A Comprehensive Review on Lithium-Ion Battery Lifetime Prediction and Aging Mechanism Analysis

Abstract

1. Introduction

Structure of the Review

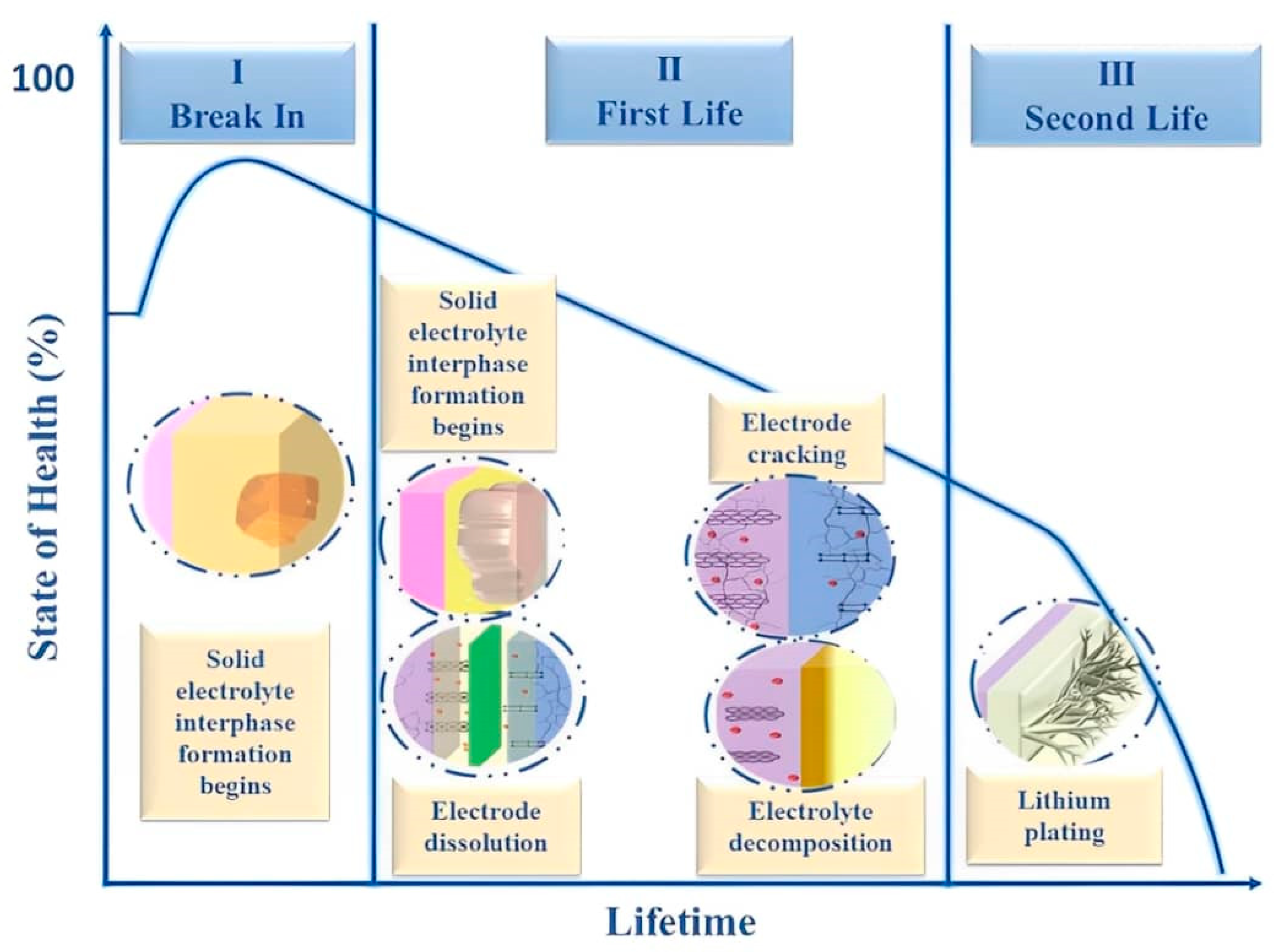

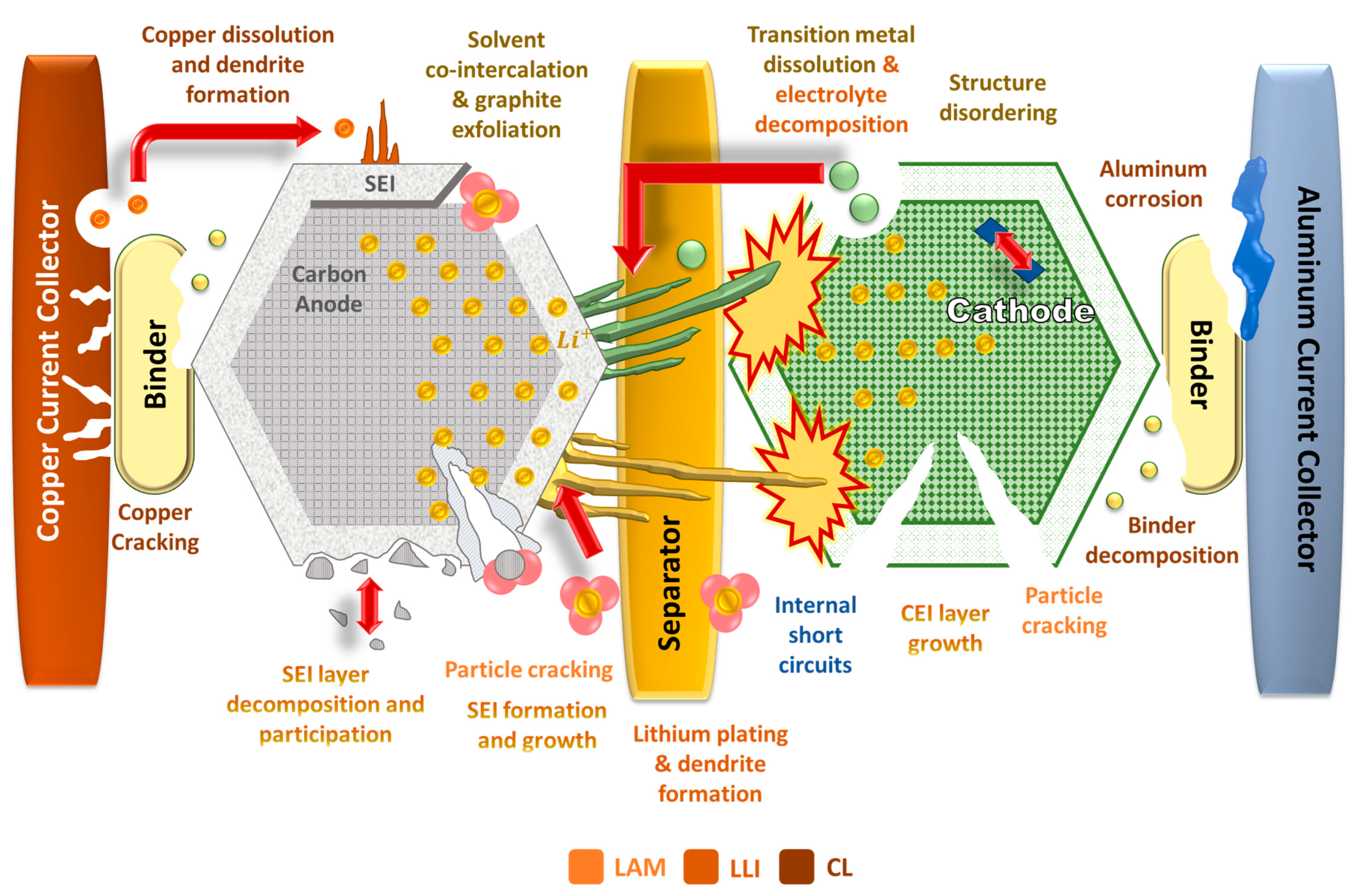

2. Aging of Lithium-Ion Batteries

2.1. Calendar Aging

2.2. Cycle Aging

| Focus Area | Methodology | Battery Type | Degradation Model | Key Findings | Ref. |

|---|---|---|---|---|---|

| Lifetime prediction of high-power batteries | Experimental investigation and parameterization of semi-empirical aging model coupled with impedance-based electrical-thermal model | NMC/Graphite | Semi-empirical aging model | Accurate lifetime prediction based on drive cycles and management strategies | [30,63,70] |

| Cycle-life prediction using the grey model | Data-driven grey model with smoothing methods to predict cycle life | Phosphate Iron & Manganese Oxide Lithium-ion batteries | Grey model for life-end prediction | Efficient lifetime prediction with fewer cycles, without needing detailed aging mechanism knowledge | [64,71] |

| Calendar and cycle aging tests | Mathematical equations derived from voltage, temperature, cycle depth, and SOC | - | Impedance-based electrical-thermal model | Comprehensive aging model for optimizing different drive cycles and battery management strategies | [65,72] |

| Accelerated lifetime testing for wind power applications | Accelerated aging conditions and performance-degradation model validation with mission profiles | - | Performance-degradation lifetime model | Optimized battery selection, operation, and maintenance for improved performance and longevity | [66,73,74] |

| Establishment of life test protocols for high-power lithium-ion cells in HEV applications | Aging experiments on 18,650-size cells; developed inductive models | High-power lithium-ion cells | Inductive models for power fade, capacity loss, and impedance rise | Accurate lifetime predictions under various operating conditions | [22,37,67] |

| Aging tests on NMC batteries for EV applications | Accelerated aging tests using standardized driving cycle (WLTC) and temperature profiles | NMC | - | Insights into capacity fade and internal resistance increase in NMC batteries | [68,75] |

| Lifespan estimation of lithium-ion batteries | High-voltage testing, accelerated aging tests with high charge rates and elevated temperatures | LiCoO2/Hard carbon cells | - | Highlighted degradation above 4 V, importance of avoiding high voltage for lifespan prediction | [69] |

