Effect of Fly Ash on Mechanical Properties of Polymer Resin Grout

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methodology

2.3. Testing Methods

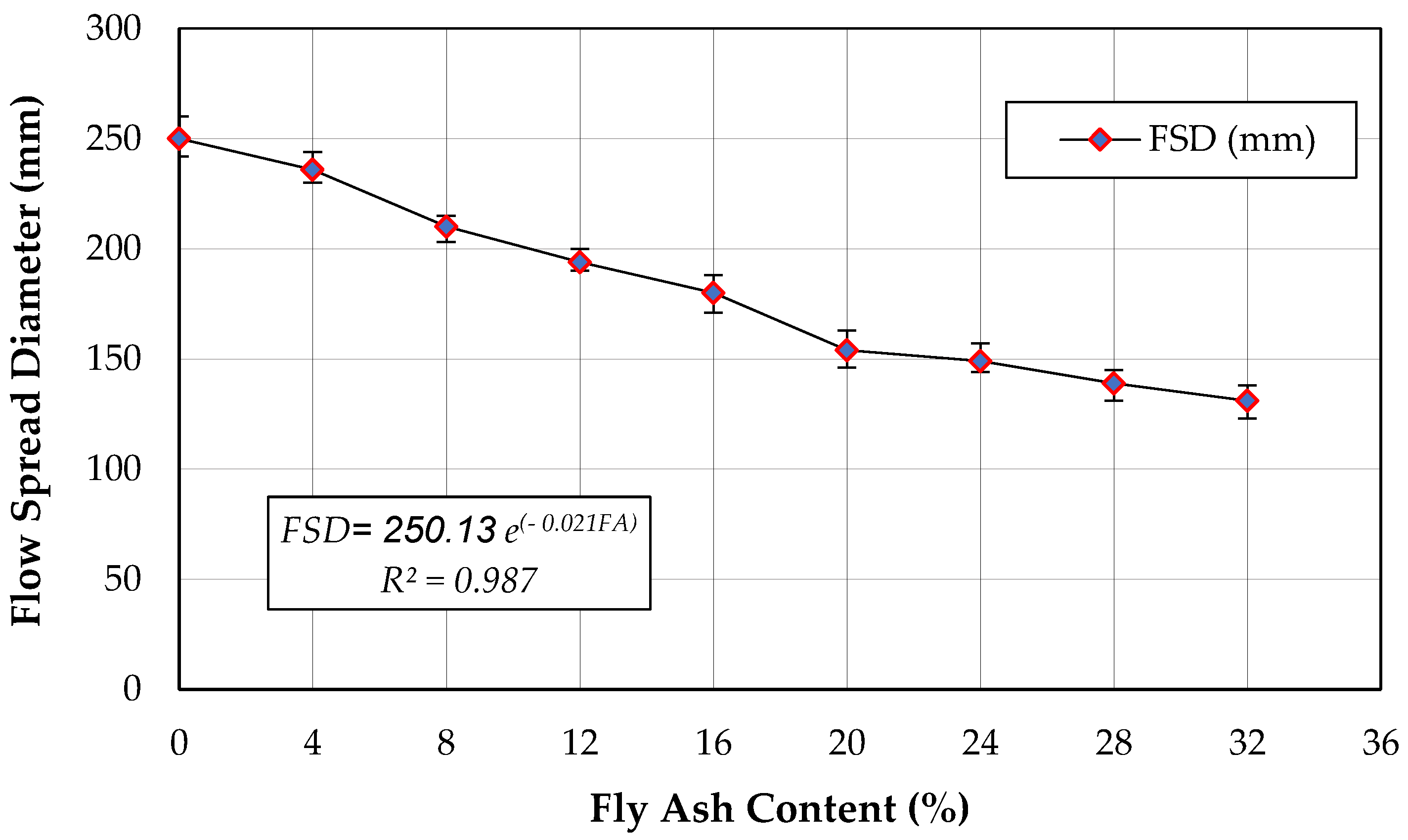

2.3.1. Flowability Test

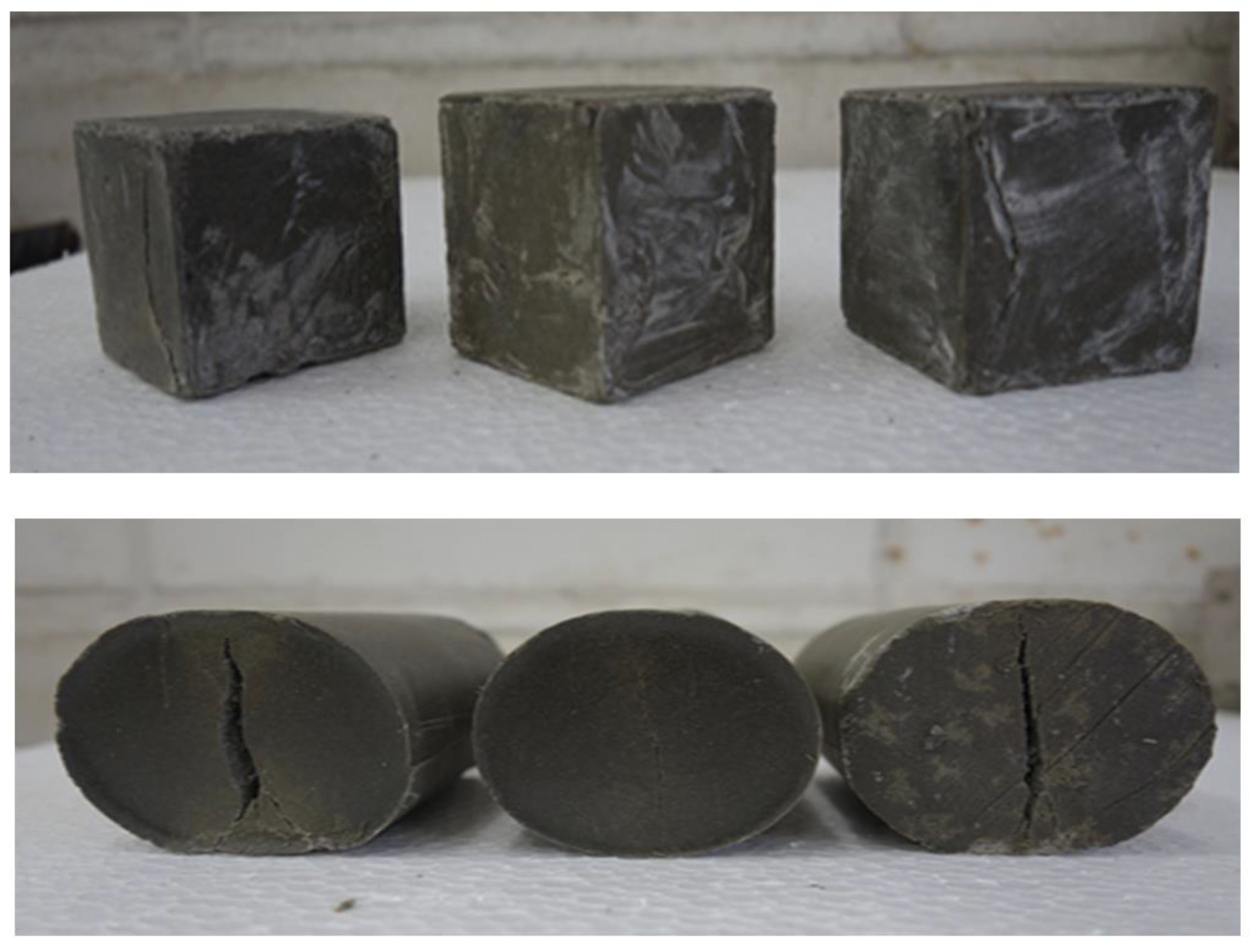

2.3.2. Compressive Strength Test

2.3.3. Splitting Tensile Test

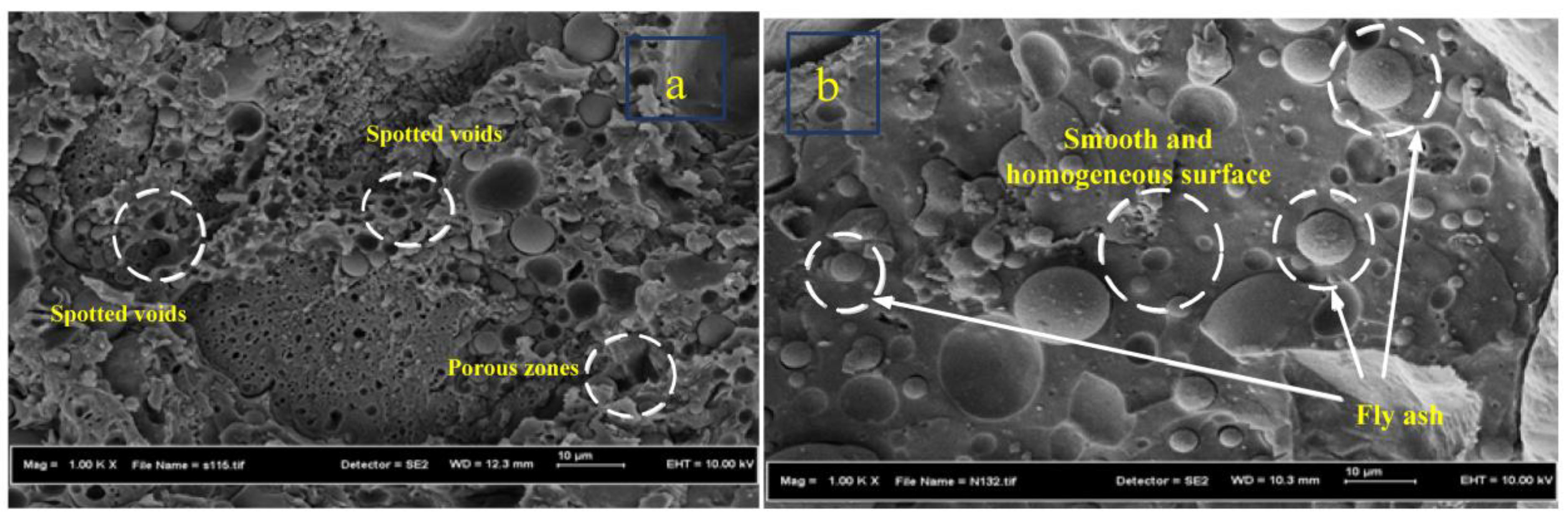

2.3.4. Scanning Electron Microscope (SEM)

3. Results and Discussion

3.1. Flowability

3.2. Compressive and Splitting Tensile Strength

3.3. Microstructure Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bărbuţă, M.; Harja, M.; Baran, I. Comparison of Mechanical Properties for Polymer Concrete with Different Types of Filler. J. Mater. Civ. Eng. 2010, 22, 696–701. [Google Scholar] [CrossRef]

- Rebeiz, K.S.; Fowler, D.W.; Paul, D.R. Polymer Concrete and Polymer Mortar Using Resins Based on Recycled Poly(Ethylene Terephthalate). J. Appl. Polym. Sci. 1992, 44, 1649–1655. [Google Scholar] [CrossRef]

- Aggarwal, L.; Thapliyal, P.; Karade, S. Properties of Polymer-Modified Mortars Using Epoxy and Acrylic Emulsions. Constr. Build. Mater. 2007, 21, 379–383. [Google Scholar] [CrossRef]

- Miller, M. Polymers in Cementitious Materials; iSmithers Rapra Publishing: Shrewsbury, UK, 2005. [Google Scholar]

- El-Hawary, M.M.; AlKhaleefi, A.M.; Abdel-Fattah, H.I. On the mechanical properties of polymer Portland cement concrete. J. Chin. Inst. Eng. 2005, 28, 155–159. [Google Scholar] [CrossRef]

