Study on High-Velocity Impact Perforation Performance of CFRP Laminates for Rail Vehicles: Experiment and Simulation

Abstract

:1. Introduction

2. Materials and Methods

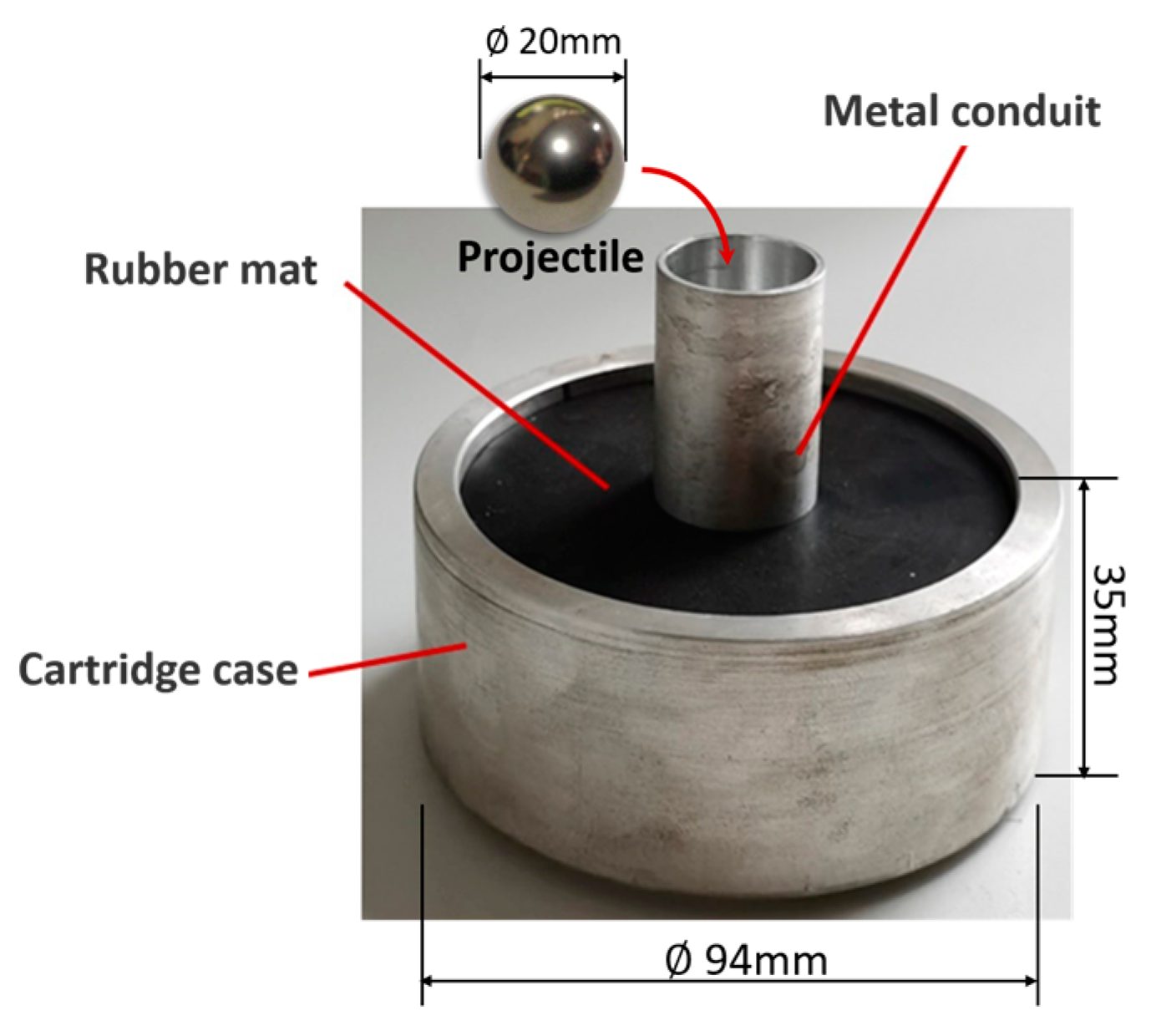

2.1. Specimen and Experimental Conditions

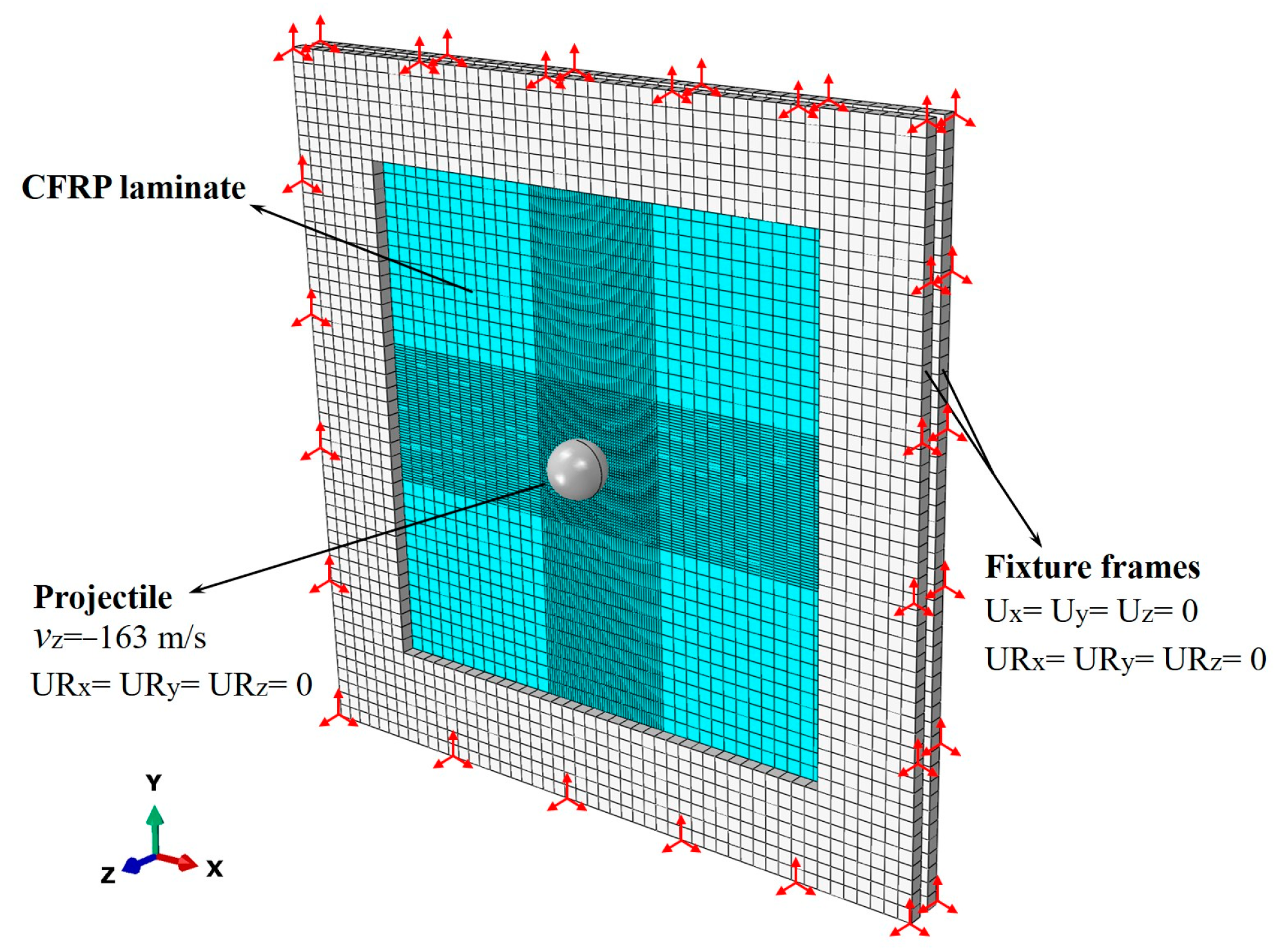

2.2. Finite Element Simulation

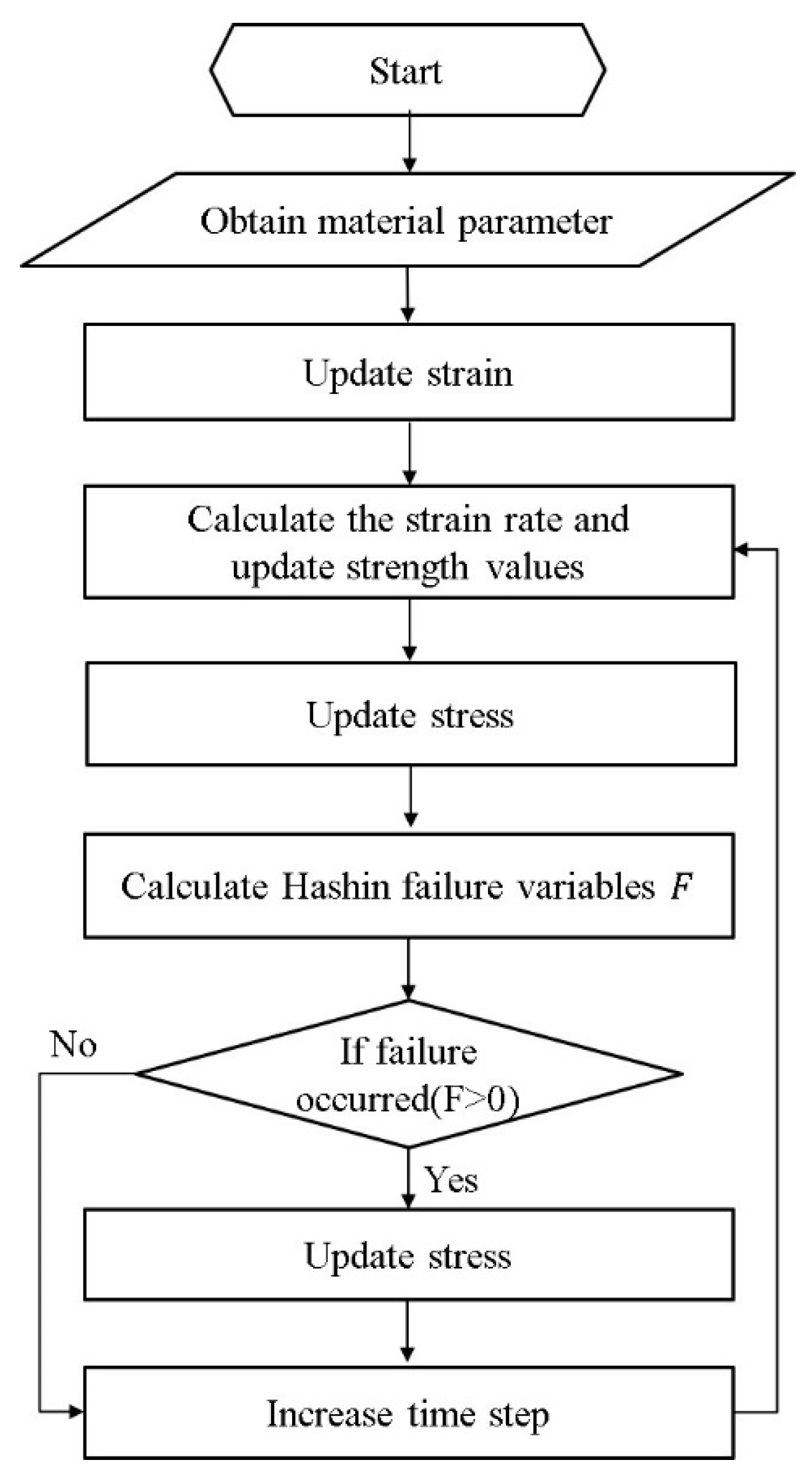

2.2.1. Intra-Laminar Damage Model

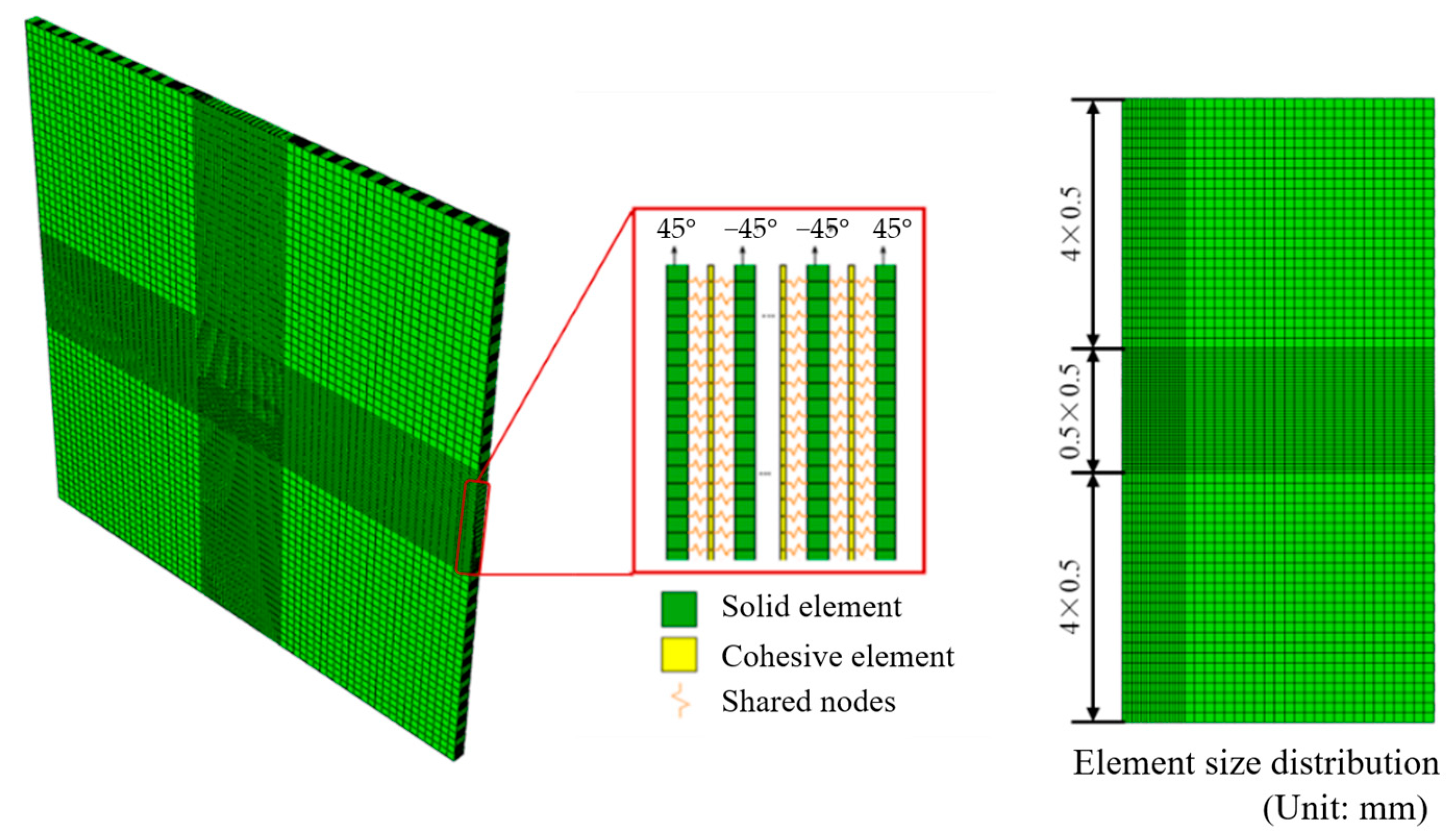

2.2.2. Inter-Laminar Damage Model

2.2.3. Details of the Finite Element Model

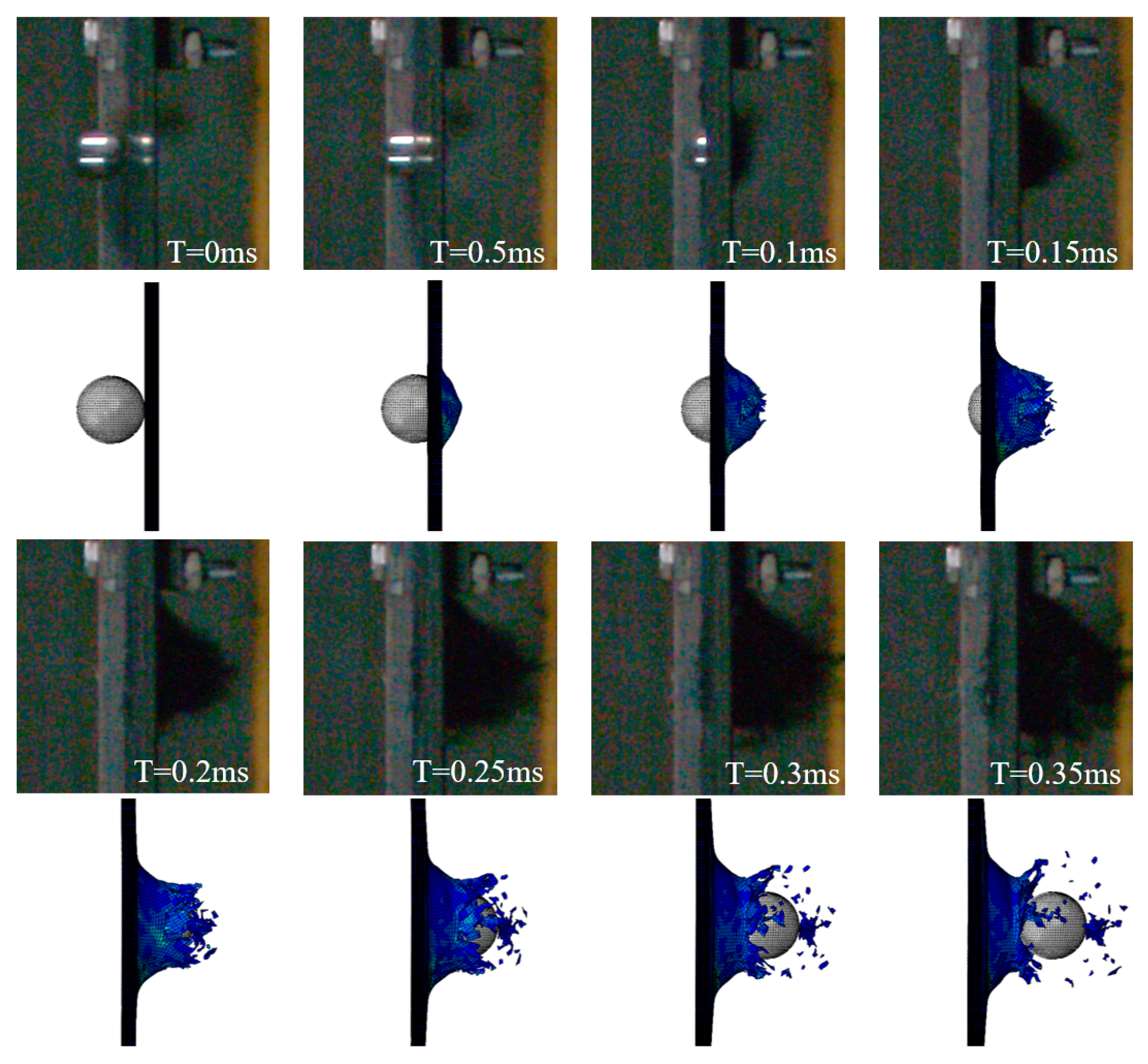

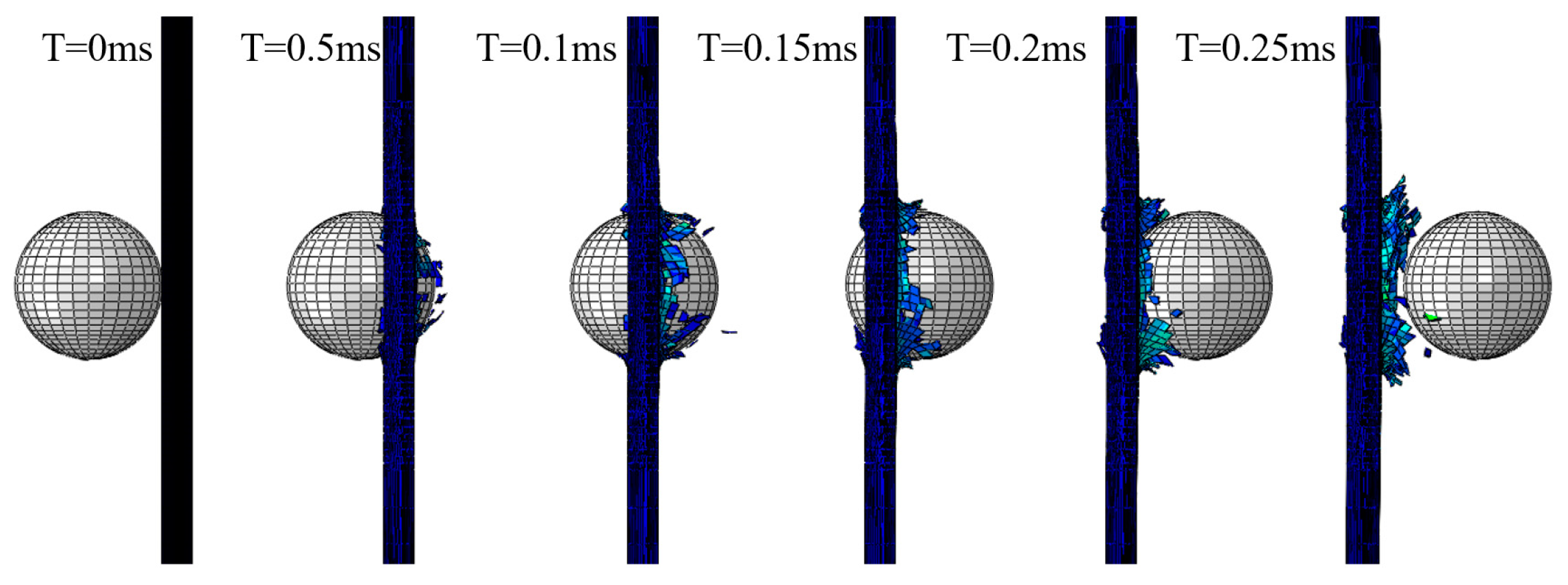

3. Results

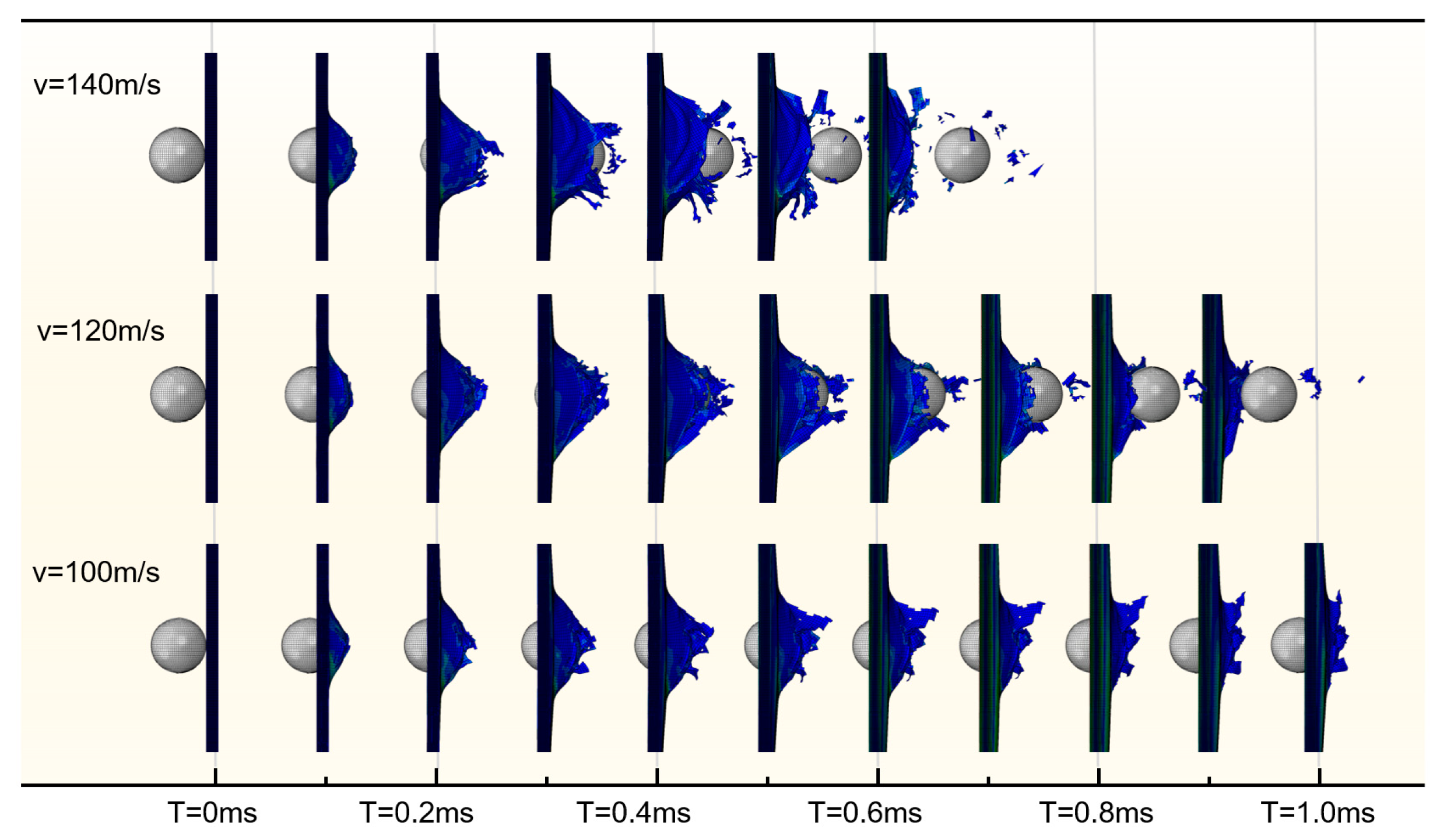

