Cell-Internal Contacting of Prismatic Lithium-Ion Batteries Using Micro-Friction Stir Spot Welding

Abstract

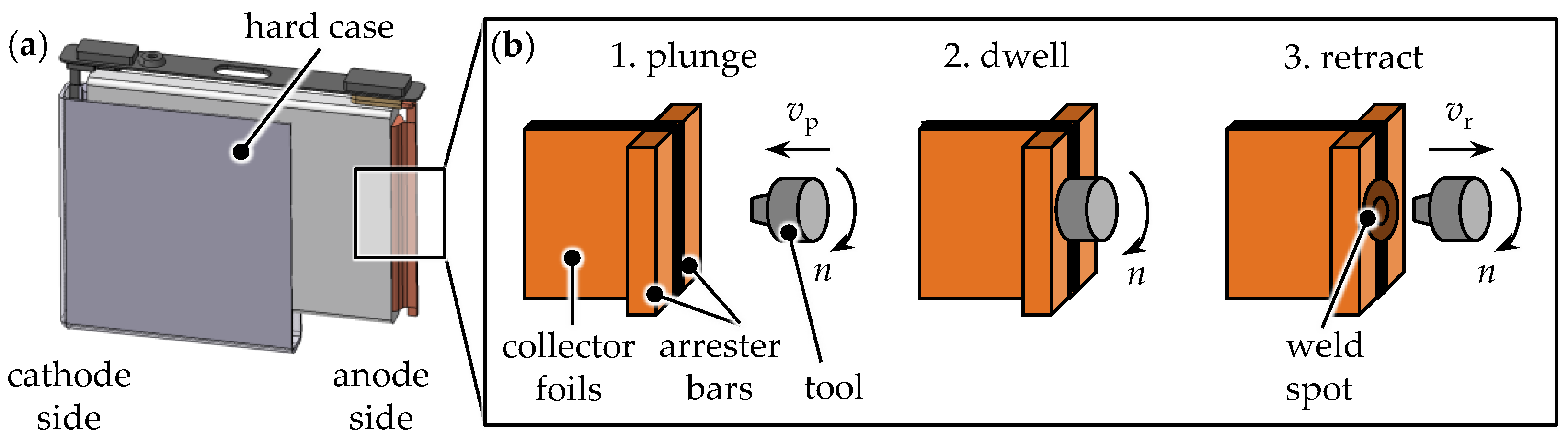

:1. Introduction and State of the Art

2. Objective, Materials and Methods

2.1. Objective of the Investigations

- R1.

- high process stability and no welding defects [5];

- R2.

- R3.

- high repeatability of the weld quality [22];

- R4.

- bonding of all foils and no damaged foils [22];

- R5.

- no thermal damaging of temperature sensitive cell components [22];

- R6.

- low electrical resistance of the joint [22];

- R7.

- high static mechanical strength of the joint [22];

- R8.

- low welding time [5].

