Continuous 3D Printing of Biomimetic Beetle Mandible Structure with Long Bundles of Aramid Fiber Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Printing of Bionic Composites

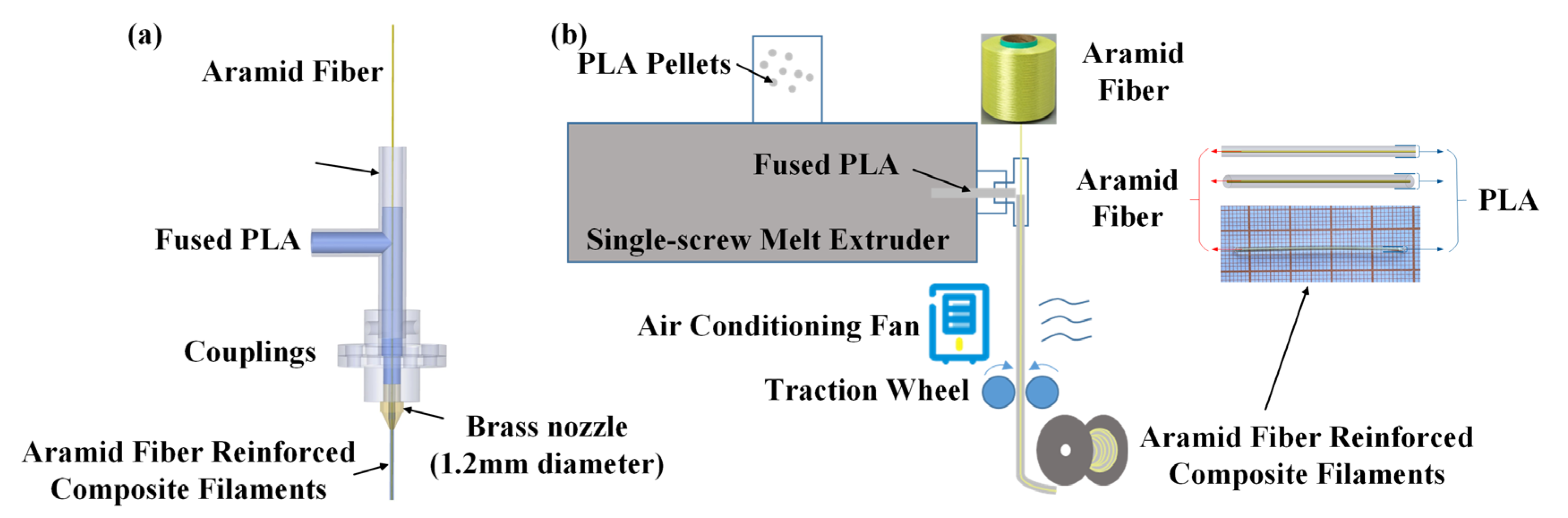

2.2.1. Preparation of Bionic Composite Filaments

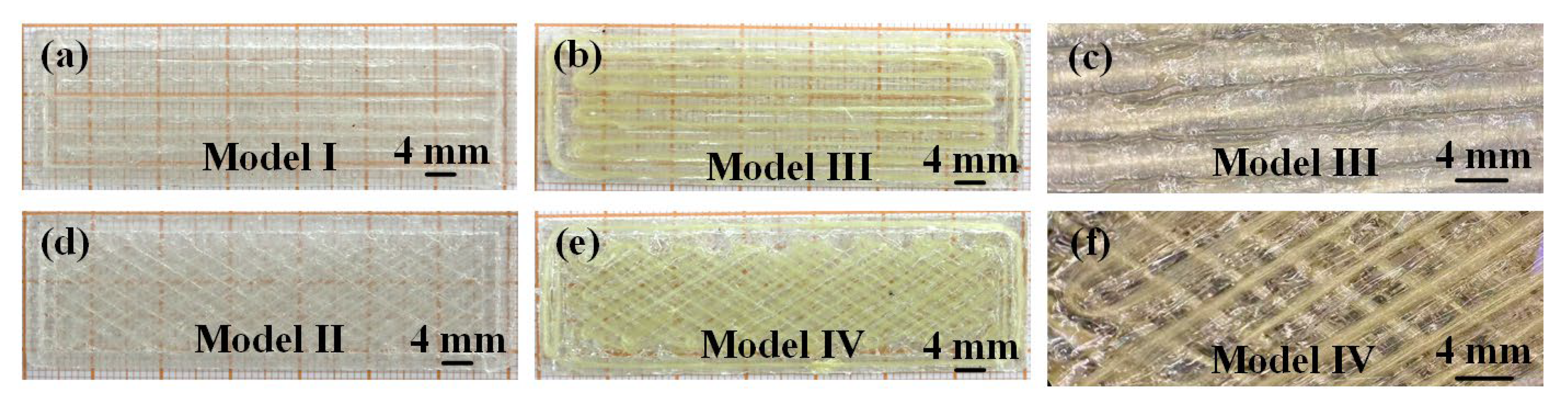

