State-of-Health Estimation of Lithium-Ion Battery Based on Constant Voltage Charging Duration

Abstract

:1. Introduction

- (1)

- Thoroughly delving into the abundant data about battery health found in the durations of CV charging and suggesting the implementation of CV charging duration statistics as indicators of battery health. A new health feature combination consists of CV charging durations, the Shannon entropy of the CV charging duration sequence, and the Shannon entropy of the CV charging duration variation sequence. The empirical evidence confirms that the suggested combination of features brings about an elevation in the accuracy of SOH estimation, enabling a more accurate estimation of the battery health status.

- (2)

- This study is completely dependent on the CV charging phase to extract features without being influenced by the initial charging point, adapting it for a wider array of application scenarios. In addition, when compared to relaxation phase feature combinations that necessitate lengthy idle periods, the precision of an SOH estimation is notably enhanced with the employment of the feature combination postulated in this paper.

2. Experimental Data Processing

2.1. Introduction to the Dataset

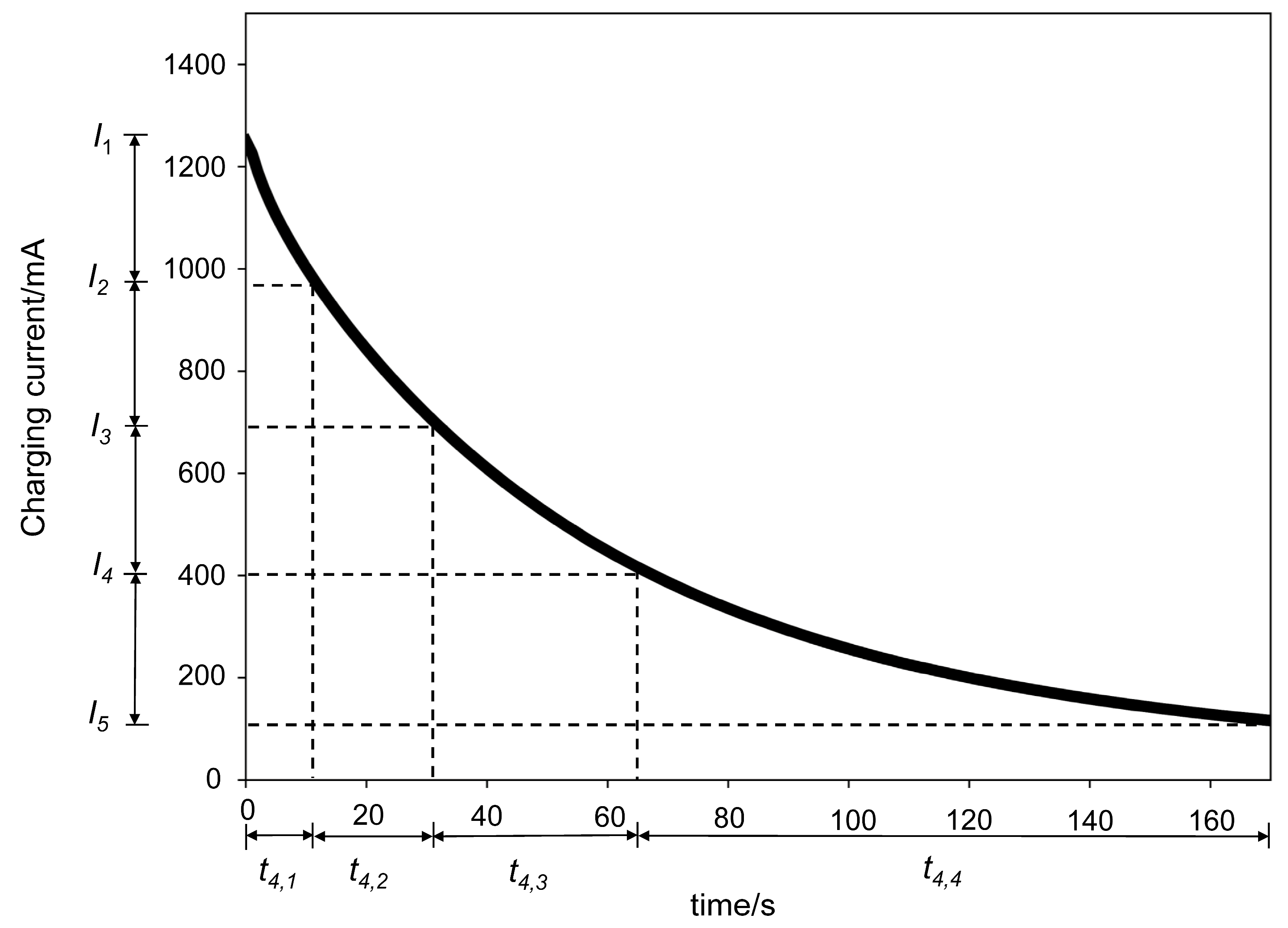

2.2. Feature Extraction

2.2.1. Data Preprocessing

2.2.2. Feature Analysis

2.2.3. Feature Correlation Analysis

3. Methodology

3.1. Mathematical Model of Elastic Net Regression

3.2. SOH Estimation Method Based on Elastic Net Regression Model

- (1)

- Data preprocessing: remove outliers, convert capacity to the SOH defined by capacity, and standardize the dataset.

- (2)

- Dataset construction: allocate the estimation dataset as a training set and a test set on a per-battery basis, with a 1:1 ratio of training batteries to test batteries.

- (3)

- Define input and output: use , , and as model inputs, with the corresponding SOH data as model output.

- (4)

- Set model hyperparameters: set the Elastic Net regression model parameters with the best regularization coefficient as 0.00001, and the Elastic Net mixing parameter as 0.1, representing a combination of L1 and L2 regularization penalties.

- (5)

- Train and test the SOH estimation model, and reverse standardize the output results.

4. Analysis of Experimental Results

4.1. Evaluation Metrics

4.2. Comparison with Other Similar Features

4.2.1. Comparison Experiment with Other Similar Features under the Same Condition

4.2.2. Comparison Experiment with Other Similar Features under the Cross Condition