2.2. Materials and Methods for the Experimental Investigations

2.3. Methods for Evaluation

3. Results and Discussion

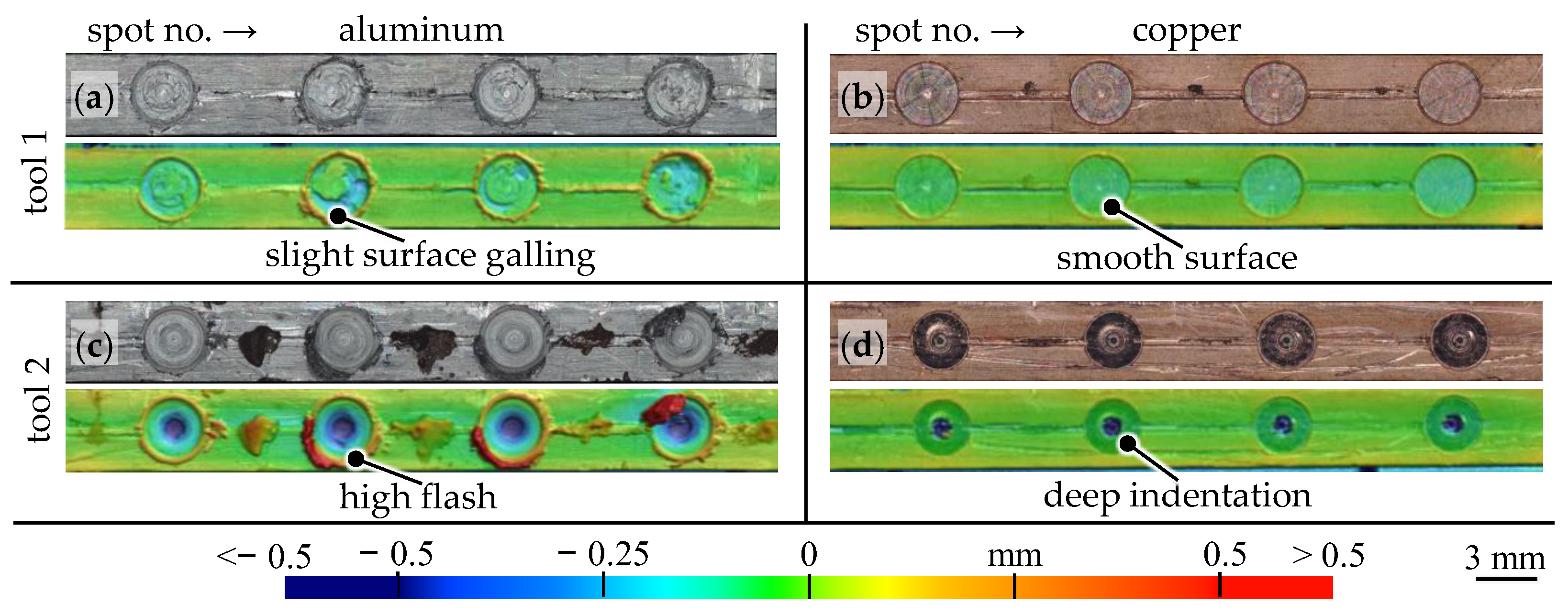

3.1. Visual Inspection and Weld Topographies (R1, R2 and R4)

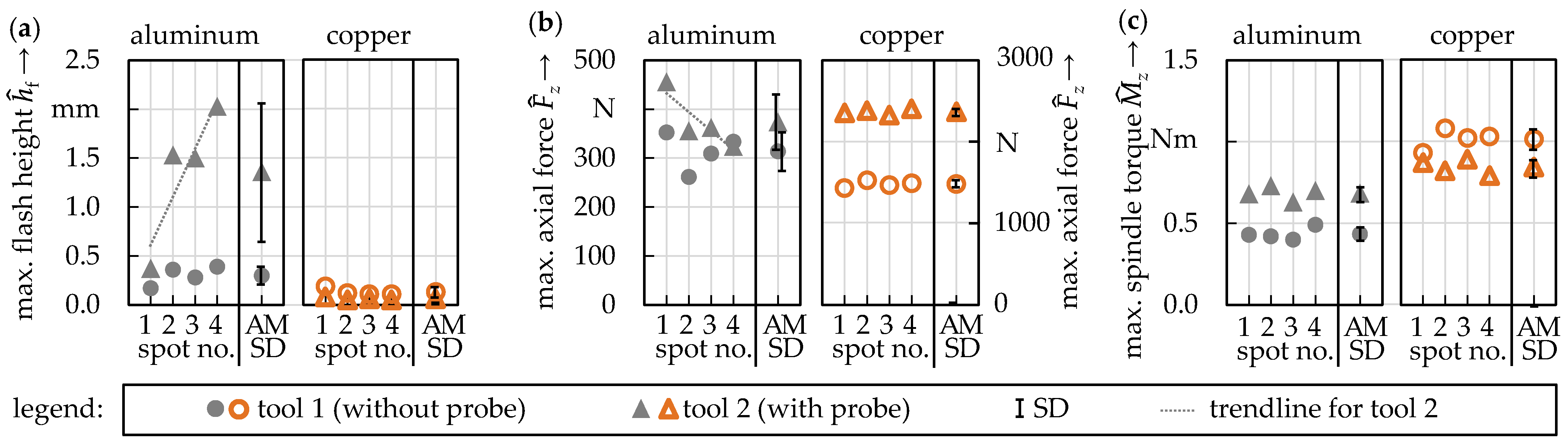

3.2. Repeatability of the Process (R3)

3.3. Temperatures in the Weld Surrounding Areas (R5)

3.4. Electrical Resistances (R6)

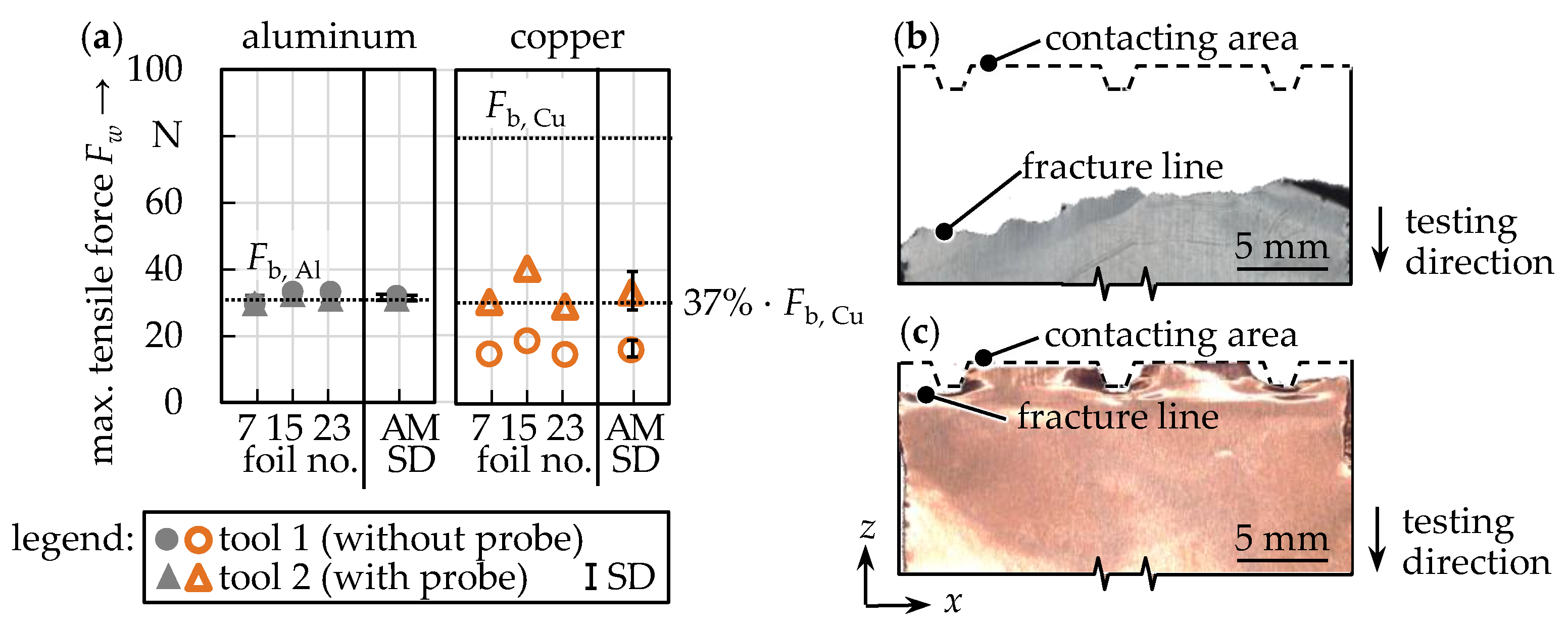

3.5. Mechanical Strength (R7)

3.6. Welding Speed (R8)

4. Conclusions and Outlook

- Using μFSSW, sound aluminium and copper spot welds without visible defects or ruptured foils can be produced. Due to the low temperatures, no thermal damaging of the battery components has to be expected.

- The tensile strengths of the aluminium samples were not impacted by welding. For the copper samples, the strengths were reduced to that of aluminium. It is hypothesized that the mechanical quality can be improved by welding with tools that enhance the material mixing (e.g., structured tools).

- For both aluminium and copper, the electrical resistances of the welding samples were higher than that of unwelded reference foils. It is expected that resistances can be improved by increasing the cross-section area of the weld, for example, by welding with larger or with structured tools. Another possibility is to produce line welds [32].

- Spot welds can be produced in 0.3 s. The welding speed can be improved by increasing the plunge (vp) and the retreat speed (vr) of the tool.

- In addition, a scaled up prismatic demonstrator, which is comprised of 100 uncoated aluminium and 100 uncoated copper foils, was produced with two arrester bars on each side (Figure 8) to show the potential of the process for the production of large-scale high-energy-dense battery cells.

- Like USW [2], μFSSW [33] is a solid-state welding process with a low energy consumption and no fumes (in contrast to LBW). The welding times of μFSSW, USW, and LBW are similar, however, with μFSSW, the required welding times are not increased by higher foil stack sizes. Both multi-sheet lap joints and multi-sheet butt joints can be fabricated by LBW and by μFSSW, but not by USW. LBW and μFSSW therefore allow for more flexibility with regard to the cell design. Both processes, however, also require good joint fit-up [2], which means a higher effort for positioning and clamping before welding.

- The experimental results show that μFSSW has a high potential for cell-internal contacting of prismatic cells. An application for other cell formats like cylindrical cells is regarded feasible by the authors and might be advantageous due to the high uniformity of the spot welds and the high speed of the process.

- Due to different applied materials and welding geometries, a literature-based comparison between μFSSW, USW, and LBW was not possible for all defined requirements. This will be a topic of future investigations.

