Impact of New Combined Treatment Method on the Mechanical Properties and Microstructure of MICP-Improved Sand

Abstract

:1. Introduction

2. Materials and Methods

2.1. Soil

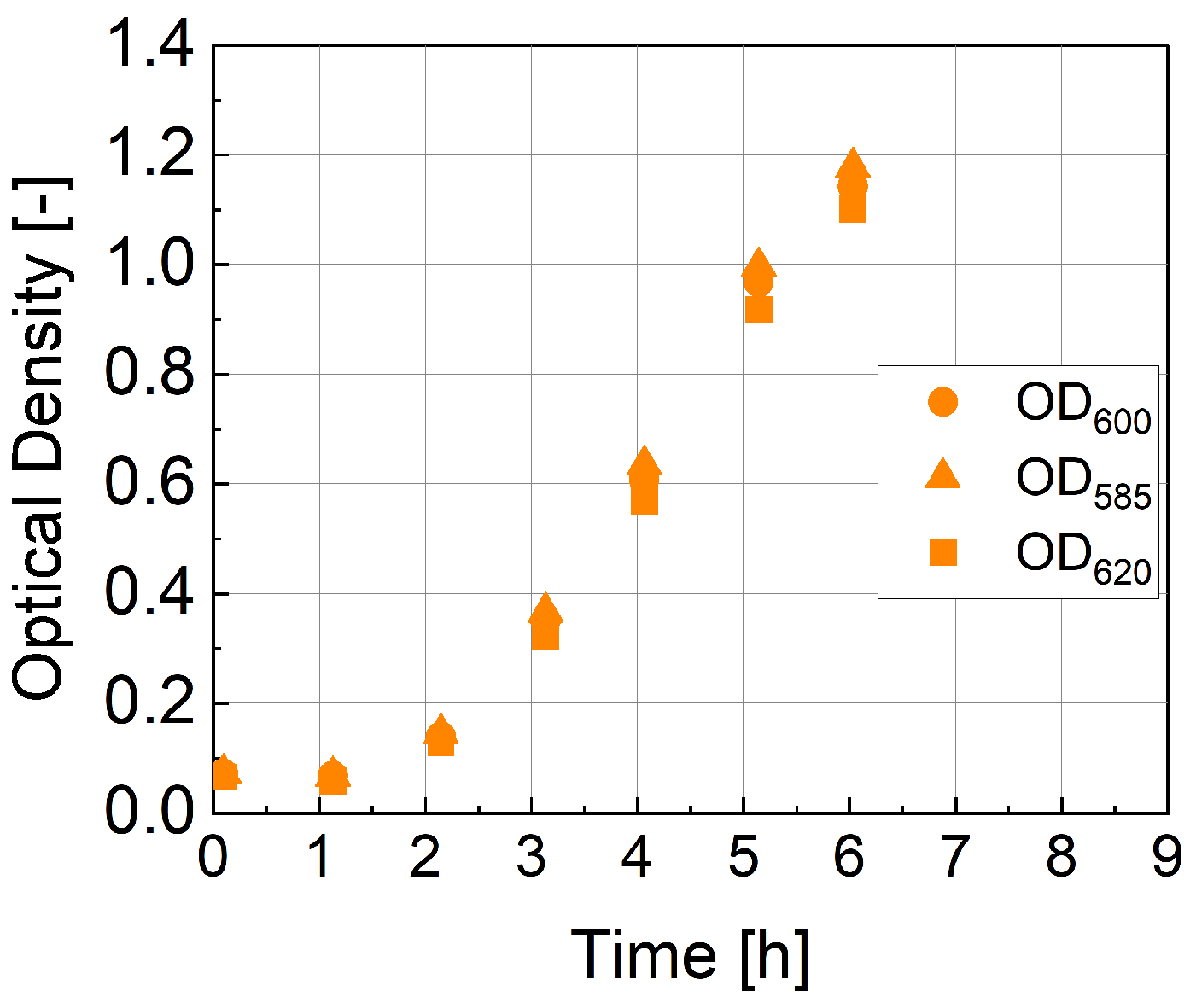

2.2. Bacteria and Feeding Solution

2.3. Sample Preparation and Experimental Setup

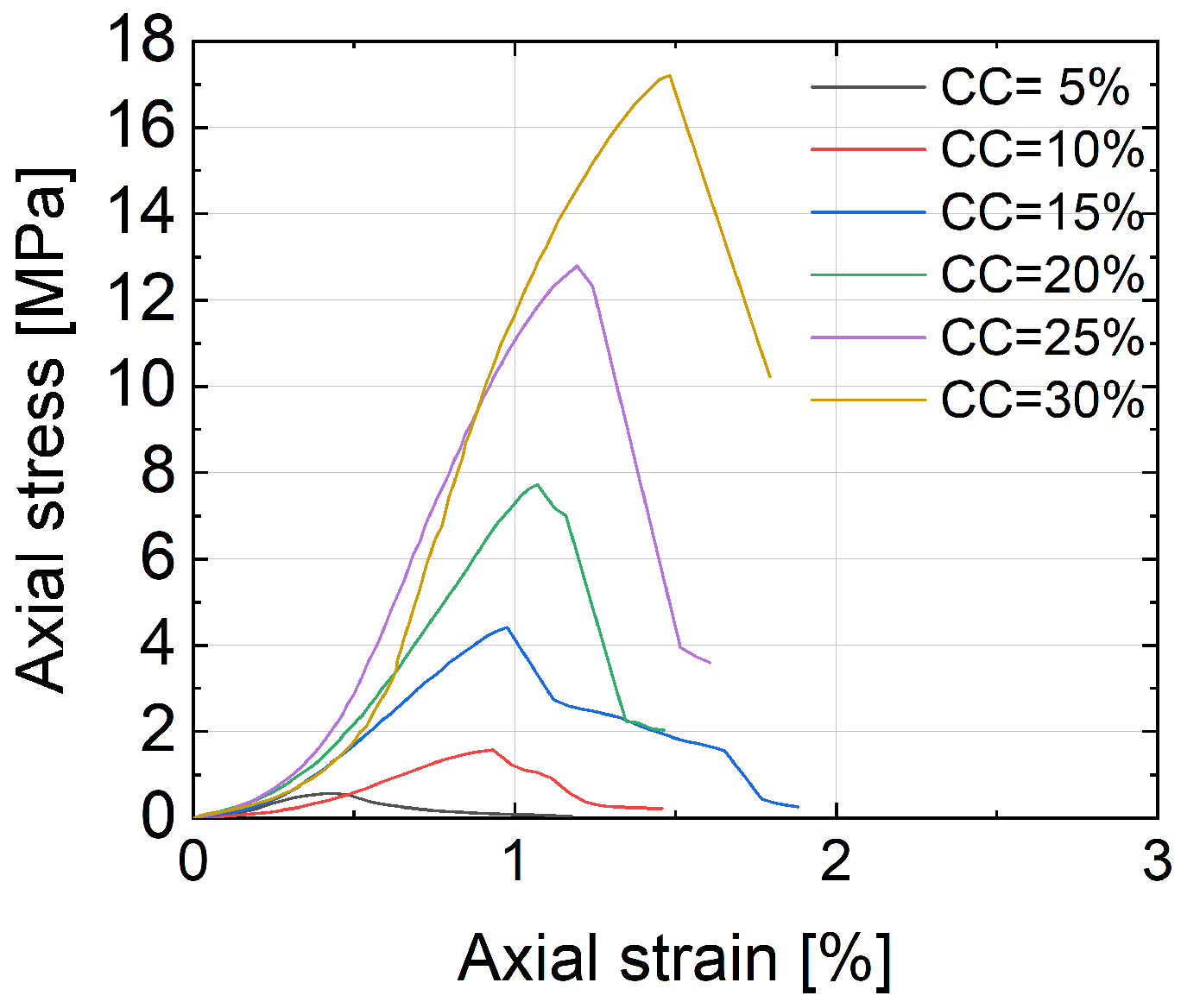

2.4. Artificial Cementation

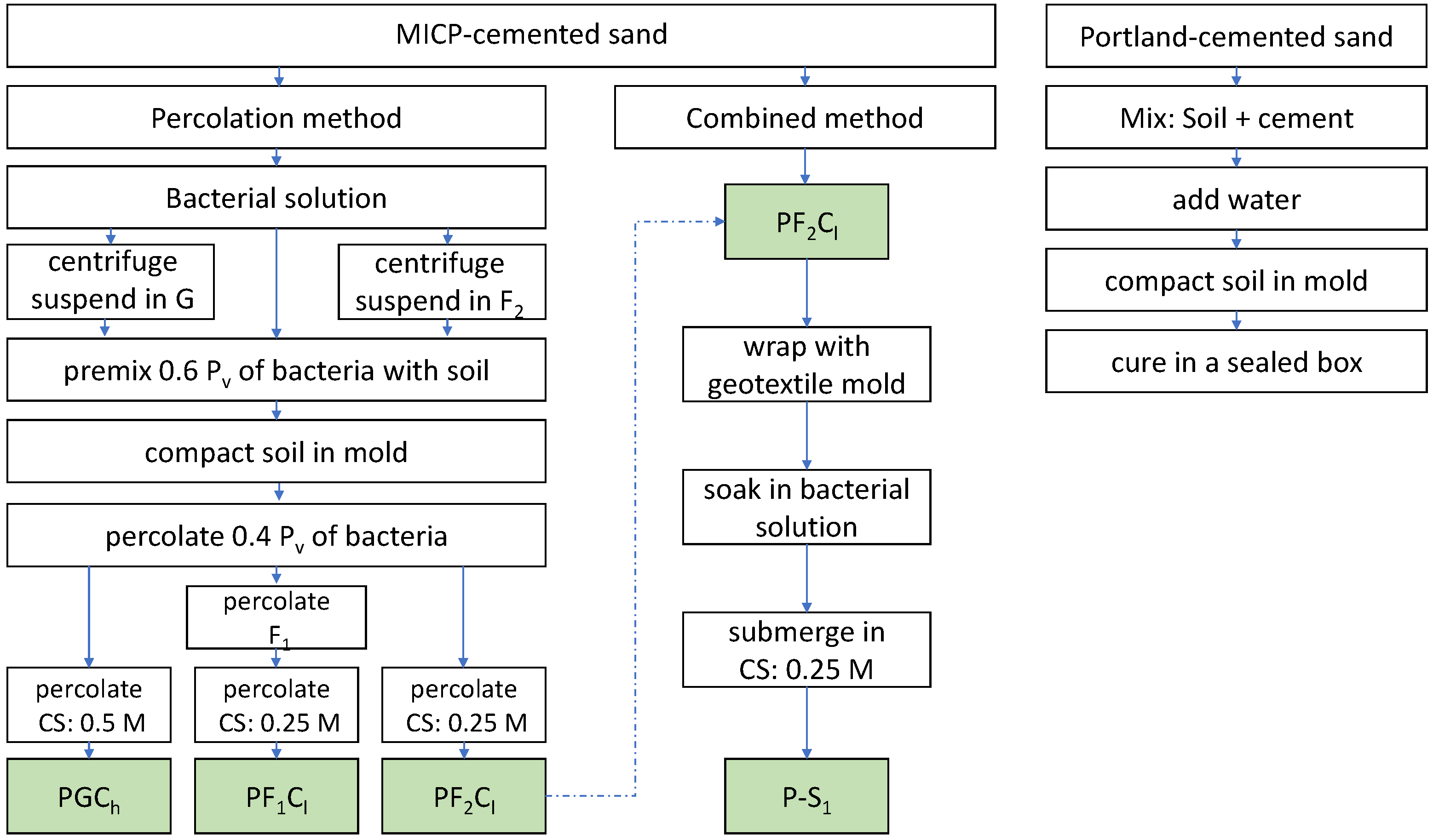

2.5. MICP Treatment

2.5.1. Percolation Method

- Sample : One pore volume of a loading solution was percolated directly after the bacteria introduction phase. contains urea, which provides bacteria with an energy source to grow and allows hydrolysis to occur before calcium carbonate precipitation upon introducing calcium ions [28]. A low concentration of 0.25 M was used for the cementation solution.

- Sample : The vegetative bacterial cells were separated from the growing medium where nutrients were consumed by centrifuging the bacterial solution twice at 4500× g for 20 min. After each centrifuging cycle, the supernatant was wasted while cells were resuspended in a loading solution , which contains calcium chloride, which fixes the bacterial cells via promoting the adsorption of microorganisms on sand grains [28]. Feeding was carried out using a low concentration, 0.25 M, of the cementation solution.

- Sample : Bacteria were centrifuged with the same protocol explained previously but they were resuspended in the growth medium. Feeding was carried out using a high concentration, 0.5 M, of the cementation solution.