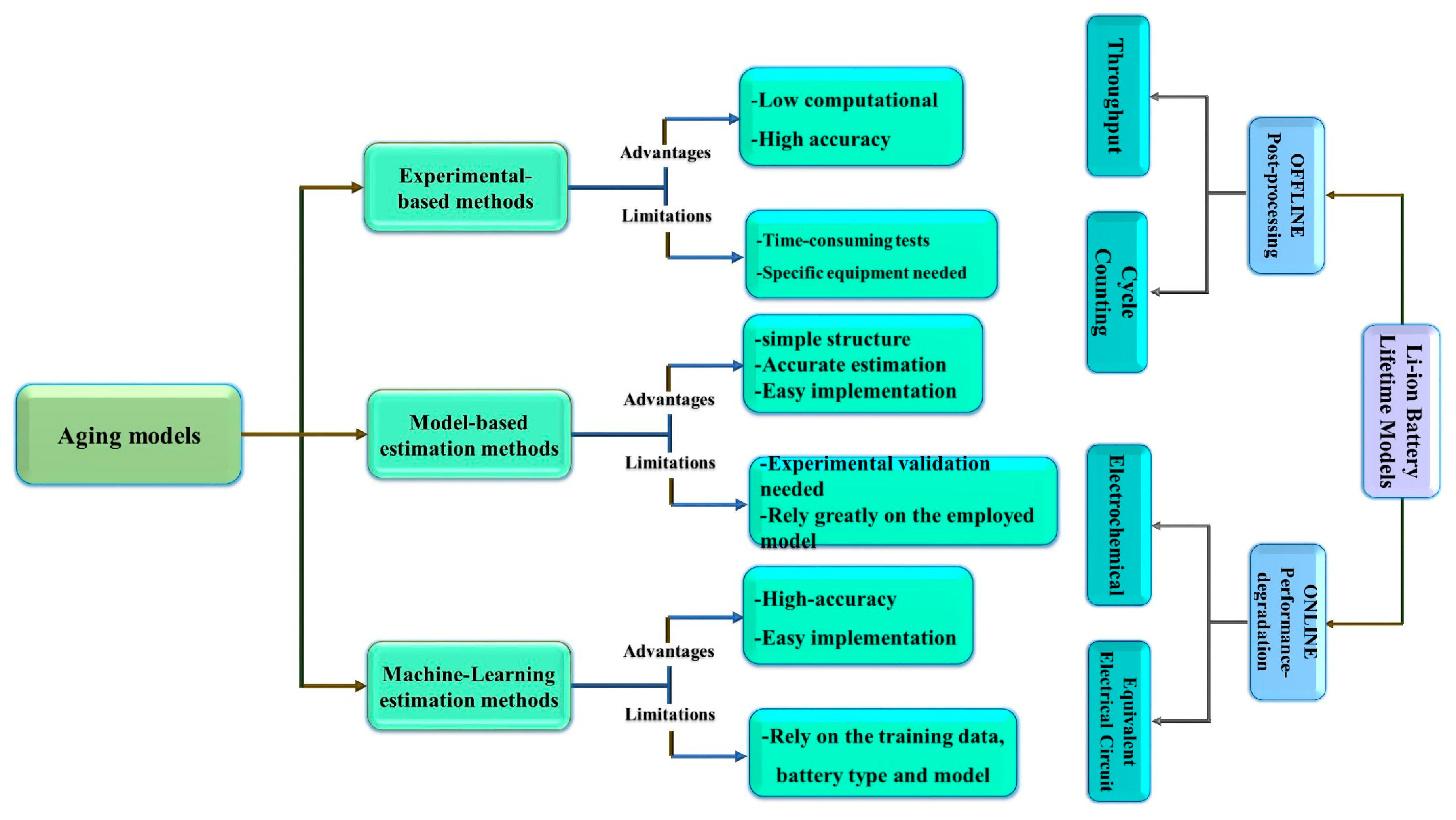

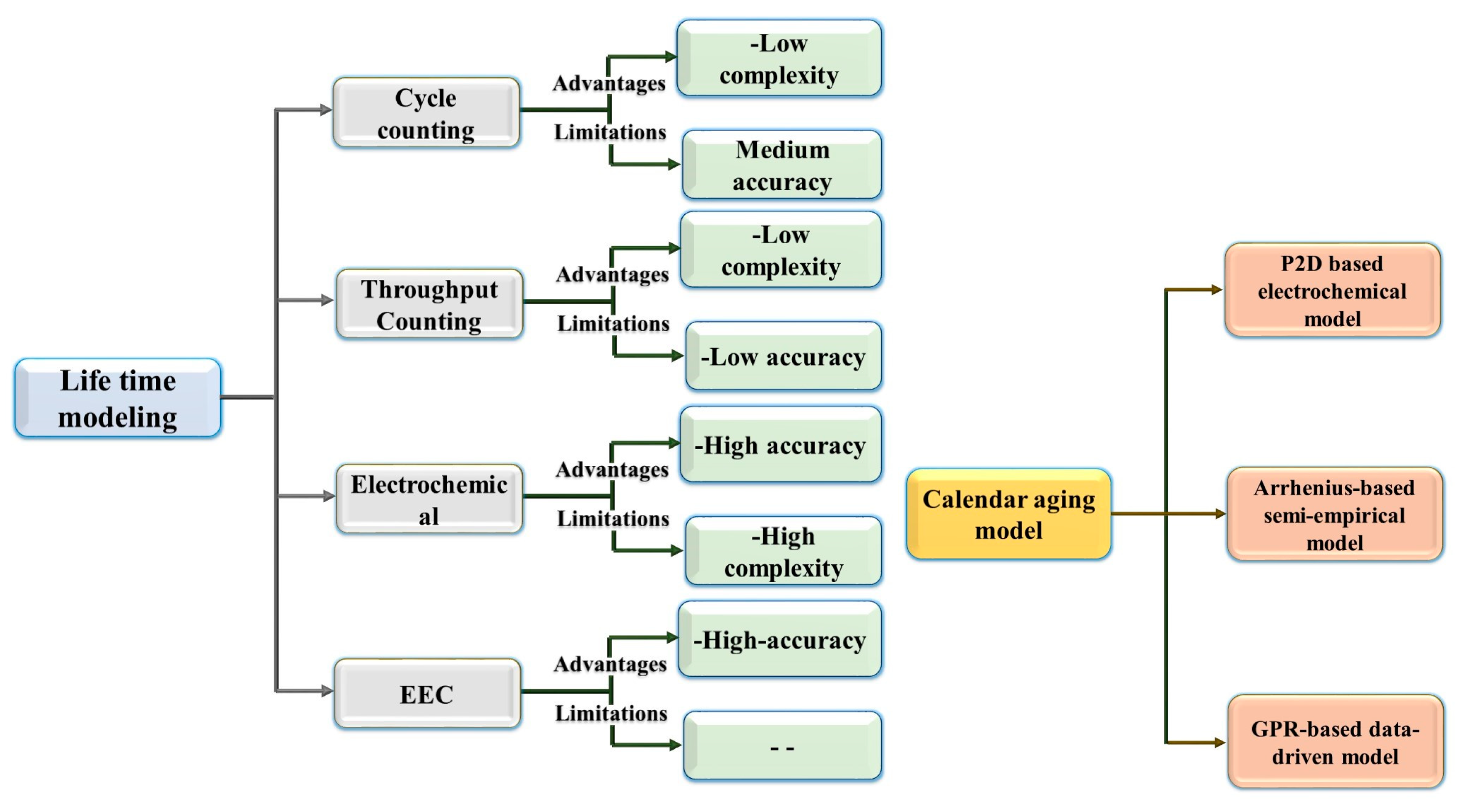

3. Modeling the Lifespan and Aging of LIBs

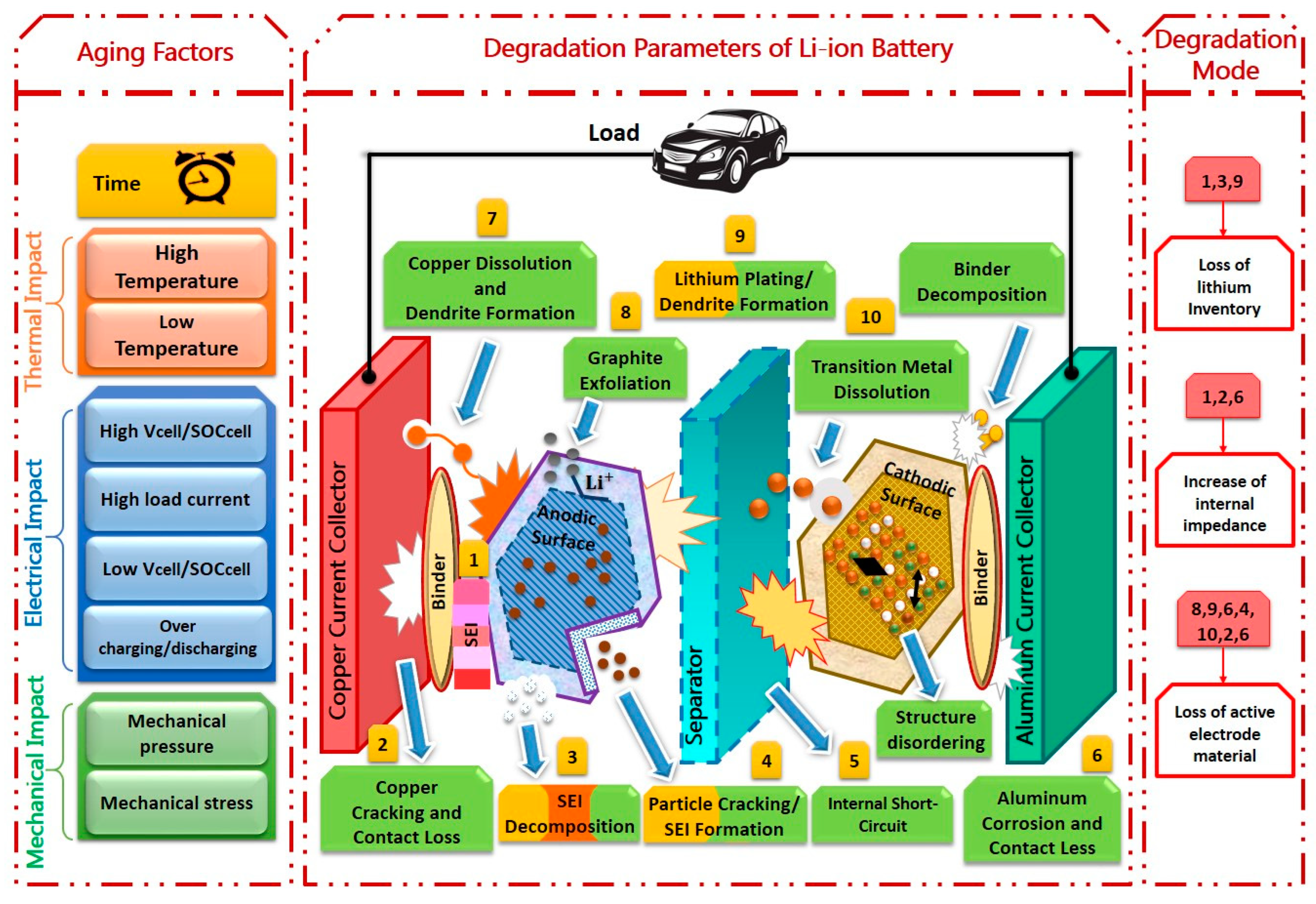

3.1. Mechanisms of Battery Aging

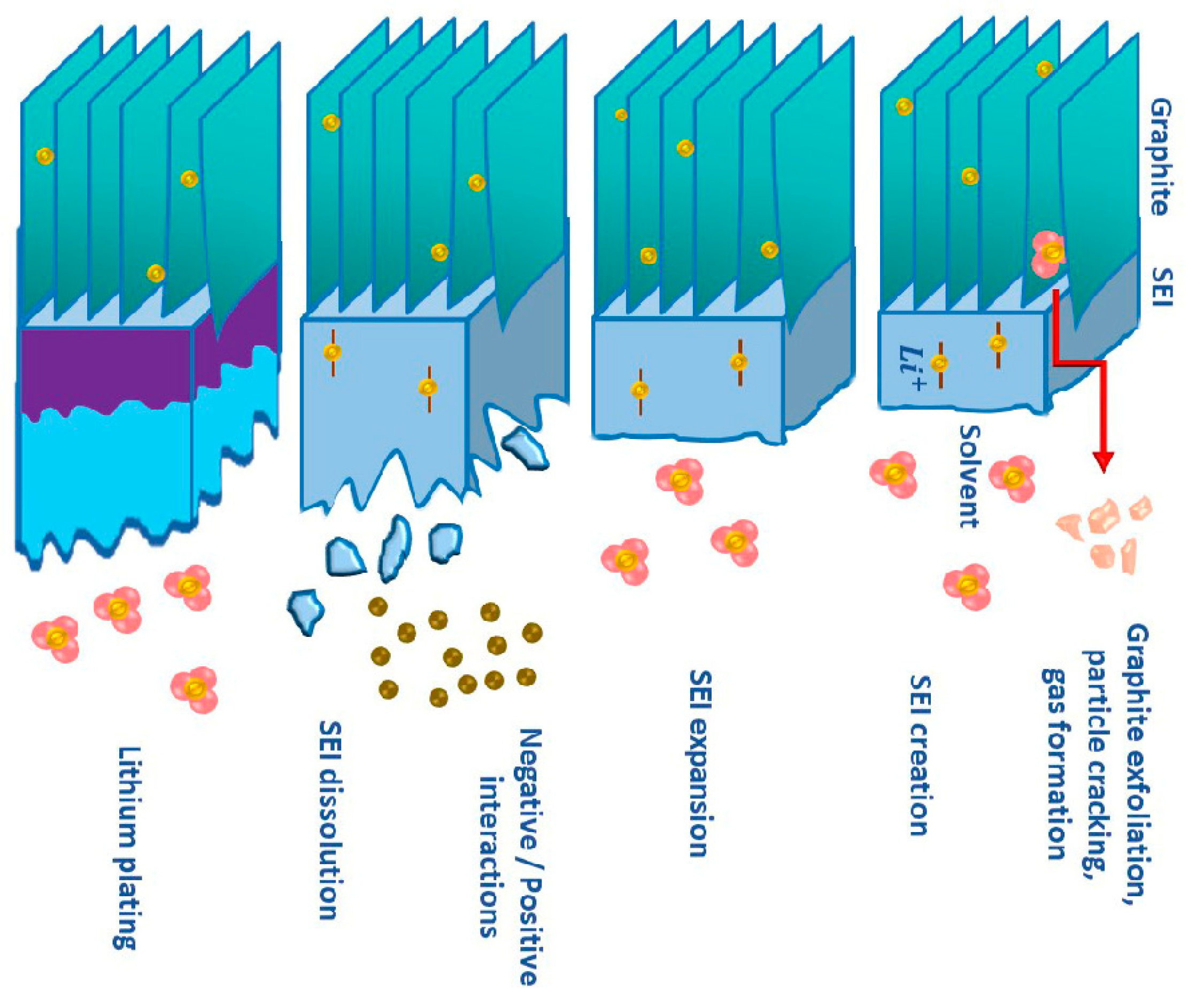

3.1.1. Electrochemical Breakdown

3.1.2. Lithium Deposition

3.1.3. Thermal and Mechanical Stress

3.2. Battery Aging and Modeling Approaches

3.2.1. Physics-Based Models

Single-Particle Model (SPM)

Doyle–Fuller–Newman (DFN) Model

3.2.2. Empirical Models

3.2.3. Electrochemical Models

Electrochemical Impedance Spectroscopy (EIS)

3.2.4. Volume Change Models

3.2.5. Combined Multiphysics- and Data-Based Models

4. Factors Affecting Lithium-Ion Battery Aging

4.1. Operating Conditions

4.2. Cycling Frequency

4.3. Temperature

4.4. State of Charge (SoC)

4.5. Cycling Rate

4.6. Environmental Factors

5. Multi-Factor Interactions in Battery Aging

5.1. Combined Effects of Temperature and SOC

5.2. Impact of Temperature and Discharge Rate

5.3. DOD and Capacity Degradation

6. Lifetime Modeling of Lithium-Ion Batteries with Different Cathode

6.1. (Nickel Cobalt Aluminum) NCA

6.2. Lithium Cobalt Oxide (LCO)

6.3. Lithium Iron Phosphate (LFP)

6.4. Nickel Cobalt Aluminum (NCA)

6.5. Lithium Manganese Oxide (LMO)

7. Indicators to Quantify the Health Level of the Battery

7.1. State of Health

7.2. EOL

7.3. RUL

7.4. Aging Estimation

| Study Focus | Key Findings | Ref. |

|---|---|---|

| EIS and Battery Aging | Discusses the importance of EIS in understanding degradation mechanisms. | [247] |

| Phenomenological Model | Investigates degradation due to cyclic fatigue, including SEI formation. | [249] |

| Current Gradients | Examines the impact of current gradients on battery degradation. | [250] |

| SEI Growth Model | Describes SEI growth during cycling and aging. | [251] |

| Corrosion in Batteries | Investigates corrosion processes in Li-ion batteries. | [252] |

| SEI Film Formation | Models the formation of the SEI film during lithium intercalation. | [253] |

| Mechanical Models | Develops models to predict mechanical phenomena during intercalation. | [254] |

| Diffusion-Induced Stress | Studies stress distributions in silicon electrodes. | [255] |

| Atomistic Modeling | Highlights the role of atomistic modeling in material design. | [256] |

| Impedance Spectroscopy | Proposes a method for online characterization of battery aging. | [257] |

| Charging Methodologies | Investigates the impact of different charging methods on battery life. | [258] |

| Universal Voltage Protocol | Introduces a new charging technique for improved efficiency. | [259] |

| Aging Parameters | Explores aging parameters for SOH estimation in Li-ion batteries. | [260] |

| ECM Parameters | Analyzes variations in ECM parameters at different SOH levels. | [261] |

| State Estimation | Investigates aging uncertainties in battery modeling for EV applications. | [264] |

| Capacity Decline | Analyzes aging mechanisms using impedance spectroscopy. | [265] |

| Impedance Techniques | Reviews various impedance techniques for aging studies. | [267] |

| Fractional Differential Model | Examines a new battery model for NMC cells. | [268] |

| Economic and Technical Models | Discusses the importance of lifespan prediction for economic viability. | [269] |

