Protective Behaviors of Bio-Inspired Honeycomb Column Thin-Walled Structure against RC Slab under Impact Loading

Abstract

:1. Introduction

- BHTS needs to be studied and applied in more depth: the scholars above only made preliminary studies on the performance of BHTS structures and underestimated the strain rate effect of aluminum alloy materials under impact load, and neglected the material failure of aluminum alloy tubes, and did not further study the design structure in actual engineering applications.

- The performance of this lightweight buffer interlayer in RC slabs (Figure 1b) was studied by dropping weight impact model to provide a reliable reference basis for large-scale AM of the BHTS.

2. Materials and Methods

2.1. Design of BHTS

2.2. Test Methods

2.2.1. Low Strain Rate Uniaxial Compression Test

2.2.2. Medium Strain Rate Uniaxial Compression Test

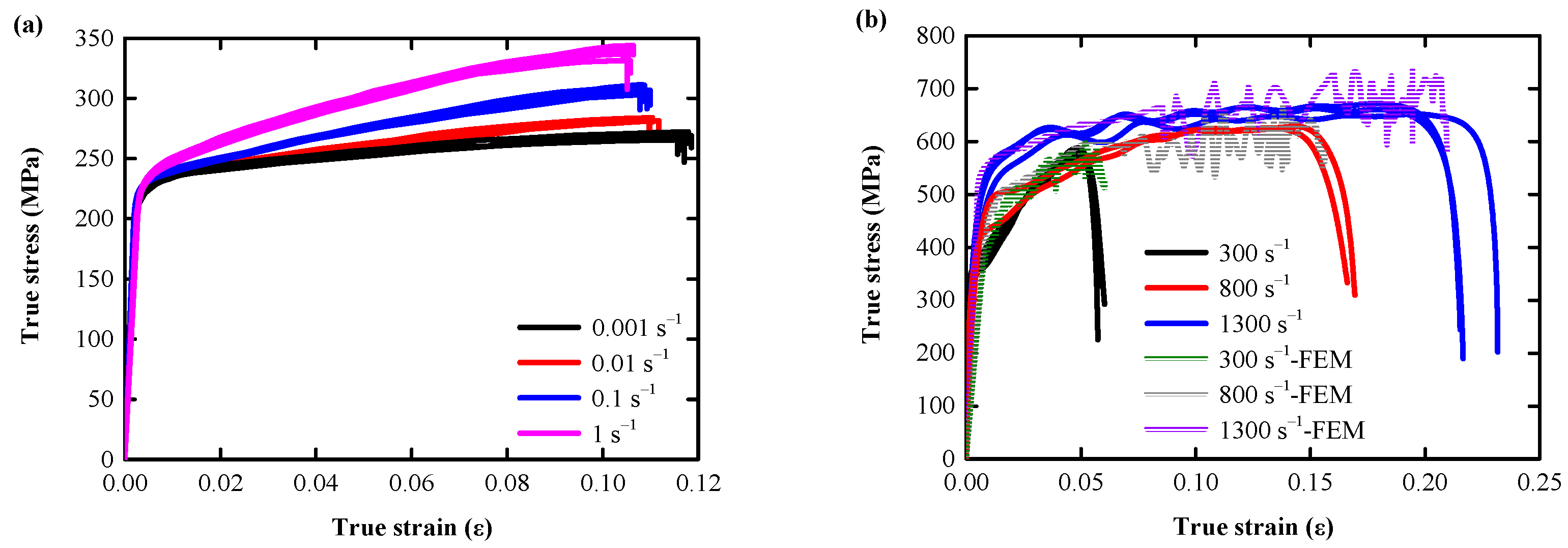

2.3. Mechanical Properties of AlSi10Mg

3. Numerical Simulation

3.1. Constitutive Model of Materials

3.1.1. Concrete Model

3.1.2. Steel Reinforcement Model

3.2. Strain Rate Effect

3.2.1. Concrete

3.2.2. Steel Reinforcement

3.3. Application of Pretightening Force to Concrete Slabs

3.4. Erosion Model for Concrete and Steel Reinforcement Elements

3.5. Numerical Simulation

3.6. Model Validation

3.6.1. Damage Status

3.6.2. Impact Force

3.6.3. Displacement Response

4. Results and Discussion

4.1. Impact Crack Patterns

4.2. Impact Force Response

4.3. Displacement Response

4.4. Energy Consumption

5. Conclusions

- AlSi10Mg is a strain-rate sensitive materials, which has a significant influence on the mechanical behavior of the material and cannot be ignored in numerical simulations;