- Mohammeda, N.S.; Abdul, A.B.; Rahmanb, N.H.A.K. Polyester Grout Incorporating Fly Ash as Potential Infill Material for Grouted Connections. J. Teknol. 2015, 77, 61–66. [Google Scholar]

- Untrauer, R.E.; Henry, R.L. Influence of Normal Pressure on Bond Strength. J. Proc. 1965, 62, 577–586. [Google Scholar]

- Raymond, J.; Sauntson, B. Resins and polymers for grouts, concrete and filled systems-A wide perspective. In Proceedings of the 5th International Congress on Polymers in Concrete. Brighton Polytechnic, Brighton, UK, 21–24 September 1987; pp. 27–31. [Google Scholar]

- Shivasharan, S.M. Polymer coatings. Proceedings of Third International Congress on Polymers in Concrete, Koriyama, Japan, 13–15 May 1981; pp. 1347–1363. [Google Scholar]

- Rebeiz, K.S.; Rosett, J.W.; Craft, A.P. Strength properties of polyester mortar using PET and fly ash wastes. J. Energy Eng. 1996, 122, 10–20. [Google Scholar] [CrossRef]

- Goulding, T.M. Epoxy resin adhesives. In Handbook of Adhesive Technology; Marcel Dekker Inc.: New York, NY, USA, 1994. [Google Scholar]

- Petrie, E. Epoxy Adhesives Formulations; McGraw-Hill: New York, NY, USA, 2005. [Google Scholar]

- Varughese, K.; Chaturvedi, B. Fly ash as fine aggregate in polyester based polymer concrete. Cem. Concr. Compos. 1996, 18, 105–108. [Google Scholar] [CrossRef]

- Soh, Y.S.; Jo, Y.K.; Park, H.S. Effect of fillers on the mechanical properties of unsaturated polyester resin mortar. Polym. Concr. 1997, 67, 74. [Google Scholar] [CrossRef]

- Atzeni, C.; Massidda, L.; Sanna, U. Mechanical properties of epoxy mortars with fly ash as filler. Cem. Concr. Compos. 1990, 12, 3–8. [Google Scholar] [CrossRef]

- Willis, M.; Masters, I. The effect of filler loading and process route on the three-point bend performance of waste based composites. Compos. Struct. 2003, 62, 475–479. [Google Scholar] [CrossRef]

- Rozman, H.D.; Musa, L.; Abubakar, A. The mechanical and dimensional properties of rice husk-unsaturated polyester composites. Polym. Technol. Eng. 2005, 44, 489–500. [Google Scholar] [CrossRef]

- Hoseinzadeh, M.; Najafpour, G.D.; Beygi, M.A. Effect of Agro-Waste Ash on Mechanical Properties of Epoxy Polymer Concrete. Iran. Iran. J. Energy Environ. 2013, 4, 283–288. [Google Scholar] [CrossRef]

- Fowler, D. Polymers in concrete: A vision for the 21st century. Cem. Concr. Compos. 1999, 21, 449–452. [Google Scholar] [CrossRef]

- Reis, J. Effect of aging on the fracture mechanics of unsaturated polyester based on recycled PET polymer concrete. Mater. Sci. Eng. A 2011, 528, 3007–3009. [Google Scholar] [CrossRef]

- Haidar, M.; Ghorbel, E.; Toutanji, H. Optimization of the formulation of micro-polymer concretes. Constr. Build. Mater. 2011, 25, 1632–1644. [Google Scholar] [CrossRef]

- Khalid, N.H.A.; Hussin, M.W.; Mirza, J.; Ariffin, N.F.; Ismail, M.A.; Lee, H.-S.; Mohamed, A.; Jaya, R.P. Palm oil fuel ash as potential green micro-filler in polymer concrete. Constr. Build. Mater. 2016, 102, 950–960. [Google Scholar] [CrossRef]

- Bedi, R.; Chandra, R.; Singh, S.P. Mechanical Properties of Polymer Concrete. J. Compos. 2013, 2013, 1–12. [Google Scholar] [CrossRef]

