Experimental Investigation of State and Parameter Estimation within Reconfigurable Battery Systems

Abstract

:1. Introduction

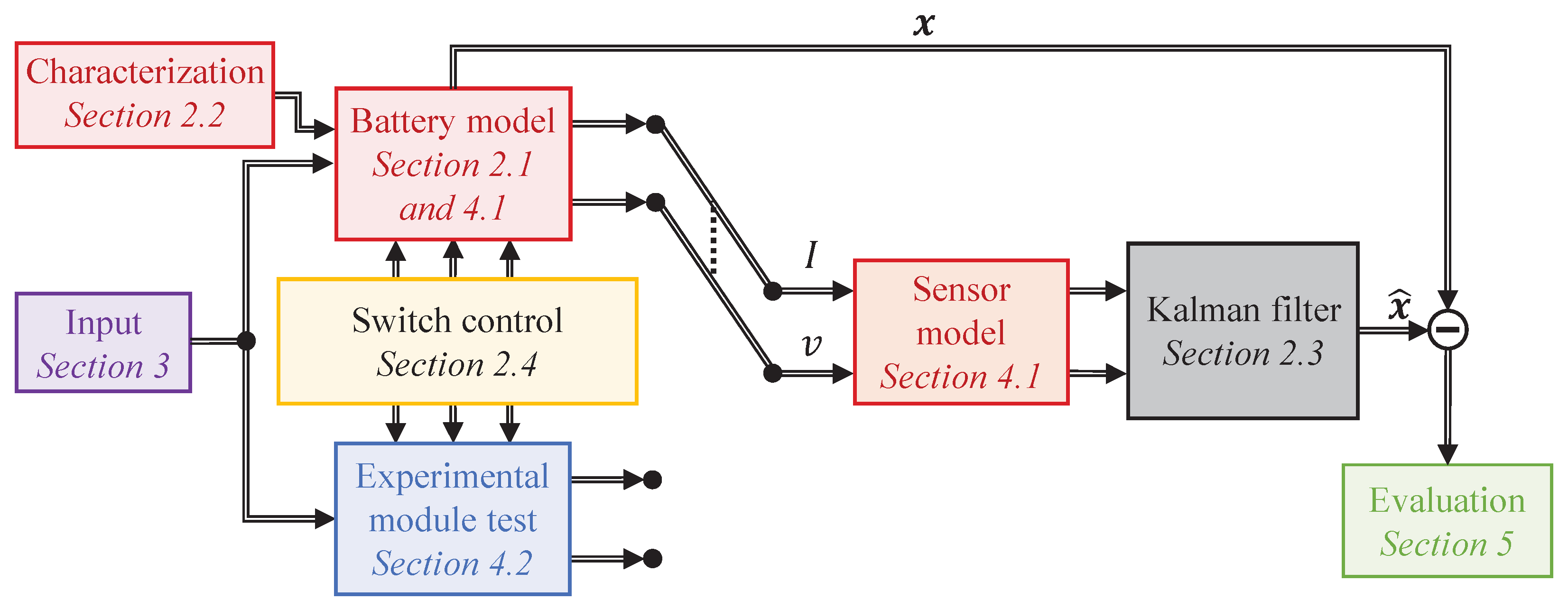

2. Enhanced State and Parameter Estimation

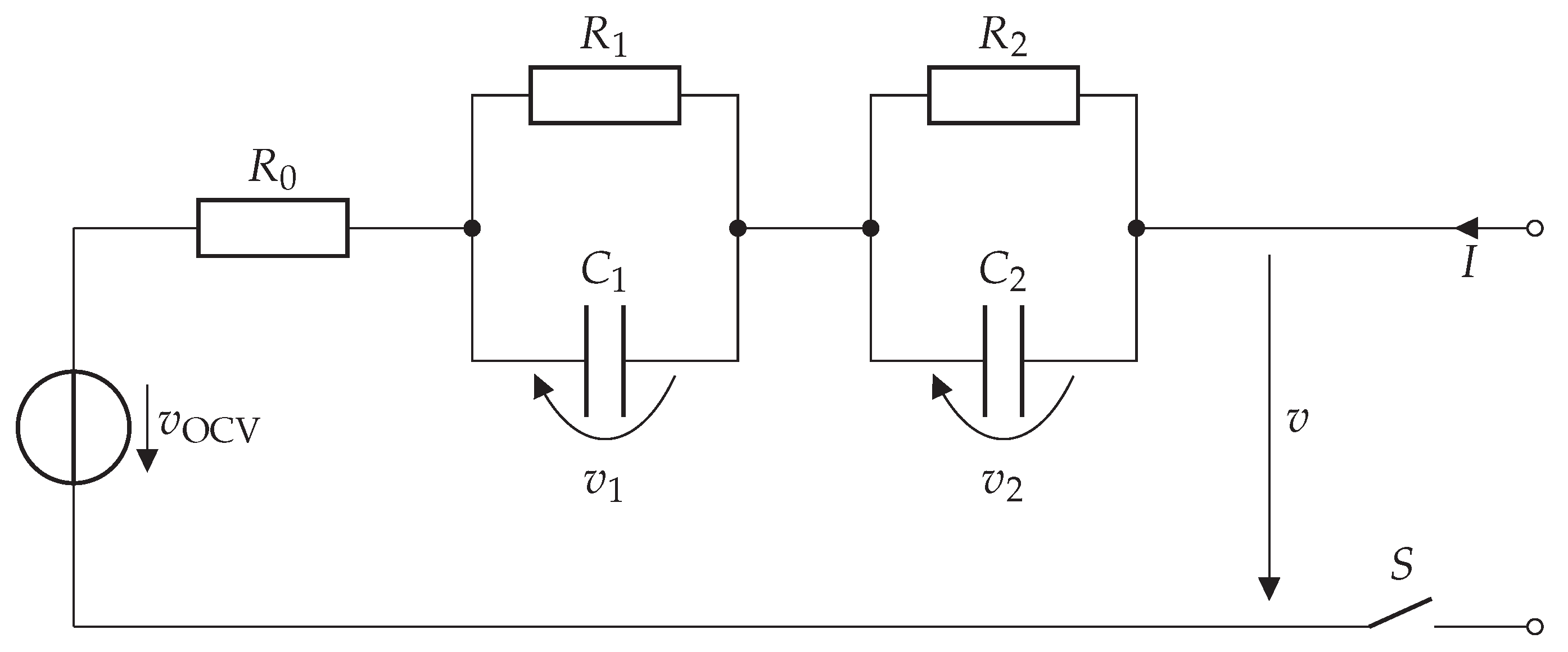

2.1. Battery Model

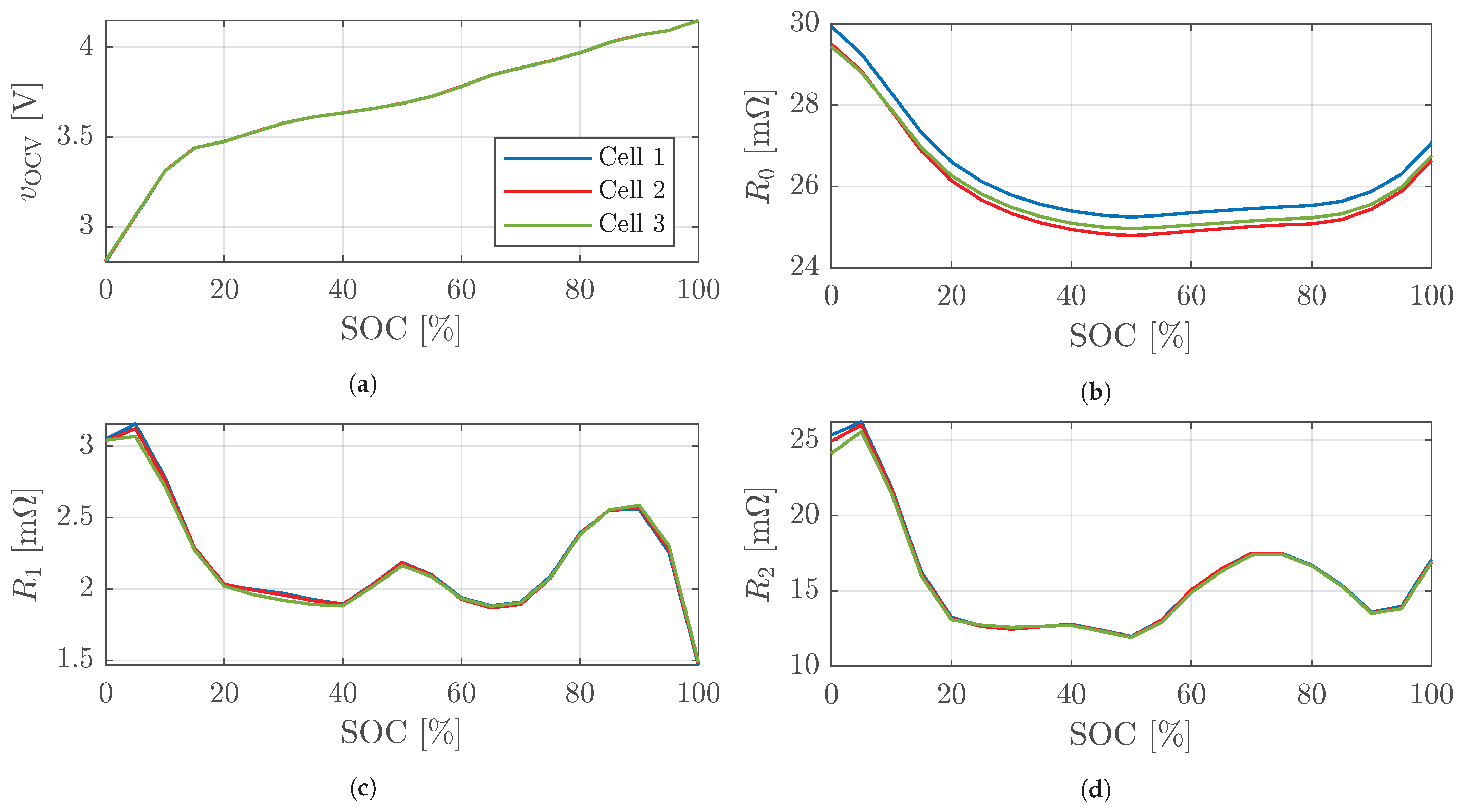

2.2. Cell characterization

2.3. Kalman Filtering

| Algorithm 1 Extended Kalman filter. |

|

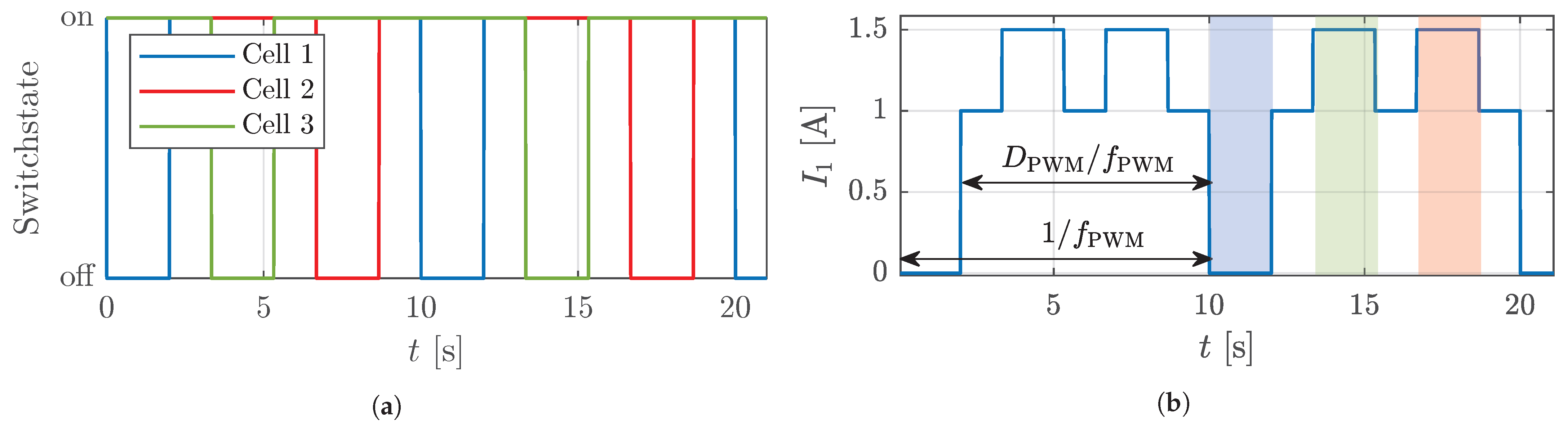

2.4. Switching

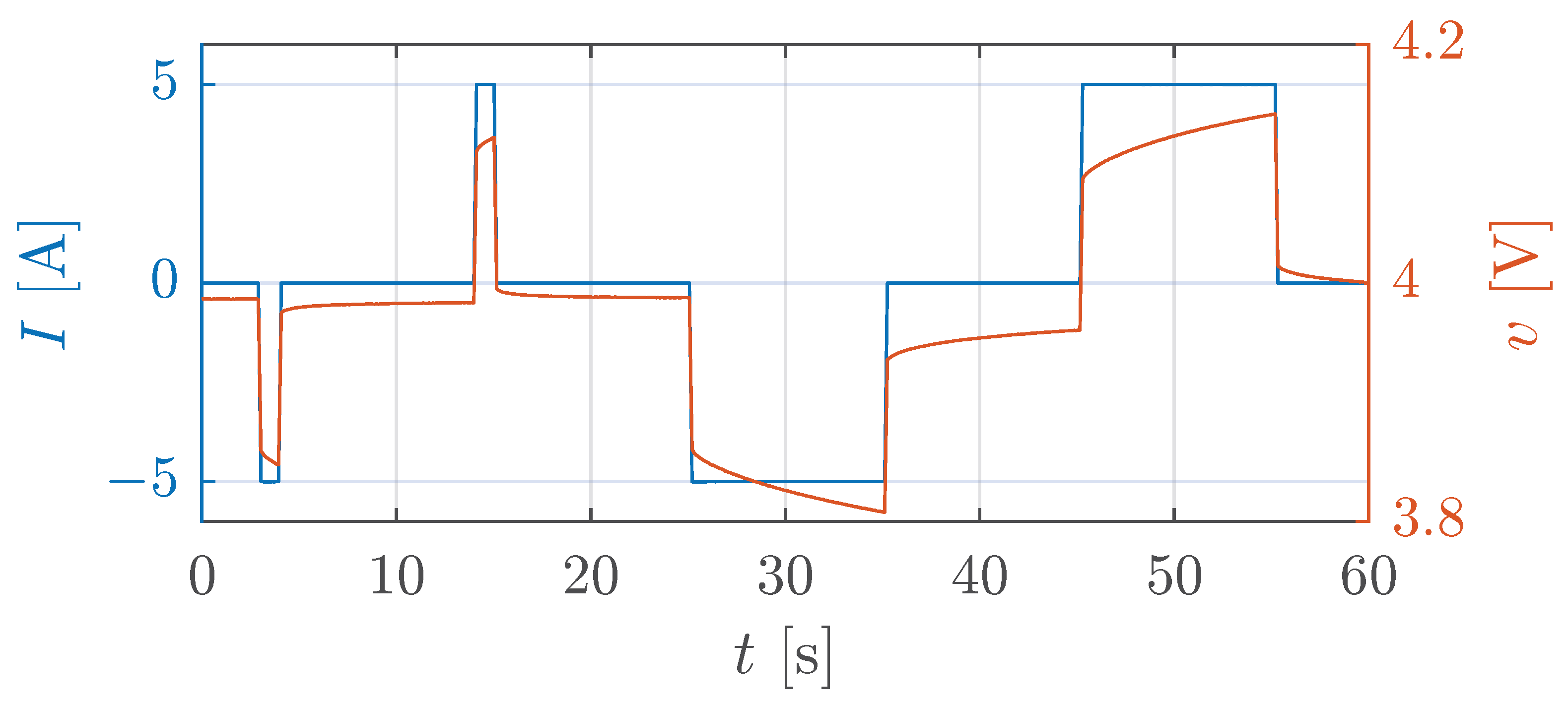

3. Input Signal Analysis

4. Implementation

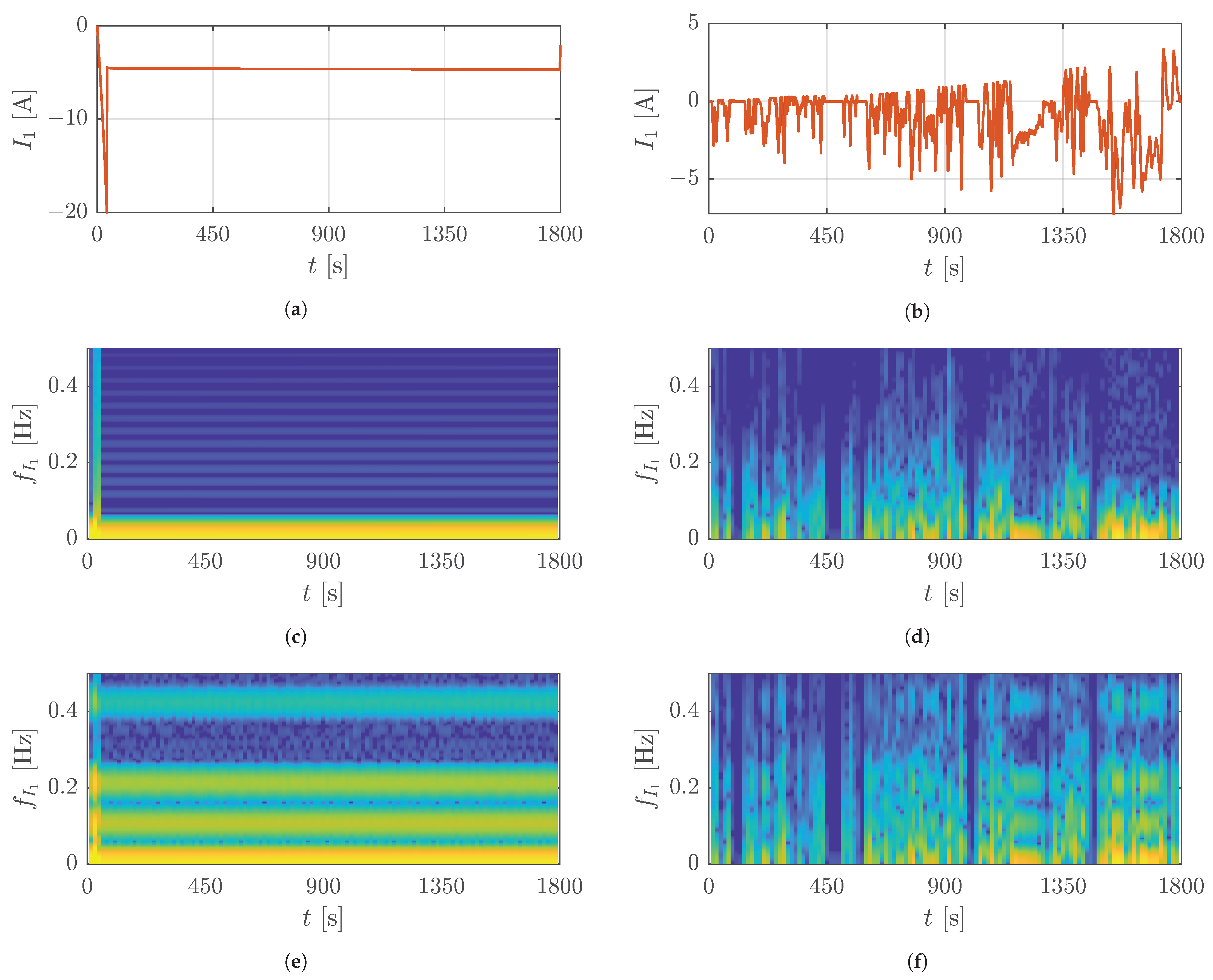

4.1. Simulation

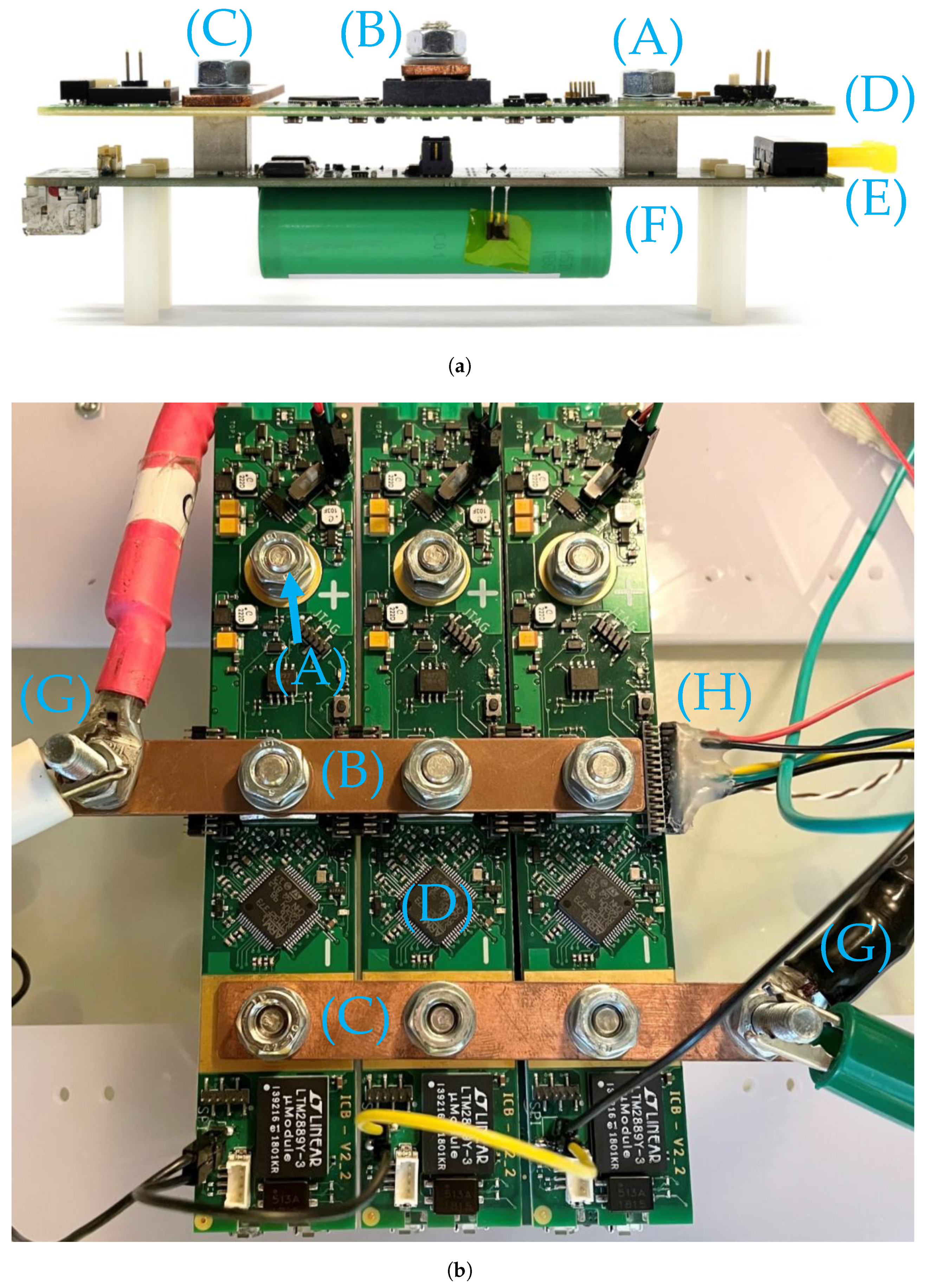

4.2. Experimental Section

5. Results and Discussion

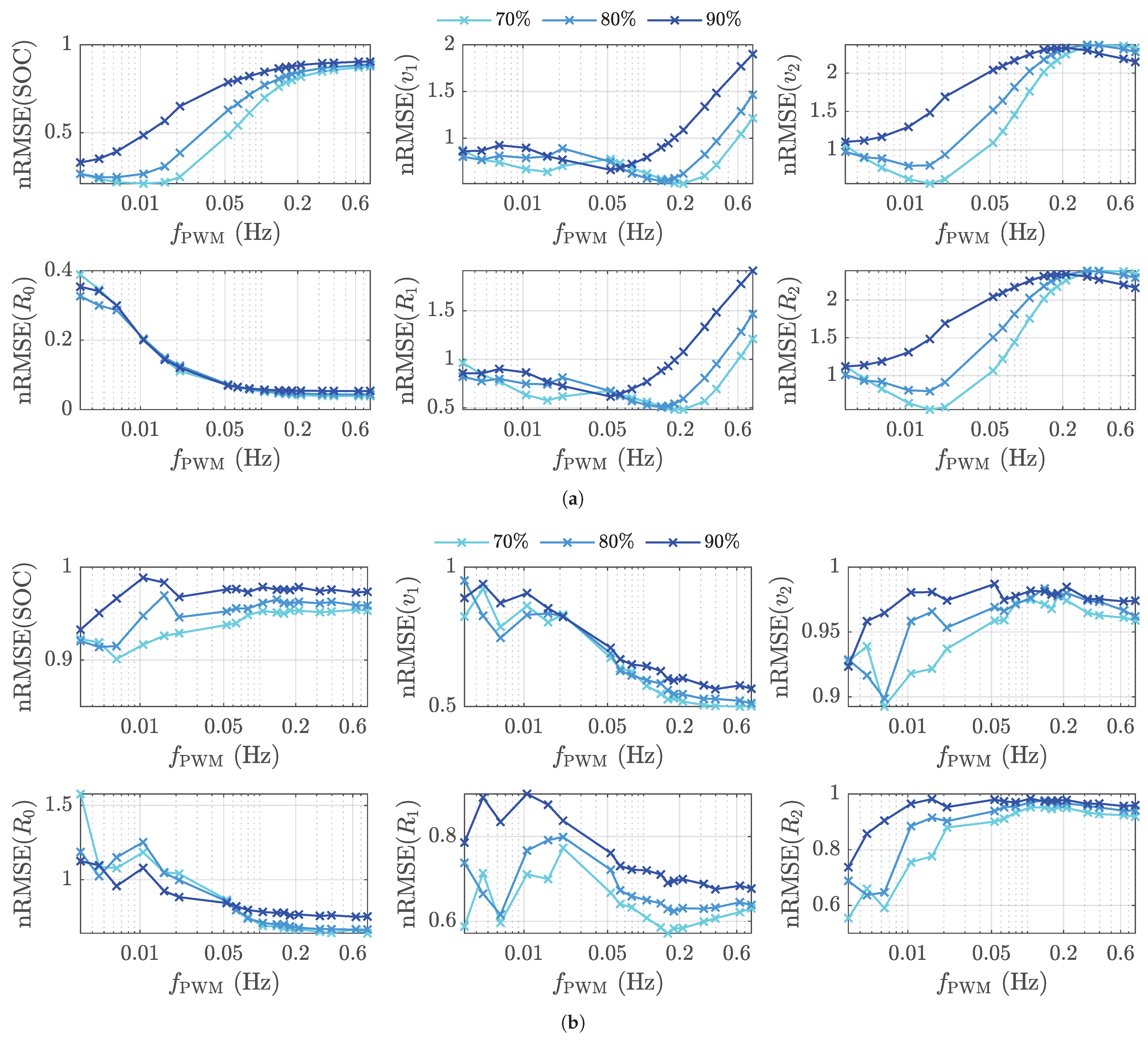

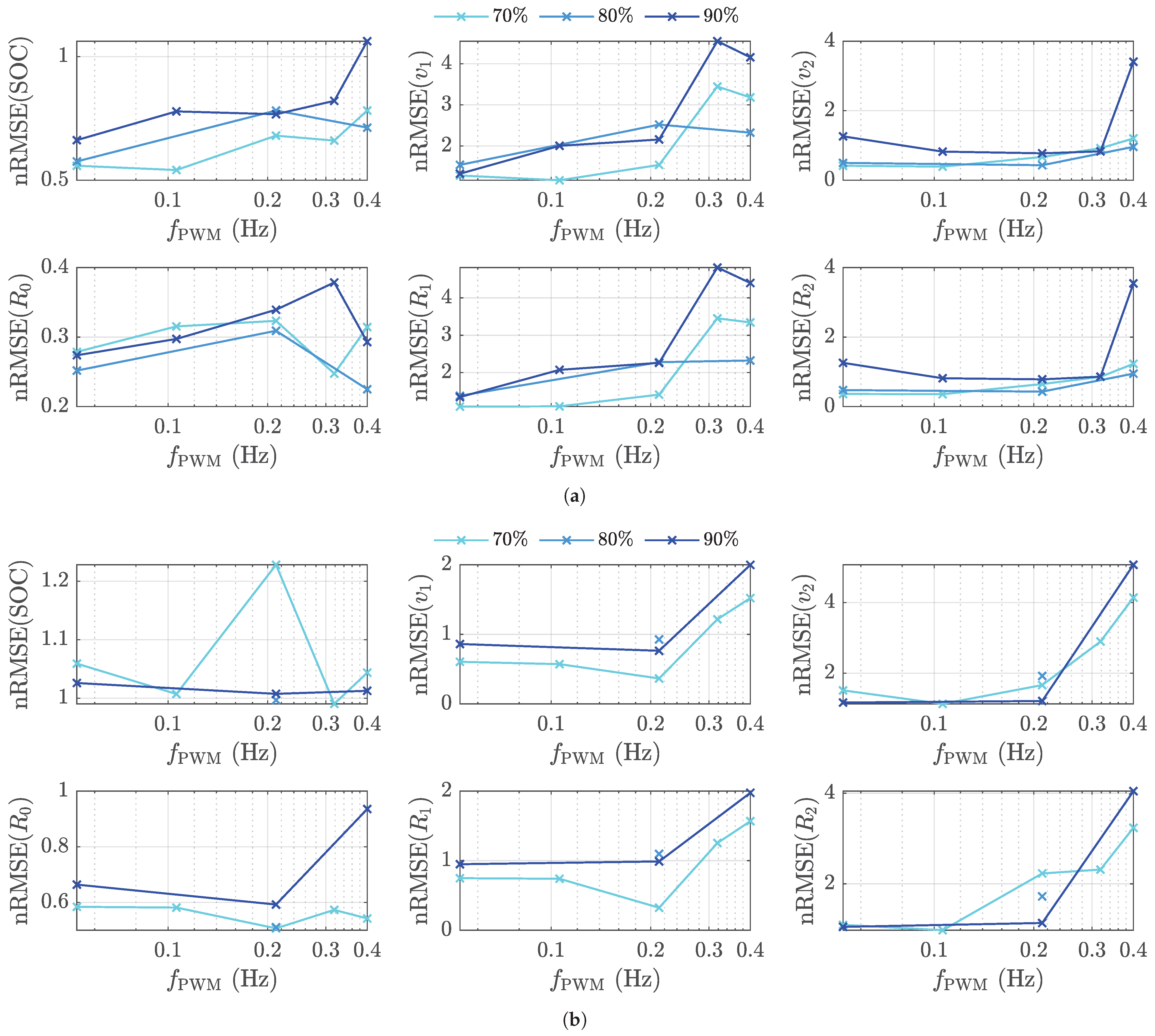

5.1. Simulation

5.2. Experimental Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BEV | Battery electric vehicle |