2.5.2. Combined Method

2.6. Mechanical Behavior

2.7. Calcium Carbonate Content

2.8. Microstructural Analysis

3. Results

3.1. Uniaxial Compression Strength (UCS)

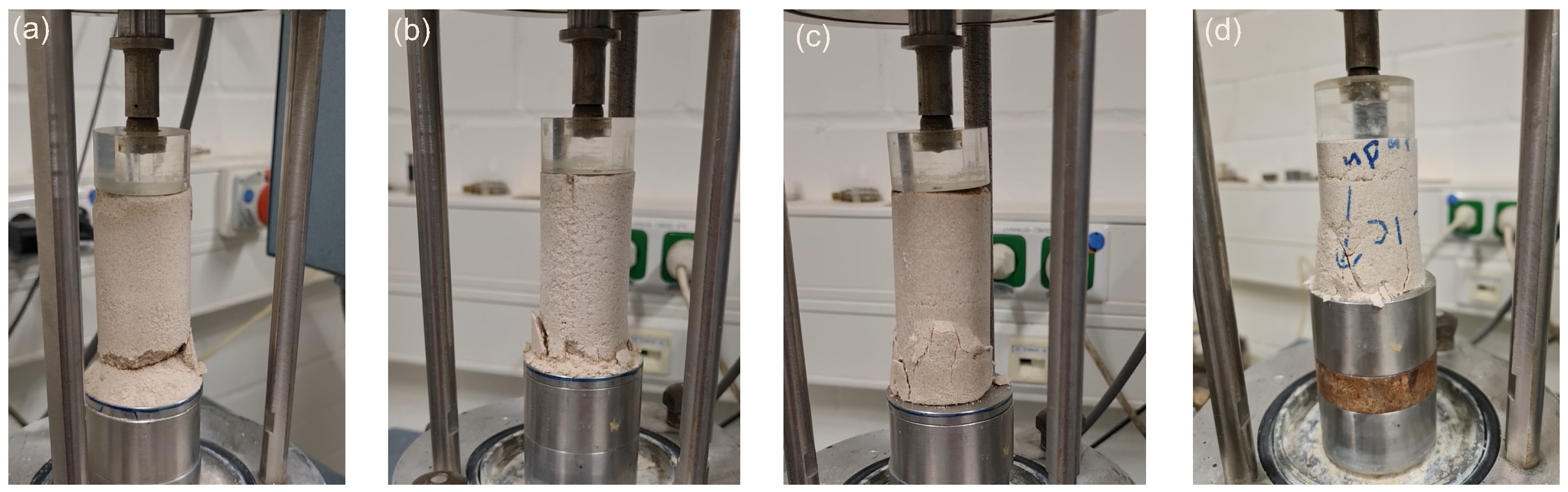

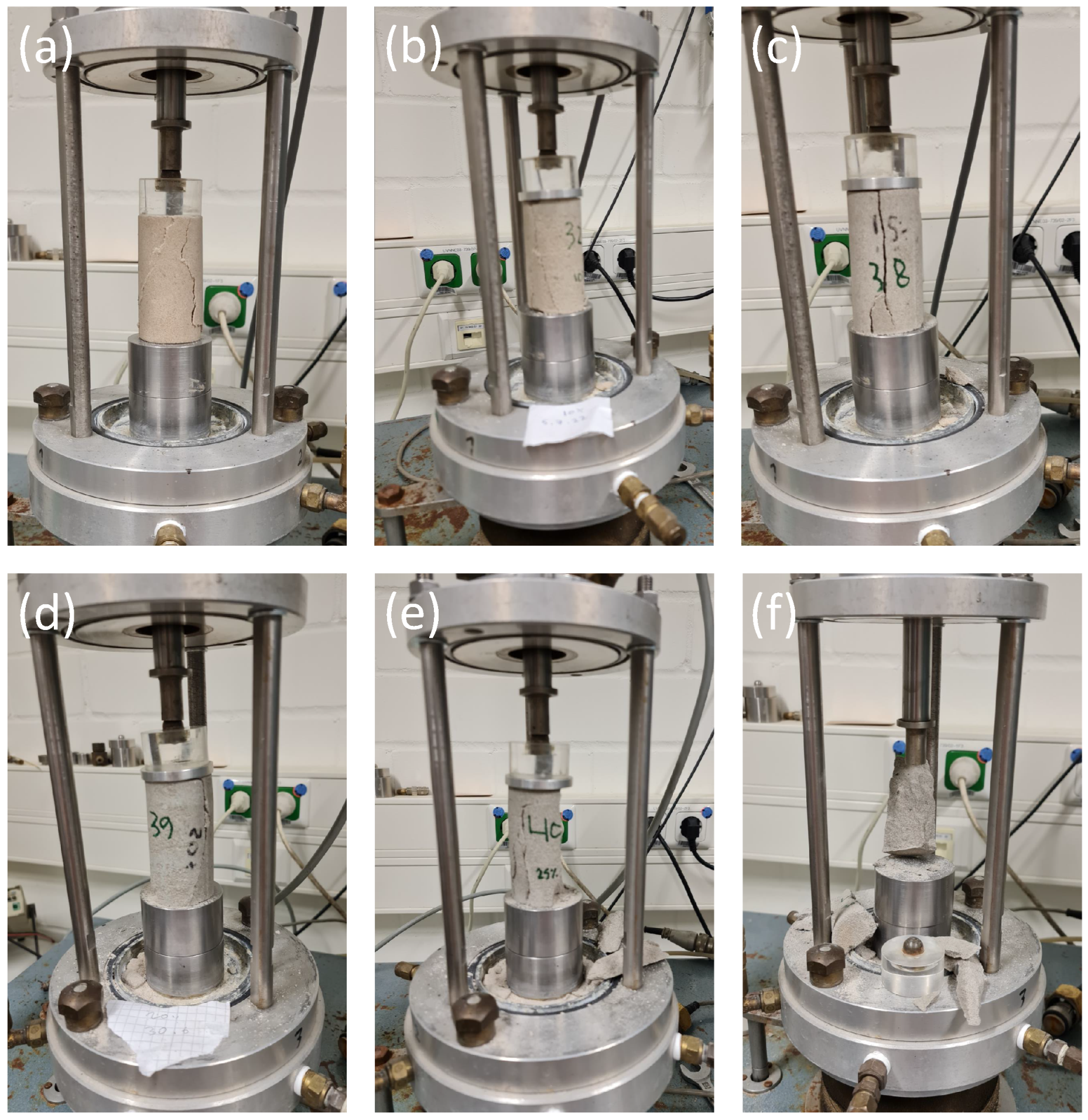

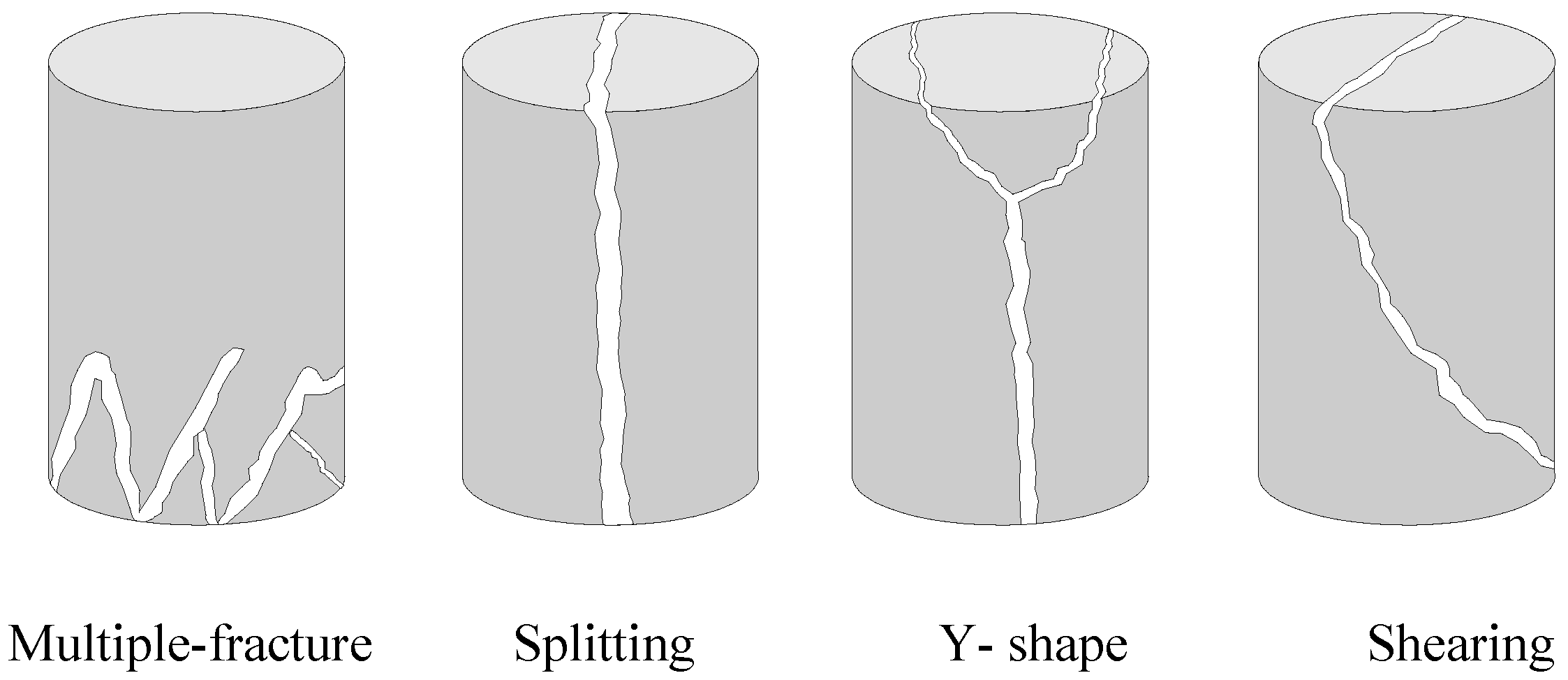

3.2. Failure Mode and Stiffness

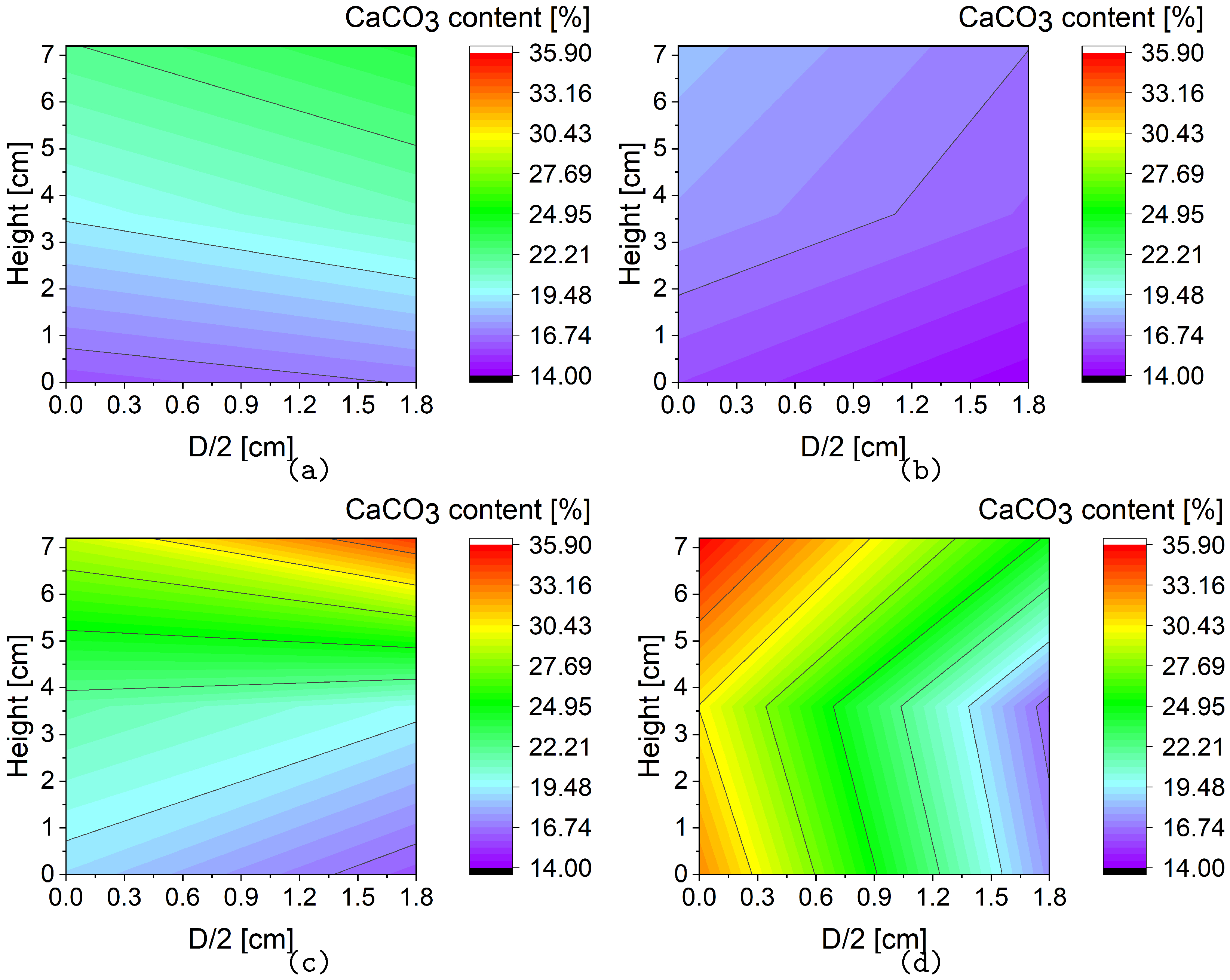

3.3. Calcium Carbonate Distribution

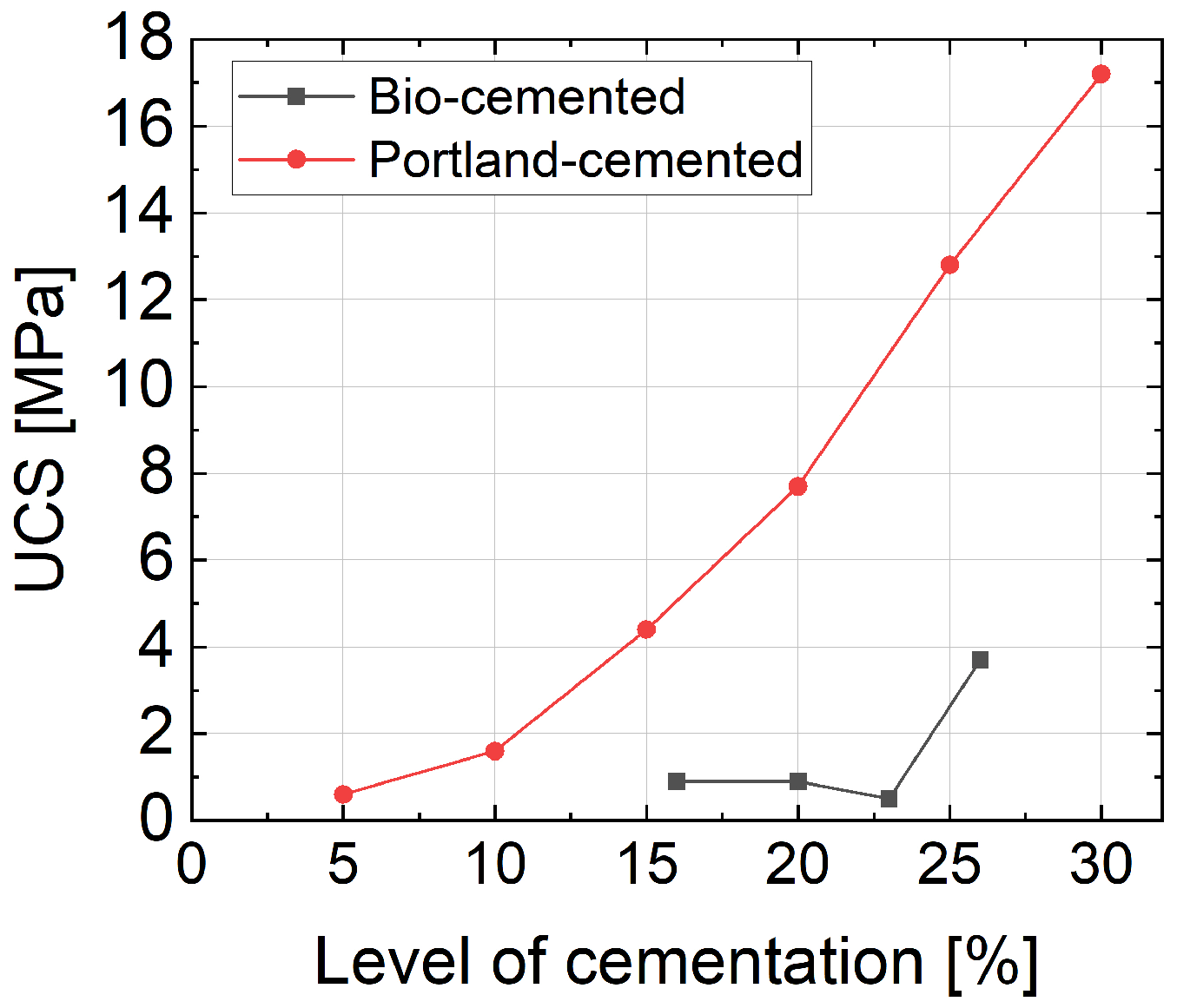

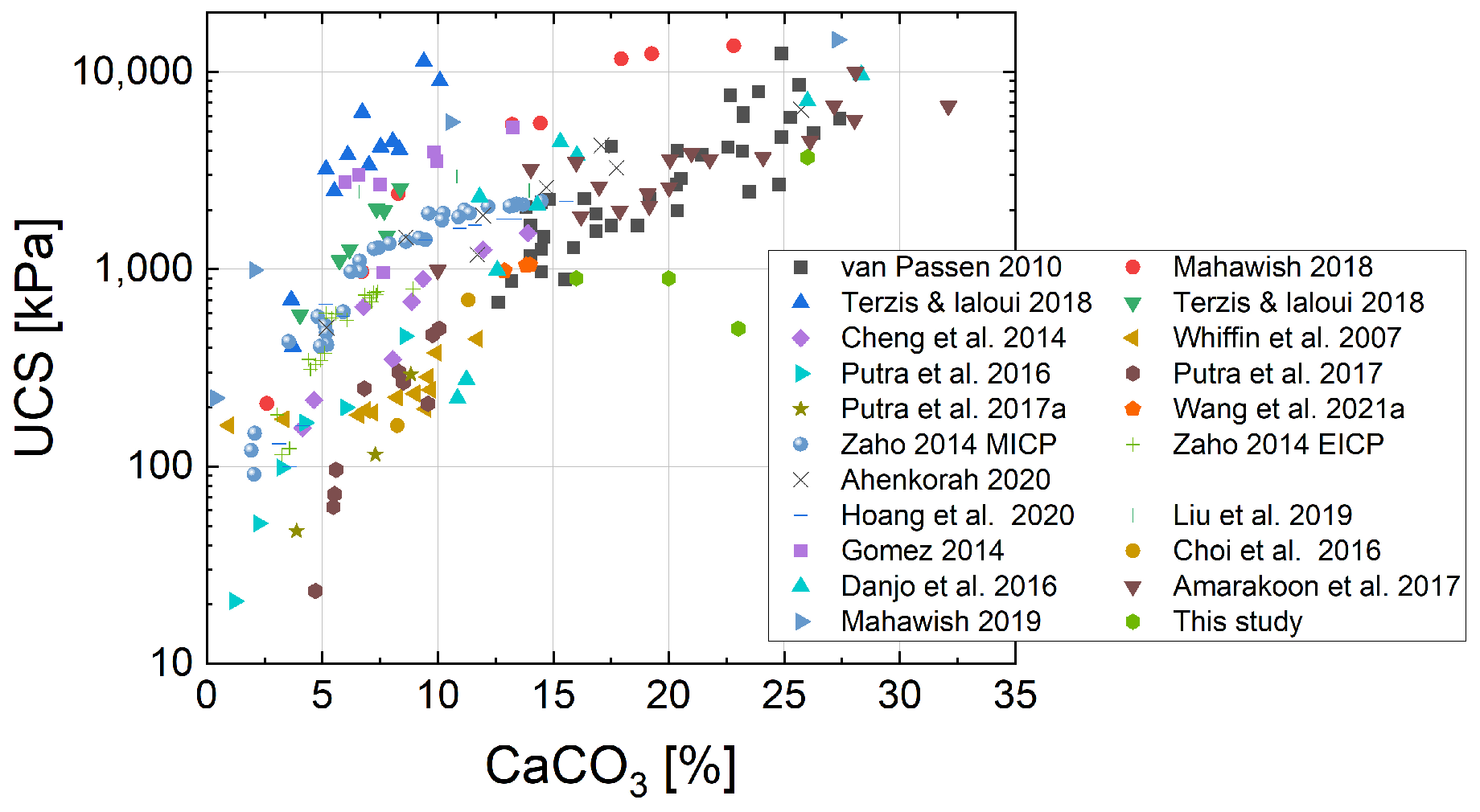