- Fadiel, A. Estimating of Compressive Strength of Rubberized Concrete Using Destructive and Non-Destructive Test Methods. In Proceedings of the National Conference on Building Materials and Structural Engineering (NCBMSE) 2022, Tripoli, Libya, 29–30 November 2022. (In Arabic). [Google Scholar]

- Fadiel, A. Use of crumb rubber to improve thermal efficiency of construction materials. Master’s Thesis, North Carolina Agricultural and Technical State University, Greensboro, NC, USA, 2013. [Google Scholar]

- Lebdeh, A.; Abu-Lebdeh, T.; Fini, E.; Fadiel, A. Thermal conductivity of rubberized gypsum board. Am. J. Eng. Appl. Sci. 2014, 7, 12–22. [Google Scholar] [CrossRef]

- Fadiel, A.; Al Rifaie, F.; Abu-Lebdeh, T.; Fini, E. Use of crumb rubber to improve thermal efficiency of cement-based materials. Am. J. Eng. Appl. Sci. 2014, 7, 1–11. [Google Scholar] [CrossRef]

- Fadiel, A.A.; Abu-Lebdeh, T.; Petrescu, F.I.T. Assessment of Woodcrete Using Destructive and Non-Destructive Test Methods. Materials 2022, 15, 3066. [Google Scholar] [CrossRef]

- JIS A 1181; Test Methods for Polymer Concrete. Japanese Industrial Standard: Tokyo, Japan, 2005.

- ASTM C 230/C 230M; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- Ameli, M.J.; Parks, J.E.; Brown, D.N.; Pantelides, C.P. Seismic evaluation of grouted splice sleeve connections for reinforced precast concrete column–to–cap beam joints in accelerated bridge construction. PCI J. 2015, 60, 80–103. [Google Scholar] [CrossRef]

- Duc, D.S. Properties of fly ash from a thermal power plant in Vietnam. Int. J. Chem. Tech. Res. 2014, 6, 2656–2659. [Google Scholar]

- Harja, M.; Barbuta, M.; Rusu, L. Obtaining and characterization of the polymer concrete with fly ash. J. Appl. Sci. 2009, 9, 88–96. [Google Scholar] [CrossRef]

- Uysal, M. Self-compacting concrete incorporating filler additives: Performance at high temperatures. Constr. Build. Mater. 2012, 26, 701–706. [Google Scholar] [CrossRef]

- Gorninski, J.; Molin, D.D.; Kazmierczak, C. Comparative assessment of isophtalic and orthophtalic polyester polymer concrete: Different costs, similar mechanical properties and durability. Constr. Build. Mater. 2007, 21, 546–555. [Google Scholar] [CrossRef]

- Fadiel, A. A review of properties of concrete containing crumb rubber from used tires. In Proceedings of the 13th Arab Structural Engineering Conference, Blida, Algeria, 13–15 December 2015. (In Arabic). [Google Scholar]

- Fadiel, A.A.M.; Abu-Lebdeh, T. Mechanical Properties of Concrete Including Wood Shavings as Fine Aggregates. Am. J. Eng. Appl. Sci. 2021, 14, 478–487. [Google Scholar] [CrossRef]

- Fadiel, A.A.M.; Mohammed, N.S.; Abu-Lebdeh, T.; Munteanu, I.S.; Niculae, E.; Petrescu, F.I.T. A Comprehensive Evaluation of the Mechanical Properties of Rubberized Concrete. J. Compos. Sci. 2023, 7, 129. [Google Scholar] [CrossRef]

- Fadiel, A.A.M.; Abu-Lebdeh, T.; Munteanu, I.S.; Niculae, E.; Petrescu, F.I.T. Mechanical Properties of Rubberized Concrete at Elevated Temperatures. J. Compos. Sci. 2023, 7, 283. [Google Scholar] [CrossRef]