8. Prospects and Challenges of Lifetime Modeling of LIBs

8.1. Prospects

8.1.1. Enhanced Battery Performance

8.1.2. Cost Reduction

8.1.3. Sustainability and Environmental Impact

8.1.4. Safety

8.2. Challenges

8.2.1. Complex Degradation Mechanisms

8.2.2. Lack of Standardization

8.2.3. Limited Long-Term Data

8.2.4. Predicting Real-World Conditions

9. Lithium-Ion Battery Material and Aging

9.1. Development of Symmetrical Electrode Materials

9.2. Structure of Electrode Materials and Lithium-Ion Battery Aging

9.2.1. Lithium-Ion Diffusion Rate

9.2.2. Thermal Stability

9.3. Degradation Mechanisms

9.4. Data Collection and Mathematical Models

9.5. Uncertainty Analysis

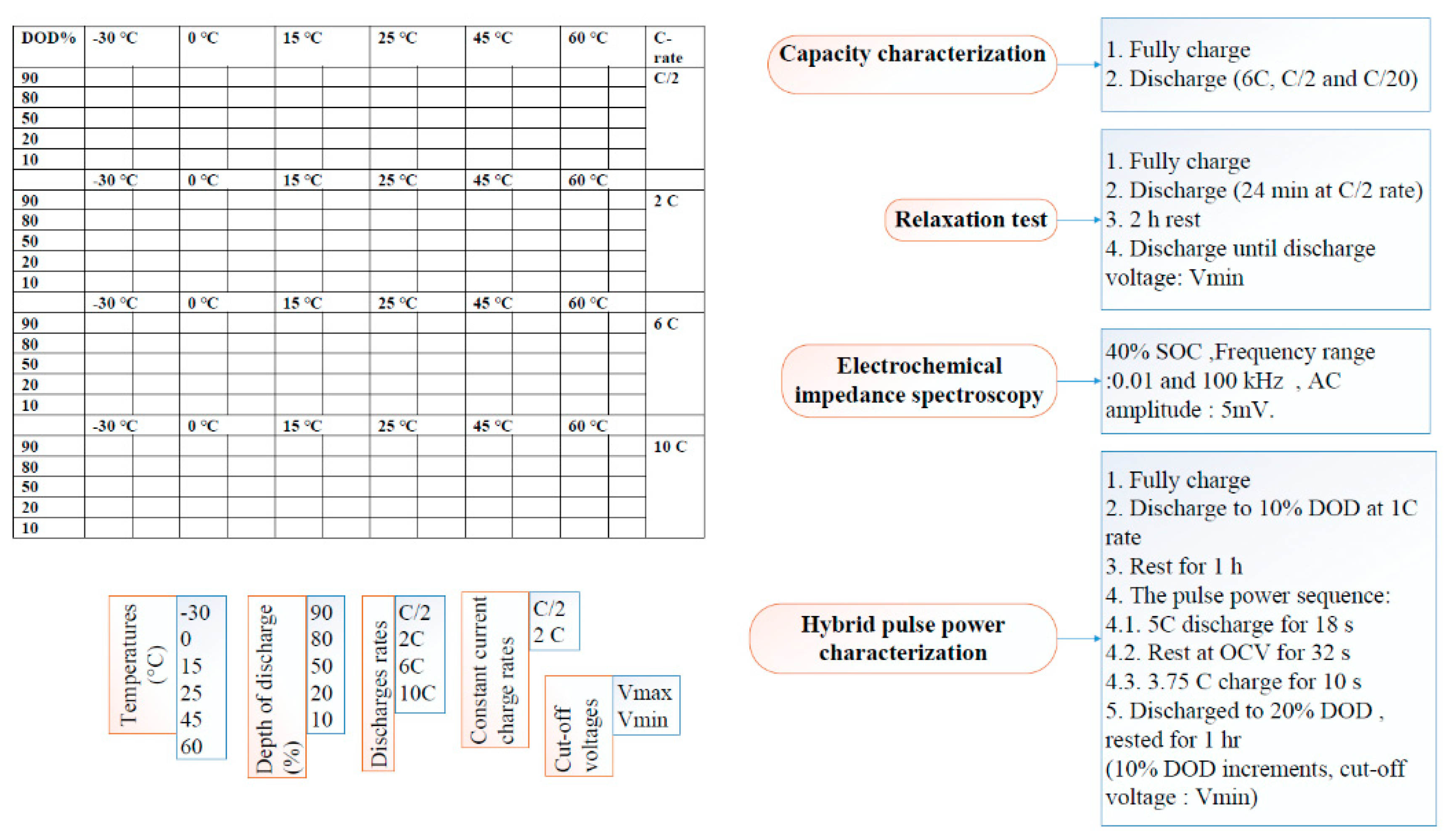

9.6. Analyzing Cell Aging Under Various Duty Cycles

| Study Focus | Key Findings | Methodologies/Approaches | Implications/Contributions | Ref. |

|---|---|---|---|---|

| Carbon-based Anode Materials | Discussed various carbon anode materials and methods to improve performance, focusing on silicon carbon anodes and metal oxide/carbon composites. | Review of carbon-based anodes, highlighting electrostatic electrospinning and templates for composites. | Enhanced electrochemical performance and wider applications for LIBs. | [293] |

| Phosphorus-Graphite Composite | Introduced a dual-temperature zone heating strategy to fabricate fibrous phosphorus for improved battery performance. | Composite fabrication and performance testing. | Demonstrated enhanced rate performance and cycle stability of LIBs. | [294] |

| Nonlinear Frequency Response Analysis | Proposed NFRA to quantify battery aging modes without prior knowledge of cell’s duty. | Experimental NFRA measurements combined with simulations. | Highlighted the importance of NFRA for aging diagnosis and battery management. | [294] |

| Aging Heterogeneity Investigation | Investigated aging heterogeneity in NMC811 and graphite cells after extensive cycling. | Synchrotron XRD radiography and electrochemical characterization. | Showcased potential for non-destructive techniques in battery research. | [296] |

| Flexible Lithium-Ion Batteries | Emphasized the potential of flexible LIBs for wearable electronics and explored carbon nanomaterials. | Review of flexible electrode materials. | Identified challenges and future directions for electrode development. | [300] |

| Capacity and Power Fading Mechanisms | Explained aging mechanisms for cathodes and anodes, focusing on structural disorder and SEI growth. | Analysis of aging mechanisms under cycling and storage. | Provided insights into performance degradation in LIBs. | [301] |

| Thermal Stability Analysis | Investigated thermal stability and reactions of active materials in LIBs. | Various thermal profiling methods, including pyrolysis-GC-MS analysis. | Identified thermal reactions affecting LIB safety. | [302] |

| Lifetime Modeling | Reviewed degradation mechanisms, data collection, and modeling for long-life LIBs. | Comprehensive review and analysis of methodologies. | Advanced understanding of battery lifespan and degradation management. | [305] |

| Parameter Estimation for Lifetime Models | Introduced a Genetic Algorithm methodology for estimating parameters in battery lifetime modeling. | Comparison of parametrization methodologies. | Improved parameter estimation for battery lifespan models. | [306] |

| Uncertainty in Battery Lifetime Prediction | Proposed a method for predicting remaining battery life, considering uncertainties. | Analytical and predictive modeling. | Aimed to aid decision-making for reused batteries in EVs. | [307] |

| Performance under Varying Conditions | Analyzed the performance of various LIB types under different discharge rates and conditions. | Experimental performance evaluation and comparison. | Highlighted significant impacts of cycling conditions on degradation. | [308] [309] [310], [311], [312] |

10. Limitations of Data-Driven Methods in Battery Life Prediction

10.1. Data Quality, Preprocessing, Overfitting and Underfitting

10.2. Insufficient Data for Training

10.3. Generalization Issues

10.4. Data Imbalance

10.5. Domain Knowledge Integration

11. Comparison of Lithium-Ion Battery Chemistries

12. Future Research Directions for Lithium-Ion Battery Aging

13. Discussion

14. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hesse, H.C.; Schimpe, M.; Kucevic, D.; Jossen, A. Lithium-ion battery storage for the grid—A review of stationary battery storage system design tailored for applications in modern power grids. Energies 2017, 10, 2107. [Google Scholar] [CrossRef]

- Huang, Y.; Li, J. Key Challenges for Grid-Scale Lithium-Ion Battery Energy Storage. Adv. Energy Mater. 2022, 12, 202202197. [Google Scholar] [CrossRef]

- Alqarni, A. Investigating the Performance and Longevity of Lithium-Ion Batteries in Grid-Scale Energy Storage Applications. 2024. Available online: https://www.preprints.org/frontend/manuscript/36ede8f9f2973b039df8c5da693985f1/download_pub (accessed on 6 March 2025).

- Shabeer, Y.; Madani, S.S.; Panchal, S.; Mousavi, M.; Fowler, M. Different Metal–Air Batteries as Range Extenders for the Electric Vehicle Market: A Comparative Study. Batteries 2025, 11, 35. [Google Scholar] [CrossRef]

- Madhavan, P.V.; Shahgaldi, S.; Li, X. Modelling Anti-Corrosion Coating Performance of Metallic Bipolar Plates for PEM Fuel Cells: A Machine Learning Approach. Energy AI 2024, 17, 100391. [Google Scholar] [CrossRef]

- Cunanan, C.; Tran, M.-K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A Review of Heavy-Duty Vehicle Powertrain Technologies: Diesel Engine Vehicles, Battery Electric Vehicles, and Hydrogen Fuel Cell Electric Vehicles. Clean. Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Tran, M.-K.; Bhatti, A.; Vrolyk, R.; Wong, D.; Panchal, S.; Fowler, M.; Fraser, R. A Review of Range Extenders in Battery Electric Vehicles: Current Progress and Future Perspectives. World Electr. Veh. J. 2021, 12, 54. [Google Scholar] [CrossRef]

- Madhavan, P.V.; Shahgaldi, S.; Li, X. Ex-situ Characterization of Nb-Ti Alloy/Pt Coated Stainless Steel Bipolar Plates for Proton Exchange Membrane Fuel Cells. Energy Convers. Manag. 2024, 311, 118536. [Google Scholar] [CrossRef]

- Reniers, J.; Howey, D.A. Digital twin of a MWh-scale grid battery system for efficiency and degradation analysis. Appl. Energy 2023, 336, 120774. [Google Scholar]

- Mathews, I.; Xu, B.; He, W.; Barreto, V.; Buonassisi, T.; Peters, I.M. Technoeconomic model of second-life batteries for utility-scale solar considering calendar and cycle aging. Appl. Energy 2020, 269, 115127. [Google Scholar]

- Reniers, J.M.; Mulder, G.; Ober-Blöbaum, S.; Howey, D.A. Improving optimal control of grid-connected lithium-ion batteries through more accurate battery and degradation modelling. J. Power Sources 2018, 379, 91–102. [Google Scholar]

- Zhao, C.; Li, X.; Yao, Y. Quality analysis of battery degradation models with real battery aging experiment data. In Proceedings of the 2023 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 13–14 February 2023; Available online: https://ieeexplore.ieee.org/abstract/document/10078599/ (accessed on 6 March 2025).

- Beaudet, A.; Larouche, F.; Amouzegar, K.; Bouchard, P.; Zaghib, K. Key Challenges and Opportunities for Recycling Electric Vehicle Battery Materials. Sustainability 2020, 12, 5837. [Google Scholar] [CrossRef]

- Zhao, J.; Zhu, Y.; Zhang, B.; Liu, M.; Wang, J.; Liu, C.; Hao, X. Review of State Estimation and Remaining Useful Life Prediction Methods for Lithium–Ion Batteries. Sustainability 2023, 15, 5014. [Google Scholar] [CrossRef]

- Madhavan, P.V.; Zeng, X.; Shahgaldi, S.; Li, X. Investigation of Cr2SiC Ceramic MAX Phase Coated Metallic Bipolar Plates in Ex-Situ Conditions for Proton Exchange Membrane Fuel Cells. Int. J. Hydrogen Energy 2024, 96, 1232–1242. [Google Scholar] [CrossRef]

- Moradizadeh, L.; Madhavan, P.V.; Chellehbari, Y.M.; Gupta, A.; Li, X.; Shahgaldi, S. Porous transport layers with low Pt loading having Nb–Ta alloy as interlayer for proton exchange membrane water electrolyzers. Int. J. Hydrogen Energy 2024, 94, 1114–1129. [Google Scholar] [CrossRef]

- Sun, Q.; Liu, H.; Wang, Z.; Meng, Y.; Xu, C.; Wen, Y.; Wu, Q. Investigation on Thermal Runaway Hazards of Cylindrical and Pouch Lithium-Ion Batteries under Low Pressure of Cruise Altitude for Civil Aircraft. Batteries 2024, 10, 298. [Google Scholar] [CrossRef]

- Iqbal, H.; Sarwar, S.; Kirli, D.; Shek, J.K.H.; Kiprakis, A.E. A survey of second-life batteries based on techno-economic perspective and applications-based analysis. Carbon Neutrality 2023, 2, 8. [Google Scholar] [CrossRef]

- Tao, J.; Wang, S.; Cao, W.; Takyi-Aninakwa, P.; Fernandez, C.; Guerrero, J.M. A comprehensive review of state-of-charge and state-of-health estimation for lithium-ion battery energy storage systems. Ionics 2024, 30, 5903–5927. [Google Scholar] [CrossRef]

- Collath, N.; Tepe, B.; Englberger, S.; Jossen, A.; Hesse, H. Aging aware operation of lithium-ion battery energy storage systems: A review. J. Energy Storage 2022, 55, 105634. [Google Scholar] [CrossRef]

- Li, S.; Pischinger, S.; He, C.; Liang, L.; Stapelbroek, M. A comparative study of model-based capacity estimation algorithms in dual estimation frameworks for lithium-ion batteries under an accelerated aging test. Appl. Energy 2018, 212, 1522–1536. [Google Scholar] [CrossRef]

- Vermeer, W.; Mouli, G.R.C.; Bauer, P. A Comprehensive Review on the Characteristics and Modeling of Lithium-Ion Battery Aging. IEEE Trans. Transp. Electrif. 2021, 8, 2205–2232. [Google Scholar] [CrossRef]

- Chen, J.; Han, X.; Sun, T.; Zheng, Y. Analysis and prediction of battery aging modes based on transfer learning. Appl. Energy 2023, 356, 122330. [Google Scholar] [CrossRef]

- Madhavan, P.V.; Moradizadeh, L.; Shahgaldi, S.; Li, X. Data-driven modelling of corrosion behaviour in coated porous transport layers for PEM water electrolyzers. Artif. Intell. Chem. 2025, 3, 100086. [Google Scholar] [CrossRef]

- Lucaferri, V.; Quercio, M.; Laudani, A.; Riganti Fulginei, F. A review on battery model-based and data-driven methods for battery management systems. Energies 2023, 16, 7807. [Google Scholar] [CrossRef]

- El-Sayed, E.I.; ElSayed, S.K.; Alsharef, M. Data-Driven Approaches for State-of-Charge Estimation in Battery Electric Vehicles Using Machine and Deep Learning Techniques. Sustainability 2024, 16, 9301. [Google Scholar] [CrossRef]

- How, D.N.T.; Hannan, M.A.; Hossain Lipu, M.S.; Ker, P.J. State of charge estimation for lithium-ion batteries using model-based and data-driven methods: A review. IEEE Access 2019, 7, 136116–136136. [Google Scholar]

- Li, Y.; Chattopadhyay, P.; Xiong, S.; Ray, A.; Rahn, C.D. Dynamic data-driven and model-based recursive analysis for estimation of battery state-of-charge. Appl. Energy 2016, 184, 266–275. [Google Scholar]

- Lin, J.; Zhang, Y.; Khoo, E. Hybrid physics-based and data-driven modeling with calibrated uncertainty for lithium-ion battery degradation diagnosis and prognosis. arXiv 2021, arXiv:2110.13661. Available online: https://arxiv.org/abs/2110.13661 (accessed on 6 March 2025).