4.3. Comparison with Relaxation Features

4.3.1. Comparison Experiment with Relaxation Features under the Same Condition

4.3.2. Comparison Experiment with Relaxation Features under the Cross Condition

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bayani, R.; Soofi, A.F.; Waseem, M.; Manshadi, S.D. Impact of Transportation Electrification on the Electricity Grid—A Review. Vehicles 2022, 4, 1042–1079. [Google Scholar] [CrossRef]

- Nguyen, R.T.; Eggert, R.G.; Severson, M.H.; Anderson, C.G. Global Electrification of Vehicles and Intertwined Material Supply Chains of Cobalt, Copper and Nickel. Resour. Conserv. Recycl. 2021, 167, 105198. [Google Scholar] [CrossRef]

- Gabbar, H.; Othman, A.; Abdussami, M. Review of Battery Management Systems (BMS) Development and Industrial Standards. Technologies 2021, 9, 28. [Google Scholar] [CrossRef]

- Cunanan, C.; Tran, M.-K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A Review of Heavy-Duty Vehicle Powertrain Technologies: Diesel Engine Vehicles, Battery Electric Vehicles, and Hydrogen Fuel Cell Electric Vehicles. Clean Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Ajanovic, A.; Glatt, A.; Haas, R. Prospects and Impediments for Hydrogen Fuel Cell Buses. Energy 2021, 235, 121340. [Google Scholar] [CrossRef]

- Mo, T.; Li, Y.; Lau, K.-T.; Poon, C.K.; Wu, Y.; Luo, Y. Trends and Emerging Technologies for the Development of Electric Vehicles. Energies 2022, 15, 6271. [Google Scholar] [CrossRef]

- Karki, A.; Phuyal, S.; Tuladhar, D.; Basnet, S.; Shrestha, B. Status of Pure Electric Vehicle Power Train Technology and Future Prospects. Appl. Syst. Innov. 2020, 3, 35. [Google Scholar] [CrossRef]

- Ho, J.C.; Huang, Y.-H.S. Evaluation of Electric Vehicle Power Technologies: Integration of Technological Performance and Market Preference. Clean. Responsible Consum. 2022, 5, 100063. [Google Scholar] [CrossRef]

- Miranda, J.P.D.; Barros, L.A.M.; Pinto, J.G. A Review on Power Electronic Converters for Modular BMS with Active Balancing. Energies 2023, 16, 3255. [Google Scholar] [CrossRef]

- Calearo, L.; Ziras, C.; Thingvad, A.; Marinelli, M. Agnostic Battery Management System Capacity Estimation for Electric Vehicles. Energies 2022, 15, 9656. [Google Scholar] [CrossRef]

- Rottoli, M.; Dirnaichner, A.; Pietzcker, R.; Schreyer, F.; Luderer, G. Alternative Electrification Pathways for Light-Duty Vehicles in the European Transport Sector. Transp. Res. D Transp. Environ. 2021, 99, 103005. [Google Scholar] [CrossRef]