3.4. Correlation between Calcium Carbonate Content and UCS

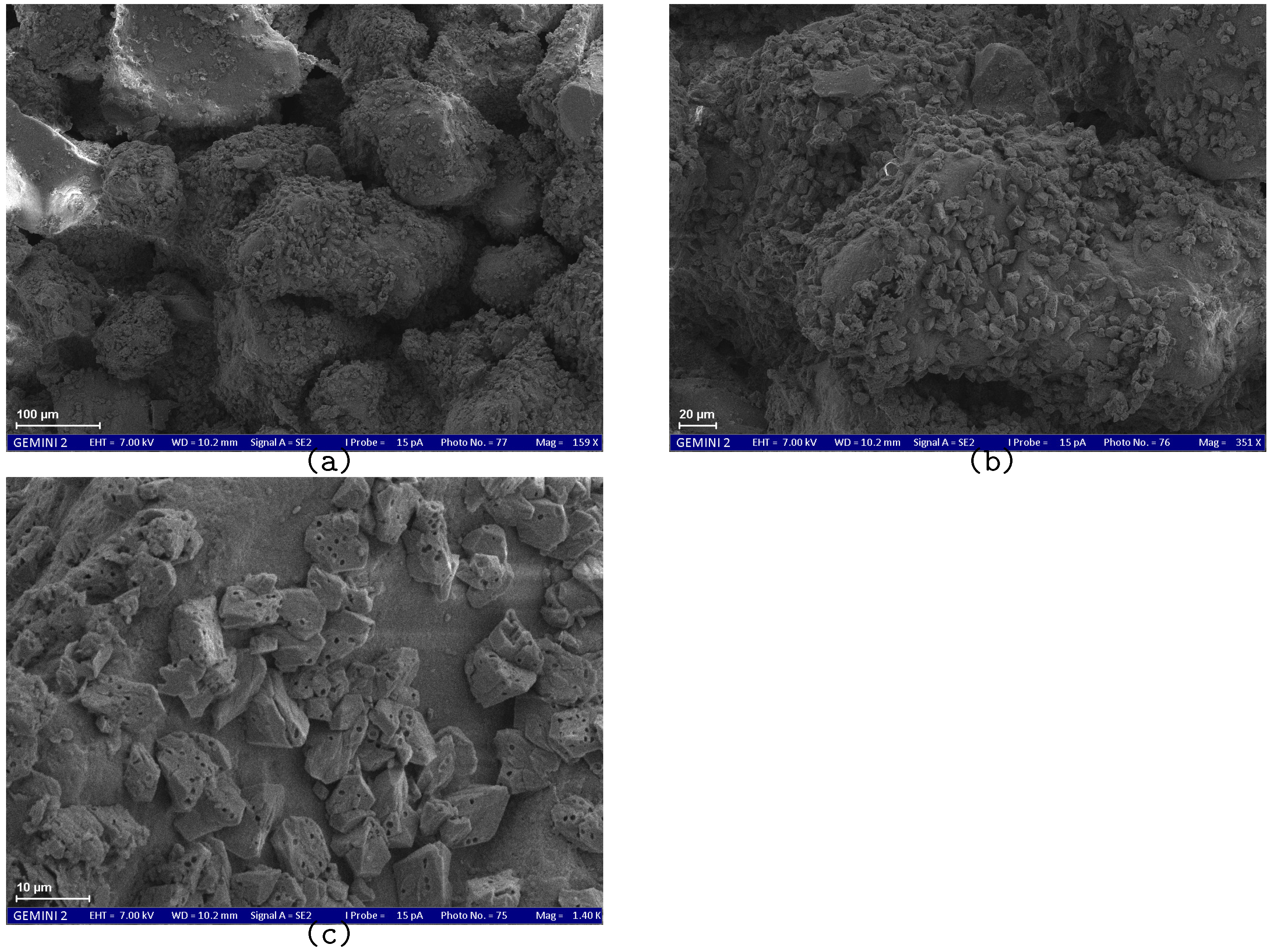

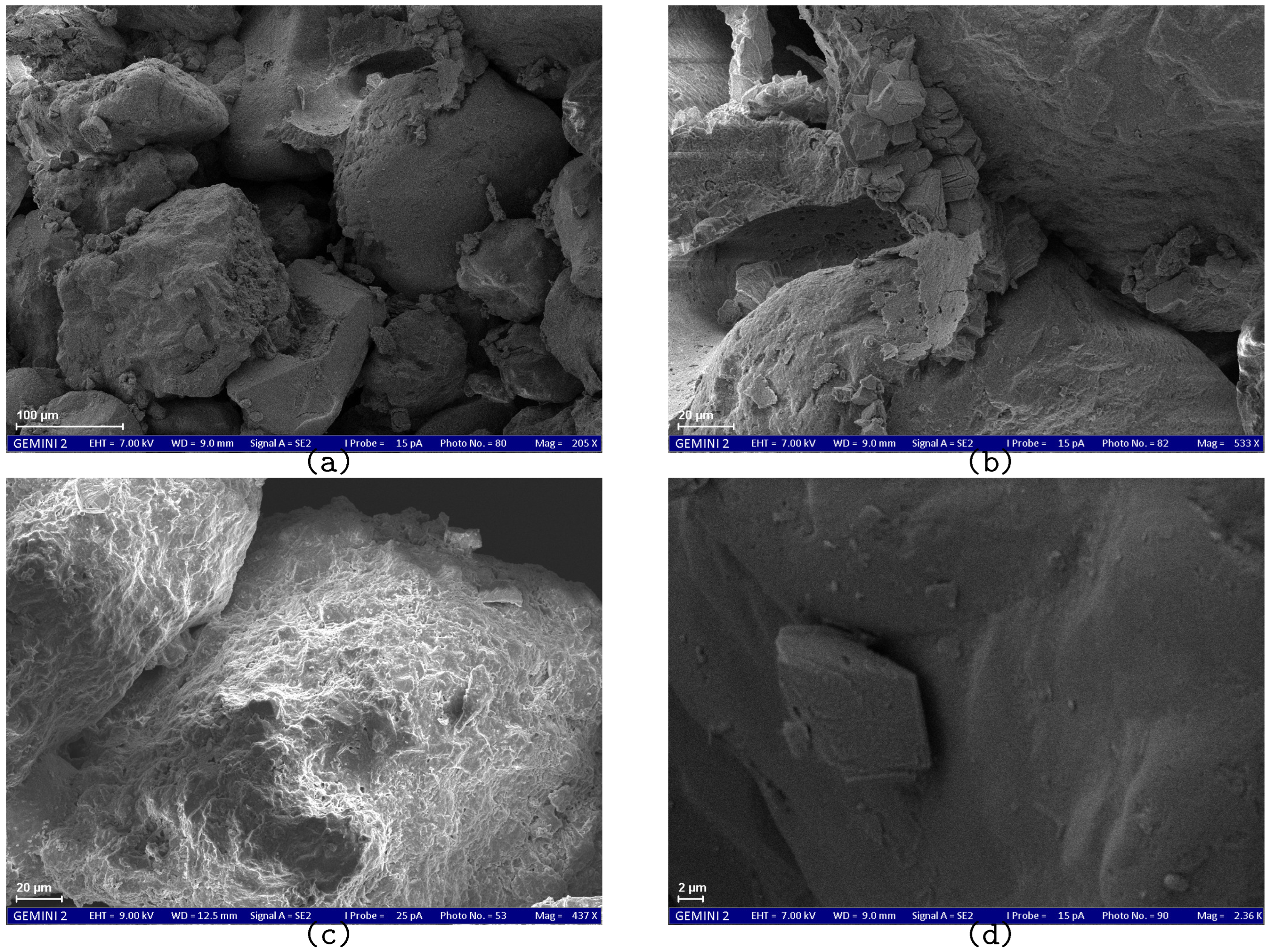

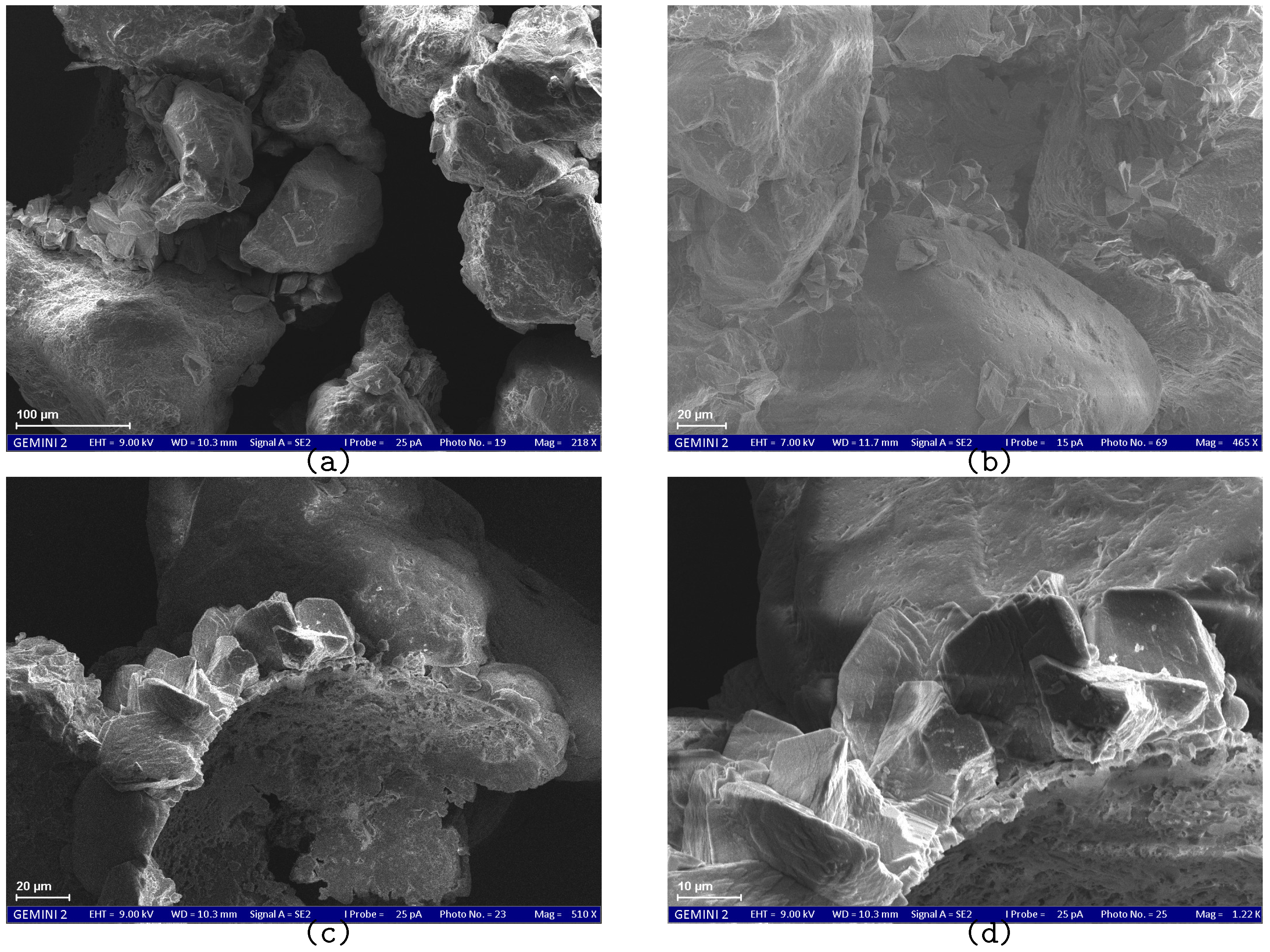

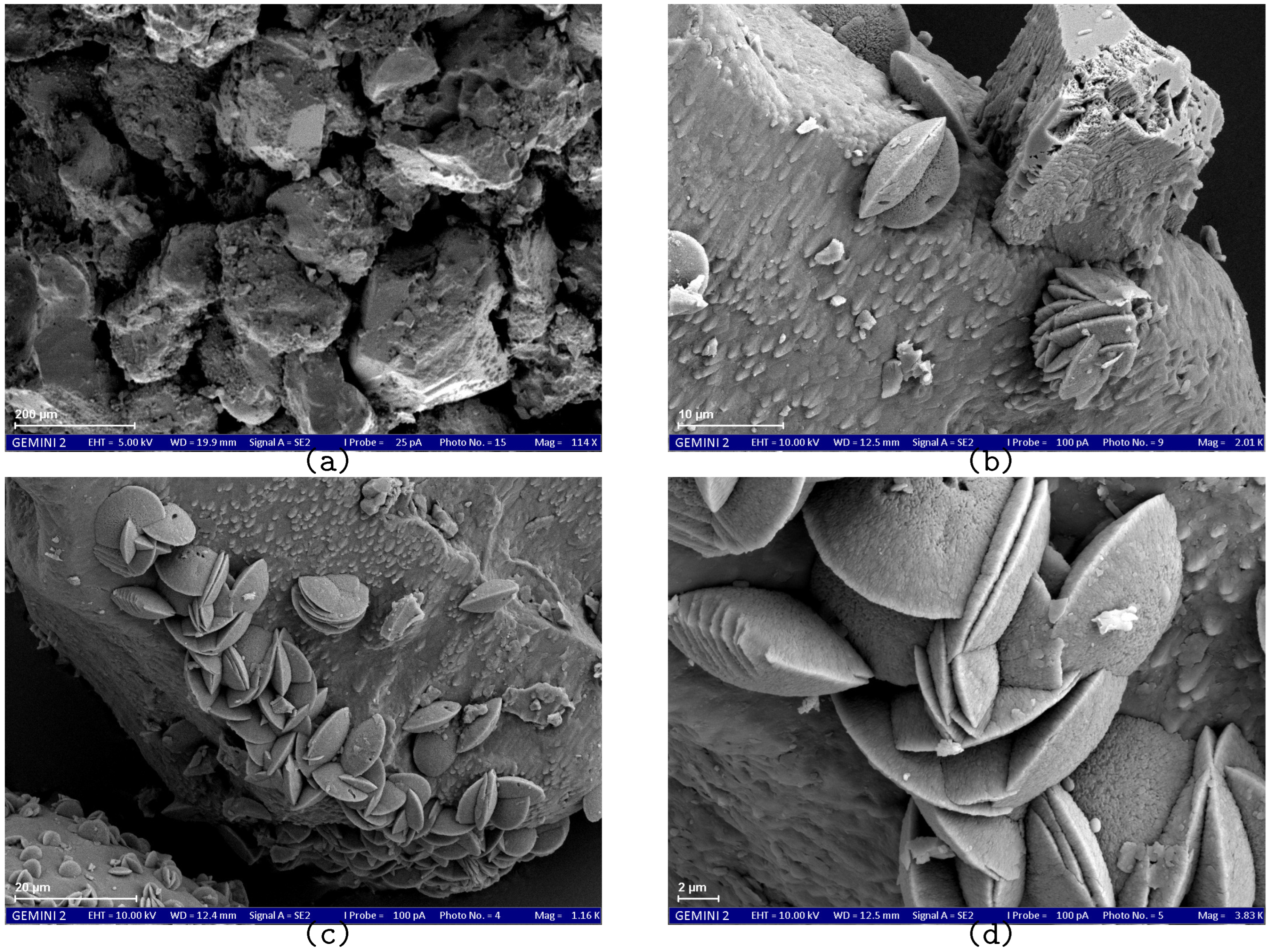

3.5. SEM Observations

4. Discussion

4.1. MICP Treatment

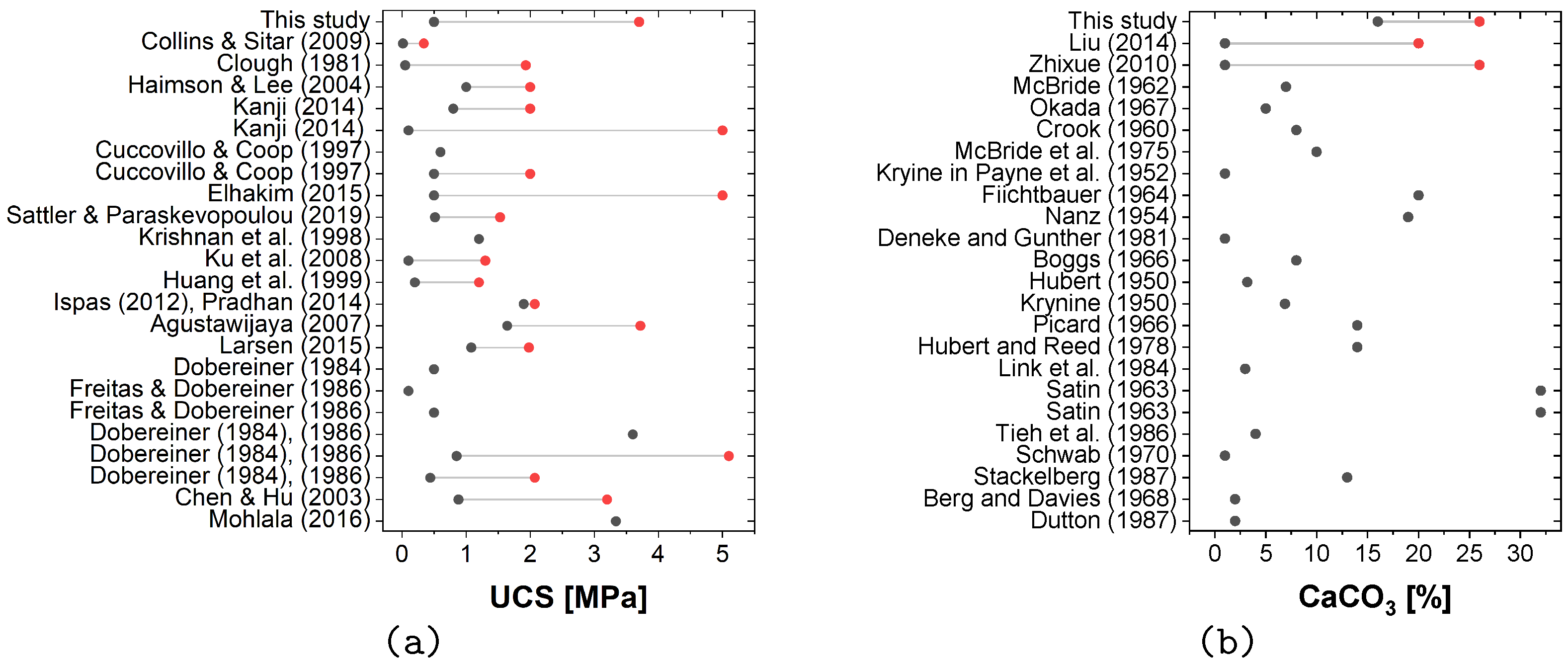

4.2. Portland-Cemented Sand versus Bio-Cemented Sand

4.3. Failure Mode and Stiffness

4.4. Calcium Carbonate Content and UCS

4.5. SEM

5. Conclusions

- Experimental data revealed that suspending bacterial cells in a calcium-containing solution is more effective than percolating the sample with a urea-containing solution.

- The combined method lead to higher strength than the percolation method by almost 3.7 times, with an increment in strength of around 2.7 MPa, indicating the ability to achieve a higher strength in a shorter time than the submerging method.

- UCS for sandy soil solidified by bio-cementation, ranging from 0.5 to 3.7 MPa, was found lower than that of samples solidified by Portland cement, ranging from 0.6 to 17.2 MPa.

- In bio-cemented sand, the failure mode was characterized by the presence of multiple fractures at the bottom of the specimen, while in Portland-cemented sand, the failure mode predominantly exhibited a y-shape pattern.

- The combined procedure yielded samples that were about 13 times stiffer than those prepared by the percolation method.

- Applying the combined method, calcium carbonate was well-distributed throughout the sample, with the exception of a lower concentration at the center of the lower section of the sample. In samples prepared by the percolation procedure, the content of calcium carbonate gradually decreased along the direction away from the sample’s surface.

- SEM results demonstrate the effect of the treatment method on the size and morphology of calcium carbonate crystals.