- Wang, J.; Liu, P.; Hicks-Garner, J.; Sherman, E.; Soukiazian, S.; Verbrugge, M.; Tataria, H.; Musser, J.; Fina-more, P. Cycle-life model for graphite-LiFePO4 cells. J. Power Sources 2011, 196, 3942–3948. [Google Scholar] [CrossRef]

- Wu, Z.; Cao, L.; Hartig, J.; Santhanagopalan, S. (Invited) Effect of Aging on Mechanical Properties of Lithium Ion Cell Components. ECS Trans. 2017, 77, 199–208. [Google Scholar] [CrossRef]

- Nagda, V.; Ekström, H.; Kulachenko, A. Impact of Mechanical Degradation in Polycrystalline NMC Particle on the Electrochemical Performance of Lithium-Ion Batteries. J. Electrochem. Soc. 2024, 171, 060526. [Google Scholar] [CrossRef]

- Sharma, N.; Meng, D.; Wu, X.; de Vasconcelos, L.S.; Li, L.; Zhao, K. Nanoindentation measurements of anisotropic mechanical properties of single crystalline NMC cathodes for Li-ion batteries. Extreme Mech. Lett. 2023, 58, 101920. [Google Scholar] [CrossRef]

- Müller, V.; Scurtu, R.-G.; Memm, M.; Danzer, M.A.; Wohlfahrt-Mehrens, M. Study of the influence of mechanical pressure on the performance and aging of Lithium-ion battery cells. J. Power Sources 2019, 440, 227148. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Hendricks, C.; Williard, N.; Mathew, S.; Pecht, M. A failure modes, mechanisms, and effects analysis (FMMEA) of lithium-ion batteries. J. Power Sources 2015, 297, 113–120. [Google Scholar] [CrossRef]

- Liu, K.; Ashwin, T.R.; Hu, X.; Lucu, M.; Widanage, W.D. An evaluation study of different modelling techniques for calendar ageing prediction of lithium-ion batteries. Renew. Sustain. Energy Rev. 2020, 131, 110017. [Google Scholar] [CrossRef]

- McBrayer, J.D.; Rodrigues, M.-T.F.; Schulze, M.C.; Abraham, D.P.; Apblett, C.A.; Bloom, I.; Carroll, G.M.; Col-clasure, A.M.; Fang, C.; Harrison, K.L.; et al. Calendar aging of silicon-containing batteries. Nat. Energy 2021, 6, 866–872. [Google Scholar] [CrossRef]

- Zilberman, I.; Ludwig, S.; Jossen, A. Cell-to-cell variation of calendar aging and reversible self-discharge in 18650 nickel-rich, silicon–graphite lithium-ion cells. J. Energy Storage 2019, 26, 100900. [Google Scholar] [CrossRef]

- Maures, M.; Zhang, Y.; Martin, C.; Delétage, J.-Y.; Vinassa, J.-M.; Briat, O. Impact of temperature on calendar ageing of Lithium-ion battery using incremental capacity analysis. Microelectron. Reliab. 2019, 100–101, 113364. [Google Scholar] [CrossRef]

- Xie, S.; Ren, L.; Yang, X.; Wang, H.; Sun, Q.; Chen, X.; He, Y. Influence of cycling aging and ambient pressure on the thermal safety features of lithium-ion battery. J. Power Sources 2020, 448, 227425. [Google Scholar] [CrossRef]

- Redondo-Iglesias, E.; Venet, P.; Pelissier, S. Modelling Lithium-Ion Battery Ageing in Electric Vehicle Applications—Calendar and Cycling Ageing Combination Effects. Batteries 2020, 6, 14. [Google Scholar] [CrossRef]

- Souid, Y.; Herlin-Boime, N.; Franger, S.; Le Caër, S. Radiation Chemistry as a Tool to Accelerate and Predict Calendar Ageing in Lithium-Ion Batteries. J. Electrochem. Soc. 2024, 171, 090527. [Google Scholar] [CrossRef]

- Plattard, T.; Barnel, N.; Assaud, L.; Franger, S.; Duffault, J.-M. Combining a Fatigue Model and an Incremental Capacity Analysis on a Commercial NMC/Graphite Cell under Constant Current Cycling with and without Calendar Aging. Batteries 2019, 5, 36. [Google Scholar] [CrossRef]

- Pender, J.P.; Jha, G.; Youn, D.H.; Ziegler, J.M.; Andoni, I.; Choi, E.J.; Heller, A.; Dunn, B.S.; Weiss, P.S.; Penner, R.M.; et al. Electrode Degradation in Lithium-Ion Batteries. ACS Nano 2020, 14, 1243–1295. [Google Scholar] [CrossRef]

- Haregewoin, A.M.; Wotango, A.S.; Hwang, B.-J. Electrolyte additives for lithium ion battery electrodes: Progress and perspectives. Energy Environ. Sci. 2016, 9, 1955–1988. [Google Scholar] [CrossRef]

- Han, J.G.; Hwang, C.; Kim, S.H.; Park, C.; Kim, J.; Jung, G.Y.; Baek, K.; Chae, S.; Kang, S.J.; Cho, J.; et al. An Antiaging Electrolyte Additive for High-Energy-Density Lithium-Ion Batteries. Adv. Energy Mater. 2020, 10, 202000563. [Google Scholar] [CrossRef]

- Steinstraeter, M.; Gandlgruber, J.; Everken, J.; Lienkamp, M. Influence of pulse width modulated auxiliary consumers on battery aging in electric vehicles. J. Energy Storage 2022, 48, 104009. [Google Scholar] [CrossRef]

- Amanor-Boadu, J.M.; Guiseppi-Elie, A.; Sánchez-Sinencio, E. The Impact of Pulse Charging Parameters on the Life Cycle of Lithium-Ion Polymer Batteries. Energies 2018, 11, 2162. [Google Scholar] [CrossRef]

- Xu, C.; Renault, S.; Ebadi, M.; Wang, Z.; Björklund, E.; Guyomard, D.; Brandell, D.; Edström, K.; Gustafsson, T. LiTDI: A Highly Efficient Additive for Electrolyte Stabilization in Lithium-Ion Batteries. Chem. Mater. 2017, 29, 2254–2263. [Google Scholar] [CrossRef]

- Lv, H.; Huang, X.; Liu, Y. Analysis on pulse charging–discharging strategies for improving capacity retention rates of lithium-ion batteries. Ionics 2020, 26, 1749–1770. [Google Scholar] [CrossRef]

- Qian, Y.; Hu, S.; Zou, X.; Deng, Z.; Xu, Y.; Cao, Z.; Kang, Y.; Deng, Y.; Shi, Q.; Xu, K.; et al. How electrolyte additives work in Li-ion batteries. Energy Storage Mater. 2019, 20, 208–215. [Google Scholar] [CrossRef]

- Spitthoff, L.; Shearing, P.R.; Burheim, O.S. Temperature, Ageing and Thermal Management of Lithium-Ion Batteries. Energies 2021, 14, 1248. [Google Scholar] [CrossRef]

- Xiong, R.; Pan, Y.; Shen, W.; Li, H.; Sun, F. Lithium-ion battery aging mechanisms and diagnosis method for automotive applications: Recent advances and perspectives. Renew. Sustain. Energy Rev. 2020, 131, 110048. [Google Scholar] [CrossRef]

- Barcellona, S.; Piegari, L. Effect of current on cycle aging of lithium ion batteries. J. Energy Storage 2020, 29, 101310. [Google Scholar] [CrossRef]

- Braco, E.; Martín, I.S.; Berrueta, A.; Sanchis, P.; Ursúa, A. Experimental assessment of cycling ageing of lithium-ion second-life batteries from electric vehicles. J. Energy Storage 2020, 32, 101695. [Google Scholar] [CrossRef]

- Kashkooli, A.G.; Fathiannasab, H.; Mao, Z.; Chen, Z. Application of Artificial Intelligence to State-of-Charge and State-of-Health Estimation of Calendar-Aged Lithium-Ion Pouch Cells. J. Electrochem. Soc. 2019, 166, A605–A615. [Google Scholar] [CrossRef]

- Ouyang, D.; Weng, J.; Chen, M.; Wang, J.; Wang, Z. Electrochemical and thermal characteristics of aging lithium-ion cells after long-term cycling at abusive-temperature environments. Process. Saf. Environ. Prot. 2022, 159, 1215–1223. [Google Scholar] [CrossRef]

- Azam, S.; Aiken, C.P.; Meisner, Q.; MacLennan, H.; Song, W.; Liu, Q.; Yoo, D.-J.; Aftanas, S.; Oxner, J.M.; Liao, C.; et al. Impact of Electrolyte Additives on the Lifetime of High Voltage NMC Lithium-Ion Pouch Cells. J. Electrochem. Soc. 2024, 171, 110510. [Google Scholar] [CrossRef]

- Abarbanel, D.W.; Nelson, K.J.; Dahn, J.R. Exploring Impedance Growth in High Voltage NMC/Graphite Li-Ion Cells Using a Transmission Line Model. J. Electrochem. Soc. 2015, 163, A522–A529. [Google Scholar] [CrossRef]

- Ma, L.; Xia, J.; Dahn, J.R. Improving the High Voltage Cycling of Li[Ni0.42Mn0.42Co0.16]O2(NMC442)/Graphite Pouch Cells Using Electrolyte Additives. J. Electrochem. Soc. 2014, 161, A2250–A2254. [Google Scholar] [CrossRef]

- Ecker, M.; Gerschler, J.B.; Vogel, J.; Käbitz, S.; Hust, F.; Dechent, P.; Sauer, D.U. Development of a lifetime prediction model for lithium-ion batteries based on extended accelerated aging test data. J. Power Sources 2012, 215, 248–257. [Google Scholar] [CrossRef]

- Gu, W.; Sun, Z.; Wei, X.; Dai, H. A new method of accelerated life testing based on the Grey System Theory for a model-based lithium-ion battery life evaluation system. J. Power Sources 2014, 267, 366–379. [Google Scholar] [CrossRef]

- Schmalstieg, J.; Kabitz, S.; Ecker, M.; Sauer, D.U. From accelerated aging tests to a lifetime prediction model: Analyzing lithium-ion batteries. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1–12. [Google Scholar] [CrossRef]

- Stroe, D.-I.; Swierczynski, M.; Stan, A.-I.; Teodorescu, R.; Andreasen, S.J. Accelerated Lifetime Testing Methodology for Lifetime Estimation of Lithium-Ion Batteries Used in Augmented Wind Power Plants. IEEE Trans. Ind. Appl. 2014, 50, 4006–4017. [Google Scholar] [CrossRef]

- Jungst, R.G.; Nagasubramanian, G.; Case, H.L.; Liaw, B.Y.; Urbina, A.; Paez, T.L.; Doughty, D.H. Accelerated calendar and pulse life analysis of lithium-ion cells. J. Power Sources 2003, 119–121, 870–873. [Google Scholar] [CrossRef]

- Stroe, D.-I.; Swierczynski, M.; Kaer, S.K.; Laserna, E.M.; Zabala, E.S. Accelerated aging of Lithium-ion batteries based on electric vehicle mission profile. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 5631–5637. [Google Scholar] [CrossRef]

- Takei, K.; Kumai, K.; Kobayashi, Y.; Miyashiro, H.; Terada, N.; Iwahori, T.; Tanaka, T. Cycle life estimation of lithium secondary battery by extrapolation method and accelerated aging test. J. Power Sources 2001, 97–98, 697–701. [Google Scholar] [CrossRef]

- Saxena, S.; Hendricks, C.; Pecht, M. Cycle life testing and modeling of graphite/LiCoO2 cells under different state of charge ranges. J. Power Sources 2016, 327, 394–400. [Google Scholar] [CrossRef]

- Amatucci, G.; Tarascon, J.; Klein, L. Cobalt dissolution in LiCoO2-based non-aqueous rechargeable batteries. Solid State Ionics 1996, 83, 167–173. [Google Scholar] [CrossRef]

- Waldmann, T.; Wilka, M.; Kasper, M.; Fleischhammer, M.; Wohlfahrt-Mehrens, M. Temperature dependent ageing mechanisms in Lithium-ion batteries—A Post-Mortem study. J. Power Sources 2014, 262, 129–135. [Google Scholar] [CrossRef]

- Diao, W.; Xing, Y.; Saxena, S.; Pecht, M. Evaluation of present accelerated temperature testing and modeling of batteries. Appl. Sci. 2018, 8, 1786. [Google Scholar] [CrossRef]

- Saxena, S.; Xing, Y.; Kwon, D.; Pecht, M. Accelerated degradation model for C-rate loading of lithium-ion batteries. Int. J. Electr. Power Energy Syst. 2018, 107, 438–445. [Google Scholar] [CrossRef]

- Leng, F.; Tan, C.M.; Pecht, M. Effect of Temperature on the Aging rate of Li Ion Battery Operating above Room Temperature. Sci. Rep. 2015, 5, 12967. [Google Scholar] [CrossRef]

- Wang, Z.; Deng, R.; Wang, Y.; Pan, F. Comparison of Construction Strategies of Solid Electrolyte Interface (SEI) in Li Battery and Mg Battery—A Review. Molecules 2024, 29, 4761. [Google Scholar] [CrossRef] [PubMed]

- Pinson, M.B.; Bazant, M.Z. Theory of SEI Formation in Rechargeable Batteries: Capacity Fade, Accelerated Aging and Lifetime Prediction. J. Electrochem. Soc. 2012, 160, A243–A250. [Google Scholar] [CrossRef]