- Lawder, M.T.; Suthar, B.; Northrop, P.W.C.; De, S.; Hoff, C.M.; Leitermann, O.; Crow, M.L.; Santhanagopalan, S.; Subramanian, V.R. Battery Energy Storage System (BESS) and Battery Management System (BMS) for Grid-Scale Applications. Proc. IEEE Inst. Electr. Electron. Eng. 2014, 102, 1014–1030. [Google Scholar] [CrossRef]

- Si, J.; Tang, Y.; Li, X.; Zhang, L. Comprehensive Reliability Assessment Method for Lithium Battery Energy Storage Systems. J. Phys. Conf. Ser. 2023, 2474, 012009. [Google Scholar] [CrossRef]

- Urquizo, J.; Singh, P. A Review of Health Estimation Methods for Lithium-Ion Batteries in Electric Vehicles and Their Relevance for Battery Energy Storage Systems. J. Energy Storage 2023, 73, 109194. [Google Scholar] [CrossRef]

- Gismero, A.; Nørregaard, K.; Johnsen, B.; Stenhøj, L.; Stroe, D.-I.; Schaltz, E. Electric Vehicle Battery State of Health Estimation Using Incremental Capacity Analysis. J. Energy Storage 2023, 64, 107110. [Google Scholar] [CrossRef]

- Meng, J.; Cai, L.; Stroe, D.-I.; Ma, J.; Luo, G.; Teodorescu, R. An Optimized Ensemble Learning Framework for Lithium-Ion Battery State of Health Estimation in Energy Storage System. Energy 2020, 206, 118140. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Liu, Y.; Sun, F.; Qiao, J.; Xu, T. Review on Degradation Mechanism and Health State Estimation Methods of Lithium-Ion Batteries. J. Traffic Transp. Eng. 2023, 10, 578–610. [Google Scholar] [CrossRef]

- Ren, Z.; Du, C. A Review of Machine Learning State-of-Charge and State-of-Health Estimation Algorithms for Lithium-Ion Batteries. Energy Rep. 2023, 9, 2993–3021. [Google Scholar] [CrossRef]

- Zhu, G.; Kong, C.; Wang, J.V.; Kang, J.; Wang, Q.; Qian, C. A Fractional-Order Electrochemical Lithium-Ion Batteries Model Considering Electrolyte Polarization and Aging Mechanism for State of Health Estimation. J. Energy Storage 2023, 72, 108649. [Google Scholar] [CrossRef]

- Liu, B.; Tang, X.; Gao, F. Joint Estimation of Battery State-of-Charge and State-of-Health Based on a Simplified Pseudo-Two-Dimensional Model. Electrochim. Acta 2020, 344, 136098. [Google Scholar] [CrossRef]

- Vennam, G.; Sahoo, A. A Dynamic SOH-Coupled Lithium-Ion Cell Model for State and Parameter Estimation. IEEE Trans. Energy Convers. 2023, 38, 1186–1196. [Google Scholar] [CrossRef]

- Amir, S.; Gulzar, M.; Tarar, M.O.; Naqvi, I.H.; Zaffar, N.A.; Pecht, M.G. Dynamic Equivalent Circuit Model to Estimate State-of-Health of Lithium-Ion Batteries. IEEE Access 2022, 10, 18279–18288. [Google Scholar] [CrossRef]

- Çarkıt, T.; Alçı, M. Investigation of Voc and SoH on Li-Ion Batteries with an Electrical Equivalent Circuit Model Using Optimization Algorithms. Electr. Eng. 2022, 1–12. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, P.; Gong, Q.; Cheng, Z. SOH Estimation of Lithium-Ion Batteries Based on Least Squares Support Vector Machine Error Compensation Model. J. Power Electron. 2021, 21, 1712–1723. [Google Scholar] [CrossRef]

- Singh, P.; Chen, C.; Tan, C.M.; Huang, S.-C. Semi-Empirical Capacity Fading Model for SoH Estimation of Li-Ion Batteries. Appl. Sci. 2019, 9, 3012. [Google Scholar] [CrossRef]

- Kheirkhah-Rad, E.; Moeini-Aghtaie, M. A Novel Data-Driven SOH Prediction Model for Lithium-Ion Batteries. In Proceedings of the 2021 31st Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 26–30 September 2021. [Google Scholar] [CrossRef]