- The results of the finite element model verification show that it is in good agreement with the experiment, having a reliable reference value, and can be used for subsequent numerical analysis and expansion research;

- The BHTS buffer interlayer can cause the redistribution of the absorbed energy of steel reinforcement and concrete in the RC slab: The average total internal energy proportion of steel reinforcement in the RC slab decreased by 5.56%, and the average decrease amplitude was 66.49%; the average total internal energy proportion of concrete decreased by 65.86%, and the average decrease amplitude was 75.76%.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Su, Y.; Li, J.; Wu, C.; Wu, P.; Li, Z.X. Effects of steel fibres on dynamic strength of UHPC. Constr. Build. Mater. 2016, 114, 708–718. [Google Scholar] [CrossRef]

- Almusallam, T.; Al-Salloum, Y.; Alsayed, S.; Iqbal, R.; Abbas, H. Effect of CFRP strengthening on the response of RC slabs to hard projectile impact. Nucl. Eng. Des. 2015, 286, 211–226. [Google Scholar]

- Siddiqui, N.A.; Khateeb, B.M.; Almusallam, T.H.; Abbas, H. Reliability of double-wall containment against the impact of hard projectiles. Nucl. Eng. Des. 2014, 270, 143–151. [Google Scholar] [CrossRef]

- Yılmaz, T.; Kıraç, N.; Anil, Ö.; Erdem, R.T.; Sezer, C. Low-velocity impact behaviour of two way RC slab strengthening with CFRP strips. Constr. Build. Mater. 2018, 186, 1046–1063. [Google Scholar]

- Liu, J.; Wu, C.; Chen, X. Numerical study of ultra-high performance concrete under non-deformable projectile penetration. Constr. Build. Mater. 2017, 135, 447–458. [Google Scholar]

- YPeng, Y.; Wu, H.; Fang, Q.; Liu, J.Z.; Gong, Z.M. Residual velocities of projectiles after normally perforating the thin ultra-high performance steel fiber reinforced concrete slabs. Int. J. Impact Eng. 2016, 97, 1–9. [Google Scholar]

- Lu, Y.E.; Zhang, L.M. Analysis of failure of a bridge foundation under rock impact. Acta Geotech. 2012, 7, 57–68. [Google Scholar] [CrossRef]

- Pham, T.M.; Elchalakani, M.; Karrech, A.; Hao, H. Axial impact behavior and energy absorption of rubberized concrete with/without fiber-reinforced polymer confinement. Int. J. Prot. Struct. 2019, 10, 154–173. [Google Scholar] [CrossRef]

- Do, T.V.; Pham, T.M.; Gehl, A.; Hao, H.; Nguyen, T.P. Impact Responses of Precast Hollow Reinforced Concrete Beams with Prestress Tendons using High-Fidelity Physics-Based Simulations. Eng. Fail. Anal. 2022, 131, 105850. [Google Scholar] [CrossRef]

- Carta, G.; Stochino, F. Theoretical models to predict the flexural failure of reinforced concrete beams under blast loads. Eng. Struct. 2013, 49, 306–315. [Google Scholar] [CrossRef]

- Pham, T.M.; Chen, W.; Elchalakani, M.; Karrech, A.; Hao, H. Experimental investigation on lightweight rubberized concrete beams strengthened with BFRP sheets subjected to impact loads. Eng. Struct. 2020, 205, 110095. [Google Scholar]

- Wang, Z.Y.; Guo, Q.Q.; Hou, C.C. Numerical study on the ballistic performance of prestressed concrete slabs subjected to hard missile impact. Int. J. Impact Eng. 2022, 168, 104318. [Google Scholar]

- Yılmaz, T.; Anil, Ö.; Erdem, R.T. Experimental and Numerical Investigation of Impact Behavior of RC Slab with Different Opening Size and Layout; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Wang, Z.; Hou, C.; Guo, Q. Numerical Simulation on the Dynamic Response of Bonded Unidirectional Prestressed Concrete Slabs Subjected to low-Velocity Impact. In Structures; Elsevier: Amsterdam, The Netherlands, 2022; Volume 38, pp. 1098–1110. [Google Scholar]