- Lee, H.; Sitapure, N.; Hwang, S.; Kwon, J.S.-I. Multiscale modeling of dendrite formation in lithium-ion batteries. Comput. Chem. Eng. 2021, 153, 107415. [Google Scholar] [CrossRef]

- Madani, S.S.; Schaltz, E.; Kær, S.K. Simulation of Thermal Behaviour of a Lithium Titanate Oxide Battery. Energies 2019, 12, 679. [Google Scholar] [CrossRef]

- Pham, T.H.; Jacob, J.; Wilkins, S.; Lauwerys, C.; Dhaens, M. Integrated model for battery Electric Vehicles with energy harvesting active suspension system. In Proceedings of the 2017 Twelfth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 11–13 April 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Madani, S.S.; Schaltz, E.; Kær, S.K.; Ziebert, C. A comprehensive heat generation study of lithium titanate oxide-based lithium-ion batteries. J. Phys. Conf. Ser. 2022, 2382, 012004. [Google Scholar] [CrossRef]

- Madani, S.S.; Ziebert, C.; Marzband, M. Thermal Behavior Modeling of Lithium-Ion Batteries: A Comprehensive Review. Symmetry 2023, 15, 1597. [Google Scholar] [CrossRef]

- Madani, S.S.; Schaltz, E.; Kær, S.K. Thermal Modelling of a Lithium Titanate Oxide Battery. ECS Trans. 2018, 87, 315–326. [Google Scholar] [CrossRef]

- Samancıoğlu, U.E.; Göçmen, S.; Madani, S.S.; Ziebert, C.; Nuno, F.; Huang, J.; Gao, F.; Çetkin, E. An experimental and comparative study on passive and active PCM cooling of a battery with/out copper mesh and investigation of PCM mixtures. J. Energy Storage 2024, 103, 114262. [Google Scholar] [CrossRef]

- Madani, S.S.; Schaltz, E.; Kær, S.K. Characterization of the Compressive Load on a Lithium-Ion Battery for Electric Vehicle Application. Machines 2021, 9, 71. [Google Scholar] [CrossRef]

- Jia, Y.; Zhao, P.; Finegan, D.P.; Xu, J. Dynamics of Intra-Cell Thermal Front Propagation in Lithium-Ion Battery Safety Issues. Adv. Energy Mater. 2024, 14, 2400621. [Google Scholar] [CrossRef]

- Jia, Y.; Gao, X.; Ma, L.; Xu, J. Comprehensive Battery Safety Risk Evaluation: Aged Cells versus Fresh Cells Upon Mechanical Abusive Loadings. Adv. Energy Mater. 2023, 13, 2300368. [Google Scholar] [CrossRef]

- Chak, C.M.; Jayakumar, R.; Shipitsyn, V.; Bass, E.; McCloskey, R.; Zuo, W.; Le, P.M.L.; Xu, J.; Ma, L. Unveiling the Thermal Stability of Sodium Ion Pouch Cells Using Accelerating Rate Calorimetry. J. Electrochem. Soc. 2024, 171, 070512. [Google Scholar] [CrossRef]

- Klein, S.; Harte, P.; Wickeren, S.; Borzutzki, K.; Röser, S.; Bärmann, P.; Nowak, S.; Winter, M.; Placke, T.; Kasnatscheew, J. Re-evaluating common electrolyte additives for high-voltage lithium ion batteries. Cell Rep. Phys. Sci. 2021, 2, 100521. [Google Scholar]

- Yue, M.; Aiken, C.; Deshmukh, J.; Garayt, M.D.L.; Johnson, M.; Dahn, J.R.; Yang, C. Improved Elevated Temperature Performance of LiFePO4/Graphite Cell by Blending NMC640 in Cathode. J. Electrochem. Soc. 2023, 170, 110532. [Google Scholar] [CrossRef]

- Galushkin, N.E.; Yazvinskaya, N.N.; Galushkin, D.N. Mechanism of Thermal Runaway in Lithium-Ion Cells. J. Electrochem. Soc. 2018, 165, A1303–A1308. [Google Scholar] [CrossRef]

- Safari, M.; Delacourt, C. Mathematical Modeling of Lithium Iron Phosphate Electrode: Galvanostatic Charge/Discharge and Path Dependence. J. Electrochem. Soc. 2011, 158, A63–A73. [Google Scholar] [CrossRef]

- Wang, Y.; Xiang, H.; Soo, Y.-Y.; Fan, X. Aging mechanisms, prognostics and management for lithium-ion batteries: Recent advances. Renew. Sustain. Energy Rev. 2024, 207, 114915. [Google Scholar] [CrossRef]

- Appleton, S.; Fotouhi, A. A Model-Based Battery Charging Optimization Framework for Proper Trade-offs Between Time and Degradation. Automot. Innov. 2023, 6, 204–219. [Google Scholar] [CrossRef]

- Tapaskar, R.P.; Revankar, P.P.; Ganachari, S.V. Advancements in Battery Management Systems for Electric Vehicles: A MATLAB-Based Simulation of 4S3P Lithium-Ion Battery Packs. World Electr. Veh. J. 2024, 15, 222. [Google Scholar] [CrossRef]

- Liaw, B.Y.; Jungst, R.G.; Urbina, A.; Paez, T.L. Modeling of Battery Life I. The Equivalent Circuit Model (ECM) Approach; Sandia National Laboratories: Albuquerque, NM, USA, 2004.

- Krupp, A.; Beckmann, R.; Diekmann, T.; Ferg, E.; Schuldt, F.; Agert, C. Calendar aging model for lithium-ion batteries considering the influence of cell characterization. J. Energy Storage 2021, 45, 103506. [Google Scholar] [CrossRef]

- Santhanagopalan, S.; Guo, Q.; Ramadass, P.; White, R.E. Review of models for predicting the cycling performance of lithium ion batteries. J. Power Sources 2006, 156, 620–628. [Google Scholar] [CrossRef]

- Xu, J.; Sun, C.; Ni, Y.; Lyu, C.; Wu, C.; Zhang, H.; Yang, Q.; Feng, F. Fast Identification of Micro-Health Parameters for Retired Batteries Based on a Simplified P2D Model by Using Padé Approximation. Batteries 2023, 9, 64. [Google Scholar] [CrossRef]

- Rechkemmer, S.K.; Zang, X.; Zhang, W.; Sawodny, O. Empirical Li-ion aging model derived from single particle model. J. Energy Storage 2019, 21, 773–786. [Google Scholar] [CrossRef]

- Zhang, D.; Dey, S.; Perez, H.E.; Moura, S.J. Real-Time Capacity Estimation of Lithium-Ion Batteries Utilizing Thermal Dynamics. IEEE Trans. Control. Syst. Technol. 2019, 28, 992–1000. [Google Scholar] [CrossRef]

- Allam, A.; Onori, S. Online Capacity Estimation for Lithium-Ion Battery Cells via an Electrochemical Model-Based Adaptive Interconnected Observer. IEEE Trans. Control. Syst. Technol. 2020, 29, 1636–1651. [Google Scholar] [CrossRef]

- Bartlett, A.; Marcicki, J.; Onori, S.; Rizzoni, G.; Yang, X.G.; Miller, T. Electrochemical Model-Based State of Charge and Capacity Estimation for a Composite Electrode Lithium-Ion Battery. IEEE Trans. Control. Syst. Technol. 2015, 24, 384–399. [Google Scholar] [CrossRef]

- Chang, C.; Chen, L.; Liu, X.; Jiang, J.; Jiang, Y.; Tian, A.; Gao, Y.; Wu, T. Electrochemical aging model of lithium-ion battery with impedance output and its parameter sensitivity analysis and identification. J. Energy Storage 2024, 86, 111277. [Google Scholar] [CrossRef]

- Iurilli, P.; Brivio, C.; Wood, V. On the use of electrochemical impedance spectroscopy to characterize and model the aging phenomena of lithium-ion batteries: A critical review. J. Power Sources 2021, 505, 229860. [Google Scholar] [CrossRef]

- Zhang, S. Chemomechanical modeling of lithiation-induced failure in high-volume-change electrode materials for lithium ion batteries. Npj Comput. Mater. 2017, 3, 7. [Google Scholar] [CrossRef]

- Garrick, T.R.; Fernandez, M.A.; Koch, B.J.; Efimoff, E.; Jones, M.; Mollah, R.; Teel, H.; Du, X.; Shimpalee, S.; Choe, S.-Y.; et al. Modeling Rate Dependent Volume Change in Porous Electrodes in Lithium-Ion Batteries. J. Electrochem. Soc. 2024, 171, 073507. [Google Scholar] [CrossRef]

- Garrick, T.R.; Koch, B.J.; Fernandez, M.A.; Efimoff, E.; Teel, H.; Jones, M.D.; Tu, M.; Shimpalee, S. Modeling Reversible Volume Change in Automotive Battery Cells with Porous Silicon Oxide-Graphite Composite Anodes. J. Electrochem. Soc. 2024, 171, 103509. [Google Scholar] [CrossRef]

- Silva, D.; Zaghib, K.; Song, S.-W.; Ali, M.A.; Da Silva, C.M.; Amon, C.H. Multiscale Modelling Methodologies of Lithium-Ion Battery Aging: A Review of Most Recent Developments. Batteries 2023, 9, 434. [Google Scholar] [CrossRef]

- Zhang, S.S. A review on the separators of liquid electrolyte Li-ion batteries. J. Power Sources 2007, 164, 351–364. [Google Scholar] [CrossRef]

- Crawford, A.J.; Huang, Q.; Kintner-Meyer, M.C.W.; Zhang, J.-G.; Reed, D.M.; Sprenkle, V.L.; Viswanathan, V.V.; Choi, D. Lifecycle comparison of selected Li-ion battery chemistries under grid and electric vehicle duty cycle combinations. J. Power Sources 2018, 380, 185–193. [Google Scholar] [CrossRef]

- Elmahallawy, M.; Elfouly, T.; Alouani, A.; Massoud, A.M. A Comprehensive Review of Lithium-Ion Batteries Modeling, and State of Health and Remaining Useful Lifetime Prediction. IEEE Access 2022, 10, 119040–119070. [Google Scholar] [CrossRef]

- Feng, F.; Lu, R.; Zhu, C. A Combined State of Charge Estimation Method for Lithium-Ion Batteries Used in a Wide Ambient Temperature Range. Energies 2014, 7, 3004–3032. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J. A review on prognostics and health monitoring of Li-ion battery. J. Power Sources 2011, 196, 6007–6014. [Google Scholar] [CrossRef]

- Chen, X.; Yang, Y.; Sun, J.; Deng, Y.; Yuan, Y. A novel time series forecasting model for capacity degradation path prediction of lithium-ion battery pack. J. Supercomput. 2024, 80, 10959–10984. [Google Scholar] [CrossRef]

- Huang, X. Separator technologies for lithium-ion batteries. J Solid State Electrochem. 2011, 15, 649–662. [Google Scholar] [CrossRef]

- Sun, S.-Y.; Zhang, X.-Q.; Wang, Y.-N.; Li, J.-L.; Zheng, Z.; Huang, J.-Q. Understanding the transport mechanism of lithium ions in solid-electrolyte interphase in lithium metal batteries with liquid electrolytes. Mater. Today 2024, 77, 39–65. [Google Scholar] [CrossRef]

- Jeon, I.; Hong, W.G.; Yoon, S.; Choi, Y.; Kim, H.J.; Kim, J.-P. Safety, high-performing and effects of the N/P ratio of a solid lithium ion battery using PEGDME based polymer electrolytes. Heliyon 2023, 9, e13292. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wu, W.; Gonzalez-Munoz, S.; Forcieri, L.; Wells, C.; Jarvis, S.P.; Wu, F.; Young, R.; Dey, A.; Isaacs, M.; et al. Nanoarchitecture factors of solid electrolyte interphase formation via 3D nano-rheology microscopy and surface force-distance spectroscopy. Nat. Commun. 2023, 14, 1321. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Z.; Yuan, R.; Zhao, T.; Kuang, Y.; Yin, B.; Liu, C.; Song, L. Advances and applications of computational simulations in the inhibition of lithium dendrite growth. Ionics 2022, 29, 879–893. [Google Scholar] [CrossRef]

- Parekh, M.N.; Rahn, C.D.; Archer, L.A. Controlling dendrite growth in lithium metal batteries through forced advection. J. Power Sources 2020, 452, 227760. [Google Scholar] [CrossRef]

- Gao, Y.; Dahn, J.R.; Huang, C.; Chang, P.; Shie, J. Comparison of modeling predictions with experimental data from plastic lithium ion cells. J. Electrochem. Soc. 1996, 143, 1890. [Google Scholar]

- Tan, X.; Tan, Y.; Zhan, D.; Yu, Z.; Fan, Y.; Qiu, J.; Li, J. Real-Time State-of-Health Estimation of Lithium-Ion Batteries Based on the Equivalent Internal Resistance. IEEE Access 2020, 8, 56811–56822. [Google Scholar] [CrossRef]

- Zhang, J.; Shao, D.; Jiang, L.; Zhang, G.; Wu, H.; Day, R.; Jiang, W. Advanced thermal management system driven by phase change materials for power lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2022, 159, 112207. [Google Scholar] [CrossRef]

- Baptista, P.; Cardoso, F.; Rosado, J.; Caldeira, F. Design of Data Management Service Platform for Intelligent Electric Vehicle Charging Controller Multi-charger Model. In Proceedings of the Energy Informatics. Academy Conference 2022, Vejle, Denmark, 24–25 August 2022; Available online: https://repositorio.ipsantarem.pt/bitstream/10400.15/4696/1/s42162-022-00219-2.pdf (accessed on 6 March 2025).

- Alghalayini, M.B.; Collins-Wildman, D.; Higa, K.; Guevara, A.; Battaglia, V.; Noack, M.M.; Harris, S.J. Machine-Learning-Based Efficient Parameter Space Exploration for Energy Storage Systems. Available online: https://papers.ssrn.com/abstract=4930405 (accessed on 6 March 2025).