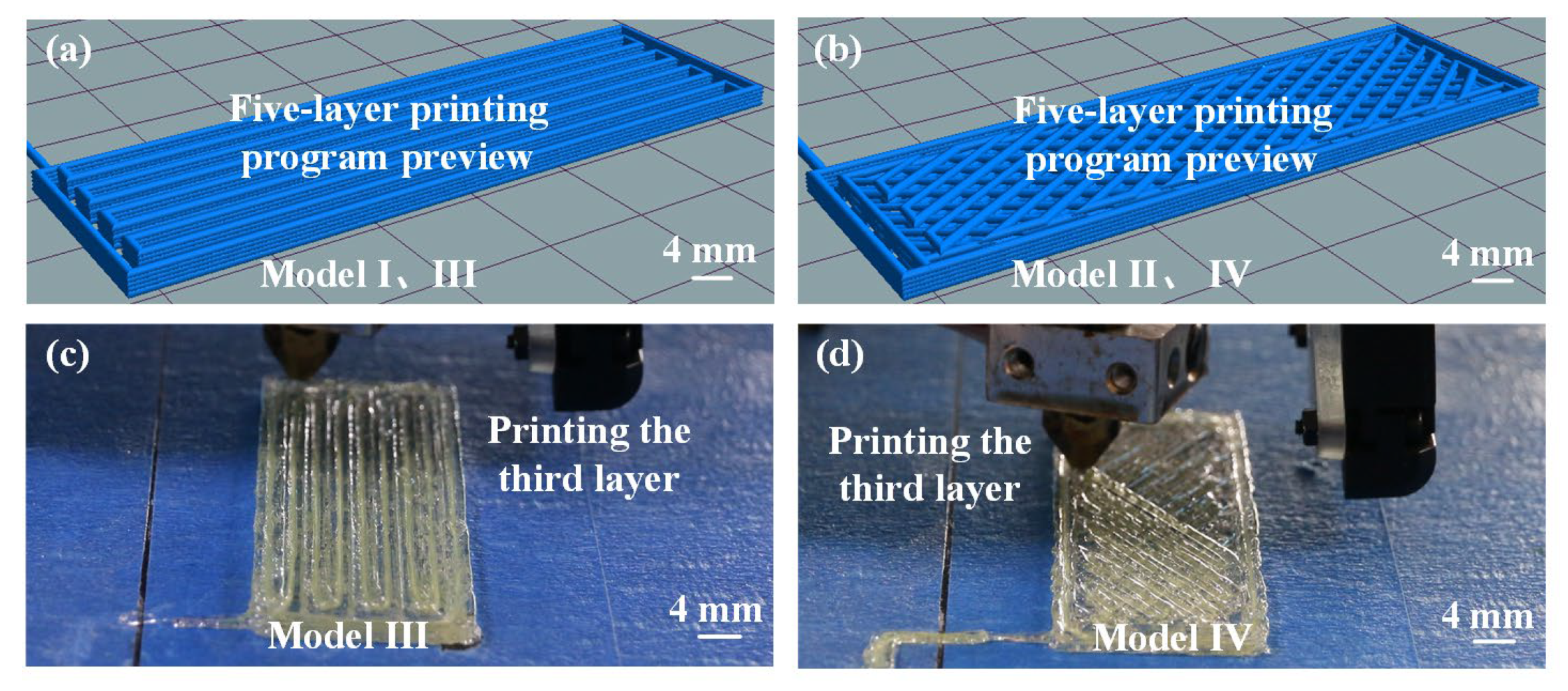

2.2.2. Printing of Bionic Composites

2.3. Characterization

2.3.1. Structure Characterizations

2.3.2. Tensile Strength

2.3.3. Impact Toughness

3. Results and Discussion

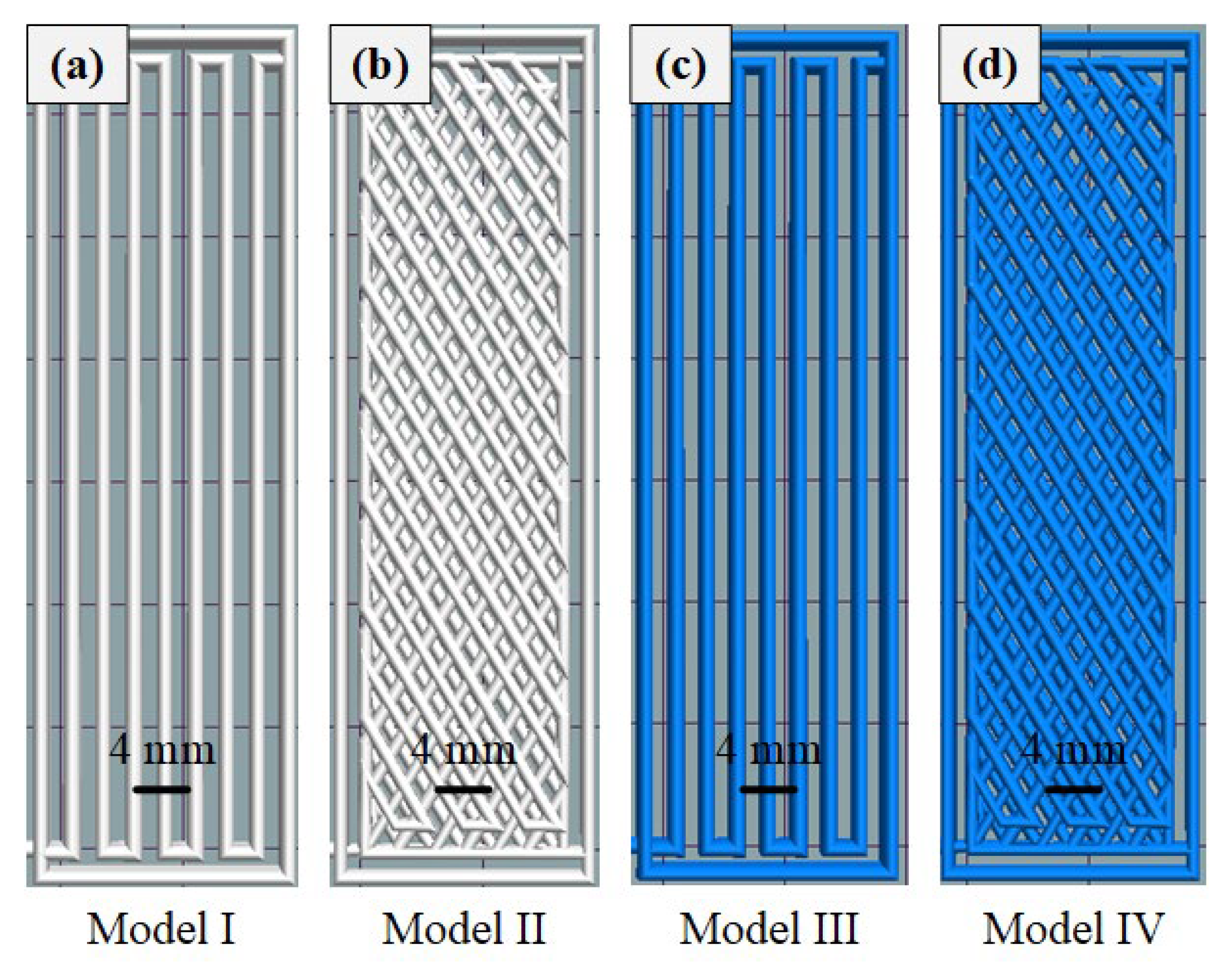

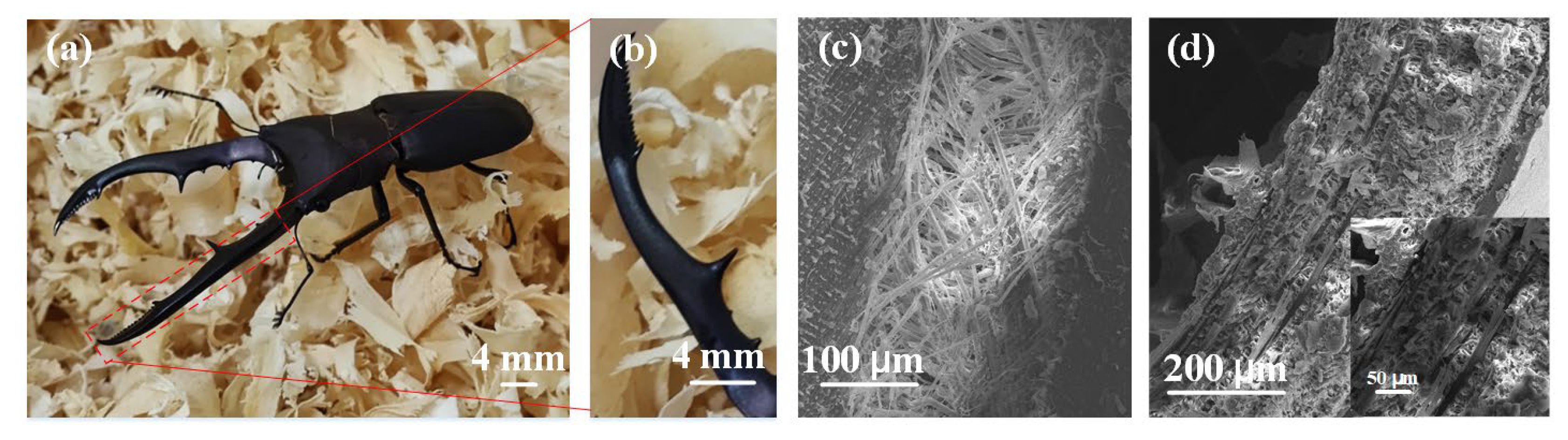