| BMS | Battery management system |

| CCCV | Constant current/constant voltage |

| DST | Dynamic stress test |

| ECM | Equivalent circuit model |

| EKF | Extended Kalman filter |

| HPPC | Hybrid pulse power characterization |

| nRMSE | Normalized root-mean-squared error |

| OCV | Open-circuit voltage |

| PRBS | Pseudo-random binary sequence |

| PWM | Pulse-width modulation |

| RBS | Reconfigurable battery system |

| RC | Resistor–capacitor |

| RMS | Root mean square |

| RMSE | Root-mean-squared error |

| SISO | Single-input, single-output |

| SOC | State of charge |

| SOH | State of health |

| UDDS | Urban Dynamometer Driving Schedule |

| WLTP | Worldwide Harmonized Light-Duty Vehicles Test Procedure |

| Nomenclature | |

| State-space system matrix | |

| State-space input matrix | |

| Capacity of the RC elements (F) | |

| State-space output matrix | |

| D | State-space feed-through scalar |

| Duty cycle of the PWM signal (%) | |

| f | Nonlinear system function |

| Frequency of the PWM signal (Hz) | |

| h | Nonlinear measurement function |

| I | Cell current (A) |

| Identity matrix | |

| k | Time step |

| K | Number of time steps |

| Kalman gain | |

| State covariance matrix | |

| Process noise | |

| Process noise covariance matrix | |

| r | Measurement noise |

| R | Measurement noise covariance |

| Internal resistance () | |

| Resistance of the RC elements () | |

| S | Switch |

| SOC | State of charge (%) |

| Time the cell is disconnected (s) | |

| u | State-space input |

| v | Terminal voltage (V) |

| Voltage of the RC elements (V) | |

| Open circuit voltage (V) | |

| State-space parameter vector | |

| State-space state vector | |

| State-space measurement | |