- Li, J.; Peng, Y.; Wang, Q.; Liu, H. Status and Prospects of Research on Lithium-Ion Battery Parameter Identification. Batteries 2024, 10, 194. [Google Scholar] [CrossRef]

- Tian, Y.; Bera, A.; Mitra, J.; Chalamala, B.; Byrne, R.H. Effect of Operating Strategies on the Longevity of Lithium-ion Battery Energy Storage Systems. In Proceedings of the 2018 IEEE Industry Applications Society Annual Meeting (IAS), Portland, OR, USA, 23–27 September 2018; pp. 1–8. [Google Scholar]

- Karunarathna, J.S.; Madawala, U.K.; Sandelic, M.; Blaabjerg, F.; Baguley, C. The Impact of Operational and Environmental Conditions on Battery Lifetime in Fast Electric Vehicle Charging Systems. IEEE Trans. Power Electron. 2023, 39, 4645–4656. [Google Scholar] [CrossRef]

- Yarimca, G.; Cetkin, E. Review of Cell Level Battery (Calendar and Cycling) Aging Models: Electric Vehicles. Batteries 2024, 10, 374. [Google Scholar] [CrossRef]

- Nekahi, A.; Anil Kumar, M.R.; Li, X.; Deng, S.; Zaghib, K. Sustainable LiFePO4 and LiMnxFe1-xPO4 (x = 0.1 − 1) cathode materials for lithium-ion batteries: A systematic review from mine to chassis. Mater. Sci. Eng. R Rep. 2024, 159, 100797. [Google Scholar] [CrossRef]

- Cardoso, J.M.; Laadjal, K.; Akbar, K.; Zou, Y.; Awais, Q.; Jabbar, M.; Baig, A.; Jamil, M. A Machine Learning-Based Robust State of Health (SOH) Prediction Model for Electric Vehicle Batteries. Electronics 2022, 11, 1216. [Google Scholar] [CrossRef]

- You, G.-W.; Park, S.; Oh, D. Real-time state-of-health estimation for electric vehicle batteries: A data-driven approach. Appl. Energy 2016, 176, 92–103. [Google Scholar] [CrossRef]

- Murnane, M.; Ghazel, A. A closer look at state of charge (SOC) and state of health (SOH) estimation techniques for batteries. Analog. Devices 2017, 2, 426–436. Available online: https://www.pvpower.co.za/wp-content/uploads/2023/01/BMS-SoC-and-SoH-Estimation.pdf (accessed on 6 March 2025).

- Vignesh, S.; Che, H.S.; Selvaraj, J.; Tey, K.S.; Lee, J.W.; Shareef, H.; Errouissi, R. State of Health (SoH) estimation methods for second life lithium-ion battery—Review and challenges. Appl. Energy 2024, 369, 123542. [Google Scholar]

- Demirci, O.; Taskin, S.; Schaltz, E.; Demirci, B.A. Review of battery state estimation methods for electric vehicles-Part I: SOC estimation. J. Energy Storage 2024, 87, 111435. [Google Scholar]

- Zhou, W.; Zheng, Y.; Pan, Z.; Lu, Q. Review on the Battery Model and SOC Estimation Method. Processes 2021, 9, 1685. [Google Scholar] [CrossRef]

- Espedal, I.B.; Jinasena, A.; Burheim, O.S.; Lamb, J.J. Current Trends for State-of-Charge (SoC) Estimation in Lithium-Ion Battery Electric Vehicles. Energies 2021, 14, 3284. [Google Scholar] [CrossRef]

- Rivera-Barrera, J.P.; Muñoz-Galeano, N.; Sarmiento-Maldonado, H.O. SoC Estimation for Lithium-ion Batteries: Review and Future Challenges. Electronics 2017, 6, 102. [Google Scholar] [CrossRef]

- Qu, X.; Shi, D.; Zhao, J.; Tran, M.; Wang, Z. Insights and reviews on battery lifetime prediction from research to practice. J. Energy Chem. 2024, 94, 716–739. [Google Scholar]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Etransportation, Y.G. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: A lifespan perspective. eTransportation 2022, 12, 100169. [Google Scholar]

- Petit, M.; Prada, E.; Sauvant-Moynot, V. Development of an empirical aging model for Li-ion batteries and application to assess the impact of Vehicle-to-Grid strategies on battery lifetime. Appl. Energy 2016, 172, 398–407. [Google Scholar]

- Saxena, S.; Le Floch, C.; MacDonald, J.; Moura, S. Quantifying EV battery end-of-life through analysis of travel needs with vehicle powertrain models. J. Power Sources 2015, 282, 265–276. [Google Scholar]

- Wang, Z.; Huang, Z.; Wu, Y.; Liu, W.; Li, H.; Peng, J. An Optimized Prediction Horizon Energy Management Method for Hybrid Energy Storage Systems of Electric Vehicles. IEEE Trans. Intell. Transp. Syst. 2023, 25, 4540–4551. [Google Scholar]

- Gomez, W.; Wang, F.-K.; Chou, J.-H. Li-ion battery capacity prediction using improved temporal fusion transformer model. Energy 2024, 296, 131114. [Google Scholar]

- Li, J.; Deng, Z.; Che, Y.; Xie, Y.; Hu, X.; Teodorescu, R. Degradation Pattern Recognition and Features Extrapolation for Battery Capacity Trajectory Prediction. IEEE Trans. Transp. Electrif. 2024, 10, 7565–7579. [Google Scholar] [CrossRef]

- Perera, M.; De Hoog, J.; Bandara, K.; Halgamuge, S. Multi-resolution, multi-horizon distributed solar PV power forecasting with forecast combinations. Expert Syst. Appl. 2022, 205, 117690. [Google Scholar]

- Zhang, Z.; Ji, C.; Liu, Y.; Wang, Y.; Wang, B.; Liu, D. Effect of Aging Path on Degradation Characteristics of Lithium-Ion Batteries in Low-Temperature Environments. Batteries 2024, 10, 107. [Google Scholar] [CrossRef]

- Ramadass, P.; Haran, B.; White, R.; Popov, B.N. Capacity fade of Sony 18,650 cells cycled at elevated temperatures. J. Power Sources 2002, 112, 606–613. [Google Scholar] [CrossRef]

- Zhang, R.; Li, X.; Sun, C.; Yang, S.; Tian, Y. State of Charge and Temperature Joint Estimation Based on Ultrasonic Reflection Waves for Lithium-Ion Battery Applications. Batteries 2023, 9, 335. [Google Scholar] [CrossRef]

- Yao, L.; Xu, S.; Tang, A.; Zhou, F.; Hou, J.; Xiao, Y.; Fu, Z. A Review of Lithium-Ion Battery State of Health Estimation and Prediction Methods. World Electr. Veh. J. 2021, 12, 113. [Google Scholar] [CrossRef]

- Sun, H.-H.; Choi, W.; Lee, J.K.; Oh, I.-H.; Jung, H.-G. Control of electrochemical properties of nickel-rich layered cathode materials for lithium ion batteries by variation of the manganese to cobalt ratio. J. Power Sources 2015, 275, 877–883. [Google Scholar] [CrossRef]

- Ouyang, M.; Ren, D.; Lu, L.; Li, J.; Feng, X.; Han, X.; Liu, G. Overcharge-induced capacity fading analysis for large format lithium-ion batteries with LiyNi1/3Co1/3Mn1/3O2 + LiyMn2O4 composite cathode. J. Power Sources 2015, 279, 626–635. [Google Scholar] [CrossRef]

- Choi, W.; Shin, H.-C.; Kim, J.M.; Choi, J.-Y.; Yoon, W.-S. Modeling and Applications of Electrochemical Impedance Spectroscopy (EIS) for Lithium-ion Batteries. J. Electrochem. Sci. Technol. 2020, 11, 1–13. [Google Scholar] [CrossRef]

- Arora, P.; White, R.E.; Doyle, M. Capacity Fade Mechanisms and Side Reactions in Lithium-Ion Batteries. J. Electrochem. Soc. 1998, 145, 3647–3667. [Google Scholar] [CrossRef]

- Zeng, Y.; Huang, Y.; Liu, N.; Wang, X.; Zhang, Y.; Guo, Y.; Wu, H.-H.; Chen, H.; Tang, X.; Zhang, Q. N-doped porous carbon nanofibers sheathed pumpkin-like Si/C composites as free-standing anodes for lithium-ion batteries. J. Energy Chem. 2021, 54, 727–735. [Google Scholar] [CrossRef]

- Yang, F.; Wang, D.; Zhao, Y.; Tsui, K.-L.; Bae, S.J. A study of the relationship between coulombic efficiency and capacity degradation of commercial lithium-ion batteries. Energy 2018, 145, 486–495. [Google Scholar] [CrossRef]

- Collath, N.; Tepe, B.; Englberger, S.; Jossen, A.; Hesse, H. Increasing the lifetime profitability of battery energy storage systems through aging aware operation. J. Energy Storage 2023, 348, 121531. [Google Scholar] [CrossRef]

- Scarfogliero, M.; Carmeli, S.; Castelli-Dezza, F.; Mauri, M.; Rossi, M.; Marchegiani, G. Lithium-ion batteries for electric vehicles: A review on aging models for vehicle-to-grid services. In Proceedings of the International Conference of Electrical and Electronic Technologies for Automotive, Milan, Italy, 9–11 July 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Schoch, J. Modeling of battery life optimal charging strategies based on empirical mobility data. IT-Inf. Technol. 2016, 58, 22–28. [Google Scholar] [CrossRef]

- Ding, S.; Li, Y.; Dai, H.; Wang, L.; He, X. Accurate Model Parameter Identification to Boost Precise Aging Prediction of Lithium-Ion Batteries: A Review. Adv. Energy Mater. 2023, 13, 2301452. [Google Scholar]

- Cheng, H.; Shapter, J.G.; Li, Y.; Gao, G. Recent progress of advanced anode materials of lithium-ion batteries. J. Energy Chem. 2021, 57, 451–468. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, Z.; Wang, Y.; Wang, H.; Wang, C.; Tong, L.; Yi, M. Overcharge Investigation of Large Format Lithium-Ion Pouch Cells with Li(Ni0.6Co0.2Mn0.2)O2 Cathode for Electric Vehicles: Degradation and Failure Mechanisms. J. Electrochem. Soc. 2018, 165, A3613–A3629. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, Z.; Wang, Y.; Wang, H.; Wang, C.; Tong, L.; Yi, M. Overcharge Investigation of Large Format Lithium-Ion Pouch Cells with Li(Ni0.6Co0.2Mn0.2)O2 Cathode for Electric Vehicles: Thermal Runaway Features and Safety Management Method. Energy 2019, 169, 868–880. [Google Scholar] [CrossRef]

- Li, A.G.; West, A.C.; Preindl, M. Towards unified machine learning characterization of lithium-ion battery degradation across multiple levels: A critical review. Appl. Energy 2022, 316, 119030. [Google Scholar]

- Anekal, L. In-Depth Study and Analysis of Lithium-Ion Battery States Using Battery Degradation Data from Electrochemical Impedance Spectroscopy. Doctoral Dissertation, University of Ontario Institute of Technology, Oshawa, ON, Canada, 2024. [Google Scholar]

- Kraytsberg, A.; Ein-Eli, Y. Degradation Processes in Current Commercialized Li-Ion Batteries and Strategies to Mitigate Them. Annu. Rev. Mater. Res. 2025, 16, 57. [Google Scholar] [CrossRef]

- Jiang, M.; Danilov, D.L.; Eichel, R.-A.; Notten, P.H.L. A Review of Degradation Mechanisms and Recent Achievements for Ni-Rich Cathode-Based Li-Ion Batteries. Adv. Energy Mater. 2021, 11, 2103005. [Google Scholar] [CrossRef]

- Wang, Z.; Song, Y.; Zhao, Q.; Shi, B.; He, J. Unveiling the electrochemical degradation behavior of 18650 lithium-ion batteries involved different humidity conditions. J. Power Sources 2025, 630, 236185. [Google Scholar] [CrossRef]

- Chen, M.; Ouyang, D.; Weng, J.; Liu, J.; Wang, J. Environmental pressure effects on thermal runaway and fire behaviors of lithium-ion battery with different cathodes and state of charge. Process Saf. Environ. Prot. 2019, 130, 250–256. [Google Scholar]

- Stroebl, F.; Petersohn, R.; Schricker, B.; Schaeufl, F.; Bohlen, O.; Palm, H. A multi-stage lithium-ion battery aging dataset using various experimental design methodologies. Sci. Data 2024, 11, 1020. [Google Scholar] [CrossRef]

- Mulpuri, S.K.; Sah, B.; Kumar, P. Unraveling capacity fading in lithium-ion batteries using advanced cyclic tests: A real-world approach. iScience 2023, 26, 107770. [Google Scholar] [PubMed]

- Wu, Y.; Keil, P.; Schuster, S.F.; Jossen, A. Impact of Temperature and Discharge Rate on the Aging of a LiCoO2/LiNi0.8Co0.15Al0.05O2 Lithium-Ion Pouch Cell. J. Electrochem. Soc. 2017, 164, A1438–A1445. [Google Scholar] [CrossRef]

- Luo, G.; Zhang, Y.; Tang, A. Capacity Degradation and Aging Mechanisms Evolution of Lithium-Ion Batteries under Different Operation Conditions. Energies 2023, 16, 4232. [Google Scholar] [CrossRef]

- Torregrosa, A.J.; Broatch, A.; Olmeda, P.; Agizza, L. A semi-empirical model of the calendar ageing of lithium-ion batteries aimed at automotive and deep-space applications. J. Energy Storage 2024, 80, 110388. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, L.; Zhang, Z.; Wang, Z.; Dorrell, D.D. Degradation characteristics investigation for lithium-ion cells with NCA cathode during overcharging. Appl. Energy 2022, 327, 120026. [Google Scholar] [CrossRef]

- Kemeny, M.; Ondrejka, P.; Mikolasek, M. Comprehensive Degradation Analysis of NCA Li-Ion Batteries via Methods of Electrochemical Characterisation for Various Stress-Inducing Scenarios. Batteries 2023, 9, 33. [Google Scholar] [CrossRef]

- Ramadass, P.; Haran, B.; Gomadam, P.M.; White, R.; Popov, B.N. Development of First Principles Capacity Fade Model for Li-Ion Cells. J. Electrochem. Soc. 2004, 151, A196–A203. [Google Scholar] [CrossRef]

- Reniers, J.M.; Mulder, G.; Howey, D.A. Review and Performance Comparison of Mechanical-Chemical Degradation Models for Lithium-Ion Batteries. J. Electrochem. Soc. 2019, 166, A3189–A3200. [Google Scholar] [CrossRef]

- Korotkin, I.; Sahu, S.; O’kane, S.E.J.; Richardson, G.; Foster, J.M. DandeLiion v1: An Extremely Fast Solver for the Newman Model of Lithium-Ion Battery (Dis)charge. J. Electrochem. Soc. 2021, 168, 060544. [Google Scholar] [CrossRef]