3.1. Bionic Structure Design

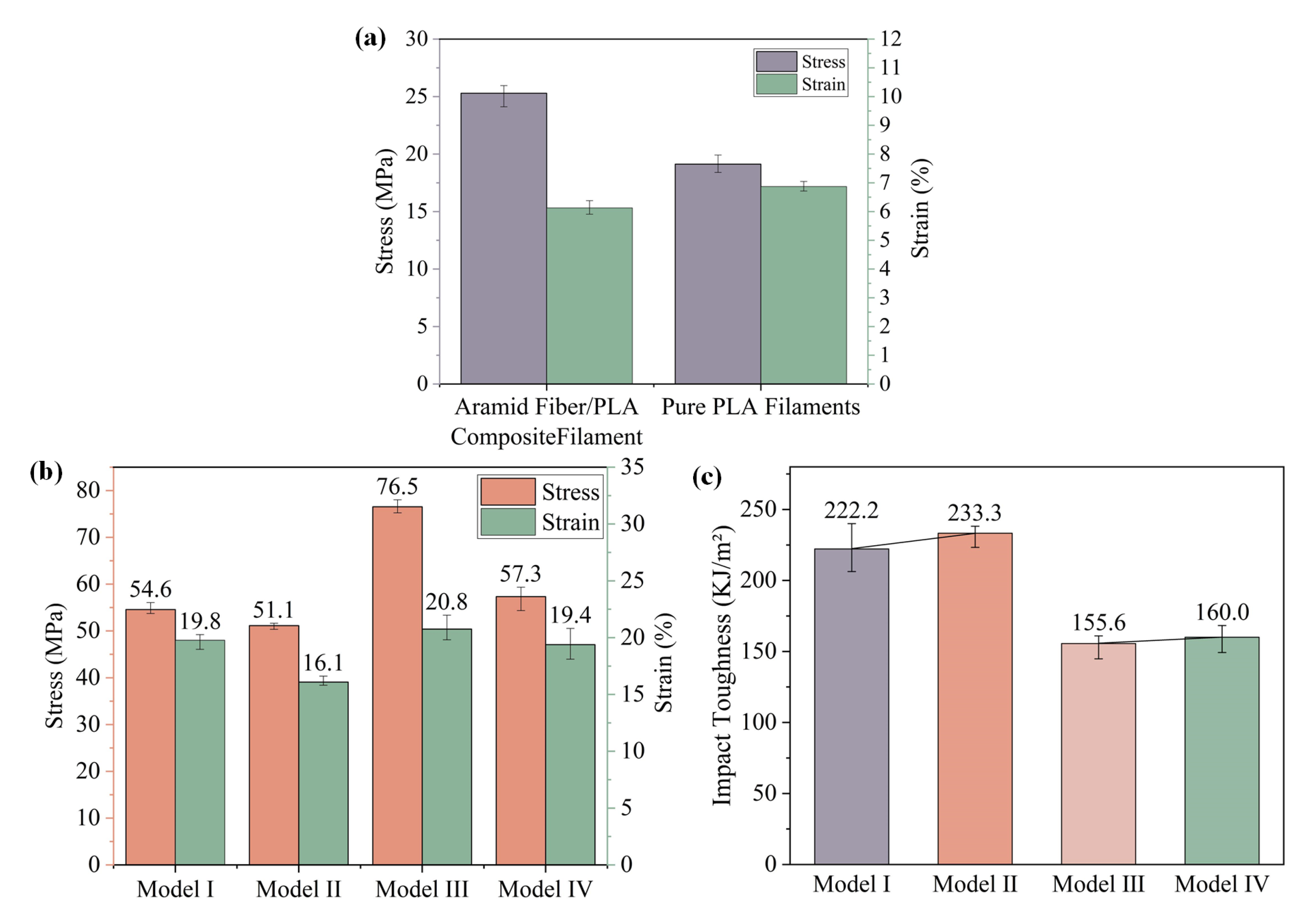

3.2. Mechanical Properties Analysis

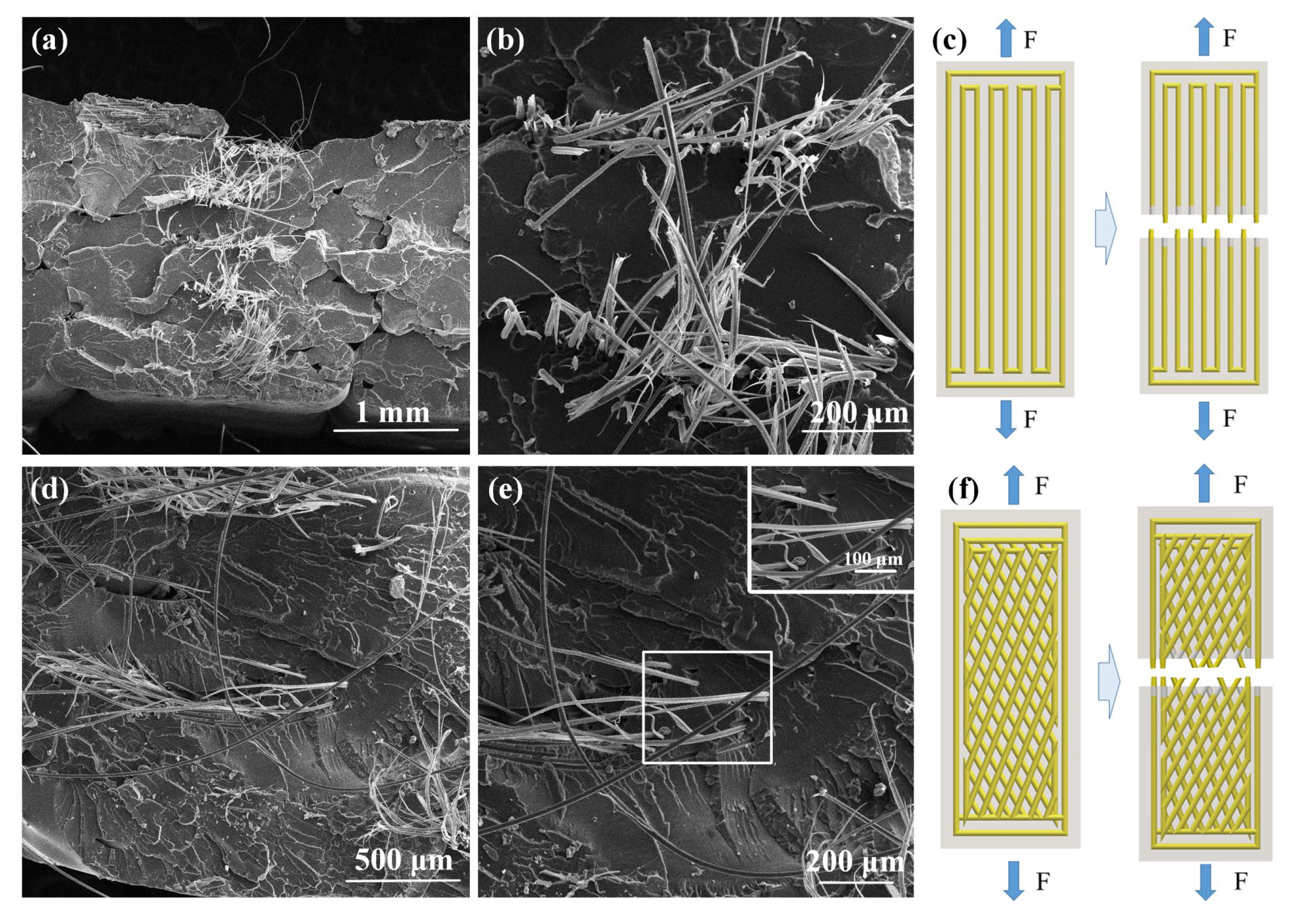

3.3. Microstructural Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, A.; Qin, R.Y.; Chow, C.L.; Lau, D. Bond integrity of aramid, basalt and carbon fiber reinforced polymer bonded wood composites at elevated temperature. Compos. Struct. 2020, 245, 9. [Google Scholar] [CrossRef]

- Qi, G.C.; Zhang, B.M.; Du, S.Y. Assessment of F-III and F-12 aramid fiber/epoxy interfacial adhesions based on fiber bundle specimens. Compos. Part A-Appl. Sci. Manuf. 2018, 112, 549–557. [Google Scholar] [CrossRef]

- Wagih, A.; Sebaey, T.A.; Yudhanto, A.; Lubineau, G. Post-impact flexural behavior of carbon-aramid/epoxy hybrid composites. Compos. Struct. 2020, 239, 9. [Google Scholar] [CrossRef]

- Zhang, B.; Jia, L.H.; Tian, M.; Ning, N.Y.; Zhang, L.Q.; Wang, W.C. Surface and interface modification of aramid fiber and its reinforcement for polymer composites: A review. Eur. Polym. J. 2021, 147, 11. [Google Scholar] [CrossRef]

- Bozkurt, O.Y. Hybridization Effects on Tensile and Bending Behavior of Aramid/Basalt Fiber Reinforced Epoxy Composites. Polym. Compos. 2017, 38, 1144–1150. [Google Scholar] [CrossRef]