- The results obtained for MICP-cemented samples were in line with the UCS values and calcium carbonate contents of naturally cemented sand.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Airey, D.W. Triaxial testing of naturally cemented carbonate soil. J. Geotech. Eng. 1993, 119, 1379–1398. [Google Scholar] [CrossRef]

- Konstantinou, C.; Biscontin, G.; Jiang, N.J.; Soga, K. Application of microbially induced carbonate precipitation to form bio-cemented artificial sandstone. J. Rock Mech. Geotech. Eng. 2021, 13, 579–592. [Google Scholar] [CrossRef]

- Clough, W.; Sitar, N.; Bachus, R. Cemented Sands under Static Loading. J. Geotech. Eng. Div. 1981, 107, 799–817. [Google Scholar] [CrossRef]

- Ahmed Ali, K.; Ahmad, M.I.; Yusup, Y. Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Ashraf, M.S.; Hassan Shah, M.U.; Bokhari, A.; Hasan, M. Less is more: Optimising the biocementation of coastal sands by reducing influent urea through response surface method. J. Clean. Prod. 2021, 315, 128208. [Google Scholar] [CrossRef]

- Omoregie, A.I. A Feasibility Study to Scale-Up The Production of Sporosarcina pasteurii, Using Industrial-Grade Reagents, For Cost-Effective In-Situ Biocementation. Ph.D. Thesis, Swinburne University of Technology Sarawak Campus, Kuching, Malaysia, 2020. [Google Scholar]

- Ahenkorah, I.; Rahman, M.M.; Karim, M.R.; Teasdale, P.R. A comparison of mechanical responses for microbial-and enzyme-induced cemented sand. Geotech. Lett. 2020, 10, 559–567. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, Australia, 2004. [Google Scholar]

- Venuleo, S.; Laloui, L.; Terzis, D.; Hueckel, T.; Hassan, M. Microbially induced calcite precipitation effect on soil thermal conductivity. Geotech. Lett. 2016, 6, 39–44. [Google Scholar] [CrossRef] [Green Version]

- Kou, H.l.; Wu, C.; Jang, B.A.; Wang, D. Spatial Distribution of CaCO3 in Biocemented Sandy Slope Using Surface Percolation. J. Mater. Civ. Eng. 2021, 33, 6021004. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Cord-Ruwisch, R. Bio-cementation of sandy soil using microbially induced carbonate precipitation for marine environments. Géotechnique 2014, 64, 1010–1013. [Google Scholar] [CrossRef] [Green Version]

- Haouzi, F.Z.; Courcelles, B. Major applications of MICP sand treatment at multi-scale levels: A review. In Proceedings of the Geo Edmonton, Edmonton, AB, Canada, 23–26 September 2018. [Google Scholar]

- Xu, X.; Guo, H.; Cheng, X.; Li, M. The promotion of magnesium ions on aragonite precipitation in MICP process. Constr. Build. Mater. 2020, 263, 120057. [Google Scholar] [CrossRef]

- Abdel Gawwad, H.A.; Mohamed, S.A.E.A.; Mohammed, S.A. Impact of magnesium chloride on the mechanical properties of innovative bio-mortar. Mater. Lett. 2016, 178, 39–43. [Google Scholar] [CrossRef]

- Cui, M.J.; Lai, H.J.; Hoang, T.; Chu, J. One-phase-low-pH enzyme induced carbonate precipitation (EICP) method for soil improvement. Acta Geotech. 2021, 16, 481–489. [Google Scholar] [CrossRef]

- Cheng, L.; Shahin, M.A.; Chu, J. Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech. 2019, 14, 615–626. [Google Scholar] [CrossRef] [Green Version]

- Xiao, P.; Liu, H.; Stuedlein, A.W.; Evans, T.M.; Xiao, Y. Effect of relative density and biocementation on cyclic response of calcareous sand. Can. Geotech. J. 2019, 56, 1849–1862. [Google Scholar] [CrossRef] [Green Version]

- Yasuhara, H.; Neupane, D.; Hayashi, K.; Okamura, M. Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation. Soils Found. 2012, 52, 539–549. [Google Scholar] [CrossRef] [Green Version]

- Mujah, D.; Shahin, M.A.; Cheng, L. State-of-the-Art Review of Biocementation by Microbially Induced Calcite Precipitation (MICP) for Soil Stabilization. Geomicrobiol. J. 2017, 34, 524–537. [Google Scholar] [CrossRef]

- Centeno Dias, F.; Borges, I.; Duarte, S.O.; Monteiro, G.A.; Cardoso, R. Comparison of experimental techniques for biocementation of sands considering homogeneous volume distribution of precipitated calcium carbonate. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2020; Volume 195. [Google Scholar] [CrossRef]

- Terzis, D.; Hicher, P.; Laloui, L. Benefits and drawbacks of applied direct currents for soil improvement via carbonate mineralization. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2020; Volume 195. [Google Scholar] [CrossRef]

- Zhao, Q.; Li, L.; Li, C.; Li, M.; Amini, F.; Zhang, H. Factors affecting improvement of engineering properties of MICP-treated soil catalyzed by bacteria and urease. J. Mater. Civ. Eng. 2014, 26, 4014094. [Google Scholar] [CrossRef]

- Wen, K.; Li, Y.; Liu, S.; Bu, C.; Li, L. Development of an Improved Immersing Method to Enhance Microbial Induced Calcite Precipitation Treated Sandy Soil through Multiple Treatments in Low Cementation Media Concentration. Geotech. Geol. Eng. 2019, 37, 1015–1027. [Google Scholar] [CrossRef]

- Wichtmann, T.; Triantafyllidis, T. An experimental database for the development, calibration and verification of constitutive models for sand with focus to cyclic loading: Part I—Tests with monotonic loading and stress cycles. Acta Geotech. 2016, 11, 739–761. [Google Scholar] [CrossRef]

- Wichtmann, T.; Triantafyllidis, T. An experimental database for the development, calibration and verification of constitutive models for sand with focus to cyclic loading: Part II—Tests with strain cycles and combined loading. Acta Geotech. 2016, 11, 763–774. [Google Scholar] [CrossRef]

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; Van’t Riet, K. Modeling of the bacterial growth curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef]

- Cui, M.J.; Zheng, J.J.; Zhang, R.J.; Lai, H.J. Soil bio-cementation using an improved 2-step injection method. Arab. J. Geosci. 2020, 13. [Google Scholar] [CrossRef]

- Terzis, D.; Bernier-Latmani, R.; Laloui, L. Fabric characteristics and mechanical response of bio-improved sand to various treatment conditions. Geotech. Lett. 2016, 6, 1–8. [Google Scholar] [CrossRef] [Green Version]

- ASTM. Standard Test Method of Unconfined Compressive Strength of Intact Rock Core Specimens; ASTM Publication: West Conshohocken, PA, USA, 1986. [Google Scholar]

- Rebata-Landa, V. Microbial Activity in Sediments: Effects on Soil Behavior. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2007. [Google Scholar]

- Li, Y.; Guo., Z.; Yang, Z.; Li, Y.; Xu, M. Experimental study on the reaction process and engineering characteristics of marine calcareous sand reinforced by eco-friendly methods. Appl. Ocean. Res. 2023, 138, 103641. [Google Scholar] [CrossRef]

- Karimian, A.; Hassanlourad, M.; Karimi, G. Insight into the Properties of Surface Percolated Biocemented Sand. Geomicrobiology 2020, 38, 138–149. [Google Scholar] [CrossRef]

- Al Qabany, A.; Soga, K.; Santamarina, C. Factors affecting efficiency of microbially induced calcite precipitation. J. Geotech. Geoenviron. Eng. 2012, 138, 992–1001. [Google Scholar] [CrossRef]

- Lai, H.J.; Cui, M.J.; Wu, S.F.; Yang, Y.; Chu, J. Retarding effect of concentration of cementation solution on biocementation of soil. Acta Geotech. 2021, 16, 1457–1472. [Google Scholar] [CrossRef]

- Liu, L.; Chen, Y.; Gao, Y.; Liu, B.; Zhou, Y.; Li, C. Effect of urease enrichment degree of multiple sources of urease on bio-cementation efficacy via enzyme-induced carbonate precipitation. Can. Geotech. J. 2023. [Google Scholar] [CrossRef]

- Fu, T.; Saracho, A.C.; Haigh, S.K. Microbially induced carbonate precipitation (MICP) for soil strengthening: A comprehensive review. Biogeotechnics 2023, 1, 100002. [Google Scholar] [CrossRef]

- Chu, J.; Ivanov, V.; Naeimi, M.; Stabnikov, V.; Liu, H.L. Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech. 2014, 9, 277–285. [Google Scholar] [CrossRef]

- Yang, X.; Xiao, W.; Ma, G.; He, X.; Wu, H.; Shi, J. Mechanical Performance of Biotreated Sandy Road Bases. J. Perform. Constr. Facil. 2022, 36, 4021111. [Google Scholar] [CrossRef]

- Mujah, D.; Cheng, L.; Shahin, M.A. Microstructural and Geomechanical Study on Biocemented Sand for Optimization of MICP Process. J. Mater. Civ. Eng. 2019, 31, 04019025. [Google Scholar] [CrossRef] [Green Version]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M.A. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Fang, X.; Yang, Y.; Chen, Z.; Liu, H.; Xiao, Y.; Shen, C. Influence of Fiber Content and Length on Engineering Properties of MICP-Treated Coral Sand. Geomicrobiol. J. 2020, 37, 582–594. [Google Scholar] [CrossRef]

- Basu, A.; Mishra, D.; Roychowdhury, K. Rock failure modes under uniaxial compression, Brazilian, and point load tests. Bull. Eng. Geol. Environ. 2013, 72, 457–475. [Google Scholar] [CrossRef]

- Chakraborty, S.; Bisai, R.; Palaniappan, S.K.; Pal, S.K. Failure modes of rocks under uniaxial compression tests: An experimental approach. J. Adv. Geotech. Eng. 2019, 2, 1–8. [Google Scholar]

- Yu, T.; Souli, H.; Pechaud, Y.; Fleureau, J.M. Review on engineering properties of micp-treated soils. Geomech. Eng. 2021, 27, 13–30. [Google Scholar] [CrossRef]

- Yin, J.; Wu, J.X.; Zhang, K.; Shahin, M.A.; Cheng, L. Comparison between MICP-Based Bio-Cementation Versus Traditional Portland Cementation for Oil-Contaminated Soil Stabilisation. Sustainability 2022, 15, 434. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hora, R.N.; Ahenkorah, I.; Beecham, S.; Karim, M.R.; Iqbal, A. State-of-the-Art Review of Microbial-Induced Calcite Precipitation and Its Sustainability in Engineering Applications. Sustainability 2020, 12, 6281. [Google Scholar] [CrossRef]