- Hu, C.; Hong, M.; Li, Y.; Jeong, H.-L. On-Board Analysis of Degradation Mechanisms of Lithium-Ion Battery Using Differential Voltage Analysis. In Proceedings of the ASME 2016 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016; Volume 2A-2016. [Google Scholar]

- Feng, Y.; Zhou, L.; Ma, H.; Wu, Z.; Zhao, Q.; Li, H.; Zhang, K.; Chen, J. Challenges and advances in wide-temperature rechargeable lithium batteries. Energy Environ. Sci. 2022, 15, 1711–1759. [Google Scholar] [CrossRef]

- Cao, R.; Cheng, H.; Jia, X.; Gao, X.; Zhang, Z.; Wang, M.; Li, S.; Zhang, C.; Ma, B.; Liu, X.; et al. Non-invasive Characteristic Curve Analysis of Lithium-ion Batteries Enabling Degradation Analysis and Data-Driven Model Construction: A Review. Automot. Innov. 2022, 5, 146–163. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Calendar Aging of NCA Lithium-Ion Batteries Investigated by Differential Voltage Analysis and Coulomb Tracking. J. Electrochem. Soc. 2016, 164, A6066–A6074. [Google Scholar] [CrossRef]

- Paulson, N.H.; Kubal, J.; Ward, L.; Saxena, S.; Lu, W.; Babinec, S.J. Feature engineering for machine learning enabled early prediction of battery lifetime. J. Power Sources 2022, 527, 231127. [Google Scholar] [CrossRef]

- Pelletier, S.; Jabali, O.; Laporte, G.; Veneroni, M. Battery degradation and behaviour for electric vehicles: Review and numerical analyses of several models. Transp. Res. Part B Methodol. 2017, 103, 158–187. [Google Scholar] [CrossRef]

- Goodenough, J.B.; Park, K.-S. The Li-Ion Rechargeable Battery: A Perspective. J. Am. Chem. Soc. 2013, 135, 1167–1176. [Google Scholar] [CrossRef]

- Languang, L.; Jianqiu, L.; Jianfeng, H.; Minggao, O. A review on the key issues of the lithium-ion battery management. Sci. Technol. Rev. 2016, 34, 39–51. [Google Scholar] [CrossRef]

- Tarascon, J.-M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef]

- Marcicki, J.; Todeschini, F.; Onori, S.; Canova, M. Nonlinear parameter estimation for capacity fade in Lithium-ion cells based on a reduced-order electrochemical model. In Proceedings of the 2012 American Control Conference, Montreal, QC, Canada, 27–29 June 2012; pp. 572–577. [Google Scholar]

- Attia, P.M.; Grover, A.; Jin, N.; Severson, K.A.; Markov, T.M.; Liao, Y.-H.; Chen, M.H.; Cheong, B.; Perkins, N.; Yang, Z.; et al. Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nature 2020, 578, 397–402. [Google Scholar] [CrossRef]

- Sours, T.; Agarwal, S.; Cormier, M.; Crivelli-Decker, J.; Ridderbusch, S.; Glazier, S.L.; Aiken, C.P.; Singh, A.R.; Xiao, A.; Allam, O. Early-Cycle Internal Impedance Enables ML-Based Battery Cycle Life Predictions Across Manufacturers. arXiv 2024, arXiv:2410.05326. [Google Scholar]

- Schaeffer, J.; Galuppini, G.; Rhyu, J.; Asinger, P.A.; Droop, R.; Findeisen, R.; Braatz, R.D. Cycle Life Prediction for Lithium-ion Batteries: Machine Learning and More. arXiv 2024, arXiv:2404.04049. [Google Scholar]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, B.; Lu, Y. Progress and perspective of high-voltage lithium cobalt oxide in lithium-ion batteries. J. Energy Chem. 2022, 74, 283–308. [Google Scholar] [CrossRef]

- Xiong, R.; Wang, P.; Jia, Y.; Shen, W.; Sun, F. Multi-factor aging in Lithium Iron phosphate batteries: Mechanisms and insights. Appl. Energy 2025, 382, 125250. [Google Scholar] [CrossRef]

- Wong, D.; Shrestha, B.; Wetz, D.A.; Heinzel, J.M. Impact of high rate discharge on the aging of lithium nickel cobalt aluminum oxide batteries. J. Power Sources 2015, 280, 363–372. [Google Scholar] [CrossRef]

- Wang, J.; Purewal, J.; Liu, P.; Hicks-Garner, J.; Soukazian, S.; Sherman, E.; Sorenson, A.; Vu, L.; Tataria, H.; Verbrugge, M.W. Degradation of lithium ion batteries employing graphite negatives and nickel–cobalt–manganese oxide+ spinel manganese oxide positives: Part 1, aging. J. Power Sources 2014, 269, 937–948. [Google Scholar] [CrossRef]

- Taborelli, C.; Onori, S.; Maes, S.; Sveum, P.; Al Hallaj, S.; Al Khayat, N. Advanced battery management system design for SOC/SOH estimation for e-bikes applications. Int. J. Powertrains 2016, 5, 325. [Google Scholar] [CrossRef]

- Lanubile, A.; Bosoni, P.; Pozzato, G.; Allam, A.; Acquarone, M.; Onori, S. Domain knowledge-guided machine learning framework for state of health estimation in Lithium-ion batteries. Commun. Eng. 2024, 3, 168. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Tian, H.; Qin, P.; Li, K.; Zhao, Z. A review of the state of health for lithium-ion batteries: Research status and suggestions. J. Clean. Prod. 2020, 261, 120813. [Google Scholar] [CrossRef]

- Mawonou, K.S.; Eddahech, A.; Dumur, D.; Beauvois, D.; Godoy, E. State-of-health estimators coupled to a random forest approach for lithium-ion battery aging factor ranking. J. Power Sources 2021, 484, 229154. [Google Scholar] [CrossRef]

- Feng, X.; Li, J.; Ouyang, M.; Lu, L.; Li, J.; He, X. Using probability density function to evaluate the state of health of lithium-ion batteries. J. Power Sources 2013, 232, 209–218. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, X.; Du, Z.; Liao, Q. Aging performance characterization and state-of-health assessment of retired lithium-ion battery modules. J. Energy Storage 2021, 40, 102743. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Vinassa, J.-M. Determination of lithium-ion battery state-of-health based on constant-voltage charge phase. J. Power Sources 2014, 258, 218–227. [Google Scholar] [CrossRef]

- Tang, X.; Zou, C.; Yao, K.; Chen, G.; Liu, B.; He, Z.; Gao, F.A. A fast estimation algorithm for lithium-ion battery state of health. J. Power Sources 2018, 396, 453–458. [Google Scholar] [CrossRef]

- Weng, C.; Cui, Y.; Sun, J.; Peng, H. On-board state of health monitoring of lithium-ion batteries using incremental capacity analysis with support vector regression. J. Power Sources 2013, 235, 36–44. [Google Scholar] [CrossRef]

- Yurkovich, B.J.; Sharma, O.P.; Guezennec, Y.; Onori, S. Battery Life Estimation in PHEV Applications: A Monte Carlo Simulation Study. IFAC Proc. Vol. 2012, 45, 108–115. [Google Scholar] [CrossRef]

- Di Filippi, A.; Stockar, S.; Onori, S.; Canova, M.; Guezennec, Y. Model-based life estimation of Li-ion batteries in PHEVs using large scale vehicle simulations: An introductory study. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, VPPC 2010, Lille, France, 1–3 September 2010. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Li, D.; Cui, X.; Wang, L.; Li, L.; Wang, K. Electrochemical Impedance Spectroscopy: A New Chapter in the Fast and Accurate Estimation of the State of Health for Lithium-Ion Batteries. Energies 2023, 16, 1599. [Google Scholar] [CrossRef]

- Feng, L.; Jiang, L.; Liu, J.; Wang, Z.; Wei, Z.; Wang, Q. Dynamic overcharge investigations of lithium ion batteries with different state of health. J. Power Sources 2021, 507, 230262. [Google Scholar] [CrossRef]

- Mollah, S.; Behdani, B. Sustainability, Resource Efficiency, and Recyclability in EV Battery Supply Chains: An Exploratory Study of Challenges and Key Enablers. In International Conference on Applied Economics and Business; Springer: Cham, Switzerland, 2024; pp. 301–313. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Malladi, S.; Zayas, I.C. End-of-Life Management of Electric Vehicle Lithium-Ion Batteries in the United States. Clean Technol. 2022, 4, 1162–1174. [Google Scholar] [CrossRef]

- Akram, M.N.; Abdul-Kader, W. Sustainable Development Goals and End-of-Life Electric Vehicle Battery: Literature Review. Batteries 2023, 9, 353. [Google Scholar] [CrossRef]

- Karagoz, S.; Aydin, N.; Simic, V. End-of-life vehicle management: A comprehensive review. J. Mater. Cycles Waste Manag. 2019, 22, 416–442. [Google Scholar] [CrossRef]

- Daigle, M.; Kulkarni, C.S. End-of-discharge and End-of-life Prediction in Lithium-ion Batteries with Electrochemistry-based Aging Models. In Proceedings of the AIAA Infotech @ Aerospace, San Diego, CA, USA, 4–8 January 2016; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2016. [Google Scholar] [CrossRef]

- Stroe, A.-I.; Knap, V.; Stroe, D.-I. Comparison of lithium-ion battery performance at beginning-of-life and end-of-life. Microelectron. Reliab. 2018, 88–90, 1251–1255. [Google Scholar] [CrossRef]

- Aydogan, H. Electric Vehicles and Renewable Energy. J. Phys. Conf. Ser. 2024, 2777, 012007. [Google Scholar] [CrossRef]

- Chen, Z.; Yildizbasi, A.; Wang, Y.; Sarkis, J. Safety Concerns for the Management of End-of-Life Lithium-Ion Batteries. Glob. Challenges 2022, 6, 2200049. [Google Scholar] [CrossRef]

- Kupper, C.; Weißhar, B.; Rißmann, S.; Bessler, W.G. End-of-Life Prediction of a Lithium-Ion Battery Cell Based on Mechanistic Aging Models of the Graphite Electrode. J. Electrochem. Soc. 2018, 165, A3468–A3480. [Google Scholar] [CrossRef]

- Ramoni, M.O.; Zhang, H.-C. End-of-life (EOL) issues and options for electric vehicle batteries. Clean Technol. Environ. Policy 2013, 15, 881–891. [Google Scholar] [CrossRef]

- Sekeran, M.S.; Živadinović, M.; Spiliopoulou, M. Transferability of a Battery Cell End-of-Life Prediction Model Using Survival Analysis. Energies 2022, 15, 2930. [Google Scholar] [CrossRef]

- Kandasamy, N.K.; Mohamed, N.B.; Hao, J.; Beng, S.C.; Lock, D.S.C.; Wei, F.; Sivaneasan, B.; Tan, K.T. Preemptive Identification of End-of-Life for Stationary Battery Systems. In Proceedings of the 2021 IEEE 2nd International Conference on Smart Technologies for Power, Energy and Control (STPEC), Bilaspur, Chhattisgarh, India, 19–22 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Zhu, J.; Mathews, I.; Ren, D.; Li, W.; Cogswell, D.; Xing, B.; Sedlatschek, T.; Kantareddy, S.N.R.; Yi, M.; Gao, T.; et al. End-of-life or second-life options for retired electric vehicle batteries. Cell Rep. Phys. Sci. 2021, 2, 100537. [Google Scholar] [CrossRef]

- Sun, C.; Lu, T.; Li, Q.; Liu, Y.; Yang, W.; Xie, J. Predicting the Future Capacity and Remaining Useful Life of Lithium-Ion Batteries Based on Deep Transfer Learning. Batteries 2024, 10, 303. [Google Scholar] [CrossRef]

- Zhong, R.; Hu, B.; Feng, Y.; Lou, S.; Hong, Z.; Wang, F.; Li, G.; Tan, J. Lithium-ion battery remaining useful life prediction: A federated learning-based approach. Energy Ecol. Environ. 2024, 9, 549–562. [Google Scholar] [CrossRef]

- Jafari, S.; Byun, Y.C. Accurate remaining useful life estimation of lithium-ion batteries in electric vehicles based on a measurable feature-based approach with explainable AI. J. Supercomput. 2023, 80, 4707–4732. [Google Scholar] [CrossRef]

- Feng, R.; Wang, S.; Yu, C.; Fernandez, C. Remaining useful life prediction of lithium-ion batteries based on performance degradation mechanism analysis and improved Deep Extreme Learning Machine model. Ionics 2024, 30, 5449–5471. [Google Scholar] [CrossRef]

- Liu, K.; Shang, Y.; Ouyang, Q.; Widanage, W.D. A Data-Driven Approach with Uncertainty Quantification for Predicting Future Capacities and Remaining Useful Life of Lithium-ion Battery. IEEE Trans. Ind. Electron. 2020, 68, 3170–3180. [Google Scholar] [CrossRef]

- Wei, J.; Dong, G.; Chen, Z. Remaining Useful Life Prediction and State of Health Diagnosis for Lithium-Ion Batteries Using Particle Filter and Support Vector Regression. IEEE Trans. Ind. Electron. 2017, 65, 5634–5643. [Google Scholar] [CrossRef]

- Zhang, D.; Dey, S.; Perez, H.E.; Moura, S.J. Remaining useful life estimation of lithium-ion batteries based on thermal dynamics. In Proceedings of the 2017 American Control Conference (ACC), Seattle, WA, USA, 24–26 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 4042–4047. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M. Validation and verification of a hybrid method for remaining useful life prediction of lithium-ion batteries. J. Clean. Prod. 2019, 212, 240–249. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Qu, X.; Pecht, M. Aging characteristics-based health diagnosis and remaining useful life prognostics for lithium-ion batteries. eTransportation 2019, 1, 100004. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Lithium-Ion Battery Remaining Useful Life Prediction With Box–Cox Transformation and Monte Carlo Simulation. IEEE Trans. Ind. Electron. 2018, 66, 1585–1597. [Google Scholar] [CrossRef]

- Xu, X.; Tang, S.; Yu, C.; Xie, J.; Han, X.; Ouyang, M. Remaining Useful Life Prediction of Lithium-ion Batteries Based on Wiener Process Under Time-Varying Temperature Condition. Reliab. Eng. Syst. Saf. 2021, 214, 107675. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, R.; Yang, D.; Tang, X.; Chen, Z. Remaining Useful Life Prediction of Lithium-ion Battery Based on Discrete Wavelet Transform. Energy Procedia 2017, 105, 2053–2058. [Google Scholar] [CrossRef]

