A Fast Grasp Planning Algorithm for Humanoid Robot Hands

Abstract

1. Introduction

2. Problem Formulation

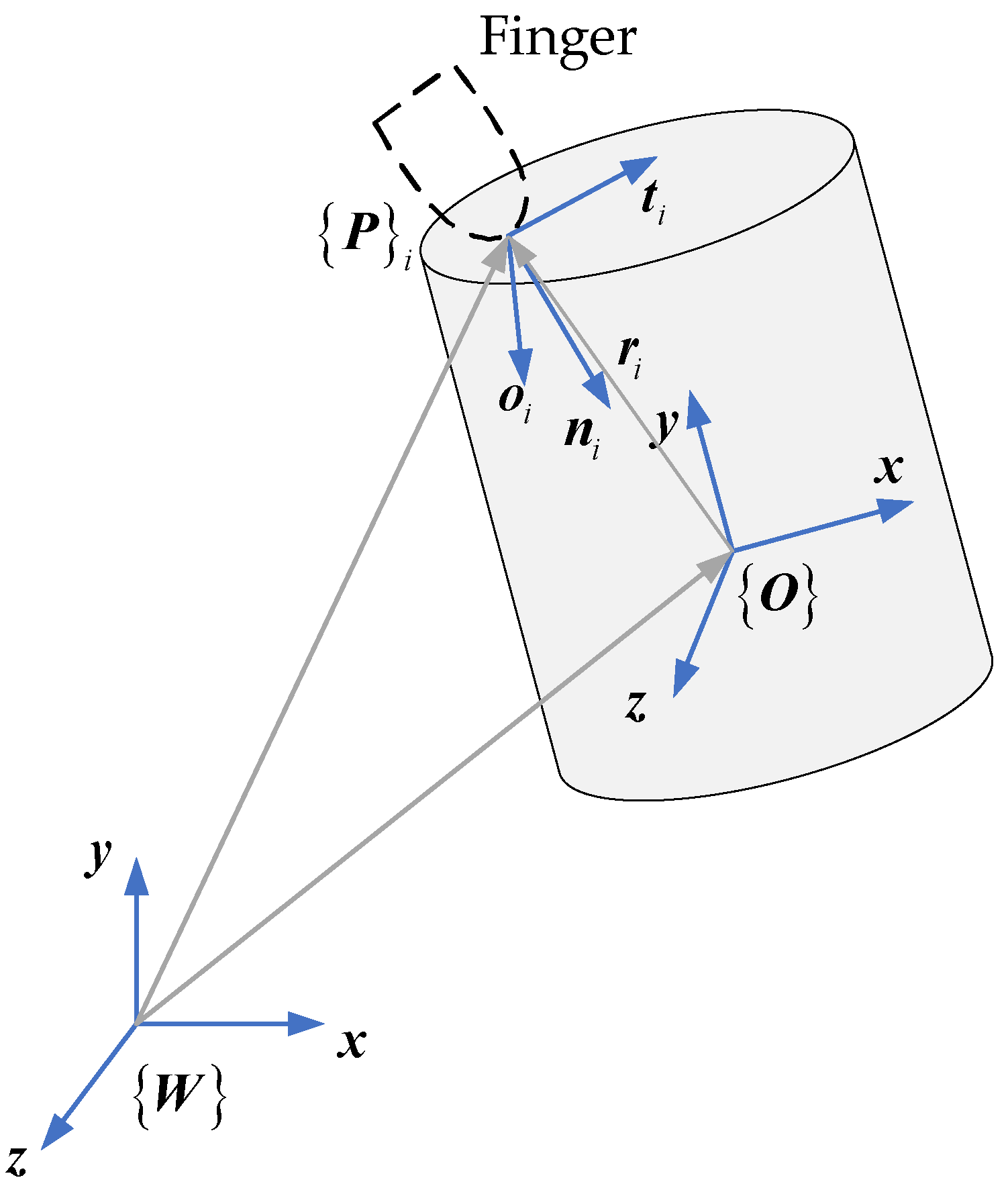

2.1. Contact Model

2.2. Grasp Analysis

2.3. A Sufficient Condition for Four-Finger Force-Closure Grasps of 3-D Objects

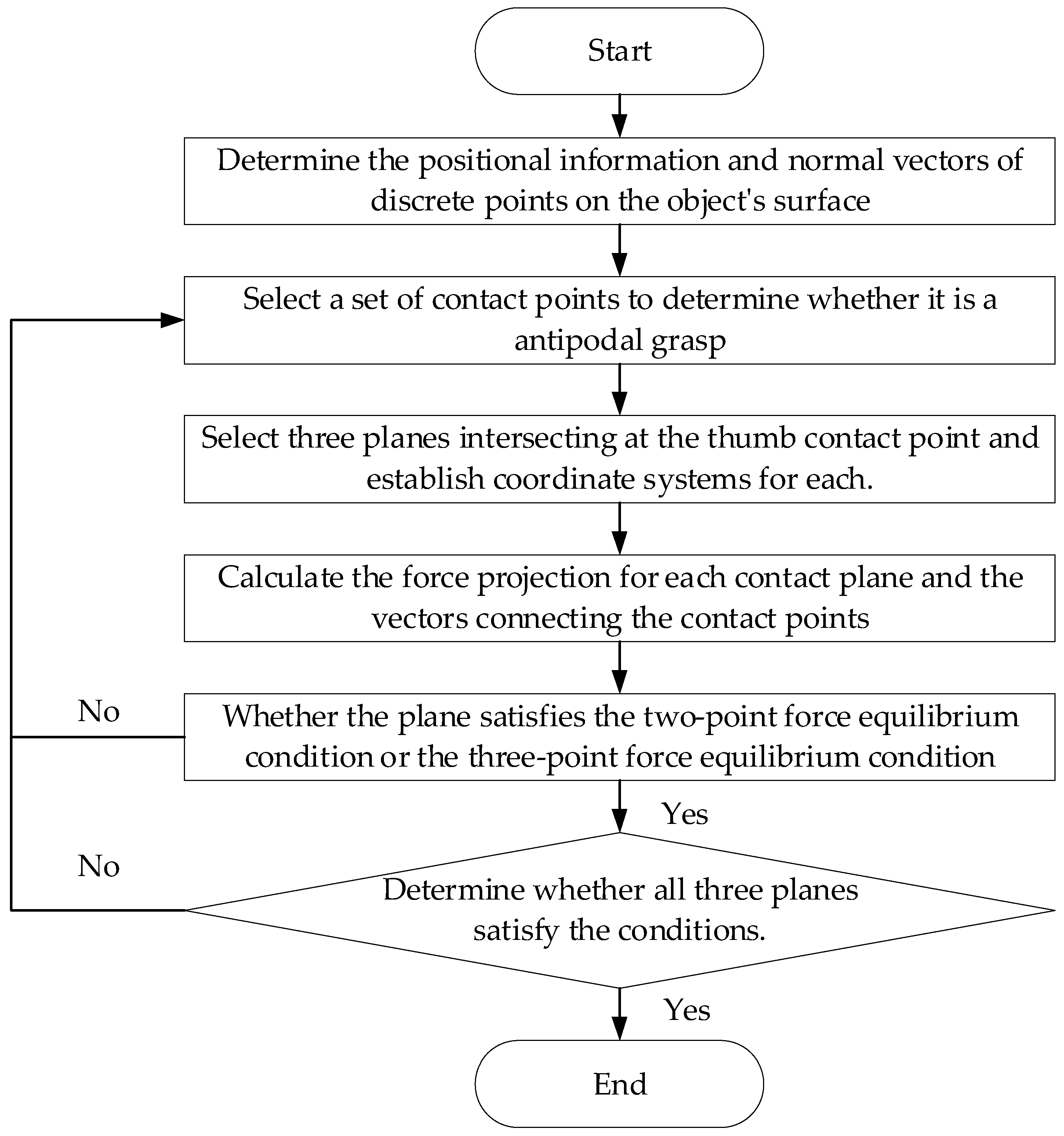

3. Algorithm

3.1. Contact Force Analysis in Contact Plane

3.2. Force Equilibrium Grasps

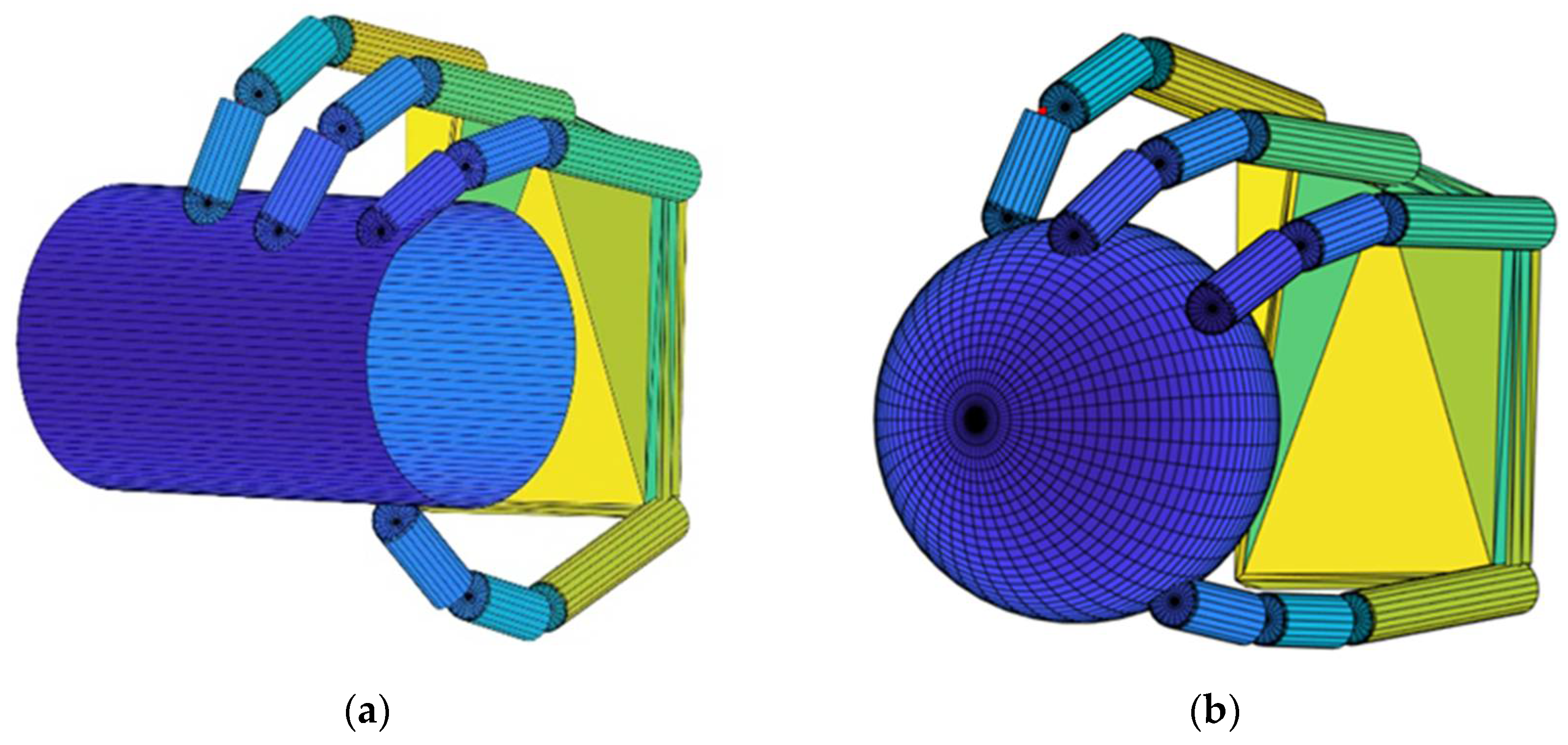

4. Application Examples

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shadow Hand & Glove-Shadow Robot. Available online: https://www.shadowrobot.com/shadow-hand-glove/ (accessed on 14 August 2022).

