Author Contributions

Conceptualization, M.A.H. and M.K.H.; methodology, M.A.H.; software, A.H.; validation, M.A.H., M.K.H. and M.O.T.; formal analysis, M.A.H.; investigation, M.A.H.; resources, A.H.; data curation, A.H.; writing—original draft preparation, M.A.H.; writing—review and editing, M.K.H. and M.O.T.; supervision, M.K.H.; project administration, A.H.; funding acquisition, M.K.H. All authors have read and agreed to the published version of the manuscript.

Figure 1.

FNN lifetime battery degradation prediction model. The input battery data are detonated by = [, , , where , , represent the time, current and the voltage at time step . The estimated is the output of the FNN at each time step .

Figure 1.

FNN lifetime battery degradation prediction model. The input battery data are detonated by = [, , , where , , represent the time, current and the voltage at time step . The estimated is the output of the FNN at each time step .

Figure 2.

LSTM cell structure in RNN degradation network. Where and are the input layer state at current time step , and hidden layer state at past time step . , , , and are input, forget, memory cell, and output gate.

Figure 2.

LSTM cell structure in RNN degradation network. Where and are the input layer state at current time step , and hidden layer state at past time step . , , , and are input, forget, memory cell, and output gate.

Figure 3.

Flowchart of the battery cycle life test for 500 cycles. In this configuration, one cycle consists of charging the battery to its highest voltage of 4.2 V and then discharging it to its minimum value of 2.75 V.

Figure 3.

Flowchart of the battery cycle life test for 500 cycles. In this configuration, one cycle consists of charging the battery to its highest voltage of 4.2 V and then discharging it to its minimum value of 2.75 V.

Figure 4.

Test bench for battery cell testing comprising a host computer, Neware (BTS4000), TCP/IP PORT, an air conditioner, and the internet.

Figure 4.

Test bench for battery cell testing comprising a host computer, Neware (BTS4000), TCP/IP PORT, an air conditioner, and the internet.