- Qiu, J.; Fan, Y.; Wang, S.; Yang, X.; Qiao, J.; Liu, D. Research on the remaining useful life prediction method of lithium-ion batteries based on aging feature extraction and multi-kernel relevance vector machine optimization model. Int. J. Energy Res. 2022, 46, 13931–13946. [Google Scholar] [CrossRef]

- Sadabadi, K.K.; Jin, X.; Rizzoni, G. Prediction of remaining useful life for a composite electrode lithium ion battery cell using an electrochemical model to estimate the state of health. J. Power Sources 2021, 481, 228861. [Google Scholar] [CrossRef]

- Nozarijouybari, Z.; Allam, A.; Onori, S.; Fathy, H.K. On the Feasibility of Electrode Concentration Distribution Estimation in Single-Particle Lithium-Ion Battery Models. IEEE Control. Syst. Lett. 2022, 7, 1099–1104. [Google Scholar] [CrossRef]

- Tjandra, R.; Jiang, H.; Zainudin, E.B.; Yasmin, M.I.B.; Soh, C.B.; Feng, E. Early Identification of Battery End-of-Life Using Machine Learning. In Proceedings of the 13th International Conference on Power, Energy and Electrical Engineering (CPEEE), Tokyo, Japan, 25–27 February 2023. [Google Scholar] [CrossRef]

- Madani, S.S.; Schaltz, E.; Kær, S.K. An Electrical Equivalent Circuit Model of a Lithium Titanate Oxide Battery. Batteries 2019, 5, 31. [Google Scholar] [CrossRef]

- Madani, S.S.; Schaltz, E.; Kær, S.K. A Review of Different Electric Equivalent Circuit Models and Parameter Identification Methods of Lithium-Ion Batteries. ECS Trans. 2018, 87, 23–37. [Google Scholar] [CrossRef]

- Goussian, A.; Assaud, L.; Baghdadi, I.; Nouillant, C.; Franger, S. A Novel Reaction Rate Parametrization Method for Lithium-Ion Battery Electrochemical Modelling. Batteries 2024, 10, 205. [Google Scholar] [CrossRef]

- Kuchly, J.; Goussian, A.; Merveillaut, M.; Baghdadi, I.; Franger, S.; Nelson-Gruel, D.; Nouillant, C.; Chamail-lard, Y. Li-ion battery SOC estimation method using a Neural Network trained with data generated by a P2D model. IFAC-PapersOnLine 2021, 54, 336–343. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, R.; Ren, Y.; Jiao, M.; Liu, H.; Lian, C. Advanced data-driven techniques in AI for predicting lithium-ion battery remaining useful life: A comprehensive review. Green Chem. Eng. 2024, 6, 139–153. [Google Scholar] [CrossRef]

- Gaberšček, M. Understanding Li-based battery materials via electrochemical impedance spectroscopy. Nat. Commun. 2021, 12, 6513. [Google Scholar] [CrossRef]

- Meddings, N.; Heinrich, M.; Overney, F.; Lee, J.S.; Ruiz, V.; Napolitano, E.; Seitz, S.; Hinds, G.; Raccichini, R.; Gaberšček, M.; et al. Application of electrochemical impedance spectroscopy to commercial Li-ion cells: A review. J. Power Sources 2020, 480, 228742. [Google Scholar] [CrossRef]

- Narayanrao, R.; Joglekar, M.M.; Inguva, S. A Phenomenological Degradation Model for Cyclic Aging of Lithium Ion Cell Materials. J. Electrochem. Soc. 2012, 160, A125–A137. [Google Scholar] [CrossRef]

- Horstkötter, I.; Gesner, P.; Hadler, K.; Bäker, B. A phenomenological ageing study of lithium-ion batteries under dynamic loads. J. Energy Storage 2021, 42, 102962. [Google Scholar] [CrossRef]

- Weng, A.; Olide, E.; Kovalchuk, I.; Siegel, J.B.; Stefanopoulou, A. Phenomenological model of lithium-ion battery formation cycling and aging. arXiv 2023, arXiv:2305.18722. [Google Scholar]

- Langner, T.; Sieber, T.; Rietig, A.; Merk, V.; Pfeifer, L.; Acker, J. A phenomenological and quantitative view on the degradation of positive electrodes from spent lithium-ion batteries in humid atmosphere. Sci. Rep. 2023, 13, 5671. [Google Scholar] [CrossRef]

- Yan, J.; Xia, B.-J.; Su, Y.-C.; Zhou, X.-Z.; Zhang, J.; Zhang, X.-G. Phenomenologically modeling the formation and evolution of the solid electrolyte interface on the graphite electrode for lithium-ion batteries. Electrochim. Acta 2008, 53, 7069–7078. [Google Scholar] [CrossRef]

- Oh, K.-Y.; Epureanu, B.I.; Siegel, J.B.; Stefanopoulou, A.G. Phenomenological force and swelling models for rechargeable lithium-ion battery cells. J. Power Sources 2016, 310, 118–129. [Google Scholar] [CrossRef]

- Li, J.; Fang, Q.; Wu, H.; Liu, Y.; Wen, P. Investigation into diffusion induced plastic deformation behavior in hollow lithium ion battery electrode revealed by analytical model and atomistic simulation. Electrochim. Acta 2015, 178, 597–607. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Bai, Q.; Mo, Y.; Zhu, Y. From atomistic modeling to materials design: Computation-driven material development in lithium-ion batteries. Sci. China Chem. 2023, 67, 276–290. [Google Scholar] [CrossRef]

- Tröltzsch, U.; Kanoun, O.; Tränkler, H.-R. Characterizing aging effects of lithium ion batteries by impedance spectroscopy. Electrochim. Acta 2005, 51, 1664–1672. [Google Scholar] [CrossRef]

- Monem, M.A.; Trad, K.; Omar, N.; Hegazy, O.; Mantels, B.; Mulder, G.; Van den Bossche, P.; Van Mierlo, J. Lithium-ion batteries: Evaluation study of different charging methodologies based on aging process. Appl. Energy 2015, 152, 143–155. [Google Scholar] [CrossRef]

- Guo, Z.; Liaw, B.Y.; Qiu, X.; Gao, L.; Zhang, C. Optimal charging method for lithium ion batteries using a universal voltage protocol accommodating aging. J. Power Sources 2015, 274, 957–964. [Google Scholar] [CrossRef]

- Prasad, G.K.; Rahn, C.D. Model based identification of aging parameters in lithium ion batteries. J. Power Sources 2013, 232, 79–85. [Google Scholar] [CrossRef]

- Xia, Z.; Abu Qahouq, J.A. Evaluation of Parameter Variations of Equivalent Circuit Model of Lithium-ion Battery under Different SOH Conditions. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1519–1523. [Google Scholar] [CrossRef]

- Serrao, L.; Onori, S.; Rizzoni, G.; Guezennec, Y. A Novel Model-Based Algorithm for Battery Prognosis. IFAC Proc. Vol. 2009, 42, 923–928. [Google Scholar] [CrossRef]

- Che, Y.; Zheng, Y.; Onori, S.; Hu, X.; Teodorescu, R. Increasing generalization capability of battery health estimation using continual learning. Cell Rep. Phys. Sci. 2023, 4, 101743. [Google Scholar] [CrossRef]

- Gong, X. Modeling of Lithium-Ion Battery Considering Temperature and Aging Uncertainties. Ph.D. Thesis, University of Michigan-Dearborn, Dearborn, MI, USA, 2016. [Google Scholar]

- Stiaszny, B.; Ziegler, J.C.; Krauß, E.E.; Schmidt, J.P.; Ivers-Tiffée, E. Electrochemical characterization and post-mortem analysis of aged LiMn2O4–Li(Ni0.5Mn0.3Co0.2)O2/graphite lithium ion batteries. Part I: Cycle aging. J. Power Sources 2014, 251, 439–450. [Google Scholar] [CrossRef]

- Khan, M.A.; Thatipamula, S.; Onori, S. Onboard Health Estimation using Distribution of Relaxation Times for Lithium-ion Batteries. IFAC-PapersOnLine 2024, 58, 917–922. [Google Scholar]

- Hu, W.; Peng, Y.; Wei, Y.; Yang, Y. Application of Electrochemical Impedance Spectroscopy to Degradation and Aging Research of Lithium-Ion Batteries. J. Phys. Chem. C 2023, 127, 4465–4495. [Google Scholar] [CrossRef]

- De Sutter, L.; Firouz, Y.; De Hoog, J.; Omar, N.; Van Mierlo, J. Battery aging assessment and parametric study of lithium-ion batteries by means of a fractional differential model. Electrochim. Acta 2019, 305, 24–36. [Google Scholar] [CrossRef]

- Stroe, D.I. Lifetime Models for Lithium-Ion Batteries Used in Virtual Power Plant Applications. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2014. [Google Scholar]

- Rizzoni, G.; Onori, S.; Rubagotti, M. Diagnosis and Prognosis of Automotive Systems: Motivations, history and some results. IFAC Proc. Vol. 2009, 42, 191–202. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, Q.; Wang, F.; Wang, D.; He, Z. An electrochemical-thermal-aging effects coupled model for lithium-ion batteries performance simulation and state of health estimation. Appl. Therm. Eng. 2023, 239, 122128. [Google Scholar] [CrossRef]

- Bruce, P.G.; Freunberger, S.A.; Hardwick, L.J.; Tarascon, J.-M. Li–O2 and Li–S batteries with high energy storage. Nat. Mater. 2011, 11, 19–29. [Google Scholar] [CrossRef]

- Dunn, B.; Kamath, H.; Tarascon, J.-M. Electrical Energy Storage for the Grid: A Battery of Choices. Science 2011, 334, 928–935. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, L.; Terekhov, A.; Warnberg, D.; Zhao, P. Thermal runaway of Li-ion battery with different aging histories. Process. Saf. Environ. Prot. 2024, 185, 910–917. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Doyle, M.; Newman, J. The use of mathematical modeling in the design of lithium/polymer battery systems. Electrochimica Acta 1995, 40, 2191–2196. [Google Scholar] [CrossRef]

- Birkl, C.R.; Roberts, M.R.; McTurk, E.; Bruce, P.G.; Howey, D.A. Degradation diagnostics for lithium ion cells. J. Power Sources 2017, 341, 373–386. [Google Scholar] [CrossRef]

- Prada, E.; Di Domenico, D.; Creff, Y.; Bernard, J.; Sauvant-Moynot, V.; Huet, F. A Simplified Electrochemical and Thermal Aging Model of LiFePO4-Graphite Li-ion Batteries: Power and Capacity Fade Simulations. J. Electrochem. Soc. 2013, 160, A616–A628. [Google Scholar] [CrossRef]

- Jung, S.K.; Gwon, H.; Hong, J.; Park, K.Y.; Seo, D.H.; Kim, H.; Hyun, J.; Yang, W.; Kang, K. Understanding the Degradation Mechanisms of LiNi0.5Co0.2Mn0.3O2 Cathode Material in Lithium Ion Batteries. Adv. Energy Mater. 2013, 4, 1300787. [Google Scholar] [CrossRef]

- Deshpande, R.; Verbrugge, M.; Cheng, Y.-T.; Wang, J.; Liu, P. Battery Cycle Life Prediction with Coupled Chemical Degradation and Fatigue Mechanics. J. Electrochem. Soc. 2012, 159, A1730–A1738. [Google Scholar] [CrossRef]

- Agubra, V.; Fergus, J. Lithium Ion Battery Anode Aging Mechanisms. Materials 2013, 6, 1310–1325. [Google Scholar] [CrossRef]

- Tang, S.; Liang, Y.; Zhong, C.; Peng, Y.; Hu, Y.; Hu, W.; Liao, Y.; Lin, J.; Yang, X.; Zhang, H.; et al. Revisiting the overdischarge process as a novel accelerated aging method for LiFePO4/Graphite batteries through the unveiling of SEI evolution mechanism. Energy Storage Mater. 2025, 74, 103916. [Google Scholar]

- Christensen, J.; Newman, J. Stress generation and fracture in lithium insertion materials. J. Solid State Electrochem. 2006, 10, 293–319. [Google Scholar] [CrossRef]

- Gulbinska, M.K. Lithium-Ion Battery Materials and Engineering: Current Topics and Problems from the Manufacturing Perspective; Springer: London, UK, 2014. [Google Scholar]

- Shchurov, N.I.; Dedov, S.I.; Malozyomov, B.V.; Shtang, A.A.; Martyushev, N.V.; Klyuev, R.V.; Andriashin, S.N. Degradation of Lithium-Ion Batteries in an Electric Transport Complex. Energies 2021, 14, 8072. [Google Scholar] [CrossRef]

- Li, Z.; Huang, J.; Liaw, B.Y.; Metzler, V.; Zhang, J. A review of lithium deposition in lithium-ion and lithium metal secondary batteries. J. Power Sources 2014, 254, 168–182. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters—A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Liu, J.; Yue, M.; Wang, S.; Zhao, Y.; Zhang, J. A Review of Performance Attenuation and Mitigation Strategies of Lithium-Ion Batteries. Adv. Funct. Mater. 2021, 32, 2107769. [Google Scholar] [CrossRef]

- Whittingham, M.S. Electrical Energy Storage and Intercalation Chemistry. Science 1976, 192, 1126–1127. [Google Scholar] [CrossRef]

- Bini, M.; Capsoni, D.; Ferrari, S.; Quartarone, E.; Mustarelli, P. 1—Rechargeable lithium batteries: Key scientific and technological challenges. In Rechargeable Lithium Batteries; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2015; pp. 1–17. [Google Scholar] [CrossRef]

- Goodenough, J.B.; Kim, Y. Challenges for Rechargeable Li Batteries. Chem. Mater. 2009, 22, 587–603. [Google Scholar] [CrossRef]

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Chen, Y. Improvement and Development Prospects of Carbon Anode Materials for Lithium-ion Batteries. Highlights Sci. Eng. Technol. 2024, 83, 127–132. [Google Scholar] [CrossRef]

- Gao, X.; Liu, L.; Zu, L.; Lian, H.; Cui, X.; Wang, X. Facile fabrication of fibrous phosphorus as anode material for lithium-ion batteries with long cycle life and high rate performance. J. Power Sources 2024, 595, 234077. [Google Scholar] [CrossRef]