- Ruehl, S.W.; Parlitz, C.; Heppner, G.; Hermann, A.; Roennau, A.; Dillmann, R. Experimental Evaluation of the Schunk 5-Finger Gripping Hand for Grasping Tasks. In Proceedings of the 2014 IEEE International Conference on Robotics and Biomimetics (ROBIO 2014), Bali, Indonesia, 5–10 December 2014; pp. 2465–2470. [Google Scholar]

- Mnyusiwalla, H.; Vulliez, P.; Gazeau, J.-P.; Zeghloul, S. A New Dexterous Hand Based on Bio-Inspired Finger Design for Inside-Hand Manipulation. IEEE Trans. Syst. Man Cybern. Syst. 2016, 46, 809–817. [Google Scholar] [CrossRef]

- Cao, B.; Gu, Y.; Sun, K.; Jin, M.; Liu, H. Development of HIT Humanoid Robot. In Proceedings of the Intelligent Robotics and Applications; Huang, Y., Wu, H., Liu, H., Yin, Z., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 286–297. [Google Scholar]

- Marwan, Q.M.; Chua, S.C.; Kwek, L.C. Comprehensive Review on Reaching and Grasping of Objects in Robotics. Robotica 2021, 39, 1849–1882. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, J.; Sun, S.; Lan, X. Robotic Grasping from Classical to Modern: A Survey. arXiv 2022, arXiv:2202.03631. [Google Scholar]