- Future research will also deal with an assertion of the electrochemical performance of lithium-ion cells, which were produced using μFSSW.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

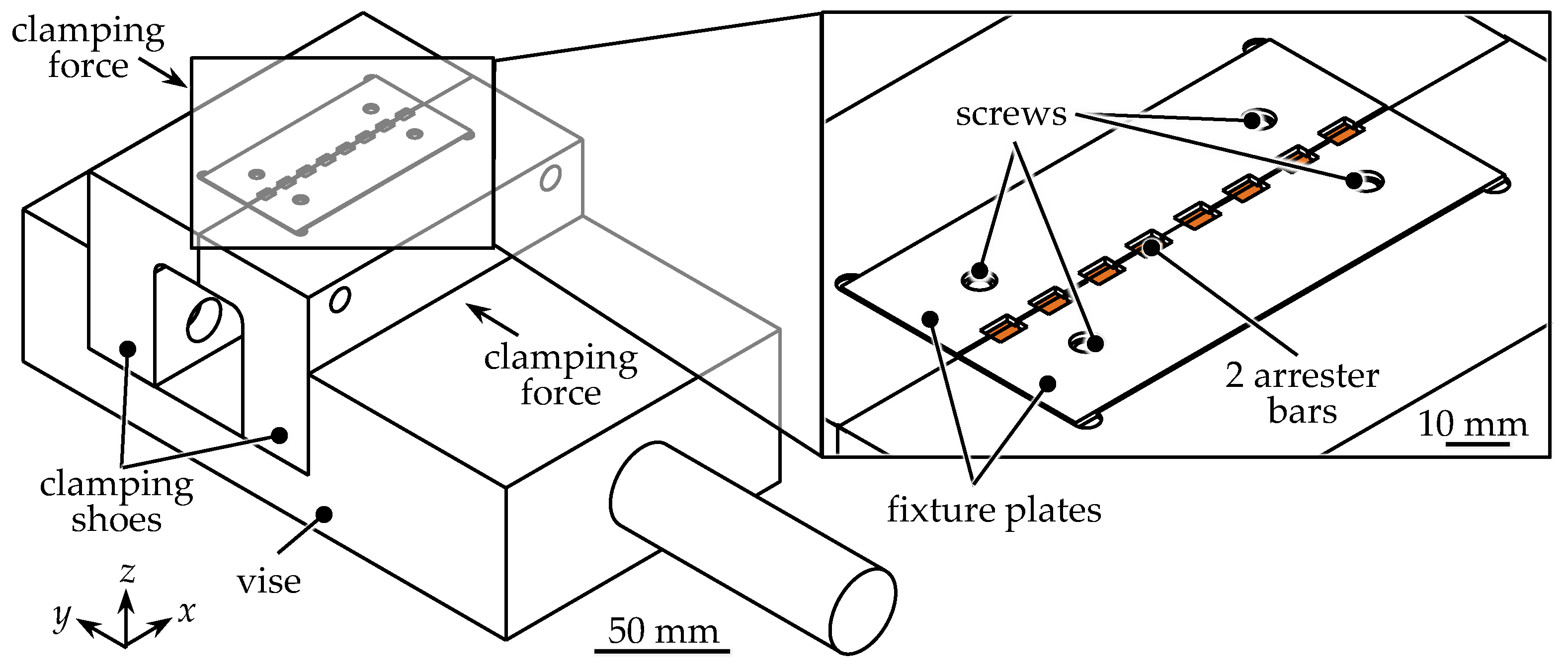

Appendix A. Setup for the Welding Experiments

Appendix A.1. Welding Machine, Clamping System and Part Fit-Up

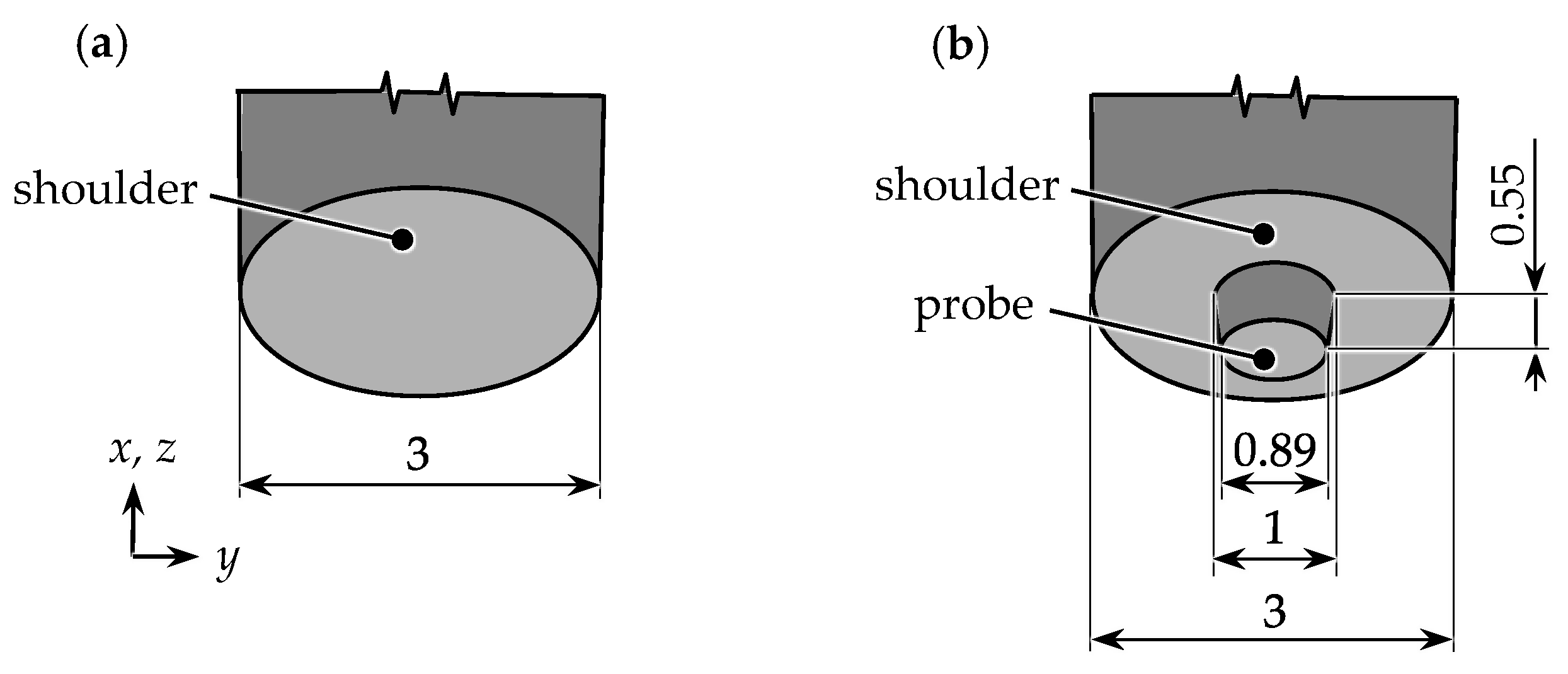

Appendix A.2. Welding Tools and Process Parameters

Appendix B. Setup for Testing

Appendix B.1. Visual Inspection

Appendix B.2. Topographical Data

Appendix B.3. Process Variable Data

Appendix B.4. Temperature Measurement

Appendix B.5. Electrical Resistance Measurement

Appendix B.6. Tensile Strength Measurement

Appendix B.7. Welding Time Calculation

Appendix C. Experimental Data

| Tool No. | Spot No. | Material | Max. Flash

Height in mm | Electrical Resistances Rw in μΩ | Max. Tensile Forces Fw 1 in N | Fracture Locations 1 | Max. Temperature in °C | Max. Axial

Force z in N | Max. Spindle Torque z in Nm |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | aluminium | 0.17 | – | – | – | 33.32 | 352.32 | 0.43 |