- Xiong, W.; Mo, Y.; Yan, C. Online State-of-Health Estimation for Second-Use Lithium-Ion Batteries Based on Weighted Least Squares Support Vector Machine. IEEE Access 2021, 9, 1870–1881. [Google Scholar] [CrossRef]

- Aggab, T.; Avila, M.; Vrignat, P.; Kratz, F. Unifying Model-Based Prognosis with Learning-Based Time-Series Prediction Methods: Application to Li-Ion Battery. IEEE Syst. J. 2021, 15, 5245–5254. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, N.; Ji, Y.; Niu, M.; Wang, Y. Lithium-Ion Batteries Remaining Useful Life Prediction Based on BLS-RVM. Energy 2021, 234, 121269. [Google Scholar] [CrossRef]

- Heinrich, F.; Pruckner, M. Virtual Experiments for Battery State of Health Estimation Based on Neural Networks and In-Vehicle Data. J. Energy Storage 2022, 48, 103856. [Google Scholar] [CrossRef]

- Liu, Q.; Kang, Y.; Qu, S.; Duan, B.; Wen, F.; Zhang, C. An Online SOH Estimation Method Based on the Fusion of Improved ICA and LSTM. In Proceedings of the 2020 IEEE/IAS Industrial and Commercial Power System Asia (I&CPS Asia), Weihai, China, 13–15 July 2020; pp. 1163–1167. [Google Scholar] [CrossRef]

- Ma, Y.; Shan, C.; Gao, J.; Chen, H. A Novel Method for State of Health Estimation of Lithium-Ion Batteries Based on Improved LSTM and Health Indicators Extraction. Energy 2022, 251, 123973. [Google Scholar] [CrossRef]

- Wang, J.; Deng, Z.; Yu, T.; Yoshida, A.; Xu, L.; Guan, G.; Abudula, A. State of Health Estimation Based on Modified Gaussian Process Regression for Lithium-Ion Batteries. J. Energy Storage 2022, 51, 104512. [Google Scholar] [CrossRef]

- He, Y.-J.; Shen, J.-N.; Shen, J.-F.; Ma, Z.-F. State of Health Estimation of Lithium-Ion Batteries: A Multiscale Gaussian Process Regression Modeling Approach. AIChE J. 2015, 61, 1589–1600. [Google Scholar] [CrossRef]

- Fan, Y.; Xiao, F.; Li, C.; Yang, G.; Tang, X. A Novel Deep Learning Framework for State of Health Estimation of Lithium-Ion Battery. J. Energy Storage 2020, 32, 101741. [Google Scholar] [CrossRef]

- He, W.; Li, Z.; Liu, T.; Liu, Z.; Guo, X.; Du, J.; Li, X.; Sun, P.; Ming, W. Research Progress and Application of Deep Learning in Remaining Useful Life, State of Health and Battery Thermal Management of Lithium Batteries. J. Energy Storage 2023, 70, 107868. [Google Scholar] [CrossRef]

- Pózna, A.I.; Hangos, K.M.; Magyar, A. Design of Experiments for Battery Aging Estimation. IFAC-PapersOnLine 2018, 51, 386–391. [Google Scholar] [CrossRef]

- Gong, D.; Gao, Y.; Kou, Y.; Wang, Y. State of Health Estimation for Lithium-Ion Battery Based on Energy Features. Energy 2022, 257, 124812. [Google Scholar] [CrossRef]

- Guo, P.; Cheng, Z.; Yang, L. A Data-Driven Remaining Capacity Estimation Approach for Lithium-Ion Batteries Based on Charging Health Feature Extraction. J. Power Sources 2019, 412, 442–450. [Google Scholar] [CrossRef]

- Ghosh, N.; Garg, A.; Warnecke, A.; Panigrahi, B.K. State of Health Estimation of Lithium-Ion Batteries for Dynamic Driving Profiles Based on Feature Extraction from Battery Relaxation Time Using Machine Learning. In Proceedings of the IECON 2022—48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022. [Google Scholar] [CrossRef]

- Baghdadi, I.; Briat, O.; Gyan, P.; Vinassa, J.M. State of Health Assessment for Lithium Batteries Based on Voltage–Time Relaxation Measure. Electrochim. Acta 2016, 194, 461–472. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Y.; Huang, Y.; Bhushan Gopaluni, R.; Cao, Y.; Heere, M.; Mühlbauer, M.J.; Mereacre, L.; Dai, H.; Liu, X.; et al. Data-Driven Capacity Estimation of Commercial Lithium-Ion Batteries from Voltage Relaxation. Nat. Commun. 2022, 13, 2261. [Google Scholar] [CrossRef]