| Step size (s) | |

| Coulombic efficiency | |

| Standard deviation of the current (A) | |

| Standard deviation of the voltage (V) | |

| Time constant of the RC elements (s) | |

| Real numbers | |

| Expectation | |

| Diagonal matrix | |

| Transpose | |

| Estimation |

References

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J. A review on prognostics and health monitoring of Li-ion battery. J. Power Sources 2011, 196, 6007–6014. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; van Mierlo, J.; van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Rivera-Barrera, J.; Muñoz-Galeano, N.; Sarmiento-Maldonado, H. SoC Estimation for Lithium-ion Batteries: Review and Future Challenges. Electronics 2017, 6, 102. [Google Scholar] [CrossRef] [Green Version]

- Adaikkappan, M.; Sathiyamoorthy, N. Modeling, state of charge estimation, and charging of lithium–ion battery in electric vehicle: A review. Int. J. Energy Res. 2021, 46, 2141–2165. [Google Scholar] [CrossRef]

- Wang, Q.; Kang, J.; Tan, Z.; Luo, M. An online method to simultaneously identify the parameters and estimate states for lithium ion batteries. Electrochim. Acta 2018, 289, 376–388. [Google Scholar] [CrossRef]

- Wang, S.L.; Fernandez, C.; Cao, W.; Zou, C.Y.; Yu, C.M.; Li, X.X. An adaptive working state iterative calculation method of the power battery by using the improved Kalman filtering algorithm and considering the relaxation effect. J. Power Sources 2019, 428, 67–75. [Google Scholar] [CrossRef]

- Yang, R.; Xiong, R.; He, H.; Mu, H.; Wang, C. A novel method on estimating the degradation and state of charge of lithium-ion batteries used for electrical vehicles. Appl. Energy 2017, 207, 336–345. [Google Scholar] [CrossRef]