- Al-Rousan, R.Z.; Alhassan, M.A.; Al-Salman, H. Impact resistance of polypropylene fiber reinforced concrete two-way slabs. Struct. Eng. Mech. 2017, 62, 373–380. [Google Scholar]

- Xiao, Y.; Li, B.; Fujikake, K. Behavior of reinforced concrete slabs under low-velocity impact. ACI Struct. J. 2017, 114, 643–658. [Google Scholar] [CrossRef]

- Masuya, H. Impact Problem Concerning Rock Falls and Research Activities of Related Field in Japan. In Proceedings of the 6th Asia-Pacific Conference on Shock & Impact Loads on Structures, Perth, Australia, 7–9 December 2005; pp. 63–70. [Google Scholar]

- Jacquemoud, J. Swiss Guideline for the Design of Protection Galleries: Background, Safety Concept and Case Histories. In Joint Japan-Swiss Scientific Seminar on Impact Load by Rock Falls and Design of Protection Structures; Masuya, H., Labiouse, V., Eds.; Kanazawa University: Ishikawa, Japan, 1999; pp. 95–102. [Google Scholar]

- Volkwein, A.; Schellenberg, K.; Labiouse, V.; Agliardi, F.; Berger, F.; Bourrier, F.; Dorren, L.K.A.; Gerber, W.; Jaboyedoff, M. Rockfall characterisation and structural protection–a review. Nat. Hazards Earth Syst. Sci. 2011, 11, 2617–2651. [Google Scholar]

- Rogala, M.; Gajewski, J.; Gawdzińska, K. Crashworthiness analysis of thin-walled aluminum columns filled with aluminum–silicon carbide composite foam. Compos. Struct. 2022, 299, 116102. [Google Scholar] [CrossRef]

- Rogala, M.; Tuchowski, W.; Czarnecka-Komorowska, D.; Gawdzińska, K. Analysis and Assessment of Aluminum and Aluminum-Ceramic Foams Structure. Adv. Sci. Technol. Res. J. 2022, 16, 287–297. [Google Scholar]

- Yılmaz, T.; Kıraç, N.; Anil, Ö.; Erdem, R.T.; Kaçaran, G. Experimental investigation of impact behaviour of RC slab with different reinforcement ratios. KSCE J. Civ. Eng. 2020, 24, 241–254. [Google Scholar] [CrossRef]

- Xu, X.; Ma, T.; Ning, J. Failure analytical model of reinforced concrete slab under impact loading. Constr. Build. Mater. 2019, 223, 679–691. [Google Scholar] [CrossRef]

- Pham, T.T.; Kurihashi, Y.; Masuya, H. Performance of reinforced concrete beam with cushion subjected to impact loading. Case Stud. Constr. Mater. 2022, 16, e00893. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamnam, S.; Rodsin, K.; Banthia, N. Use of rubberized concrete as a cushion layer in bulletproof fiber reinforced concrete panels. Constr. Build. Mater. 2013, 41, 801–811. [Google Scholar] [CrossRef]

- Sun, J.; Chu, Z.; Liu, Y.; Luo, W.; Wang, M. Performance of Used Tire Cushion Layer under Rockfall Impact. Shock. Vib. 2016, 2016, 1–10. [Google Scholar] [CrossRef]

- Hao, H.; Tran, T.T.; Li, H.; Pham, T.M.; Chen, W. On the Accuracy, Reliability and Controllability of Impact Tests of RC Beams. Int. J. Impact Eng. 2021, 157, 103979. [Google Scholar] [CrossRef]

- Li, H.; Chen, W.; Hao, H. Influence of drop weight geometry and interlayer on impact behavior of RC beams. Int. J. Impact Eng. 2019, 131, 222–237. [Google Scholar]

- Zhang, J.; Ye, Y.; Qin, Q.; Wang, T. Low-velocity impact of sandwich beams with fibre-metal laminate face-sheets. Compos. Sci. Technol. 2018, 168, 152–159. [Google Scholar]

- Sun, M.; Wowk, D.; Mechefske, C.; Kim, I.Y. An analytical study of the plasticity of sandwich honeycomb panels subjected to low-velocity impact. Compos. Part B Eng. 2019, 168, 121–128. [Google Scholar] [CrossRef]