- Liang, H.; Cong, L.; Hendrich, N.; Li, S.; Sun, F.; Zhang, J. Multifingered Grasping Based on Multimodal Reinforcement Learning. IEEE Robot. Autom. Lett. 2022, 7, 1174–1181. [Google Scholar] [CrossRef]

- Duan, H.; Wang, P.; Li, Y.; Li, D.; Wei, W. Learning Human-to-Robot Dexterous Handovers for Anthropomorphic Hand. IEEE Trans. Cogn. Dev. Syst. 2022, 15, 1224–1238. [Google Scholar] [CrossRef]

- Sahbani, A.; El-Khoury, S.; Bidaud, P. An Overview of 3D Object Grasp Synthesis Algorithms. Robot. Auton. Syst. 2012, 60, 326–336. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Z.; Jiao, Z.; Zhu, Y.; Zhu, S.-C. Synthesizing Diverse and Physically Stable Grasps with Arbitrary Hand Structures Using Differentiable Force Closure Estimator. IEEE Robot. Autom. Lett. 2022, 7, 470–477. [Google Scholar] [CrossRef]

- Bohg, J.; Morales, A.; Asfour, T.; Kragic, D. Data-Driven Grasp Synthesis—A Survey. IEEE Trans. Robot. 2014, 30, 289–309. [Google Scholar] [CrossRef]

- Caldera, S.; Rassau, A.; Chai, D. Review of Deep Learning Methods in Robotic Grasp Detection. Multimodal Technol. Interact. 2018, 2, 57. [Google Scholar] [CrossRef]

- Du, G.; Wang, K.; Lian, S.; Zhao, K. Vision-Based Robotic Grasping from Object Localization, Object Pose Estimation to Grasp Estimation for Parallel Grippers: A Review. Artif. Intell. Rev. 2021, 54, 1677–1734. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, J.; Chen, J.; Xu, Y.; Li, P.; Liu, T.; Wang, H. DexGraspNet: A Large-Scale Robotic Dexterous Grasp Dataset for General Objects Based on Simulation. In Proceedings of the 2023 IEEE International Conference on Robotics and Automation (ICRA), London, UK, 29 May–June 2023; pp. 11359–11366. [Google Scholar]

- Mnyussiwalla, H.; Seguin, P.; Vulliez, P.; Gazeau, J.P. Evaluation and Selection of Grasp Quality Criteria for Dexterous Manipulation. J. Intell. Robot. Syst. 2022, 104, 20. [Google Scholar] [CrossRef]

- Li, J.-W.; Liu, H.; Cai, H.-G. On Computing Three-Finger Force-Closure Grasps of 2-d and 3-d Objects. IEEE Trans. Robot. Autom. 2003, 19, 155–161. [Google Scholar] [CrossRef]

- Liu, Y.-H. Qualitative Test and Force Optimization of 3-D Frictional Form-Closure Grasps Using Linear Programming. IEEE Trans. Robot. Autom. 1999, 15, 163–173. [Google Scholar] [CrossRef]

- Zheng, Y.; Qian, W.-H. An Enhanced Ray-Shooting Approach to Force-Closure Problems. J. Manuf. Sci. Eng. 2006, 128, 960–968. [Google Scholar] [CrossRef]

- Zheng, Y.; Qian, W.-H. Simplification of the Ray-Shooting Based Algorithm for 3-D Force-Closure Test. IEEE Trans. Robot. 2005, 21, 470–473. [Google Scholar] [CrossRef]

- Zheng, Y. Computing the Best Grasp in a Discrete Point Set with Wrench-Oriented Grasp Quality Measures. Auton. Robot. 2019, 43, 1041–1062. [Google Scholar] [CrossRef]

- Markenscoff, X.; Ni, L.; Papadimitriou, C.H. The Geometry of Grasping. Int. J. Robot. Res. 1990, 9, 61–74. [Google Scholar] [CrossRef]

- Nguyen, V.-D. Constructing Force- Closure Grasps. Int. J. Robot. Res. 1988, 7, 3–16. [Google Scholar] [CrossRef]

- Ponce, J.; Faverjon, B. On Computing Three-Finger Force-Closure Grasps of Polygonal Objects. IEEE Trans. Robot. Autom. 1995, 11, 868–881. [Google Scholar] [CrossRef]

- Ponce, J.; Sullivan, S.; Boissonnat, J.-D.; Merlet, J.-P. On Characterizing and Computing Three- and Four-Finger Force-Closure Grasps of Polyhedral Objects. In Proceedings of the [1993] Proceedings IEEE International Conference on Robotics and Automation, Atlanta, GA, USA, 2–6 May 1993; Volume 2, pp. 821–827. [Google Scholar]