- Jin, Y.; Petrescu, F.I.T.; Wang, Y.; Li, X.; Li, Y.; Shi, G. Spiropyran-Based Soft Substrate with SPR, Anti-Reflection and Anti-NRET for Enhanced Visualization/Fluorescence Dual Response to Metal Ions. Materials 2023, 16, 3746. [Google Scholar] [CrossRef]

- Kang, P.; Petrescu, F.I.T.; Wu, Y.; Li, Y.; Li, X.; Wang, L.; Shi, G. A Novel Photo-Thermal-Electric Conversion System with an Integrated Support Material. Nanomaterials 2023, 13, 1301. [Google Scholar] [CrossRef]

- Li, X.; Petrescu, F.I.T.; Danzeng, Q.; Zhu, H.; Li, Y.; Shi, G. A Bioinspired Ag Nanoparticle/PPy Nanobowl/TiO2 Micropyramid SERS Substrate. Nanomaterials 2022, 12, 4104. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Petrescu, F.I.T.; Li, Y.; Song, D.; Shi, G. A Novel Bio-Inspired Ag/3D-TiO2/Si SERS Substrate with Ordered Moth-like Structure. Nanomaterials 2022, 12, 3127. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Chen, J.; Zheng, J.; Chen, X.; Xu, H.; Petrescu, F.I.T.; Ungureanu, L.M.; Li, Y.; Shi, G. A Simple Polypyrrole/Polyvinylidene Fluoride Membrane with Hydrophobic and Self-Floating Ability for Solar Water Evaporation. Nanomaterials 2022, 12, 859. [Google Scholar] [CrossRef] [PubMed]

| Property | Value |

|---|---|

| Styrene monomer content, (%) | 39–44 |

| Viscosity (Brookfield) at 25 °C, 60 rpm (cps) | 538 |

| Gel time, (min) | 15 |

| Barcol hardness | 56 |

| Density, (g/cm3) | 1.1 |

| Tensile strength, (MPa) | 7 |

| Mix ID | Binder Content (Polyester Resin) (%) | Filler Content (Sand and Fly Ash) (%) | Fly Ash (%) | Sand (%) |

|---|---|---|---|---|

| PRG-40-0 | 40 | 60 | 0 | 60 |

| PRG-40-4 | 4 | 56 | ||

| PRG-40-8 | 8 | 52 | ||

| PRG-40-12 | 12 | 48 | ||

| PRG-40-16 | 16 | 44 | ||

| PRG-40-20 | 20 | 40 | ||

| PRG-40-24 | 24 | 36 | ||

| PRG-40-28 | 28 | 32 | ||

| PRG-40-32 | 32 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fadiel, A.A.M.; Mohammed, N.S.; Rahman, A.B.A.; Ali, E.A.B.; Abu-Lebdeh, T.; Petrescu, F.I.T. Effect of Fly Ash on Mechanical Properties of Polymer Resin Grout. Biomimetics 2023, 8, 392. https://doi.org/10.3390/biomimetics8050392

Fadiel AAM, Mohammed NS, Rahman ABA, Ali EAB, Abu-Lebdeh T, Petrescu FIT. Effect of Fly Ash on Mechanical Properties of Polymer Resin Grout. Biomimetics. 2023; 8(5):392. https://doi.org/10.3390/biomimetics8050392

Chicago/Turabian StyleFadiel, Ashraf A. M., Nuria S. Mohammed, Ahmad Baharuddin Abdul Rahman, Esam Abu Baker Ali, Taher Abu-Lebdeh, and Florian Ion Tiberiu Petrescu. 2023. "Effect of Fly Ash on Mechanical Properties of Polymer Resin Grout" Biomimetics 8, no. 5: 392. https://doi.org/10.3390/biomimetics8050392

APA StyleFadiel, A. A. M., Mohammed, N. S., Rahman, A. B. A., Ali, E. A. B., Abu-Lebdeh, T., & Petrescu, F. I. T. (2023). Effect of Fly Ash on Mechanical Properties of Polymer Resin Grout. Biomimetics, 8(5), 392. https://doi.org/10.3390/biomimetics8050392