- Riccio, A.; Raimondo, A.; Saputo, S.; Sellitto, A.; Battaglia, M.; Petrone, G. A numerical study on the impact behaviour of natural fibres made honeycomb cores. Compos. Struct. 2018, 202, 909–916. [Google Scholar] [CrossRef]

- Hou, S.; Shu, C.; Zhao, S.; Liu, T.; Han, X.; Li, Q. Experimental and numerical studies on multi-layered corrugated sandwich panels under crushing loading. Compos. Struct. 2015, 126, 371–385. [Google Scholar] [CrossRef]

- San Ha, N.; Pham, T.M.; Tran, T.T.; Hao, H.; Lu, G. Mechanical properties and energy absorption of bio-inspired hierarchical circular honeycomb. Compos. Part B Eng. 2022, 236, 109818. [Google Scholar]

- Wu, Y.; Liu, Q.; Fu, J.; Li, Q.; Hui, D. Dynamic crash responses of bio-inspired aluminum honeycomb sandwich structures with CFRP panels. Compos. Part B Eng. 2017, 121b, 122–133. [Google Scholar]

- Hu, D.; Wang, Y.; Song, B.; Dang, L.; Zhang, Z. Energy-absorption characteristics of a bionic honeycomb tubular nested structure inspired by bamboo under axial crushing. Compos. Part B Eng. 2019, 162, 21–32. [Google Scholar]

- Chen, J.; Xie, J.; Zhu, H.; Guan, S.; Wu, G.; Noori, M.N.; Guo, S. Integrated honeycomb structure of a beetle forewing and its imitation. Mater. Sci. Eng. C 2012, 32, 613–618. [Google Scholar]

- Rahman, H.; Yarali, E.; Zolfagharian, A.; Serjouei, A.; Bodaghi, M. Energy Absorption and Mechanical Performance of Functionally Graded Soft–Hard Lattice Structures. Materials 2021, 14, 1366. [Google Scholar] [CrossRef] [PubMed]

- Xiang, J.; Du, J. Energy absorption characteristics of bio-inspired honeycomb structure under axial impact loading. Mater. Sci. Eng. A 2017, 696, 283–289. [Google Scholar]

- Chen, J.; Ni, Q.Q.; Xu, Y.; Iwamoto, M. Lightweight composite structures in the forewings of beetles. Compos. Struct. 2007, 79, 331–337. [Google Scholar]

- Chen, J.; Dai, G.; Xu, Y.; Iwamoto, M. Basic study of biomimetic composite materials in the forewings of beetles. Mater. Sci. Eng. A 2008, 483, 625–628. [Google Scholar] [CrossRef]

- Chen, J.; Gu, C.; Guo, S.; Wan, C.; Wang, X.; Xie, J.; Hu, X. Integrated honeycomb technology motivated by the structure of beetle forewings. Mater. Sci. Eng. C 2012, 32, 1813–1817. [Google Scholar]

- Chen, J.; He, C.; Gu, C.; Liu, J.; Mi, C.; Guo, S. Compressive and flexural properties of biomimetic integrated honeycomb plates. Mater. Des. 2014, 64, 214–220. [Google Scholar]

- Chen, J.; Zu, Q.; Wu, G.; Xie, J.; Tuo, W. Review of beetle forewing structures and their biomimetic applications in China: (I) On the structural colors and the vertical and horizontal cross-sectional structures–ScienceDirect. Mater. Sci. Eng. C 2015, 55, 605–619. [Google Scholar]

- Hao, P.; Du, J. Energy Absorption Characteristics of Bio-Inspired Honeycomb Column Thin-Walled Structure Under Impact Loading. J. Mech. Behav. Biomed. Mater. 2018, 79, 301. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Development of Additive Manufacturing Technology. In Additive Manufacturing Technologies; Springer: Cham, Switzerland.

- Dizon, J.; Espera, A.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Xia, H.; Sun, Q.; Liu, Y. Energy Absorption Characteristics of Bio-Inspired Honeycomb Column Thin-Walled Structure under Low Strain Rate Uniaxial Compression Loading. Energies 2022, 15, 6957. [Google Scholar] [CrossRef]

- Wang, S.; Xia, H.; Liu, Y. Energy Absorption Characteristics of Polygonal Bio-Inspired Honeycomb Column Thin-Walled Structure under Quasi-Static Uniaxial Compression Loading. Biomimetics 2022, 7, 201. [Google Scholar] [CrossRef]