- Yang, J.; Li, X.; Sun, X.; Cai, Y.; Mi, C. An Efficient and Robust Method for Lithium-Ion Battery Capacity Estimation Using Constant-Voltage Charging Time. Energy 2023, 263, 125743. [Google Scholar] [CrossRef]

- Wang, Z.; Zeng, S.; Guo, J.; Qin, T. State of Health Estimation of Lithium-Ion Batteries Based on the Constant Voltage Charging Curve. Energy 2019, 167, 661–669. [Google Scholar] [CrossRef]

- Yang, J.; Cai, Y.; Mi, C.C. State-of-Health Estimation for Lithium-Ion Batteries Based on Decoupled Dynamic Characteristic of Constant-Voltage Charging Current. IEEE Trans. Transp. Electrif. 2022, 8, 2070–2079. [Google Scholar] [CrossRef]

- Yun, Z.; Qin, W. Remaining Useful Life Estimation of Lithium-Ion Batteries Based on Optimal Time Series Health Indicator. IEEE Access 2020, 8, 55447–55461. [Google Scholar] [CrossRef]

- Pan, W.; Chen, Q.; Zhu, M.; Tang, J.; Wang, J. A Data-Driven Fuzzy Information Granulation Approach for Battery State of Health Forecasting. J. Power Sources 2020, 475, 228716. [Google Scholar] [CrossRef]

- Qiu, Y.; Cao, W.; Peng, P.; Jiang, F. A Novel Entropy-Based Fault Diagnosis and Inconsistency Evaluation Approach for Lithium-Ion Battery Energy Storage Systems. J. Energy Storage 2021, 41, 102852. [Google Scholar] [CrossRef]

- Zhang, Z.; Lai, Z.; Xu, Y.; Shao, L.; Wu, J.; Xie, G.-S. Discriminative Elastic-Net Regularized Linear Regression. IEEE Trans. Image Process. 2017, 26, 1466–1481. [Google Scholar] [CrossRef]

- Scarpelli, C.; Gazzarri, J.; Huria, T.; Lutzemberger, G.; Ceraolo, M. Neural Network for the Estimation of LFP Battery SOH Cycled at Different Power Levels. J. Energy Storage 2023, 66, 107027. [Google Scholar] [CrossRef]

| Dataset | Charge Voltage—Discharge Voltage (V) | Capacity in Ampere-Hours (Ah) | Cycle Temperature (°C) | Charge Current/Discharge Current Multiplier |

|---|---|---|---|---|

| NCA | 4.2–2.65 | 3.5 | 25 | 0.25/1 |

| 0.5/1 | ||||

| 1/1 | ||||

| 35 | 0.5/1 | |||

| 45 | 0.5/1 | |||

| NCM | 4.2–2.5 | 3.5 | 25 | 0.5/1 |

| 35 | 0.5/1 | |||

| 45 | 0.5/1 | |||

| NCM + NCA | 4.2–2.5 | 2.5 | 25 | 0.5/1 |

| 0.5/2 | ||||

| 0.5/4 |

| Feature | Pearson’s Correlation |

|---|---|

| Tcv | −0.99 |

| Tsha | 0.96 |

| Tsha2 | 0.97 |

| Condition | Tcv, Tsha, Tsha2 | Only Tcv | Only Tsha | Only Tsha2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MAE/% | RMSE/% | R2 | MAE/% | RMSE/% | R2 | MAE/% | RMSE/% | R2 | MAE/% | RMSE/% | R2 | |

| Condition 1 | 0.38 | 0.53 | 0.97 | 1.14 | 1.69 | 0.72 | 0.45 | 0.60 | 0.96 | 3.07 | 3.38 | −0.14 |

| Condition 2 | 1.08 | 1.19 | 0.96 | 2.31 | 2.42 | 0.84 | 3.82 | 4.19 | 0.53 | 1.68 | 2.47 | 0.84 |

| Condition 3 | 0.33 | 0.50 | 0.99 | 0.50 | 0.71 | 0.98 | 0.63 | 1.00 | 0.96 | 1.54 | 2.35 | 0.78 |

| Condition 4 | 0.45 | 0.63 | 1.00 | 0.70 | 0.84 | 0.99 | 2.28 | 2.67 | 0.92 | 1.99 | 2.33 | 0.94 |