| 2 3 4 | 0.36 0.28 0.39 | 1599.28 ± 13.82 | 29.71, 33.32, 33.33 | o, o, o | 34.37 22.22 37.66 | 261.29 309.40 333.54 | 0.42 0.40 0.49 | ||

| 2 | 1 | aluminium | 0.37 | – | – | – | 52.08 | 455.40 | 0.68 |

| 2 3 4 | 1.53 1.50 2.03 | 1577.78 ± 12.38 | 29.80, 32.58, 31.09 | o, w, o | 67.70 68.17 60.11 | 355.47 362.32 323.43 | 0.73 0.63 0.70 | ||

| 1 | 1 2 3 | copper | 0.19 0.12 0.11 | 1690.57 ± 2.96 | 14.87, 18.89, 14.83 | w, w, w | 42.52 58.13 54.78 | 1434.16 1528.92 1471.24 | 0.93 1.08 1.02 |

| 4 | 0.11 | – | – | – | 42.09 | 1490.44 | 1.03 | ||

| 2 | 1 2 3 | copper | 0.08 0.05 0.06 | 1627.53 ± 0.45 | 30.40, 40.46, 29.13 | w, w, w | 58.77 61.89 65.47 | 2354.08 2380.80 2328.61 | 0.87 0.82 0.89 |

| 4 | 0.05 | – | – | – | 47.95 | 2403.32 | 0.79 |

References

- Thielmann, A.; Sauer, A.; Wietschel, M. Gesamt-Roadmap Lithium-Ionen-Batterien 2030 (Translated Title: “Complete Roadmap Lithium-Ion Batteries 2030”); Fraunhofer-Institut für System- und Innovationsforschung ISI: Karlsruhe, Germany, 2015. [Google Scholar]