- Tian, Y.; Lai, R.; Li, X.; Xiang, L.; Tian, J. A combined method for state-of-charge estimation for lithium-ion batteries using a long short-term memory network and an adaptive cubature Kalman filter. Appl. Energy 2020, 265, 114789. [Google Scholar] [CrossRef]

- Plett, G.L. Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs: Part 2. Modeling and identification. J. Power Sources 2004, 134, 262–276. [Google Scholar] [CrossRef]

- Kim, I.S. The novel state of charge estimation method for lithium battery using sliding mode observer. J. Power Sources 2006, 163, 584–590. [Google Scholar] [CrossRef]

- Meng, J.; Boukhnifer, M.; Diallo, D.; Wang, T. A New Cascaded Framework for Lithium-Ion Battery State and Parameter Estimation. Appl. Sci. 2020, 10, 1009. [Google Scholar] [CrossRef] [Green Version]

- Schneider, D.; Liebhart, B.; Endisch, C. Active state and parameter estimation as part of intelligent battery systems. J. Energy Storage 2021, 39, 102638. [Google Scholar] [CrossRef]

- Nejad, S.; Gladwin, D.T.; Stone, D.A. A hybrid battery parameter identification concept for lithium-ion energy storage applications. In Proceedings of the IECON 2016-42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 1980–1985. [Google Scholar] [CrossRef] [Green Version]

- Wei, Z.; Zhao, J.; He, H.; Ding, G.; Cui, H.; Liu, L. Future smart battery and management: Advanced sensing from external to embedded multi-dimensional measurement. J. Power Sources 2021, 489, 229462. [Google Scholar] [CrossRef]

- Komsiyska, L.; Buchberger, T.; Diehl, S.; Ehrensberger, M.; Hanzl, C.; Hartmann, C.; Hölzle, M.; Kleiner, J.; Lewerenz, M.; Liebhart, B.; et al. Critical Review of Intelligent Battery Systems: Challenges, Implementation and Potential for Electric Vehicles. Energies 2021, 14, 5989. [Google Scholar] [CrossRef]