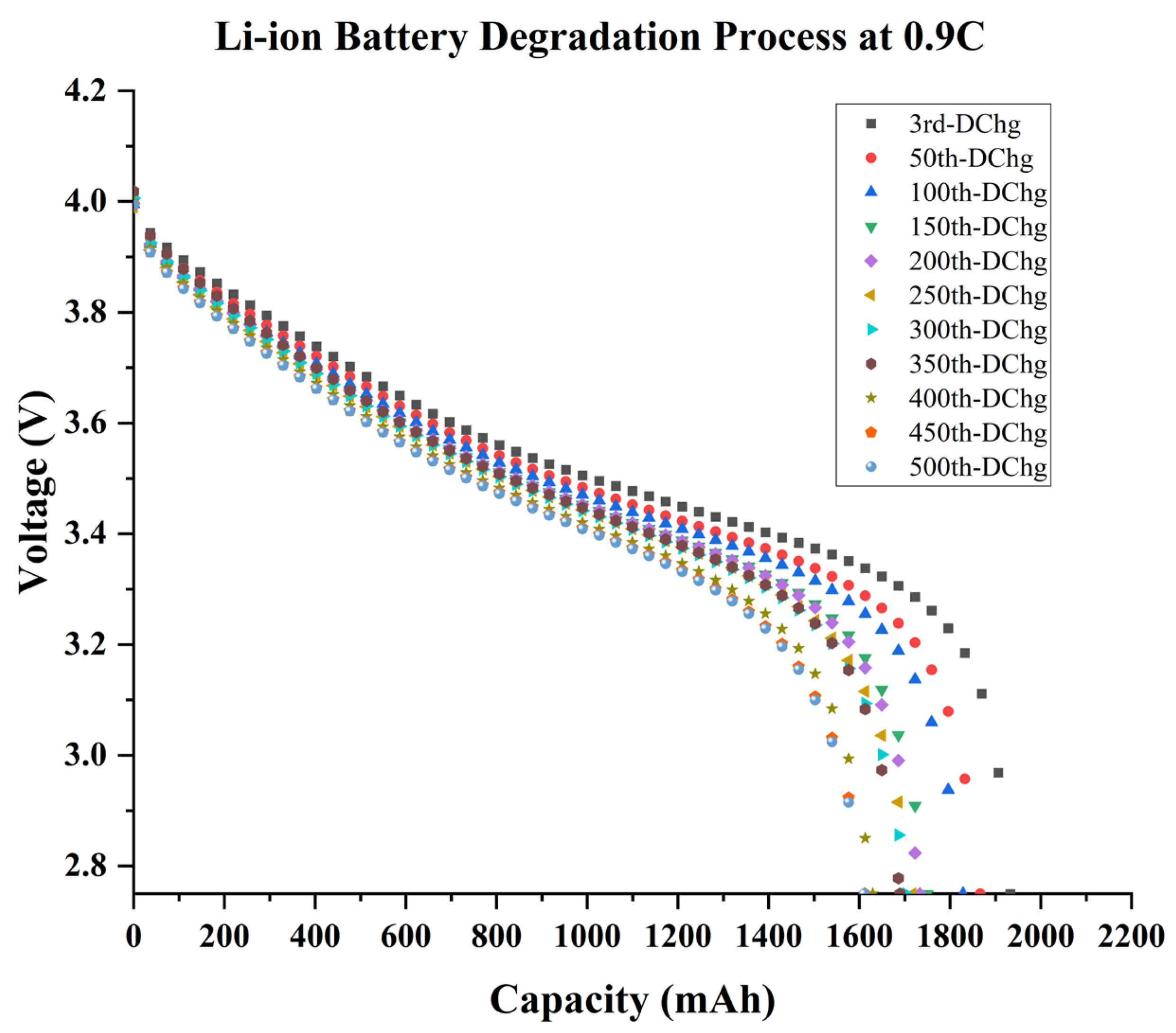

Figure 5.

The battery degradation process at 0.9 C-rate for 500 cycles, where degradation is shown every 50 cycles.

Figure 5.

The battery degradation process at 0.9 C-rate for 500 cycles, where degradation is shown every 50 cycles.

Figure 6.

The battery degradation process at 1.3 C-rate for 500 cycles, where degradation is displayed every 50 cycles.

Figure 6.

The battery degradation process at 1.3 C-rate for 500 cycles, where degradation is displayed every 50 cycles.

Figure 7.

The battery degradation process at 1.6 C-rate for 500 cycles, where degradation is shown every 50 cycles.

Figure 7.

The battery degradation process at 1.6 C-rate for 500 cycles, where degradation is shown every 50 cycles.

Figure 8.

Comparison of battery degradation model performance with experimental and simulated data for individual battery capacity fades at 0.9C, 1.3C, and 1.6C.

Figure 8.

Comparison of battery degradation model performance with experimental and simulated data for individual battery capacity fades at 0.9C, 1.3C, and 1.6C.

Figure 9.

Selection of the permanent hidden layer with the FNN network based on the least-error values MAE (%), MSE (%) and RMSE (%) at hidden layers ranged from (3–10).

Figure 9.

Selection of the permanent hidden layer with the FNN network based on the least-error values MAE (%), MSE (%) and RMSE (%) at hidden layers ranged from (3–10).

Figure 10.

The MAE (%), MSE (%), and RMSE (%) values, achieved with the FNN degradation model at three different accelerated discharging rates: 0.9C, 1.3C, and 1.6C.

Figure 10.

The MAE (%), MSE (%), and RMSE (%) values, achieved with the FNN degradation model at three different accelerated discharging rates: 0.9C, 1.3C, and 1.6C.