- Das, A.; Li, D.; Williams, D.; Greenwood, D. Joining Technologies for Automotive Battery Systems Manufacturing. World Electr. Veh. J. 2018, 9, 22. [Google Scholar] [CrossRef] [Green Version]

- Korthauer, R. (Ed.) Lithium-Ion Batteries: Basics and Applications; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-662530-71-9. [Google Scholar]

- Kleiner, J.; Komsiyska, L.; Elger, G.; Endisch, C. Thermal Modelling of a Prismatic Lithium-Ion Cell in a Battery Electric Vehicle Environment: Influences of the Experimental Validation Setup. Energies 2020, 13, 62. [Google Scholar] [CrossRef] [Green Version]

- Schedewy, R.; Beyer, E.; Brenner, B.; Standfuss, J. Prospects of welding foils with solid state laser for lithium-ion batteries. In International Congress on Applications of Lasers & Electro-Optics, Proceedings of the 30th International Congress on Laser Materials Processing, Laser Microprocessing and Nanomanufacturing (ICALEO), Orlando, FL, USA, 23–27 October 2011; Laser Institute of America: Orlando, FL, USA, 2011. [Google Scholar]

- Keppeler, M.; Roessler, S.; Braunwarth, W. Production Research as Key Factor for Successful Establishment of Battery Production on the Example of Large-Scale Automotive Cells Containing Nickel-Rich LiNi 0.8 Mn 0.1 Co 0.1 O 2 Electrodes. Energy Technol. 2020, 8, 2000183. [Google Scholar] [CrossRef]

- Duffner, F.; Mauler, L.; Wentker, M.; Leker, J.; Winter, M. Large-scale automotive battery cell manufacturing: Analyzing strategic and operational effects on manufacturing costs. Int. J. Prod. Econ. 2021, 232, 107982. [Google Scholar] [CrossRef]

- Grabmann, S.; Kriegler, J.; Harst, F.; Günter, F.J.; Zaeh, M.F. Laser welding of current collector foil stacks in battery production–mechanical properties of joints welded with a green high-power disk laser. Int. J. Adv. Manuf. Technol. 2022, 118, 2571–2586. [Google Scholar] [CrossRef]

- Lee, S.S.; Kim, T.H.; Hu, S.J.; Cai, W.W.; Abell, J.A. Joining Technologies for Automotive Lithium-Ion Battery Manufacturing: A Review. In Proceedings of the International Manufacturing Science and Engineering Conference (ASME), Erie, PA, USA, 12–15 October 2010. [Google Scholar]

- Balz, I.; Rosenthal, E.; Reimer, A.; Turiaux, M.; Schiebahn, A.; Reisgen, U. Analysis of the thermo-mechanical mechanism during ultrasonic welding of battery tabs using high-speed image capturing. Weld World 2019, 63, 1573–1582. [Google Scholar] [CrossRef]

- Knoche, T.; Reinhart, G. Electrolyte Filling of Large-Scale Lithium-Ion Batteries: Challenges for Production Technology and Possible Approaches. Appl. Mech. Mater. 2015, 794, 11–18. [Google Scholar] [CrossRef]

- Kwade, A.; Haselrieder, W.; Leithoff, R.; Modlinger, A.; Dietrich, F.; Droeder, K. Current status and challenges for automotive battery production technologies. Nat. Energy 2018, 3, 290–300. [Google Scholar] [CrossRef]

- Grabmann, S.; Kick, M.K.; Geiger, C.; Harst, F.; Zaeh, M.F. Toward the Flexible Production of Large-Format Lithium-Ion Batteries Using Laser-Based Cell-Internal Contacting. Procedia CIRP, 2022; in press. [Google Scholar]

- ISO 18785-1; Friction Stir Spot Welding—Aluminium—Part 1: Vocabulary. Beuth: Berlin, Germany, 2018.