- Fan, B.H.; He, D.L.; Liu, Y.; Bai, J.B. Influence of Thermal Treatments on the Evolution of Conductive Paths in Carbon Nanotube-Al2O3 Hybrid Reinforced Epoxy Composites. Langmuir 2017, 33, 9680–9686. [Google Scholar] [CrossRef]

- Zhao, Q.; Liu, C.; Liang, Y.H.; Lin, Z.H.; Han, Z.W.; Ren, L. Integration 3D printing of bionic continuous carbon fiber reinforced resin composite. Mater. Res. Express 2021, 8, 7. [Google Scholar] [CrossRef]

- Liang, Y.H.; Liu, C.; Zhao, Q.; Lin, Z.H.; Han, Z.W.; Ren, L.Q. Bionic Design and 3D Printing of Continuous Carbon Fiber-Reinforced Polylactic Acid Composite with Barbicel Structure of Eagle-Owl Feather. Materials 2021, 14, 3618. [Google Scholar] [CrossRef]

- Obande, W.; Bradaigh, C.M.O.; Ray, D. Continuous fibre-reinforced thermoplastic acrylic-matrix composites prepared by liquid resin infusion-A review. Compos. Part B-Eng. 2021, 215, 26. [Google Scholar] [CrossRef]

- Dong, K.; Panahi-Sarmad, M.; Cui, Z.Y.; Huang, X.Y.; Xiao, X.L. Electro-induced shape memory effect of 4D printed auxetic composite using PLA/TPU/CNT filament embedded synergistically with continuous carbon fiber: A theoretical & experimental analysis. Compos. Part B-Eng. 2021, 220, 11. [Google Scholar] [CrossRef]

- Mazur, K.; Siwy, Z.S.; Adamczyk, A.; Kuciel, S.L. Synergistic effect of aramid and basalt fibers on mechanical, thermal and dynamic properties of polylactide hybrid composites. Ind. Crops Prod. 2023, 198, 10. [Google Scholar] [CrossRef]

- Klaser, T.; Balen, L.; Skoko, Z.; Pavic, L.; Santic, A. Polylactic Acid-Glass Fiber Composites: Structural, Thermal, and Electrical Properties. Polymers 2022, 14, 4012. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; Joralmon, D.; Shan, W.T.; Chen, Y.Y.; Rong, J.H.; Zhao, H.Y.; Xiao, S.Q.; Li, X.J. 3D printing biomimetic materials and structures for biomedical applications. Bio-Des. Manuf. 2021, 4, 405–428. [Google Scholar] [CrossRef]

- Ma, S.Q.; Jiang, Z.Y.; Wang, M.; Zhang, L.; Liang, Y.H.; Zhang, Z.H.; Ren, L.; Ren, L.Q. 4D printing of PLA/PCL shape memory composites with controllable sequential deformation. Bio-Des. Manuf. 2021, 4, 867–878. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ali, K.S.A.; Ranganathan, K.; Jeffrey, J.A.; Ravikumar, M.M.; Rajkumar, S. The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater. Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- O’Hara, W.J.; Kish, J.M.; Werkheiser, M.J. Turn-key use of an onboard 3D printer for international space station operations. Addit. Manuf. 2018, 24, 560–565. [Google Scholar] [CrossRef]

- Tan, C.L.; Zou, J.; Li, S.; Jamshidi, P.; Abena, A.; Forsey, A.; Moat, R.J.; Essa, K.; Wang, M.S.; Zhou, K.S.; et al. Additive manufacturing of bio-inspired multi-scale hierarchically strengthened lattice structures. Int. J. Mach. Tools Manuf. 2021, 167, 13. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B-Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Bochnia, J.; Kozior, T.; Blasiak, M. The Mechanical Properties of Thin-Walled Specimens Printed from a Bronze-Filled PLA-Based Composite Filament Using Fused Deposition Modelling. Materials 2023, 16, 3241. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, H.; Gu, X.S. In-plane shear response of unidirectional fiber reinforced and fabric reinforced carbon/epoxy composites. Polym. Test. 2013, 32, 594–601. [Google Scholar] [CrossRef]