- Xia, H.; Sun, Q.; Wang, S. Influence of strain rate effect on energy absorption characteristics of bio-inspired honeycomb column thin-walled structure under impact loading. Case Stud. Constr. Mater. 2023, 18, e01761. [Google Scholar] [CrossRef]

- China National Standardization Administration Committee. Test Method for Flatwise Compression Properties of Sandwich Constructions or Cores; China Standard Publishing House: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Bai, Y.L.; Yan, Z.W.; Jia, J.F.; Ozbakkaloglu, T.; Liu, Y. Dynamic compressive behavior of concrete confined with unidirectional natural flax FRP based on SHPB tests. Compos. Struct. 2021, 259, 113233. [Google Scholar]

- Liu, P.; Hu, D.; Wu, Q.; Liu, X. Sensitivity and uncertainty analysis of interfacial effect in SHPB tests for concrete-like materials. Constr. Build. Mater. 2018, 163, 414–427. [Google Scholar]

- L. S. T. Corporation. LS-DYNA Keyword User’s Manual Volume II Material Models; Livermore Software Technology Corporation: Livermore, CA, USA, 2014; Available online: https://ftp.lstc.com/anonymous/outgoing/jday/manuals/LS-DYNA_manual_Vol_II_R7.1.pdf (accessed on 20 January 2023).

- Jones, N. Structural Impact; Cambridge University Impress: Cambridge, UK, 2011. [Google Scholar]

- Sadraie, H.; Khaloo, A.; Soltani, H. Dynamic performance of concrete slabs reinforced with steel and GFRP bars under impact loading. Eng. Struct. 2019, 191, 62–81. [Google Scholar]

- Anil, Ö.; Kantar, E.; Yilmaz, M.C. Low velocity impact behavior of RC slabs with different support types. Constr. Build. Mater. 2015, 93, 1078–1088. [Google Scholar]

- Korucu, H.; Irfanoglu, A. Response of reinforced concrete beams to high-velocity fluid impact. Part II: Numerical modeling and simulation. Struct. Concr. 2018, 19, 1115–1121. [Google Scholar] [CrossRef]

- Liao, W.; Li, M.; Zhang, W.; Tian, Z. Experimental studies and numerical simulation of behavior of RC beams retrofitted with HSSWM-HPM under impact loading. Eng. Struct. 2016, 149, 131–146. [Google Scholar]

- Jonak, J.; Karpiński, R.; Wójcik, A.; Siegmund, M.; Kalita, M. Determining the Effect of Rock Strength Parameters on the Breakout Area Utilizing the New Design of the Undercut/Breakout Anchor. Materials 2022, 15, 851. [Google Scholar] [PubMed]

- Kong, S.Y.; Remennikov, A.M.; Uy, B. Numerical simulation of the response of non-composite steel-concrete-steel sandwich panels to impact loading. Aust. J. Struct. Eng. 2012, 12, 211–223. [Google Scholar]

- Soltani, H.; Khaloo, A.; Sadraie, H. Dynamic performance enhancement of RC slabs by steel fibers vs. externally bonded GFRP sheets under impact loading. Eng. Struct. 2020, 213, 110539. [Google Scholar] [CrossRef]

- Murray, Y.D. Users Manual for LS-DYNA Concrete Material Model 159; United States Federal Highway Administration Office of Research, Development, and Technology: 2007. Federal Highway Administration, United States. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/05062/05062.pdf (accessed on 20 January 2023).

- Beton, E. CEB-FIP Model Code 1990. Bull. Dinformation 1991. [Google Scholar] [CrossRef]

- Malvar, L.J.; Crawford, J.E.; Wesevich, J.W.; Simons, D. A plasticity concrete material model for DYNA3D. Int. J. Impact Eng. 1997, 19, 847–873. [Google Scholar]

- Do, T.V.; Pham, T.M.; Hao, H. Numerical investigation of the behavior of precast concrete segmental columns subjected to vehicle collision. Eng. Struct. 2018, 156, 375–393. [Google Scholar]

- Pham, T.; Do, T.; Hao, H. Distinguished Impact Response of Hollow Reinforced Concrete Beams under Impact Loading. 2020. Available online: https://www.researchgate.net/profile/Tin-Do/publication/342911468_Distinguished_Impact_Response_of_Hollow_Reinforced_Concrete_Beams_under_Impact_Loading/links/609db2cc299bf14769963473/Distinguished-Impact-Response-of-Hollow-Reinforced-Concrete-Beams-under-Impact-Loading.pdf (accessed on 20 January 2023).