- Lohwasser, D.; Chen, Z. Introduction. In Friction Stir Welding: From Basics to Applications; Lohwasser, D., Chen, Z., Eds.; CRC Press LLC: Oxford, UK, 2010; pp. 1–12. ISBN 978-1-845697-71-6. [Google Scholar]

- Kallee, S.W. Industrial applications of friction stir welding. In Friction Stir Welding: From Basics to Applications; Lohwasser, D., Chen, Z., Eds.; CRC Press LLC: Oxford, UK, 2010; pp. 118–163. ISBN 978-1-845697-71-6. [Google Scholar]

- Sen, M.; Shankar, S.; Chattopadhyaya, S. Micro-friction stir welding (μFSW)—A review. Mater. Today Proc. 2020, 27, 2469–2473. [Google Scholar] [CrossRef]

- Hartl, R.; Bachmann, A.; Habedank, J.B.; Semm, T.; Zaeh, M.F. Process Monitoring in Friction Stir Welding Using Convolutional Neural Networks. Metals 2021, 11, 535. [Google Scholar] [CrossRef]

- Tchouaha Tankoua, A.; Köhler, T.; Bergmann, J.P.; Grätzel, M.; Betz, P.; Lindenau, D. Tool Downscaling Effects on the Friction Stir Spot Welding Process and Properties of Current-Carrying Welded Aluminum–Copper Joints for E-Mobility Applications. Metals 2021, 11, 1949. [Google Scholar] [CrossRef]

- Sigl, M.E.; Bachmann, A.; Mair, T.; Zaeh, M.F. Torque-Based Temperature Control in Friction Stir Welding by Using a Digital Twin. Metals 2020, 10, 914. [Google Scholar] [CrossRef]

- Gera, D.; Fu, B.; Suhuddin, U.F.H.R.; Plaine, A.; Alcantara, N.; dos Santos, J.F.; Klusemann, B. Microstructure, mechanical and functional properties of refill friction stir spot welds on multilayered aluminum foils for battery application. J. Mater. Res. Technol. 2021, 13, 2272–2286. [Google Scholar] [CrossRef]

- Grabmann, S.; Tomcic, L.; Zaeh, M.F. Laser beam welding of copper foil stacks using a green high power disk laser. Procedia CIRP 2020, 94, 582–586. [Google Scholar] [CrossRef]

- Sun, Y.; Yuan, Y.; Lu, L.; Han, X.; Kong, X.; Wang, H.; Ouyang, M.; Gao, P.; Zheng, H.; Wang, K. A comprehensive research on internal short circuits caused by copper particle contaminants on cathode in lithium-ion batteries. eTransportation 2022, 13, 100183. [Google Scholar] [CrossRef]

- Lundgren, H.; Svens, P.; Ekström, H.; Tengstedt, C.; Lindström, J.; Behm, M.; Lindbergh, G. Thermal Management of Large-Format Prismatic Lithium-Ion Battery in PHEV Application. J. Electrochem. Soc. 2016, 163, A309–A317. [Google Scholar] [CrossRef]

- Korff AG. Technisches Datenblatt zu Reinaluminiumfolie (Translated Title: "Technical Datasheet for Pure Aluminum Foil"); Korff AG: Oberbipp, Switzerland, 2021. [Google Scholar]

- DIN EN 13599; Copper and Copper Alloys-Copper Plate, Sheet and Strip for Electrical Purposes. Beuth: Berlin, Germany, 2014.

- Schiefer, H.; Schiefer, F. Statistics for Engineers; Springer Fachmedien: Wiesbaden, Germany, 2021; ISBN 978-3-658-32396-7. [Google Scholar]

- Celgard, LLC. High Performance Battery Separators: Technical Datasheet; Celgard, LLC: Charlotte, NC, USA, 2009. [Google Scholar]

- Shin, S.; Nam, S.; Yu, J.; Park, J.; Kim, D. Ultrasonic Metal Welding of Multilayered Copper Foils to Nickel-Plated Copper Sheet in Lithium-Ion Battery Cell. Metals 2021, 11, 1195. [Google Scholar] [CrossRef]

- Hufschmied Zerspanungssysteme GmbH. Special Tools for Machining Aluminum: Product Catalog; Hufschmied Zerspanungssysteme GmbH: Bobingen, Germany, 2022. [Google Scholar]

- Schlenk Metal Foils GmbH & Co. KG. Cu-PHC: Technical Datasheet; Schlenk Metal Foils GmbH & Co. KG: Roth-Barnsdorf, Germany, 2019. [Google Scholar]

- Sigl, M.E.; Grabmann, S.; Zens, A.; Hartl, R.; Zaeh, M.F. Friction Stir Welding of Carrier Foils and Arresters for Prismatic Battery Cells. In Proceedings of the DVS Congress, Koblenz, Germany, 19–21 September 2022. [Google Scholar]

- Akinlabi, E.T.; Akinlabi, S.A. Friction Stir Welding Process: A Green Technology. Int. J. Mech. Mechatron. Eng. 2012, 6, 2514–2516. [Google Scholar] [CrossRef]

- ISO 18785-5; Friction Stir Spot Welding—Aluminium—Part 5: Quality and Inspection Requirements. Beuth: Berlin, Germany, 2018.