- Bouchhima, N.; Schnierle, M.; Schulte, S.; Birke, K.P. Active model-based balancing strategy for self-reconfigurable batteries. J. Power Sources 2016, 322, 129–137. [Google Scholar] [CrossRef]

- Schmid, M.; Gebauer, E.; Hanzl, C.; Endisch, C. Active Model-Based Fault Diagnosis in Reconfigurable Battery Systems. IEEE Trans. Power Electron. 2021, 36, 2584–2597. [Google Scholar] [CrossRef]

- Rodriguez, J.; Lai, J.S.; Peng, F.Z. Multilevel inverters: A survey of topologies, controls, and applications. IEEE Trans. Ind. Electron. 2002, 49, 724–738. [Google Scholar] [CrossRef] [Green Version]

- Lain, M.J.; Brandon, J.; Kendrick, E. Design Strategies for High Power vs. High Energy Lithium Ion Cells. Batteries 2019, 5, 64. [Google Scholar] [CrossRef] [Green Version]

- Schmid, M.; Vögele, U.; Endisch, C. A novel matrix-vector-based framework for modeling and simulation of electric vehicle battery packs. J. Energy Storage 2020, 32, 101736. [Google Scholar] [CrossRef]

- Yang, J.; Xia, B.; Shang, Y.; Huang, W.; Mi, C.C. Adaptive State-of-Charge Estimation Based on a Split Battery Model for Electric Vehicle Applications. IEEE Trans. Veh. Technol. 2017, 66, 10889–10898. [Google Scholar] [CrossRef]

- Bar-Shalom, Y.; Li, X.R.; Kirubarajan, T. Estimation with Applications to Tracking and Navigation: Theory Algorithms and Software; John Wiley & Sons, Inc.: New York, NY, USA, 2001. [Google Scholar] [CrossRef]

- Theiler, M.; Schneider, D.; Endisch, C. Kalman Filter Tuning Using Multi-Objective Genetic Algorithm for State and Parameter Estimation of Lithium-Ion Cells. Batteries 2022, 8, 104. [Google Scholar] [CrossRef]

- Schneider, D.; Liebhart, B.; Endisch, C.; Kennel, R. Enhanced State and Parameter Estimation within Reconfigurable Battery Systems for Electric Vehicles. In Proceedings of the 2022 12th International Conference on Power, Energy and Electrical Engineering (CPEEE), Shiga, Japan, 25–27 February 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 71–77. [Google Scholar] [CrossRef]

- Juang, L.W.; Kollmeyer, P.J.; Anders, A.E.; Jahns, T.M.; Lorenz, R.D.; Gao, D. Investigation of the influence of superimposed AC current on lithium-ion battery aging using statistical design of experiments. J. Energy Storage 2017, 11, 93–103. [Google Scholar] [CrossRef]

- Ngaleu, G.; Theiler, M.; Straßer, X.; Hanzl, C.; Komsiyska, L.; Endisch, C.; Lewerenz, M. Influence of Switching on the Aging of High Power Lithium-Ion Cells. Batteries 2022, 8, 33. [Google Scholar] [CrossRef]

| Manufacturer | Samsung |

|---|---|

| Type | INR18650-25R |

| Format | 18650 |

| Chemistry | NCA/graphite |

| Charge cut-off voltage | V |

| Discharge cut-off voltage | V |

| Maximum constant charge current | A |

| Maximum constant discharge current | A |

| Nominal voltage | V |

| Nominal capacity @ C | Ah |

| Energy density | 216 Wh/kg |

| Power density | 1.7 kW/kg |

| mHz | ×∘ | × | ×∘ |

| mHz | ×∘ | × | |

| mHz | ×∘ | ×∘ | ×∘ |

| mHz | ×∘ | × | |

| mHz | ×∘ | × | ×∘ |

| Quantity | SOC | |||||

|---|---|---|---|---|---|---|

| WLTP | 0.90 | 0.50 | 0.89 | 0.64 | 0.57 | 0.55 |

| Highway | 0.21 | 0.51 | 0.56 | 0.04 | 0.48 | 0.55 |

| Quantity | SOC | |||||

|---|---|---|---|---|---|---|

| WLTP | 0.99 | 0.37 | 1.13 | 0.51 | 0.32 | 0.98 |

| Highway | 0.54 | 1.17 | 0.38 | 0.22 | 1.10 | 0.36 |

| Passive | ||||

|---|---|---|---|---|

| WLTP | A | A | A | A |

| Highway | A | A | A | A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Theiler, M.; Schneider, D.; Endisch, C. Experimental Investigation of State and Parameter Estimation within Reconfigurable Battery Systems. Batteries 2023, 9, 145. https://doi.org/10.3390/batteries9030145

Theiler M, Schneider D, Endisch C. Experimental Investigation of State and Parameter Estimation within Reconfigurable Battery Systems. Batteries. 2023; 9(3):145. https://doi.org/10.3390/batteries9030145

Chicago/Turabian StyleTheiler, Michael, Dominik Schneider, and Christian Endisch. 2023. "Experimental Investigation of State and Parameter Estimation within Reconfigurable Battery Systems" Batteries 9, no. 3: 145. https://doi.org/10.3390/batteries9030145

APA StyleTheiler, M., Schneider, D., & Endisch, C. (2023). Experimental Investigation of State and Parameter Estimation within Reconfigurable Battery Systems. Batteries, 9(3), 145. https://doi.org/10.3390/batteries9030145