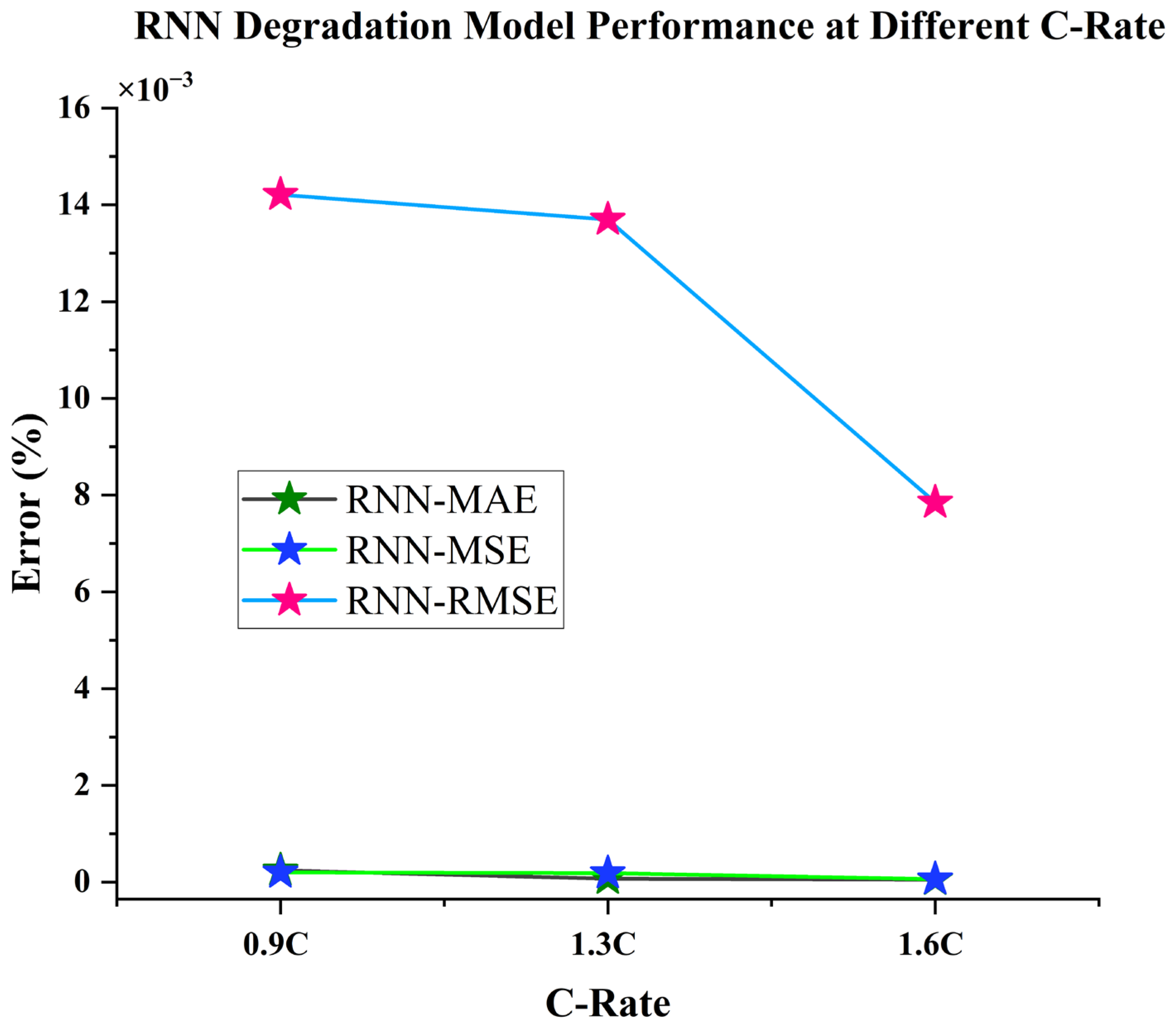

Figure 11.

The performance of the RNN degradation model based on the MAE (%), MSE (%), and RMSE (%) values at 3 separate accelerated discharge rates: 0.9C, 1.3C, and 1.6C.

Figure 11.

The performance of the RNN degradation model based on the MAE (%), MSE (%), and RMSE (%) values at 3 separate accelerated discharge rates: 0.9C, 1.3C, and 1.6C.

Figure 12.

Comparison of the performance of RNN and FNN degradation models at 3 separate accelerated discharge rates: 0.9C, 1.3C, and 1.6C on the basis of MAE (%), MSE (%), and RMSE (%) values.

Figure 12.

Comparison of the performance of RNN and FNN degradation models at 3 separate accelerated discharge rates: 0.9C, 1.3C, and 1.6C on the basis of MAE (%), MSE (%), and RMSE (%) values.

Table 1.