- Gleadall, A. FullControl GCode Designer: Open-source software for unconstrained design in additive manufacturing. Addit. Manuf. 2021, 46, 15. [Google Scholar] [CrossRef]

- Wen, S.M.; Chen, S.M.; Gao, W.T.; Zheng, Z.J.; Bao, J.Z.; Cui, C.; Liu, S.; Gao, H.L.; Yu, S.H. Biomimetic Gradient Bouligand Structure Enhances Impact Resistance of Ceramic-Polymer Composites. Adv. Mater. 2023, 35, 9. [Google Scholar] [CrossRef] [PubMed]

| Model I | Model II | Model III | Model IV | |

|---|---|---|---|---|

| Speed | 120 mm/min | 120 mm/min | 120 mm/min | 120 mm/min |

| Printing Rate | 100% | 100% | 80% | 75% |

| Layer Thickness | 0.4 mm | 0.4 mm | 0.4 mm | 0.4 mm |

| Nozzle Temperature | 190 °C | 190 °C | 185 °C | 185 °C |

| Nozzle Diameter | 2 mm | 2 mm | 2 mm | 2 mm |

| First Layer Bed Temperature | 50 °C | 50 °C | 50 °C | 50 °C |

| Remaining Layers Bed Temperature | 50 °C | 50 °C | 45 °C | 45 °C |

| Model I | Model II | Model III | Model IV | |

|---|---|---|---|---|

| Materials | Pure PLA | Pure PLA | Aramid Fiber/PLA | Aramid Fiber/PLA |

| Structure | Paralleled | Bionic structures | Paralleled | Bionic structures |

| Printing speed | 120 mm/min | 120 mm/min | 120 mm/min | 120 mm/min |

| Length | 70 ± 0.3 mm | 70 ± 0.3 mm | 70 ± 0.3 mm | 70 ± 0.3 mm |

| Width | 22 ± 0.3 mm | 22 ± 0.3 mm | 22 ± 0.3 mm | 22 ± 0.3 mm |

| Height | 2 ± 0.2 mm | 2 ± 0.2 mm | 2 ± 0.2 mm | 2 ± 0.2 mm |

| Weight | 4.2 ± 0.2 g | 4.2 ± 0.2 g | 4.2 ± 0.2 g | 4.2 ± 0.2 g |

| Layer Height | 0.4 mm | 0.4 mm | 0.4 mm | 0.4 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Liu, C.; Zhang, Y.; Zhang, W.; Xu, X.; Lin, Z.; Liang, Y. Continuous 3D Printing of Biomimetic Beetle Mandible Structure with Long Bundles of Aramid Fiber Composites. Biomimetics 2023, 8, 283. https://doi.org/10.3390/biomimetics8030283

Li S, Liu C, Zhang Y, Zhang W, Xu X, Lin Z, Liang Y. Continuous 3D Printing of Biomimetic Beetle Mandible Structure with Long Bundles of Aramid Fiber Composites. Biomimetics. 2023; 8(3):283. https://doi.org/10.3390/biomimetics8030283

Chicago/Turabian StyleLi, Shuigen, Chang Liu, Yulong Zhang, Wei Zhang, Xuefei Xu, Zhaohua Lin, and Yunhong Liang. 2023. "Continuous 3D Printing of Biomimetic Beetle Mandible Structure with Long Bundles of Aramid Fiber Composites" Biomimetics 8, no. 3: 283. https://doi.org/10.3390/biomimetics8030283

APA StyleLi, S., Liu, C., Zhang, Y., Zhang, W., Xu, X., Lin, Z., & Liang, Y. (2023). Continuous 3D Printing of Biomimetic Beetle Mandible Structure with Long Bundles of Aramid Fiber Composites. Biomimetics, 8(3), 283. https://doi.org/10.3390/biomimetics8030283