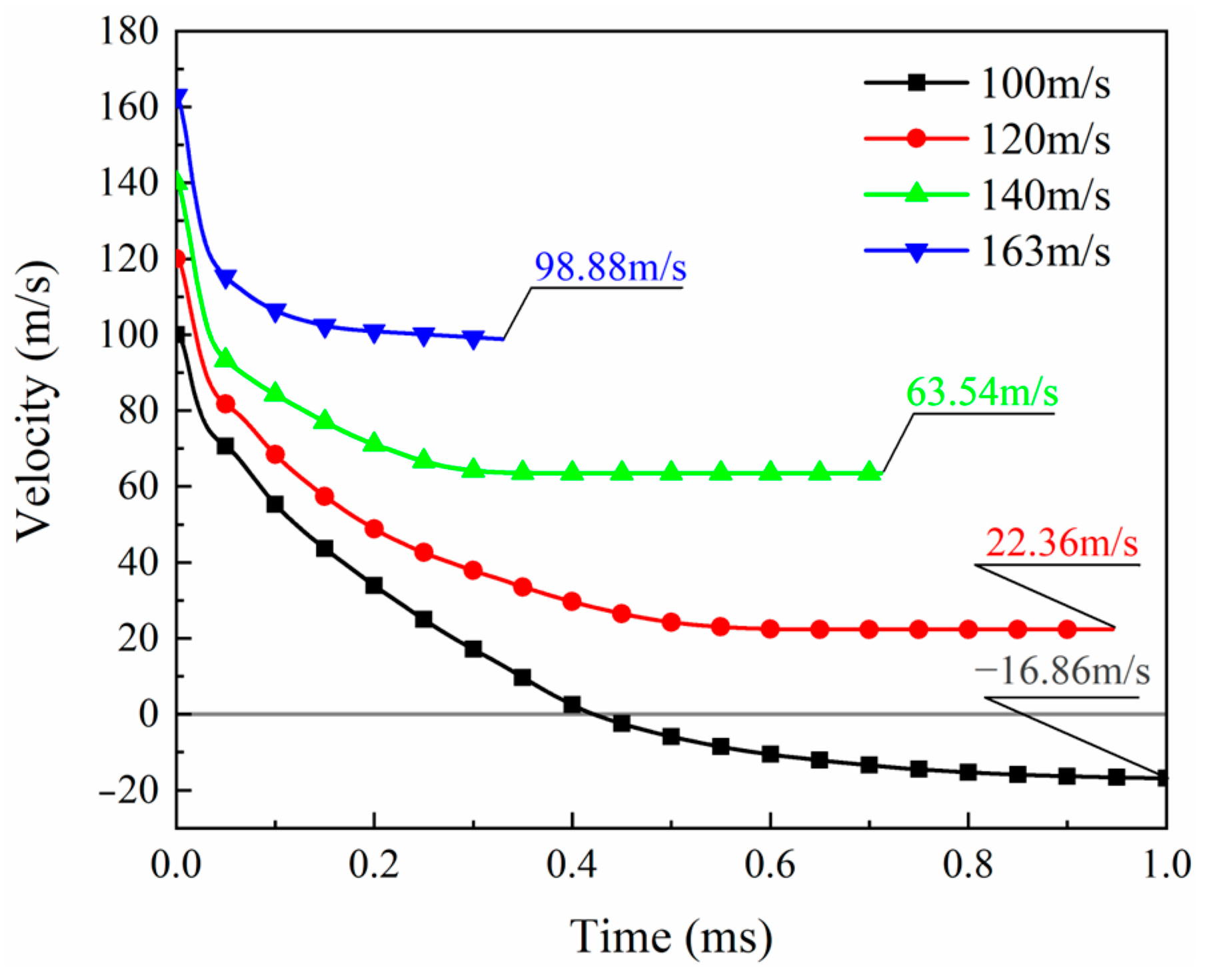

3.1. Velocity History and Energy

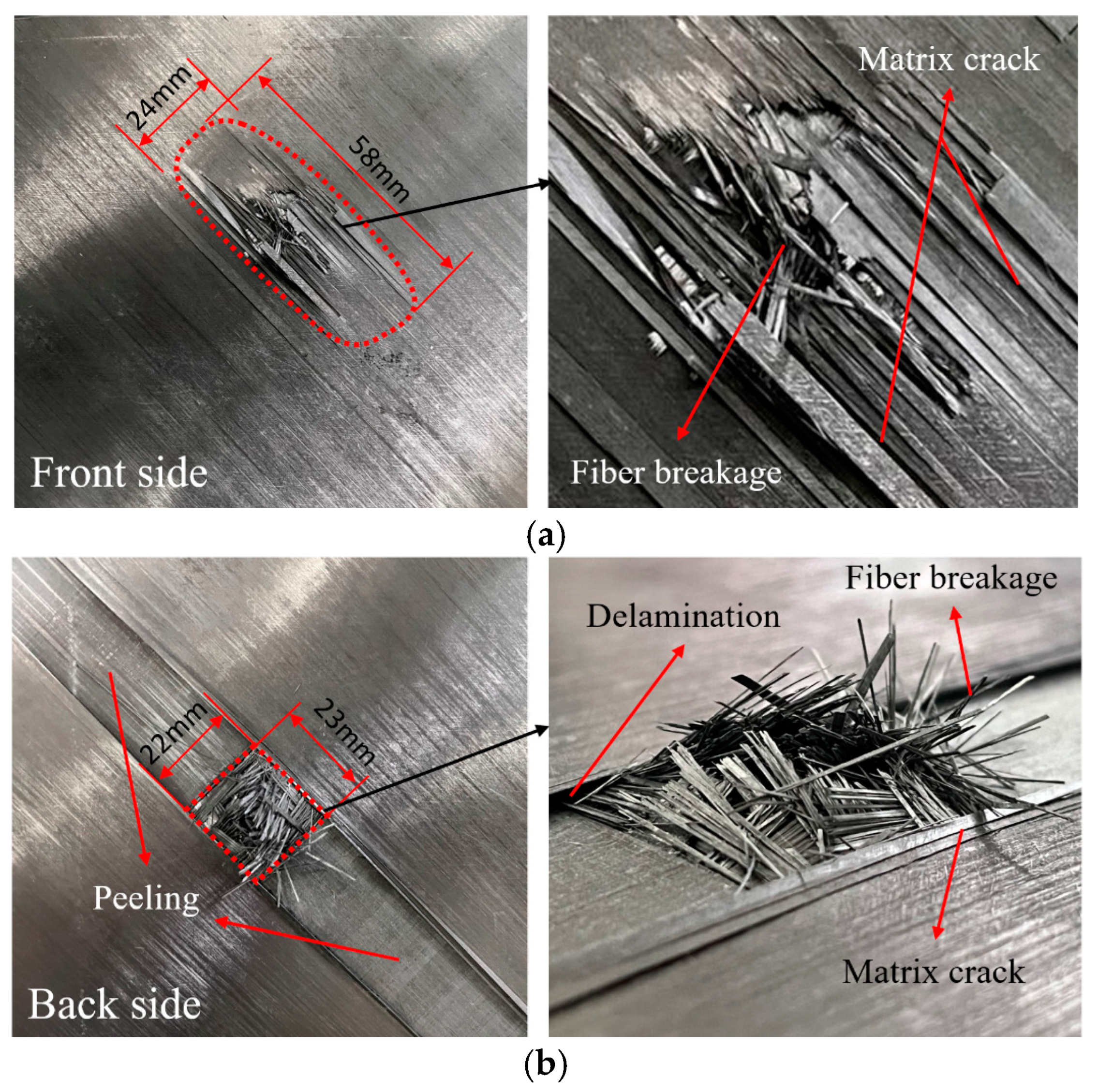

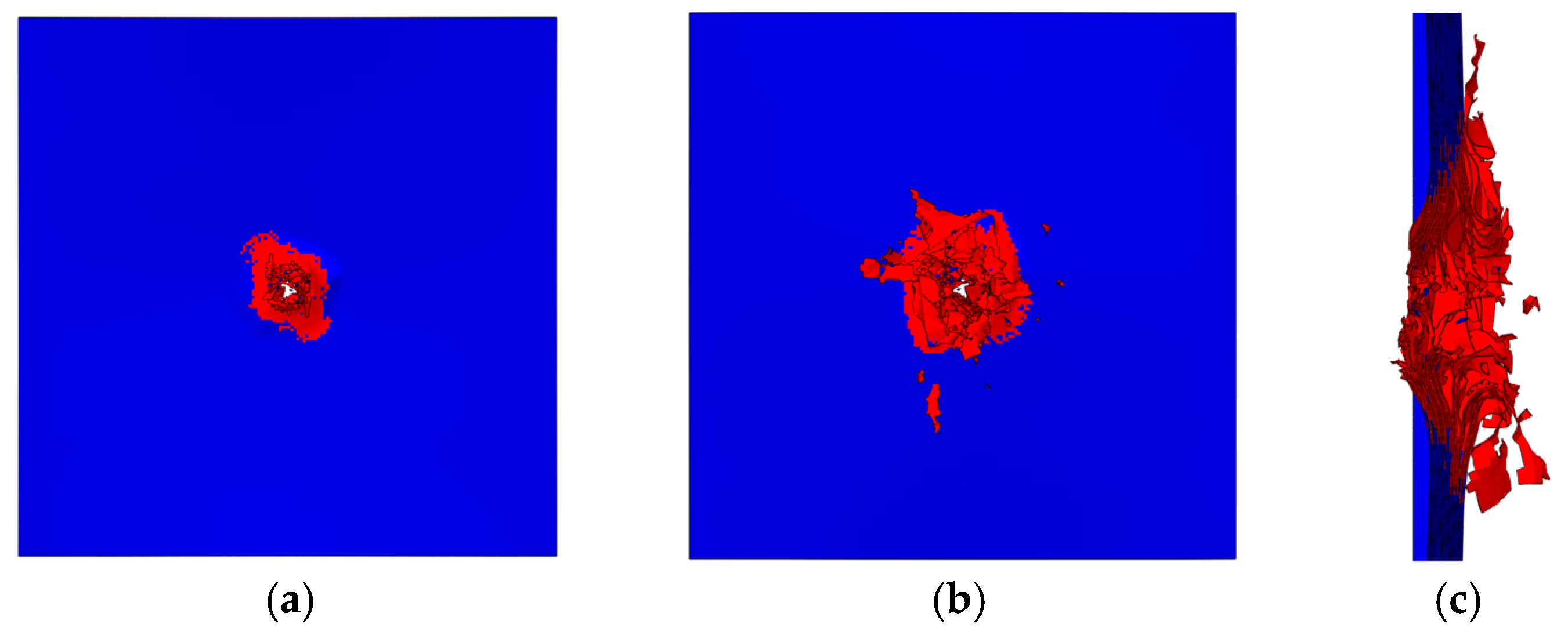

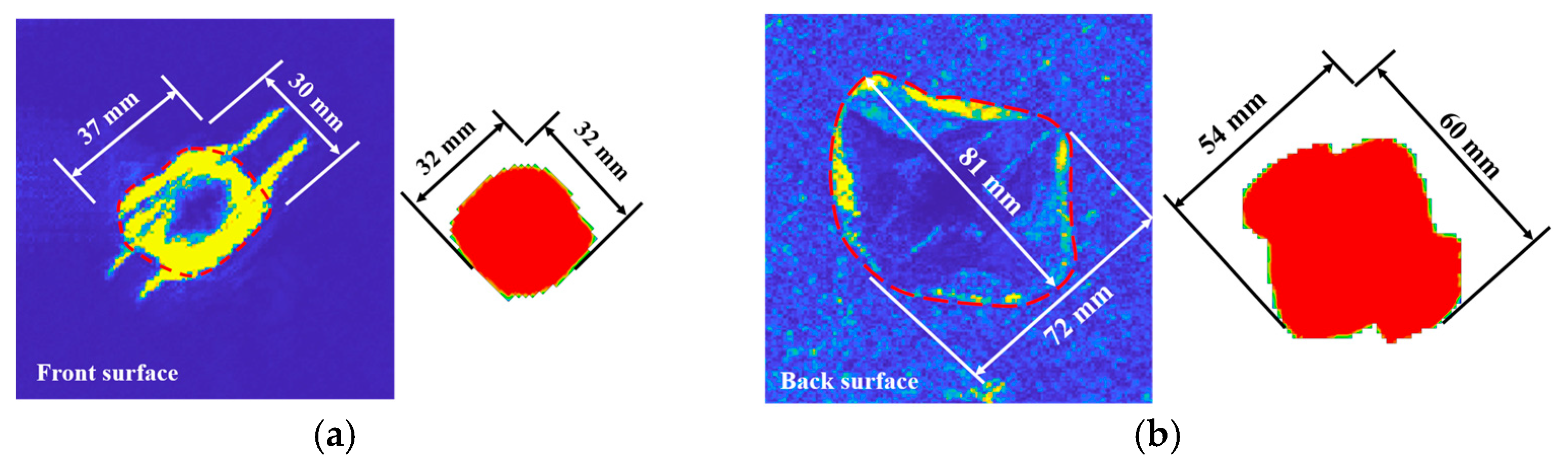

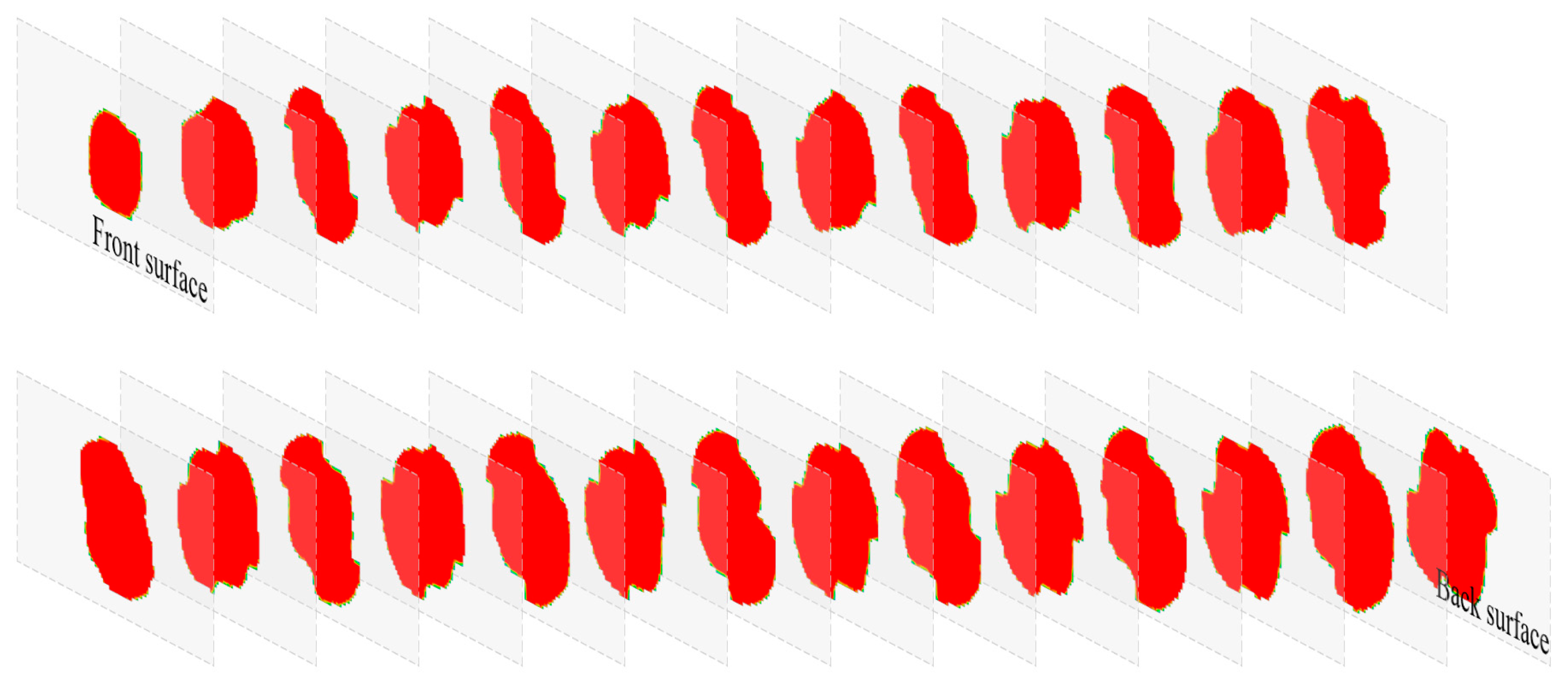

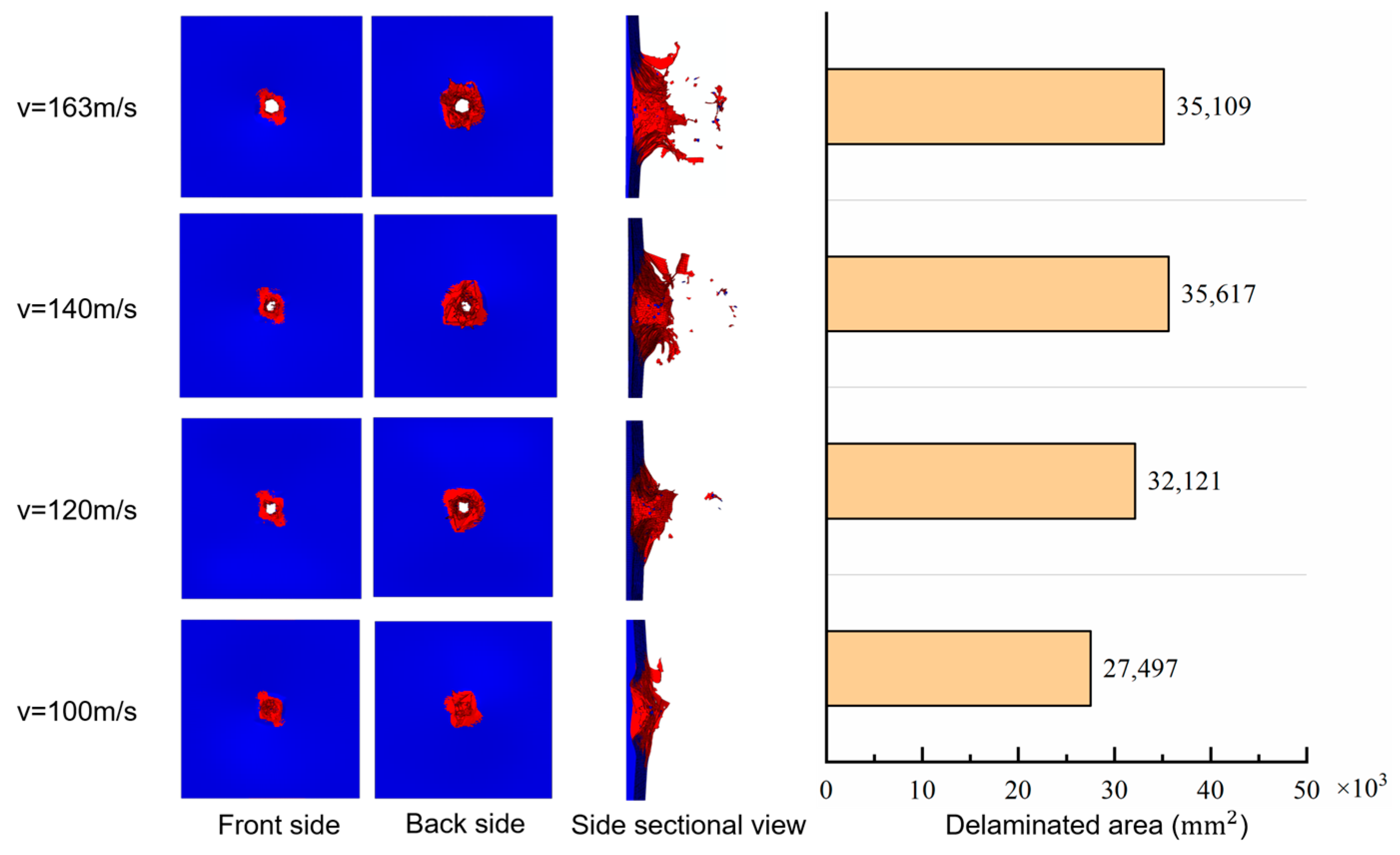

3.2. Damage Profiles

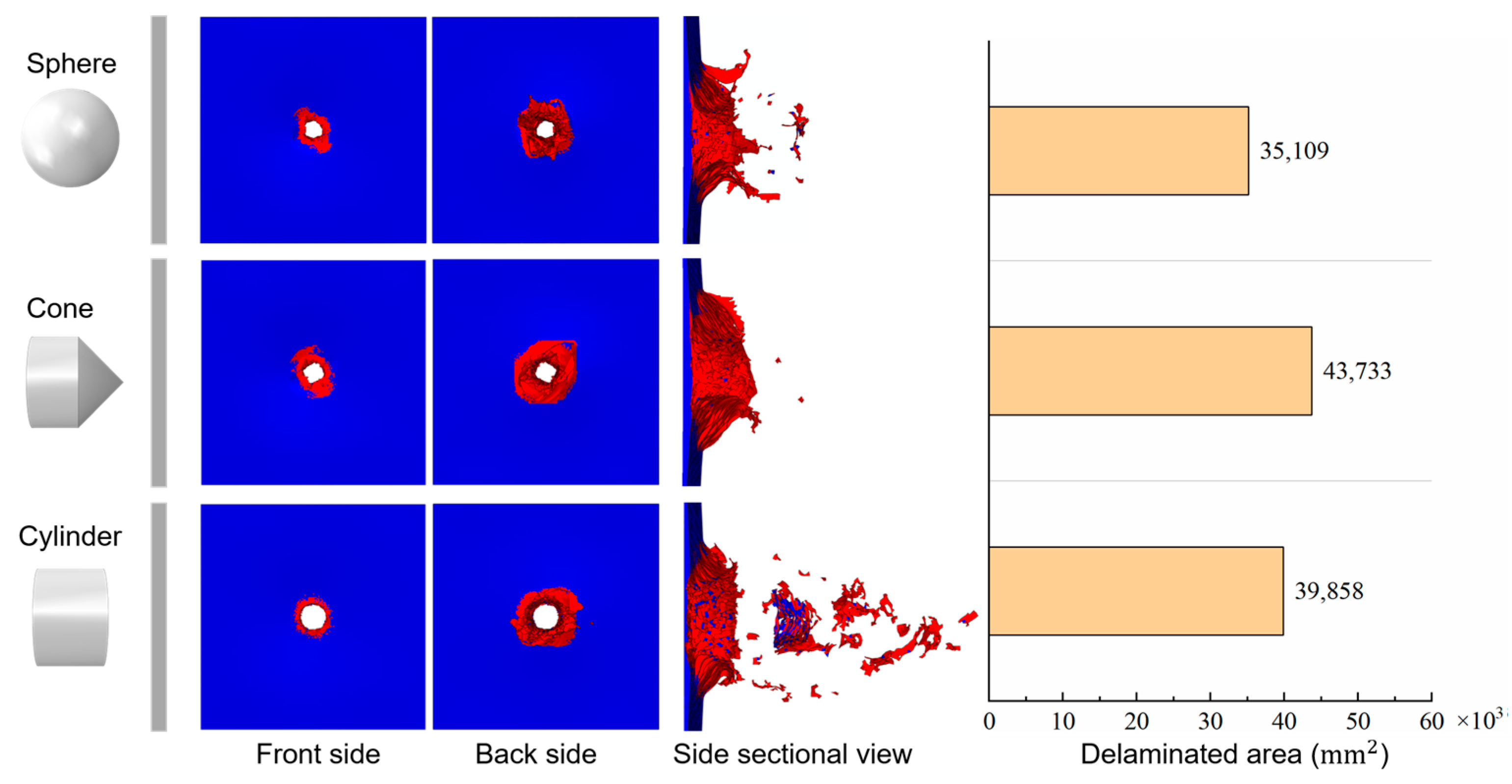

4. Discussion

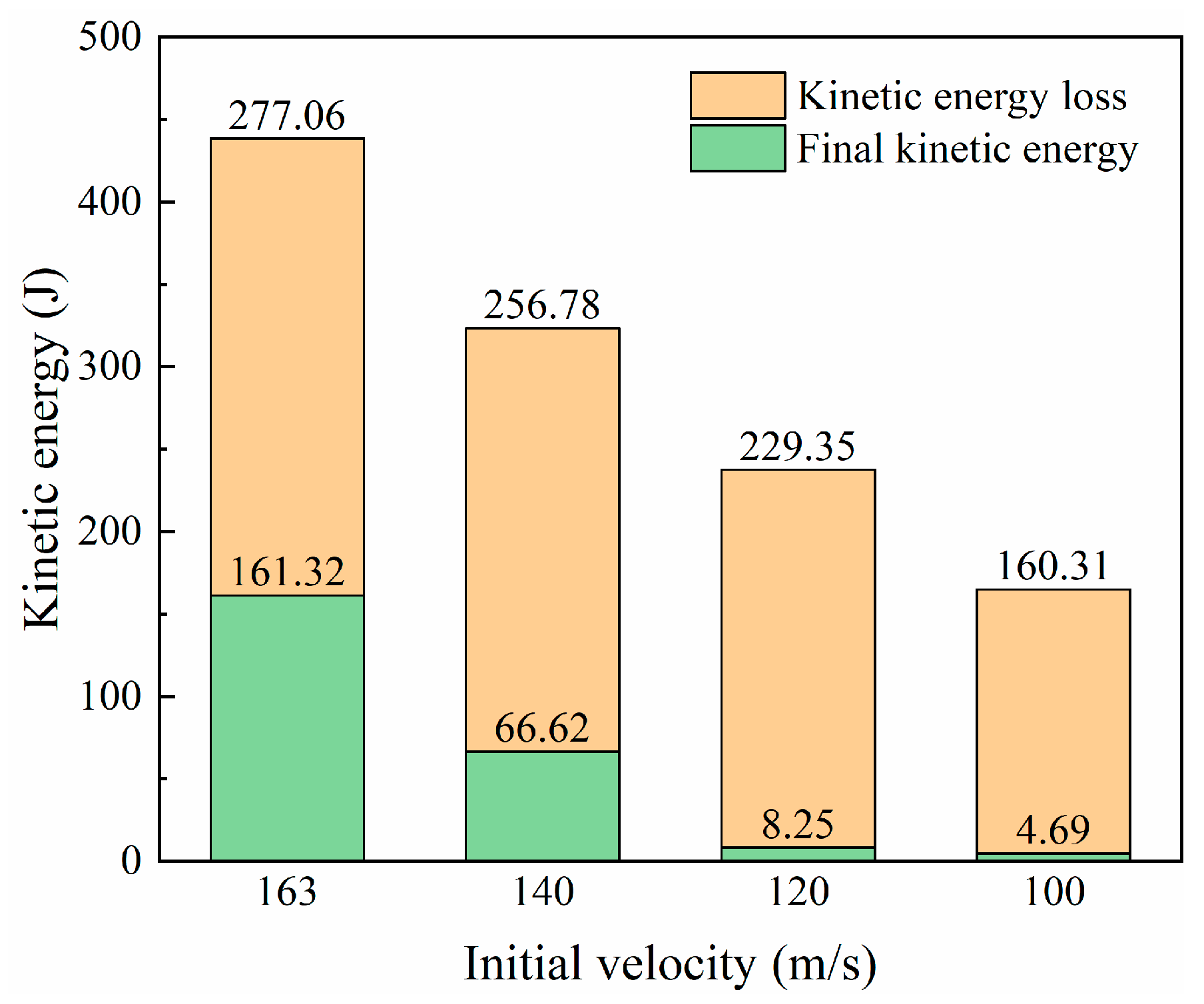

4.1. Effect of Impact Velocity

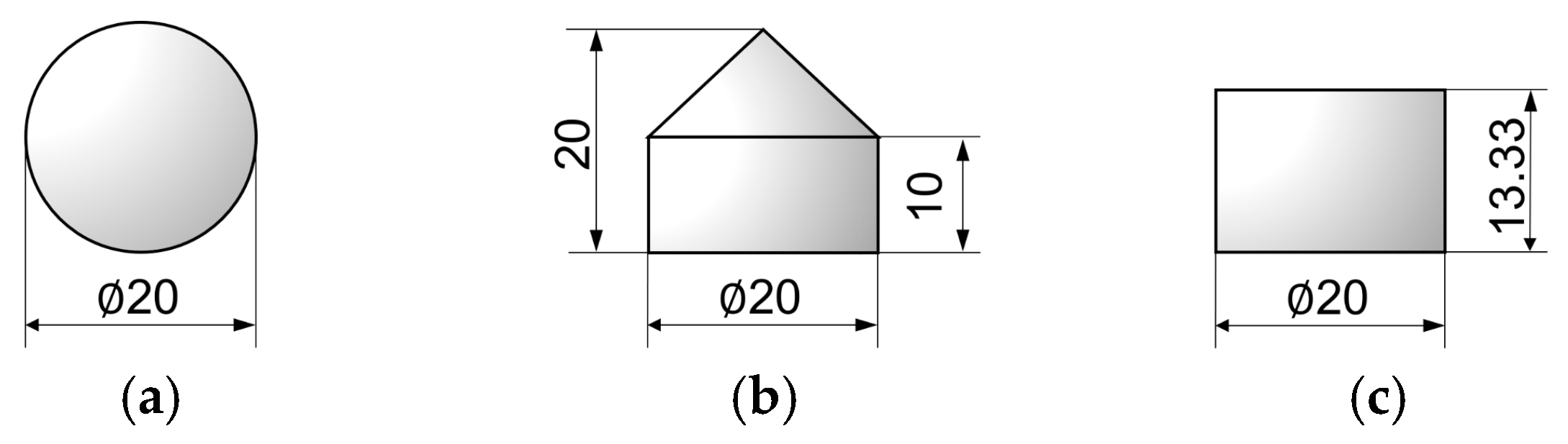

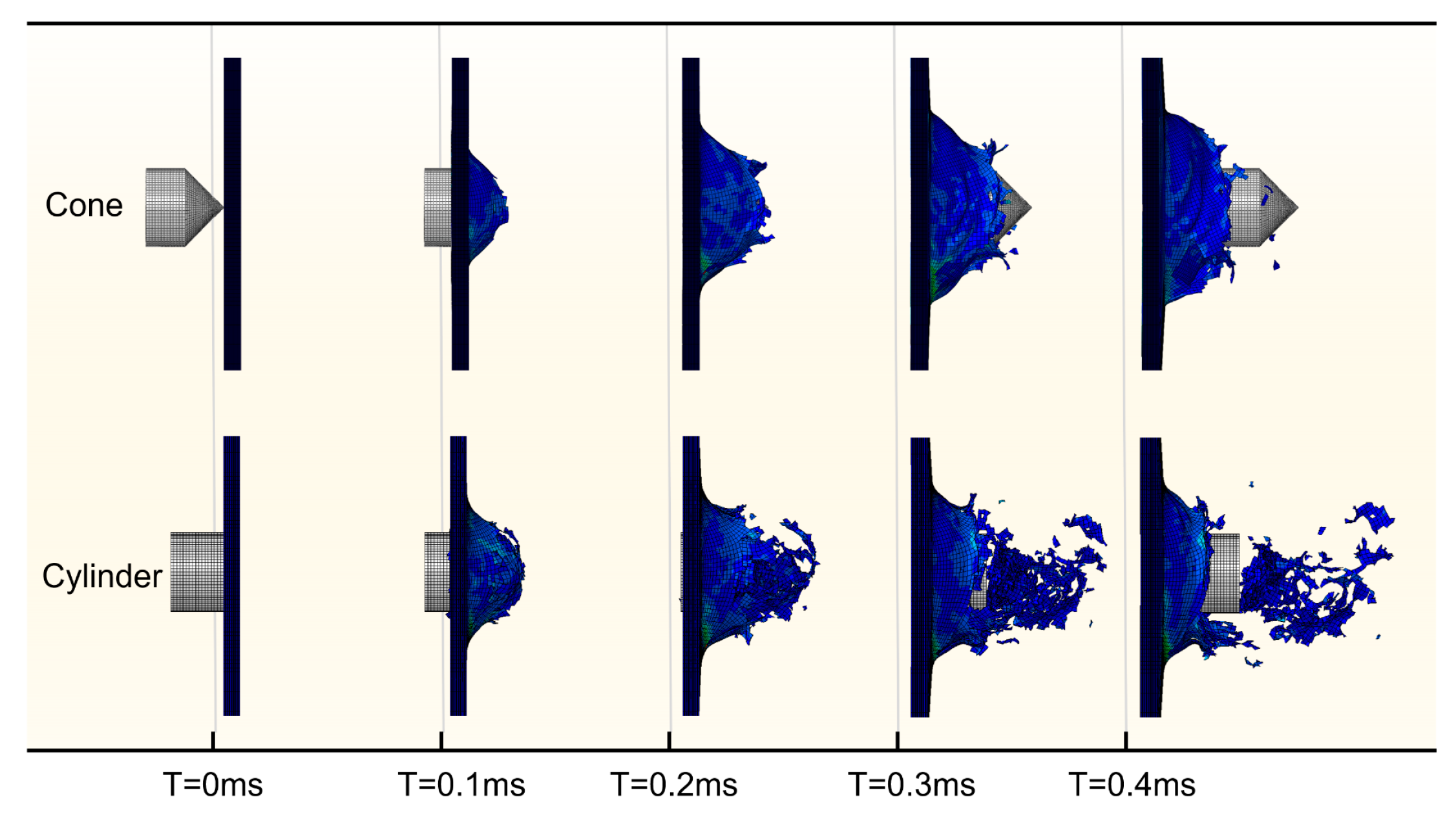

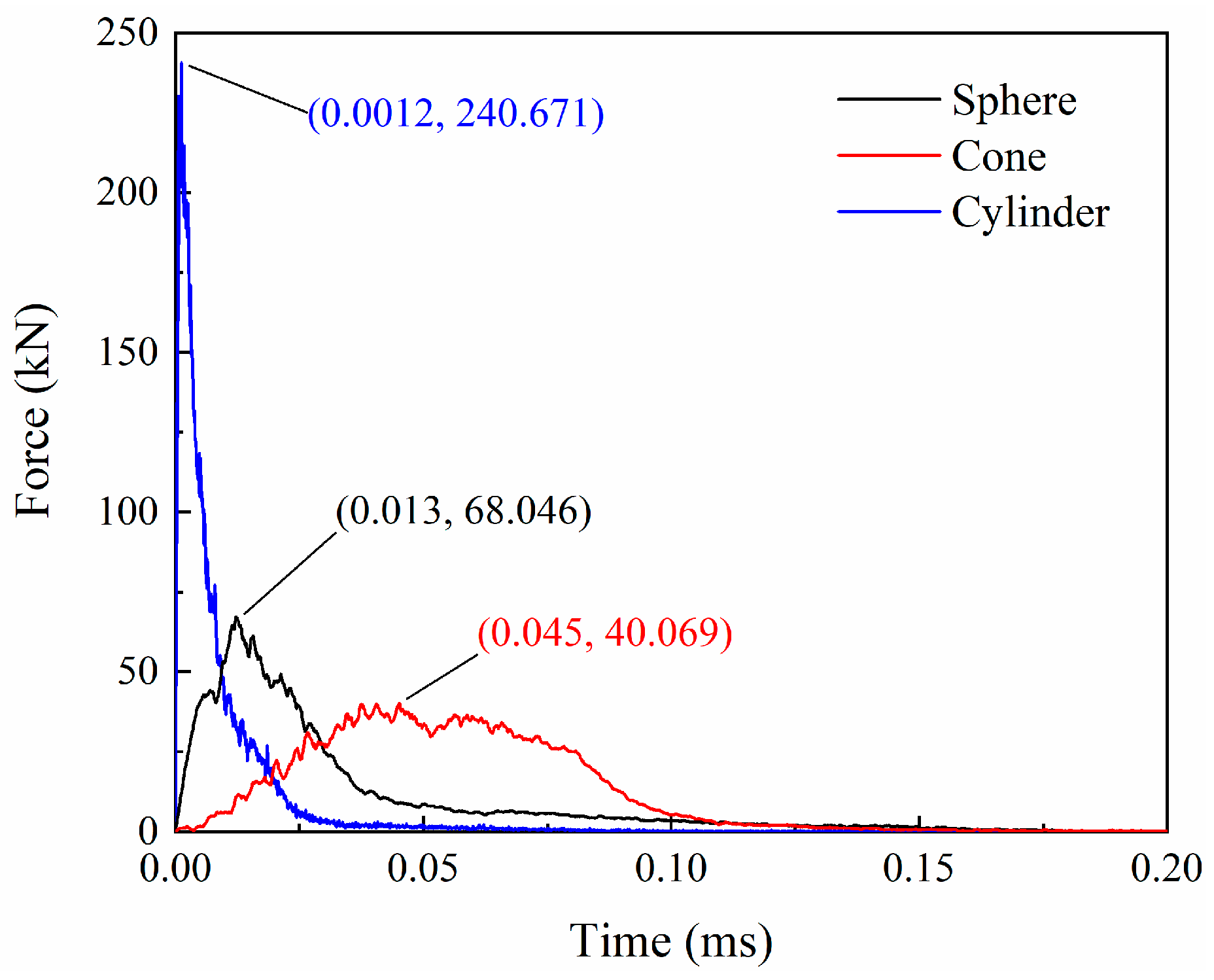

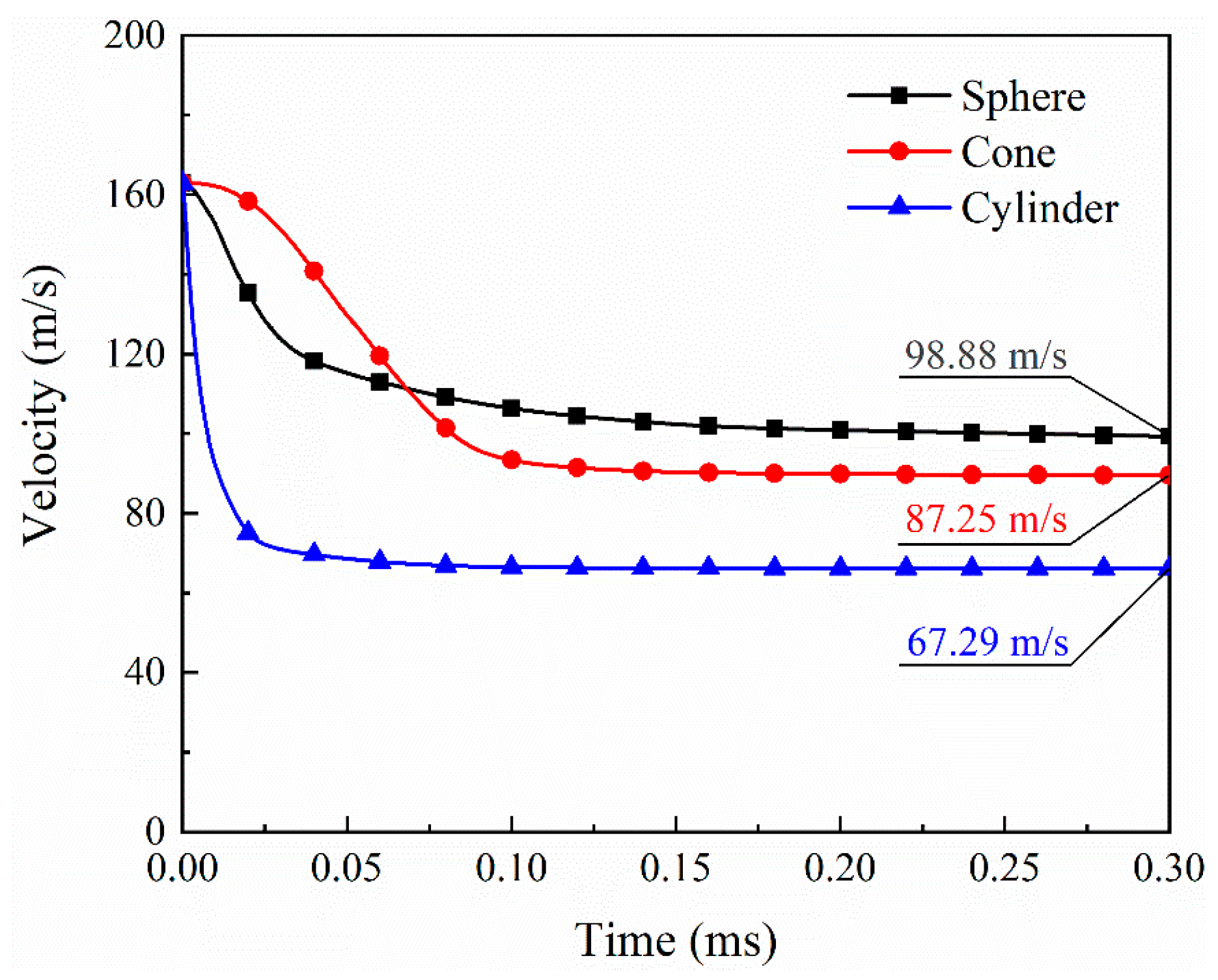

4.2. Effect of Impactor Shape

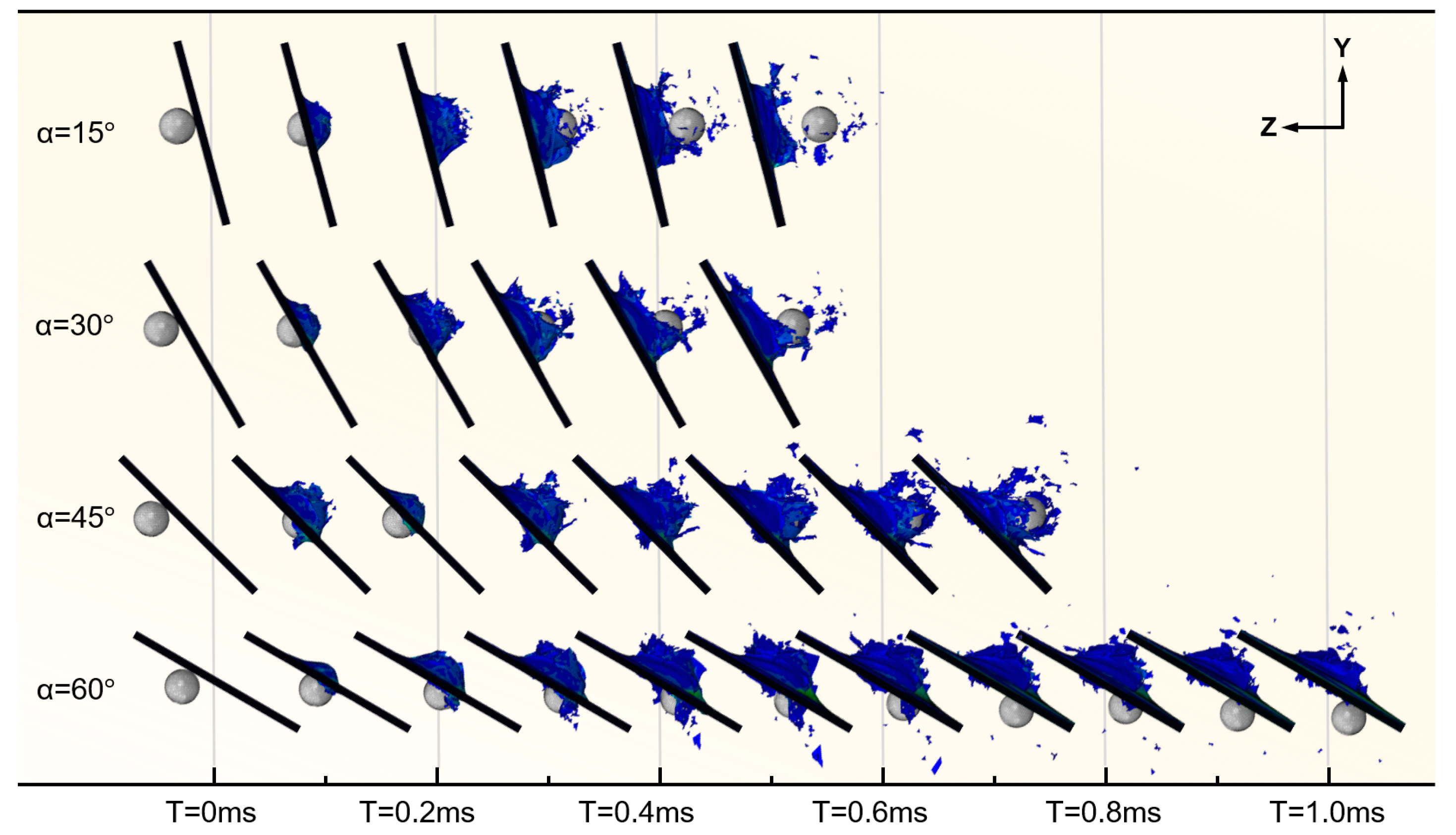