Battery specification of A18650 model of Hongli Li-ion battery.

Table 1.

Battery specification of A18650 model of Hongli Li-ion battery.

| Battery Parameter | Specification |

|---|

| Cell Voltage | 3.7 V |

| Nominal Capacity | 2200 mAh |

| Max Voltage | 4.2 V |

| Min Voltage | 2.5 V |

| Energy | 8.14 Wh |

Table 2.

Neware battery tester BTS4000 equipment specification.

Table 2.

Neware battery tester BTS4000 equipment specification.

| Cycling Builder | NEWARE BTS4000 |

|---|

| Cycling tester rating | 5 V/6 A |

| Test Channels | 0–8 |

| Accuracy | ≥1% |

| Sample frequency | 10 Hz |

Table 3.

The degree of capacity fade at 0.9C, 1.3C, and 1.6C for every 50 cycles throughout its lifetime.

Table 3.

The degree of capacity fade at 0.9C, 1.3C, and 1.6C for every 50 cycles throughout its lifetime.

| Cycle Number | Capacity Fade (%) |

|---|

| | 0.9C | 1.3C | 1.6C |

|---|

| 50 | 4.08 | 1.98 | 6.25 |

| 100 | 4.94 | 4.33 | 20.78 |

| 150 | 8.46 | 11.34 | 35.59 |

| 200 | 10.43 | 14.25 | 60.87 |

| 250 | 10.57 | 22.51 | 72.23 |

| 300 | 11.38 | 27.12 | - |

| 350 | 13.39 | 32.84 | - |

| 400 | 13.49 | 36.82 | - |

| 450 | 14.07 | 41.31 | - |

| 500 | 15.14 | 45.05 | - |

Table 4.

The MAE, MSE, and RMSE values with the hidden layers ranged between (3–10).

Table 4.

The MAE, MSE, and RMSE values with the hidden layers ranged between (3–10).

| N.H. Layers | MAE | MSE | RMSE |

|---|

| 3 | 2.26 × 10−8 | 1.43 × 10−8 | 1.92 × 10−4 |

| 4 | 1.21 × 10−6 | 3.12 × 10−4 | 1.76 × 10−4 |

| 5 | 1.64 × 10−7 | 1.45 × 10−5 | 3.84 × 10−3 |

| 6 | 1.54 × 10−9 | 4.51 × 10−8 | 2.12 × 10−4 |

| 7 | 1.67 × 10−8 | 9.92 × 10−8 | 3.15 × 10−4 |

| 8 | 1.31 × 10−9 | 8.17 × 10−9 | 9.04 × 10−5 |

| 9 | 5.14 × 10−9 | 2.77 × 10−6 | 1.01 × 10−3 |

| 10 | 4.98 × 10−9 | 4.91 × 10−9 | 1.67 × 10−3 |

Table 5.

FNN degradation model performance based on MAE, MSE, and RMSE values at various discharge rates: 0.9C, 1.3C, and 1.6C.

Table 5.

FNN degradation model performance based on MAE, MSE, and RMSE values at various discharge rates: 0.9C, 1.3C, and 1.6C.

| C-Rate | MAE | MSE | RMSE |

|---|

| 0.9C | 2.12 × 10−4 | 3.17 × 10−4 | 1.78 × 10−2 |

| 1.3C | 1.12 × 10−4 | 1.62 × 10−4 | 1.27 × 10−2 |

| 1.6C | 4.49 × 10−5 | 1.04 × 10−4 | 1.02 × 10−2 |

Table 6.

RNN degradation model performance based on MAE, MSE, and RMSE values at various discharge rates: 0.9C, 1.3C, and 1.6C.

Table 6.

RNN degradation model performance based on MAE, MSE, and RMSE values at various discharge rates: 0.9C, 1.3C, and 1.6C.

| C-Rate | MAE | MSE | RMSE |

|---|

| 0.9C | 2.44 × 10−4 | 2.02 × 10−4 | 1.42 × 10−2 |

| 1.3C | 7.03 × 10−5 | 1.88 × 10−4 | 1.37 × 10−2 |

| 1.6C | 5.27 × 10−5 | 6.16 × 10−5 | 7.85 × 10−3 |