- ISO 17637; Non-Destructive Testing of Welds–Visual Testing of Fusion-Welded Joints. Beuth: Berlin, Germany, 2016.

- Hartl, R.; Bachmann, A.; Liebl, S.; Zens, A.; Zaeh, M.F. Automated surface inspection of friction stir welds by means of structured light projection. IOP Conf. Ser. Mater. Sci. Eng. 2019, 480, 012035. [Google Scholar] [CrossRef]

- Krutzlinger, M.; Bachmann, A.; Wirth, F.X.; Roth, A.; Sünger, S.; Pieczona, S.J.; Zah, M.F. Implementierung einer Messsensorik in ein Fräsbearbeitungszentrum zur Ermittlung der Prozesskräfte und des Prozessmoments beim Rührreibschweißen (Translated title: “Implementation of a measuring system in a milling machining center to determine the process forces and the process torque during friction stir welding”). In Proceedings of the DVS Congress, Duesseldorf, Germany, 15–17 September 2015. [Google Scholar]

- DIN EN 60584-1; Thermocouples–Part 1: EMF Specifications and Tolerances. Beuth: Berlin, Germany, 2014.

- Grabmann, S.; Mayr, L.; Kick, M.K.; Zaeh, M.F. Enhancing laser-based contacting of aluminum current collector foils for the production of lithium-ion batteries using a nanosecond pulsed fiber laser. Procedia CIRP 2022, 111, 778–783. [Google Scholar] [CrossRef]

| Electrode | Part | Material | Size in mm³ | Quantity | Supplier |

|---|---|---|---|---|---|

| cathode | arrester bars | EN AW-1050A 1 | 80 × 2 × 1 | 2 | Korff AG 4 |

| carrier foils | EN AW-1050A 1 | 75 × 0.015 × 60 | 30 | Korff AG 4 | |

| anode | arrester bars | Cu-ETP 2 | 80 × 2 × 1 | 2 | KME Mansfeld GmbH 5 |

| carrier foils | Cu-PHC 3 | 75 × 0.010 × 60 | 30 | Schlenk AG 6 |

| Testing and Evaluation Methods with Descriptions in Appendix B | Evaluation Criteria | |

|---|---|---|

| R1 | visual inspection of the weld (Appendix B.1) | no welding defects |

| R2 | visual inspection during the welding process (Appendix B.1) | no detached particles |

| R3 | statistical analysis of the data of four identical spot welding experiments: topography (Appendix B.2) and process variables (Appendix B.3) | no trend, low standard deviations (SD) and low coefficients of variation (CV) 1 |

| R4 | visual inspection of the workpiece (Appendix B.2) | no loose and/or no ripped foils |

| R5 | measurement of the maximum temperatures surrounding the weld area (Appendix B.4) | < 90 °C 2 |

| R6 | measurement of the electrical resistances of the weld samples Rw, Al and Rw, Cu (Appendix B.5) | low electrical resistances Rw, Al and Rw, Cu 3 |

| R7 | mechanical testing of single welded foils: measurement of maximum tensile forces Fw, Al and Fw, Cu (Appendix B.6) | high maximum tensile forces Fw, Al and Fw, Cu 3 |

| R8 | welding times tweld per spot welding experiment (Appendix B.7) | tweld < 0.3 s (USW) or 1 s (LBW) 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sigl, M.E.; Grabmann, S.; Kick, L.-F.; Zens, A.; Hartl, R.; Zaeh, M.F. Cell-Internal Contacting of Prismatic Lithium-Ion Batteries Using Micro-Friction Stir Spot Welding. Batteries 2022, 8, 174. https://doi.org/10.3390/batteries8100174

Sigl ME, Grabmann S, Kick L-F, Zens A, Hartl R, Zaeh MF. Cell-Internal Contacting of Prismatic Lithium-Ion Batteries Using Micro-Friction Stir Spot Welding. Batteries. 2022; 8(10):174. https://doi.org/10.3390/batteries8100174

Chicago/Turabian StyleSigl, Martina E., Sophie Grabmann, Luca-Felix Kick, Amanda Zens, Roman Hartl, and Michael F. Zaeh. 2022. "Cell-Internal Contacting of Prismatic Lithium-Ion Batteries Using Micro-Friction Stir Spot Welding" Batteries 8, no. 10: 174. https://doi.org/10.3390/batteries8100174

APA StyleSigl, M. E., Grabmann, S., Kick, L.-F., Zens, A., Hartl, R., & Zaeh, M. F. (2022). Cell-Internal Contacting of Prismatic Lithium-Ion Batteries Using Micro-Friction Stir Spot Welding. Batteries, 8(10), 174. https://doi.org/10.3390/batteries8100174