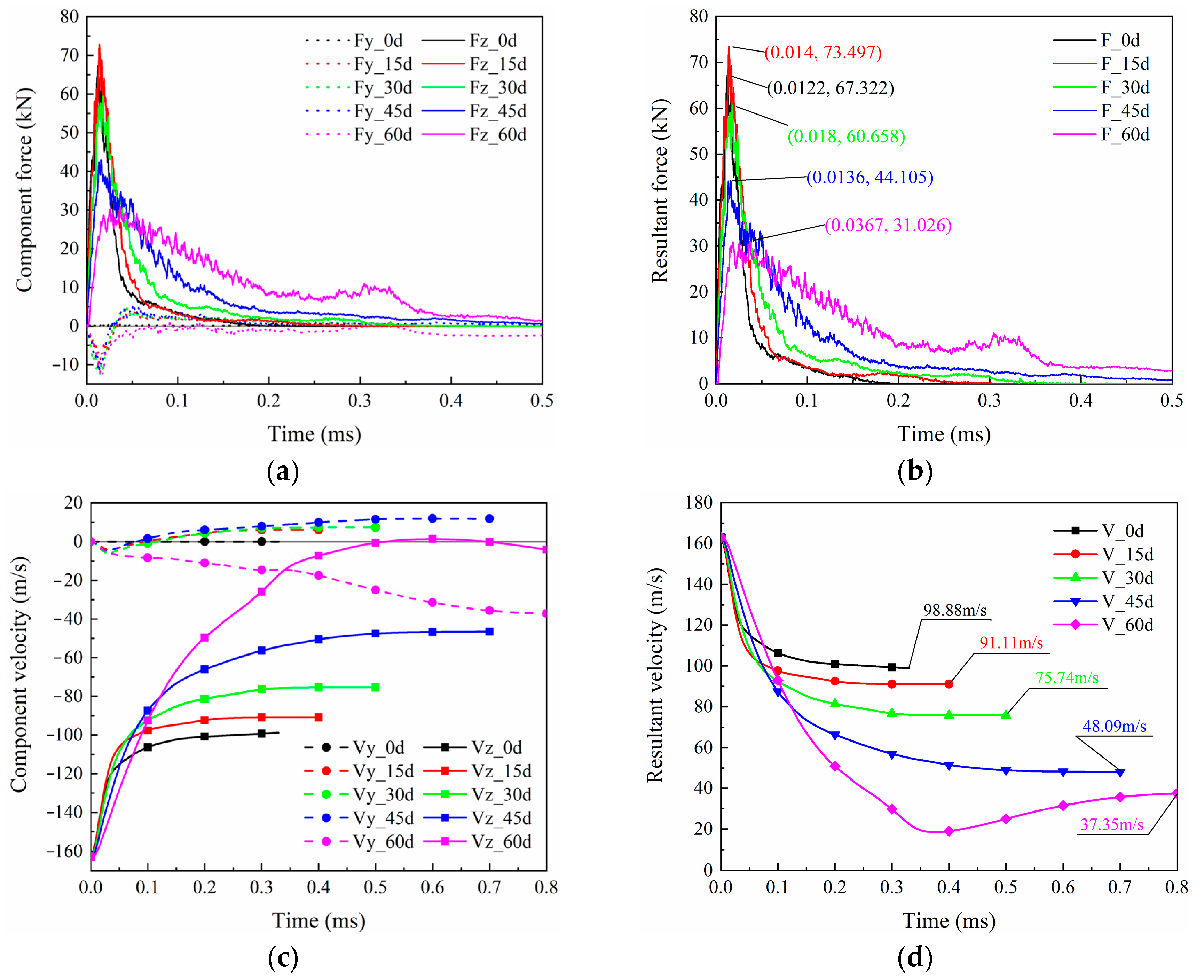

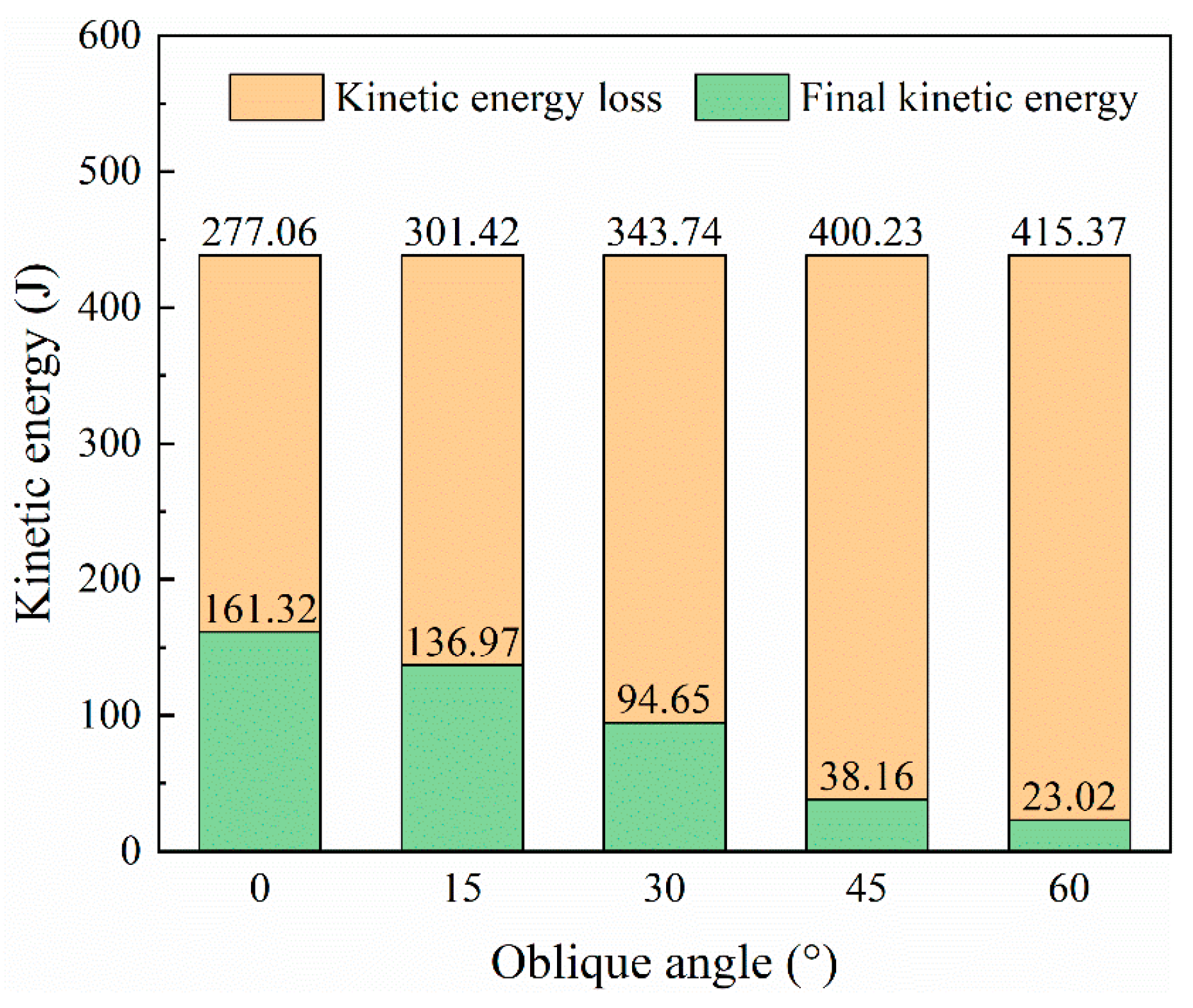

4.3. Effect of Oblique Angle

5. Conclusions

- The ballistic limit of the laminate is within the speed range of 100–120 m/s. There is a positive correlation between impact velocity and peak impact force, impact velocity, and projectile kinetic energy loss. The delaminated area decreased by 22.8% when the speed decreased from 140 m/s to 100 m/s. In contrast, the delamination area at an impact velocity of 163 m/s differs from that at 140 m/s by only 1.4%.

- The shear plugging by the cylindrical projectile’s flat end produces many material fragments in the central area. The