- Hua, J.; Mi, G.C. An effective numerical simulation methodology to predict the impact response of pre-stressed concrete members–ScienceDirect. Eng. Fail. Anal. 2015, 55, 63–78. [Google Scholar]

- Sadiq, M.; Yun, Z.X.; Rong, P. Simulation analysis of impact tests of steel plate reinforced concrete and reinforced concrete slabs against aircraft impact and its validation with experimental results. Nucl. Eng. Des. 2014, 273, 653–667. [Google Scholar] [CrossRef]

- Hallquist, J.O. LS-DYNA® Keyword User’s Manual Volume I; Livermore Software Technology Corporation: Livermore, CA, USA, 2009. [Google Scholar]

- Şengel, S.; Erol, H.; Yılmaz, T.; Anıl, Ö. Investigation of the effects of impactor geometry on impact behavior of reinforced concrete slabs. Eng. Struct. 2022, 263, 114429. [Google Scholar] [CrossRef]

- Anas, S.M.; Alam, M.; Shariq, M. Damage response of conventionally reinforced two-way spanning concrete slab under eccentric impacting drop weight loading. Def. Technol. 2022, 19, 12–34. [Google Scholar]

- Li, Z.C.; Jia, P.C.; Jia, J.Y.; Wu, H.; Ma, L.L. Impact-resistant design of RC slabs in nuclear power plant buildings. Nucl. Eng. Technol. 2022, 54, 3745–3765. [Google Scholar]

| MID | RO | NPLOT | INCRE | IRATE | ERODE | RECOV | ITRETRC |

|---|---|---|---|---|---|---|---|

| 1 | 2.4 × 10−9 | 1 | 0 | 1 | 1.05 | 10 | 0 |

| PRED | |||||||

| 0 | |||||||

| G | K | ALPHA | THETA | LAMDA | BETA | NH | CH |

| 1.125 × 104 | 1.231 × 104 | 14.56 | 0.2979 | 10.51 | 1.929 × 10−2 | 0 | 0 |

| ALPHA1 | THETA1 | LAMDA1 | BETA1 | ALPHA2 | THETA2 | LAMDA2 | BETA2 |

| 0.7473 | 1.139 × 10−3 | 0.17 | 7.014 × 10−2 | 0.66 | 1.374 × 10−3 | 0.160 | 0.07014 |

| R | XO | W | D1 | D2 | |||

| 5 | 90.74 | 0.05 | 2.5 × 10−4 | 3.492 × 10−7 | |||

| B | GFC | D | GFT | GFS | PWRC | PWRT | PMOD |

| 1.00 × 102 | 9.487 | 0.1 | 9.49 × 10−2 | 9.49 × 10−2 | 5 | 1 | 0 |

| ETAOC | NC | ETAOT | NT | OVERC | OVERT | SRATE | REPOW |

| 1.003 × 10−4 | 0.78 | 6.22 × 10−5 | 0.48 | 21.63 | 21.63 | 1 | 1 |

| Component | Material Model | The Main Parameters of the Material |

|---|---|---|

| Concrete | *MAT_CSCM | |

| Steel reinforcement | *MAT_PIECEWISE_LINEAR_PLASTICITY | |

| BHTS buffer interlayer | *MAT_PLASTIC_KINEMATC | |

| Drop hammer | *MAT_ELASTIC | |

| Support | *MAT_ ELASTIC | |

| Slab roof constraint | *MAT_ADD_THERMAL_EXPANSION |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Xia, H. Protective Behaviors of Bio-Inspired Honeycomb Column Thin-Walled Structure against RC Slab under Impact Loading. Biomimetics 2023, 8, 73. https://doi.org/10.3390/biomimetics8010073

Wang S, Xia H. Protective Behaviors of Bio-Inspired Honeycomb Column Thin-Walled Structure against RC Slab under Impact Loading. Biomimetics. 2023; 8(1):73. https://doi.org/10.3390/biomimetics8010073

Chicago/Turabian StyleWang, Shijie, and Hongxiang Xia. 2023. "Protective Behaviors of Bio-Inspired Honeycomb Column Thin-Walled Structure against RC Slab under Impact Loading" Biomimetics 8, no. 1: 73. https://doi.org/10.3390/biomimetics8010073