- Putra, H.; Yasuhara, H.; Erizal; Sutoyo; Fauzan, M. Review of enzyme-induced calcite precipitation as a ground-improvement technique. Infrastructures 2020, 5, 66. [Google Scholar] [CrossRef]

- Mahawish, A.; Bouazza, A.; Gates, W.P. Unconfined compressive strength and visualization of the microstructure of coarse sand subjected to different biocementation levels. J. Geotech. Geoenviron. Eng. 2019, 145, 4019033. [Google Scholar] [CrossRef]

- Hoang, T.; Alleman, J.; Cetin, B.; Choi, S.G. Engineering properties of biocementation coarse-and fine-grained sand catalyzed by bacterial cells and bacterial enzyme. J. Mater. Civ. Eng. 2020, 32, 4020030. [Google Scholar] [CrossRef]

- Liu, L.; Liu, H.; Stuedlein, A.W.; Evans, T.M.; Xiao, Y. Strength, stiffness, and microstructure characteristics of biocemented calcareous sand. Can. Geotech. J. 2019, 56, 1502–1513. [Google Scholar] [CrossRef]

- Gomez, M.G.; Anderson, C.M.; DeJong, J.T.; Nelson, D.C.; Lau, X.H. Stimulating in situ soil bacteria for bio-cementation of sands. In Proceedings of the Geo-Congress 2014: Geo-characterization and Modeling for Sustainability, Atlanta, GA, USA, 23–26 February 2014; pp. 1674–1682. [Google Scholar]

- Choi, S.G.; Wang, K.; Chu, J. Properties of biocemented, fiber reinforced sand. Constr. Build. Mater. 2016, 120, 623–629. [Google Scholar] [CrossRef]

- Danjo, T.; Kawasaki, S. Microbially induced sand cementation method using Pararhodobacter sp. strain SO1, inspired by beachrock formation mechanism. Mater. Trans. 2016, 57, 428–437. [Google Scholar] [CrossRef] [Green Version]

- Amarakoon, G.; Kawasaki, S. Factors Affecting Sand Solidification Using MICP with Pararhodobacter sp. Mater. Trans. 2017, 59, 72–81. [Google Scholar] [CrossRef] [Green Version]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Neupane, D.; Lu, C.W. Effect of magnesium as substitute material in enzyme-mediated calcite precipitation for soil-improvement technique. Front. Bioeng. Biotechnol. 2016, 4, 37. [Google Scholar] [CrossRef] [Green Version]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Hirata, A. Application of magnesium to improve uniform distribution of precipitated minerals in 1-m column specimens. Geomech. Eng. 2017, 12, 803–813. [Google Scholar] [CrossRef]

- Putra, H.; Yasuhara, H.; Kinoshita, N. Applicability of natural zeolite for NH-forms removal in enzyme-mediated calcite precipitation technique. Geosciences 2017, 7, 61. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, C.; Wang, C.; Gao, Y. Improving the Erosion Resistance Performance of Pisha Sandstone Weathered Soil Using MICP Technology. Crystals 2021, 11, 1112. [Google Scholar] [CrossRef]

- Whiffin, V.S.; Van Paassen, L.A.; Harkes, M.P. Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- van Paassen, L.A.; Ghose, R.; van der Linden, T.J.M.; van der Star, W.R.L.; van Loosdrecht, M.C.M. Quantifying Biomediated Ground Improvement by Ureolysis: Large-Scale Biogrout Experiment. J. Geotech. Geoenviron. Eng. 2010, 136, 1721–1728. [Google Scholar] [CrossRef]

- Collins, B.D.; Sitar, N. Geotechnical properties of cemented sands in steep slopes. J. Geotech. Geoenviron. Eng. 2009, 135, 1359–1366. [Google Scholar] [CrossRef]

- Liu, S.; Huang, S.; Shen, Z.; Lü, Z.; Song, R. Diagenetic fluid evolution and water-rock interaction model of carbonate cements in sandstone: An example from the reservoir sandstone of the Fourth Member of the Xujiahe Formation of the Xiaoquan-Fenggu area, Sichuan Province, China. Sci. China Earth Sci. 2014, 57, 1077–1092. [Google Scholar] [CrossRef]

- Sun, Z.; Sun, Z.; Lu, H.; Yin, X. Characteristics of carbonate cements in sandstone reservoirs: A case from Yanchang Formation, middle and southern Ordos Basin, China. Pet. Explor. Dev. 2010, 37, 543–551. [Google Scholar] [CrossRef]

- McBride, E.F. Quartz cement in sandstones: A review. Earth-Sci. Rev. 1989, 26, 69–112. [Google Scholar] [CrossRef]

- Terzis, D.; Laloui, L. Cell-free soil bio-cementation with strength, dilatancy and fabric characterization. Acta Geotech. 2019, 14, 639–656. [Google Scholar] [CrossRef]

- Al-Thawadi, S. High Strength In-Situ Biocementation of Soil by Calcite Precipitating Locally Isolated Ureolytic Bacteria. Ph.D. Dissertation, Murdoch University, Perth, Australia, 2008. [Google Scholar]

- Terzis, D.; Hicher, P.; Laloui, L. Direct currents stimulate carbonate mineralization for soil improvement under various chemical conditions. Sci. Rep. 2020, 10, 17014. [Google Scholar] [CrossRef]

- Omoregie, A.I.; Palombo, E.A.; Ong, D.E.L.; Nissom, P.M. A feasible scale-up production of Sporosarcina pasteurii using custom-built stirred tank reactor for in-situ soil biocementation. Biocatal. Agric. Biotechnol. 2020, 24, 101544. [Google Scholar] [CrossRef]

- Al-Thawadi, S.; Cord-Ruwisch, R. Calcium carbonate crystals formation by ureolytic bacteria isolated from Australian soil and sludge. J. Adv. Sci. Eng. Res. 2012, 2, 12–26. [Google Scholar]

- Bosak, T.; Newman, D.K. Microbial kinetic controls on calcite morphology in supersaturated solutions. J. Sediment. Res. 2005, 75, 190–199. [Google Scholar] [CrossRef] [Green Version]

| Peptone from Casein | Soy Meal | NaCl | Urea | Agar | Water |

|---|---|---|---|---|---|

| 15 g | 5 g | 5 g | 20 g | 15 g | 1 L |

| Urea | Calcium Chloride | Ammonium Chloride | Sodium Carbonate | Nutrient Broth |

|---|---|---|---|---|

| 0.25 M | 0.25 M | 0.187 M | 2.12 g/L | 3 g/L |

| 0.5 M | 0.5 M | 0.187 M | 2.12 g/L | 3 g/L |

| Loading Solution | Urea | Calcium Chloride | Ammonium Chloride | Nutrient Broth |

|---|---|---|---|---|

| F | 0.5 M | 0 | 0.187 M | 3 g/L |

| F | 0 | 0.1 M | 0.187 M | 3 g/L |

| Specimen | Method | Strategy | CS |

|---|---|---|---|

| Percolation | Percolating | 0.25 M | |

| Percolation | Suspending in | 0.25 M | |

| Percolation | Suspending in G | 0.5 M | |

| Combined | - | 0.25 M |

| Method | Specimen | (MPa) | (%) | * (MPa) |

|---|---|---|---|---|

| Percolation | 0.9 | 4.0 | 23 | |

| Percolation | 0.9 | 2.6 | 35 | |

| Percolation | 0.5 | 2.4 | 18 | |

| Combined | 3.7 | 0.8 | 467 |

| Cement Content (%) | (MPa) | (%) | (MPa) |

|---|---|---|---|

| 5 | 0.6 | 0.4 | 128 |

| 10 | 1.6 | 0.9 | 169 |

| 15 | 4.4 | 1.0 | 453 |

| 20 | 7.7 | 1.1 | 722 |

| 25 | 12.8 | 1.2 | 1071 |

| 30 | 17.2 | 1.5 | 1161 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeitouny, J.; Lieske, W.; Alimardani Lavasan, A.; Heinz, E.; Wichern, M.; Wichtmann, T. Impact of New Combined Treatment Method on the Mechanical Properties and Microstructure of MICP-Improved Sand. Geotechnics 2023, 3, 661-685. https://doi.org/10.3390/geotechnics3030036

Zeitouny J, Lieske W, Alimardani Lavasan A, Heinz E, Wichern M, Wichtmann T. Impact of New Combined Treatment Method on the Mechanical Properties and Microstructure of MICP-Improved Sand. Geotechnics. 2023; 3(3):661-685. https://doi.org/10.3390/geotechnics3030036

Chicago/Turabian StyleZeitouny, Jude, Wolfgang Lieske, Arash Alimardani Lavasan, Eva Heinz, Marc Wichern, and Torsten Wichtmann. 2023. "Impact of New Combined Treatment Method on the Mechanical Properties and Microstructure of MICP-Improved Sand" Geotechnics 3, no. 3: 661-685. https://doi.org/10.3390/geotechnics3030036

APA StyleZeitouny, J., Lieske, W., Alimardani Lavasan, A., Heinz, E., Wichern, M., & Wichtmann, T. (2023). Impact of New Combined Treatment Method on the Mechanical Properties and Microstructure of MICP-Improved Sand. Geotechnics, 3(3), 661-685. https://doi.org/10.3390/geotechnics3030036