peak impact force is highest for the cylindrical projectile, 253.7% higher than in the spherical projectile, and 500.6% higher than in the case of the conical projectile. However, the residual velocity of the spherical projectile is higher than that of the other two projectiles, 13.3% higher than that of the conical projectile, and 46.9% higher than that of the cylindrical projectile. The conical projectile penetrated the laminate with the most negligible impedance but produced the largest delaminated area compared to the other two projectiles.

- The oblique angle of the target significantly influences the perforation performance of the laminate. Increasing the oblique angle can reduce the peak impact force. The longer the impact path of the projectile, the larger the damaged area of the laminate, which is conducive to the consumption of the impact energy of the projectile. Compared with the baseline model, when the oblique angle of the laminate is 60°, the peak impact force decreases by 57.8%, the residual velocity decreases by 62.2%, and the delaminated area increases by 43.4%.

- The results obtained in this study show that CFRP laminates currently used in rail vehicles cannot resist the risk of high-speed impacts of foreign objects that may be faced during operation. Optimization of the layup and biomimetic sandwich structure can be used to improve the structural impact resistance in practical applications. In addition, if the train encounters hailstorms, windstorms, and other weather conditions during operation, it is necessary to slow down or stop the operation as appropriate.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jagadeesh, P.; Puttegowda, M.; Oladijo, O.P.; Lai, C.W.; Gorbatyuk, S.; Matykiewicz, D.; Rangappa, S.M.; Siengchin, S. A comprehensive review on polymer composites in railway applications. Polym. Compos. 2022, 43, 1238–1251. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, H.; Wang, T.; Yang, M.; Wang, K.; Meng, W.; Wang, D. Energy consumption analysis and multiple-criteria evaluation of high-speed trains with different marshaled forms in China. Sci. Total Environ. 2021, 759, 143678. [Google Scholar] [CrossRef] [PubMed]

- Robinson, M. Applications in trains and railways. Compr. Compos. Mater. 2000, 6, 395–428. [Google Scholar] [CrossRef]

- Seo, S.I.; Kim, J.S.; Cho, S.H. Development of a hybrid composite bodyshell for tilting trains. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit. 2008, 222, 1–13. [Google Scholar] [CrossRef]

- Railway Technology. Available online: https://www.railway-technology.com/news/china-fastest-maglev-transportation-system/ (accessed on 20 April 2022).

