 |

| 10 | FC-40 | 0.01 | 2C | 2.5 |

| 11 | FC-40 | 0.01 | 3C | 2.5 |

| 12 | FC-40 | 0.01 | 4C | 2.5 |

| 13 | FC-40 | 0.01 | 5C | 2.5 |

| Performance Metric | Air | Mineral Oil | FC-40 |

|---|---|---|---|

| Density (kg/m3) | 1.225 | 1080.92 | 1855 |

| Specific heat (J/(kg K) | 1006.43 | 896.66 | 1100 |

| Thermal conductivity (W/m K) | 0.0242 | 0.149 | 0.065 |

| Viscosity (kg/m s) | 1.79 × 10−5 | 0.075 | 0.0041 |

| Max cell temperature (°C) | 45.6 | 33.03 | 30.5 |

| Temperature uniformity indicator (°C) | 0.4 | 11.55 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Afia, S.; Hidki, R.; Jurado, F.; Cano-Ortega, A. Numerical Investigation into 18650 Li-Ion Battery Temperature Control Applying Immersion Cooling with FC-40 Dielectric Fluid. Batteries 2025, 11, 397. https://doi.org/10.3390/batteries11110397

El Afia S, Hidki R, Jurado F, Cano-Ortega A. Numerical Investigation into 18650 Li-Ion Battery Temperature Control Applying Immersion Cooling with FC-40 Dielectric Fluid. Batteries. 2025; 11(11):397. https://doi.org/10.3390/batteries11110397

Chicago/Turabian StyleEl Afia, Sara, Rachid Hidki, Francisco Jurado, and Antonio Cano-Ortega. 2025. "Numerical Investigation into 18650 Li-Ion Battery Temperature Control Applying Immersion Cooling with FC-40 Dielectric Fluid" Batteries 11, no. 11: 397. https://doi.org/10.3390/batteries11110397

APA StyleEl Afia, S., Hidki, R., Jurado, F., & Cano-Ortega, A. (2025). Numerical Investigation into 18650 Li-Ion Battery Temperature Control Applying Immersion Cooling with FC-40 Dielectric Fluid. Batteries, 11(11), 397. https://doi.org/10.3390/batteries11110397