- Ponce, J.; Sullivan, S.; Sudsang, A.; Boissonnat, J.-D.; Merlet, J.-P. On Computing Four-Finger Equilibrium and Force-Closure Grasps of Polyhedral Objects. Int. J. Robot. Res. 1997, 16, 11–35. [Google Scholar] [CrossRef]

- Daoud, N.; Gazeau, J.P.; Zeghloul, S.; Arsicault, M. A Fast Grasp Synthesis Method for Online Manipulation. Robot. Auton. Syst. 2011, 59, 421–427. [Google Scholar] [CrossRef]

- Bounab, B.; Sidobre, D.; Zaatri, A. on computing multi-finger force-closure grasps of 2D objects. In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics-Volume 2: ICINCO; SciTePress: Angers, France, 2007. [Google Scholar]

- Nenchev, D.N.; Konno, A.; Tsujita, T. Humanoid Robots: Modeling and Control; Butterworth-Heinemann: Oxford, UK; Cambridge, MA, USA, 2019; ISBN 978-0-12-804560-2. [Google Scholar]

- Nguyen, V.-D. Constructing Force-Closure Grasps. In Proceedings of the 1987 IEEE International Conference on Robotics and Automation Proceedings, Raleigh, NC, USA, 31 March–3 April 1987; Volume 3, pp. 1368–1373. [Google Scholar]

- Salisbury, J.K.; Craig, J.J. Articulated Hands: Force Control and Kinematic Issues. Int. J. Robot. Res. 1982, 1, 4–17. [Google Scholar] [CrossRef]

- Cutkosky, M.R. On Grasp Choice, Grasp Models, and the Design of Hands for Manufacturing Tasks. IEEE Trans. Robot. Autom. 1989, 5, 269–279. [Google Scholar] [CrossRef]

- Sudsang, A.; Ponce, J. New Techniques for Computing Four-Finger Force-Closure Grasps of Polyhedral Objects. In Proceedings of the Proceedings of 1995 IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995; IEEE: Nagoya, Japan, 1995; Volume 2, pp. 1355–1360. [Google Scholar]

- El-Khoury, S.; Sahbani, A. A Sufficient Condition For Computing N-Finger Force-Closure Grasps of 3D Objects. In Proceedings of the 2008 IEEE Conference on Robotics, Automation and Mechatronics, Chengdu, China, 21–24 September 2008; IEEE: Chengdu, China, 2008; pp. 791–796. [Google Scholar]

- Mishra, B.; Schwartz, J.T.; Sharir, M. On the Existence and Synthesis of Multifinger Positive Grips. Algorithmica 1987, 2, 541–558. [Google Scholar] [CrossRef]

- Rimon, E.D. Geometric Characterization of the Planar Multi-Finger Equilibrium Grasps. IEEE Robot. Autom. Lett. 2021, 6, 7933–7940. [Google Scholar] [CrossRef]

- Liu, Q.; Jiang, B.; Dou, Q. On Force-Closure Grasping of Three-Fingered Robot Hand. Mech. Sci. Technol. Aerosp. Eng. 2010, 29, 498–503. [Google Scholar]

| Object | Antipodal Grasps | Force-Closure Grasps | Force-Closure Grasp Ratio | Computation Time (ms) |

|---|---|---|---|---|

| Cylinder | 842 | 302 | 35.87% | 103 |

| Ball | 2455 | 1178 | 47.98% | 283 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Jiang, L.; Cheng, M. A Fast Grasp Planning Algorithm for Humanoid Robot Hands. Biomimetics 2024, 9, 599. https://doi.org/10.3390/biomimetics9100599

Liu Z, Jiang L, Cheng M. A Fast Grasp Planning Algorithm for Humanoid Robot Hands. Biomimetics. 2024; 9(10):599. https://doi.org/10.3390/biomimetics9100599

Chicago/Turabian StyleLiu, Ziqi, Li Jiang, and Ming Cheng. 2024. "A Fast Grasp Planning Algorithm for Humanoid Robot Hands" Biomimetics 9, no. 10: 599. https://doi.org/10.3390/biomimetics9100599

APA StyleLiu, Z., Jiang, L., & Cheng, M. (2024). A Fast Grasp Planning Algorithm for Humanoid Robot Hands. Biomimetics, 9(10), 599. https://doi.org/10.3390/biomimetics9100599