- Kim, J.S.; Jeong, J.C.; Lee, S.J. Numerical and experimental studies on the deformational behavior a composite train carbody of the Korean tilting train. Compos. Struct. 2007, 81, 168–175. [Google Scholar] [CrossRef]

- Kim, J.S.; Yoon, H.J. Structural behaviors of a GFRP composite bogie frame for urban subway trains under critical load conditions. Procedia Eng. 2011, 10, 2375–2380. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, W.G.; Kim, I.K. Manufacturing and testing of a GFRP composite bogie frame with straight side beam members. J. Mech. Sci. Technol. 2013, 27, 2761–2767. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, S.J.; Shin, K.B. Manufacturing and structural safety evaluation of a composite train carbody. Compos. Struct. 2007, 78, 468–476. [Google Scholar] [CrossRef]

- Kim, J. Fire resistance evaluation of a train carbody made of composite material by large scale tests. Compos. Struct. 2008, 83, 295–303. [Google Scholar] [CrossRef]

- Goo, J.S.; Kim, J.S.; Shin, K.B. Evaluation of structural integrity after ballast-flying impact damage of a GFRP lightweight bogie frame for railway vehicles. J. Mech. Sci. Technol. 2015, 29, 2349–2356. [Google Scholar] [CrossRef]

- Onder, A.; ONeill, C.; Robinson, M. Flying ballast resistance for composite materials in railway vehicle carbody shells. Transp. Res. Procedia 2016, 14, 595–604. [Google Scholar] [CrossRef]

- Jeon, K.W.; Shin, K.B.; Kim, J.S. A study on fatigue life and strength of a GFRP composite bogie frame for urban subway trains. Procedia Eng. 2011, 10, 2405–2410. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, J.C. Natural frequency evaluation of a composite train carbody with length of 23 m. Compos. Sci. Technol. 2006, 66, 2272–2283. [Google Scholar] [CrossRef]

- Andrew, J.J.; Srinivasan, S.M.; Arockiarajan, A.; Dhakal, H.N. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Compos. Struct. 2019, 224, 111007. [Google Scholar] [CrossRef]

- Chen, F.; Peng, Y.; Chen, X.; Wang, K.; Liu, Z.; Chen, C. Investigation of the ballistic performance of GFRP Laminate under 150 m/s high-velocity impact: Simulation and experiment. Polymers 2021, 13, 604. [Google Scholar] [CrossRef]

- Tang, E.; Yin, H.; Gao, X.; Han, Y.; Chen, C. Damage mechanism of CFRP laminates with different curvatures impacted by ice projectile at high velocity. Polym. Test. 2021, 93, 106939. [Google Scholar] [CrossRef]

- Ghazlan, A.; Ngo, T.; Tan, P.; Tran, P.; Xie, Y. A numerical modelling framework for investigating the ballistic performance of bio-inspired body armours. Biomimetics 2023, 8, 195. [Google Scholar] [CrossRef]

- Fujii, K.; Aoki, M.; Kiuchi, N.; Yasuda, E.; Tanabe, Y. Impact perforation behavior of CFRPs using high-velocity steel sphere. Int. J. Impact Eng. 2002, 27, 497–508. [Google Scholar] [CrossRef]

- Karthikeyan, K.; Russell, B.P.; Fleck, N.A.; Wadley, H.N.G.; Deshpande, V.S. The effect of shear strength on the ballistic response of laminated composite plates. Eur. J. Mech./A Solids 2013, 42, 35–53. [Google Scholar] [CrossRef]

- Huang, T.; Liu, Z.C.; Wang, Y.L. Experimental and numerical analysis of normal and lateral high-velocity impacts on carbon fiber-reinforced polymer laminates. Strength Mater. 2016, 48, 183–192. [Google Scholar] [CrossRef]

- López-Puente, J.; Zaera, R.; Navarro, C. An analytical model for high velocity impacts on thin CFRPs woven laminated plates. Int. J. Solids Struct. 2007, 44, 2837–2851. [Google Scholar] [CrossRef]

- Yuan, K.; Liu, K.; Wang, Z.; Wei, K.; Yang, M. Dynamic fracture in CFRP laminates: Effect of projectile mass and dimension. Eng. Fract. Mech. 2021, 251, 107764. [Google Scholar] [CrossRef]

- Kumar, K.S.; Bhat, T.B. Response of composite laminates on impact of high velocity projectiles. Key Eng. Mater. 1997, 141–143, 337–348. [Google Scholar] [CrossRef]

- Yang, I.Y.; Cho, Y.J.; Im, K.H.; Cha, C.S.; Kim, Y.N. Penetration fracture characteristics of CFRP curved shells according to oblique impact. Key Eng. Mater. 2006, 306–308, 291–296. [Google Scholar] [CrossRef]

- López-Puente, J.; Zaera, R.; Navarro, C. Experimental and numerical analysis of normal and oblique ballistic impacts on thin carbon/epoxy woven laminates. Compos. Part A Appl. Sci. Manuf. 2008, 39, 374–387. [Google Scholar] [CrossRef]

- Pernas-Sánchez, J.; Artero-Guerrero, J.A.; Varas, D.; López-Puente, J. Experimental analysis of normal and oblique high velocity impacts on carbon/epoxy tape laminates. Compos. Part A Appl. Sci. Manuf. 2014, 60, 24–31. [Google Scholar] [CrossRef]

- Xie, W.; Zhang, W.; Kuang, N.; Li, D.; Huang, W.; Gao, Y.; Ye, N.; Guo, L.; Ren, P. Experimental investigation of normal and oblique impacts on CFRPs by high velocity steel sphere. Compos. Part B Eng. 2016, 99, 483–493. [Google Scholar] [CrossRef]

- Falaschetti, M.P.; Scafé, M.; Zavatta, N.; Troiani, E. Hygrothermal ageing influence on bvi-damaged carbon/epoxy coupons under compression load. Polymers 2021, 13, 2038. [Google Scholar] [CrossRef]

- Liu, X.; Gu, W.; Liu, Q.; Lai, X.; Liu, L. Damage of hygrothermally conditioned carbon epoxy composites under high-velocity impact. Materials 2018, 11, 2525. [Google Scholar] [CrossRef]

- Malhotra, A.; Guild, F.J. Impact damage to composite laminates: Effect of impact location. Appl. Compos. Mater. 2014, 21, 165–177. [Google Scholar] [CrossRef]

- Nassir, N.; Guan, Z.W.; Birch, R.S.; Cantwell, W.J. Damage initiation in composite materials under off-centre impact loading. Polym. Test. 2018, 69, 456–461. [Google Scholar] [CrossRef]

- Huang, Z.; Li, H.; Pan, Z.; Wei, Q.; Chao, Y.J.; Li, X. Uncovering high-strain rate protection mechanism in nacre. Sci. Rep. 2011, 1, 148. [Google Scholar] [CrossRef]

- Li, H.; Shen, J.; Wei, Q.; Li, X. Dynamic self-strengthening of a bio-nanostructured armor—Conch shell. Mater. Sci. Eng. C 2019, 103, 109820. [Google Scholar] [CrossRef] [PubMed]

- Al-Zubaidy, H.; Zhao, X.-L.; Al-Mahaidi, R. Mechanical characterisation of the dynamic tensile properties of CFRP sheet and adhesive at medium strain rates. Compos. Struct. 2013, 96, 153–164. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Shi, Y.; Cui, J.; Zhang, X. Static and dynamic material properties of CFRP/epoxy laminates. Constr. Build. Mater. 2016, 114, 38–49. [Google Scholar] [CrossRef]

- Naresh, K.; Shankar, K.; Velmurugan, R.; Gupta, N.K. High strain rate studies for different laminate configurations of bi-directional glass/epoxy and carbon/epoxy composites using DIC. Structures 2020, 27, 2451–2465. [Google Scholar] [CrossRef]

- Al-Mosawe, A.; Al-Mahaidi, R.; Zhao, X.-L. Engineering properties of CFRP laminate under high strain rates. Compos. Struct. 2017, 180, 9–15. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D.; Zhang, H.; Yao, Y.; Mobasher, B.; Huang, L. Mechanical properties and failure characteristics of CFRP under intermediate strain rates and varying temperatures. Compos. Part B Eng. 2016, 95, 123–136. [Google Scholar] [CrossRef]

- Wang, K.; Cai, R.; Zhang, Z.; Liu, J.; Ahzi, S.; Peng, Y.; Rao, Y. Compressive behaviors of 3D printed polypropylene-based composites at low and high strain rates. Polym. Test. 2021, 103, 107321. [Google Scholar] [CrossRef]

- Tserpes, K.; Labeas, G.; Papanikos, P.; Kermanidis, T. Strength prediction of bolted joints in graphite/epoxy composite laminates. Compos. Part B Eng. 2002, 33, 521–529. [Google Scholar] [CrossRef]

- Ye, Y.; Zhu, W.; Jiang, J.; Xu, Q.; Ke, Y. Computational modelling of postbuckling behavior of composite T-stiffened panels with different bonding methods. Compos. Part B Eng. 2019, 166, 247–256. [Google Scholar] [CrossRef]

- Sitnikova, E.; Guan, Z.W.; Schleyer, G.K.; Cantwell, W.J. Modelling of perforation failure in fibre metal laminates subjected to high impulsive blast loading. Int. J. Solids Struct. 2014, 51, 3135–3146. [Google Scholar] [CrossRef]

- Hassan, N.M.; Batra, R.C. Modeling damage in polymeric composites. Compos. Part B Eng. 2008, 39, 66–82. [Google Scholar] [CrossRef]

- Xu, M.; Yang, Y.; Lei, H.; Wang, P.; Li, X.; Zhang, Z.; Fang, D. Dynamic response of fiber metal laminates subjected to localized high impulse blast loading. Compos. Struct. 2020, 243, 112216. [Google Scholar] [CrossRef]

- Chang, T.; Zhan, L.; Tan, W.; Wu, X. Cohesive zone modeling of the autoclave pressure effect on the delamination behavior of composite laminates. J. Reinf. Plast. Compos. 2018, 37, 1468–1480. [Google Scholar] [CrossRef]

| Damage Modes | Damage Criteria | Degradation Constant |

|---|---|---|

| Fiber tensile | ||

| Fiber compression () | ||

| Matrix tensile | ||

| Matrix compression ) |

| Item | Symbol and Value |

|---|---|

| Density | |

| Poisson’s ratio | , |

| Modulus | , |

| Shear modulus | , |

| Longitudinal strength | , |

| Transversal strength | , |

| Shear strength | , |

| Parameter | |||||

|---|---|---|---|---|---|

| Value | 0.1 | 0.123 | 0.131 |

| Material Property | Symbol and Value | ||

|---|---|---|---|

| Modulus | |||

| Strength | 65.43 MPa | 98.15 MPa | 98.15 MPa |

| Fracture toughness | 0.37 N/mm | N/mm | N/mm |

| Density | 1.44 g/cm3 | ||

| Experiment | Simulation without Strain Rate Effect | Simulation with Strain Rate Effect | |

|---|---|---|---|

| Remaining velocity | 102.78 m/s | 112.52 m/s | 98.88 m/s |

| Error | - | 9.48% | 3.79% |

| Kinetic energy loss | 264.09 J | 229.49 J | 277.06 J |

| Error | - | 13.10% | 4.91% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Peng, Y.; Wang, K.; Wang, X.; Liu, Z.; Huang, Z.; Zhang, H. Study on High-Velocity Impact Perforation Performance of CFRP Laminates for Rail Vehicles: Experiment and Simulation. Biomimetics 2023, 8, 568. https://doi.org/10.3390/biomimetics8080568

Chen X, Peng Y, Wang K, Wang X, Liu Z, Huang Z, Zhang H. Study on High-Velocity Impact Perforation Performance of CFRP Laminates for Rail Vehicles: Experiment and Simulation. Biomimetics. 2023; 8(8):568. https://doi.org/10.3390/biomimetics8080568

Chicago/Turabian StyleChen, Xuanzhen, Yong Peng, Kui Wang, Xin Wang, Zhixiang Liu, Zhiqiang Huang, and Honghao Zhang. 2023. "Study on High-Velocity Impact Perforation Performance of CFRP Laminates for Rail Vehicles: Experiment and Simulation" Biomimetics 8, no. 8: 568. https://doi.org/10.3390/biomimetics8080568

APA StyleChen, X., Peng, Y., Wang, K., Wang, X., Liu, Z., Huang, Z., & Zhang, H. (2023). Study on High-Velocity Impact Perforation Performance of CFRP Laminates for Rail Vehicles: Experiment and Simulation. Biomimetics, 8(8), 568. https://doi.org/10.3390/biomimetics8080568