| Condition 5 | 0.62 | 0.82 | 0.99 | 1.06 | 1.25 | 0.98 | 2.46 | 3.06 | 0.89 | 1.63 | 2.00 | 0.96 |

| Cross Condition | 0.98 | 1.20 | 0.98 | 1.09 | 1.35 | 0.98 | 2.52 | 3.04 | 0.89 | 2.03 | 2.48 | 0.93 |

| Overall Mean | 0.64 | 0.81 | 0.98 | 1.13 | 1.38 | 0.92 | 2.03 | 2.43 | 0.86 | 1.99 | 2.50 | 0.72 |

| Condition | Tcv, Tsha, Tsha2 | Tcv, Tsha | Tcv, Tsha2 | Tsha, Tsha2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MAE/% | RMSE/% | R2 | MAE/% | RMSE/% | R2 | MAE/% | RMSE/% | R2 | MAE/% | RMSE/% | R2 | |

| Condition 1 | 0.38 | 0.53 | 0.97 | 0.68 | 0.92 | 0.92 | 0.56 | 0.79 | 0.94 | 0.45 | 0.60 | 0.96 |

| Condition 2 | 1.08 | 1.19 | 0.96 | 1.18 | 1.29 | 0.96 | 2.46 | 2.55 | 0.82 | 1.51 | 2.32 | 0.85 |

| Condition 3 | 0.33 | 0.50 | 0.99 | 0.40 | 0.53 | 0.99 | 0.33 | 0.52 | 0.99 | 0.51 | 0.71 | 0.98 |

| Condition 4 | 0.45 | 0.63 | 1.00 | 0.45 | 0.63 | 1.00 | 0.55 | 0.73 | 0.99 | 2.01 | 2.42 | 0.93 |

| Condition 5 | 0.62 | 0.82 | 0.99 | 0.62 | 0.82 | 0.99 | 1.01 | 1.24 | 0.98 | 1.46 | 1.76 | 0.97 |

| Cross Condition | 0.98 | 1.20 | 0.98 | 1.00 | 1.22 | 0.98 | 1.12 | 1.37 | 0.98 | 2.03 | 2.52 | 0.93 |

| Overall Mean | 0.64 | 0.81 | 0.98 | 0.72 | 0.90 | 0.97 | 1.01 | 1.20 | 0.95 | 1.33 | 1.72 | 0.94 |

| Condition | (Tcv, Tsha, Tsha2) | (Var, Ske, Max) | ||||

|---|---|---|---|---|---|---|

| MAE/% | RMSE/% | R2 | MAE/% | RMSE/% | R2 | |

| Condition 1 | 0.38 | 0.53 | 0.97 | 0.63 | 0.87 | 0.93 |

| Condition 2 | 1.08 | 1.19 | 0.96 | 1.82 | 2.45 | 0.84 |

| Condition 3 | 0.33 | 0.50 | 0.99 | 0.79 | 0.93 | 0.97 |

| Condition 4 | 0.45 | 0.63 | 1.00 | 0.72 | 0.87 | 0.99 |

| Condition 5 | 0.62 | 0.82 | 0.99 | 1.17 | 1.28 | 0.98 |

| Cross Condition | 0.98 | 1.20 | 0.98 | 1.38 | 1.83 | 0.96 |

| Overall Mean Value | 0.64 | 0.81 | 0.98 | 1.09 | 1.37 | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Chen, D.; Han, X.; Li, Z.; Zhang, W.; Lai, C.S. State-of-Health Estimation of Lithium-Ion Battery Based on Constant Voltage Charging Duration. Batteries 2023, 9, 565. https://doi.org/10.3390/batteries9120565

Chen J, Chen D, Han X, Li Z, Zhang W, Lai CS. State-of-Health Estimation of Lithium-Ion Battery Based on Constant Voltage Charging Duration. Batteries. 2023; 9(12):565. https://doi.org/10.3390/batteries9120565

Chicago/Turabian StyleChen, Jinyu, Dawei Chen, Xiaolan Han, Zhicheng Li, Weijun Zhang, and Chun Sing Lai. 2023. "State-of-Health Estimation of Lithium-Ion Battery Based on Constant Voltage Charging Duration" Batteries 9, no. 12: 565. https://doi.org/10.3390/batteries9120565

APA StyleChen, J., Chen, D., Han, X., Li, Z., Zhang, W., & Lai, C. S. (2023). State-of-Health Estimation of Lithium-Ion Battery Based on Constant Voltage Charging Duration. Batteries, 9(12), 565. https://doi.org/10.3390/batteries9120565